Patents

Literature

86results about How to "Strong convenience" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Smart watch car remote starting system and method

ActiveCN105607467AStrong convenienceImprove securityAnti-theft devicesTime-pieces with integrated devicesRemote controlEngineering

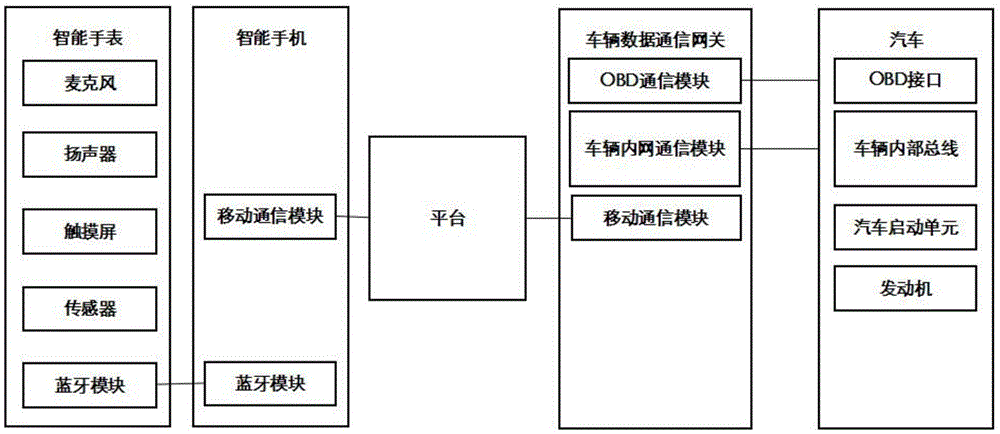

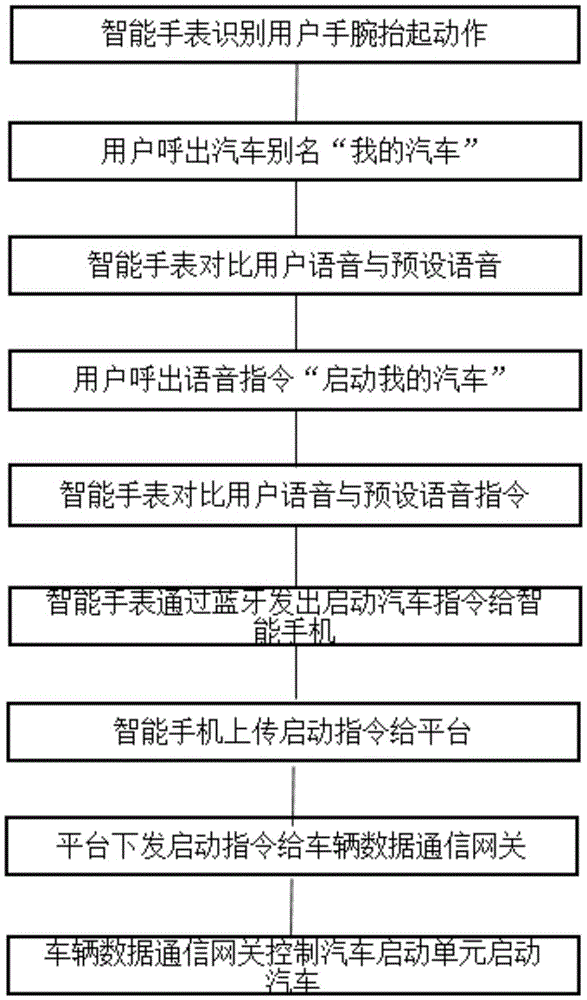

The invention provides a smart watch car remote starting system and method, belonging to the field of smart wearable devices. The system and the method are used for solving the technical problem that existing smart watch does not have a remote control car starting ability, the smart watch is in a real-time starting state in use, the excessive power of the smart watch is consumed, and thus the use time of the smart watch after one time of charging and is not long. The system comprises a smart watch and a smart mobile phone. When the smart watch receives a voice command, corresponding command information is identified and generated, the command information is sent to the smart watch, and the smart watch remotely transmits the command information to a cloud platform. The cloud platform receives the command information sent by the smart watch and remotely sends the control command information corresponding to the command information to a car data communication gateway. The car data communication gateway receives the control command information of the cloud platform and executes car starting or stalling. The system and the method have the effect that the starting and stopping of a car can be remotely controlled by the smart watch.

Owner:DALIAN ROILAND SCI & TECH CO LTD

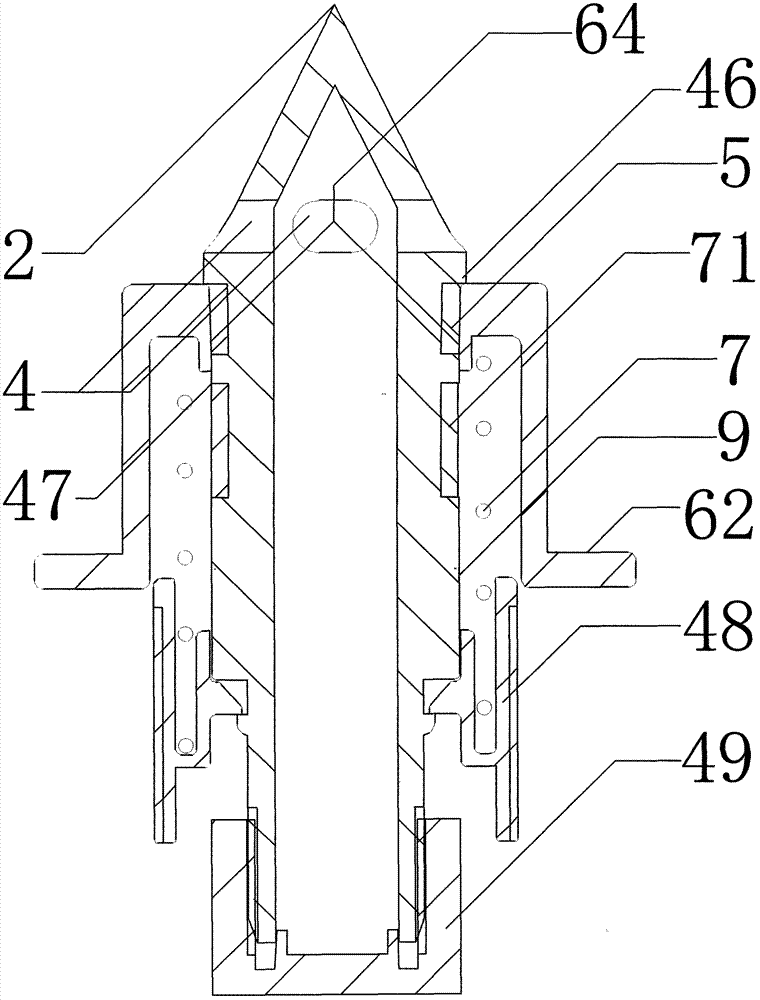

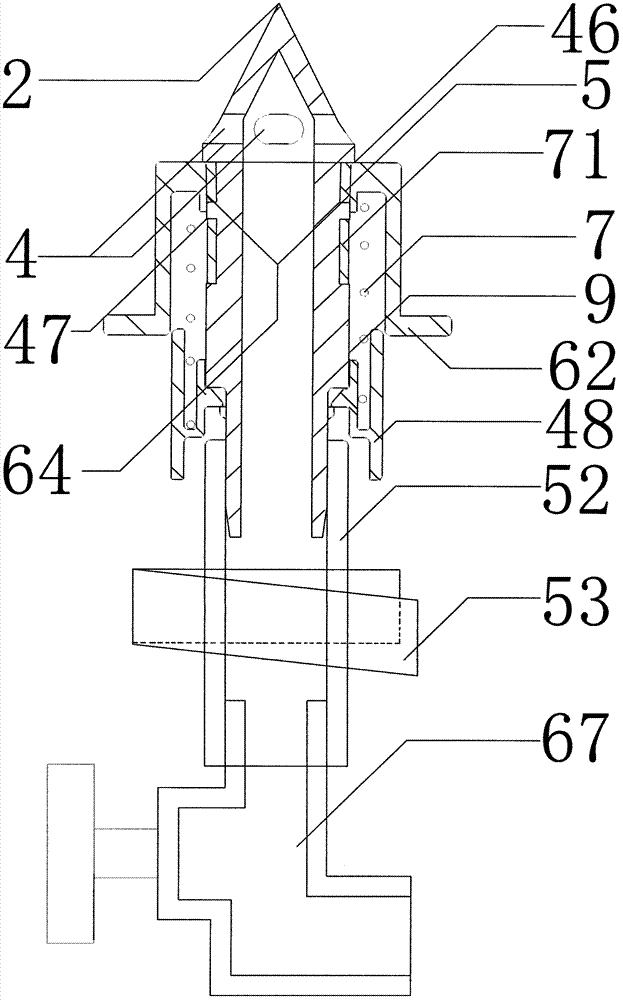

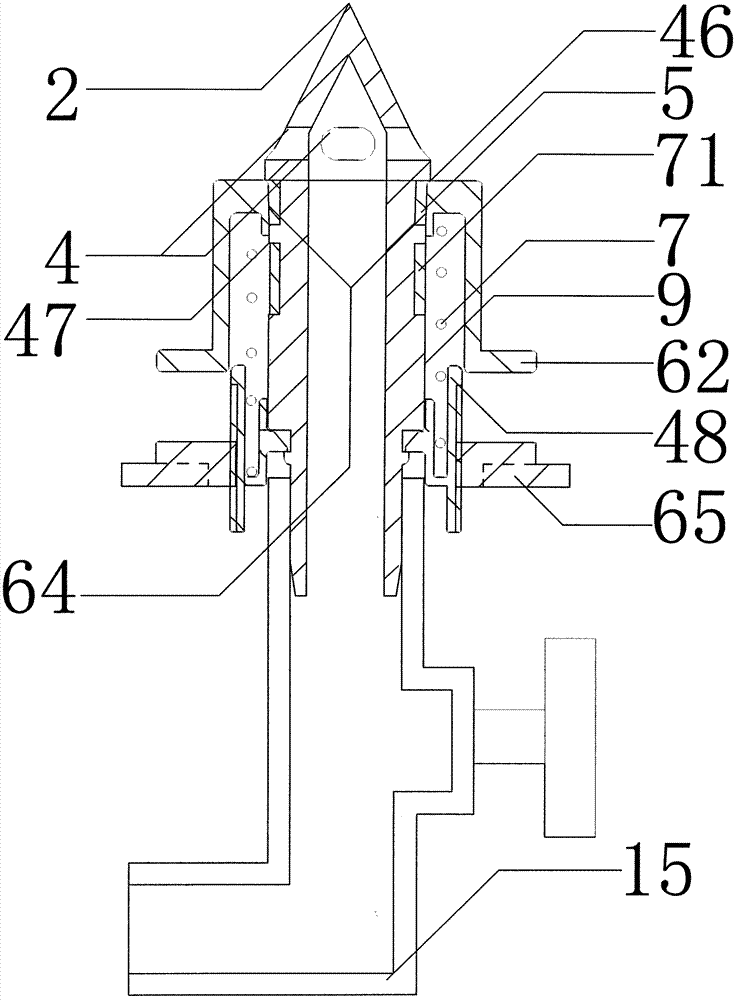

Taking machine for liquid or ropy material with better liquidity in high-capacity plastic flexible package

InactiveCN102765518ALow costImprove economyArticle unpackingDischarging meansFilm resistanceStopcock

The invention relates to a taking machine for liquid or ropy material with better liquidity in a high-capacity plastic flexible package. The taking machine comprises a thimble provided with a limit table and a film resistance table, a locking slide bush A or a locking slide bush B or a locking slide bush C or a base provided with a locking face, a locking seal part, a seal element, a spring, a spring slot, a stopcock or a valve or a water suction pump and a cover or a plug. The beneficial effects of the taking machine are as follows: the possibility that the material in the high-capacity plastic flexible package outflows during the package puncturing process or leaks due to imperfect sealing in use process is completely eradicated; the taking machine provided by the invention can be independently or be connected with a clamp, a stopcock and a valve or a water suction pump for being repeatedly applied to the high-capacity plastic flexible package; and based on the taking machine, a novel portable taking machine, or a connecting device or an all-in-one machine in upper material taking pipeline connecting type, an upper material taking floater connecting type, a lower material taking fixing thimble pipeline connecting type, a lower material taking fixing thimble floater connecting type, a lower material taking movable thimble pipeline connecting type and a lower material movable thimble floater connecting type can be assembled.

Owner:欧阳军

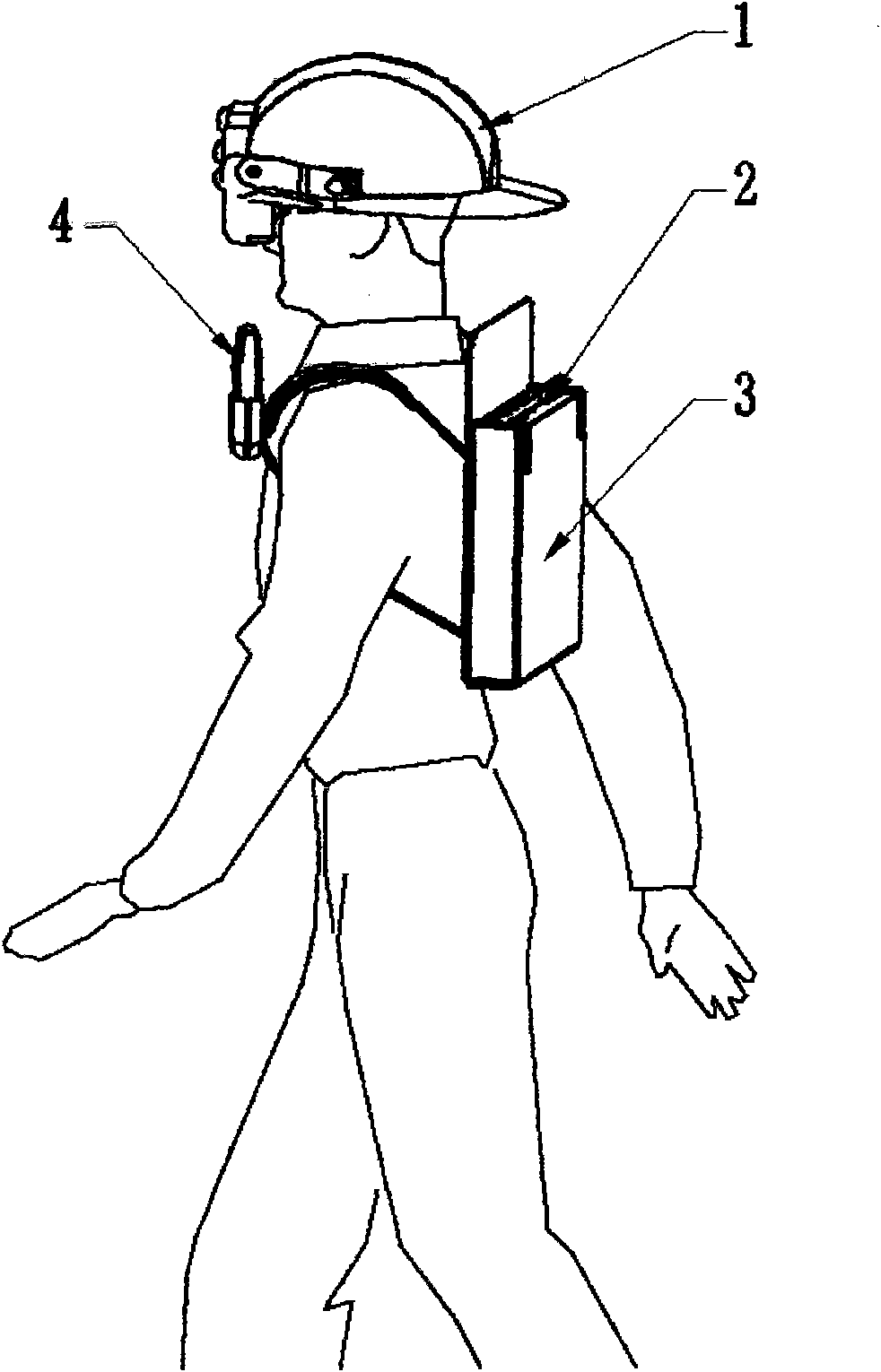

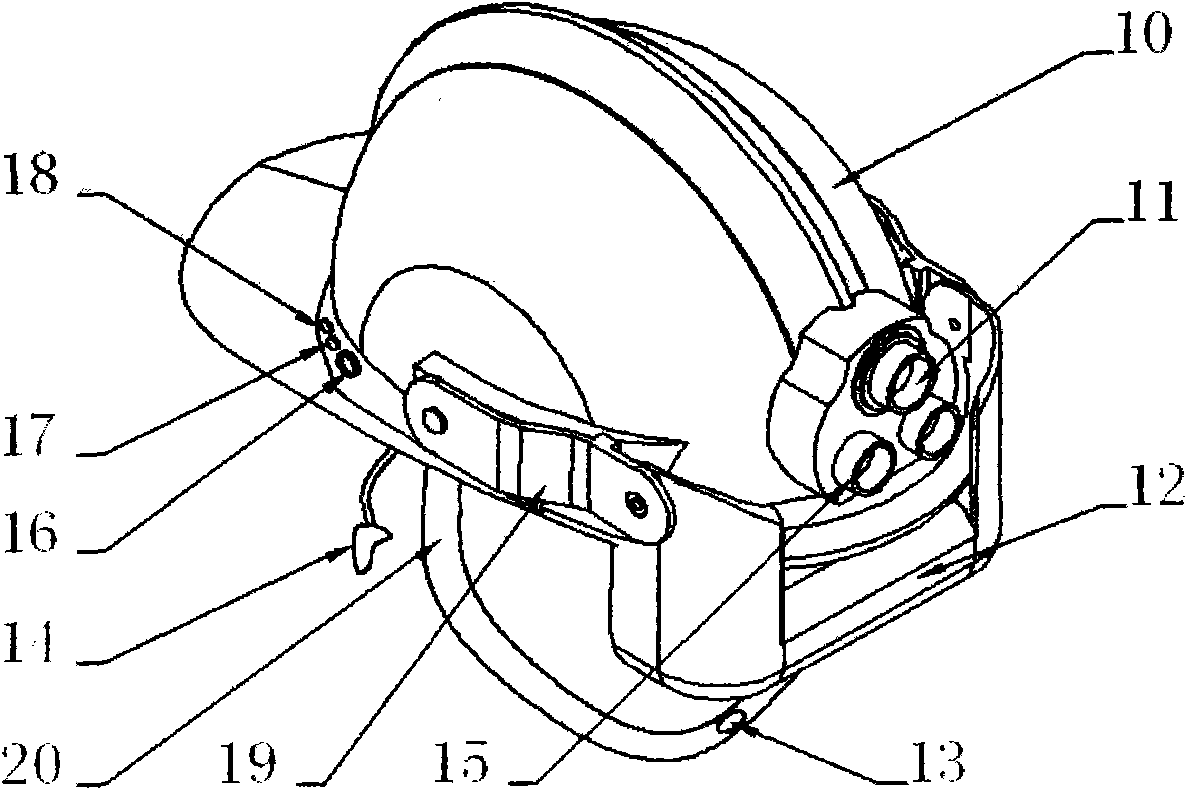

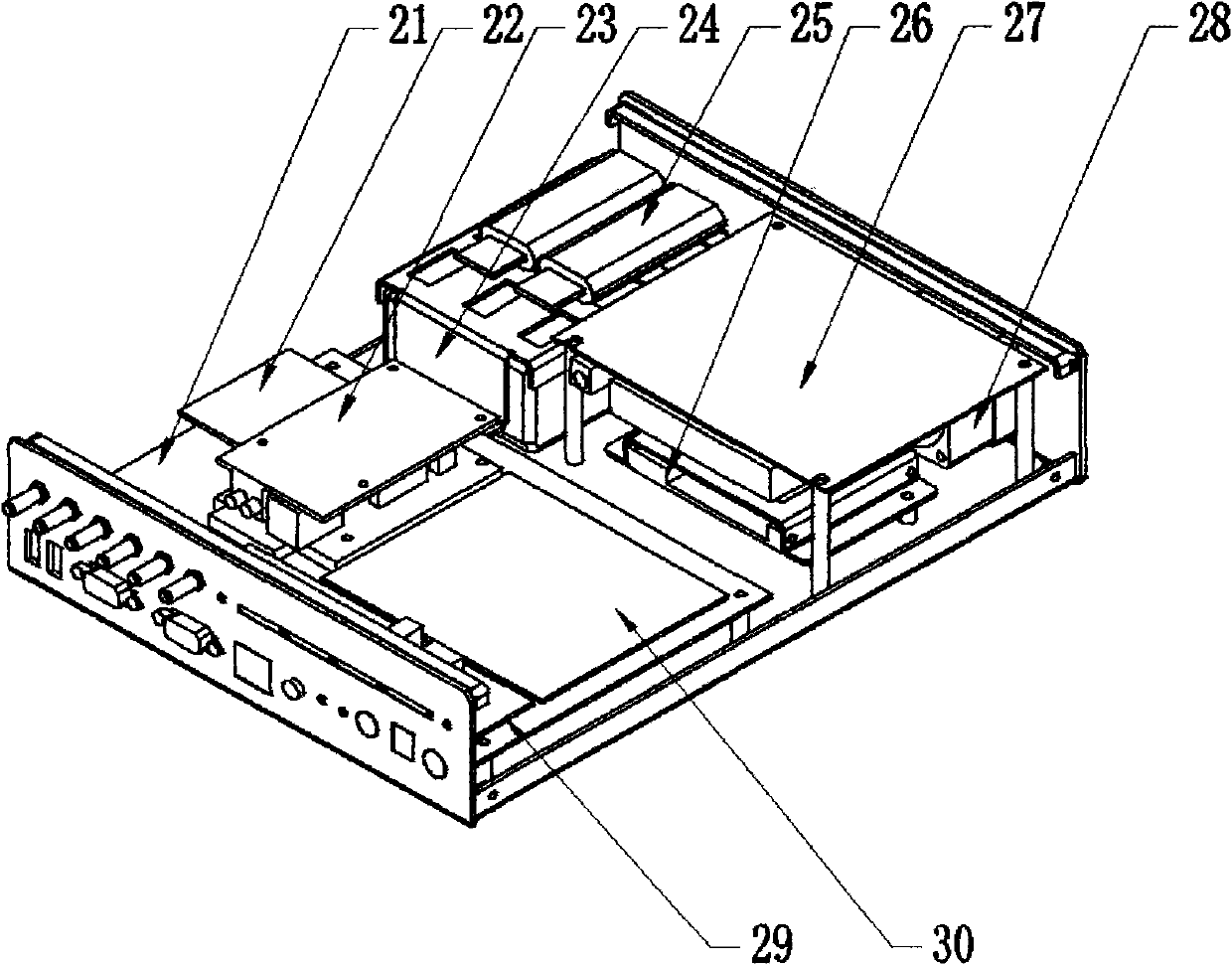

Individual soldier helmet type emergency command system based on various 3G (3rd-Generation) wireless networks

InactiveCN101997563ASolve the problem of needing additional access to image display devicesReduce volumeTelevision conference systemsTwo-way working systemsWireless mesh networkData acquisition

The invention relates to an individual soldier helmet type emergency command system based on various 3G (3rd-Generation) wireless networks, belonging to a system for wireless multifunctional communication based on an individual soldier knapsack and a helmet platform structure. The individual soldier helmet type emergency command system comprises a fully functional helmet, a master controller, the individual soldier knapsack and an operation box. The fully functional helmet is provided with a video camera, an illuminating lamp, a video display unit, a touch sensing type microphone and bony earphones. The master controller is arranged in the individual soldier knapsack. A wireless communication module, a five-path communication antenna, a multi-mode wireless communication module, a network exchange module and a data acquisition and exchange interface are arranged in the master controller. An individual soldier knapsack belt is provided with the operation box. The system does not need to be externally connected with display devices, supports traditional various 3G networks for two-way wireless transmission and interaction of audio and video signals and data, and can be used for executing a plurality of functions, such as remote command, wireless video sessions, image transmission, wireless reconnaissance, wireless measurement, and the like.

Owner:SHAANXI EYINHE ELECTRONICS

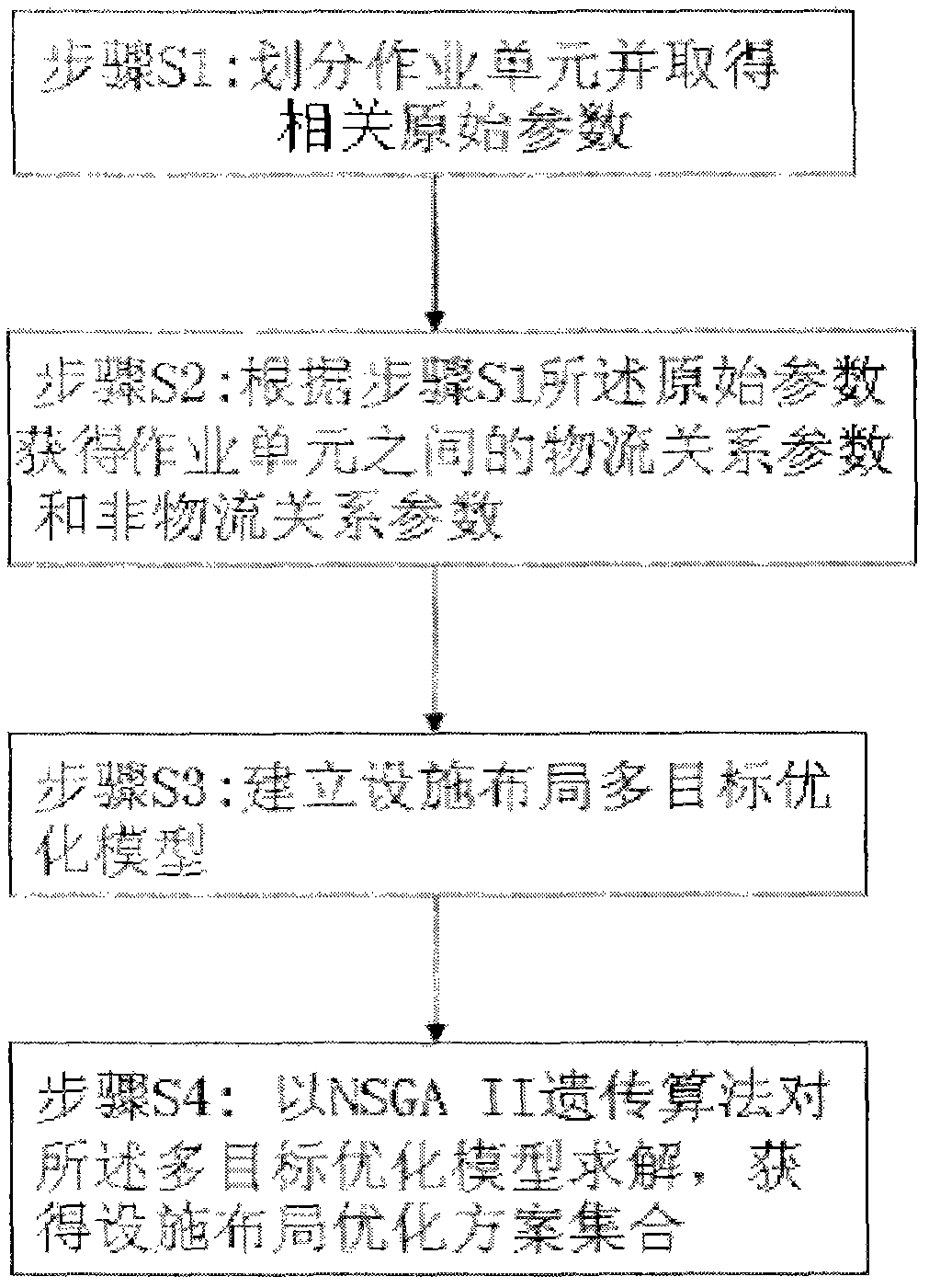

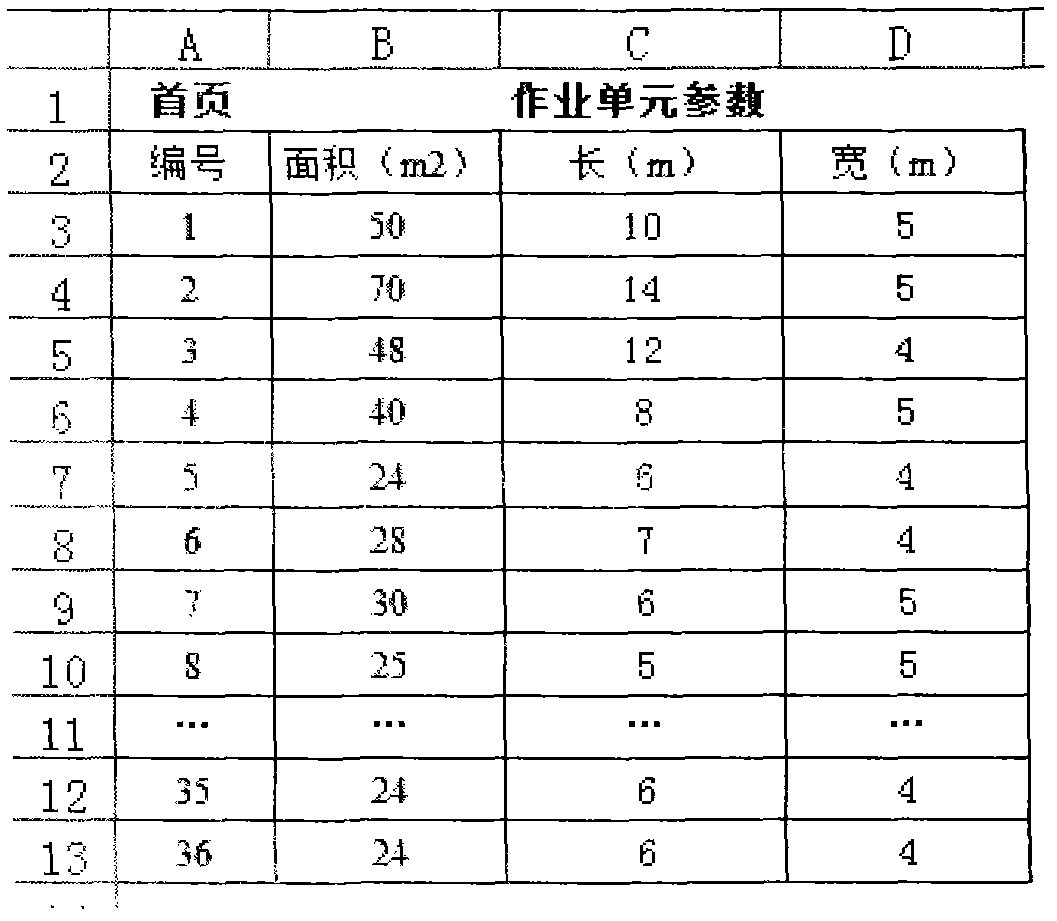

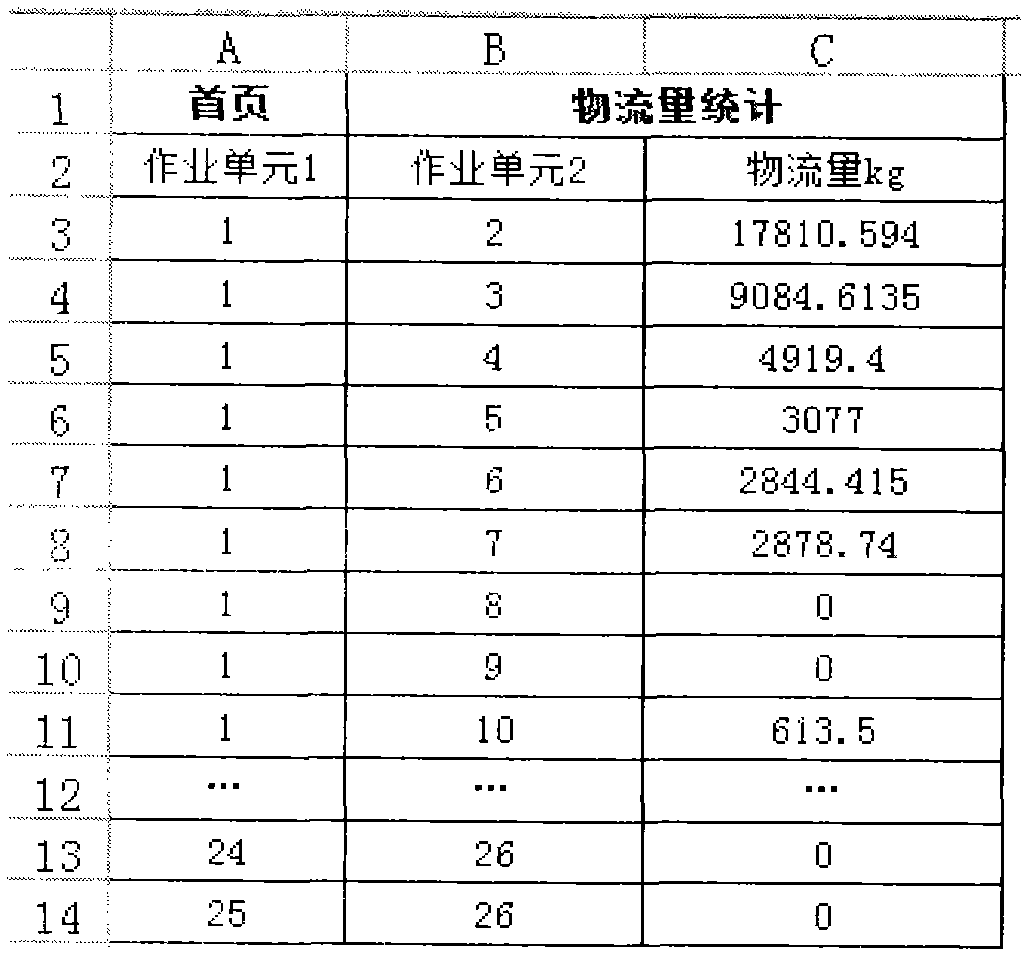

Multipurpose optimization method for distribution of facilities in plant

InactiveCN102214333AReduce Handling CrossoversIncrease intimacyInstrumentsComputer sciencePareto solution

The invention provides a multipurpose optimization method for distribution of facilities in a plant, which comprises the steps of: 1. dividing distribution areas of facilities in the plant into operation units and obtaining related original parameters; 2. obtaining logistic relation parameters and non-logistic relation parameters of the operation units according to the original parameters obtained from the step 1; 3. building a multipurpose facility distribution optimization model; and 4. solving the multipurpose optimization model by using an NSGA (non-dominated sorting genetic algorithm) II, thus obtaining a Pareto solution set as a facility distribution optimization scheme set. With the method, the technical problem that multipurpose optimization distribution is carried out on the facilities in a building of the plant is solved, and the use of the method has the advantages of high distribution efficiency, high operation vision degree, good optimization effect, low use cost and strong university.

Owner:HENAN POLYTECHNIC UNIV

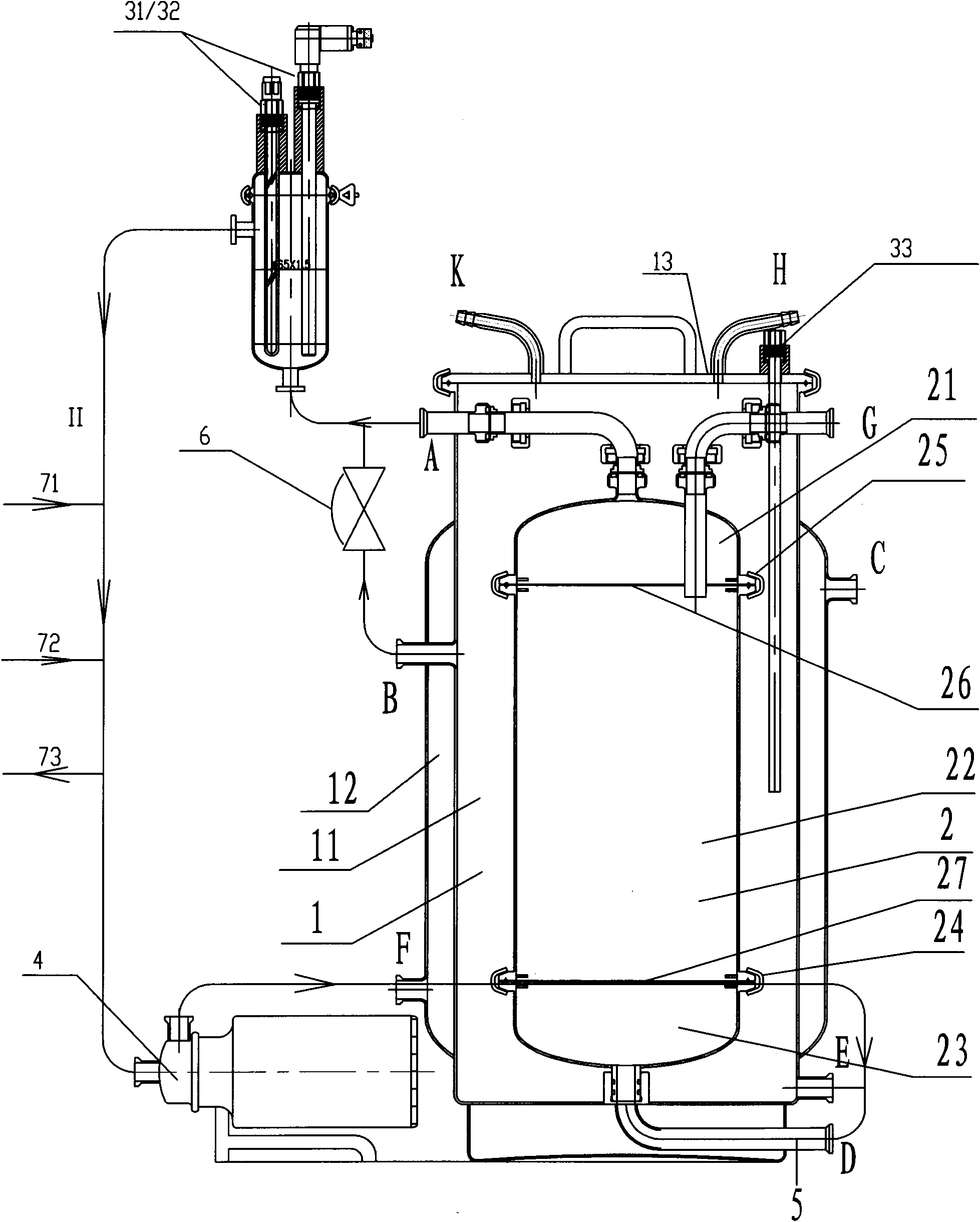

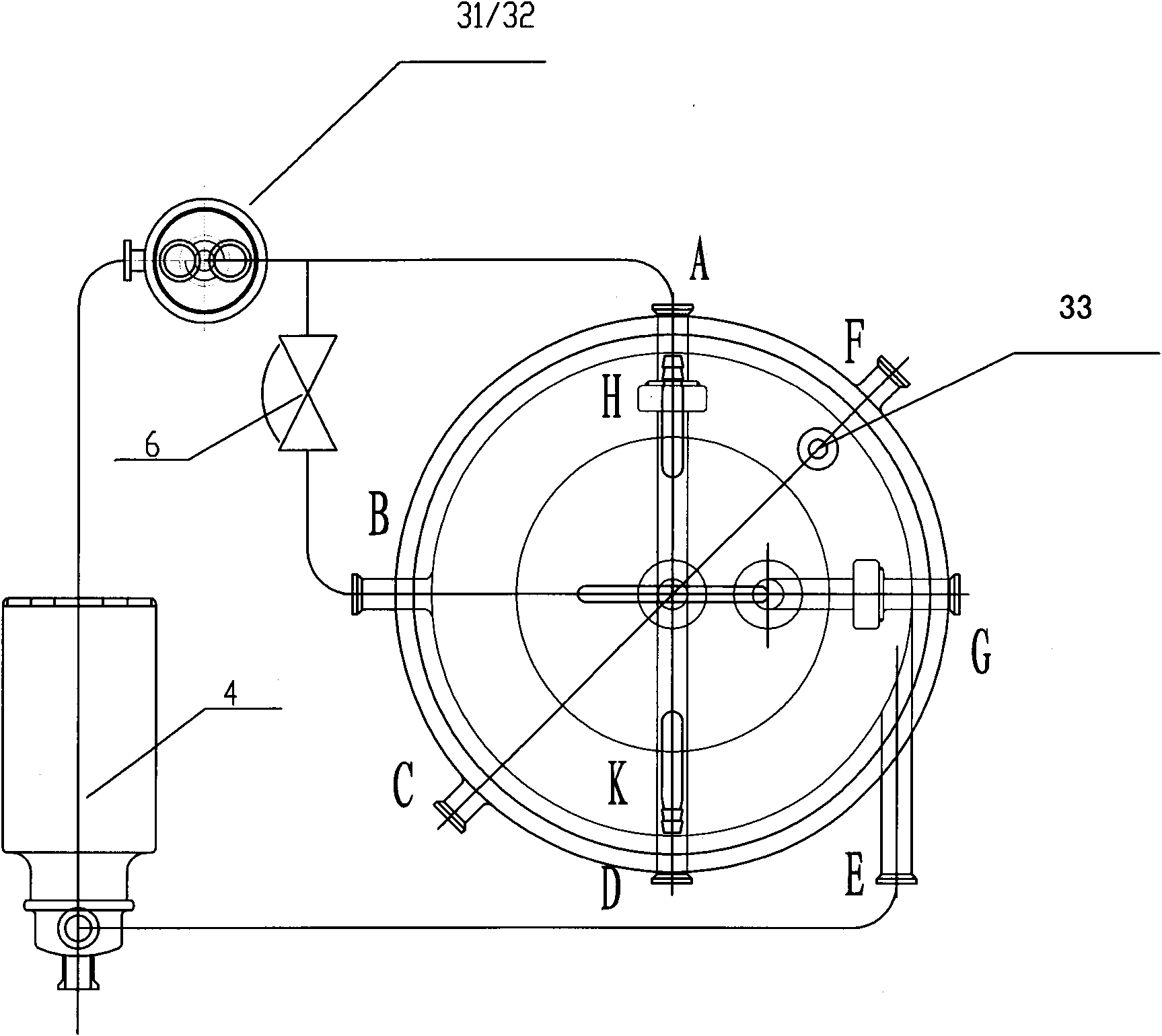

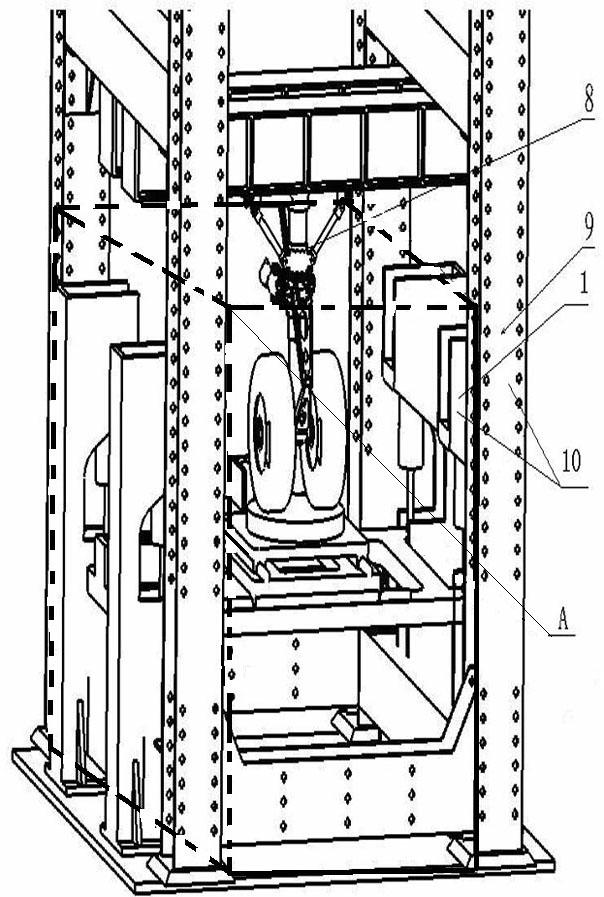

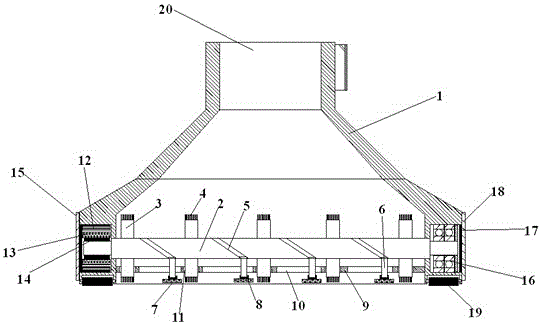

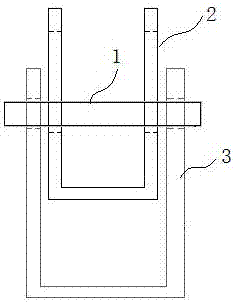

External circulation animal cell culture bioreactor

ActiveCN101899394AOptimize layoutFunctionalBioreactor/fermenter combinationsBiological substance pretreatmentsPeristaltic pumpControl system

The invention relates to an external circulation animal cell culture bioreactor which comprises a tank body, an external circulation pipeline, a heater, a peristaltic pump and a control system, wherein the tank body comprises a large tank and a small tank; the small tank is sheathed in the large tank and is clamped and fixed with the large tank respectively through ducts D, A and G; the external circulation pipeline comprises a tank external circulation pipeline and ducts A, B, E and D; on the upper part of the outside of the tank body, the ducts A and B are connected with the tank external circulation pipeline through a tee joint; on the lower part of the outside of the tank body, the ducts E and D are connected with the tank external circulation pipeline through a tee joint; the tank external circulation pipeline penetrates through the peristaltic pump; and the lowest position of the duct D is connected with a drainage pipe. The invention fully displays the characteristics of the animal cell large-scale culture technique, has the characteristics of thorough sterilization, simple operation, low pollution rate of cell culture, good quality and high yield, has favorable functionality and economical efficiency, and can be widely used for animal cell microcarrier suspension culture and animal cell suspension culture.

Owner:罗火生

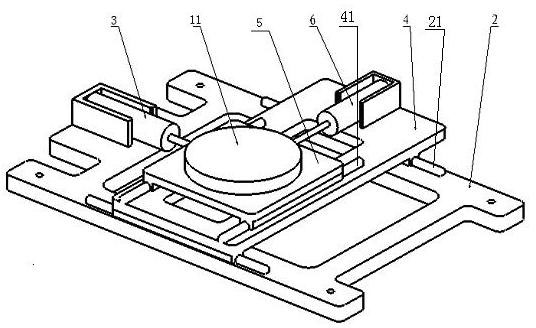

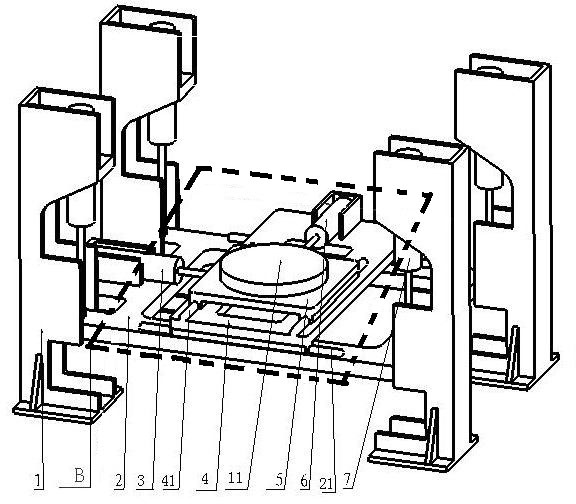

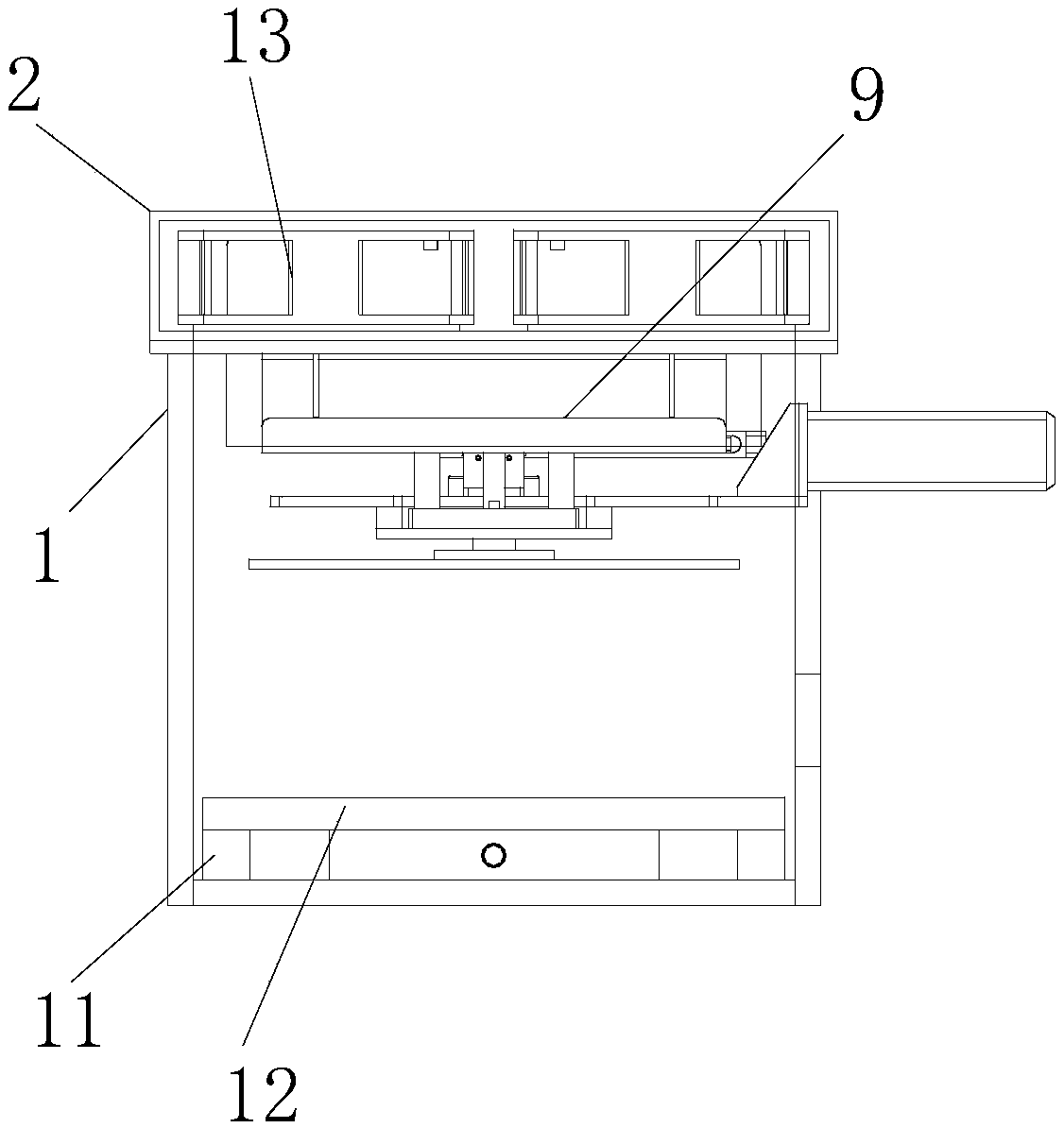

Three-dimensional steering mechanism load simulator and loading method therefor

ActiveCN102582846AMeet the Turn TestPracticalAircraft components testingAirplaneFrictional resistance

The invention relates to a three-dimensional steering mechanism load simulator and a loading method for the load simulator, belonging to the technical field of an airplane steering system test. The simulator consists of a base, an X-axis reciprocating straight-line mechanism, a Y-axis reciprocating straight-line mechanism, a Z-axis reciprocating straight-line mechanism, a bottom platform, a middle platform and a top platform. The method includes the steps that a front landing gear experimental prototype is firstly clamped on the base vertically, then the X-axis reciprocating straight-line mechanism, the Y-axis reciprocating straight-line mechanism and the Z-axis reciprocating straight-line mechanism are controlled to respectively drive the middle platform, the top platform and the bottom platform to do the left-and-right movement, the front-and-back movement and the up-and-down movement, so as to simulate the transverse frictional resistance and the lateral tire force on the airplane when front wheels of an airplane make a turn, namely, various working conditions of the wheels of the airplane in the static turning when the wheels of the airplane are under different ground loads can be simulated. The simulator and the method can achieve the turning test of the front wheels of the airplane under different conditions, and therefore, the practicability and the convenience are very strong, the whole set of device is simple in structure and high in safety.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

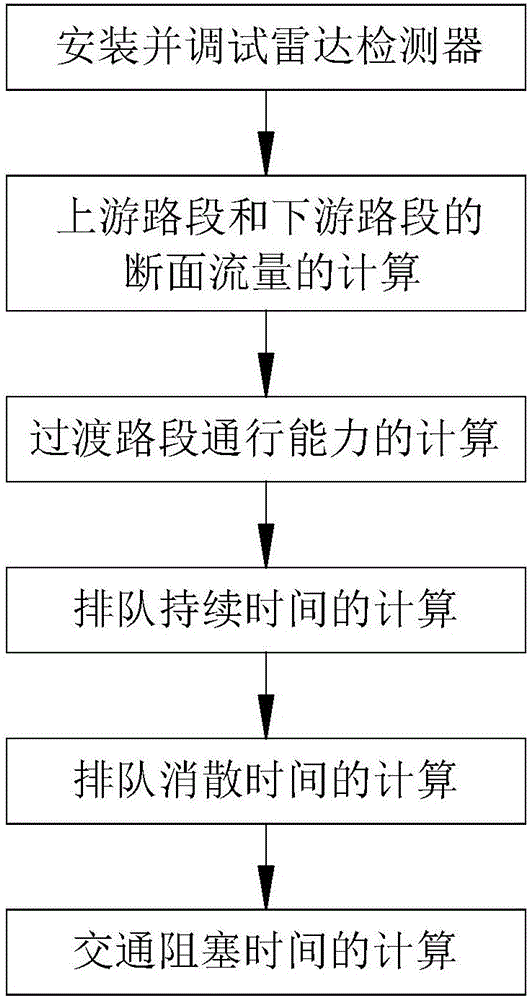

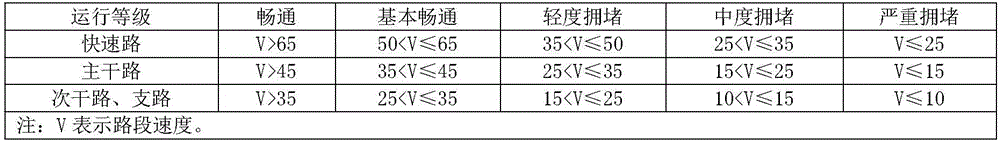

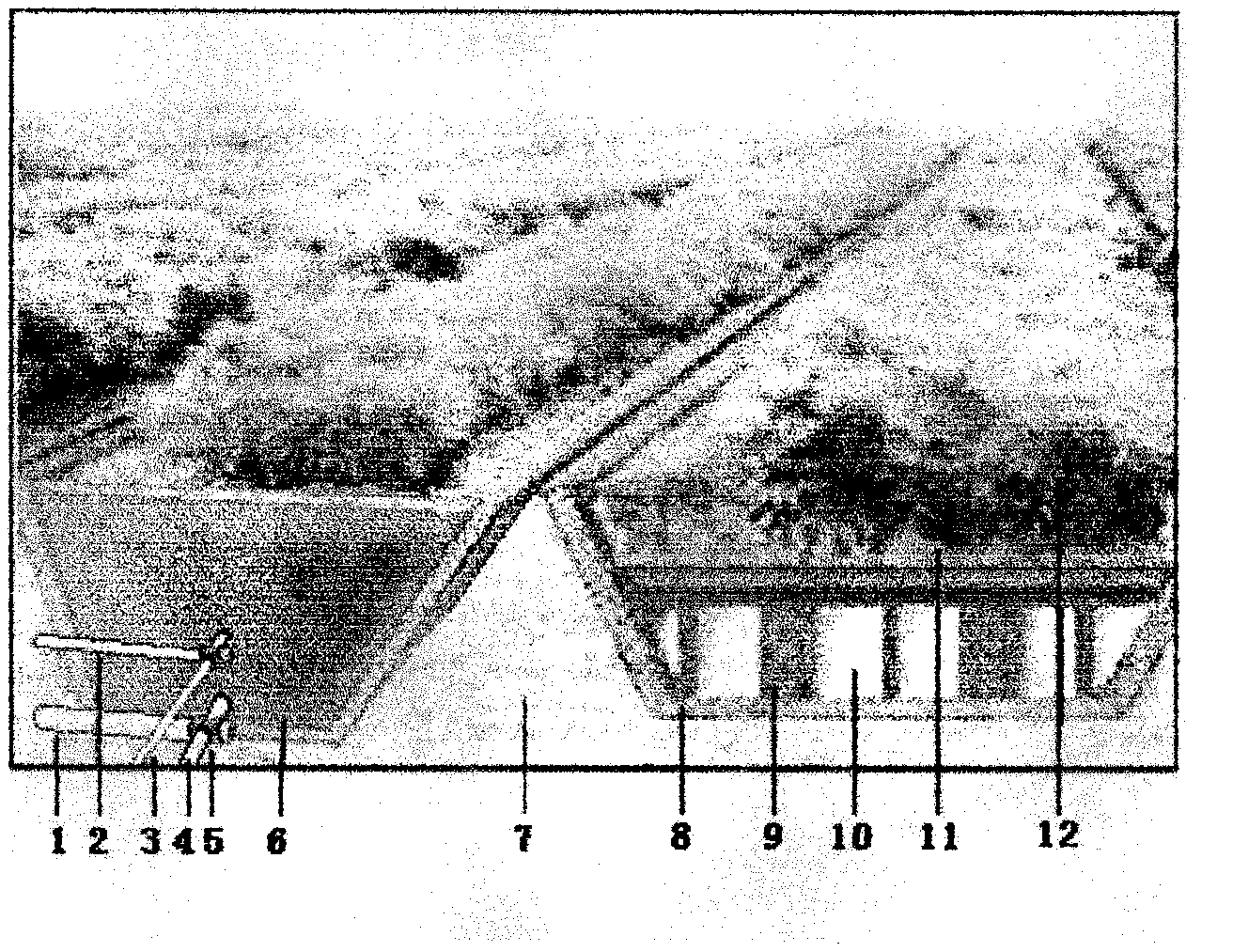

Traffic jam time calculation method for transition road segment

InactiveCN106327881AConvenient early deployment and controlEnsure safe operationRoad vehicles traffic controlTraffic capacityInformatization

The invention belongs to the technical field of urban transportation informatization, and particularly relates to a traffic jam time calculation method for a transition road segment. The method comprises the following steps that 1, a radar detector is installed and debugged; 2, the section flow of the upstream segment and the section flow of the downstream segment are acquired; 3, the traffic capacity of the transition road segment is calculated; 4, the queuing duration time is calculated; 5, the queuing dispersing time is calculated; 6, the traffic jam time is calculated. By means of the method, a traffic commanding center can remind a driver to reasonably set the car speed or reselect a travel route in advance, and then the maximum traffic capacity of the transition road segment is achieved on the premise that safe operation of the transition road segment is guaranteed. Even different emergency measures can be taken according to the different traffic jam times, so that reliable running of a whole traffic system in daily operation is guaranteed.

Owner:ANHUI SUN CREATE ELECTRONICS

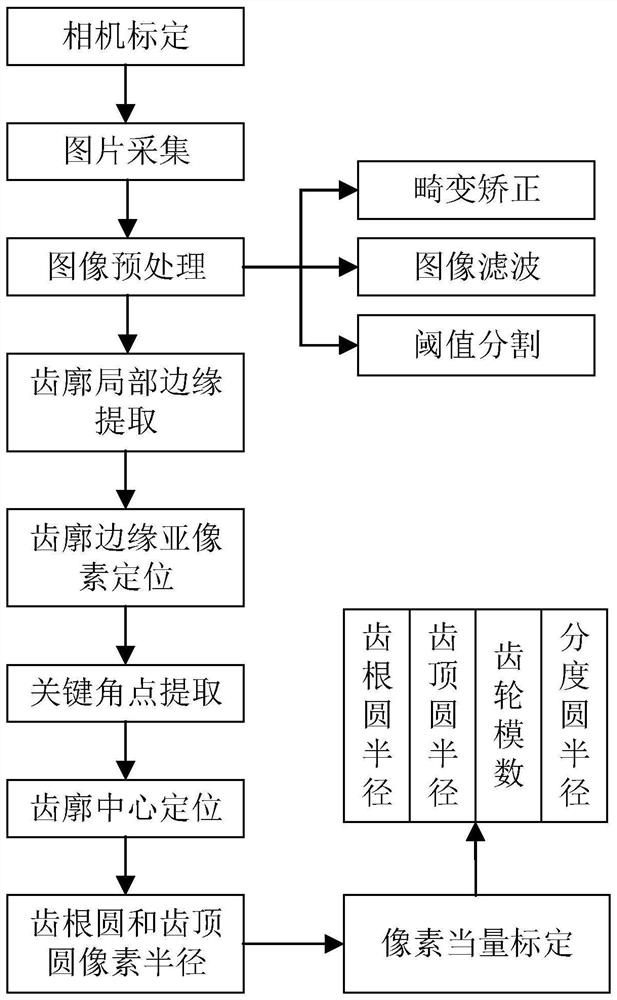

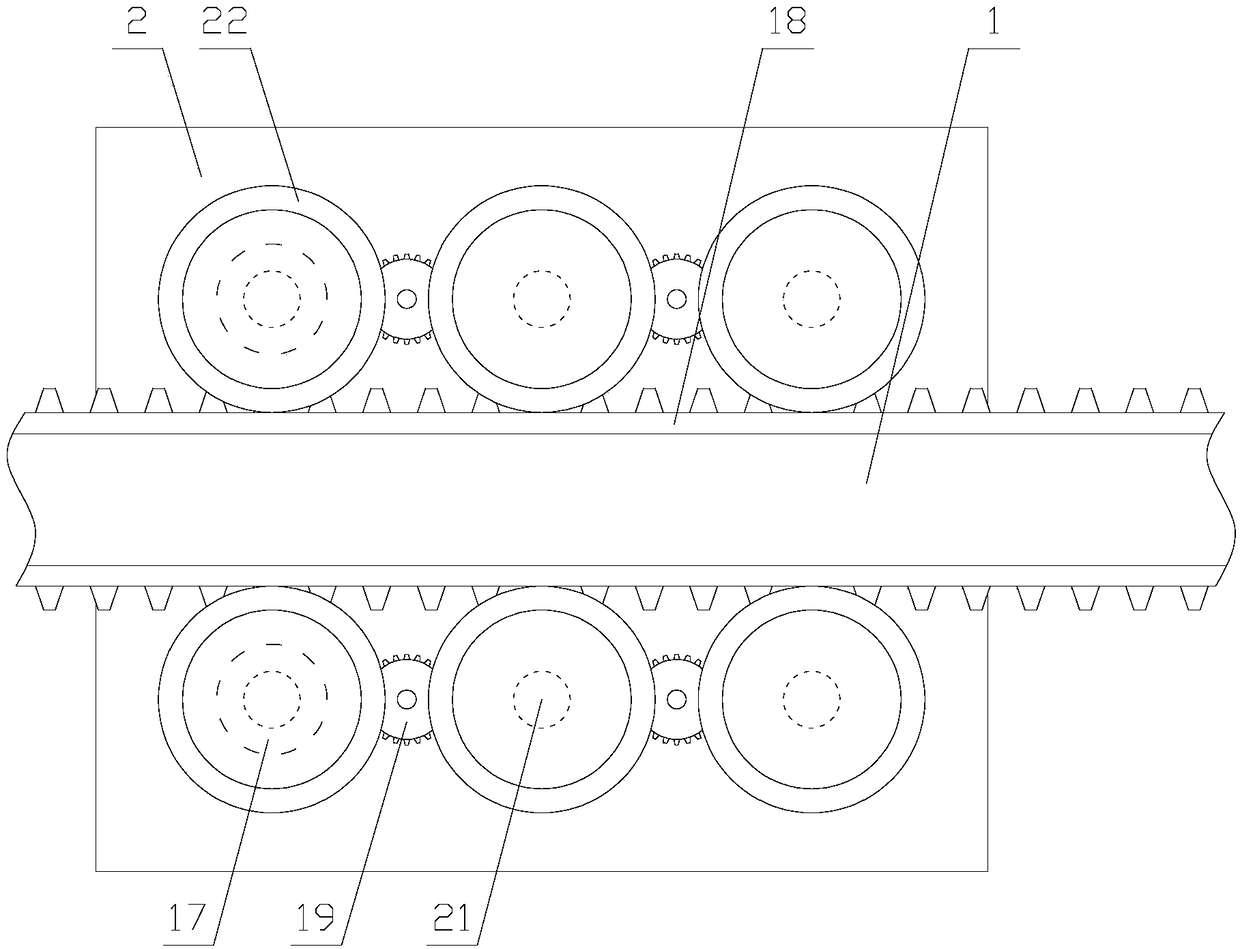

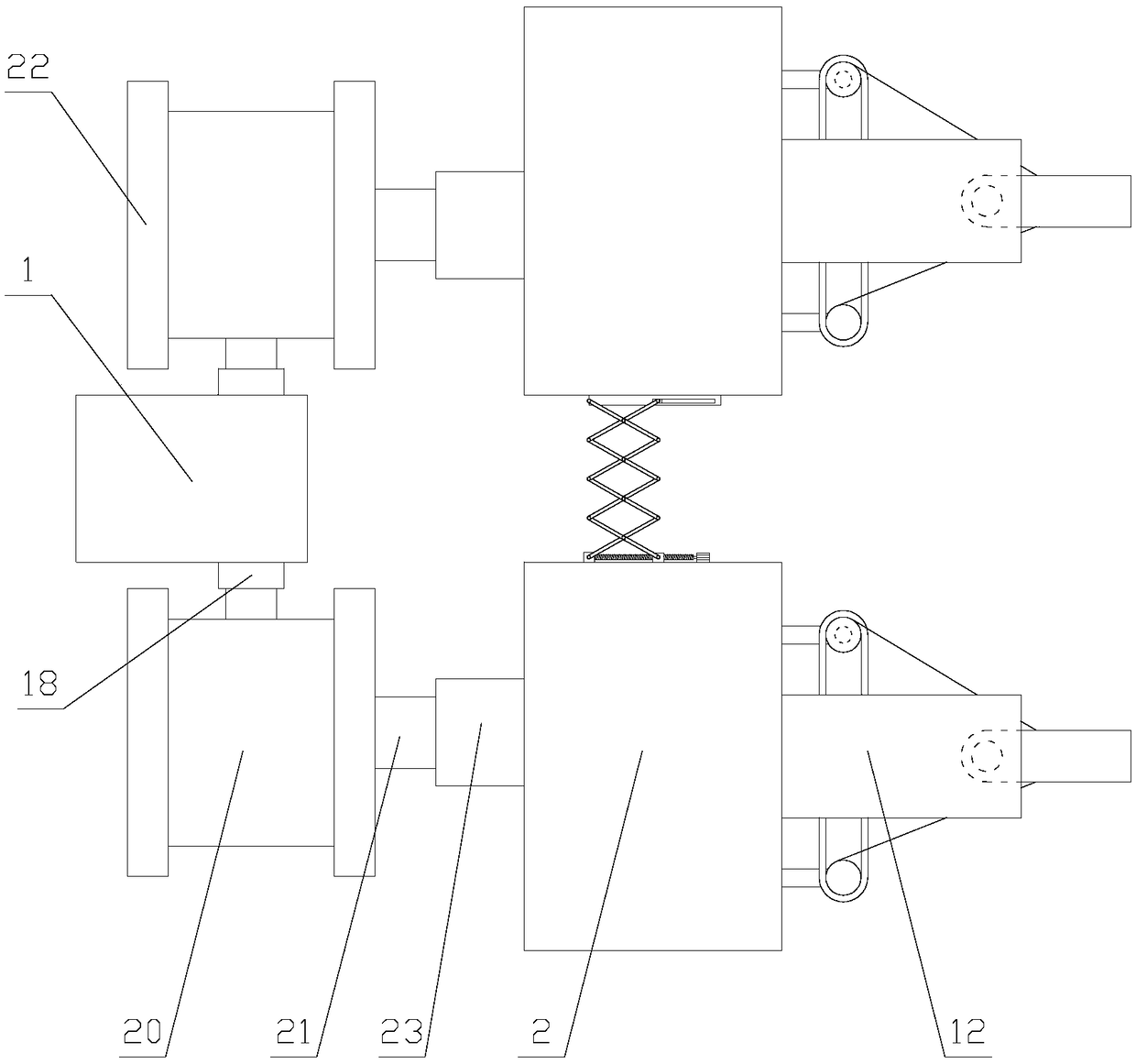

Large spur gear geometric parameter measurement system and method based on machine vision

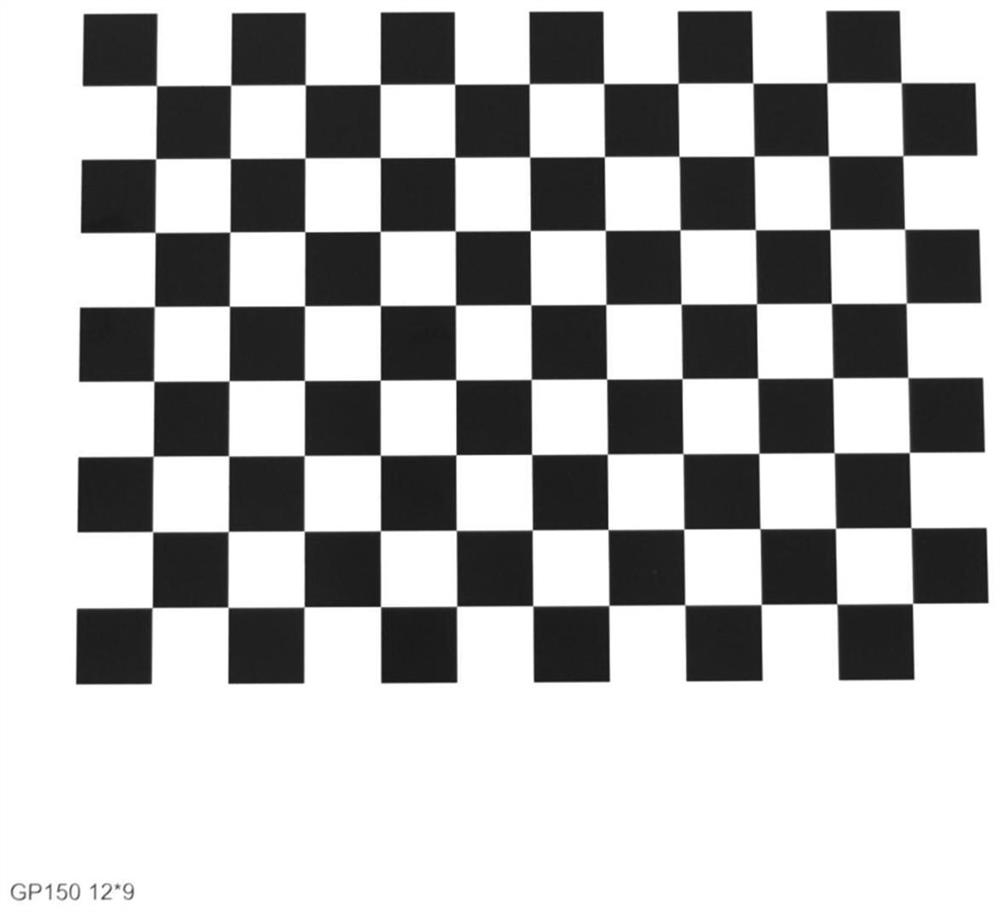

PendingCN114494045AEasy to measureHigh degree of automationImage enhancementImage analysisImaging processingMachine vision

The invention provides a large straight gear geometric parameter measurement system and method based on machine vision, and the method comprises the steps: firstly adjusting a camera to a proper position, and enabling the camera to clearly shoot a needed picture; calibrating the camera to obtain an internal reference matrix and a distortion vector of the camera; preprocessing the shot tooth profile local image, wherein the preprocessing comprises distortion correction, image filtering and threshold segmentation; extracting a tooth profile edge local image by using an edge extraction algorithm, and further finely positioning the edge by using a sub-pixel method to obtain a sub-pixel edge; then, extracting key angular points of the tooth profile by using an angular point extraction algorithm, and determining a sub-pixel center of the tooth profile according to the angular points; according to the sub-pixel center, obtaining a gear root circle radius and an addendum circle radius under the pixel coordinate; and through pixel equivalent calibration, obtaining a real root circle radius and an addendum circle radius of the gear, thereby calculating a modulus and a reference circle radius of the gear, and completing measurement of geometric parameters of the large straight gear. According to the method, the measurement automation degree of the geometric parameters of the large straight gear is higher, the function of integrating monocular camera calibration, image processing, parameter measurement and calculation can be achieved, the input cost is low, and the engineering application value is high.

Owner:NANJING GONGDA CNC TECH

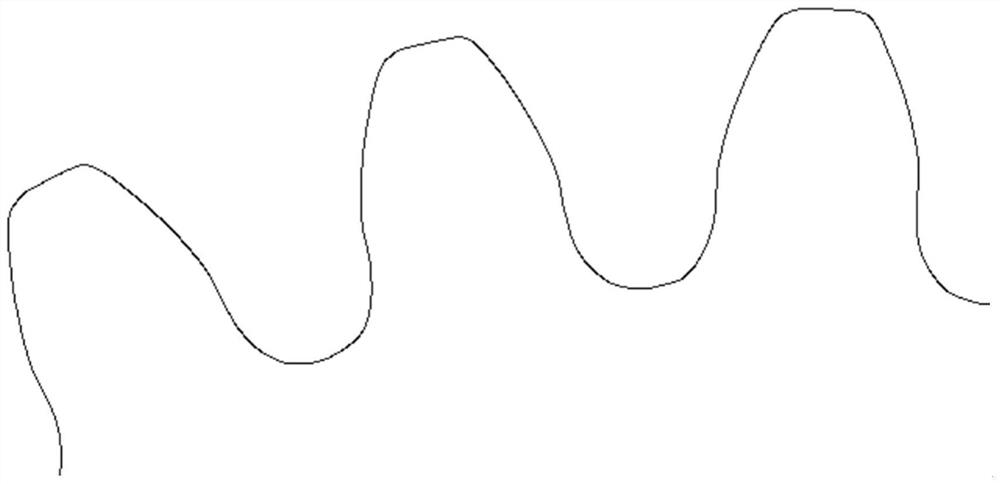

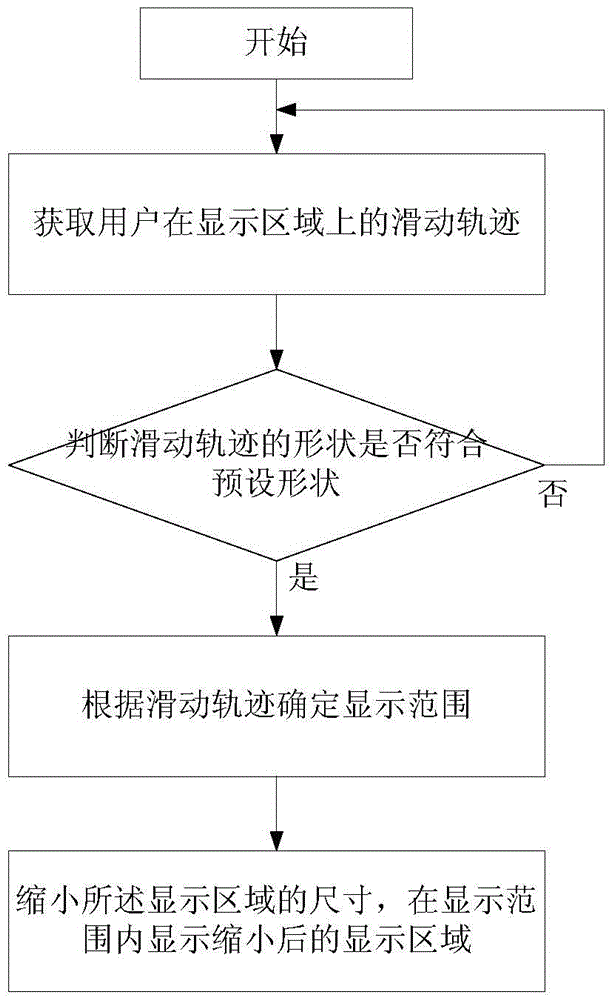

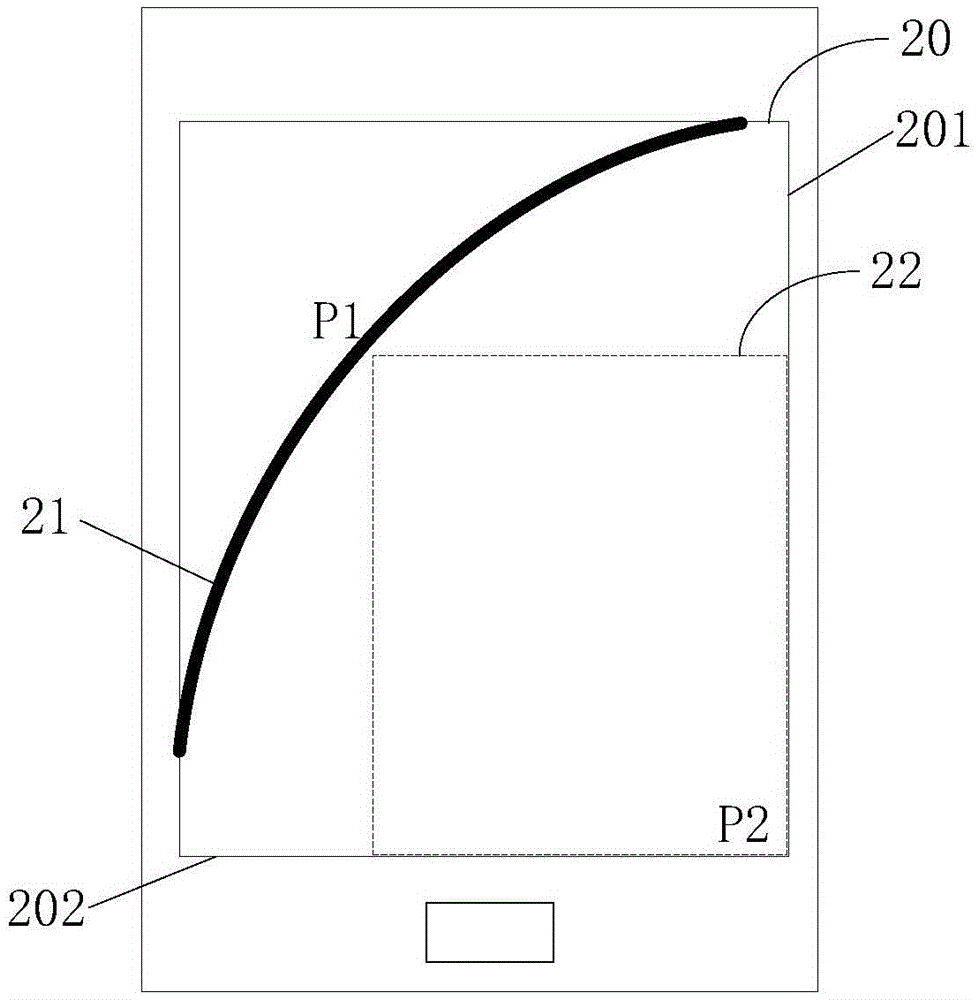

Display region adjustment method and apparatus

InactiveCN105867800AAvoid misuseIncrease flexibilityInput/output processes for data processingComputer graphics (images)

Owner:LEMOBILE INFORMATION TECH BEIJING

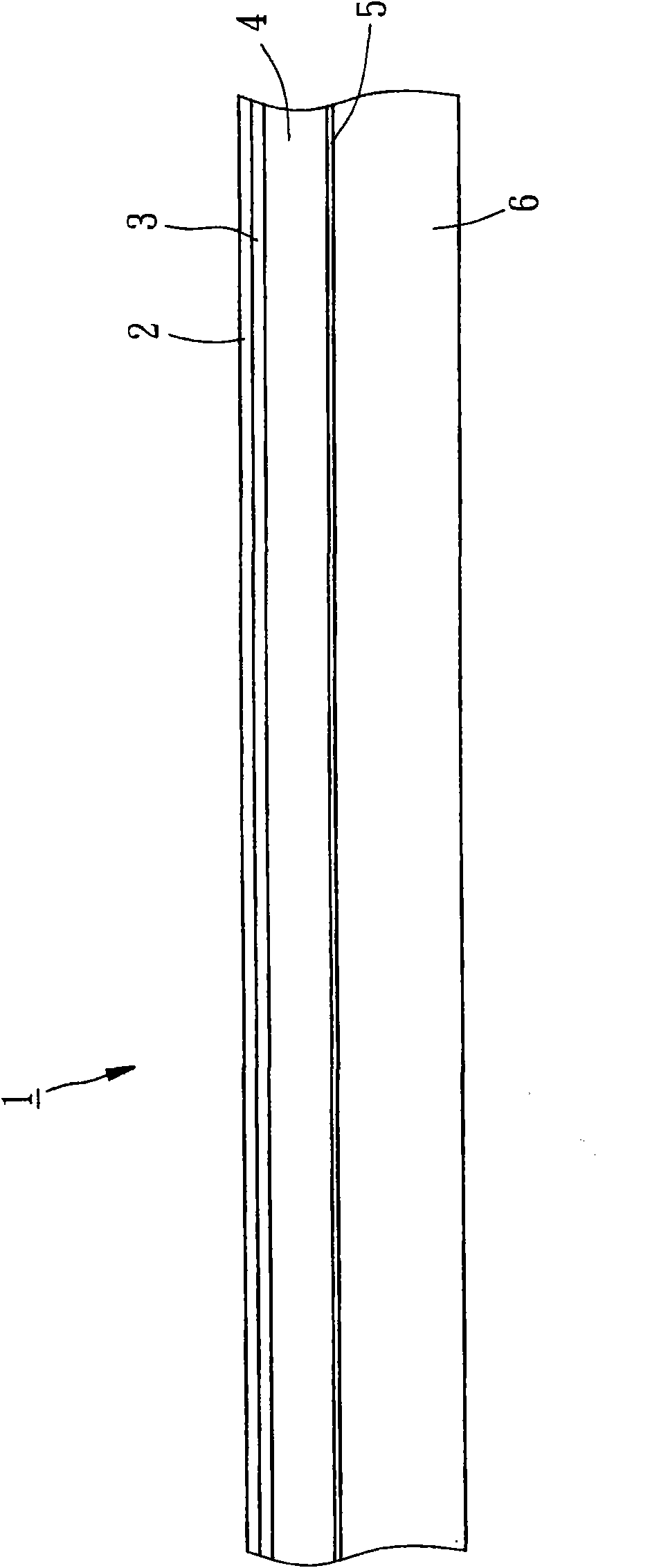

Metallic transfer printing film

InactiveCN101579972ASimplify the stepsStrong convenienceDuplicating/marking methodsSynthetic resin layered productsPolyesterEngineering

The invention relates to a metallic transfer printing film which is provided with a first side and a second side and sequentially comprises an anti-after tack layer, a PET layer, a release layer, a protection layer, a resin layer, a metal layer and a glue layer from the first side to the second side, wherein the protection layer can be made of thermoplastic polyurethane (TPU), polythene (PE) or thermoplastic polyester elastomer (TPEE). Therefore, the metallic transfer printing film not only has convenient use but also has no toxicity.

Owner:TAIWAN GINKGO FILM COATING TECH CORP

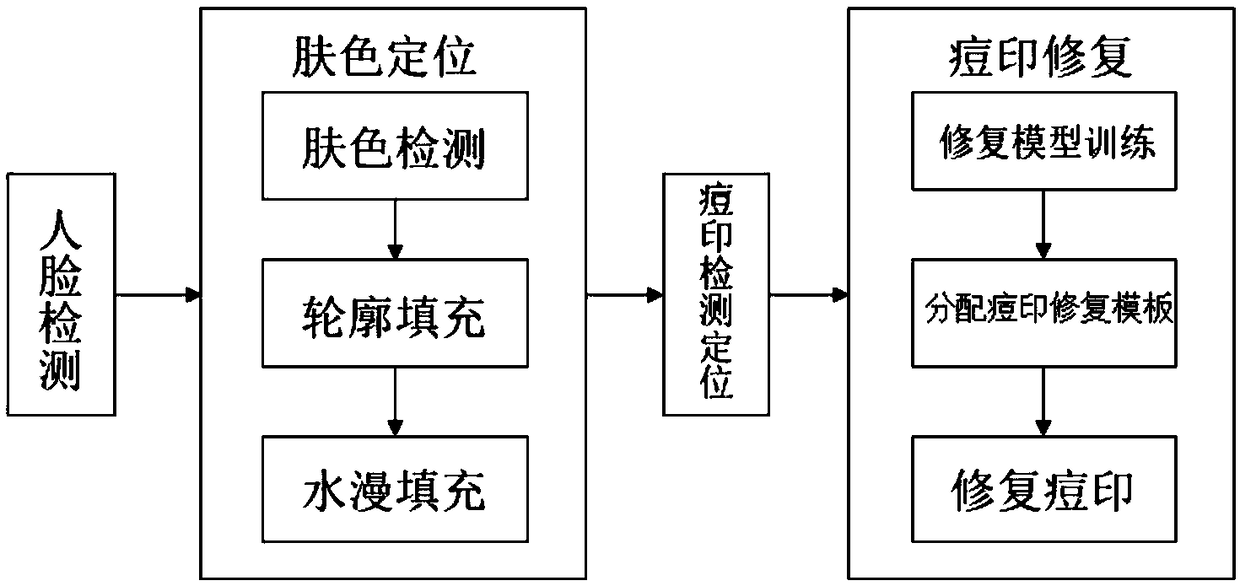

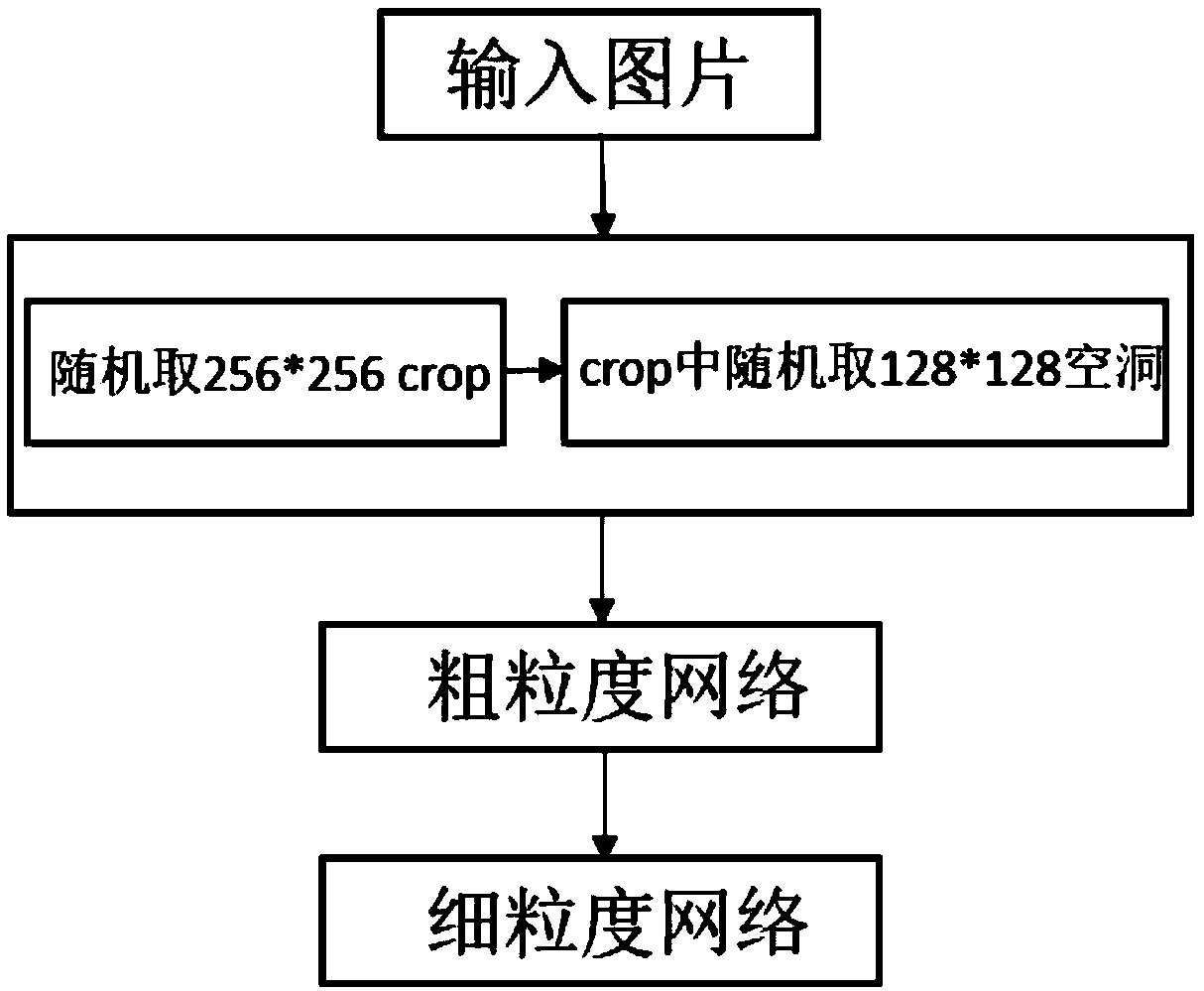

An automatic face acne removing method based on image inpainting model

ActiveCN109345480AImprove experienceClean up thoroughlyImage enhancementImage analysisFace detectionPimple

The invention relates to a method for automatically removing human face pox based on an image inpainting model, which adopts the following steps: step 1, determining the human face position in a picture, recognizing the human face in the picture through a human face detection module, locating the human face range through 68 key points of the human face, and obtaining a rectangular frame of the human face range; 2, determine a human face skin color range, taking a rectangular frame of that human face range as a kernel, and construct a filling region along the periphery of the rectangular frameof the human face range; The RGB skin color detection algorithm is used to locate the skin color region, the contour filling method is used to fill each detected skin color region, and then the flooding filling method is used to lock the face skin color region. User experience is good, do not need user to specify the location of the pimple, the algorithm can be automatically completed to remove the pimple.

Owner:GUANGZHOU YUNCONG ARTIFICIAL INTELLIGENCE TECH CO LTD

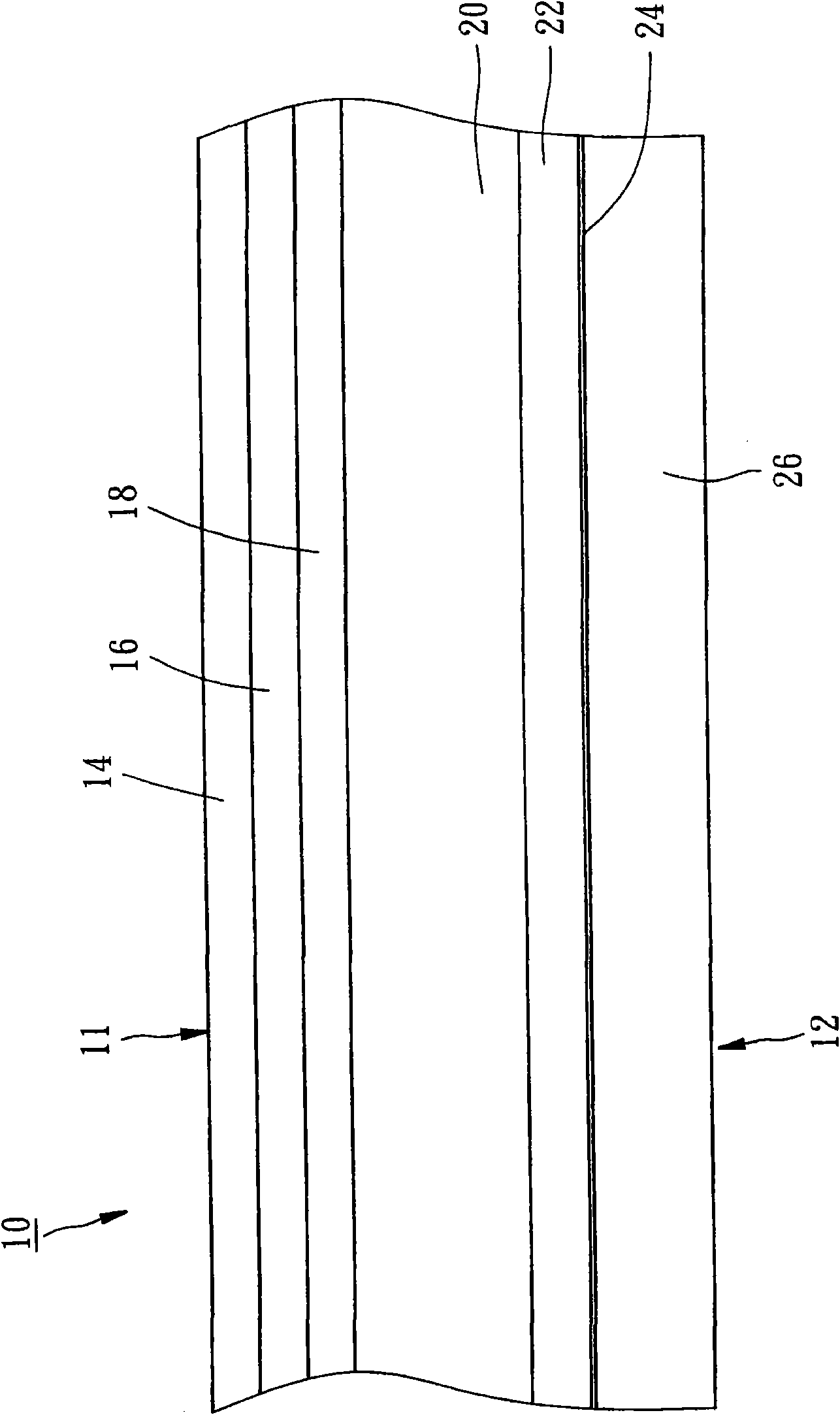

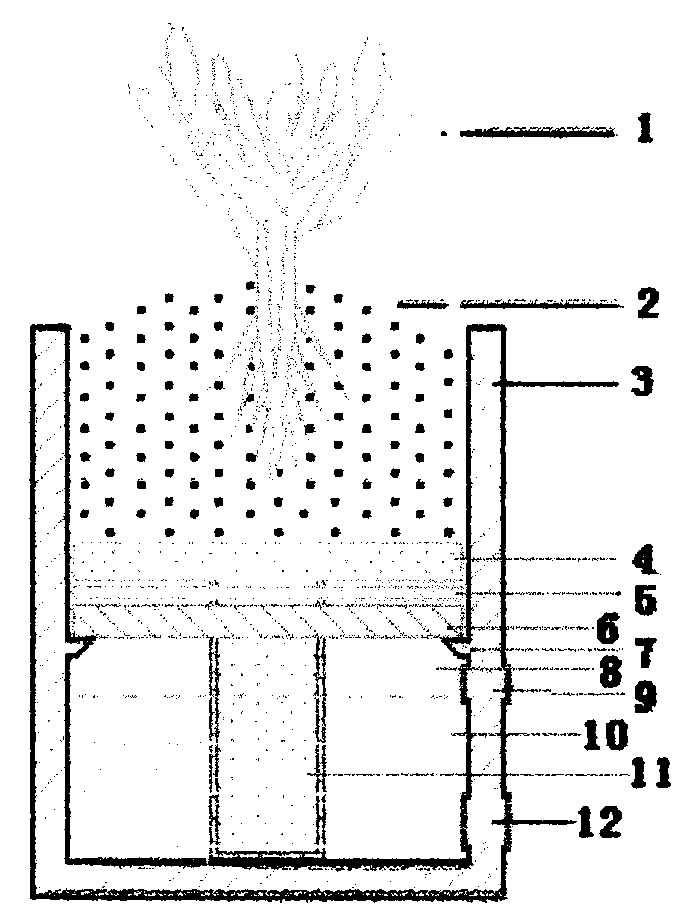

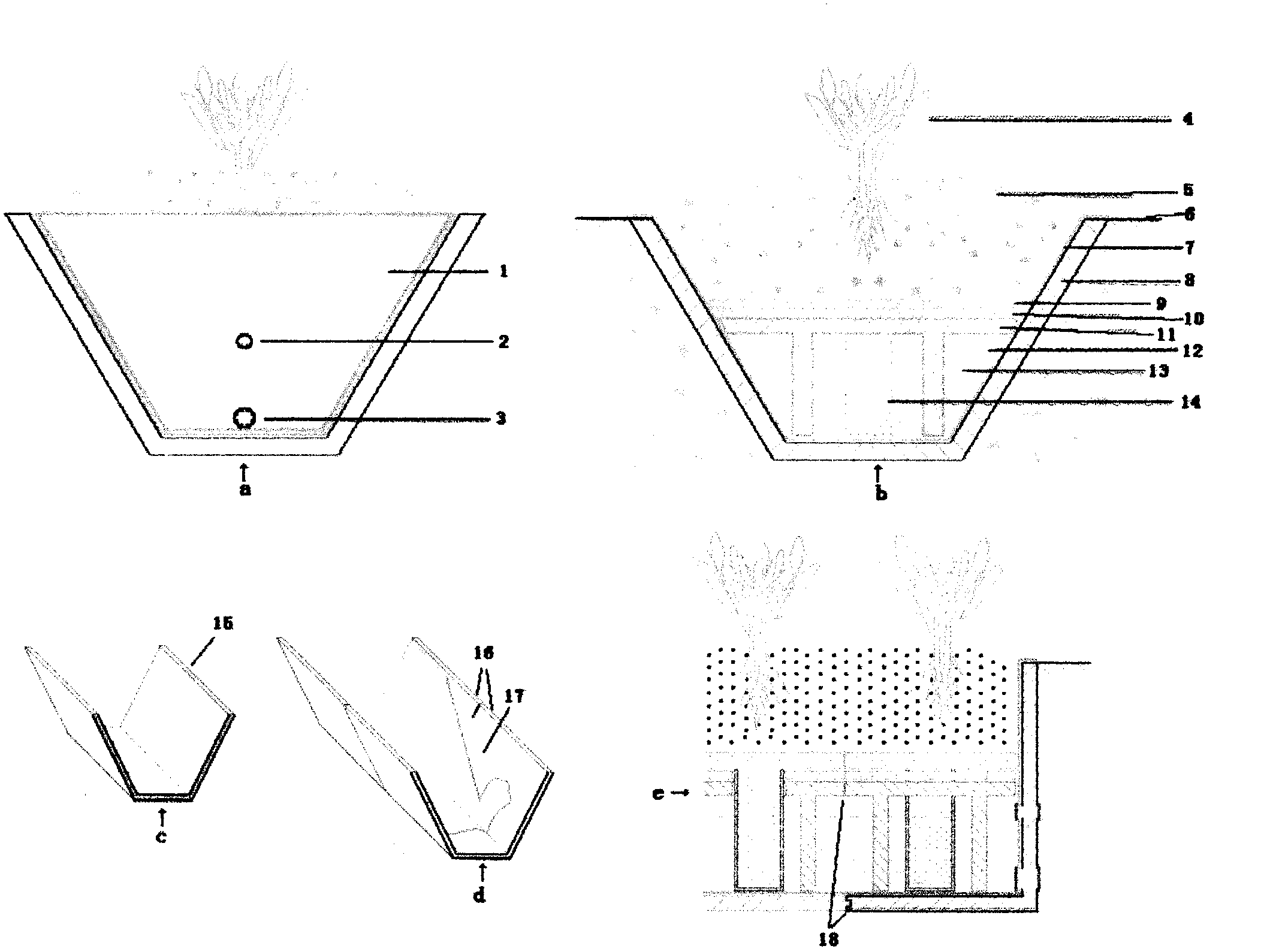

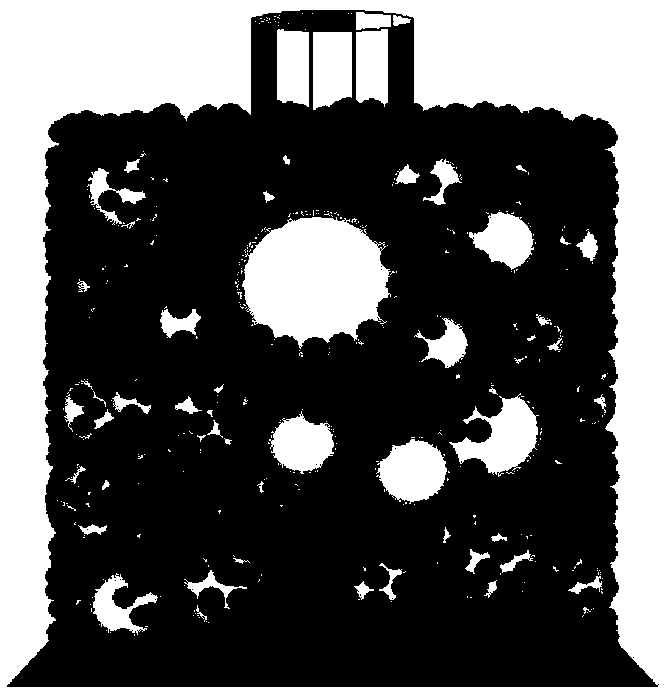

Self-circulation green plant container series

InactiveCN103283521AIncrease productivityIncrease productionWatering devicesCultivating equipmentsTerrainEcological environment

The invention relates to a self-circulation green plant container series. A green plant container consists of a plant layer 1, a soil layer 2, a container housing 3, a permeable plate layer 4, a stem baffle layer 5, a bracket plate layer 6, support feet 7, a breathable layer 8, an air transmission port 9, a water storage layer 10, a water conveying core 11, and a water delivery port 12. When a plant is grown in the container, and a water source is injected into the container, self moisturizing, irrigation, moisture regulation, water storage and fertilizer maintenance states can be realized, the plant can be moisturized for several days, and the performances such as efficient water saving irrigation and energy conservation are reached. Particularly, the green plant container series is provided with any herbal or woody plant grown in any terrain and any environment; mixed dirty sea and rain water and the like are completely used as the irrigation water source, the plant and the ecological environment are not polluted, the irrigation water source can be obtained, so that the irrigated land resource utilization rate is increased greatly, the comprehensive treatment cost of the ecological environment is reduced greatly, the circulation sustainability of the ecological environment of the green plant is facilitated, and multiple effects such as high economic and social benefits are realized.

Owner:郭仲秋

Dust collection brush head of dust collector

The invention discloses a dust collection brush head of a dust collector. The dust collection brush head comprises a brush head main body shell and a rotating shaft, wherein the rotating shaft is directly driven to rotate by virtue of a direct drive motor which is arranged in the brush head main body shell; and a plurality of rotary brushes, which are rotated along with the rotating shaft, and a movable brush, which can do reciprocating moving in an axial direction of the rotating shaft under the rotating driving of the rotating shaft, are arranged on the rotating shaft. When the dust collector provided by the invention is used for collecting dust, the movable brush is driven to do reciprocating moving by virtue of a guide rotary groove when brush bristles, driven by the rotating shaft, are rotated to remove dirt and collect dust so as to scrub and collect dirt in a transverse direction; therefore, a dust collection effect is enhanced; moreover, with the adoption of the direct drive motor, the volume of the brush head is greatly diminished and the convenience of the dust collector is enhanced, so that the dust collector can collect dust at various corners conveniently; and the dust collector provided by the invention is original in structure, convenient and reliable to use and quite strong in practicability.

Owner:宿州学院

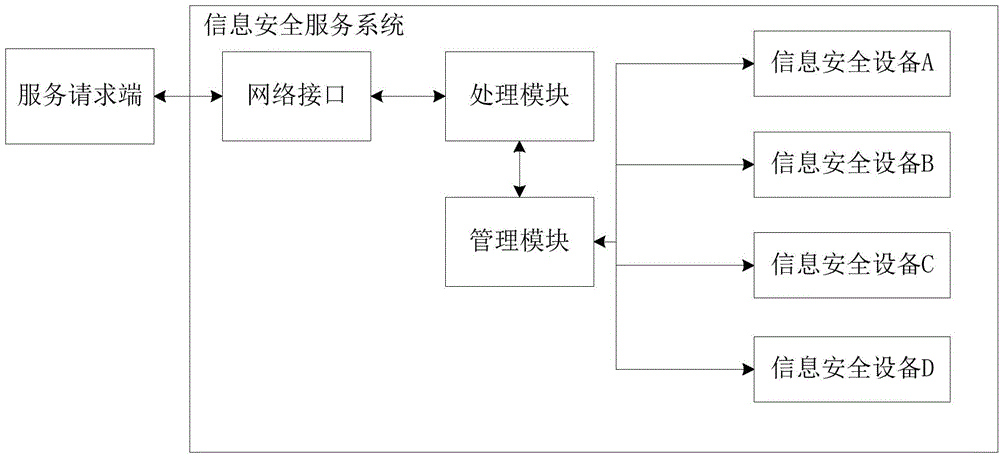

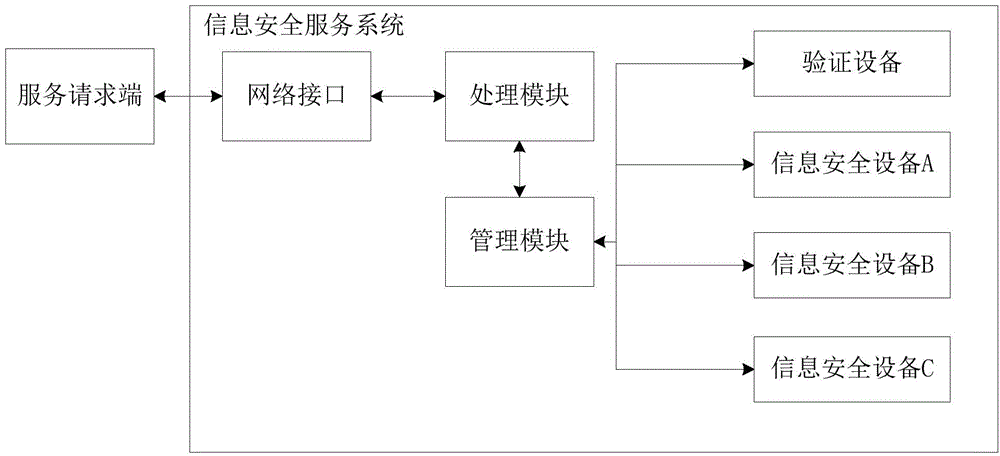

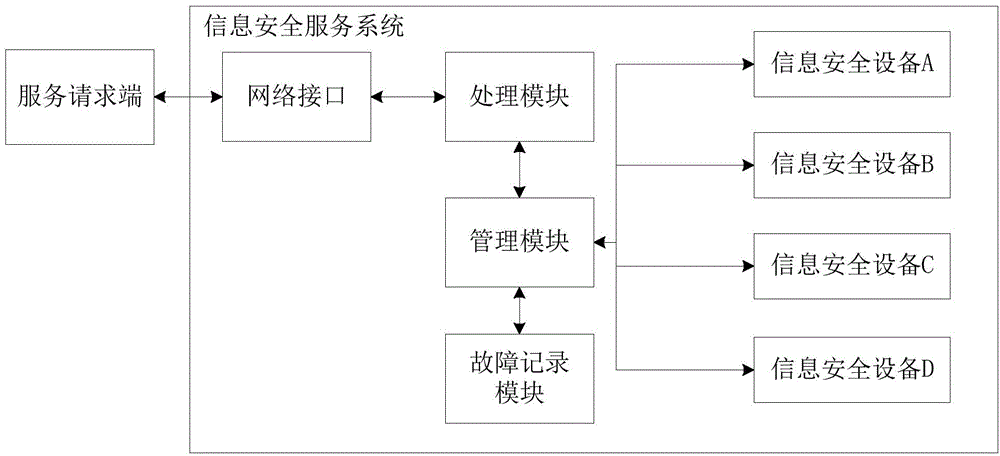

Expandable information safety service system and method

The invention discloses an expandable information safety service system which comprises a network interface, a processing module, a management module and a plurality of pieces of information safety equipment, wherein the network interface is used for receiving an information safety service request from a service requesting end by a network; the processing module is used for analyzing the received request and sending data to be processed in the request and a corresponding processing command to the management module; the management module is used for using one piece of information safety equipment as target equipment according to working states of the pieces of information safety equipment and sending the data to be processed and the processing command to the target equipment; each information safety equipment is used for carrying out information safety processing on the data to be processed according to the processing command and returning the processed data to the management module; the processed data is sent to the service requesting end by the management module, the processing module and the network interface. The invention further discloses an expandable information safety service method. By the expandable information safety service system and the expandable information safety service method, required information safety processing is completed through a network service; fussiness of managing information safety equipment is avoided; the expandable information safety service system and the expandable information safety service method have high expandability.

Owner:BEIJING SENSESHIELD TECH

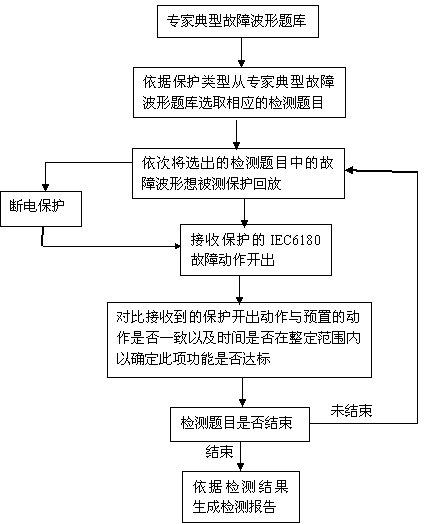

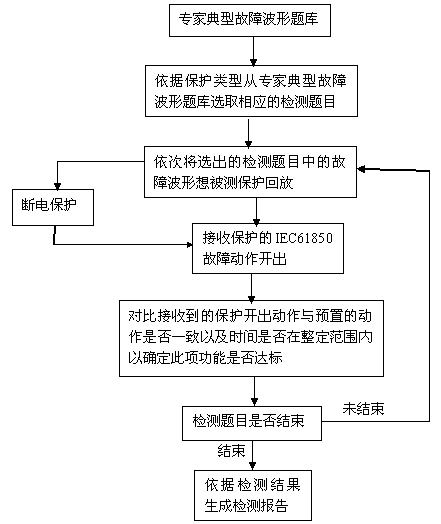

Method for realizing device test protection through recording and playback

The invention relates to the technical field of transformer substation protection devices, and specifically relates to a method for realizing device test protection through recording and playback. The method comprises the following steps: (1) the typical failure waveform question bank establishment process: 1) protection is classified according to logical functions specified by IEC61850; 2) and a corresponding typical failure waveform is recorded for each type of protection through an IED detect detector, and a test question bank is generated for an anticipated action of the corresponding failure waveform is inputted manually; (2) and the test process: 1) an appropriate test question bank is selected according to the logical function classification of the tested protection; 2) the protection is connected to the IED detect detector, and a synchronous clock is connected; 3) the test question bank is played back by the IED detect detector, and the action output of the tested protection is received by the IED detect detector; 4) and the action of the tested protection is compared with the anticipated action in the test question bank to judge the test result. The method of the invention has advantages of low cost and convenience, the protection device has advantages of small size and easy carry, so the protection device is suitable for the field tests of various transformer substations, so that advantages of easy utilization and easy operation can be realized.

Owner:ELECTRIC POWER RES INST OF GUANGXI POWER GRID CO LTD

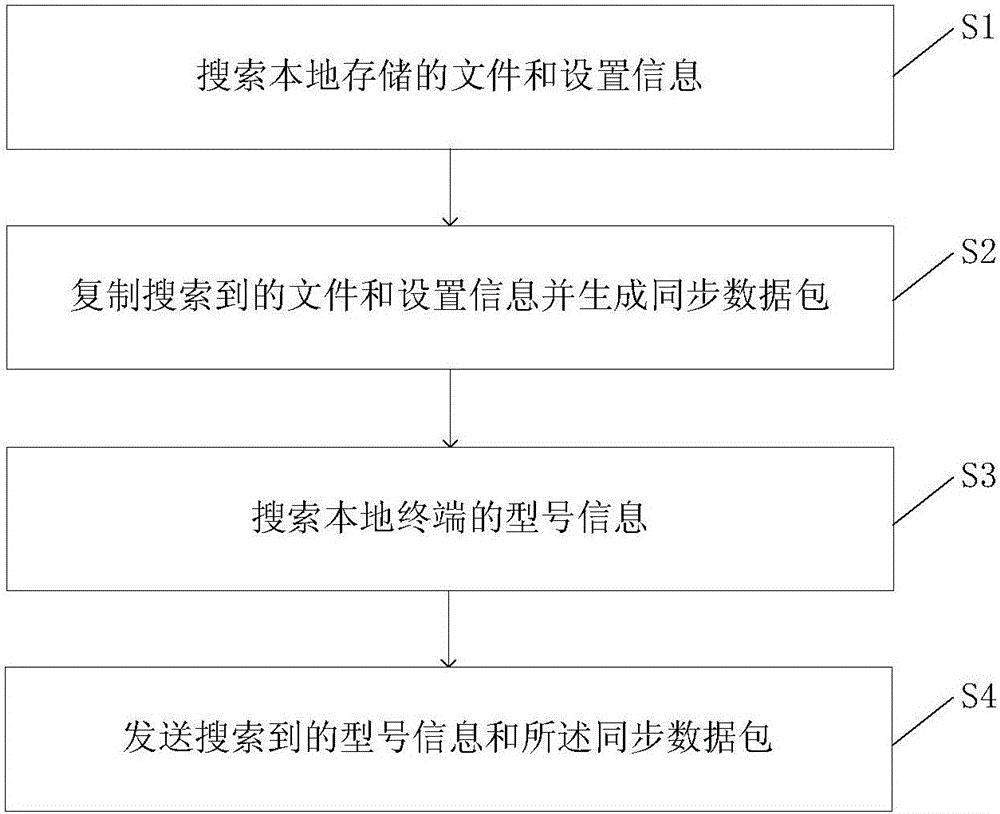

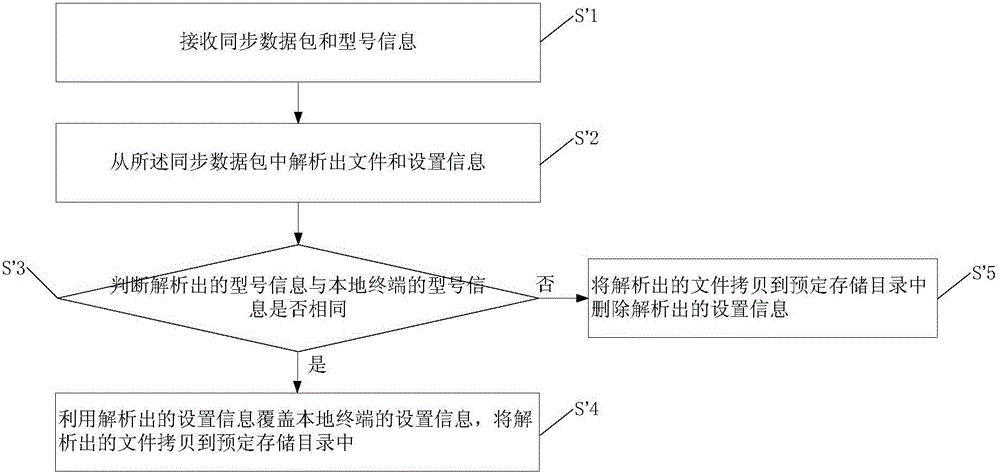

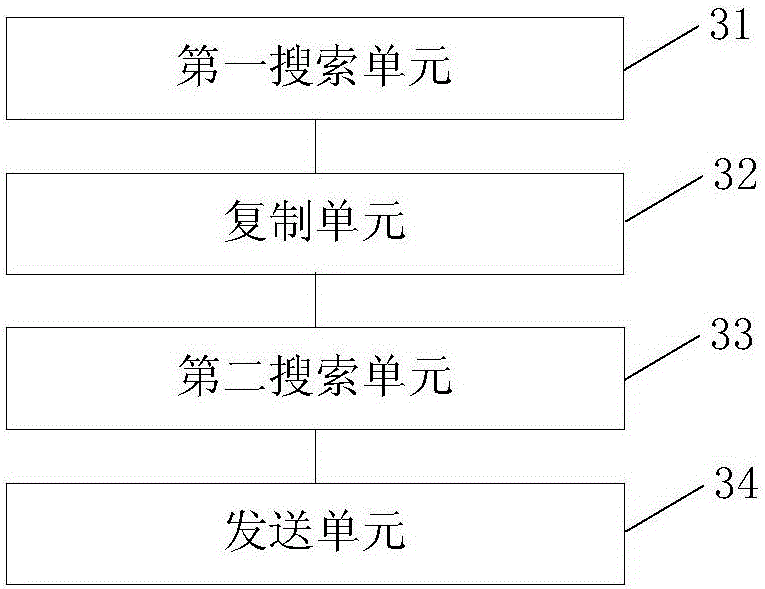

Terminal information synchronization method and device, and information synchronization system

InactiveCN105847374AMeet data synchronization needsStrong convenienceData switching networksData synchronizationNetwork packet

The invention provides a terminal information synchronization method and device, and an information synchronization system, relating to the data communication field. The terminal information synchronization method comprises: searching for files stored locally and setting information; copying searched files and setting information and generating a synchronous data packet; searching for model information of a local terminal; and sending searched model information and the synchronous data packet. The scheme realizes information synchronization among terminals without manual copy, has greater convenience and richness, and can meet data synchronization requirements when a user changes a terminal.

Owner:LETV HLDG BEIJING CO LTD +1

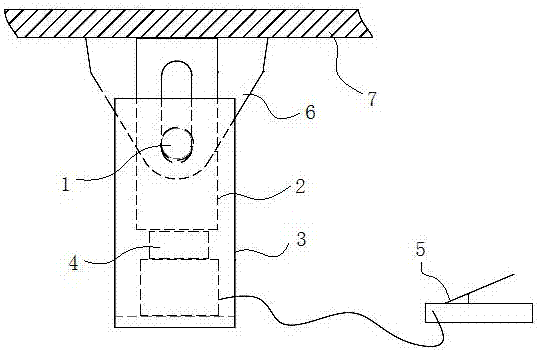

Marine suspension ring load testing device

InactiveCN107063875AStrong convenienceImprove securityMaterial strength using tensile/compressive forcesEngineeringLoad testing

The invention discloses a marine suspension ring load testing device which comprises a supporting shaft, an inner framework, an outer framework and a jack, wherein the inner framework is sheathed outside a testing suspension ring, the outer framework is sheathed outside the inner framework, and the supporting shaft penetrates through a pin hole among the suspension ring, the inner framework and the outer framework; the jack is arranged between the bottom of the inner framework and the bottom of the outer framework; and in testing, the top of the inner framework is in contact with a ship body. The device disclosed by the invention has obvious convenience, safety and economy advantages, is portable and simple, and can be carried by one person to two persons; tons of weights are not needed to be carried; the device is convenient to install and test, and safe and reliable by simulating tons of or even hundreds of tons of acting force with dozens of kilograms of acting force, and even if the suspension ring is damaged, dangers cannot be caused. The time-saving and effort-saving testing device also has obvious positive significance on inevitably shortening the construction period and saving the testing cost economically.

Owner:张曙光 +2

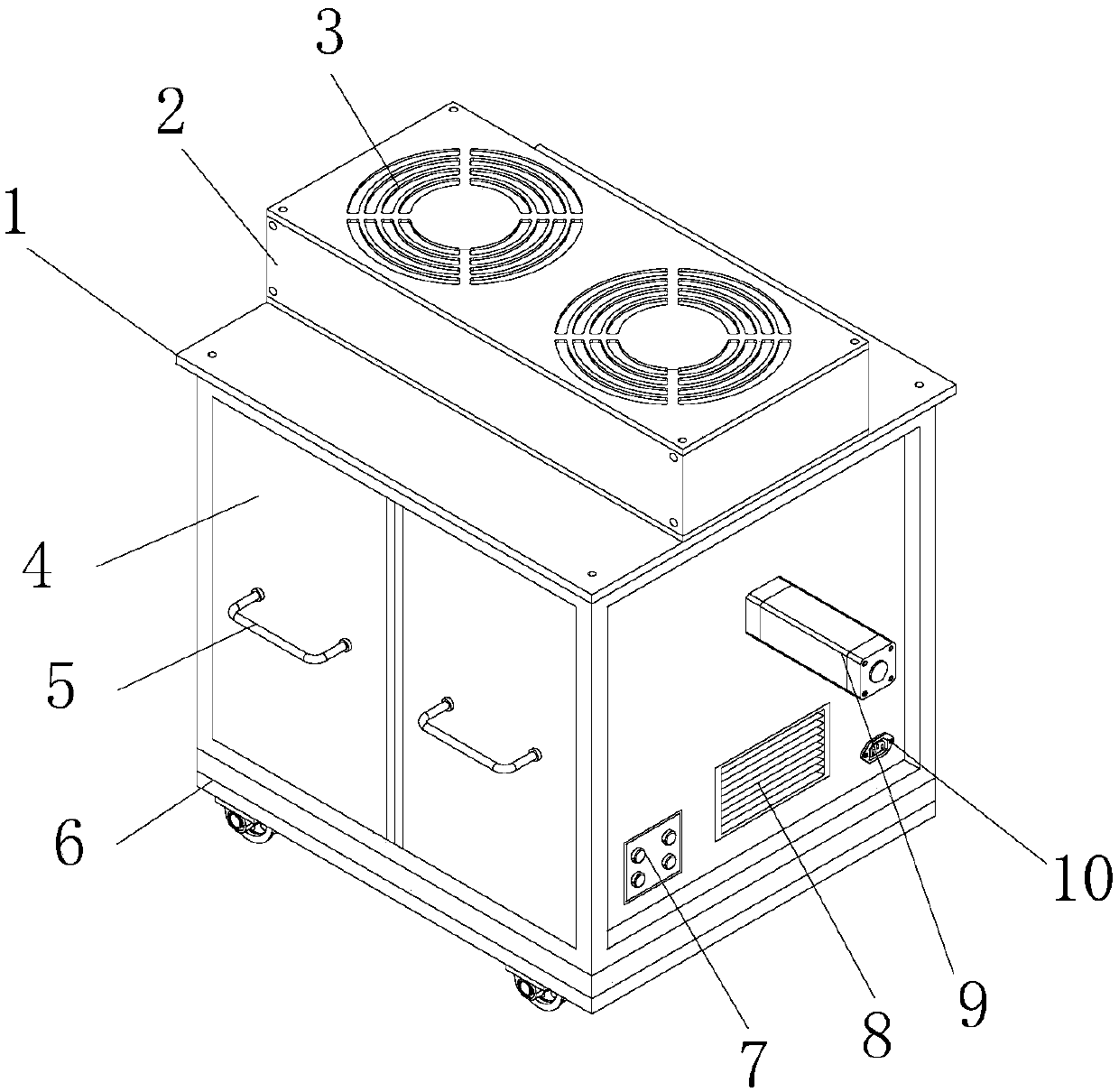

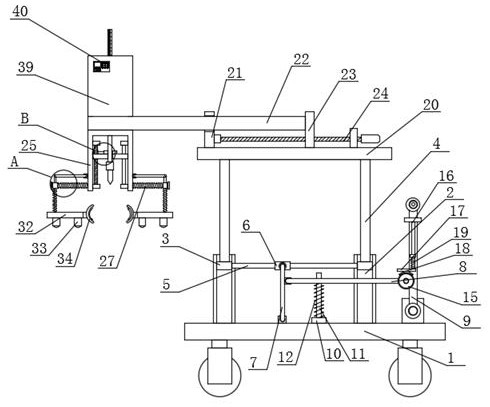

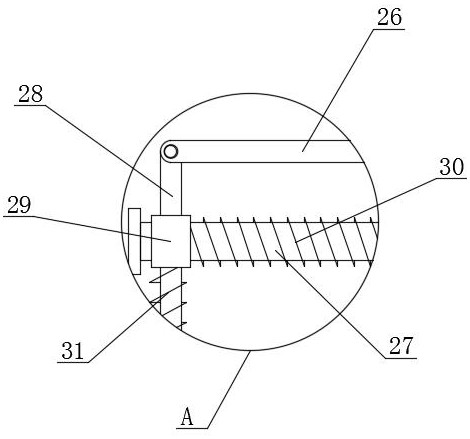

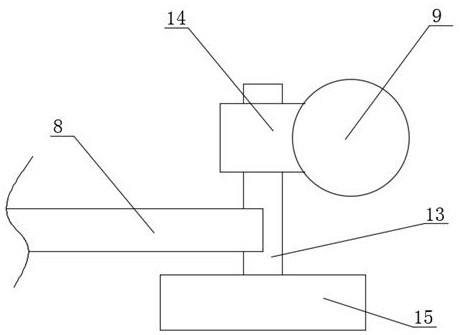

Drying oven used for ceramic product processing

InactiveCN109595888AStrong convenienceGood mobilityDrying gas arrangementsDrying solid materialsProduct processingEngineering

The invention discloses a drying oven used for ceramic product processing. The drying oven used for ceramic product processing comprises a box, a fan, a moving device, a rotary heating device and a pushing-out device. A first motor in the moving device is started to work, an output shaft on the front end face of the first motor starts to rotate and drives a coupling to enable a driving gear to move, a driven gear engaged with the right side of the driving gear also rotates and drives a spindle to rotate, the spindle drives directional wheels to rotate, power generated by the directional wheelsdrives universal wheels at the front ends of the directional wheels to rotate synchronously, users can move the universal wheels leftwards or rightwards by controlling the box by hand to exert force,then steering is achieved, and electric movement is completed. The box cannot be connected with a power line in the moving process, and a storage battery is arranged at the left end of the bottom ofan oven body to supply power demanded, so that the drying oven is convenient to use, good in mobility and capable of being electrically moved, and the problems of poor mobility and inconvenient usingof large equipment are solved.

Owner:HANGZHOU VOCATIONAL & TECHN COLLEGE

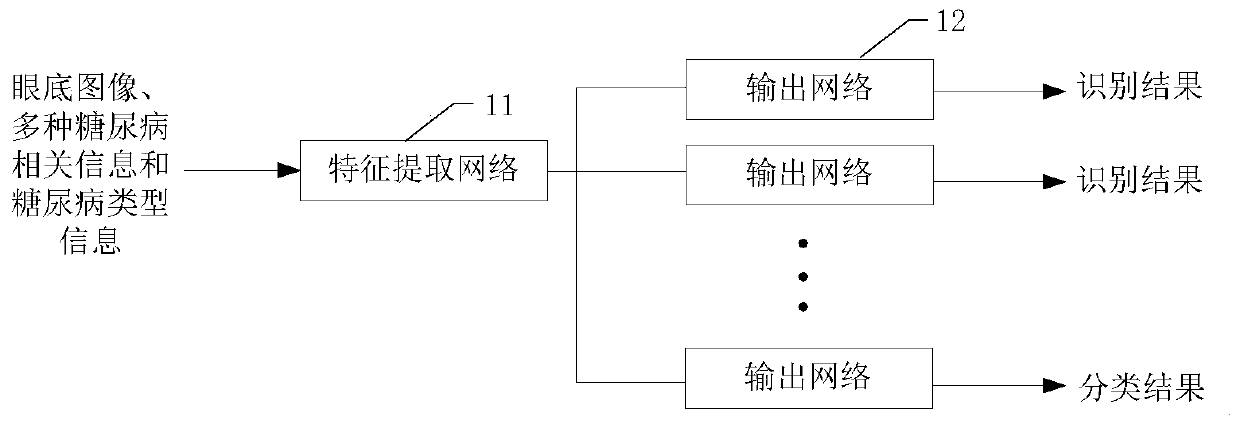

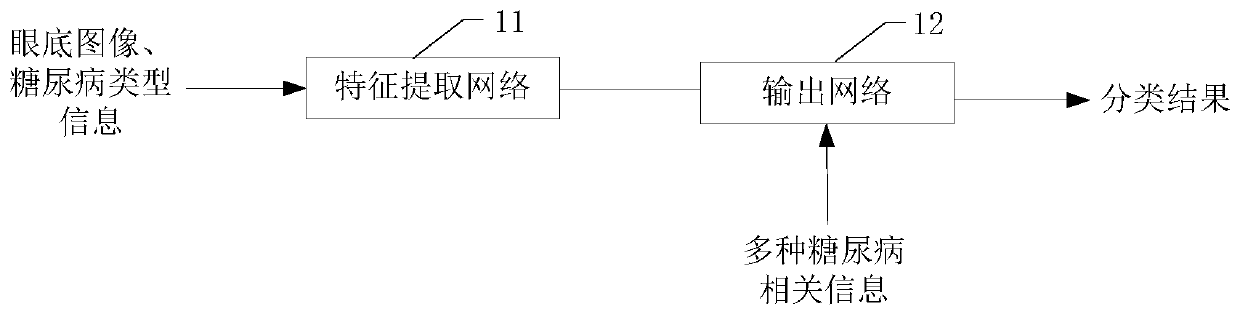

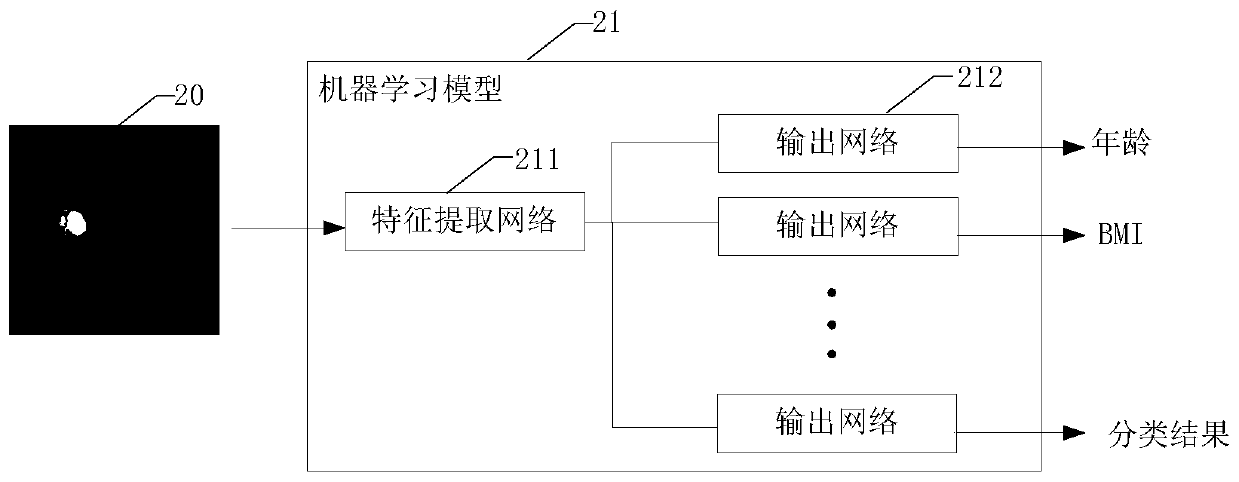

Diabetes classification method and device based on fundus images

InactiveCN111028232ALow costThe classification result is accurateImage enhancementImage analysisEvaluation resultKeywords diabetes

The invention provides a diabetes classification method and device based on a fundus image. The method comprises the steps that of acquriing fundus image of a user and identifying the fundus image byusing a machine learning model, and at least outputting a diabetes classification result. According to the machine learning model provided by the invention, various diabetes related information is introduced in the training process to optimize the classification performance. The used sample data comprises a fundus image, multiple pieces of diabetes related information and diabetes type information, and the model adjusts self parameters according to the output evaluation result and the multiple pieces of diabetes related information and diabetes type information in the sample data in the training process, so that the output classification result is more accurate.

Owner:BEIJING AIRDOC TECH CO LTD +1

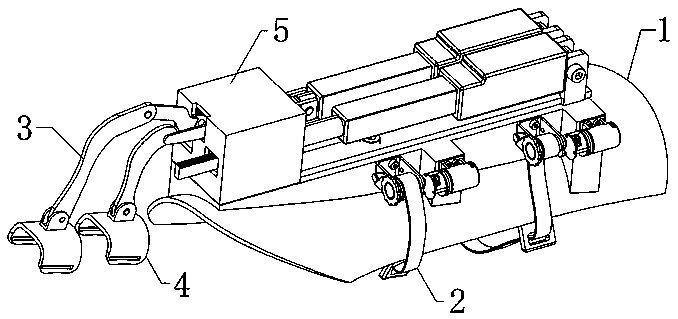

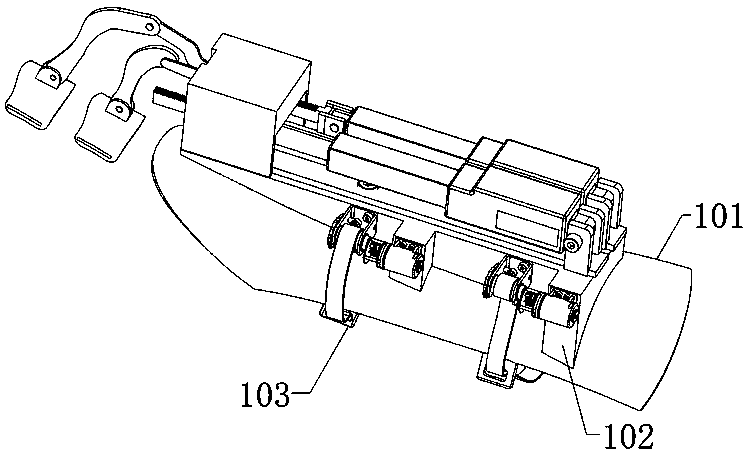

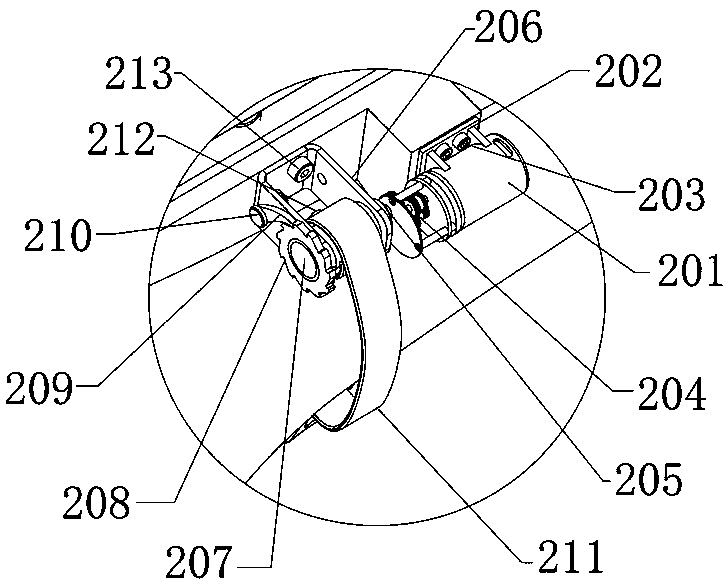

Orthopedic traction support for fingers

InactiveCN111281636AStrong convenienceImprove operational efficiencyFractureOrthopedic tractionFinger middle

The invention discloses an Orthopedic traction support for the fingers. The traction support includes an arm sleeve assembly, a bandage assembly, a fingertip traction assembly, a midfinger traction assembly, a housing and an arm sleeve body, a mounting base and a bayonet, a reduction gear set, a ratchet wheel rotating shaft, a ratchet wheel and pawls, a bandage and a fingertip push rod, a conversion support, a fingertip pushing rack, a fingertip pushing rack base, a fingertip rack sliding base, a fingertip gear rotating shaft, a fingertip transmission gear, a connecting rod transmission gear,a fingertip connecting rod, a fingertip transmission rod, a fingertip clamp, a middle finger pushing rod, a middle finger pushing rack, a middle finger pushing rack base, a middle finger rack slidingbase, a middle finger transmission gear, a middle finger connecting rod, a middle finger transmission rod and a middle finger clamp. By means of the bandage assembly on the arm sleeve body, the traction support of the finger orthopedic patient can be rapidly and conveniently fixed. Through mutual cooperation of the fingertip clamp and the finger middle clamp driven by the power source, positioningtraction of the finger of the patient and positioning adjustment in the rehabilitation process are achieved.

Owner:NANJING MEDICAL UNIV

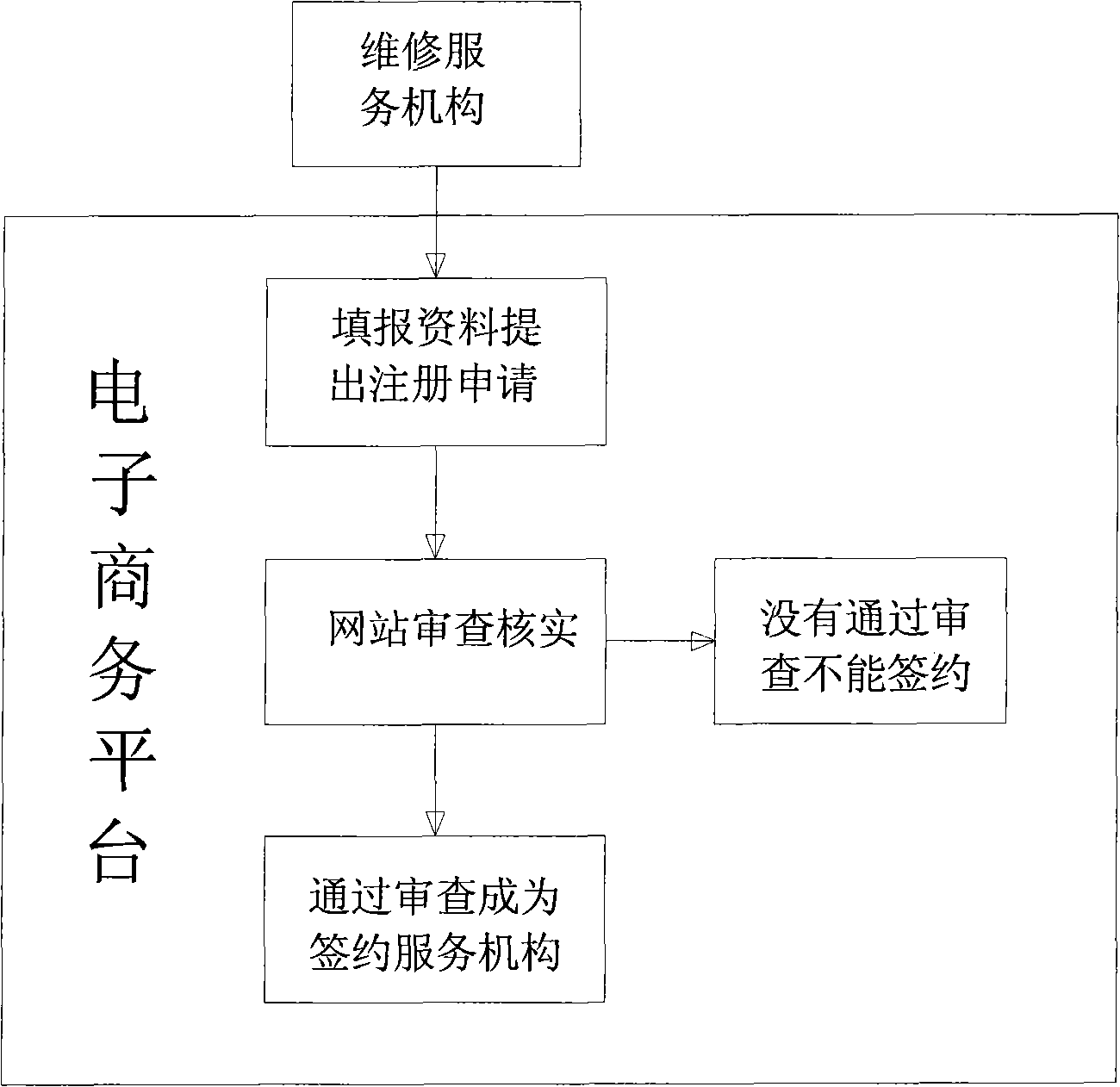

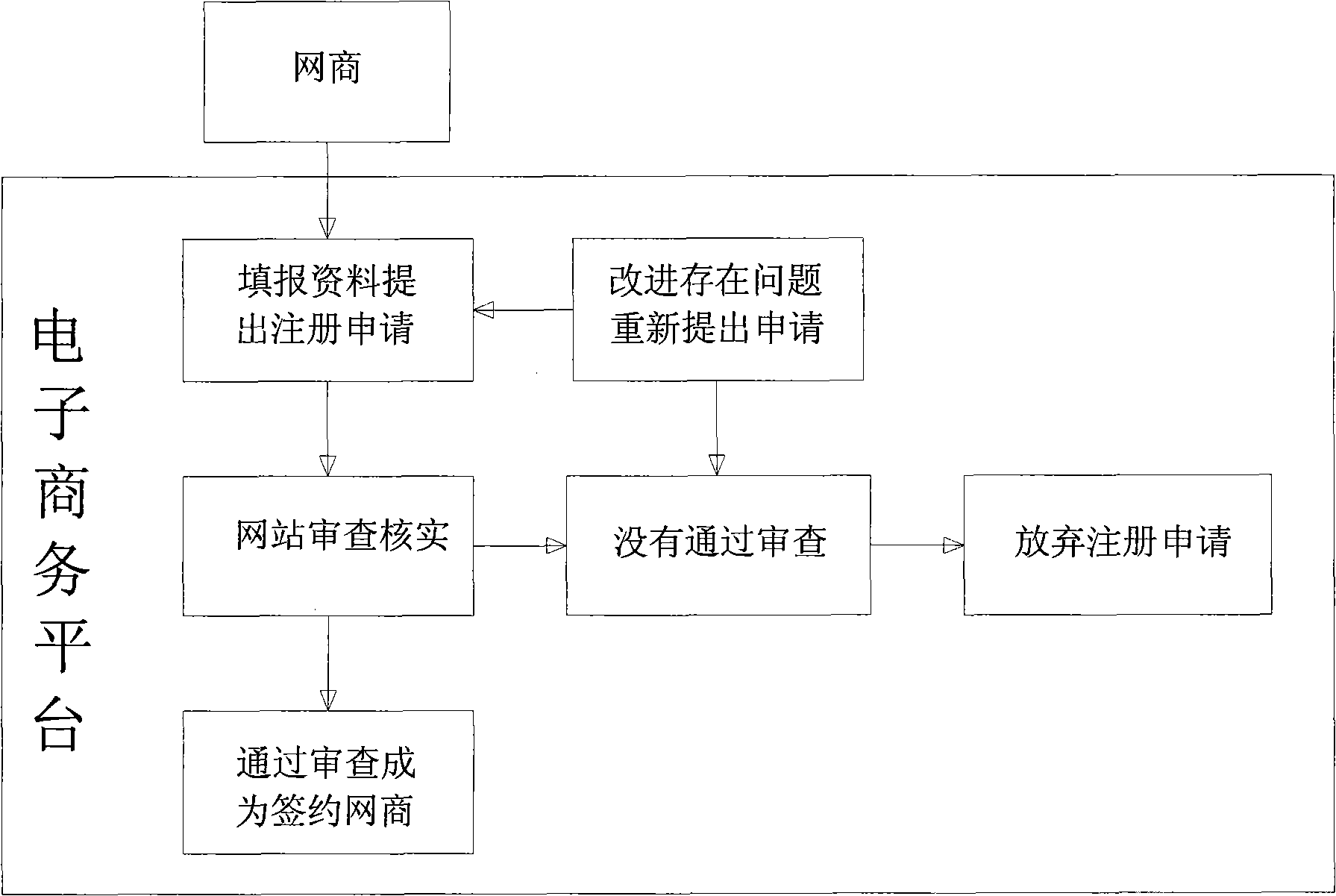

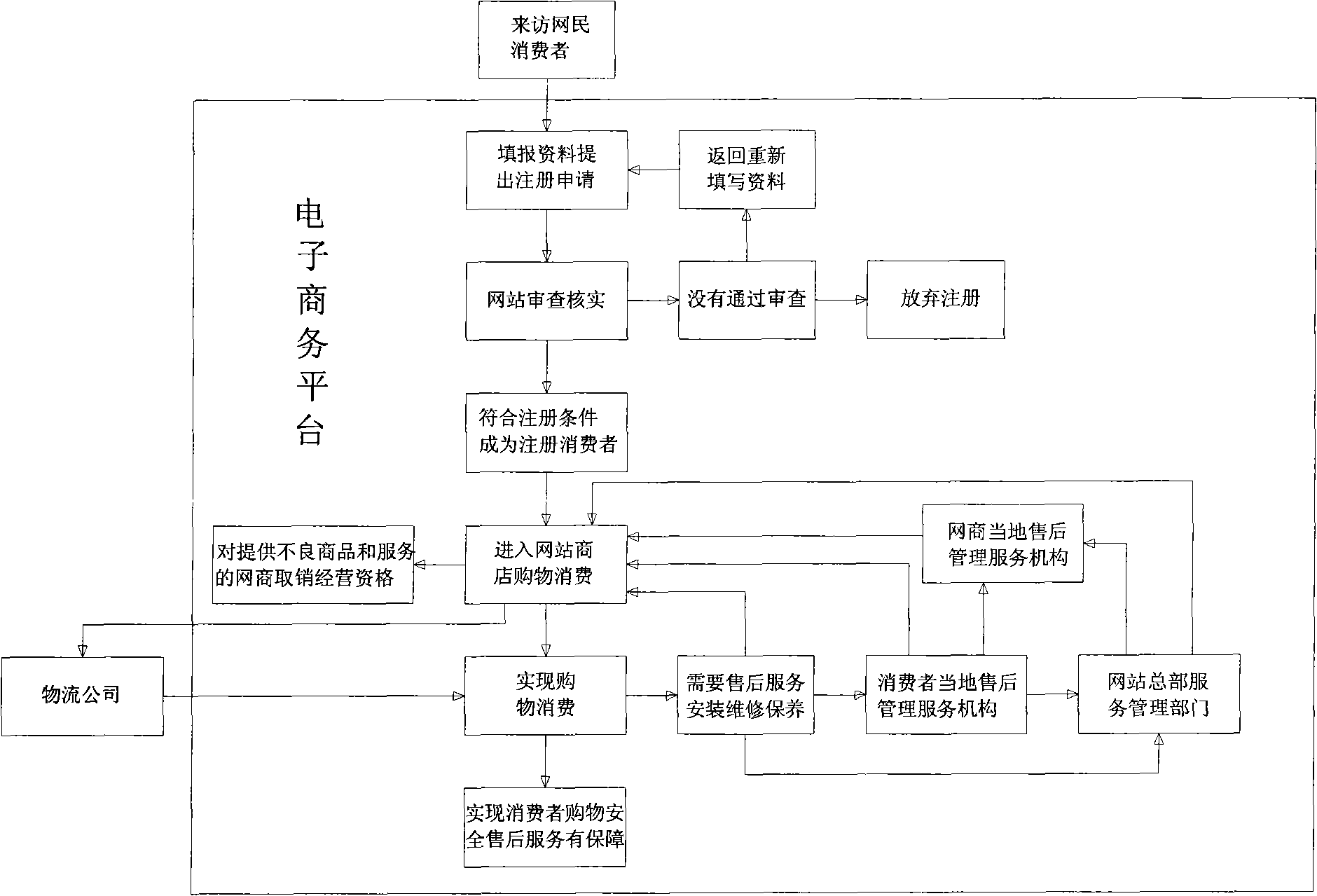

Electronic commerce mode having shopping service safety control system

InactiveCN101493916AStrong convenienceAfter-sales service guaranteeCommerceService guaranteeSafety control

The invention relates to an e-business model with a shopping service security guarantee system, which is established by network companies within the scope of the Internet or by the cooperation between the network companies and local service agencies through contract so as to effectively manage Internet businessmen, provide a full range of shopping security and an after-sales service guarantee comprising installation maintenance service, service within or after the warranty period and refunding and exchanging service, and provide consumers with shopping advice, shopping guide and e-business knowledge promotion. Consequently, more manufacturing enterprises and service suppliers can sell products online through e-business platforms and more consumers can buy products and service with low cost and good quality through the mode of online shopping.

Owner:叶萍

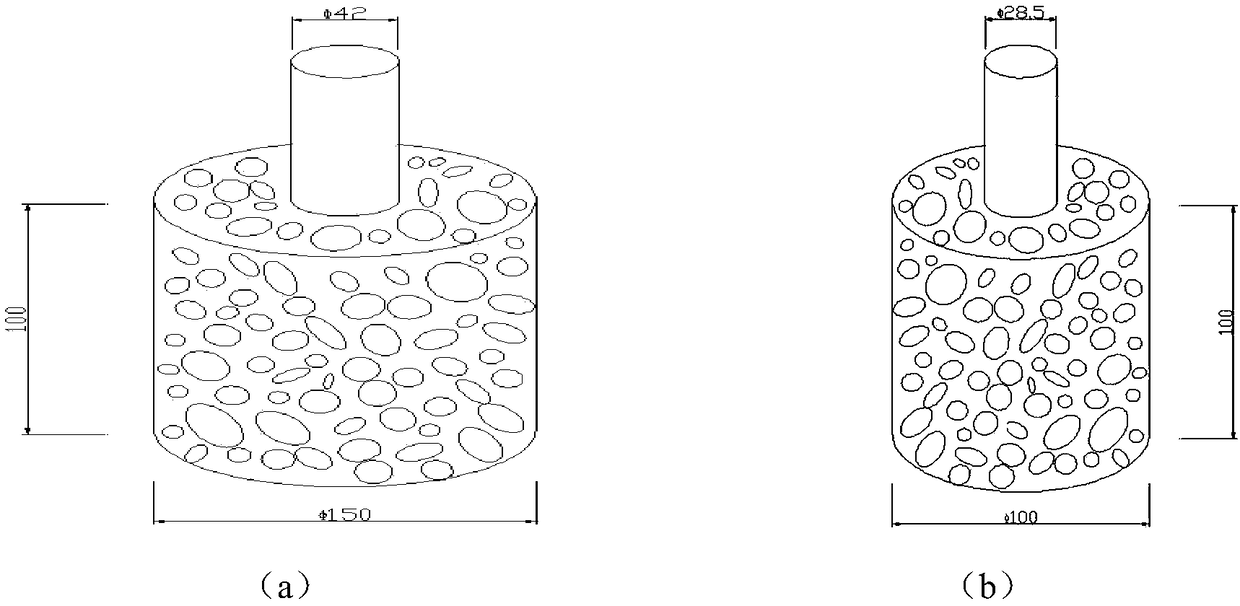

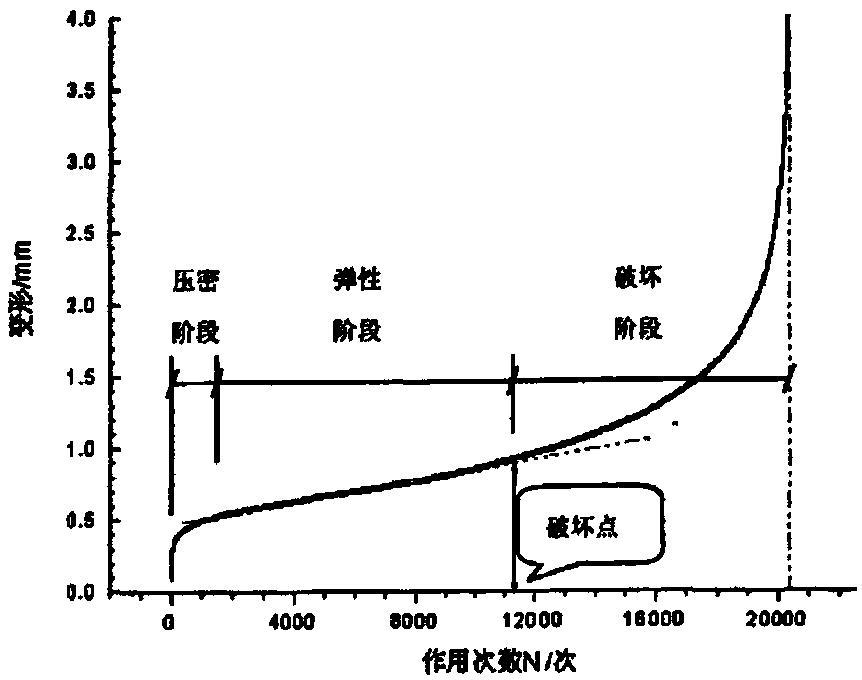

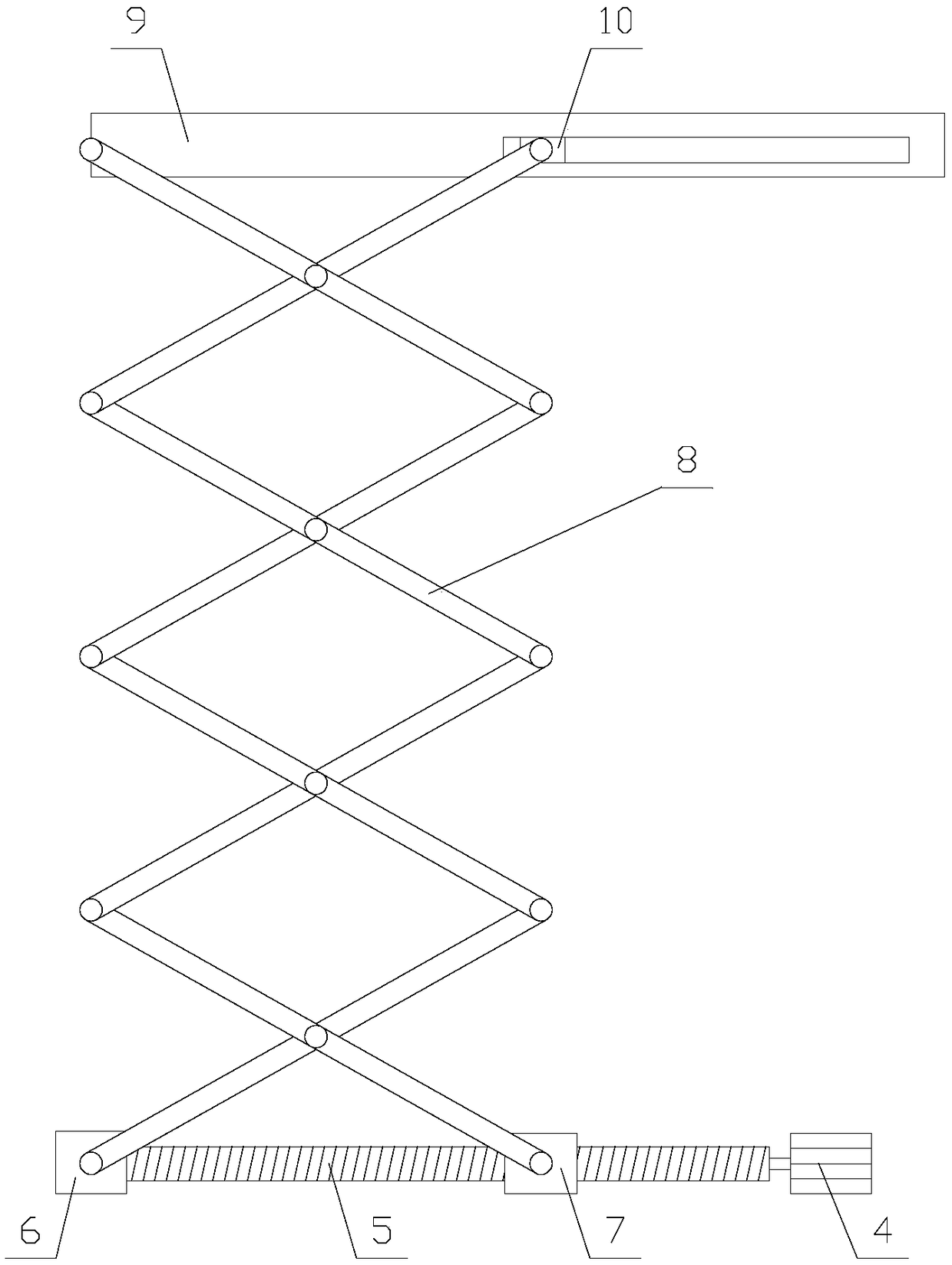

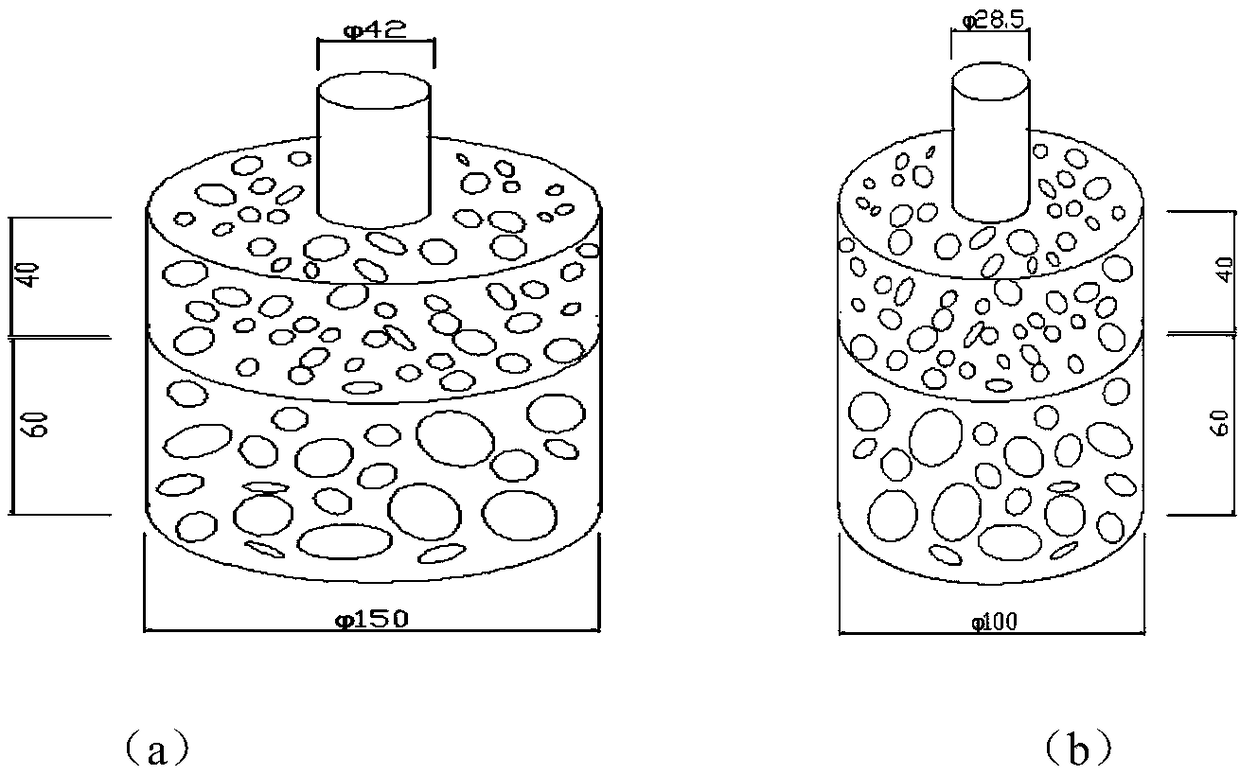

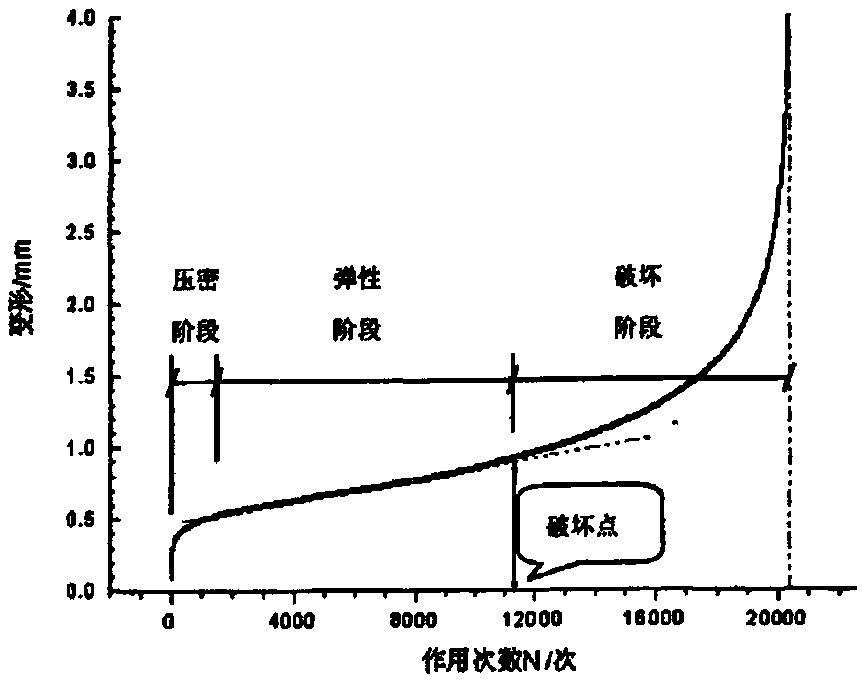

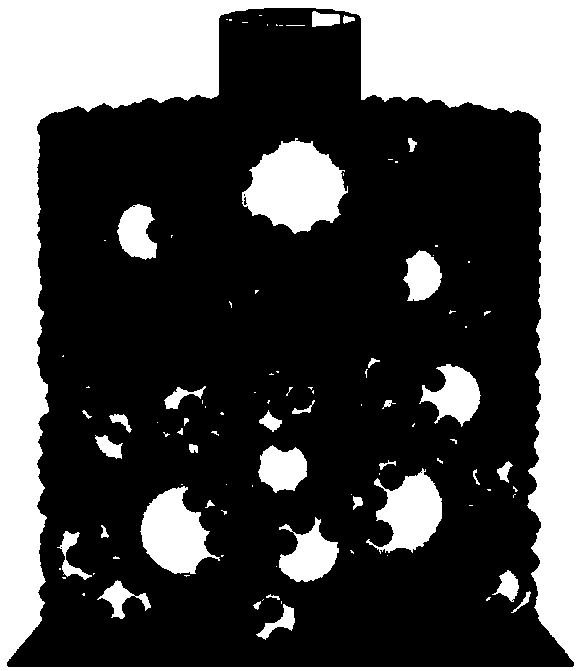

Anti-shear fatigue asphalt mixture grading and optimizing method based on virtual repeated penetration test

ActiveCN108982256AEasy to operateStrong convenienceMaterial strength using repeated/pulsating forcesRoad surfaceOperability

The invention discloses an anti-shear fatigue asphalt mixture grading and optimizing method based on a virtual repeated penetration test. The anti-shear fatigue asphalt mixture grading and optimizingmethod comprises the following steps: firstly fitting through a uniaxial creep compression test result of asphalt mortar, thus obtaining 30 DEG C asphalt mortar viscoelasticity parameters of a contactmodel; then carrying out virtual repeated shear fatigue test, repeating uniaxial penetration test through simulating asphalt mixture, determining the ineffective acting frequency N of the asphalt mixture under the action of repeated penetration, and evaluating the shear fatigue life of the asphalt mixture. According to the anti-shear fatigue asphalt mixture grading and optimizing method disclosedby the invention, an asphalt mixture shear fatigue test three-dimensional discrete element model according with target grading is randomly generated in three-dimensional discrete element software, and then grading and optimizing can be carried out according to a mechanical test value simulation result of the asphalt mixture, so that the anti-shear fatigue asphalt mixture grading and optimizing method has very strong operability, convenience and representativeness, and has a great significance in improving the pavement performance of an asphalt pavement and prolonging the service life of the asphalt pavement.

Owner:ZHEJIANG UNIV

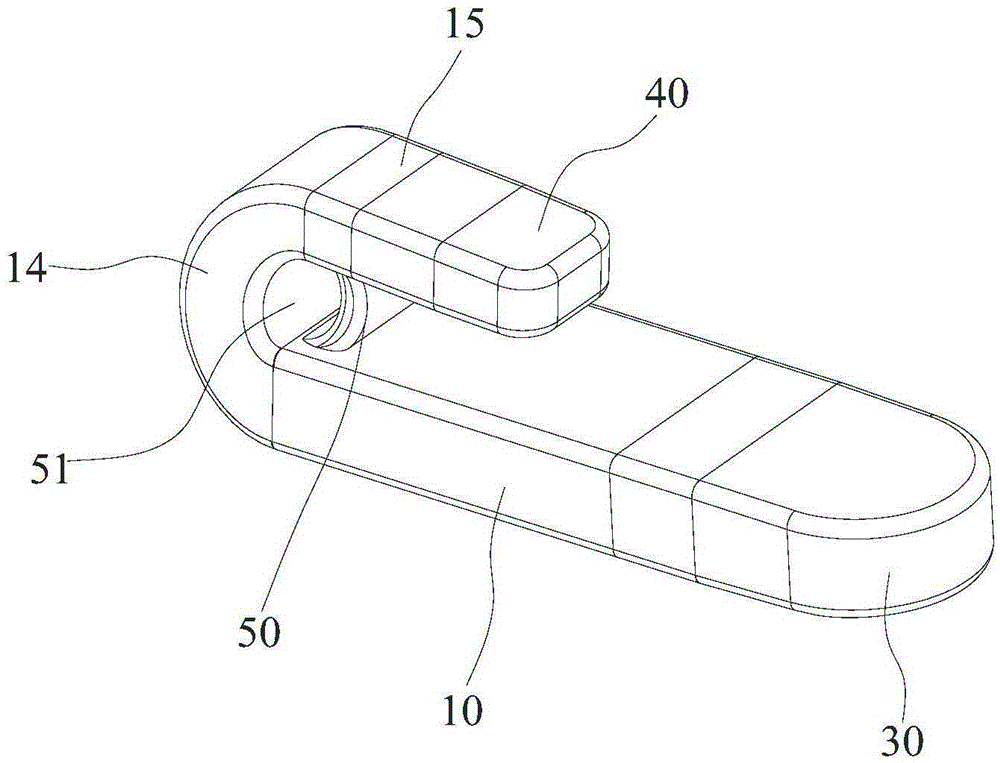

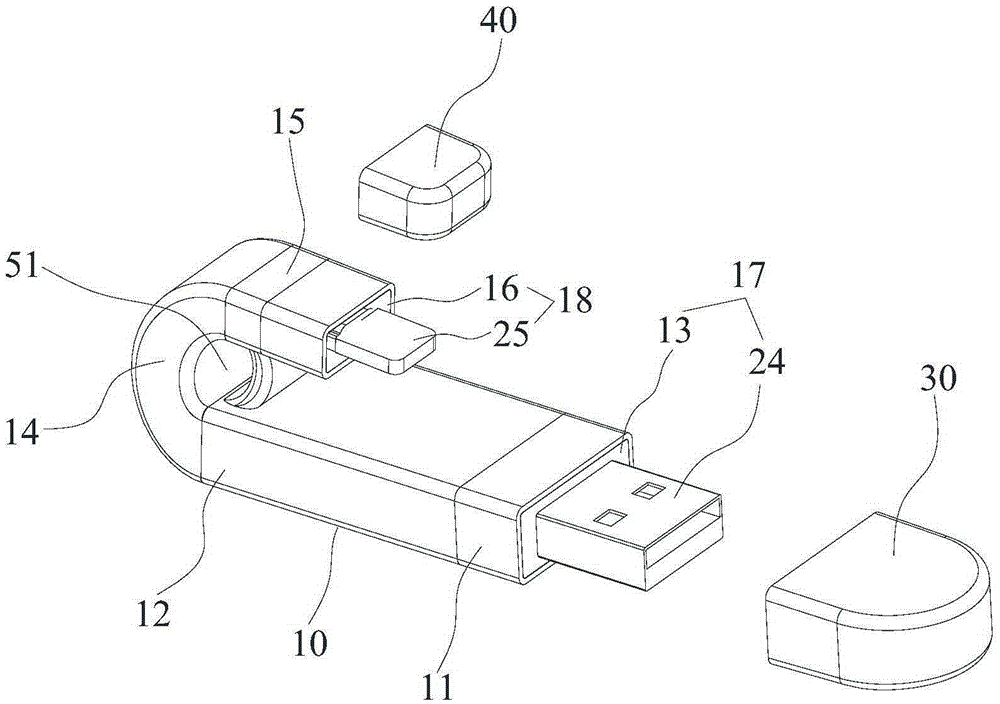

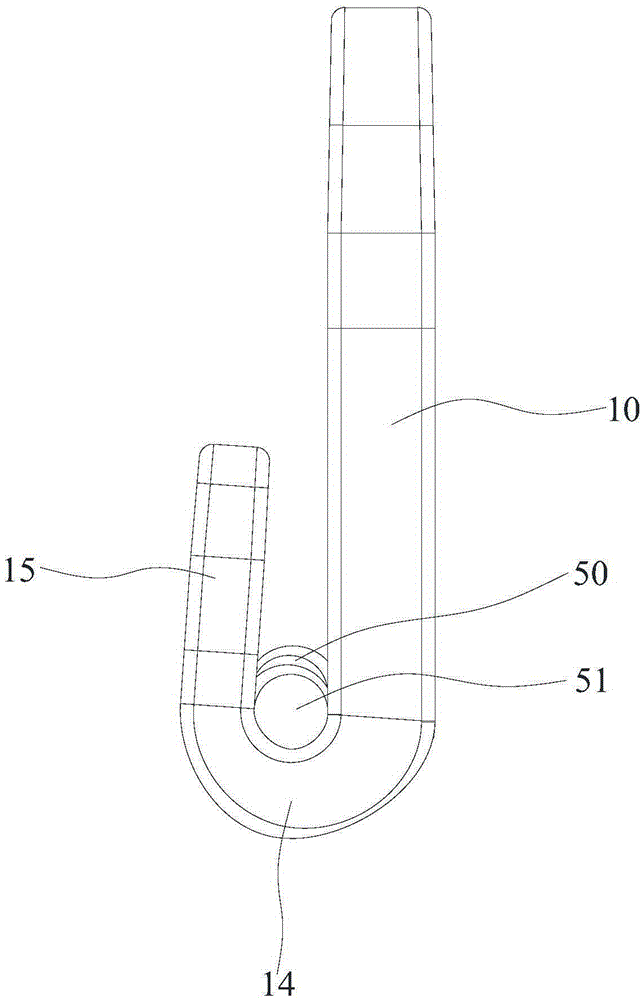

Double-interface OTG (On The Go) mobile storage device

The invention relates to the technical field of mobile storage, and provides a double-interface OTG (On The Go) mobile storage device. The storage device comprises a storage shell and a PCBA (Printed Circuit Board Assembly), wherein the PCBA comprises a PCB (Printed Circuit Board), a controller, a storage chip and a USB (Universal Serial Bus) connector; the storage shell is provided with a first end and a second end, the first end is provided with a first opening, the USB connector is arranged at the first opening to form a USB interface, and the USB interface is sleeved with a first interface cap; the controller supports an OTG function; the PCBA further comprises a connector supporting the OTG function; the second end of the storage shell extends in the direction far from the first end and then is reversely bent to form a hook, a second opening is formed at the end of the hook, the connector is arranged at the second opening to form a second interface, and the second interface is sleeved with a second interface cap. The overall storage device bent to a J shape is small and is prevented from being influenced by the outside due to over large size; and plugging of the two interfaces does not influence each other, so that the storage device can be reliably connected with external equipment.

Owner:TOPDISK ENTERPRISE CO LTD

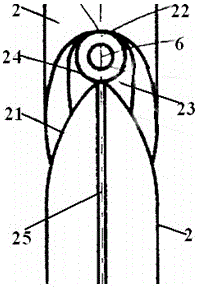

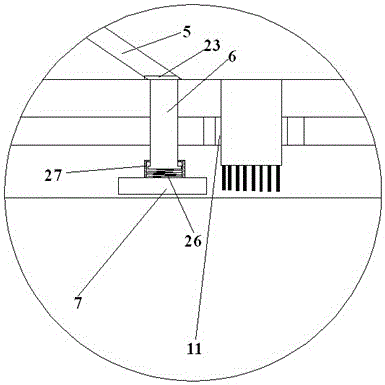

Convenient-to-dismount face tracking equipment

ActiveCN108980550AEasy to disassembleStrong convenienceCharacter and pattern recognitionStands/trestlesEngineeringTransmission belt

The invention relates to convenient-to-dismount face tracking equipment. The convenient-to-dismount face tracking equipment comprises a fixed strip, a telescopic mechanism, two movable blocks, two movable mechanisms, two cameras and two rotary mechanisms, wherein the telescopic mechanism comprises a first motor, a lead screw, a fixed block, a slide block, a telescopic frame, a connecting plate anda transmission block; and each rotary mechanism comprises a rotary shaft, a rotary assembly and two supporting plates, wherein the rotary assembly comprises a second motor, a transmission belt and two rotary units, and each rotary unit comprises a transmission wheel and a connecting wire. According to the convenient-to-dismount face tracking equipment disclosed by the invention, spacing between the two movable blocks is regulated through the telescopic mechanism, so that the face tracking equipment can be dismounted more conveniently, and therefore, convenience of the face tracking equipmentis stronger; and the positions and the angles of the cameras are regulated through the movable mechanisms and the rotary mechanisms, so that a tracked object can be continuously shot, and therefore, atracking distance of the face tracking equipment is longer, and practicability of the face tracking equipment is improved.

Owner:王伟

Anti-shear fatigue double-layer asphalt mixture grading and optimizing method based on virtual repeated penetration test

ActiveCN108982257AEasy to operateStrong convenienceMaterial strength using repeated/pulsating forcesRoad surfaceOperability

The invention discloses an anti-shear fatigue double-layer asphalt mixture grading and optimizing method based on a virtual repeated penetration test. The anti-shear fatigue double-layer asphalt mixture grading and optimizing method comprises the following steps: firstly fitting through a uniaxial creep compression test result of asphalt mortar, thus obtaining 30 DEG C asphalt mortar viscoelasticity parameters of a contact model; then carrying out virtual repeated shear fatigue test, repeating uniaxial penetration test through simulating asphalt mixture, determining the ineffective acting frequency N of the double-layer asphalt mixture under the action of repeated penetration, and evaluating the shear fatigue life of the double-layer asphalt mixture. According to the anti-shear fatigue asphalt mixture grading and optimizing method disclosed by the invention, an asphalt mixture shear fatigue test three-dimensional discrete element model according with target grading is randomly generated in three-dimensional discrete element software, and then grading and optimizing can be carried out according to a mechanical test value simulation result of the asphalt mixture, so that the anti-shear fatigue double-layer asphalt mixture grading and optimizing method has very strong operability, convenience and representativeness, and has a great significance in improving the pavement performance of an asphalt pavement and prolonging the service life of the asphalt pavement.

Owner:ZHEJIANG UNIV

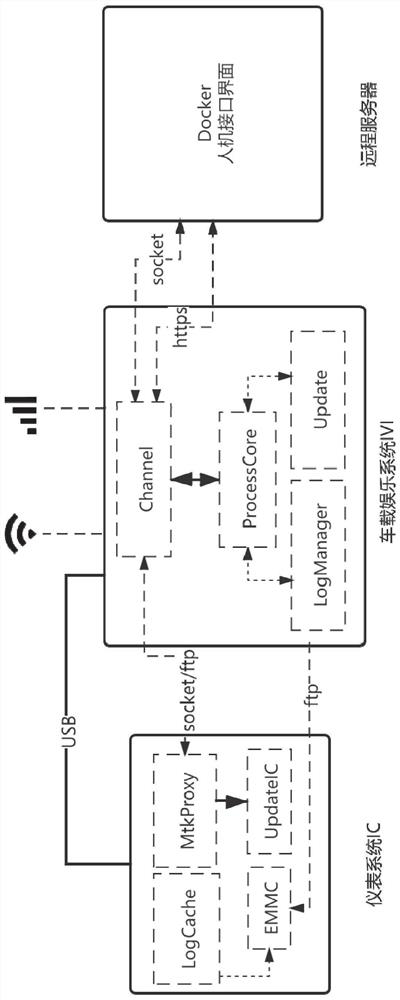

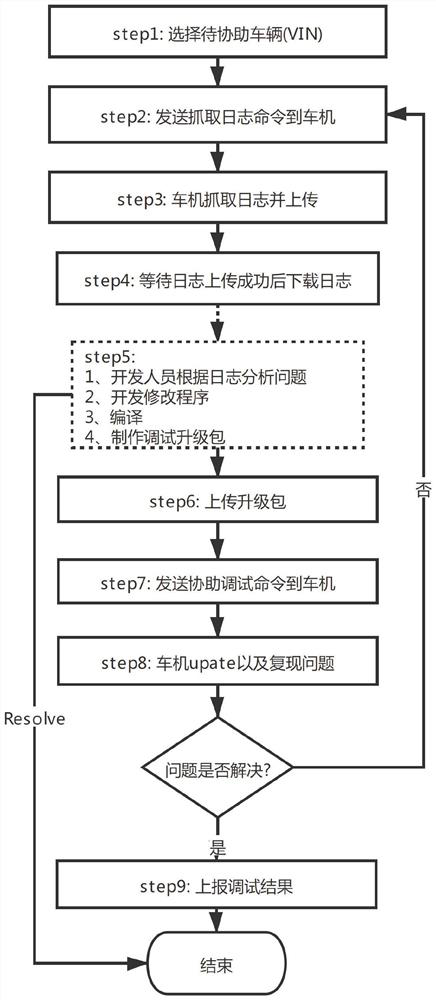

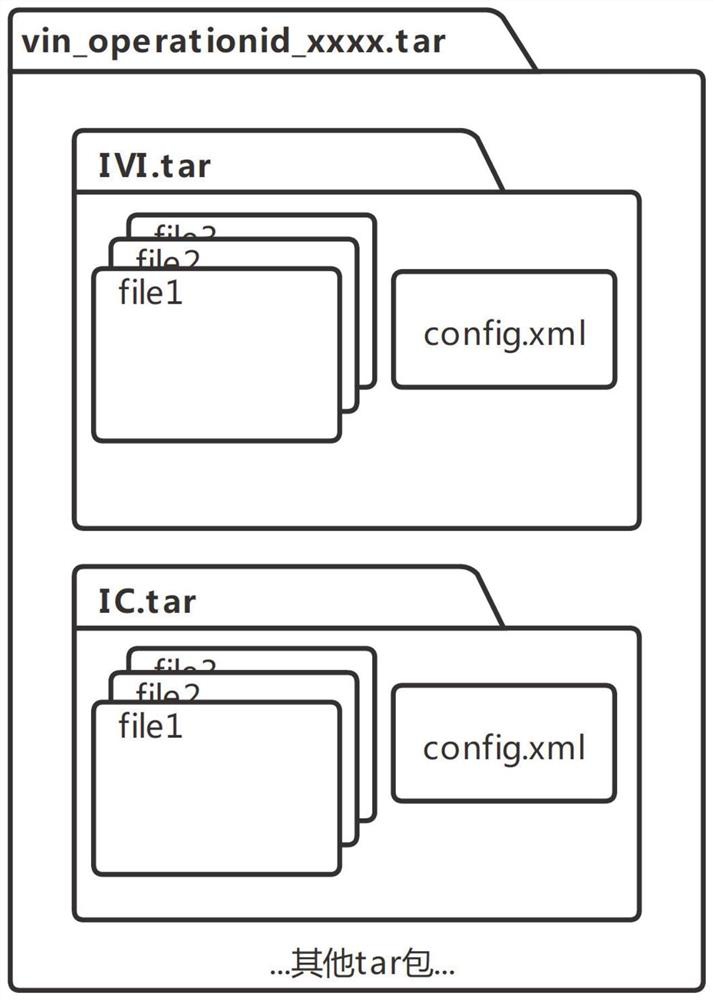

System, method and device for realizing remote assistant debugging of intelligent cabin, processor and computer readable storage medium thereof

PendingCN113220516AImprove timelinessStrong convenienceDetecting faulty hardware by remote testIn vehicleLogfile

The invention relates to a system for realizing remote assistant debugging for an intelligent cabin, and the system comprises a communication interaction function module which is used for executing system preset operation to realize communication with a vehicle-mounted system; a log management function module which is connected with the communication interaction function module and used for collecting and storing log files in the vehicle-mounted system and uploading the log files to a server; and a file updating function module which is connected with the log management function module and is used for making a corresponding debugging package for file backup and coverage according to the analyzed problems in the log file. The invention further relates to a corresponding method and device, a processor and a computer readable storage medium. By adopting the system, the method, the device, the processor and the computer readable storage medium provided by the invention, the problem that abnormal conditions of the vehicle-mounted entertainment system IVI and the instrument system IC cannot be debugged on site can be effectively solved.

Owner:DONGFENG ELECTRONICS TECH

Testing method for viscosity of organic carrier for photovoltaic front silver paste

The invention discloses a method for testing the viscosity of an organic carrier for photovoltaic positive silver paste. The steps of the test method are as follows: a. First, fill a measuring cup with 15ml-25ml of organic carrier; b. Put the measuring cup into the rotating speed Centrifuge in a centrifuge at 400rad / min~800rad / min for 3min~5min until the foaming is completely removed; c. Increase or decrease the organic carrier in the measuring cup after centrifugation to the specified capacity; d. Put the measuring cup with the specified capacity The cup is fixed in a small sample adapter with constant temperature circulating water and kept warm for 10min to 25min; e. After the viscometer is zeroed, the organic carrier after heat preservation is tested, and the viscosity value of the organic carrier at the specified speed can be read. The test method of the invention can quickly and thoroughly remove the randomly generated air bubbles in the organic carrier, improve the accuracy of the viscosity test, and improve the production efficiency and product quality stability of the photovoltaic positive silver paste.

Owner:DK ELECTRONICS MATERIALS INC

Ready-to-eat high-dietary-fiber passion fruit flavored sweet dumplings and preparation method thereof

PendingCN109965198AStrong convenienceHigh in dietary fiberFood coatingFood ingredient as mouthfeel improving agentReady to eatPassion fruit

The invention relates to the field of nutritious foods, particularly discloses ready-to-eat high-dietary-fiber passion fruit flavored sweet dumplings and a preparation method thereof and aims to solvetechnical problems of inconvenience in carrying and eating of traditional sweet dumplings and low utilization rate of passion fruit byproducts. The ready-to-eat high-dietary-fiber passion fruit flavored sweet dumplings comprise a wrapper material and filling. The filling is prepared from, by weight, 40-60 parts of passion fruit mesocarps, 15-20 parts of water, 15-25 parts of white granulated sugar, 20-30 parts of passion fruit juice, 0.1-0.3 part of phosphated distarch phosphate and 1-5 parts of pregelatinized starch. The preparation method includes steps: well mixing the raw materials according to a formula, making dough, and making wrappers; well mixing the raw materials according to a formula to obtain the filling; wrapping the filling with the prepared wrappers to obtain the ready-to-eat high-dietary-fiber passion fruit flavored sweet dumplings. By the passion fruit flavored sweet dumplings, high-value green processing of passion fruits is promoted while diversification of the sweet dumplings is realized.

Owner:YULIN NORMAL UNIVERSITY

Positioning and punching device for orthopedics department

InactiveCN114098891AStrong convenienceGuaranteed accuracyInstruments for stereotaxic surgeryHandrailMedical staff

The invention belongs to the technical field of medical instruments, particularly relates to an orthopaedic positioning and punching device, and aims to solve the problems that according to an existing orthopaedic punching device, medical staff generally punch an affected part according to experience and feeling, punching position deviation is easily caused, and later treatment is affected. The top of the movable base is connected with a supporting assembly, the right side of the top of the movable base is rotationally connected with a handrail rod, the handrail rod is connected with a connecting assembly, and the connecting assembly is connected with the supporting assembly. According to the leg perforating device, the legs of a patient can be clamped and positioned while a drill bit is aligned with the positions, needing to be perforated, of the legs of the patient, so that the accuracy can be improved when the legs of the patient are perforated, the perforating depth can be accurately controlled when the legs of the patient are opened, and the perforating efficiency is improved. Therefore, bad influence on later treatment can be avoided.

Owner:LUOYANG ORTHOPEDIC TRAUMATOLOGICAL HOSPITAL

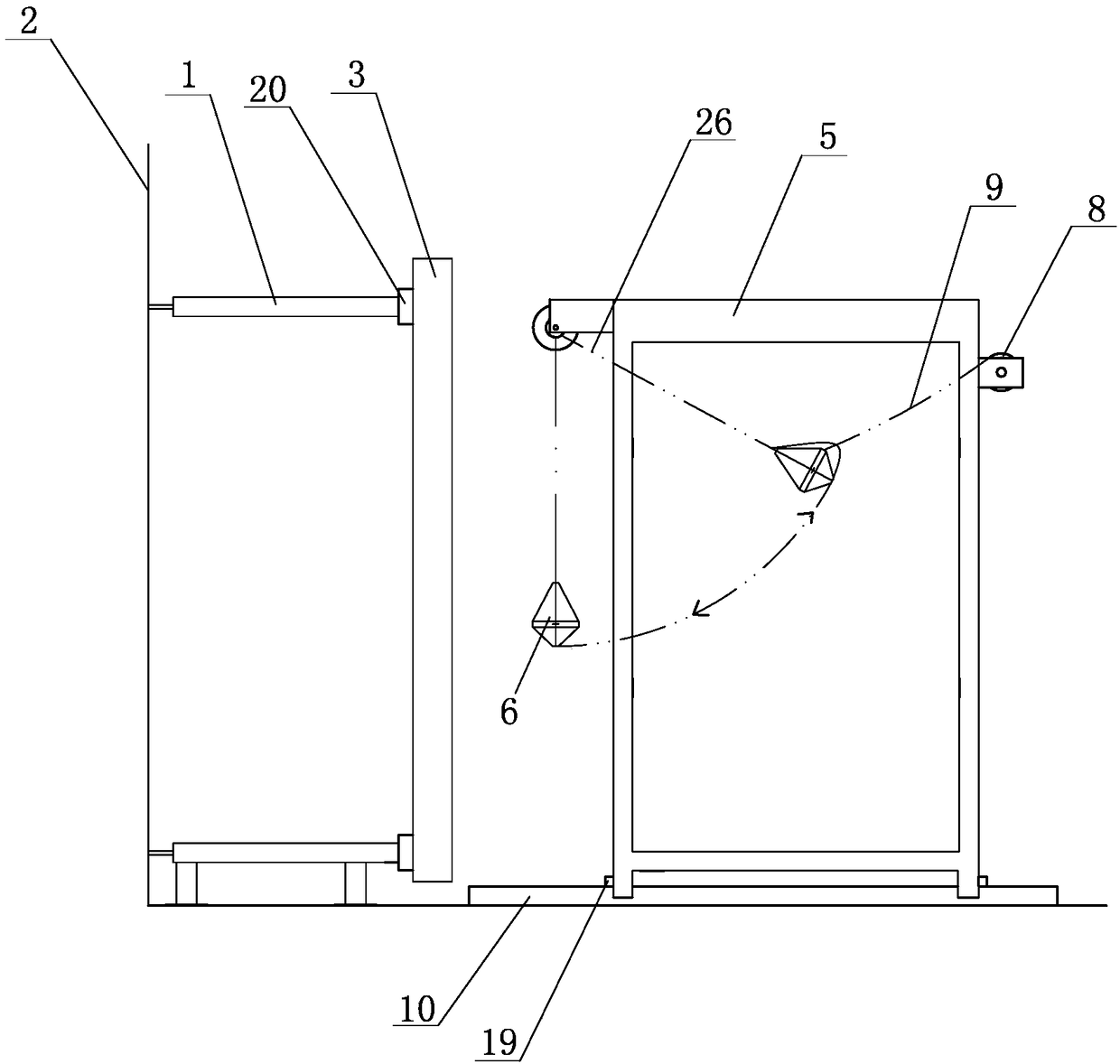

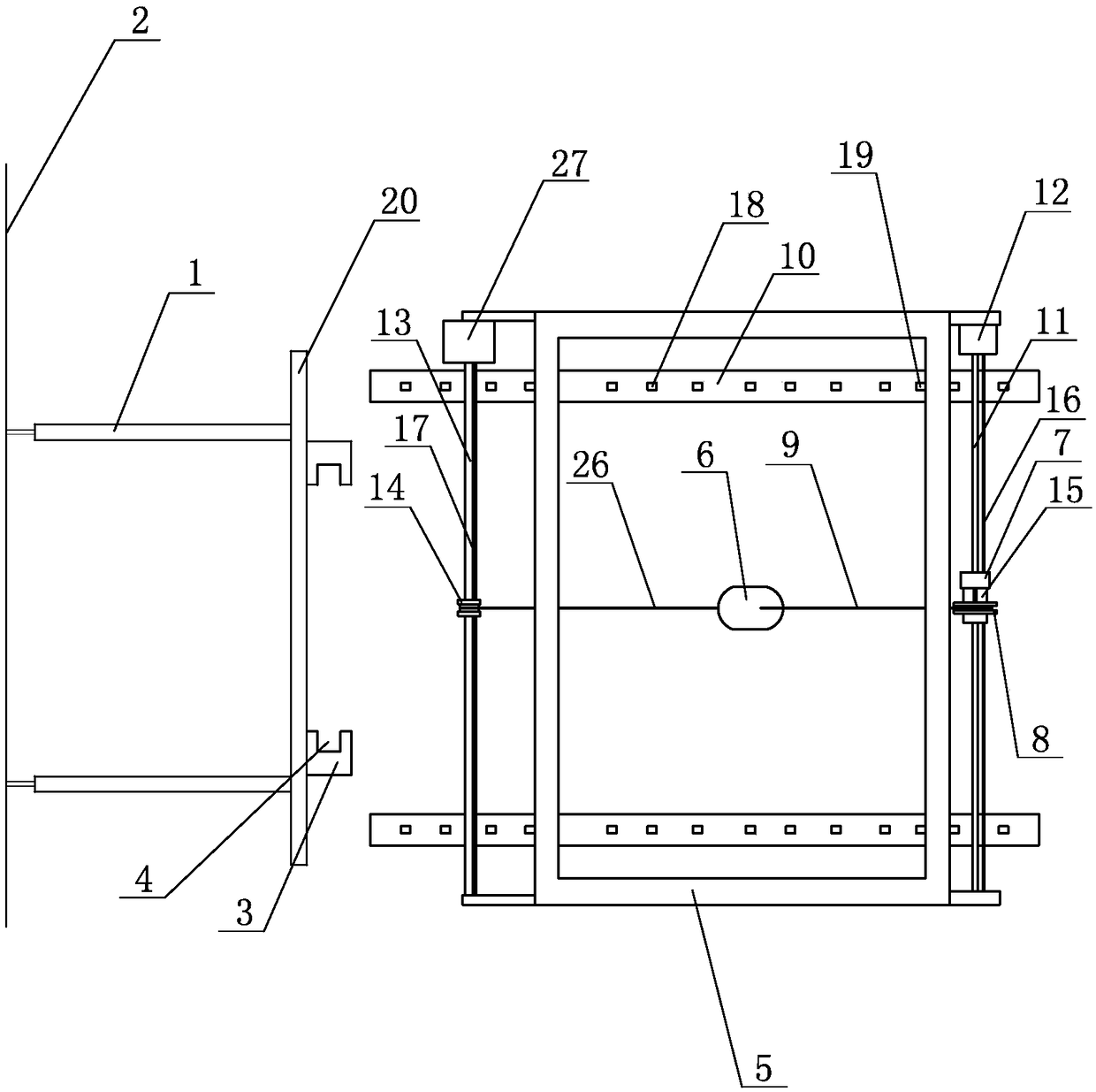

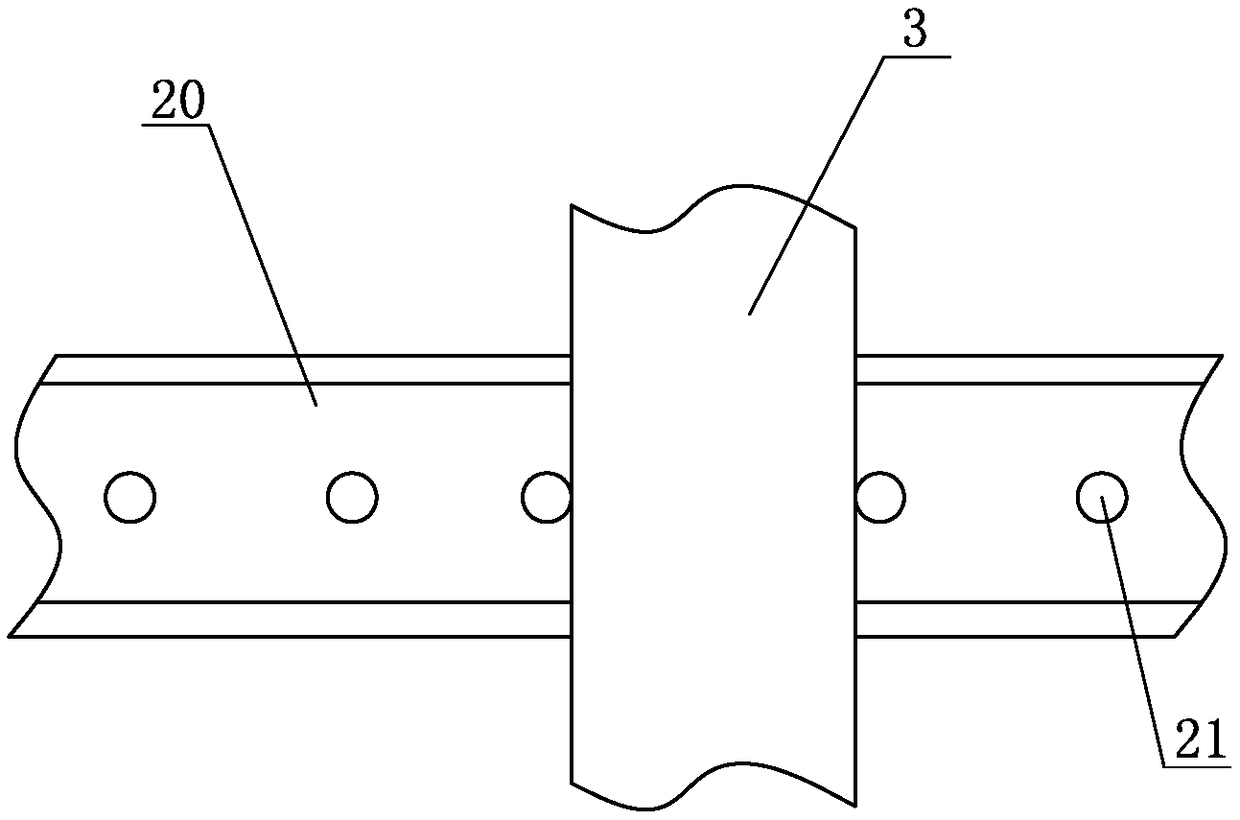

Elevator door plate impact testing device

PendingCN108918105AHigh degree of automationStrong convenienceMachine part testingEdge surfaceDrive motor

The invention discloses an elevator door plate impact testing device. The elevator door plate impact testing device is characterized in that the elevator door plate impact testing device comprises a vertical frame and an impact mechanism, two vertical columns are arranged on the two sides of the front end of the vertical frame separately, and vertical grooves are formed in the inner surfaces of the two columns; the impact mechanism comprises an impact mounting frame, a pendulum bob and a driving motor, wherein the pendulum bob and the driving motor are arranged on the impact mounting frame, the pendulum bob is arranged in the middle of the rear end face of the impact mounting frame, the top of the pendulum bob is installed on the impact mounting frame by a chain, and the driving motor is mounted at the top of the front end of the impact mounting frame; an output shaft of the driving motor is provided with a winding reel, the winding reel is provided with a pulling chain in a wound mode, one end of the pulling chain is arranged on the winding reel in a wound mode, and the other end of the pulling chain is connected to the outer edge surface of the middle portion of the pendulum bob;and a sliding rail is further arranged at the bottom of the front end of the vertical frame, and the bottom of the impact mounting frame is slidably arranged on the sliding rail. The elevator door plate impact testing device improves the application range of an elevator door plate test and improves the testing effect.

Owner:克莱斯电梯(中国)有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com