Rotary magnetorheological damper

A magneto-rheological damper, rotary type technology, applied in the direction of shock absorber, shock absorber, liquid shock absorber, etc., can solve the problem that the deployment part cannot meet the design requirements of vibration reduction, and is not suitable for rotary deployment mechanism, damping In order to achieve the effect of compact structure, large damping torque, easy processing and assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

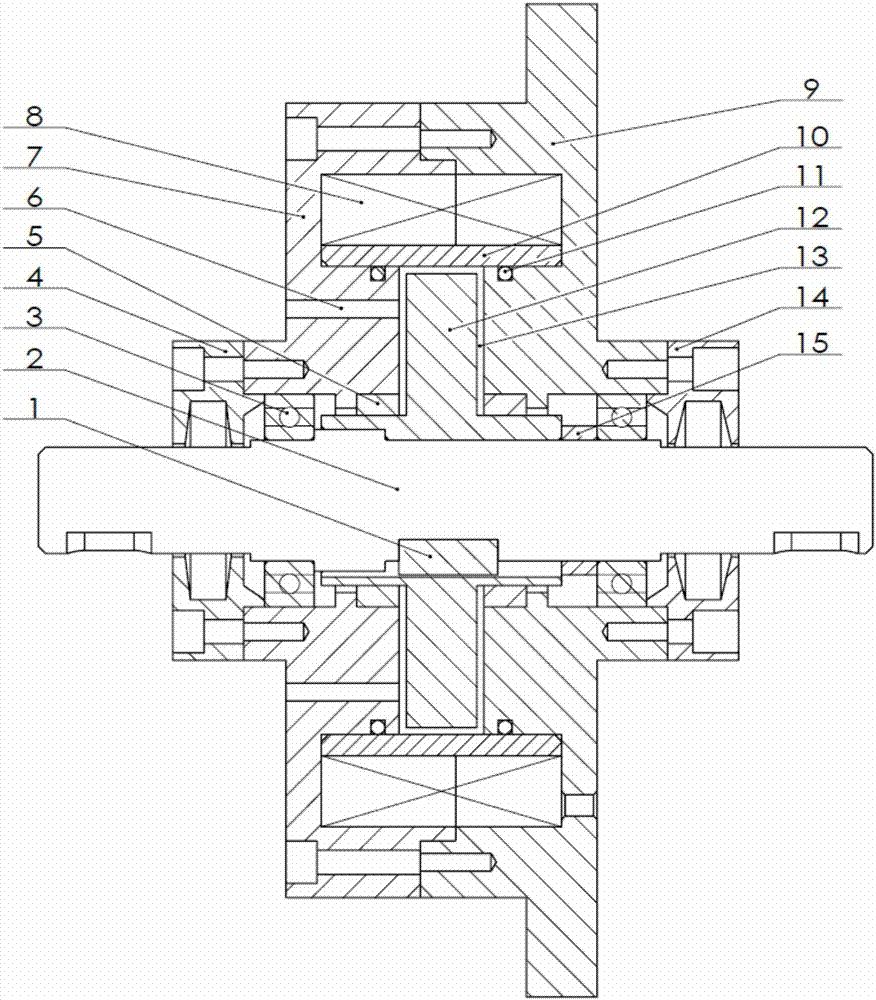

[0018] The present invention will be described in further detail below in conjunction with the accompanying drawings.

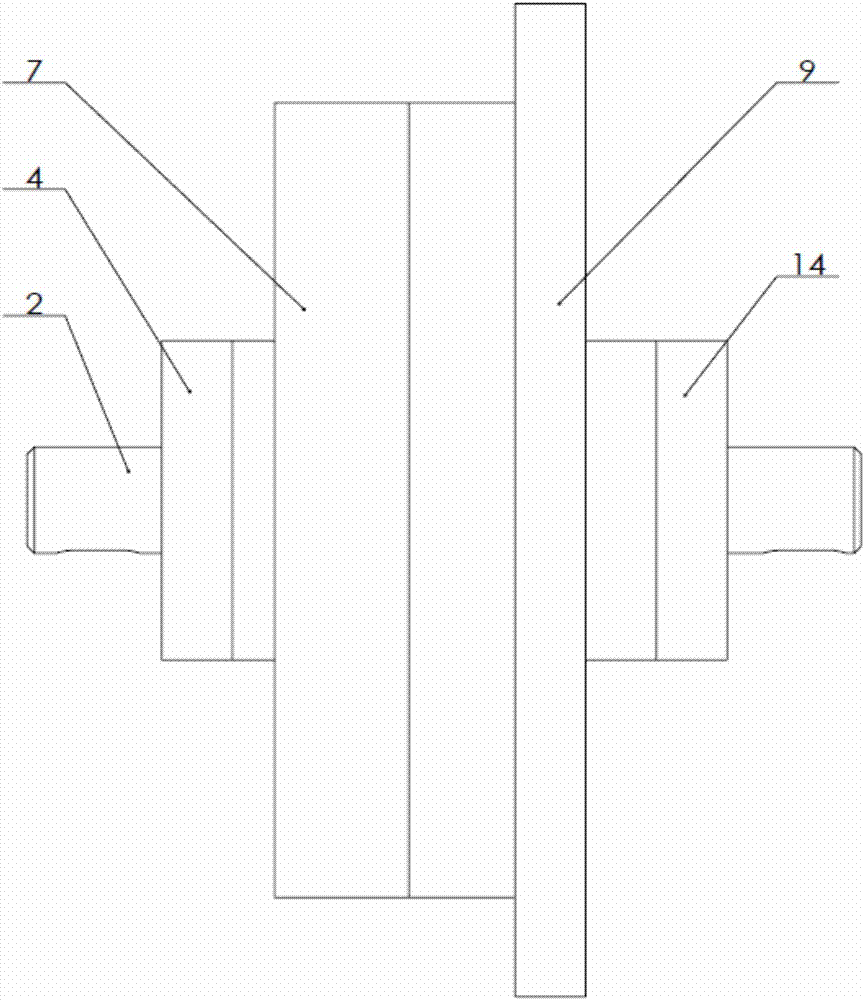

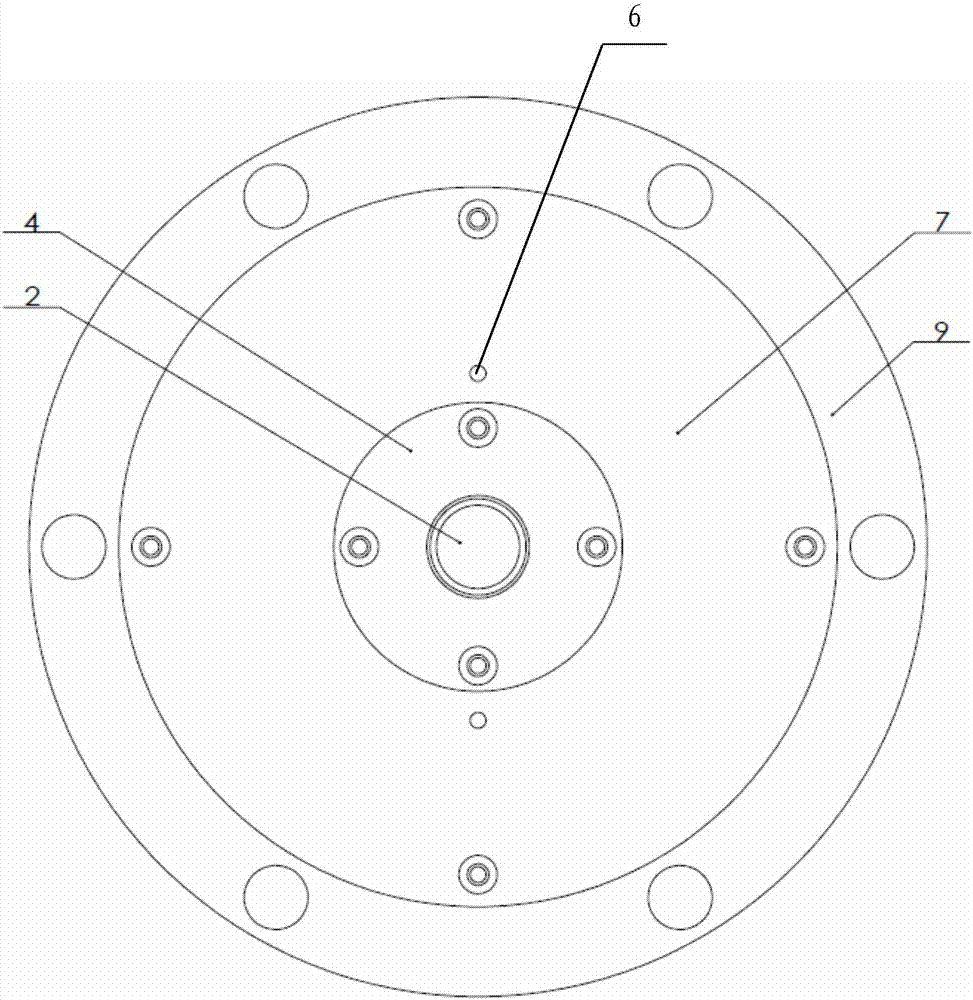

[0019] Such as Figure 1~3 As shown, the present invention includes rotating shaft 2, left end cover 4, oil seal 5, housing, excitation coil 8, copper ring 10, damping disc 12, right end cover 14 and magnetic isolation ring, wherein the housing is divided into left housing 7 And the right housing 9 is fixedly connected by bolts. The outer diameter of the right housing 9 is larger than the diameter of other parts to form a flange for connection. There are a plurality of bolt holes uniformly distributed along the circumference of the flange for damping The overall installation of the device.

[0020] The left end cover 4 is sealed and connected with the left housing 7, the right end cover 14 is sealed and connected with the right housing 9, and the rotating shaft 2 passes through the left end cover 4, the left housing 7, the right housing 9 and the right end c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com