Taking machine for liquid or ropy material with better liquidity in high-capacity plastic flexible package

A flexible packaging and large-capacity technology, applied in the field of viscous material devices, can solve problems such as easy leakage, liquid or viscous material outflow, leakage, etc., to achieve the effects of enhancing economy, convenient use, and reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

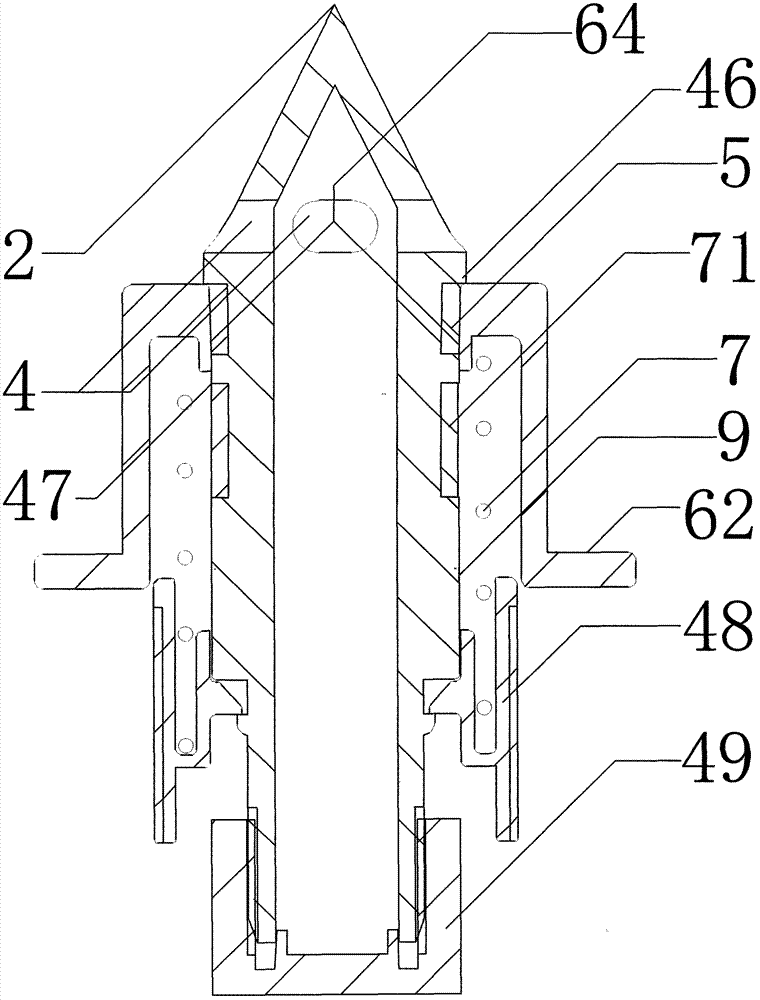

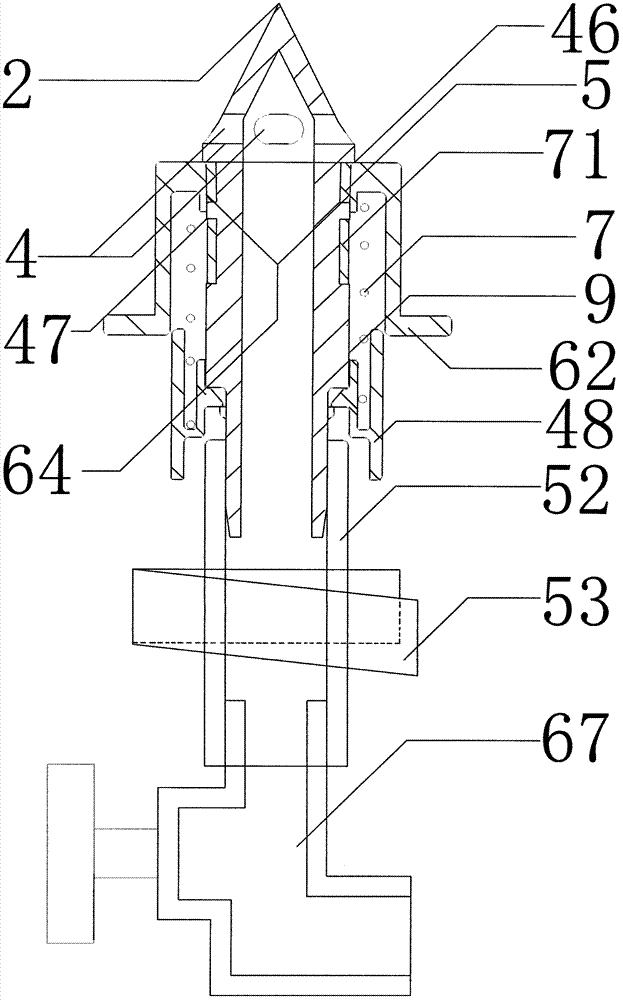

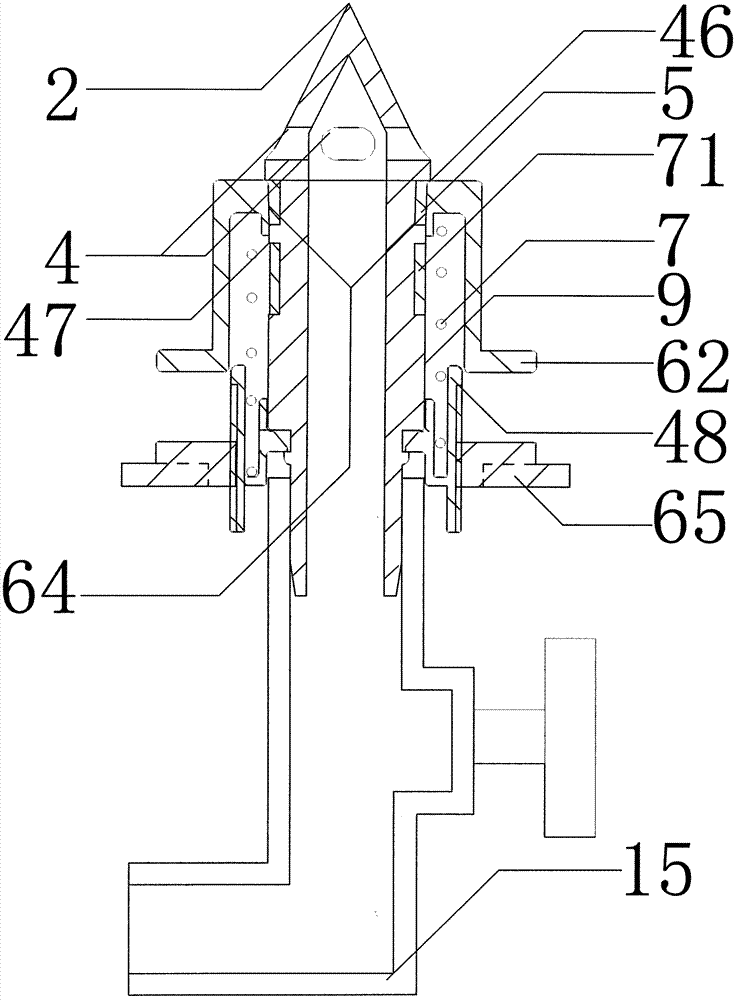

[0024] exist figure 1 , figure 2 with image 3 In the shown embodiment, the locking seal 5 is installed in the groove below the limiting platform 46, the sealing member 71 is installed in the groove below the barrier film platform 47, and the locking sliding sleeve is installed sequentially from the end of the thimble rod 9 A62, spring 7 and spring slot A48, use the index finger and middle finger of the hand on both sides of the locking sleeve A62, put the bottom end of the taker against the palm, press the locking sleeve A62 toward the palm of the hand to reach the puncture position , use the thimble head 2 to pierce down into the bag from the upward side of the large-capacity plastic bag flexible packaging bag, and after passing through the locking seal 5, the outer diameter of the locking seal 5 is only larger than the resistance film table 47 and the seal 71 is bigger, it will not cause larger holes in the packaging film, plus the packaging film has a certain degree of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com