Exhaust device and tire mold

A technology of exhaust device and exhaust end, which is applied in the direction of tires, household appliances, and other household appliances. It can solve the problems of exhaust hole blockage, easy falling off, and easy cracking, so as to avoid the formation of rubber hair, high stroke accuracy, The effect of not easy to break

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

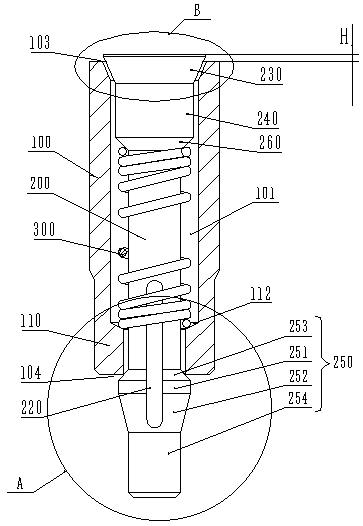

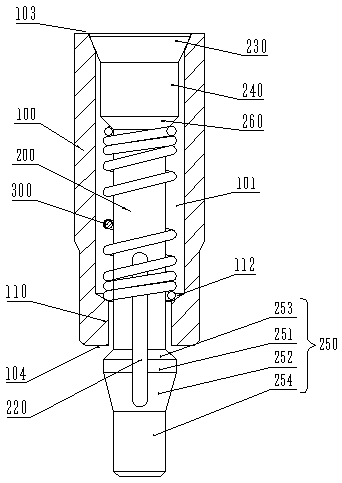

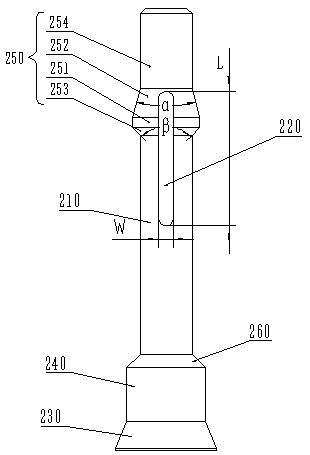

[0052] Such as figure 1 , figure 2 , image 3 with Image 6 As shown, the exhaust device provided by the embodiment of the present invention includes: a mandrel 200 and a casing 100 sheathed on the mandrel 200, an exhaust passage 101 is formed between the casing 100 and the mandrel 200, and the casing 100 has an inlet The gas end 103 and the exhaust end 104; the mandrel 200 includes a shaft body 210, one end of the shaft body 210 is connected to the shaft head 230, and the other end of the shaft body 210 is connected to the shaft end piece 250, and the shaft end piece 250 is provided with a through groove 220, through which The groove 220 runs through the shaft end piece 250, and the end of the through groove 220 away from the shaft head 230 is closed. The shaft end piece 250 is used to limit the axial position of the mandrel 200, and the shaft end piece 250 is also used to shrink and rebound. Matching shell 100 and mandrel 200 . Wherein, the shaft body 210, the shaft he...

Embodiment 2

[0077] Such as Figure 12 , 13 As shown, the difference between this embodiment and Embodiment 1 is that: a guide surface 111 is provided along the outer side of the axially limiting convex ring 110 of the sleeve 100; the guide surface 111 is used to form the exhaust end 104 of the sleeve 100 by An opening of decreasing radial size from outside to inside.

[0078] A step is formed between the first shaft section 251 and the shaft body 210 . When the exhaust device is installed, the outer edge of the first shaft section 251 near the shaft head 230 abuts against the guide surface 111 . When the mandrel 200 is disassembled from the inner cavity of the casing 100 , the shaft end piece 250 slides along the second guide surface 111 , so that the second guide surface 111 guides the shaft end piece 250 . Further, the guide surface 111 can be a conical surface, an inclined surface, an arc surface, etc., preferably a conical surface, and the cone angle θ of the guide surface 111 range...

Embodiment 3

[0081] Such as Figure 14 , 15 As shown, the difference between this embodiment and Embodiments 1 and 2 is that: the shaft end piece 250 is also used to exert a force on the mandrel 200 from the shaft head 230 toward the shaft end piece 250 so that the shaft head 230 abuts against the casing 100 , There is an air intake gap or an air inlet between the shaft head 230 and the casing 100, and the air inlet gap or the air inlet communicates with the exhaust channel 101 and the outside of the exhaust device.

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com