Ball hinge support structure of large caliber reflector of space remote sensor

A technology for large-diameter mirrors and space remote sensors, which is applied in the field of space remote sensing, can solve problems such as affecting imaging quality, difficulty in assembly, and affecting the surface shape of reflecting mirrors, and achieves the effect of satisfying task requirements, easy assembly, and avoiding assembly stress.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

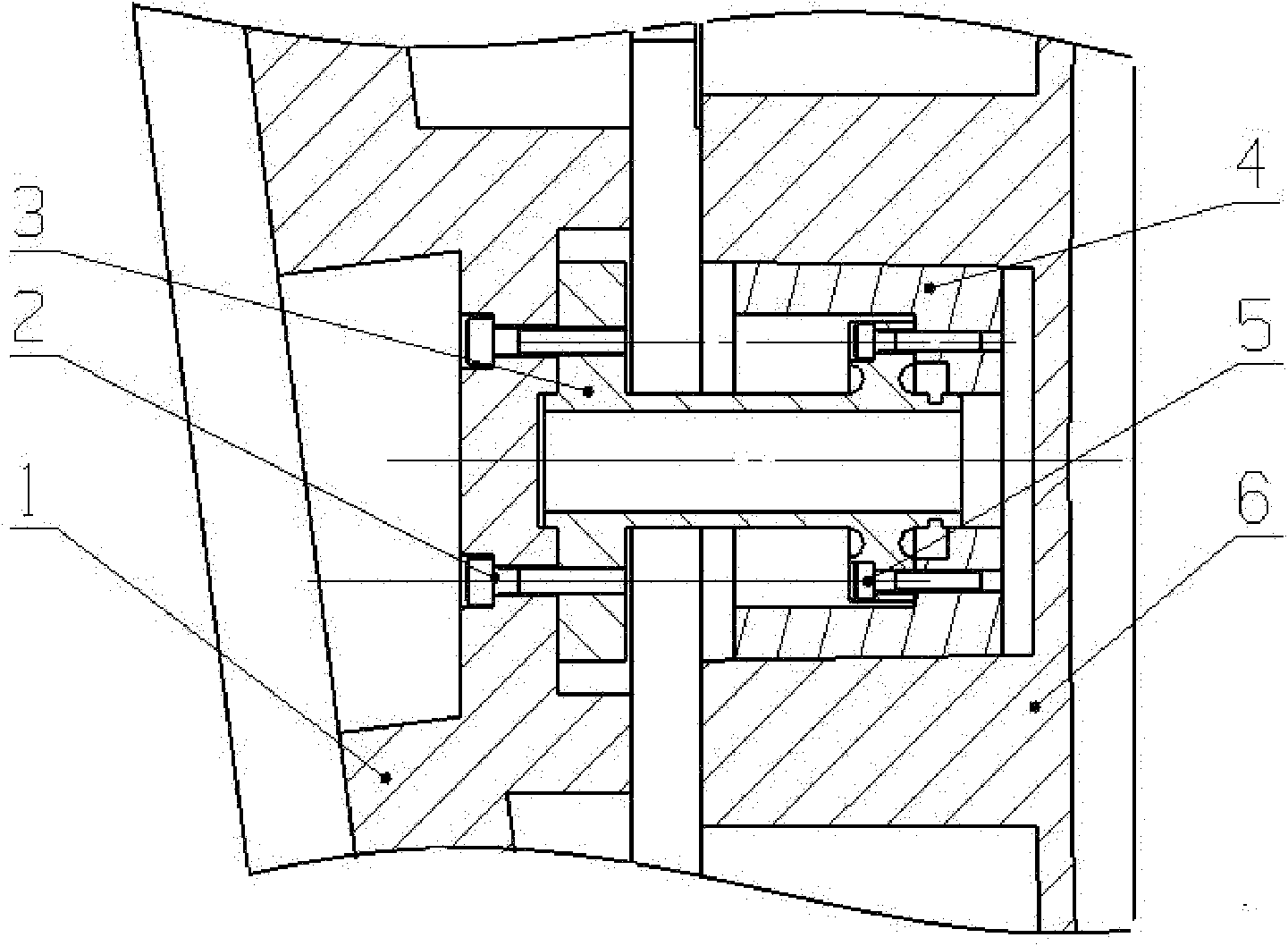

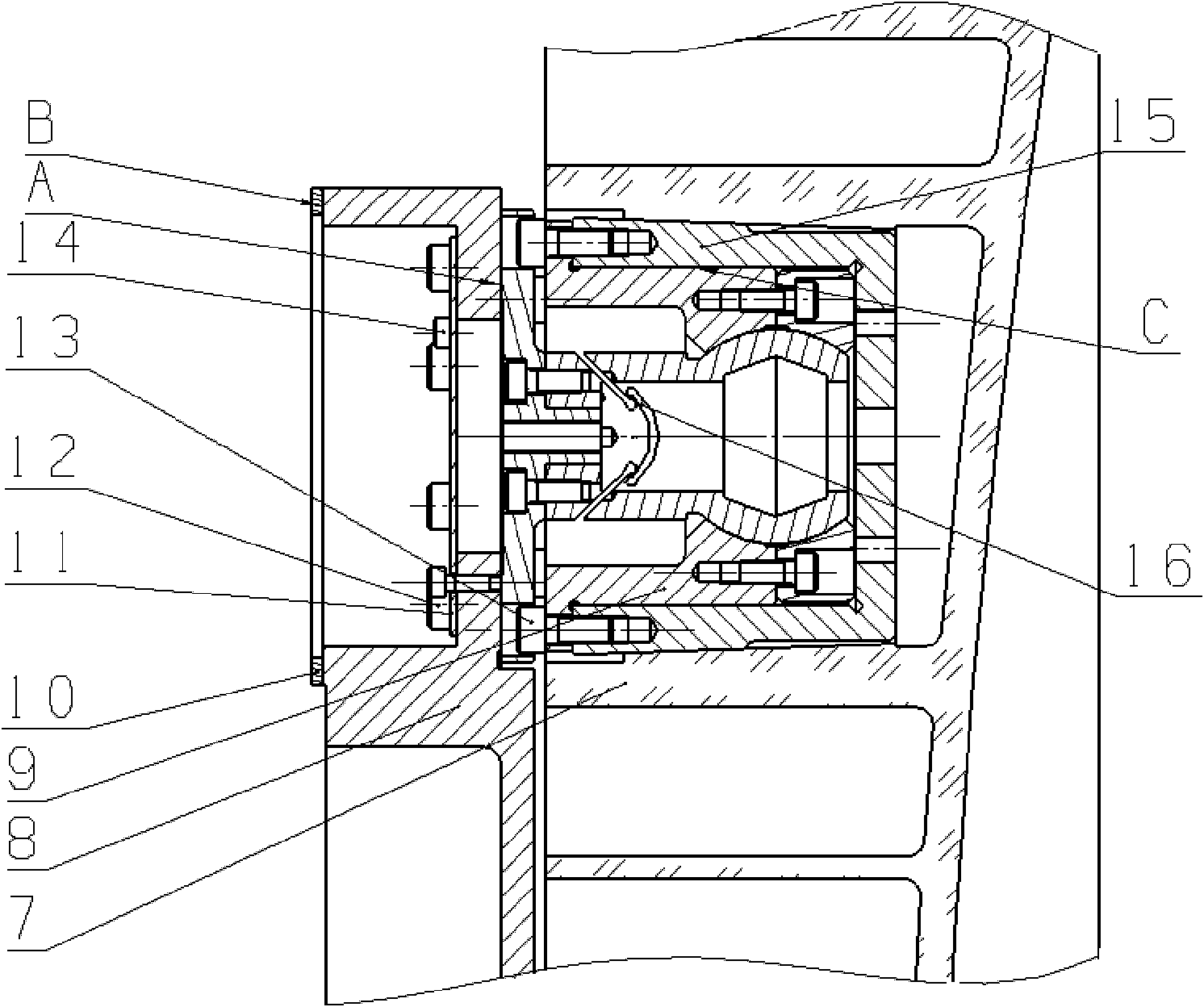

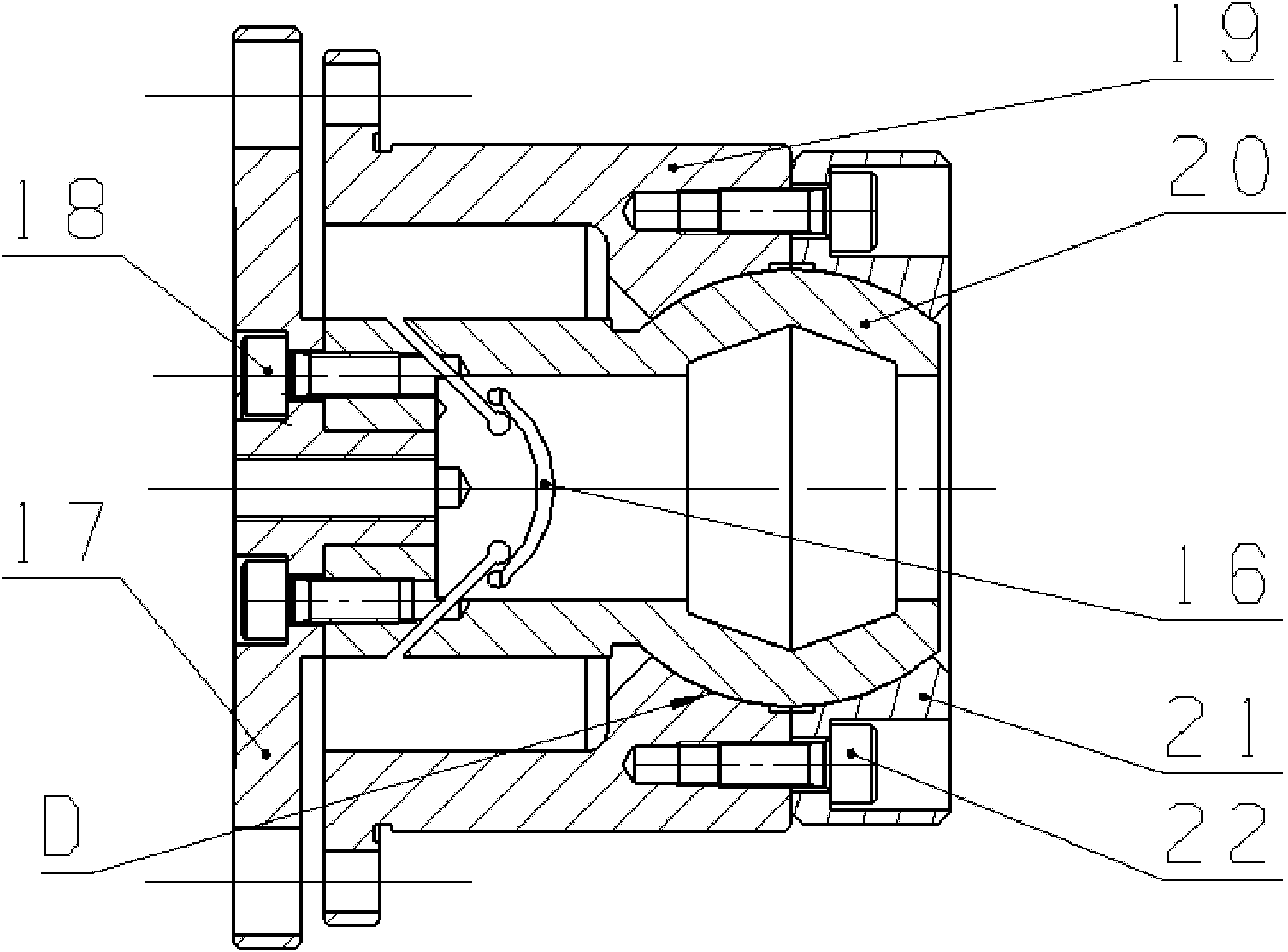

[0015] The invention according to figure 2 The structure shown is implemented. Wherein, the reflector support assembly 9 presses image 3 , Figure 4 and Figure 5 The structure shown is implemented.

[0016] Wherein, the primary mirror 7 is made of SiC material, and its size is Φ676mm in diameter and 99.7mm in thickness. The backplane 8 is made of 4J32 material and measures 402x461x38mm. The mirror assembly training pad 10 is made of 4J32 material and has a size of 151x90x2mm. The protective cover 11 is made of 2A12 material, and its size is Φ72mm in diameter and 1mm in thickness. The third screw 14 is made of 30CrMnsi. The first screw 12 and the second screw 13 are made of TB3 material. Taper sleeve 15 is made of 4J32 material, and its size is Φ79mm in diameter and 58mm in height. The connecting flange 17 is made of 4J32 material, and its size is Φ82mm in diameter and 18mm in height. The first cylindrical pin 23 and the second cylindrical pin 24 are made of TC4 ma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com