Flat pipe heat exchanger and assembly method thereof

An assembly method and heat exchanger technology, applied in the direction of assembly machines, tubular elements, heat exchange equipment, etc., can solve the adverse effects of fin and flat tube bonding, reduce the heat dissipation efficiency of heat exchanger, and the influence of fin flanging is relatively large Large and other problems, to achieve the effect of easy processing, simple structure and easy assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The structure of the heat exchanger of the present invention will be further described below with reference to the accompanying drawings.

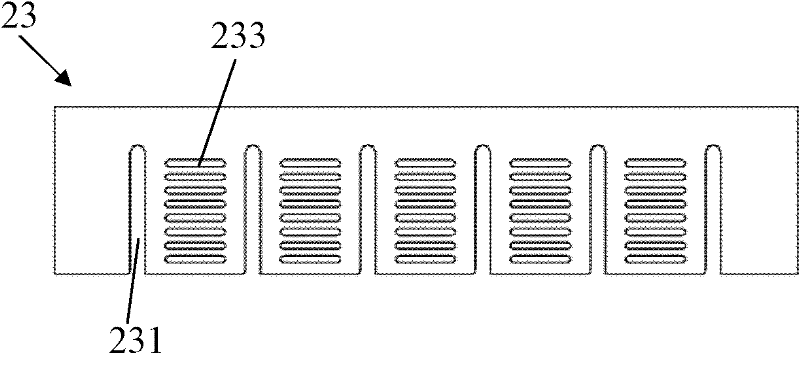

[0033] Such as image 3 As shown, the fin 23 is a rectangular aluminum sheet, on which a plurality of groups of punching holes 233 are evenly spaced, and the punching holes 233 are set along the length direction of the rectangular fin, and the punching holes 233 are conducive to the air flow inside. Through to enhance the cooling effect of the radiator. Between the two groups of punching holes 233, there is a "U"-shaped pipe groove 231, the openings of the pipe groove 231 are all set on the same side of the fin 23, and a flange 232 is arranged around the pipe groove 231, wherein , the width of the duct groove 231 is slightly greater than the thickness of the flat tube 22 described below, generally 0.5-1mm larger than the thickness of the flat tube 22, that is, the flat tube 22 can smoothly enter the duct groove 231; the width of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com