Multipurpose optimization method for distribution of facilities in plant

A multi-objective optimization and layout optimization technology, applied in the direction of instruments, etc., can solve the problems that the layout plan is greatly influenced by subjective factors, the precedent of multi-objective optimization has not been found, and the layout is greatly influenced by the designer, etc. Floor area, reduced handling cost or volume, and high layout efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040]In order to enable those skilled in the art to better understand the technical solution of the present invention, and to make the above-mentioned purpose, features and advantages of the present invention more obvious and understandable, the present invention will be further described in detail below in conjunction with the embodiments and accompanying drawings .

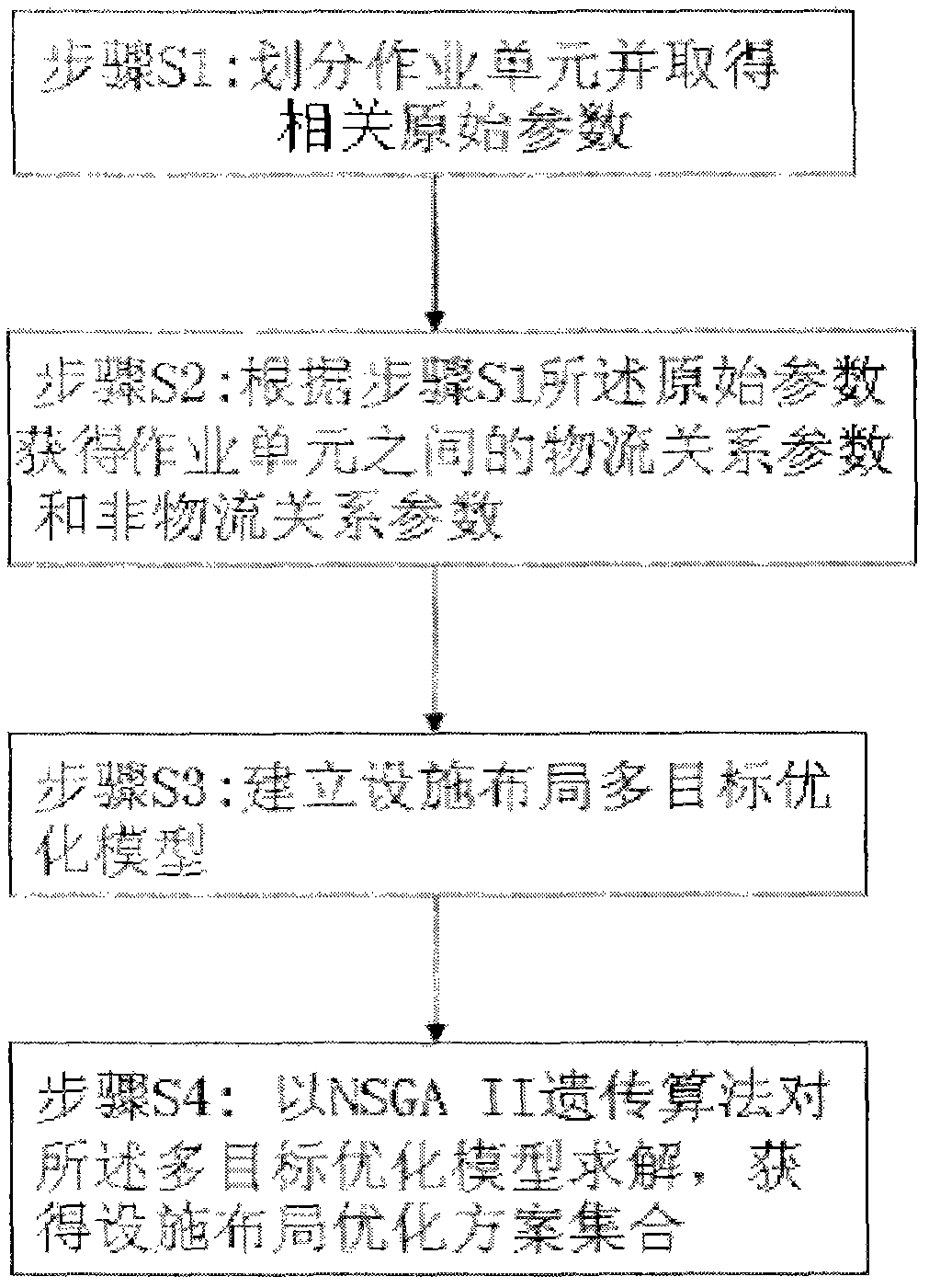

[0041] figure 1 A general flow chart of the facility layout multi-objective optimization method according to the embodiment of the present invention is shown. The facility layout multi-objective optimization method generally includes:

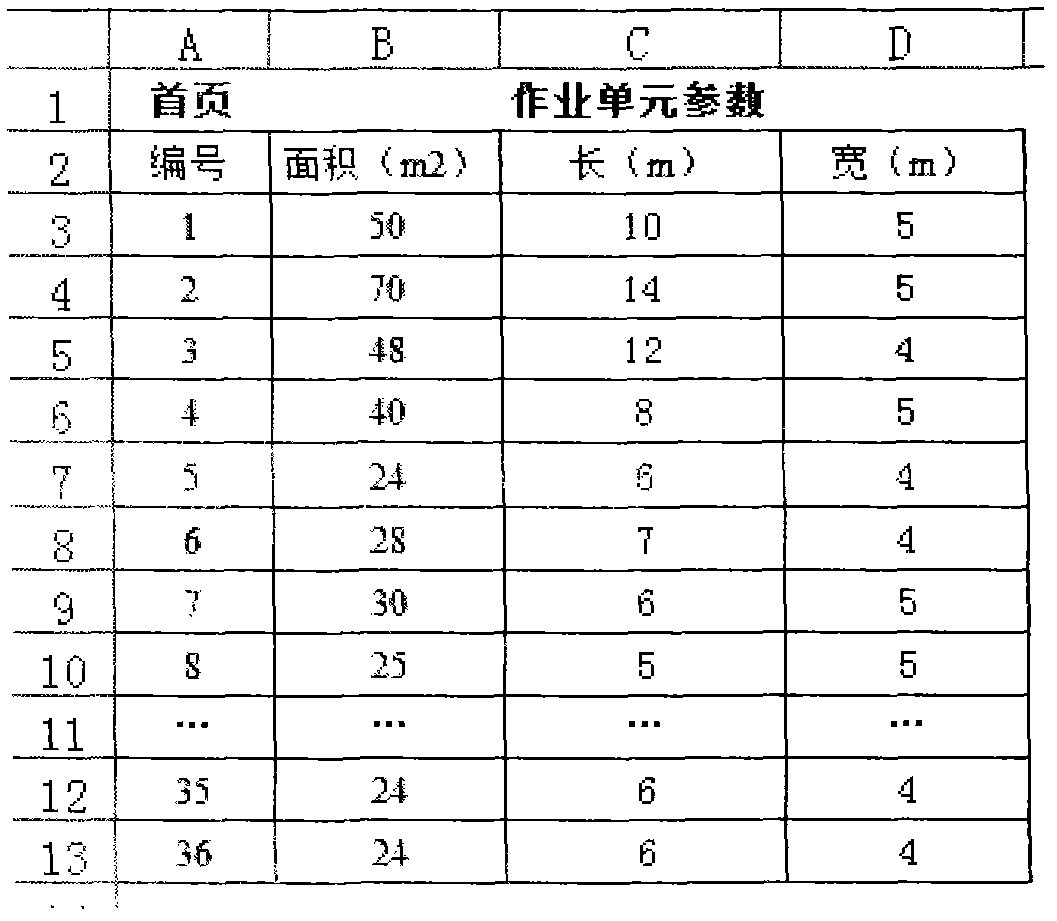

[0042] Step S1, divide the operation unit into the facility layout area in the factory building and obtain relevant original parameters;

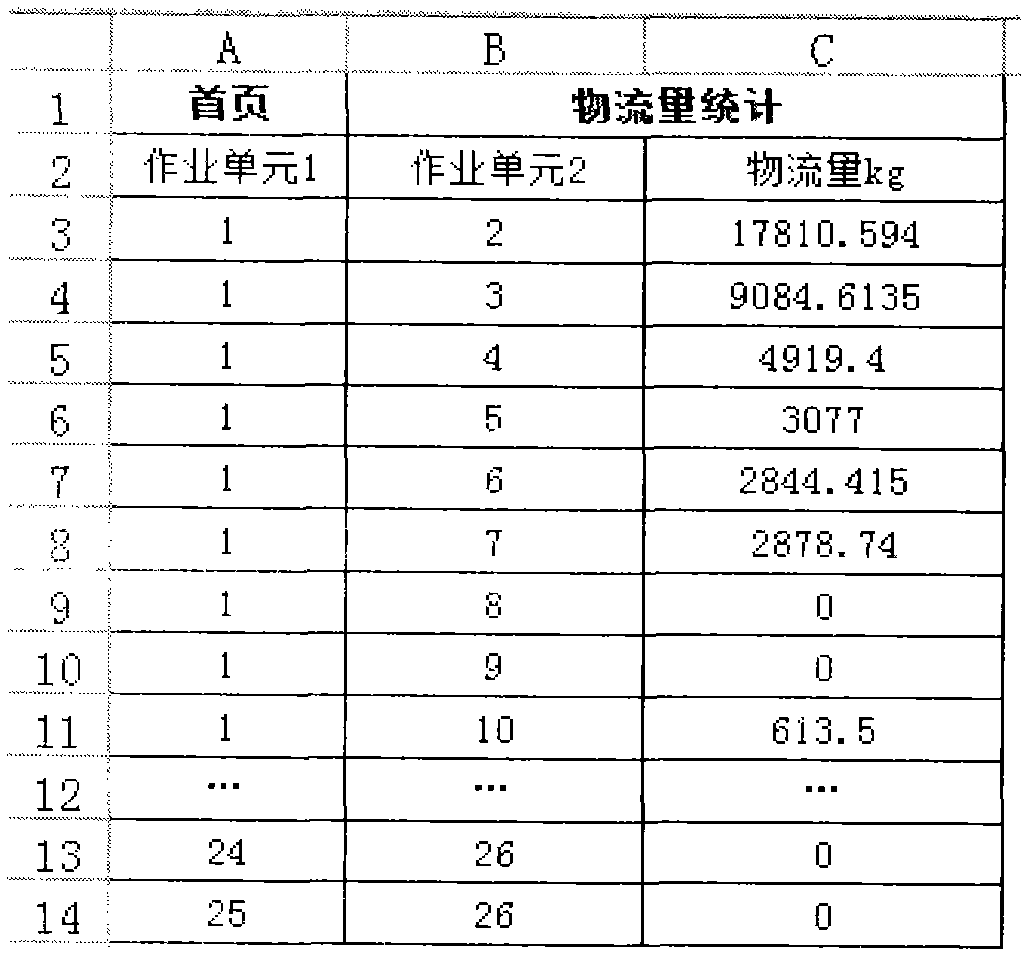

[0043] Step S2, obtaining logistics relationship parameters and non-logistics relationship parameters between operation units according to the original parameters described in step S1;

[0044] Step S3, establishing a facility layout multi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com