Patents

Literature

107 results about "Discrete element model" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

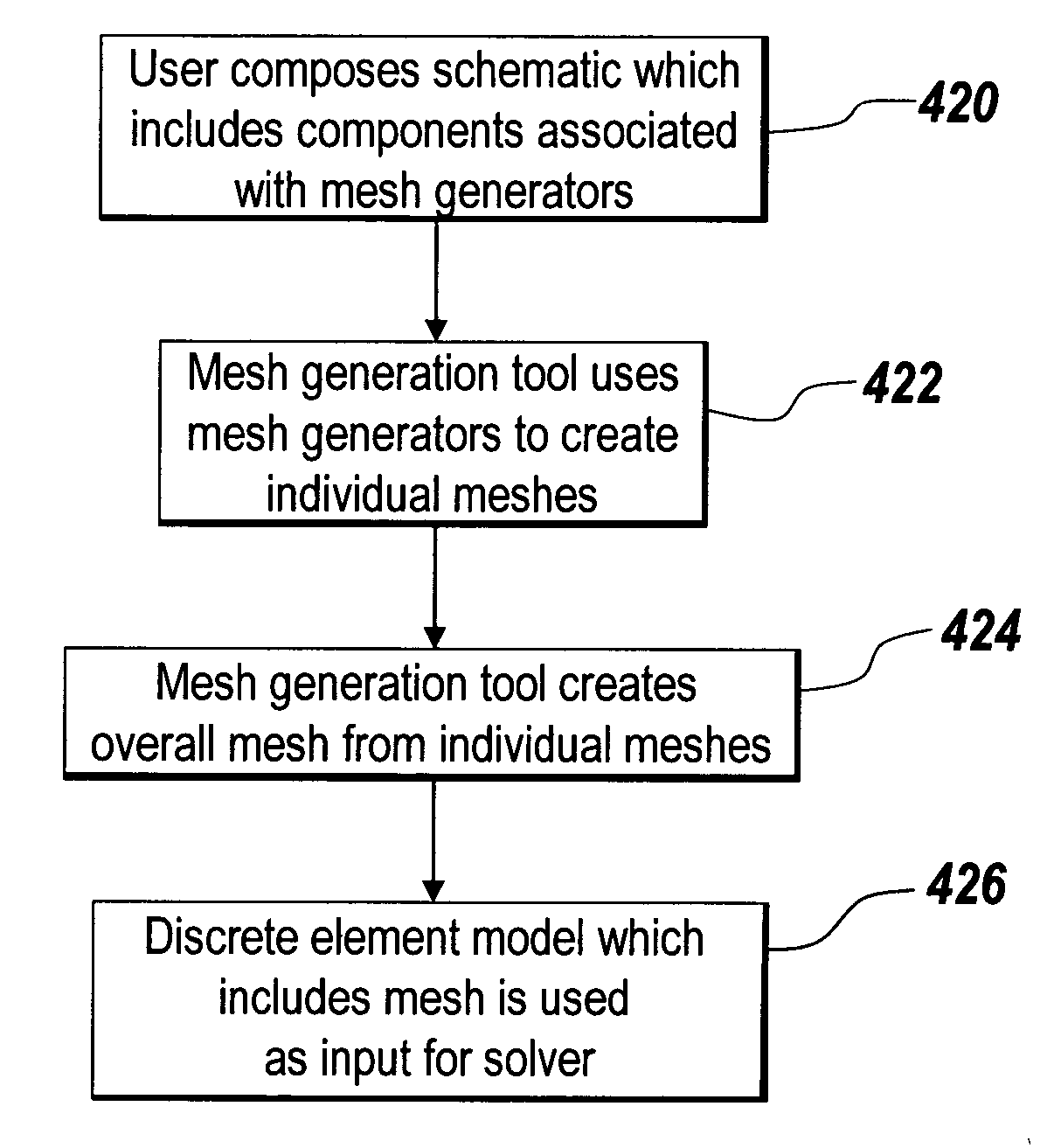

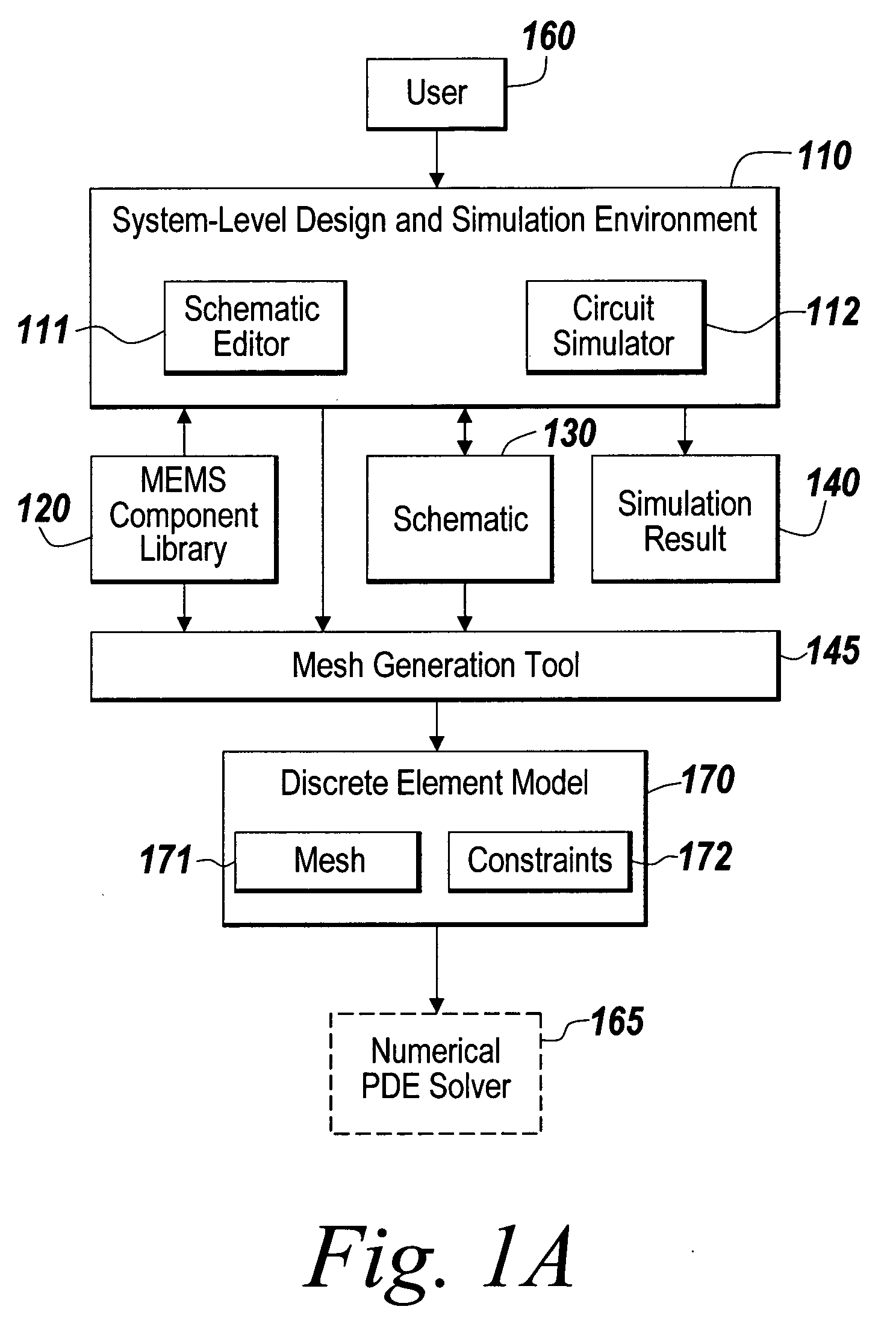

System and method for automatic mesh generation from a system-level MEMS design

ActiveUS7131105B2Rapid and efficient movementGeneration improvedDetecting faulty computer hardwareComputation using non-denominational number representationElement modelDecomposition

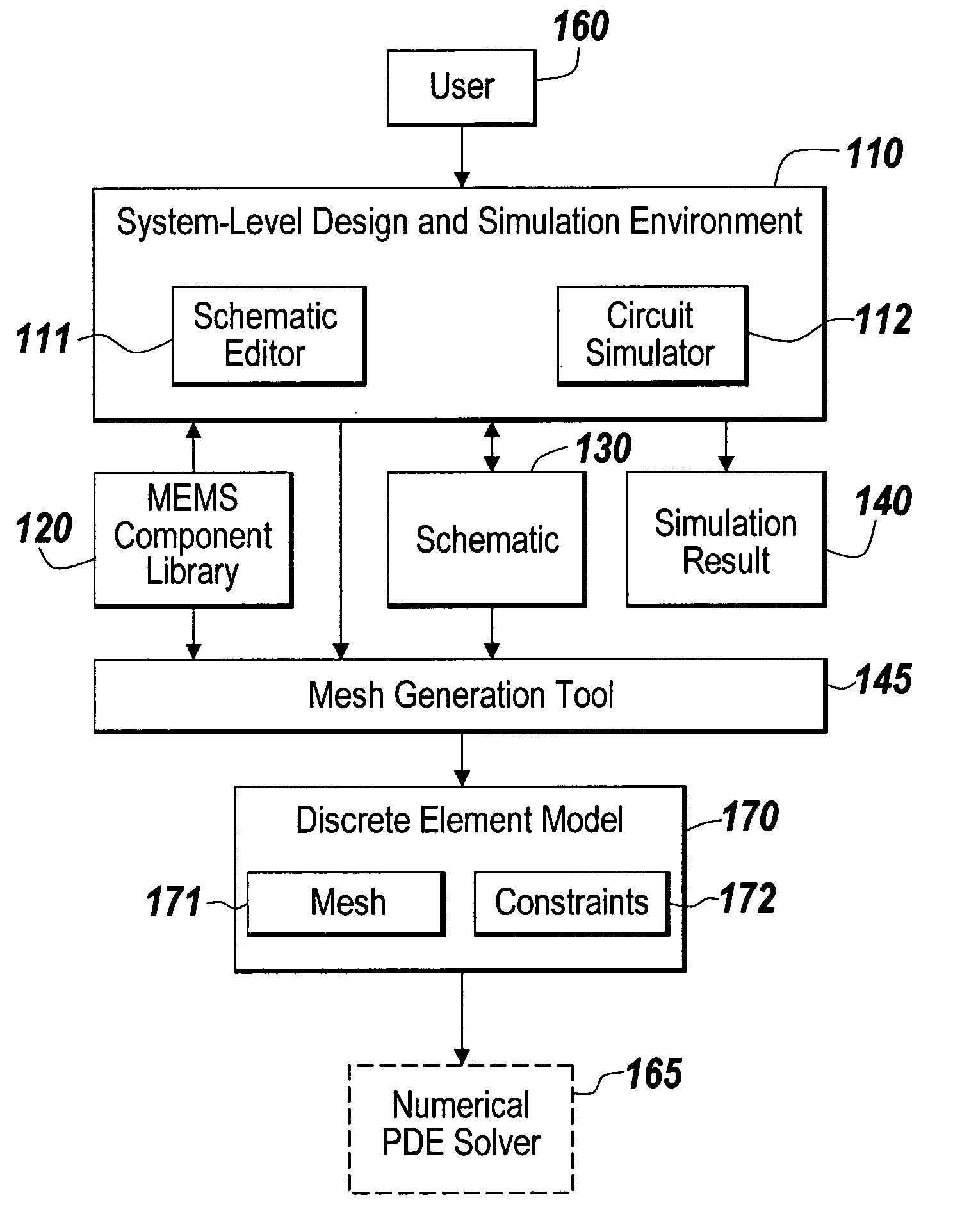

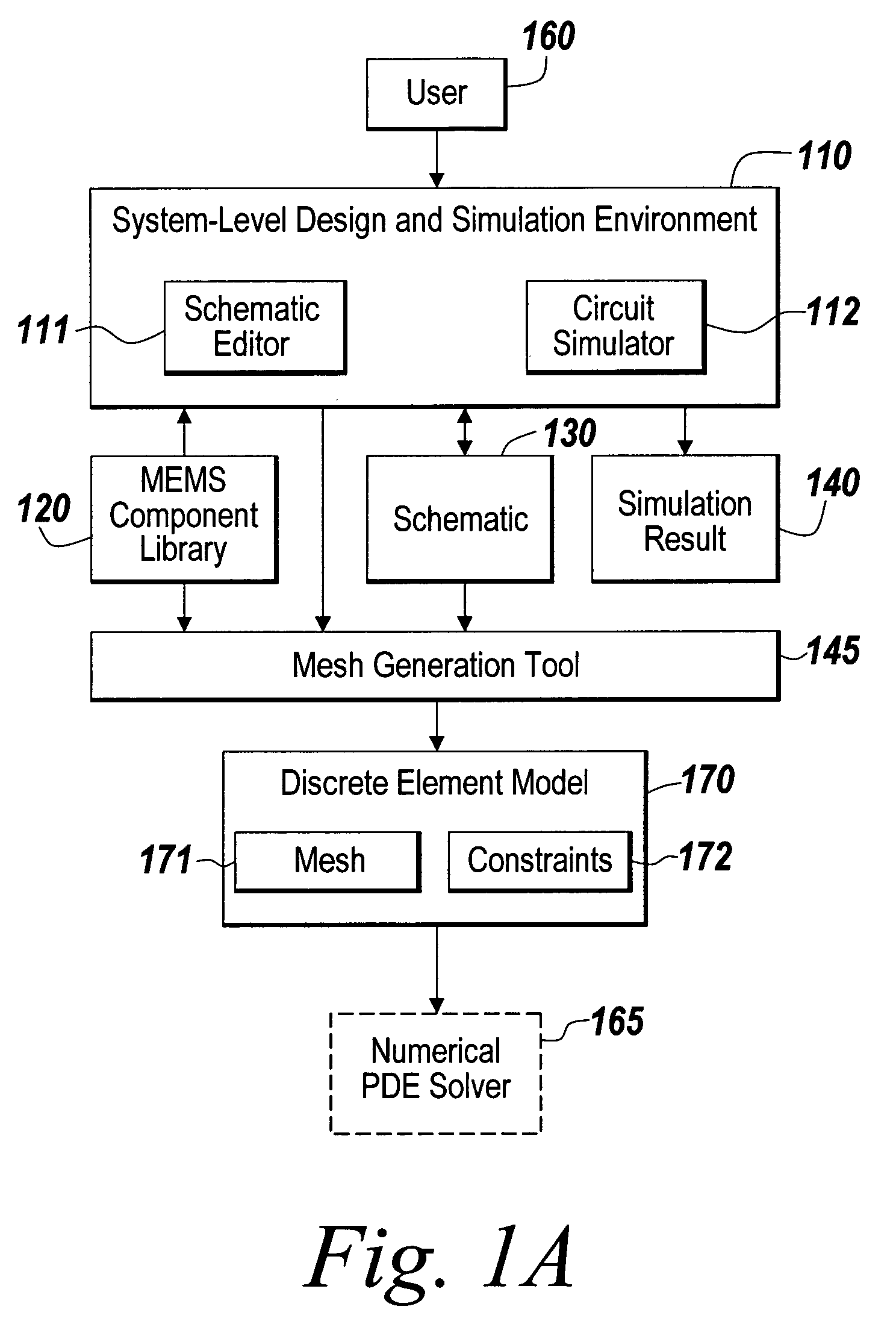

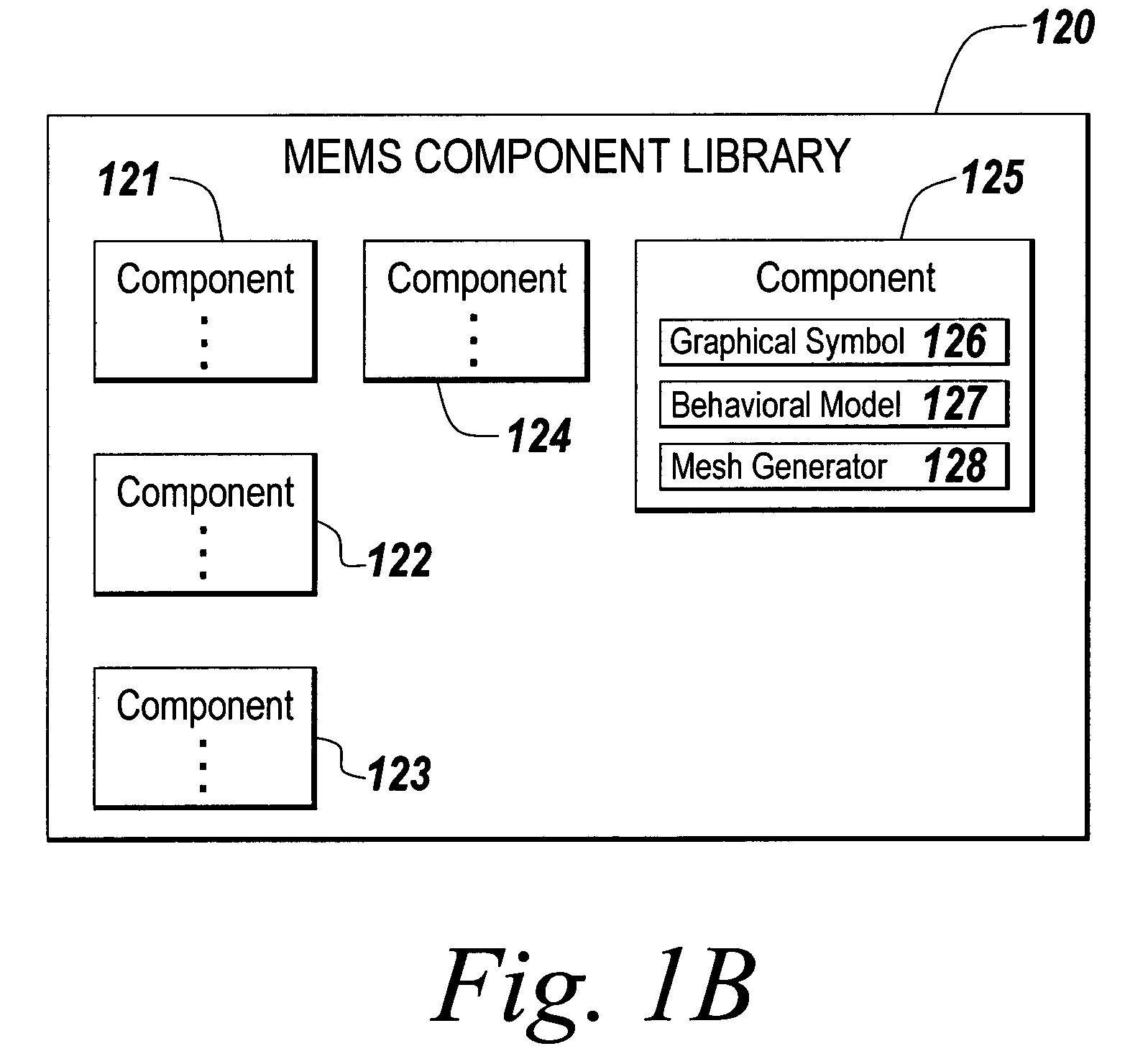

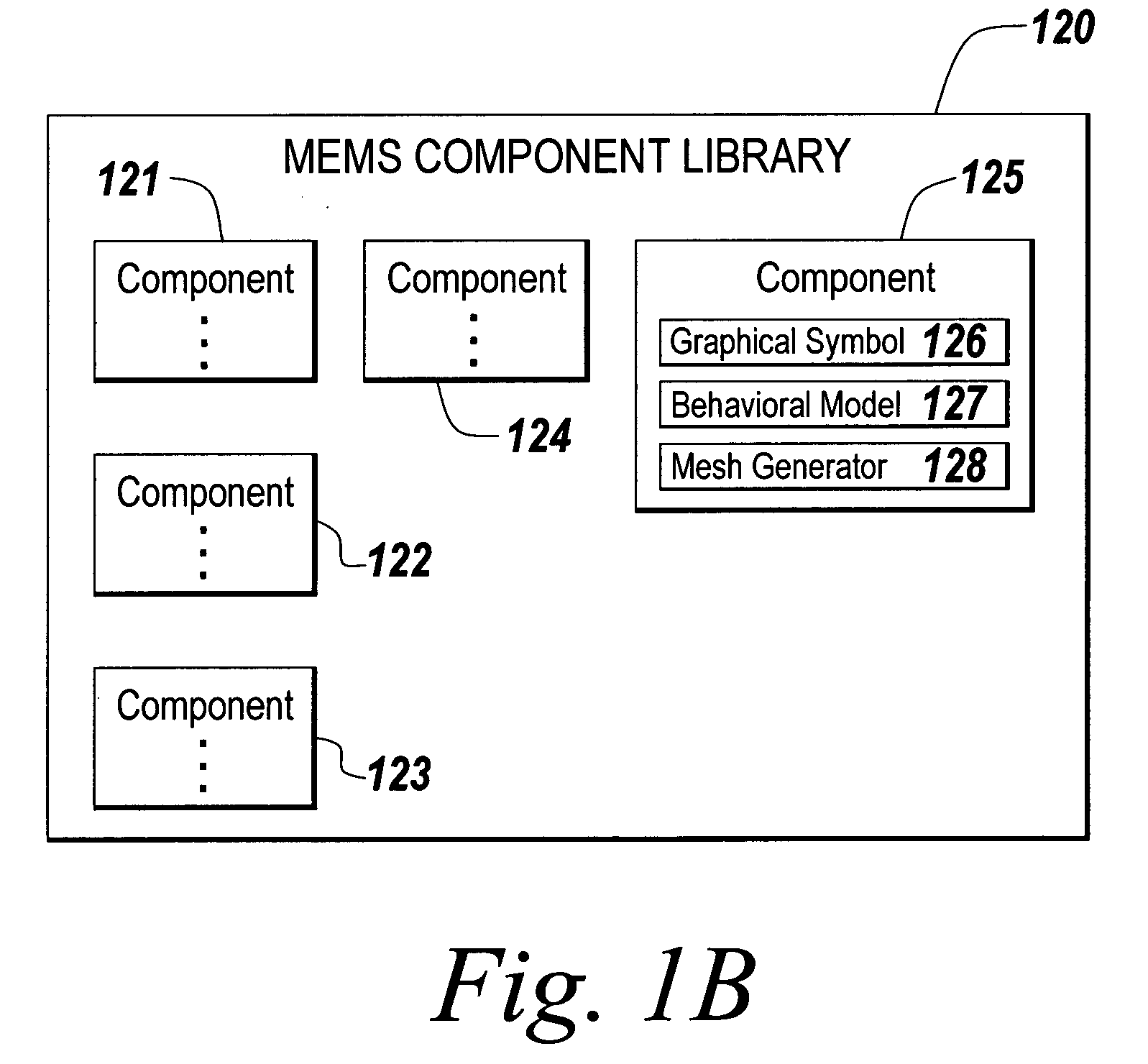

A mesh generation tool that is programmatically integrated with a system-level design and simulation environment, thereby enabling the direct generation of PDE solver input from a system-level design and simulation environment and a method for using the mesh generation tool are disclosed. Automatic mesh generation and optimization is improved by making available additional information about the nature and purpose of certain design components to the mesh generation tool. Specifically, the parameters of the components in the device schematic, which represent a user-defined decomposition of a larger MEMS design into smaller entities of clear physical purpose, are made available to the mesh generation tool. The link established between the system-level design and PDE analyses allows the user to move between the two levels of abstraction. The mesh generation tool retrieves information from the components and connectors of a schematic of a MEMS device, and produces a discrete element model suitable for numerical PDE analysis by the finite element (FEM) and boundary element (BEM) methods. A direct link from a schematic model to a mesh model helps the user to produce an optimal mesh for PDE analysis, thereby avoiding considerable unnecessary computation.

Owner:COVENTOR

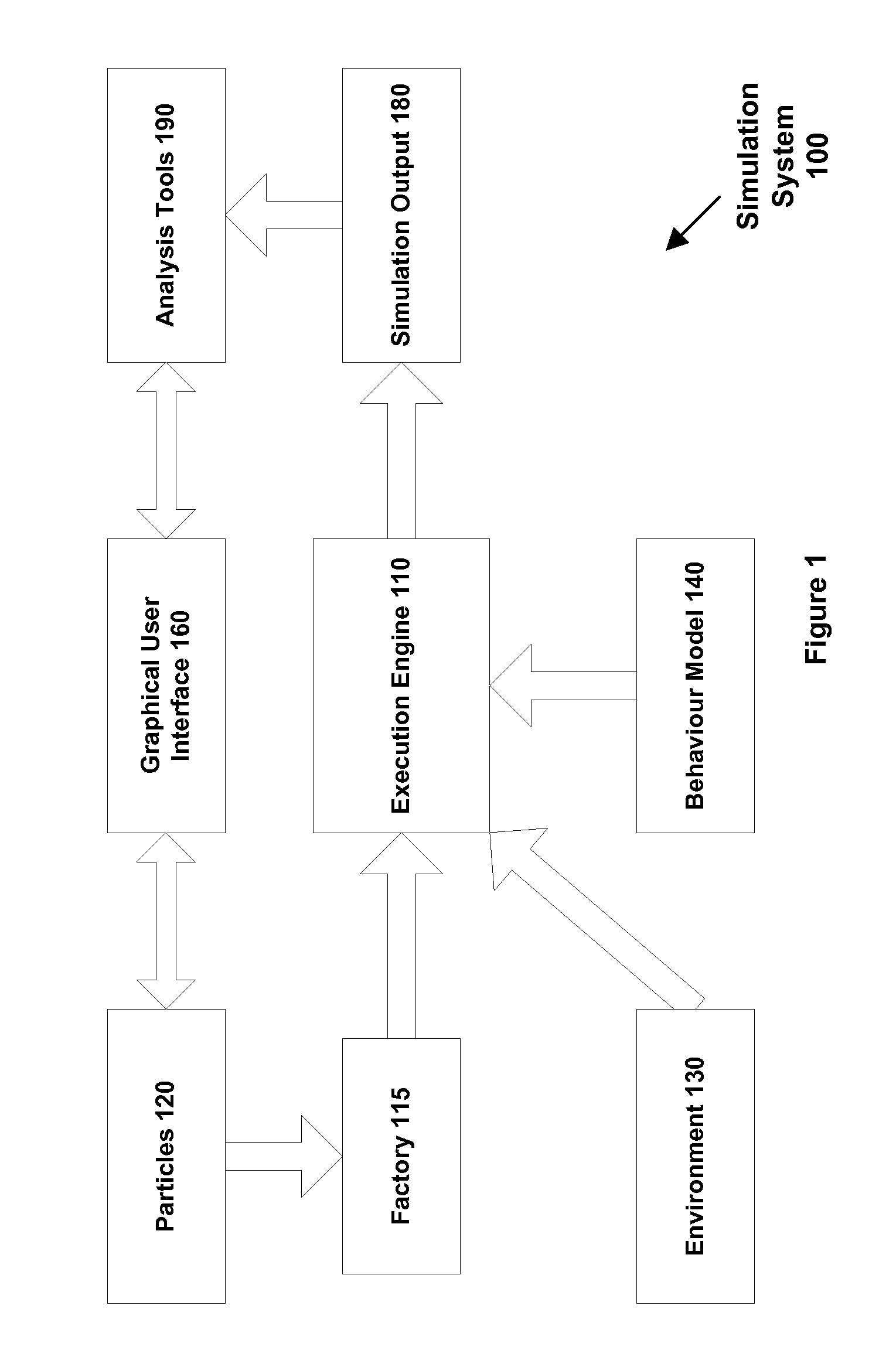

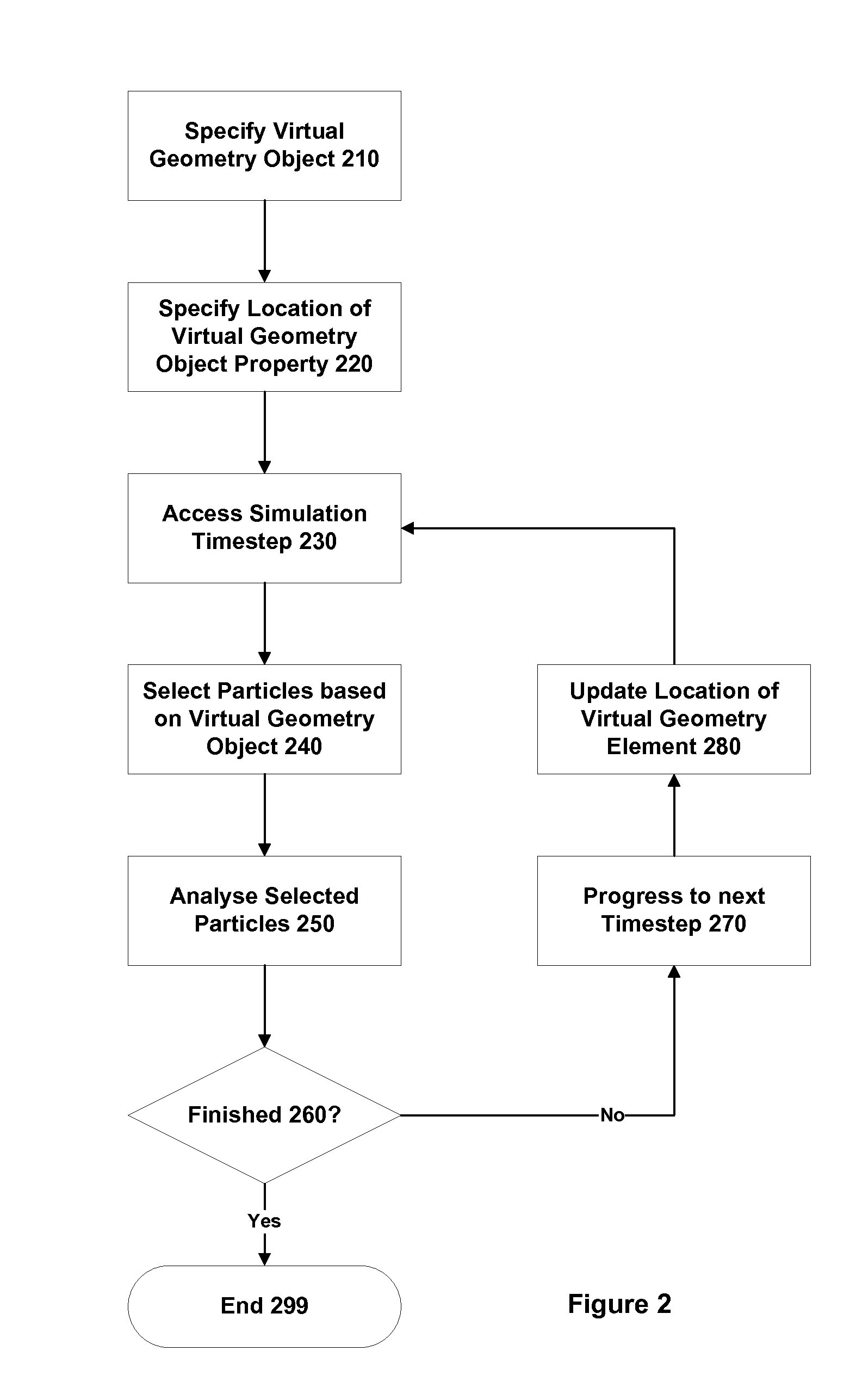

Method and apparatus for discrete element modeling with a virtual geometry object

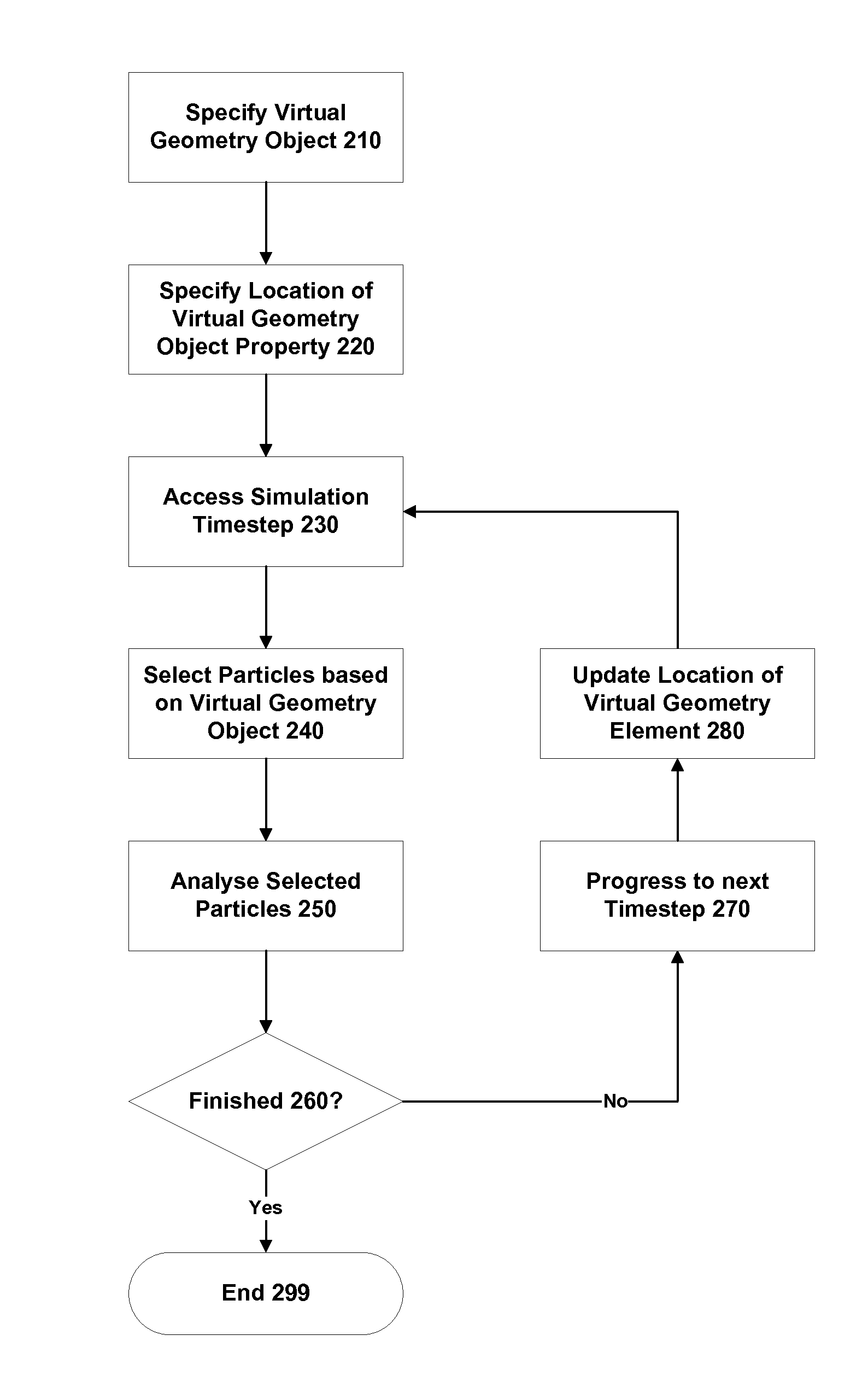

One embodiment of the invention provides a computer-implemented method for discrete element modelling of a plurality of discrete elements corresponding to particles and physical geometry elements. The modelling performs a simulation through time of physical interactions of the particles with each other and with the physical geometry elements in a three-dimensional space. The method comprises providing a virtual geometry object comprising a user-defined shape. The virtual geometry object does not undergo physical interaction with the particles or physical geometry elements during the simulation. The method further comprises receiving user-defined parameters for determining the position, orientation and any movement of the virtual geometry object with respect to the three-dimensional space. The method further comprises locating the virtual geometry object in the three-dimensional space during the simulation in accordance with the user-defined parameters and identifying the particles, physical geometry elements and / or physical interactions having a particular relationship with respect to the virtual geometry object. The identified elements can then be analysed by the user, for example to determine the number of particles located at a given time within a specific region of the simulation space (as defined by the virtual geometry object).

Owner:ALTAIR ENG LTD

System and method for automatic mesh generation from a system-level MEMS design

ActiveUS20050066301A1Rapid and efficient movementAvoiding considerable unnecessary computationDetecting faulty computer hardwareComputation using non-denominational number representationDecompositionEngineering

A mesh generation tool that is programmatically integrated with a system-level design and simulation environment, thereby enabling the direct generation of PDE solver input from a system-level design and simulation environment and a method for using the mesh generation tool are disclosed. Automatic mesh generation and optimization is improved by making available additional information about the nature and purpose of certain design components to the mesh generation tool. Specifically, the parameters of the components in the device schematic, which represent a user-defined decomposition of a larger MEMS design into smaller entities of clear physical purpose, are made available to the mesh generation tool. The link established between the system-level design and PDE analyses allows the user to move between the two levels of abstraction. The mesh generation tool retrieves information from the components and connectors of a schematic of a MEMS device, and produces a discrete element model suitable for numerical PDE analysis by the finite element (FEM) and boundary element (BEM) methods. A direct link from a schematic model to a mesh model helps the user to produce an optimal mesh for PDE analysis, thereby avoiding considerable unnecessary computation.

Owner:COVENTOR

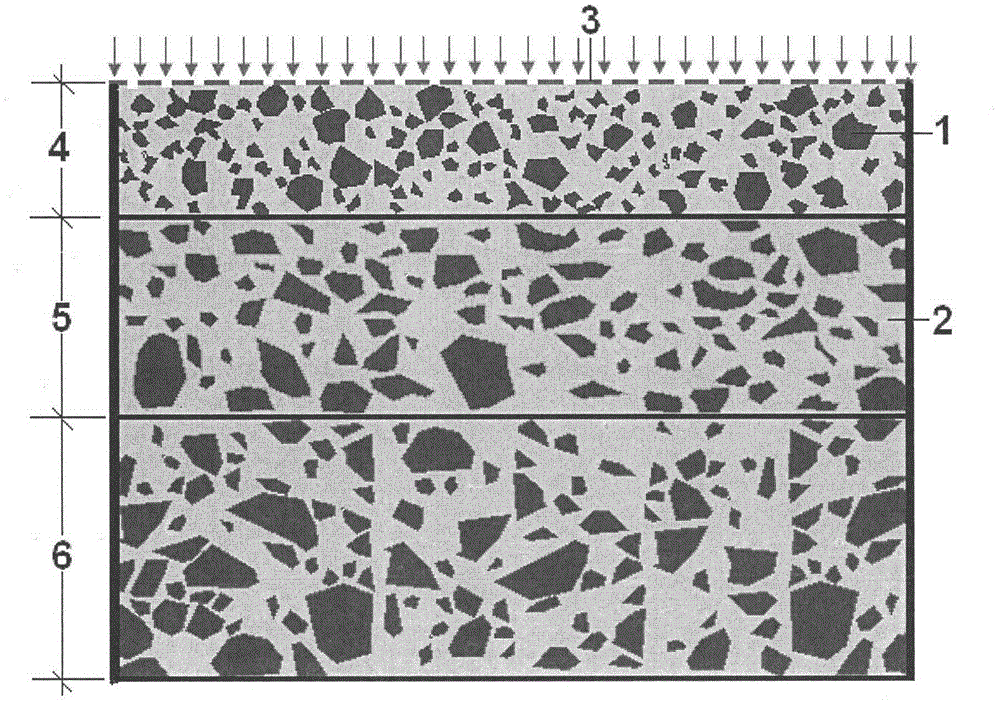

Visual uniaxial penetrating test-based bituminous mixture homogeneity evaluation method

InactiveCN105806861AThe evaluation result is accurateHigh industrial applicabilityMaterial analysis by transmitting radiationFractographyTomography

The invention discloses a visual uniaxial penetrating test-based bituminous mixture homogeneity evaluation method, which comprises the following steps: carrying out indoor molding or drilling a cylindrical core sample on site, acquiring two-dimensional horizontal section images of a plurality of bituminous mixture test pieces through tomoscan of an industrial CT machine, and then preprocessing and intensifying the two-dimensional horizontal section images acquired by the CT machine to generate gray images; recognizing and segmenting the processed bituminous mixture section gray images to obtain a boundary coordinate of each aggregate and gap in the bituminous mixture section images, establishing a three-dimensional discrete element model of the bituminous mixture and carrying out a virtual uniaxial penetration test, and evaluating the bituminous mixture homogeneity by using the uniaxial penetration strength index variable coefficient obtained by the test. The bituminous mixture homogeneity evaluation method is based on the visual uniaxial penetrating test, and the bituminous mixture homogeneity is quantitatively evaluated by using the uniaxial penetration strength index variable coefficient, so the industrial practicability and maneuverability are very strong.

Owner:ZHEJIANG UNIV

Grading optimization method for asphalt mixture under virtual state

ActiveCN106950120AEasy to operateStrong representativeMaterial strength using tensile/compressive forcesMaterial strength using steady shearing forcesOperabilityVirtual state

The invention discloses a grading optimization method for an asphalt mixture under virtual state. The method includes the steps of: on the basis of grading that needs to optimize according to practical demand, in three-dimensional discrete element software PFC3D, randomly generating an asphalt mixture mechanical test three-dimensional discrete element model (including uniaxial penetration test, low temperature split test, uniaxial compression test and shear fatigue test) which satisfies a target grading, wherein the generation process of the three-dimensional discrete element model, which satisfies the target grading, is the base of asphalt mixture grading optimization; and comparing mechanical performance evaluation results of various grading to obtain a grading having best mechanical performance. The method has strong operability, convenience and representativeness.

Owner:ZHEJIANG UNIV

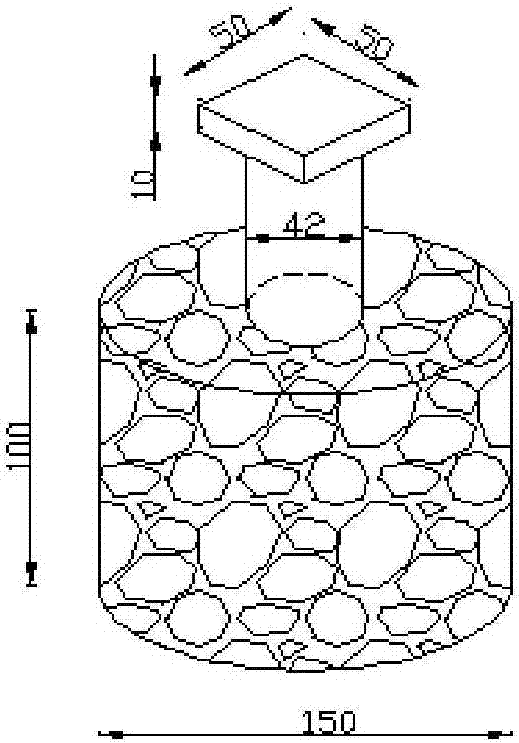

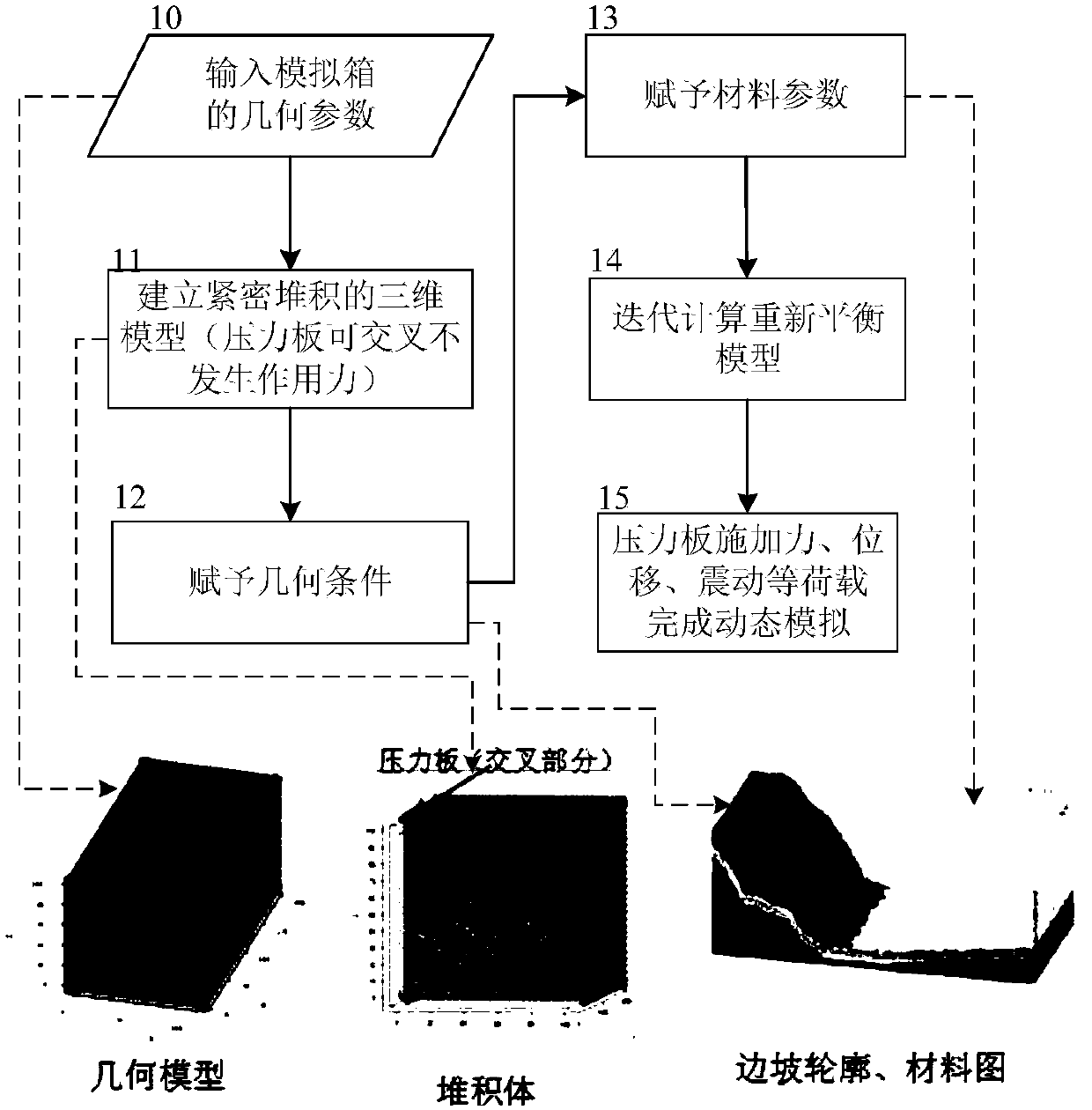

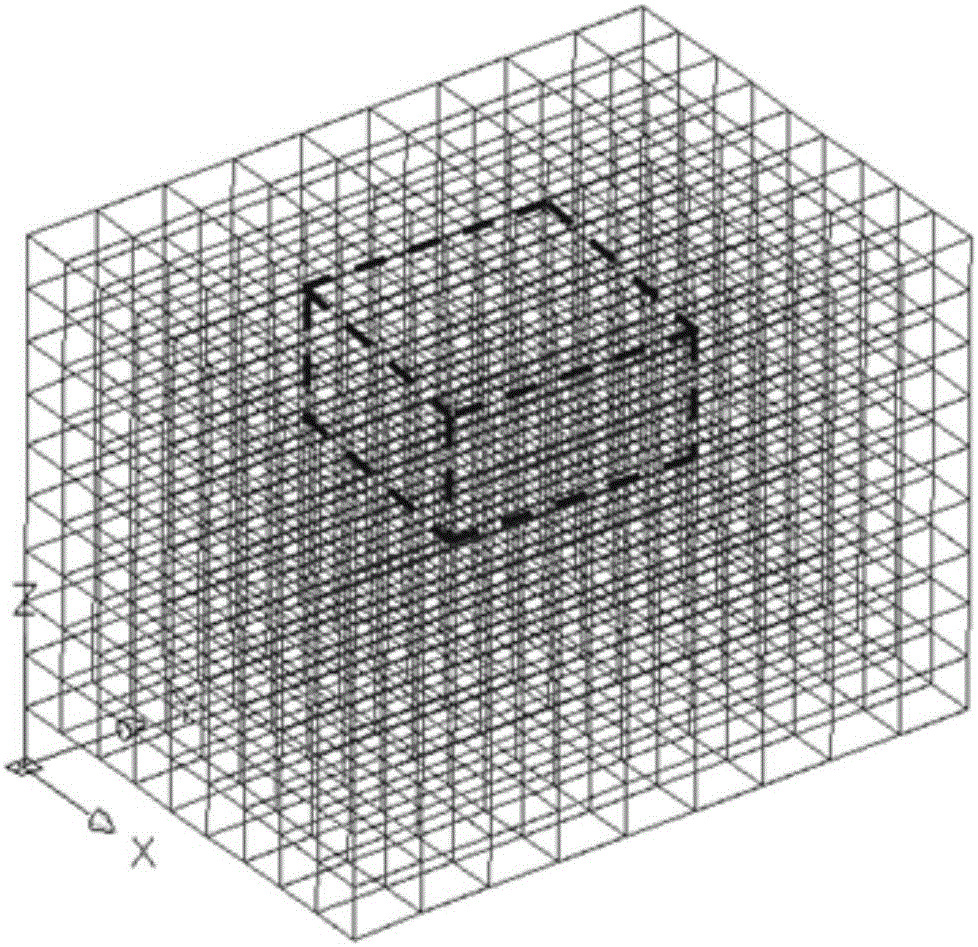

Universal numerical-value simulation box used for fast three-dimensional discrete element modeling and simulation of rock and soil mass

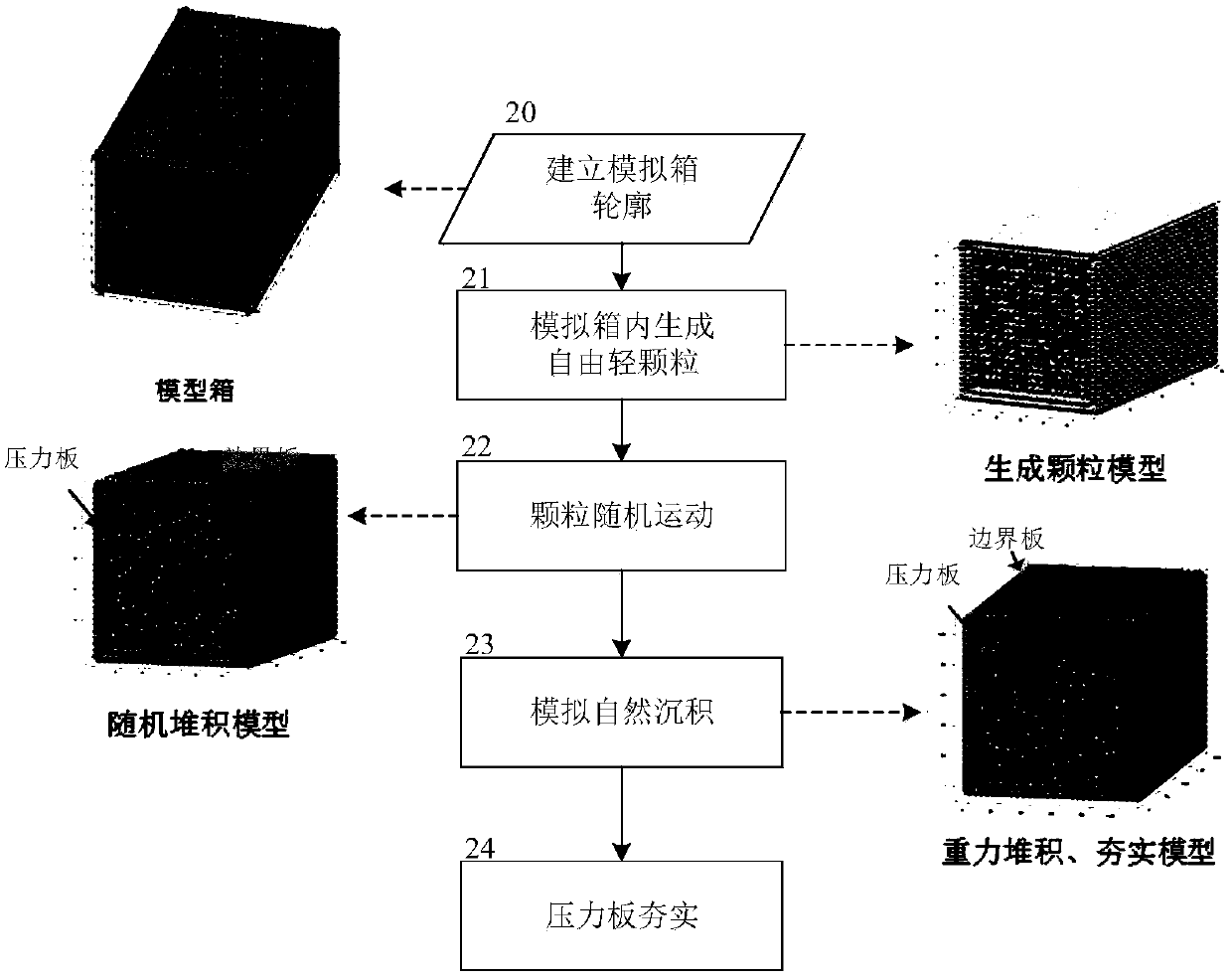

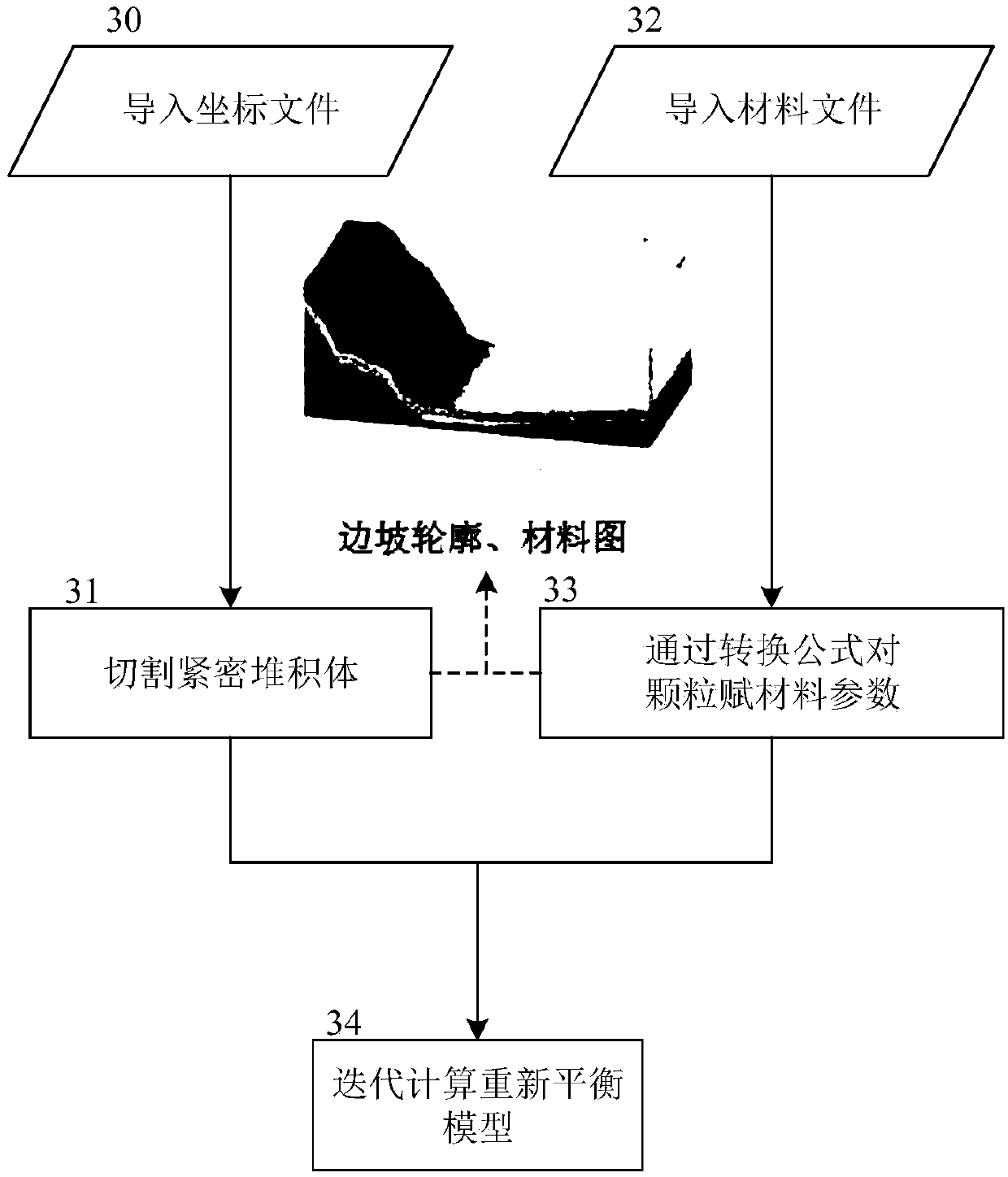

ActiveCN107644120AEfficient modeling methodEfficient modelingSpecial data processing applicationsThree dimensional simulationElement modeling

The invention discloses a universal simulation box used for three-dimensional discrete element modeling and simulation of a rock and soil mass. 1) a universal simulation box is established, specified-size boundary plates in six directions of a box body are generated, the boundary plates are composed of a series of sphere particles, smaller-size buffer boundary pressure plates are respectively generated inside the six boundary plates, and the three-dimensional simulation box is established; 2) a particle accumulation body is generated in the box body, and no-gravity particles are randomly generated in the box body; 3) a three-dimensional model of different structures is established, files including delamination and demarcation coordinate files are imported, the particles outside an outlineare removed, and the three-dimensional model of the structures is formed; 4) material properties of the rock and soil mass are assigned to the three-dimensional model, a material attribute file of therock and soil mass is imported, parameters of the rock and soil mass are converted into parameters of the particles according to conversion formulas, the parameters are assigned to the particles, anda three-dimensional discrete element model with specified elastic properties and failure properties is established; and 5) loading of force, displacement and vibration is carried out through the boundary pressure plates, displacement and vibration are applied through boundaries, loads such as stress action are applied through the pressure plates, iteration operating is carried out, and a result is output.

Owner:NANJING UNIV

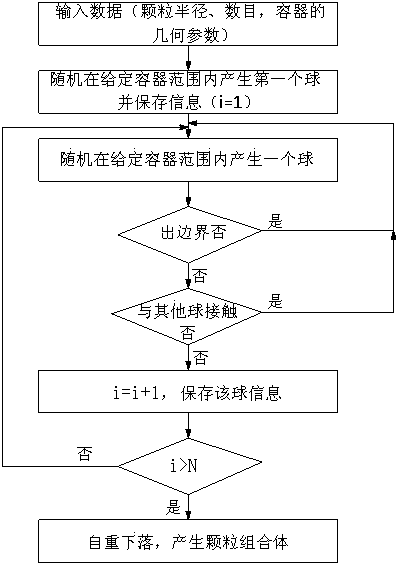

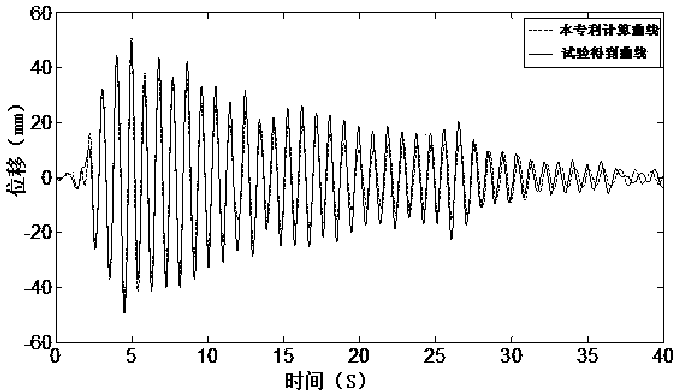

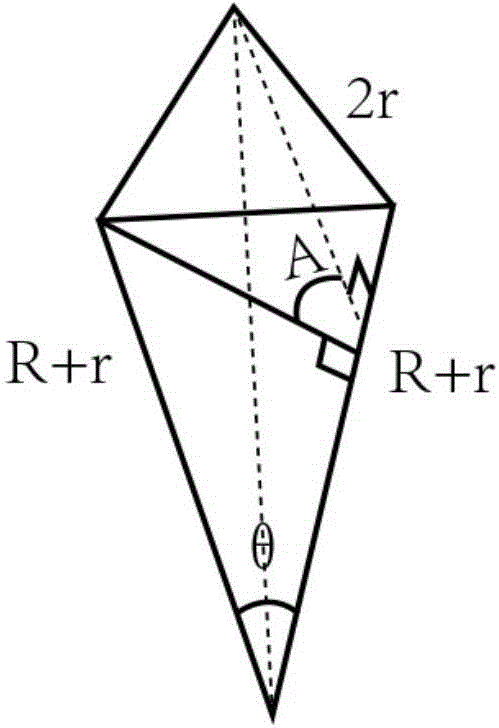

Optimum design method of particle damper

The invention discloses an optimum design method of a particle damper. A spherical particle discrete element model is established according to the discrete element method theory, and a method for producing random particle combination in a boundary in a certain shape in a simulated mode is developed; the contact collision relation between particles or between the particles and a container is simulated through the non-binary search contact inspection algorithm; the concept of effective momentum exchange is introduced, and the method for reasonably and quantitatively analyzing the particle damper performance is developed. According to the optimum design method, the procedures of particle damper analogue simulation, parameter study and performance analysis are developed based on the discrete element method theory, a traditional design method depending on the phenomenology experimental analysis is broken through, and a new way is developed for optimization design of the particle damper.

Owner:TONGJI UNIV

Construction method for two-dimensional discrete element model of mother rock and particle material thereof

ActiveCN105740532AGood simulation performanceImprove performanceSpecial data processing applicationsCAD numerical modellingPorosityElement modeling

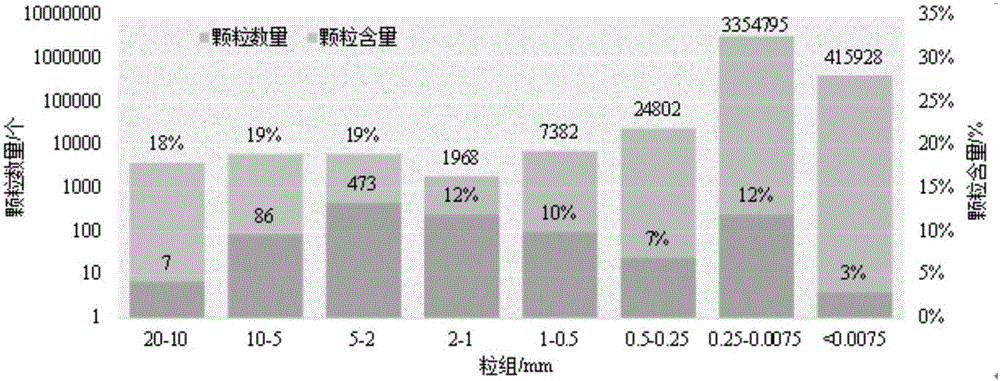

The invention discloses a construction method for a two-dimensional discrete element model of a mother rock and a particle material thereof. The construction method comprises three steps of grading curve correction, mother rock test discrete element modeling and particle material discrete element modeling. The step of grading curve correction comprises the sub-step of redistributing the mass of a smallest particle fraction to the remaining particle fractions according to the quality ratio of particles of particle fractions except the particle fraction of a finest stage in a grading curve to obtain a correction simulation curve in a computer operation simulation range and a particle diameter range of basic particle units. The particle material discrete element modeling comprises the sub-step of: firstly, randomly generating a rock area outline; secondly, forming a rock unit from the basic particle units; thirdly, assigning contact attributes in rocks; finally, assigning the contact attributes between the rocks. In rock aggregation generated according to the construction method, good randomness and diversity are available for the particle number and the form of composed rocks and the actual outline of the rocks; the rock size is generated according to a certain grading condition and satisfies the requirement of certain porosities.

Owner:重庆山渝道科技有限公司

Method for evaluating hot in-place recycling heating effect of asphalt pavement

InactiveCN104790286AReflect the advantages of discretizationAccurate heating effectRoads maintainenceEngineeringRoad surface

The invention relates to a method for accurately evaluating a hot in-place recycling heating effect of an asphalt pavement based on a discrete element method, belongs to the technical field of hot recycling of the asphalt pavement and aims at solving the problem that the evaluation of the hot in-place recycling heating effect of the asphalt pavement is not accurate. The method comprises the following steps: firstly taking a core out of the pavement, defining the structural combination of the pavement and the type of gradation of each layer, collecting an aggregate distribution digital image of each layer, and converting to a CAD (computer aided design) image format after treatment; further introducing discrete element software, and respectively generating irregular aggregate and asphalt mortar according to positions of aggregate block bodies and the asphalt mortar in each structural layer; setting boundary conditions and aggregate and asphalt mortar thermophysical parameters, as well as intra-unit thermal contact resistance and interlayer contact parameters according to a hot in-place recycling heating way and distribution characteristics of a temperature field, and establishing a discrete element model of the pavement structure; and applying a constant heat flow with a certain temperature to the surface of the model, recording the changes in temperature at different times of each layer of the pavement structure, and combining with the temperature field and a distribution cloud picture of the heat flow to analyze the temperature field of the pavement structure and evaluate the hot in-place recycling heating effect.

Owner:NANJING FORESTRY UNIV

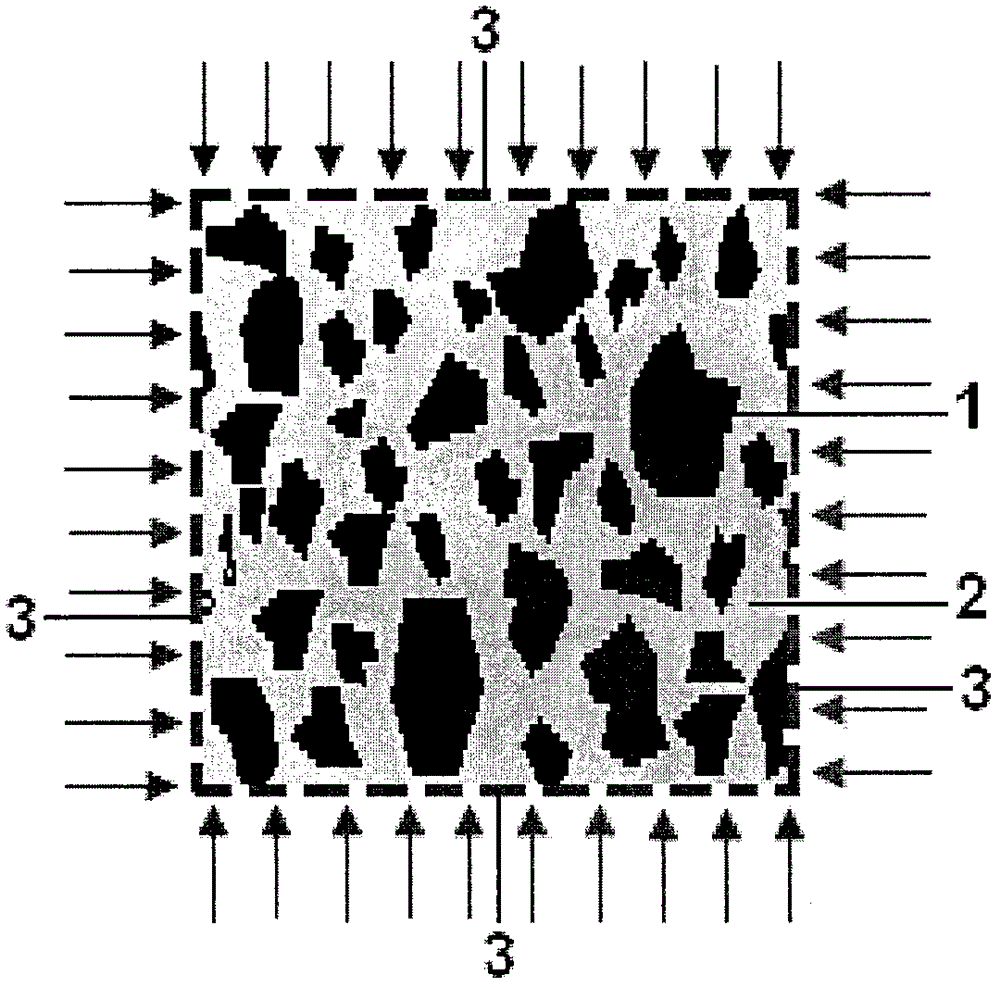

Temperature field analysis method of bituminous mixture test piece on the basis of discrete element simulation

InactiveCN104899351AAccurately establishedEmbody superioritySpecial data processing applicationsField analysisAggregate distribution

The invention discloses a temperature field analysis method of a bituminous mixture test piece on the basis of discrete element simulation, belongs to the technical field of bituminous mixture, and solves the problem that a finite element method can not accurately analyze the internal temperature field of the bituminous mixture test piece in a high-temperature environment. The temperature field analysis method comprises the following steps: firstly, forming the bituminous mixture test piece, collecting a digital image of irregular aggregate distribution, and converting the digital image into a digital test piece of a two-dimensional CAD (Computer-Aided Design) image format after the digital image is subjected to image processing; then, importing discrete element software, independently generating irregular aggregate and bituminous mortar according to the positions of aggregate blocks and the bituminous mortar, and constructing a two-dimensional test piece discrete element model; simulating a situation that the test piece is heated in the high-temperature environment, setting a boundary condition of the test piece model, the thermophysical property parameters of the aggregate and the bituminous mortar and the internal contact thermal resistance of a unit; and applying certain constant-high-temperature and room-temperature heat flow around the test piece model, recording the temperature change situations of each point in the test piece at different moments, drawing a comparison graph, and combining with a temperature field and a heat flow distribution cloud chart generated by the software to analyze the temperature field of the bituminous mixture test piece.

Owner:NANJING FORESTRY UNIV

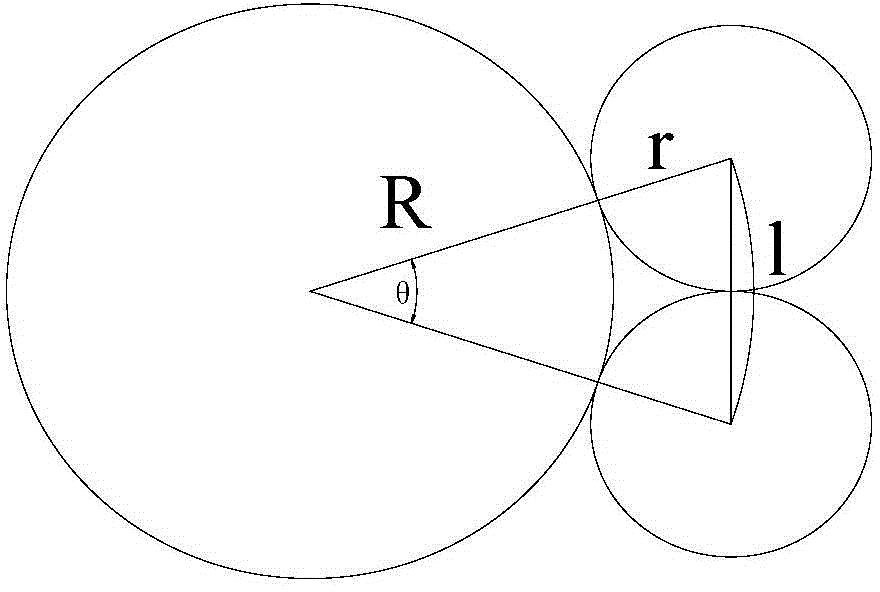

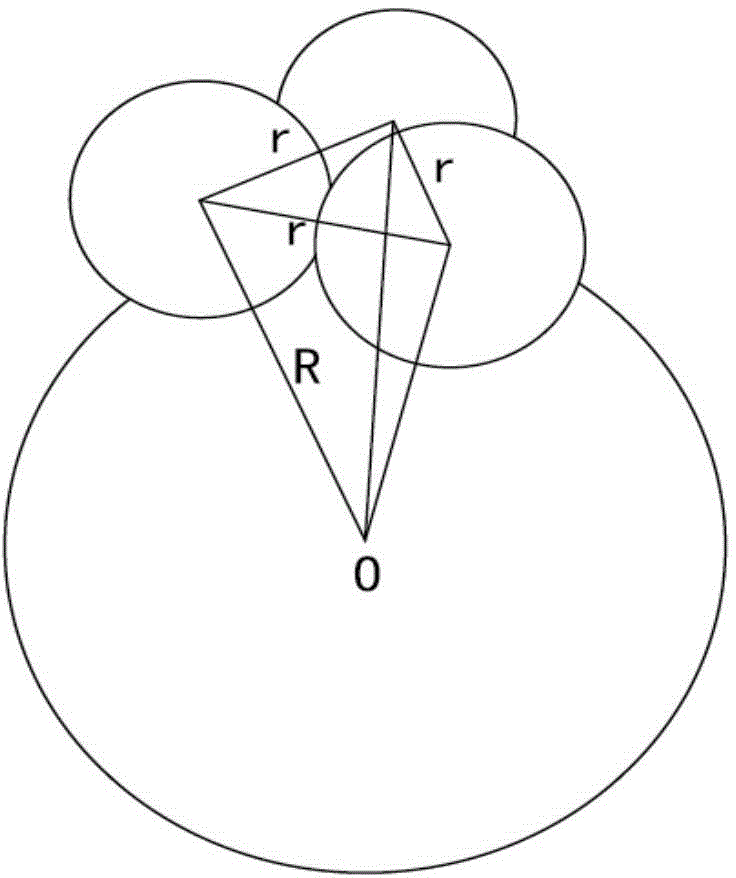

Discrete element method based method for improving particle discrete contact detection efficiency

InactiveCN103984829AReduce the number of operationsImprove efficiencySpecial data processing applicationsFinite element methodGeometric modeling

The invention discloses a discrete element method based method for improving the particle discrete contact detection efficiency and belongs to the technical field of particle discrete element model construction. The discrete element method based method for improving the particle discrete contact detection efficiency is achieved by solving the number of contactable particles of one particle at a moment. Used mathematic models in the discrete element method based method are simple geometric models, the relationship between the number of contactable particles and the semi-diameter of the central particle and contact particles is obtained due to calculation of the geometric models, calculation times are reduced due to the fact that relational expressions are added to a program, then the program for simulating the calculation is out of the loop, the calculation times are reduced, and the efficiency is improved. Compared with the existing models, the calculation amount in the discrete element method based method is effectively reduced and simulation calculation of numerical values in large scale can be performed through common devices.

Owner:李笑宇 +1

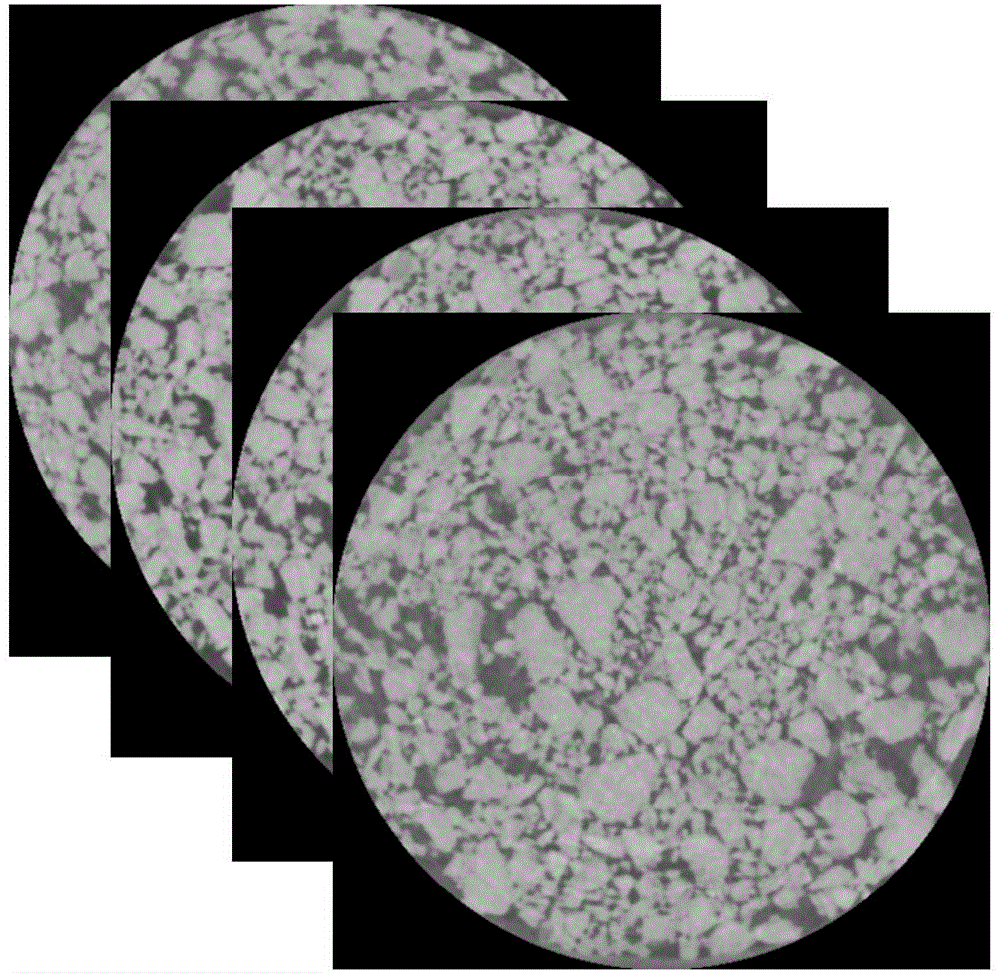

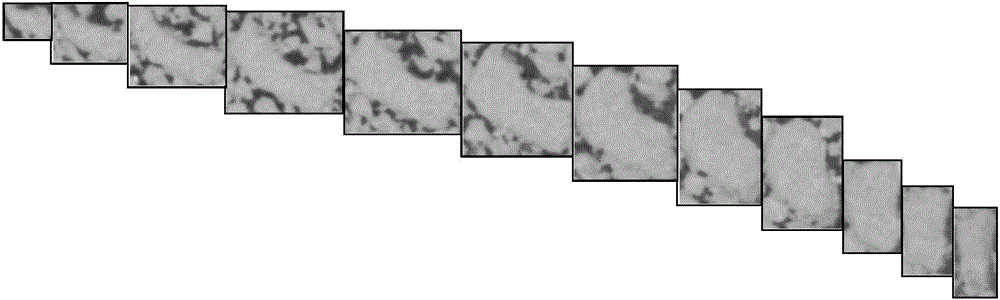

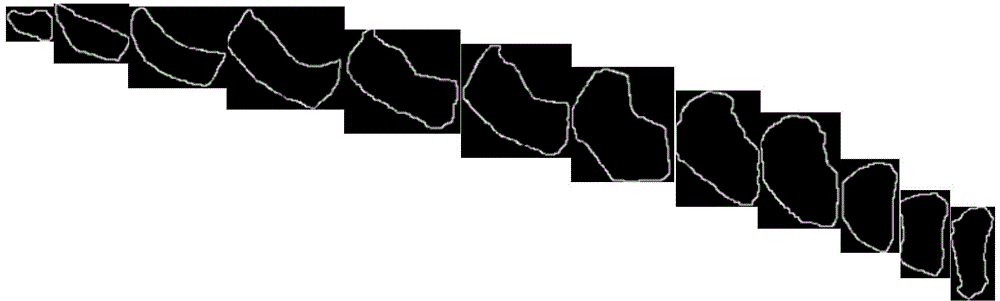

Building method of discrete element module of true aggregate particles based on X-ray CT image

The invention discloses a building method of a discrete element module of true aggregate particles based on an X-ray CT image which is provided to the aggregate particles in a bituminous mixture test piece of numerical analysis of a bituminous mixture, so as to realize that the discrete element module of true aggregate particles with highly fitted geometrical shape of a true aggregation and the minimal quantity of discrete elements can be automatically built. According to the building method provided by the invention, based on the discrete element analysis of the bituminous mixture test piece in a microstructure, the automatic switching between the X-ray CT section image of the bituminous mixture test piece and the discrete element module of true aggregate particles with precisely fitted geometrical shape of the true aggregation and the minimal quantity of discrete elements can be completed to assist the building of the discrete element module of the bituminous mixture test piece.

Owner:HEFEI UNIV OF TECH

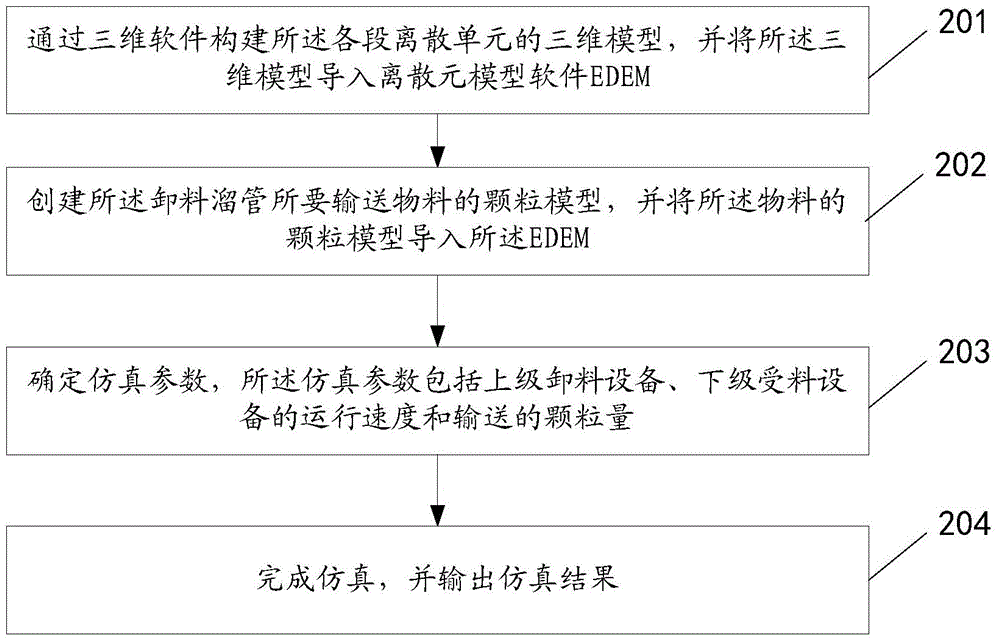

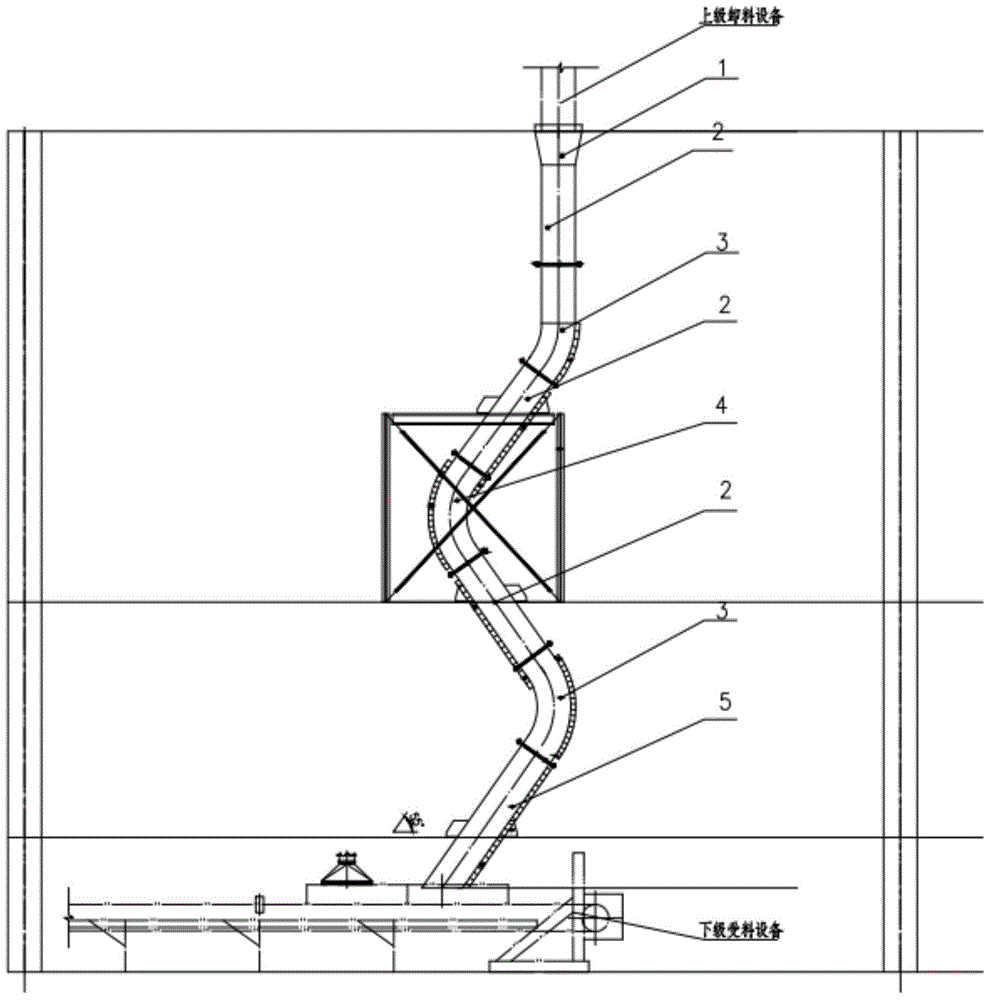

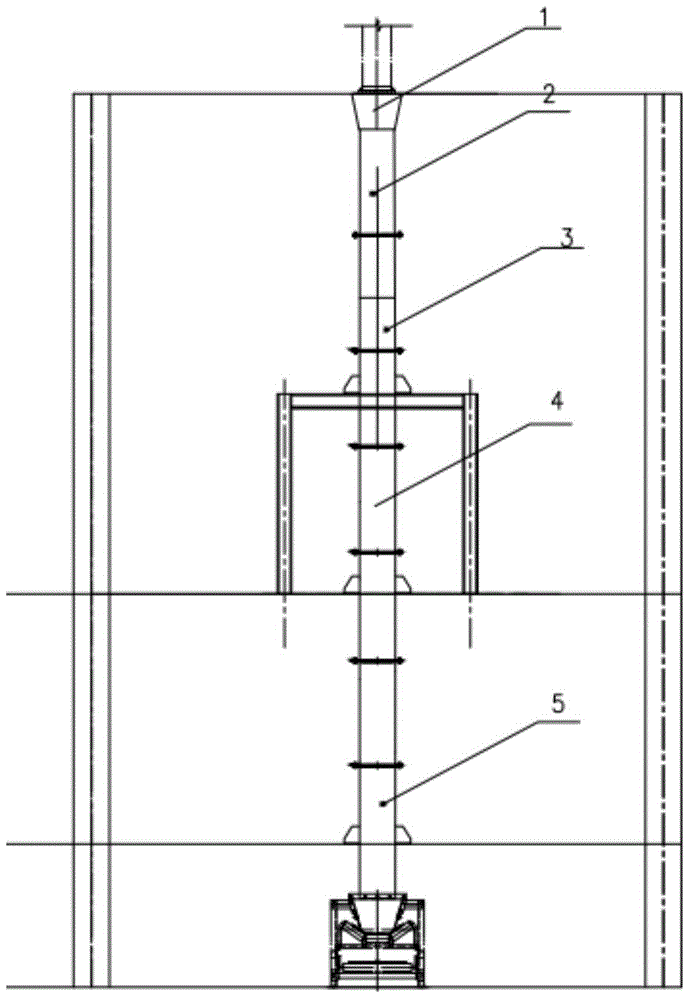

Space transhipment unloading elephant trunk design method based on discrete element method

The invention is suitable for the technical field of unloading elephant trunks, and provides a space transhipment unloading elephant trunk design method based on a discrete element method, wherein a space transhipment unloading elephant trunk is composed of discrete elements of each segment. The design method comprises the following steps of: building a three-dimensional model of the discrete element of each segment through a three-dimensional software, and importing the three-dimensional model in a discrete element model software EDEM; creating a particle model of the material to be conveyed by the unloading elephant trunk, and importing the particle model of the material in the EDEM; determining simulation parameters, wherein the simulation parameters include operating speed and particle conveying quantity of a superior unloading device and a lower receiving device, and also include own material attributes of the particle and the discrete element, and contact attribute between the two; finishing simulation, and outputting simulation result. According to the invention, the discrete element method is introduced in the design process of the space transhipment unloading elephant trunk, movement locus of material flow in the elephant trunk can be fitted accurately, and variation of stress on each part of the elephant trunk can be calculated.

Owner:WISDRI ENG & RES INC LTD

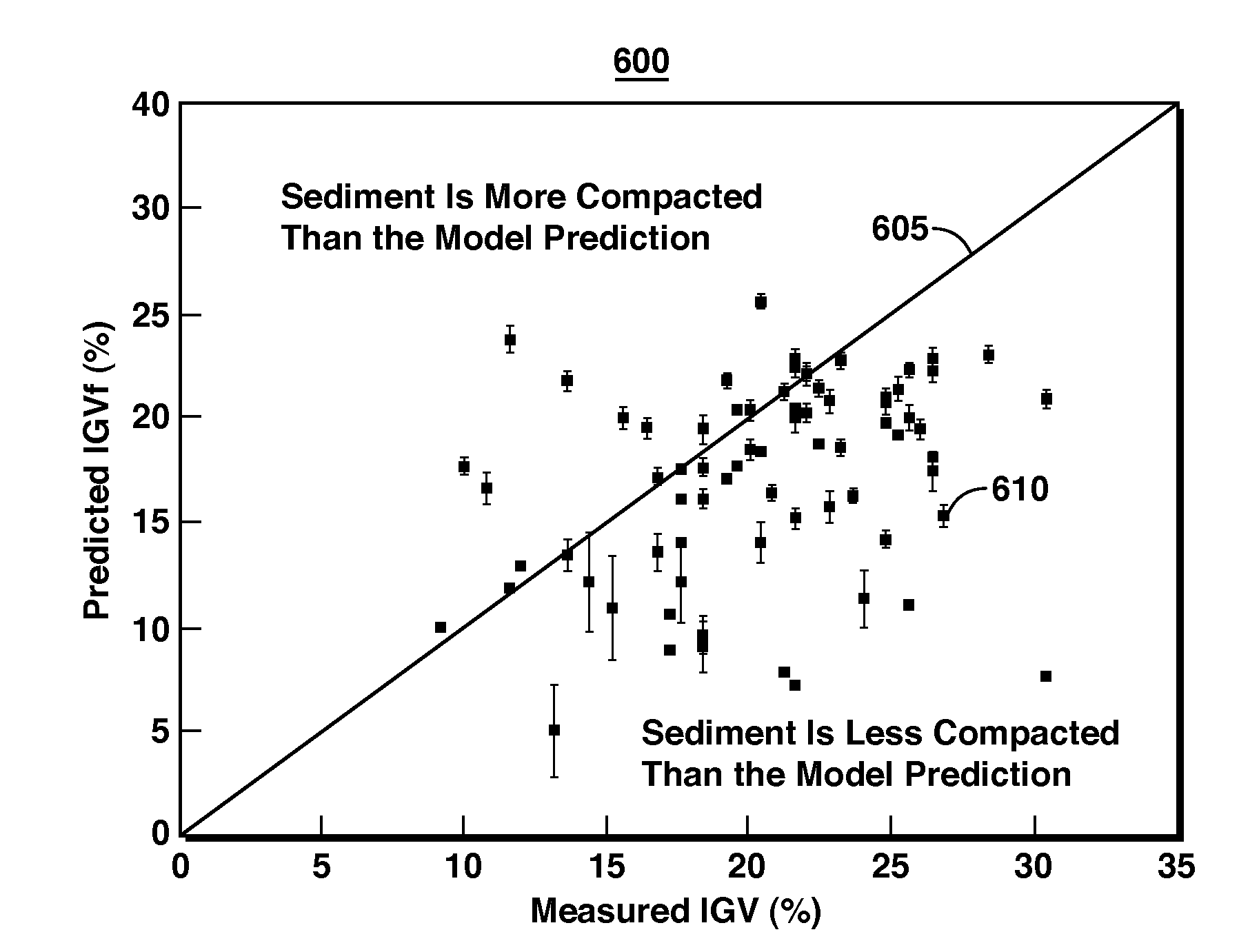

Predicting A Compaction Point Of A Clastic Sediment Based on Grain Packing

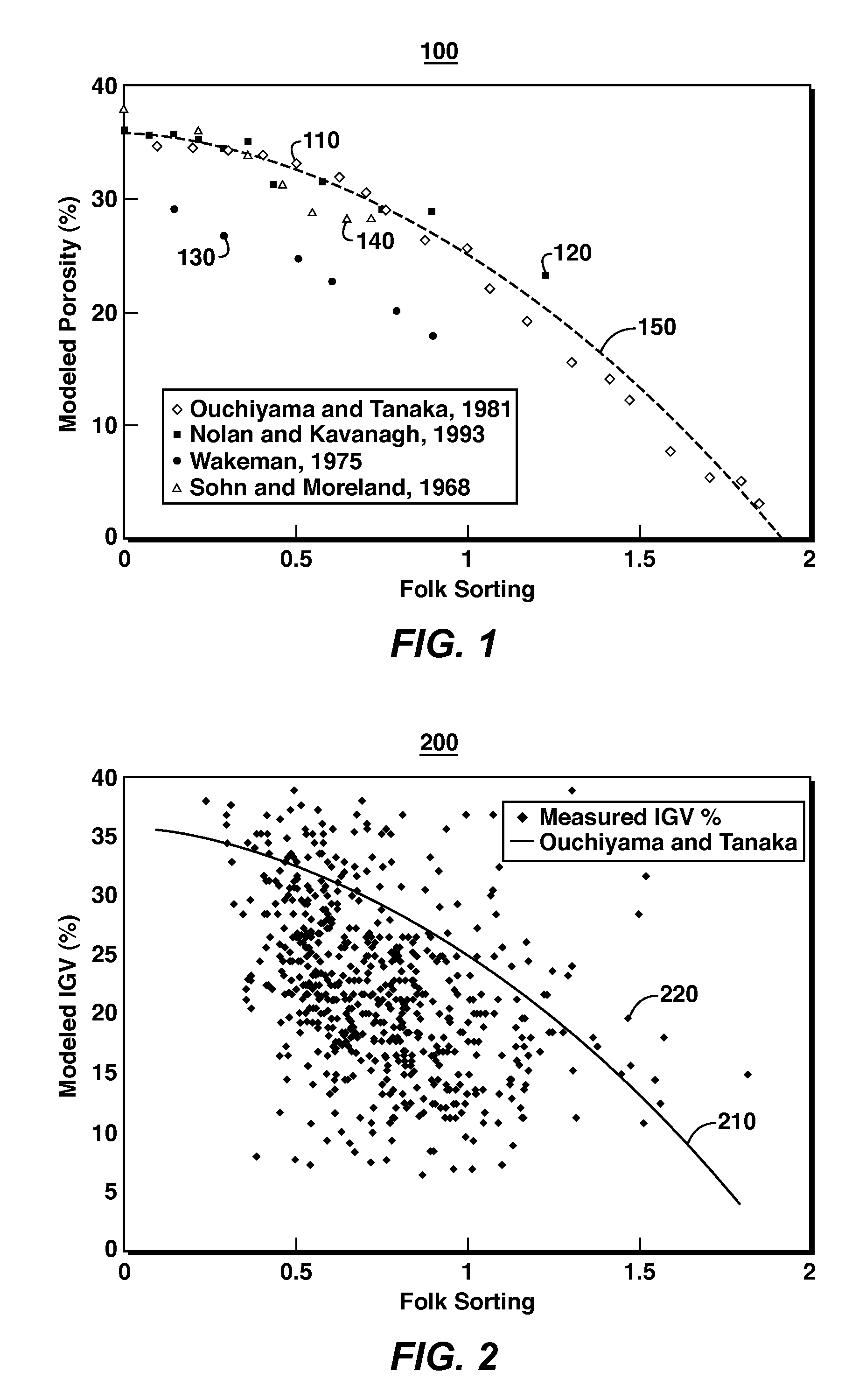

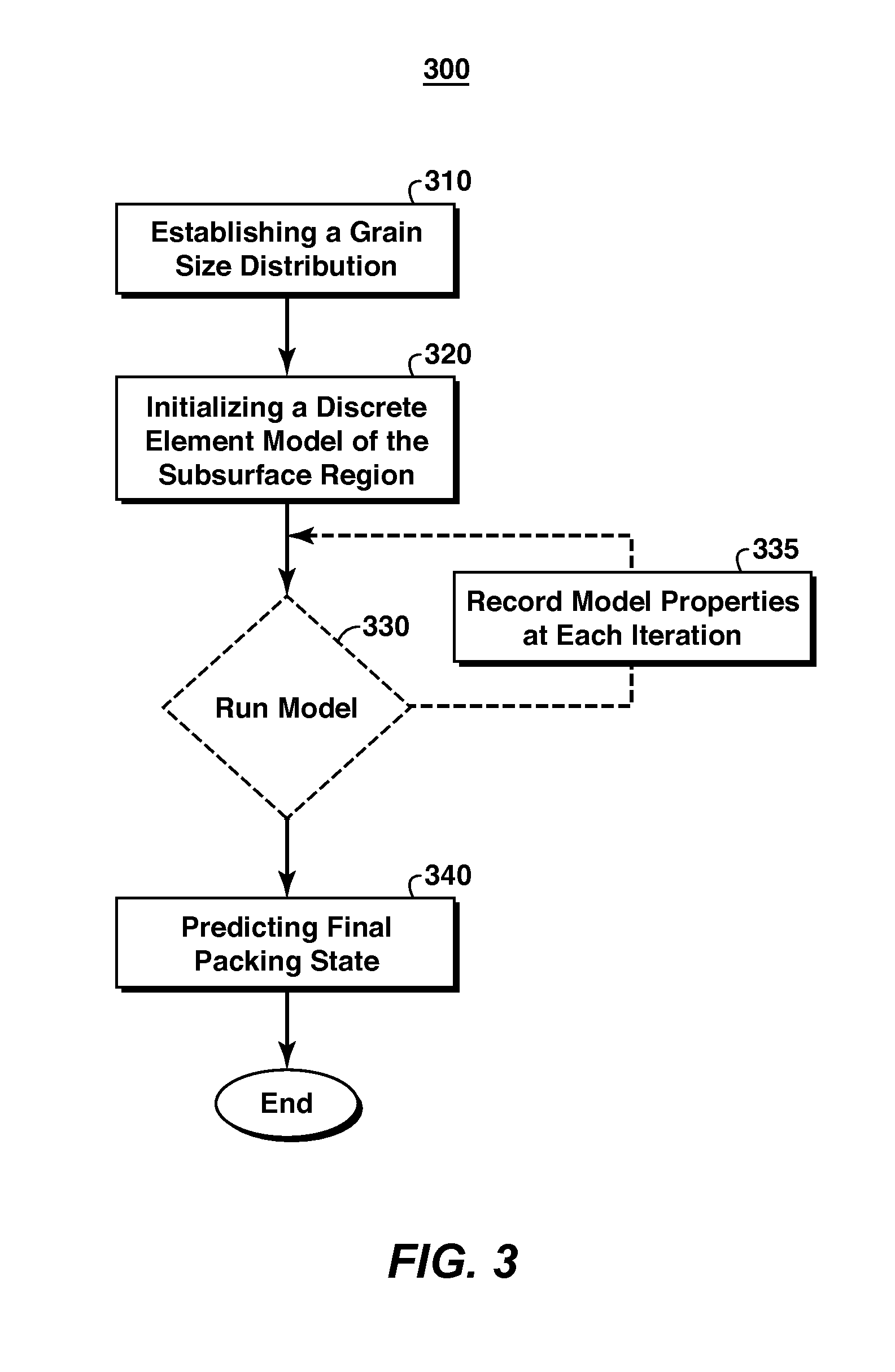

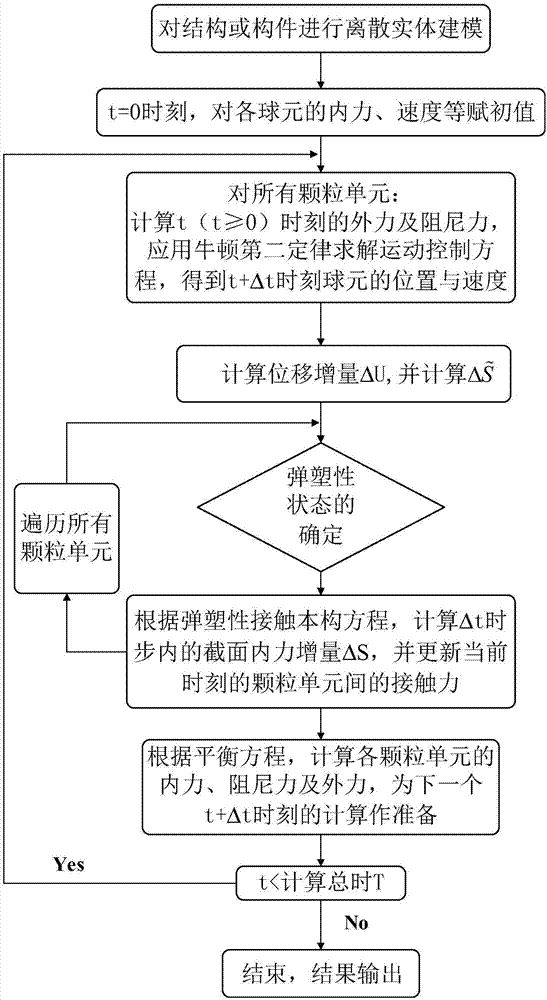

InactiveUS20110270594A1Reduced stability conditionReduced stabilityComputation using non-denominational number representationGeological measurementsPorosityGrain distribution

An end compaction point of a clastic sediment within a subsurface region is predicted by establishing a first grain size distribution, wherein the first grain size distribution is a measured grain size distribution, or a predicted grain size distribution. A discrete element model of the subsurface region is initialized, wherein the model comprises a model volume including a base, periodic horizontal boundaries, and soft objects representative of particles of the first grain distribution at a predetermined porosity. A final packing state of the clastic sediment is predicted by iteratively running the model, wherein the final packing state of the clastic sediment is based on packing of the soft objects with a pack and based on the first grain size distribution, wherein soft objects within the model are capable of overlapping with adjacent soft objects within the model.

Owner:RUDNICKI MARK A

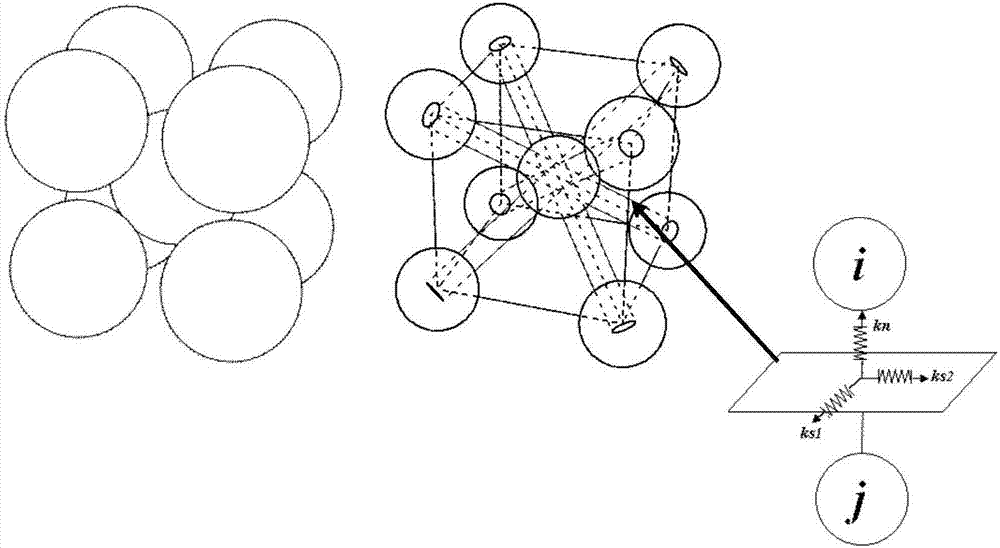

Method for solving nonlinear mechanics problem of continuous medium member by applying three-dimensional discrete entity

ActiveCN107391788ACalculation process is clearThe solution process does not changeGeometric CADDesign optimisation/simulationNonlinear mechanicsElastic plastic

The invention discloses a method for solving a nonlinear mechanics problem of a continuous medium member by applying a three-dimensional discrete entity. For the limitation of a conventional discrete unit method for calculating a continuous medium problem, discrete element models of two three-dimensional discrete entities are built by taking energy equivalence as a principle based on a mechanics theory of a continuous medium; by adding a contact spring between particle units, the Poisson ratio effect of a material is reflected; and an analytic relationship between a mesoscopic model parameter (spring stiffness) and macroscopic elastic constants (an elastic modulus and a Poisson ratio) is derived, so that a great breakthrough is achieved in simulation of the continuous medium with a large Poisson ratio in PFC software. In addition, a plastic part is added in a contact constitutive equation between the particle units. According to the method, the elastic-plastic problem of the continuous medium can be effectively subjected to simulative calculation analysis by adopting a discrete entity unit method; and the method is suitable for nonlinear mechanics problems of large deformation, damage fracture, collapse destruction and the like of a structure or the member.

Owner:SOUTHEAST UNIV

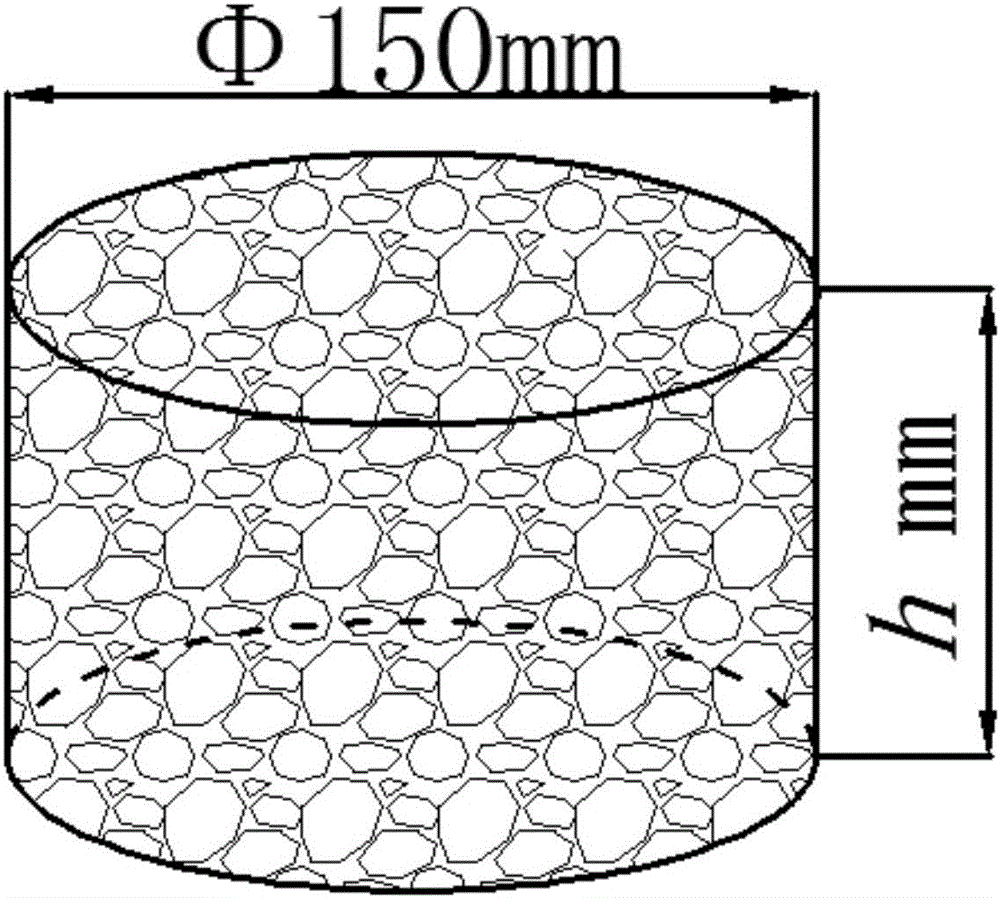

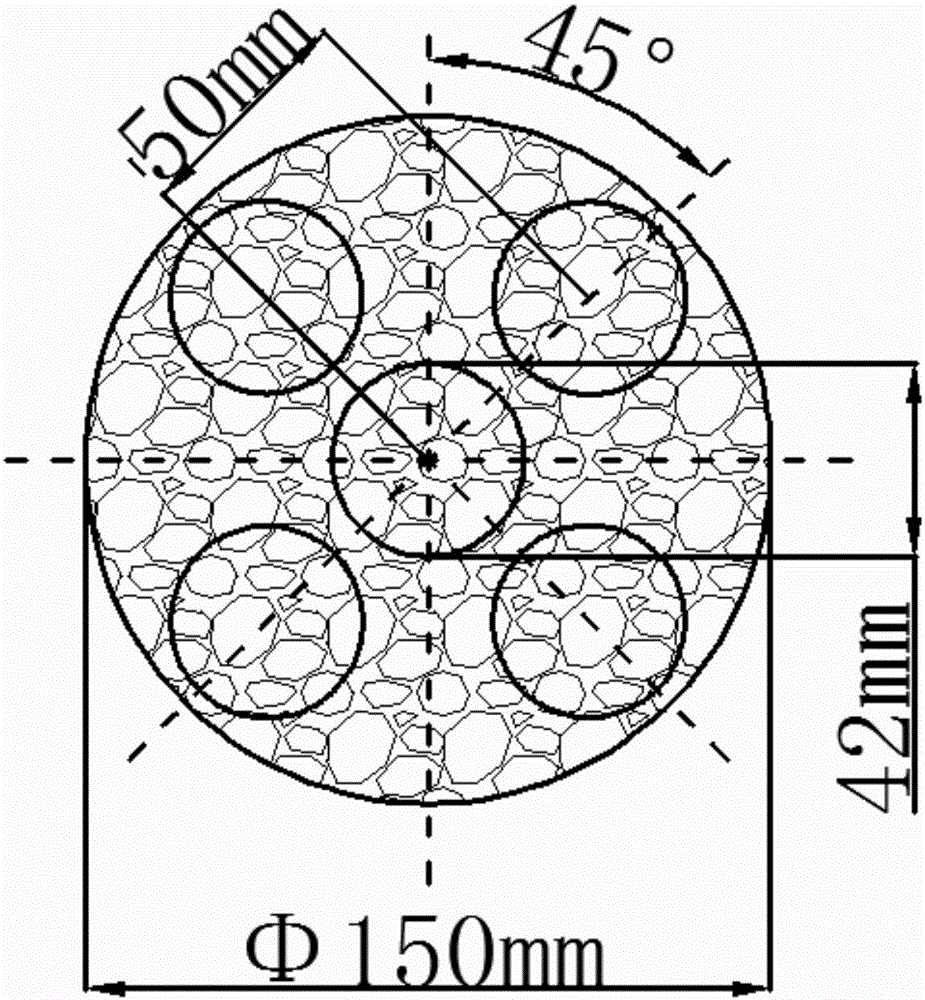

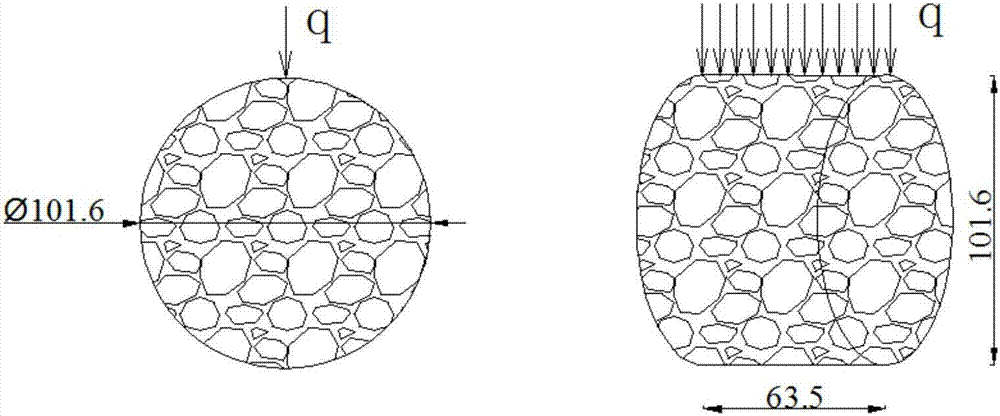

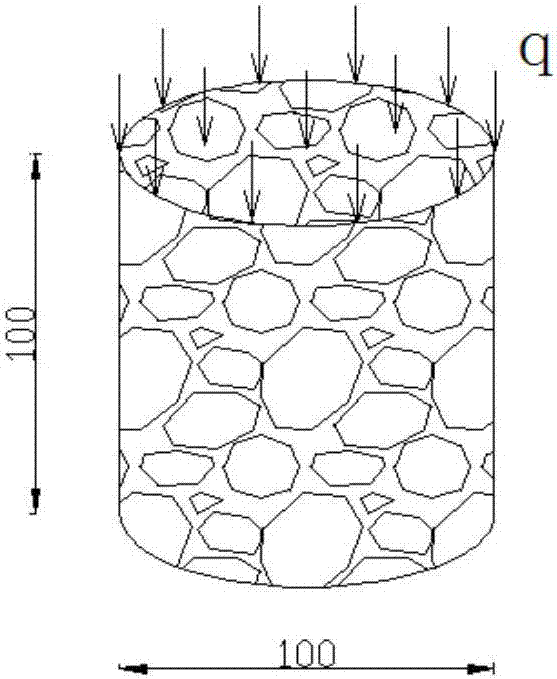

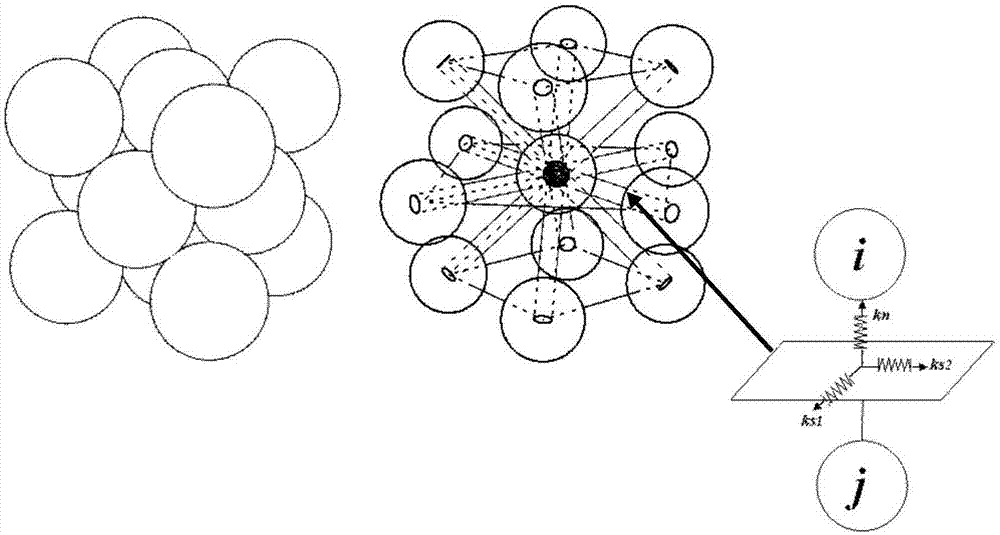

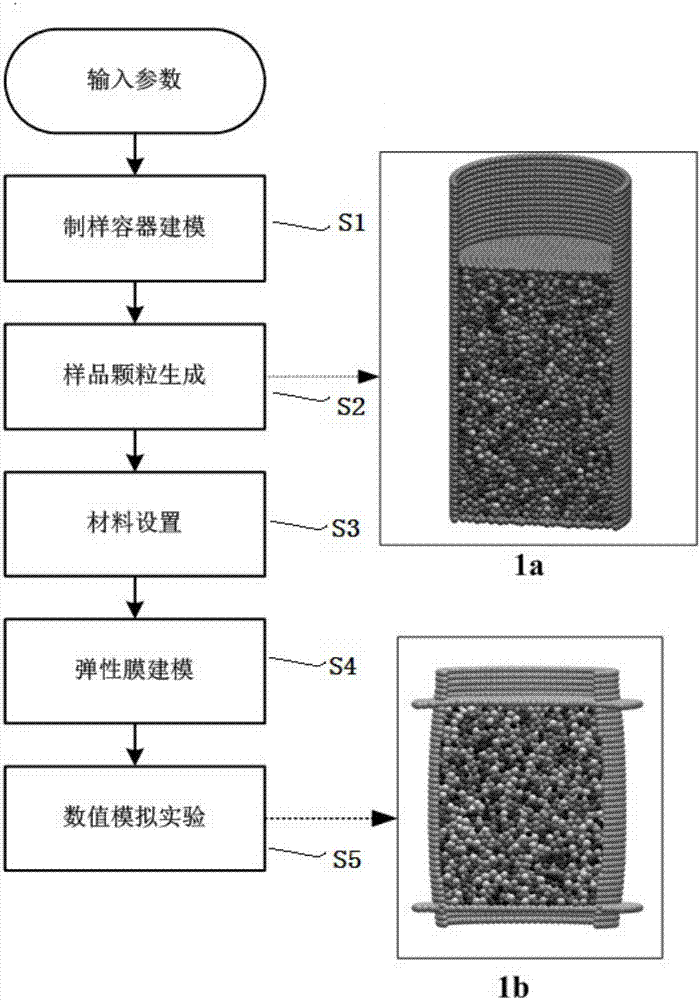

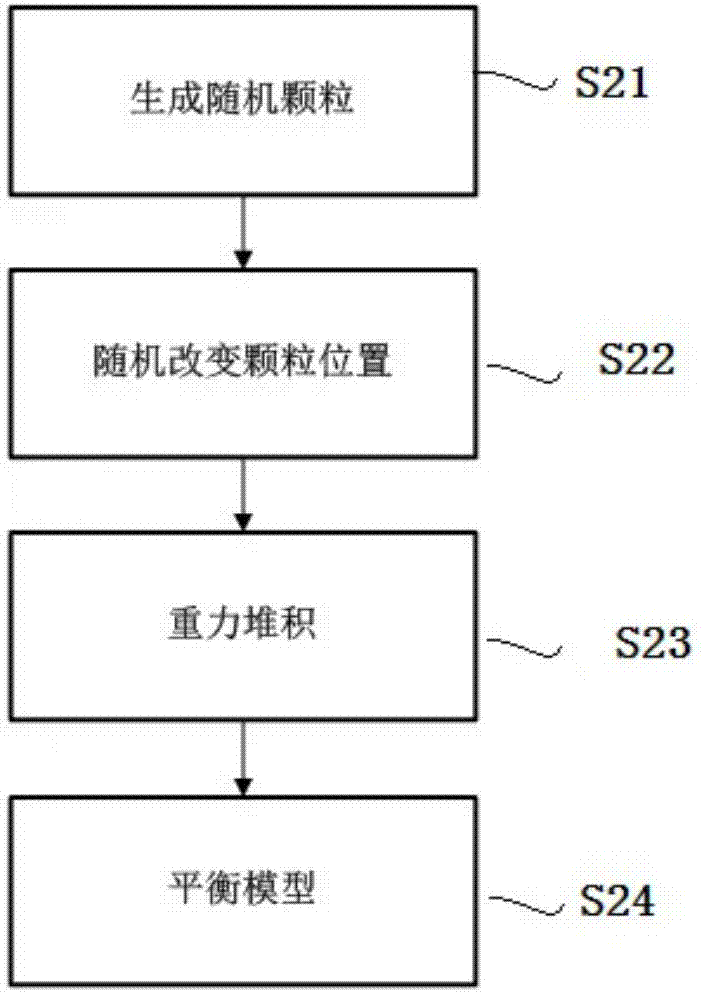

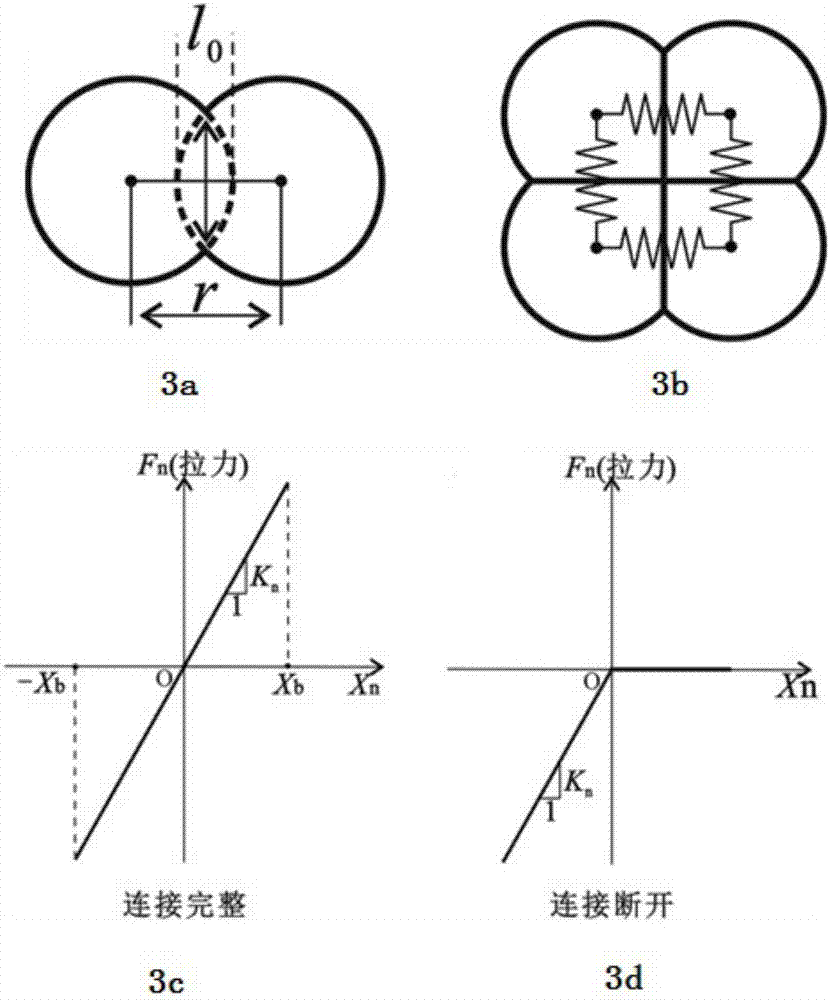

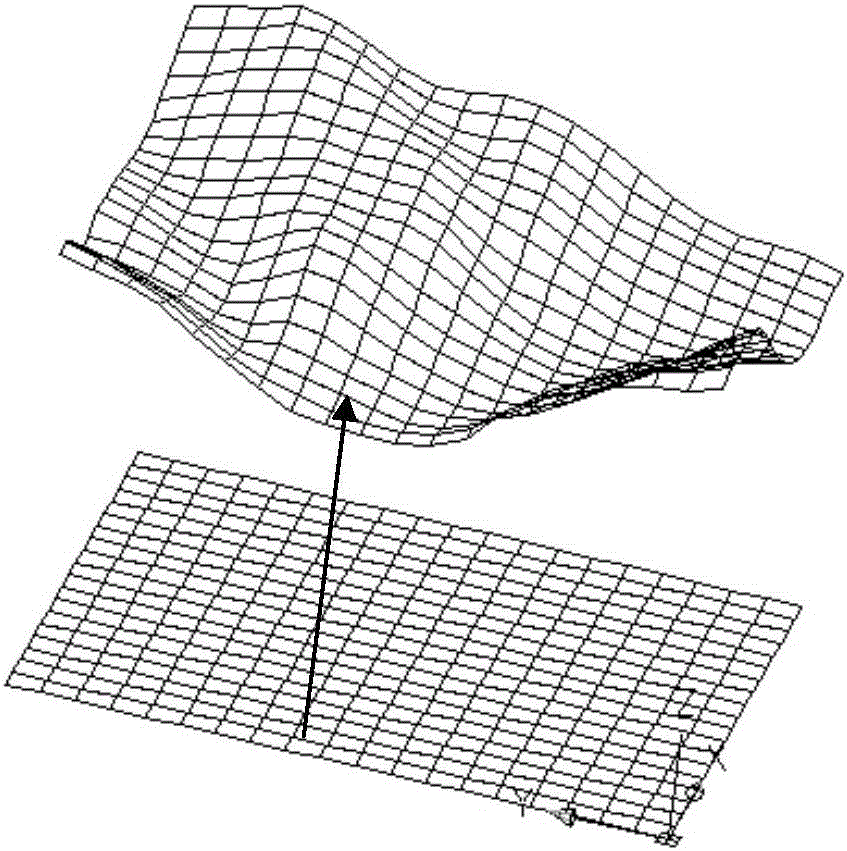

Discrete element modeling and numerical simulation method for rock and earth mass triaxial test taking film effect

InactiveCN107330227AMeet the test conditionsFlat surfaceDesign optimisation/simulationSpecial data processing applicationsTriaxial shear testElement modeling

The invention discloses a discrete element modeling method for a rock and earth mass triaxial test taking film effect. The method includes following steps: S1, modeling a sample preparing container; S2, modeling a rock-earth mass sample; S3, endowing the generated rock-earth mass sample with material attribute of given sample units, balancing stress among the sample units to complete making of the rock-earth mass sample; S4, building an elastic film, replacing a rigid barrel of a sample preparing container model with the elastic film, setting corresponding material attribute for the elastic film to complete building of a triaxial test discrete element model. Further, the invention further discloses a numerical simulation method based on the discrete element model. According to given pressurizing conditions, stress loading is adopted to axially pressurize the rock-earth mass sample, and lateral confining pressure is applied on the rock-earth mass sample through water pressure. A film unit is adopted to simulate a latex film in the triaxial test, and flexible boundary of the latex film better conforms to actual circumstance of indoor triaxial test numerical simulation.

Owner:NANJING UNIV

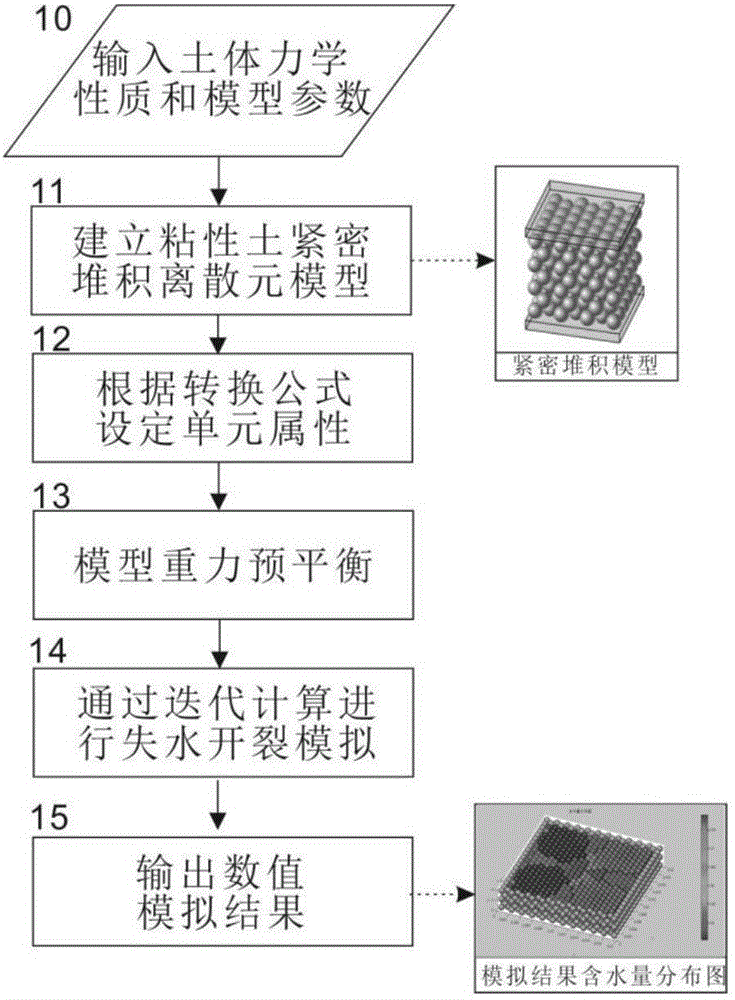

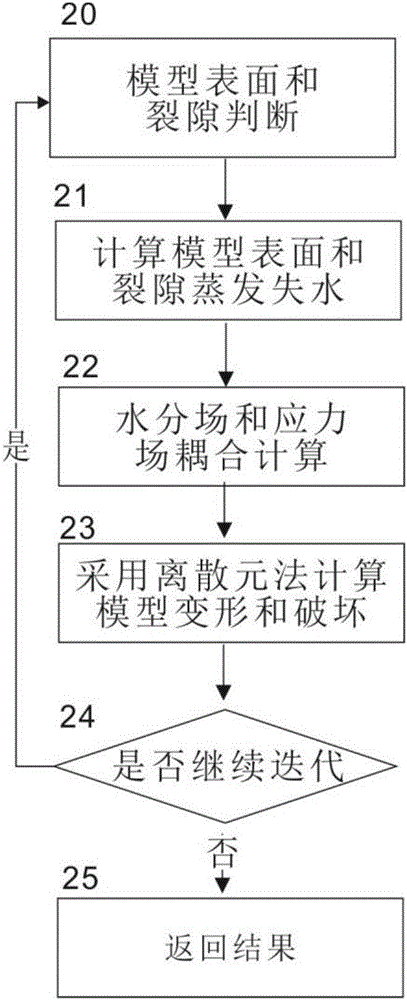

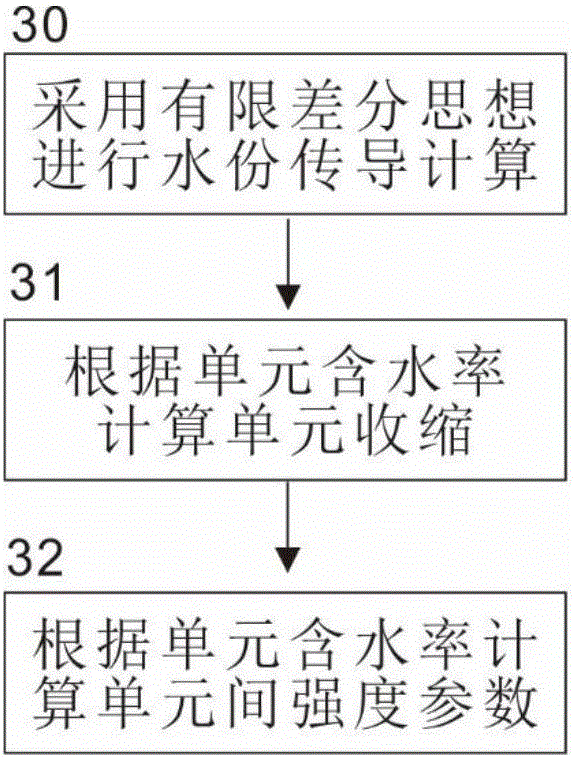

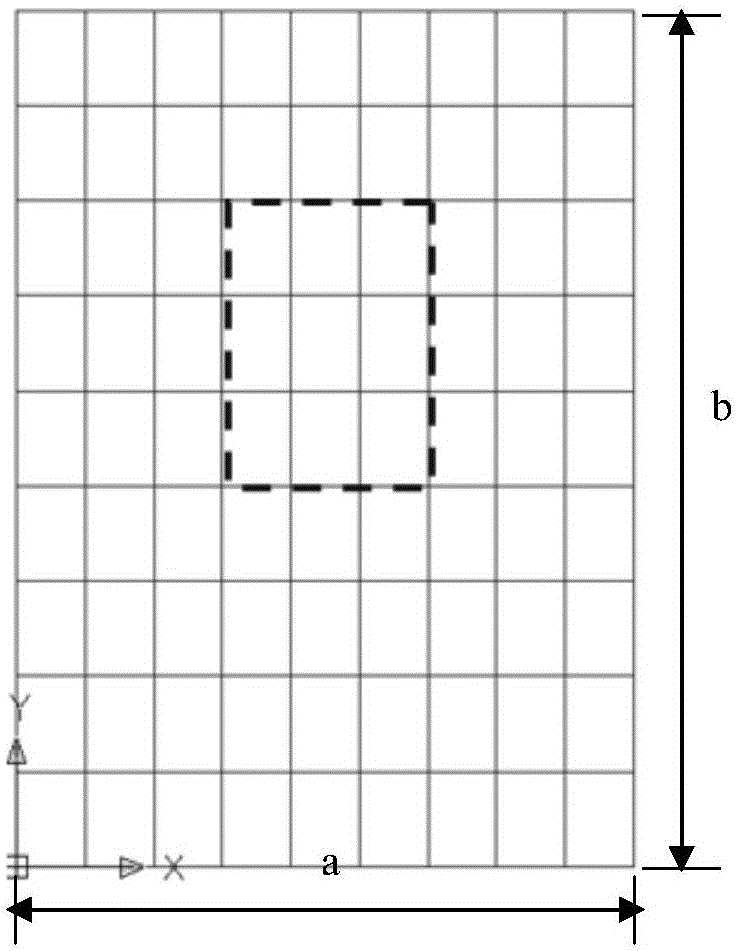

Rapid simulation modeling method for multi-field coupled discrete elements of soil water loss and cracking

ActiveCN106446402AConforms to the law of dehydration cracking testDesign optimisation/simulationSpecial data processing applicationsSoil scienceMulti field

The invention provides a rapid simulation modeling method for multi-field coupled discrete elements of soil water loss and cracking which is a multi-field coupled discrete element modeling and simulation method used in cohesive soil water loss and cracking. The method comprises following steps: 1) constructing a three-dimensional close packing discrete element model, giving the water content attribute to the element, and using the finite difference theory to simulate a water field; 2) building coupling of the water field and a stress field taking account of influences on mechanical properties such as tensile strength of discrete elements from water field; 3) assuming that the surface water content of the soil three-dimensional close packing discrete element model evaporates at a certain speed, the relationship between the water content and the three-dimensional discrete element shrinkage of the soil is established based on the experimental data, and the deformation and fracture of the three-dimensional discrete element of the soil is calculated in the discrete element method to realize rapid simulation and modeling of multi-field coupled discrete element for evaporation water loss, shrinkage and cracking deformation of clay soil. Multi-filed coupled simulation of evaporation water loss, shrinkage and cracking deformation of clay soil is achieved. The invention provides a novel method for simulating soil deformation and fracture under multi-field effect.

Owner:南京南力科技有限公司

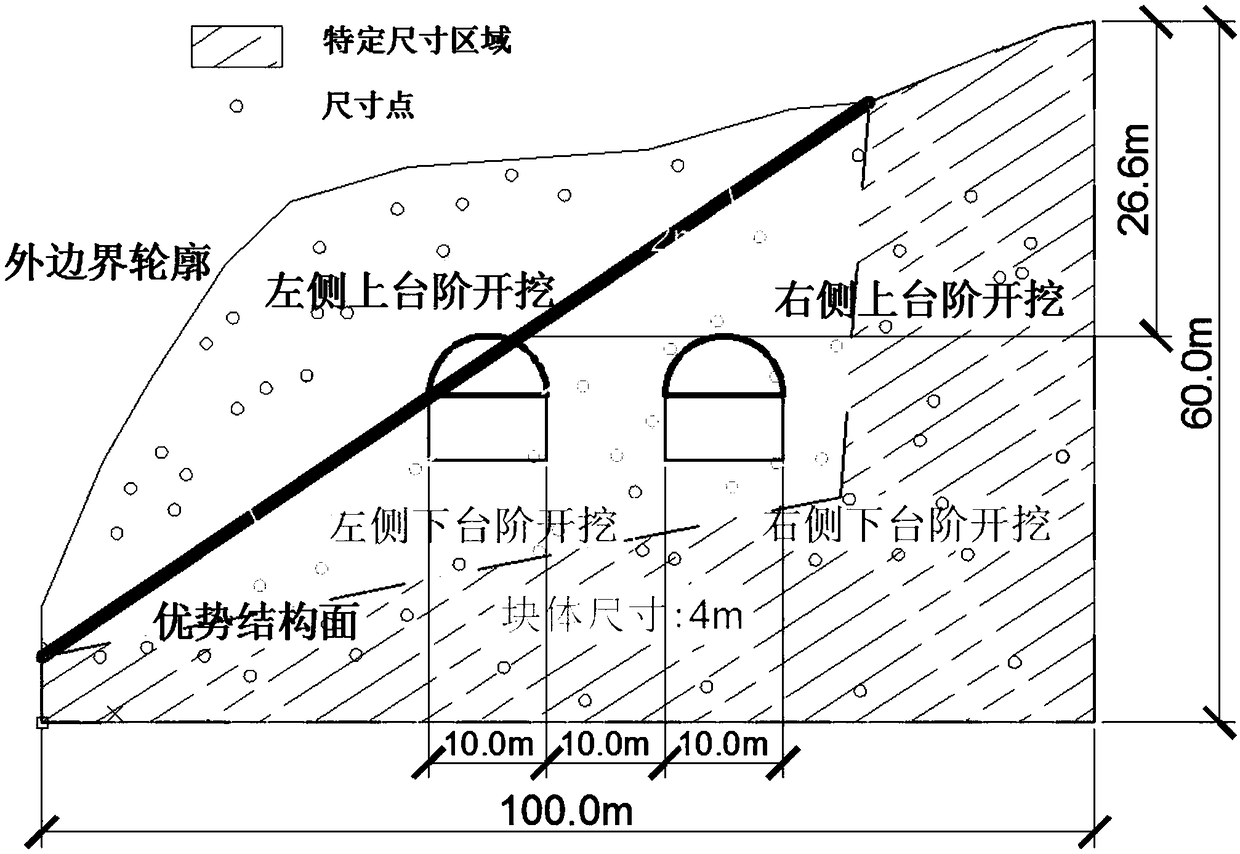

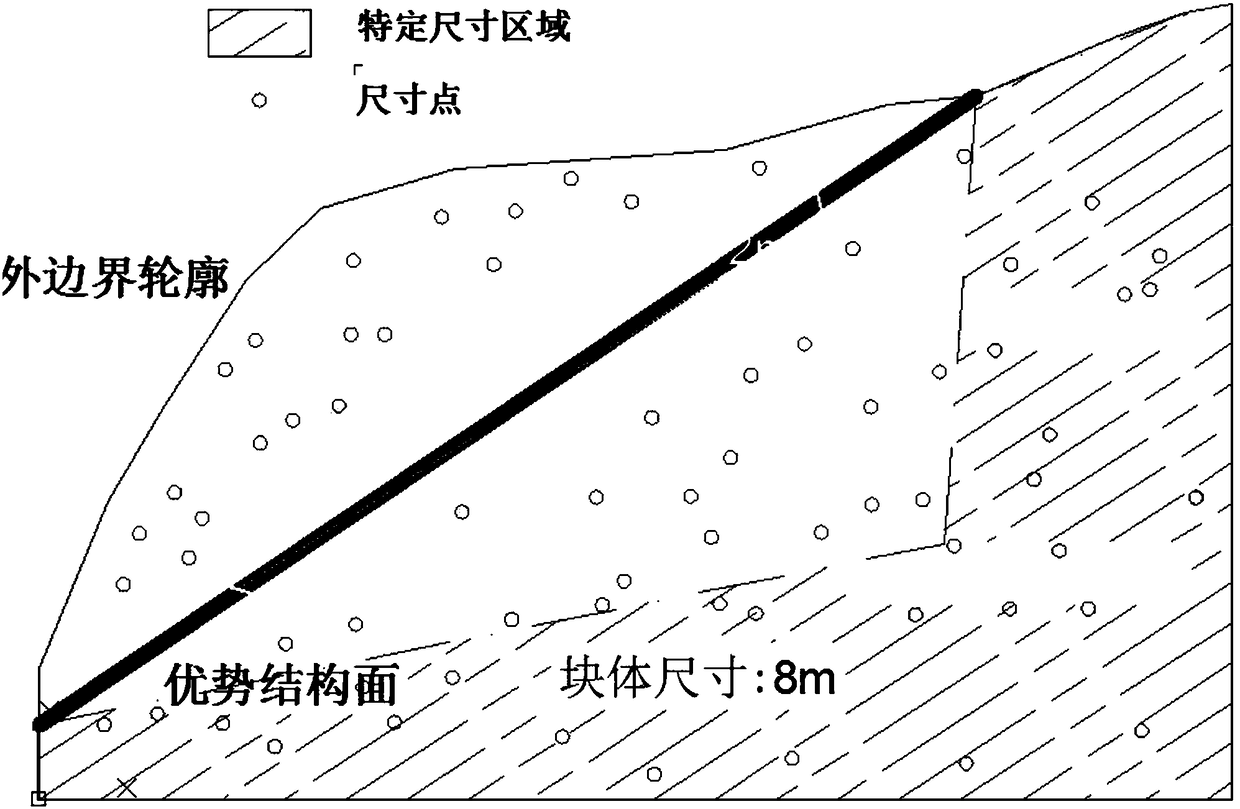

Box covering method-based slope assembly type discrete element model generating method

ActiveCN106373193AGuaranteed accuracyGuaranteed Build Accuracy3D modellingTerrainStructural engineering

The present invention discloses a box covering method-based slope assembly type discrete element model generating method. According to the method, an assembly range is designed into a regular area and is adopted as an assembly component; small cuboid units are generated based on an outer slope range according to a certain size; blocks are merged through using a box covering method, so that the number of the total blocks of a model can be minimum; and therefore, the established model can not only maintain the accuracy of surface terrain, but also can minimize the internal blocks, the construction accuracy of follow-up internal structures can be ensured, and the construction of the discrete element model can be greatly facilitated; and when the block discrete element model is constructed, a topological method is utilized to cut a tunnel, since few blocks are involved in topological analysis, virtual joints tend to generate, and therefore, the success rate of the shape cutting of the tunnel is very high. The modeling method is applicable not only to the construction of a geotechnical model, but also applicable to the construction of models in other fields such as the geological field. The method has the advantages of wide application range and high controllability. The model constructed by the method is more accurate.

Owner:HOHAI UNIV

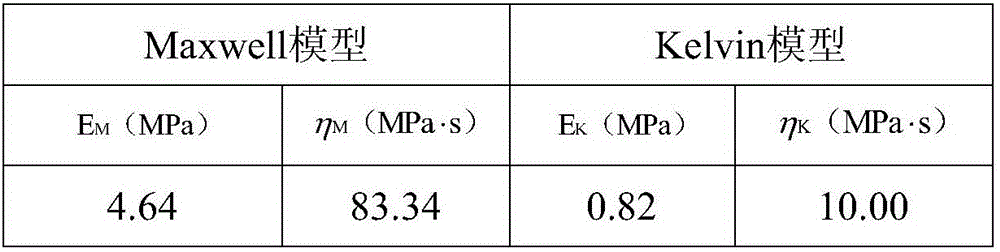

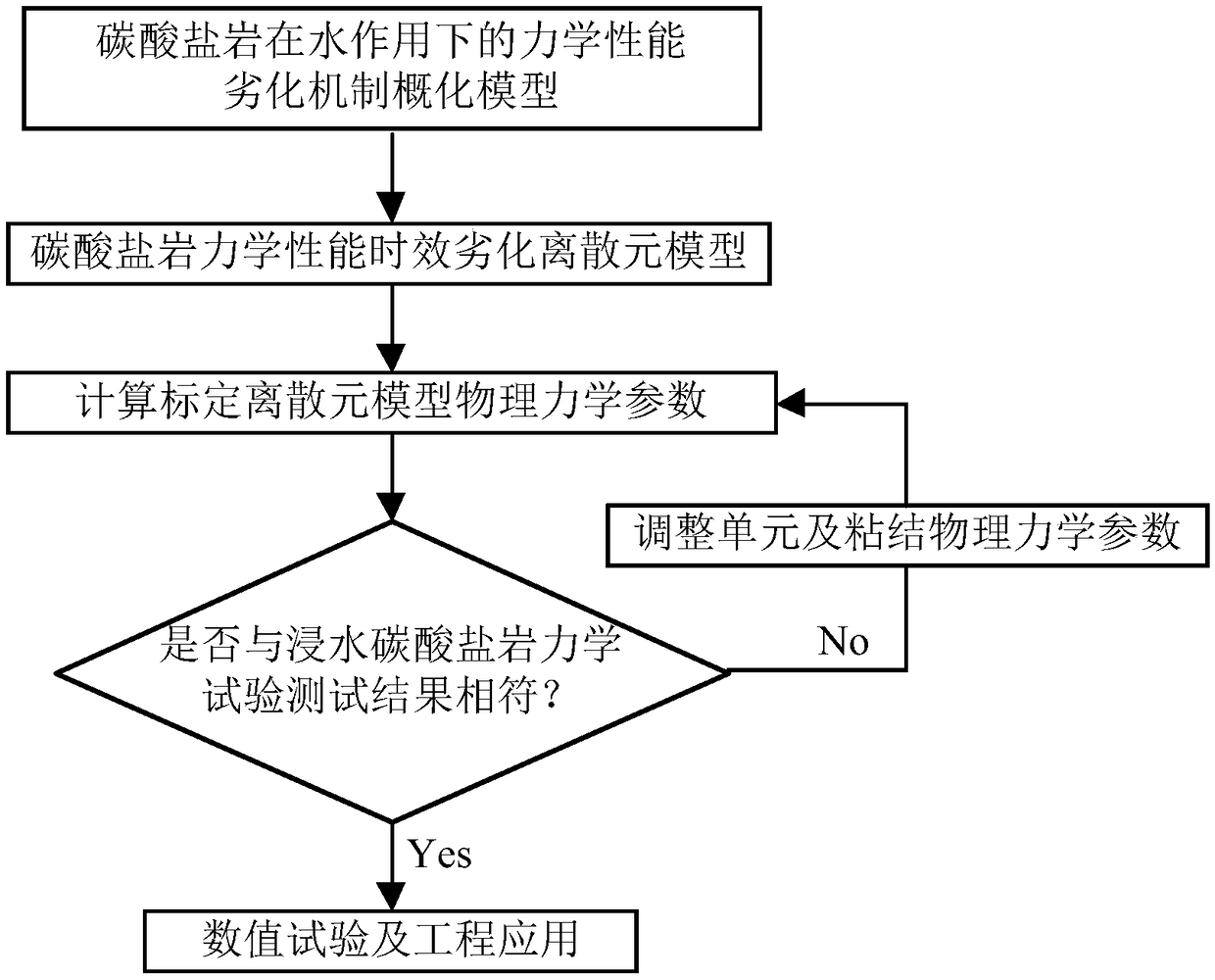

A numerical simulation method for aging degradation of mechanical properties of carbonate rock under water action

ActiveCN109344482ALow costStrong expandabilityDesign optimisation/simulationSpecial data processing applicationsDiscrete element simulationGeomorphology

the invention discloses a numerical simulation method for aging degradation of mechanical properties of carbonate rock under water action which includes such step as establishing a generalized model of mechanical property deterioration mechanism of carbonate rock under the action of water, setting up the generalized model of mechanical property deterioration mechanism of carbonate rock under the action of water, setting up the generalized model of mechanical property degradation mechanism of carbonate rock under the action of water. Step 22, establishing a discrete element model of aging deterioration of mechanical properties of carbonate rock under different immersion conditions according to the mechanism generalization model obtained in the step 1, and obtaining a quantitative correlation of mechanical properties with time of bonding between blocks of polygonal blocks under different immersion conditions; step 3, calibrating that mechanical parameters of the discrete element model; Carbonate rock mechanics tests under different immersion conditions and immersion time were carried out to calibrate the mechanical parameters of the discrete element model in step 2. Step 4, simulating the mechanical properties of carbonate rock under different immersion conditions by using the calibrated parameters of the discrete element model. The invention truly reflects the carbonate rock-water water interaction principle, a two-stage deterioration model and its discrete element simulation method are proposed.

Owner:HEBEI UNIV OF TECH

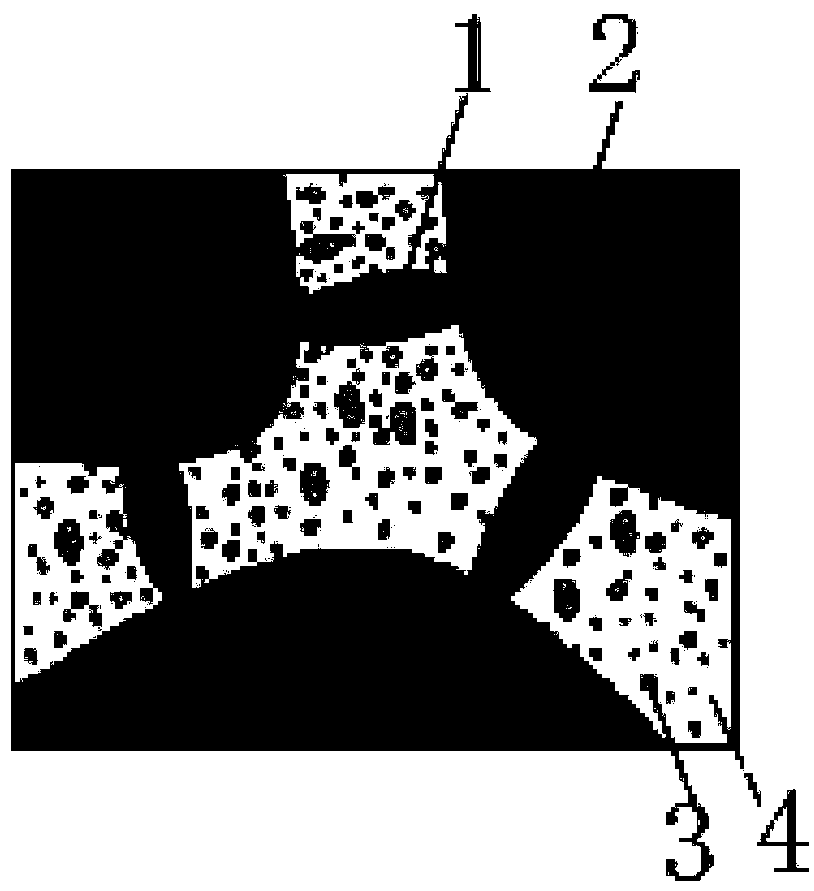

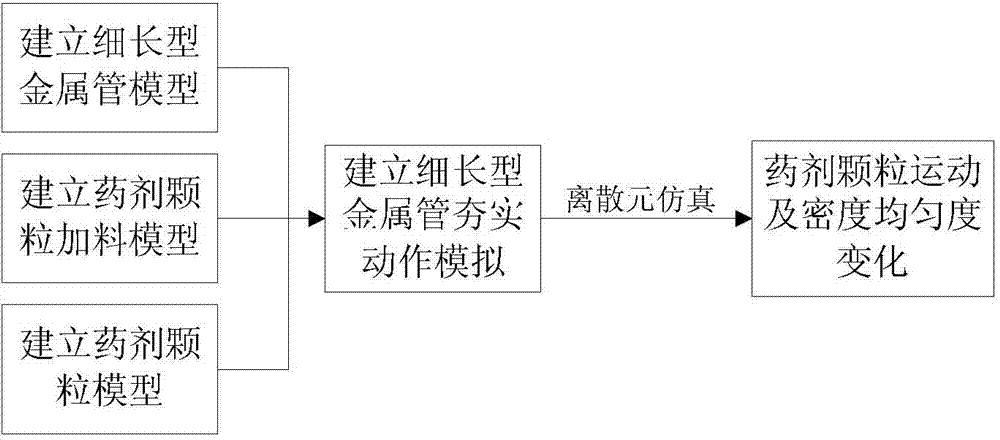

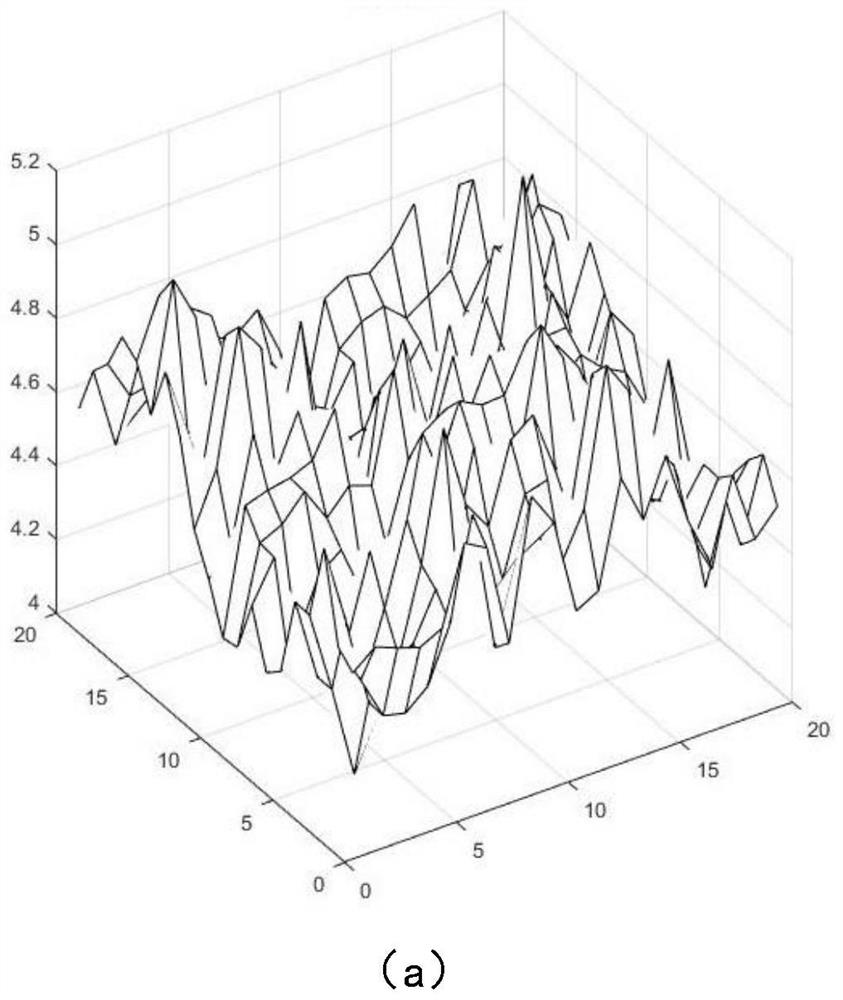

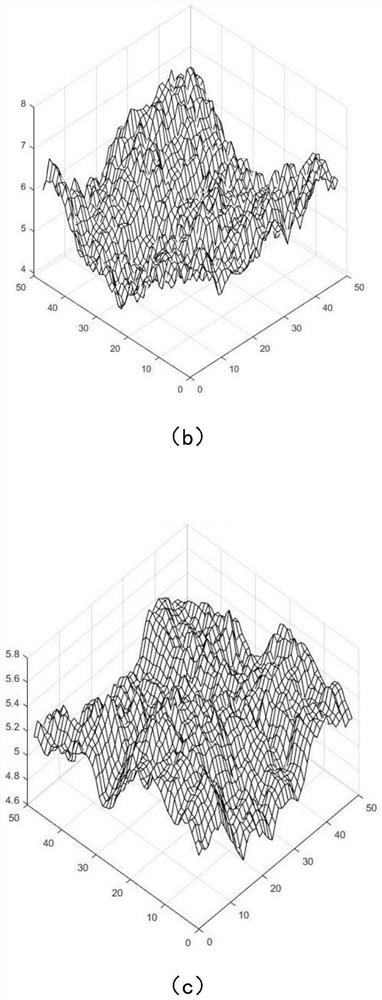

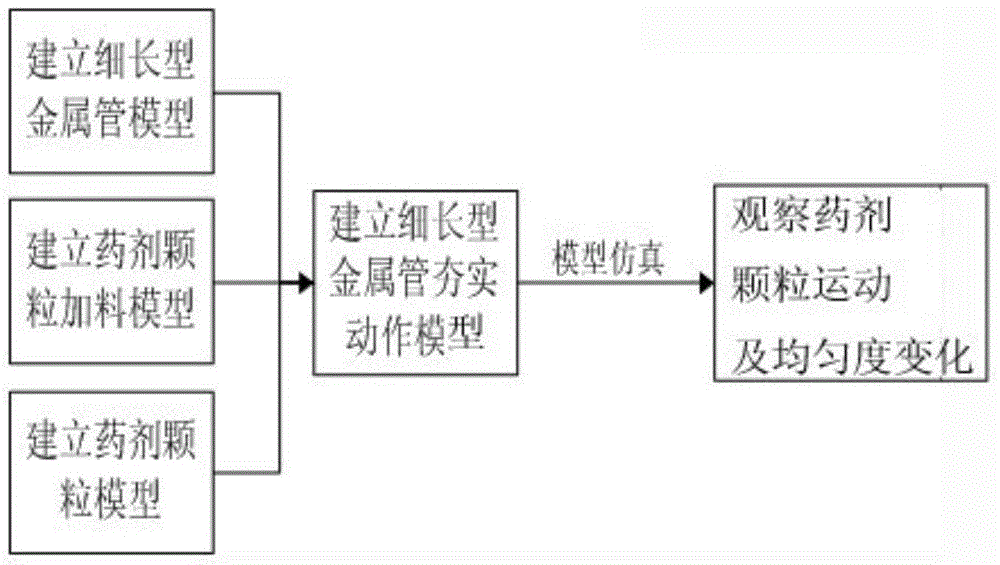

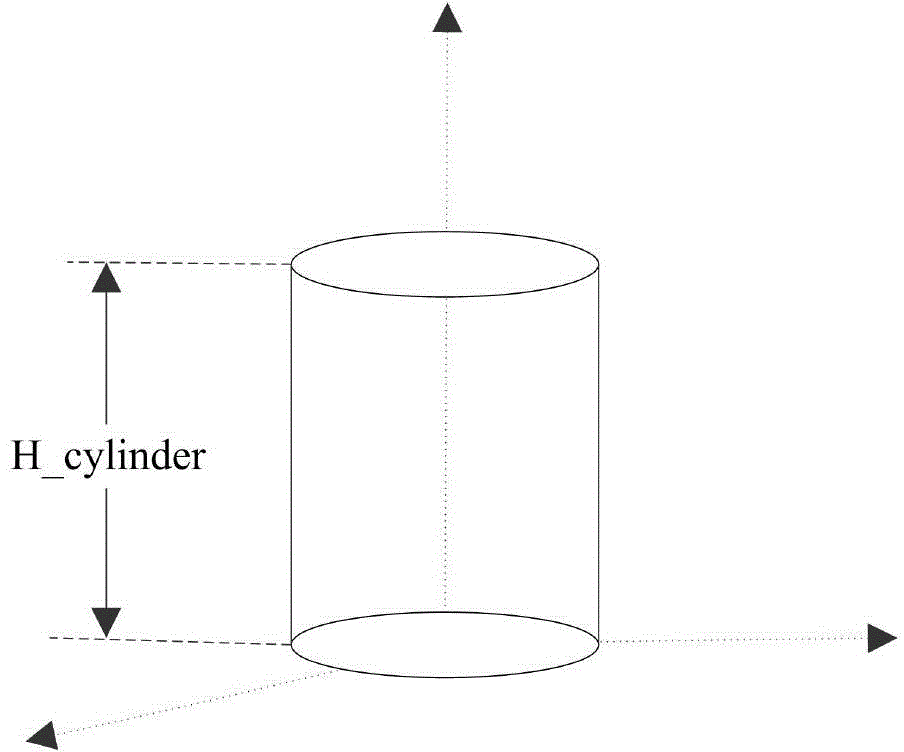

Discrete element analysis method of slender type metal tube drug tamping state

ActiveCN103177194ARealize simulation visualizationOptimum compaction timesSpecial data processing applicationsElement analysisMedicine

The invention discloses a discrete element analysis method of slender type metal tube drug tamping state, and relates to the field of computer model analysis. The method comprises the following steps: 1) establishing a slender type metal tube model; 2) establishing a drug particle feeding model; 3) establishing a drug particle model; 4) simulating of the tamping action of the slender type metal tube; 5) observing the movement, of the drug particles in the slender type metal tube and the drug particle density change process in the tamping action in simulation mode by using the established discrete element model.

Owner:贺州市八步区市场监督管理局

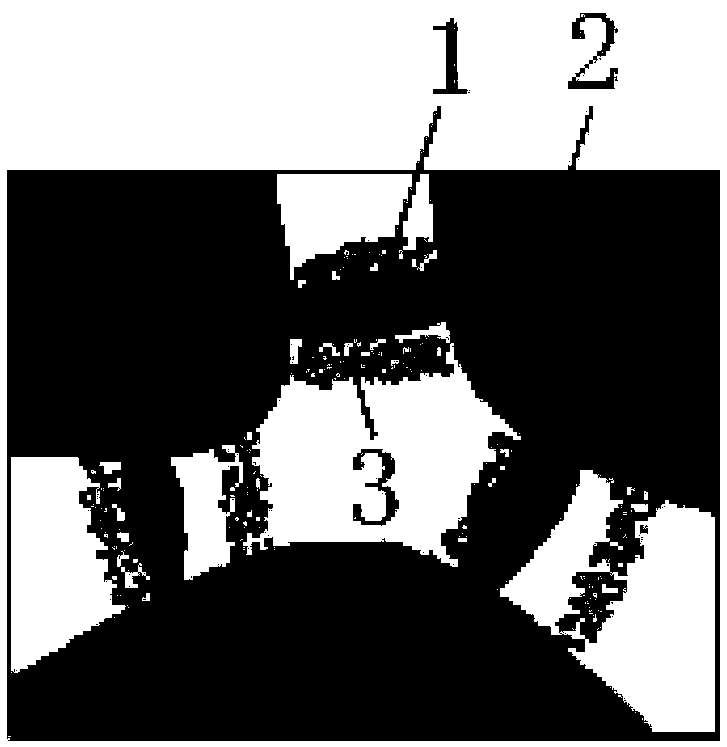

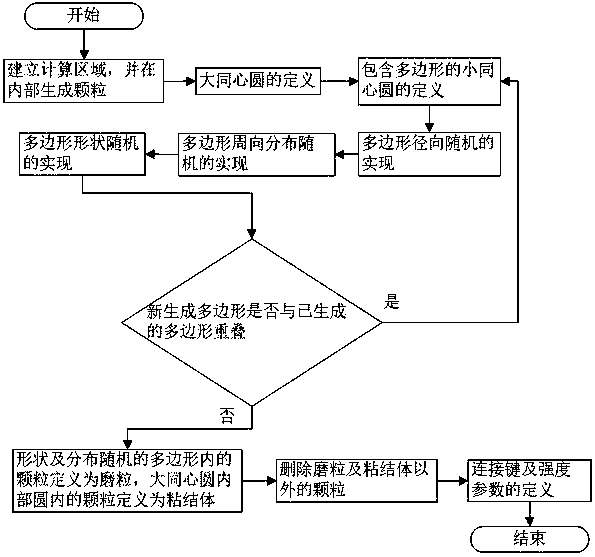

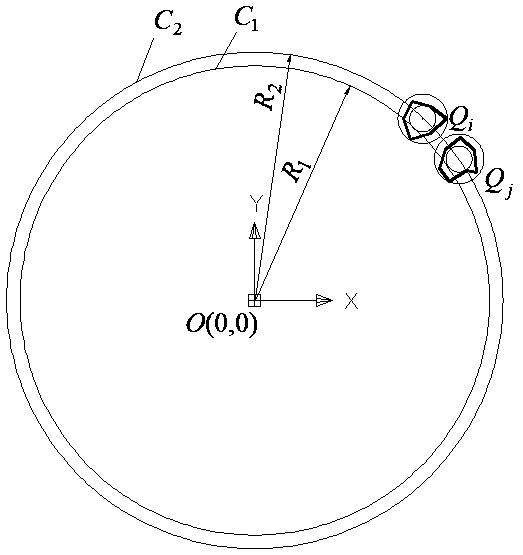

Grinding wheel discrete element modeling method with consideration of abrasive particle shape and distribution randomness

The invention provides a grinding wheel discrete element modeling method with consideration of the abrasive particle shape and distribution randomness. The grinding wheel discrete element modeling method comprises the following main steps: (1) establishing a square calculation area and generating closely-arranged particles inside the square calculation area; (2) defining two big concentric circlesat the center of the square, defining the internal circle as the outline of an adhesive body, and defining the area between the internal circle and the external circle as an abrasive particle distribution area; (3) defining two small concentric circles which comprise random polygons; (4) grouping the particles, defining the particles in the polygons as an abrasive particle group, and defining theparticles in the internal circle of the big concentric circles as an adhesive body group; (5) removing the particles outside the abrasive particle group and the adhesive body group; and (6) selectinga suitable contact model and establishing a two-dimensional grinding wheel discrete element model. According to the grinding wheel discrete element modeling method provided by the invention, the sizes and shapes of abrasive particles on the surface of a grinding wheel as well as the randomness of mutual positions among the abrasive particles are sufficiently considered, so that the actual surfaceappearance of the grinding wheel can be represented more truly and vividly.

Owner:XIANGTAN UNIV

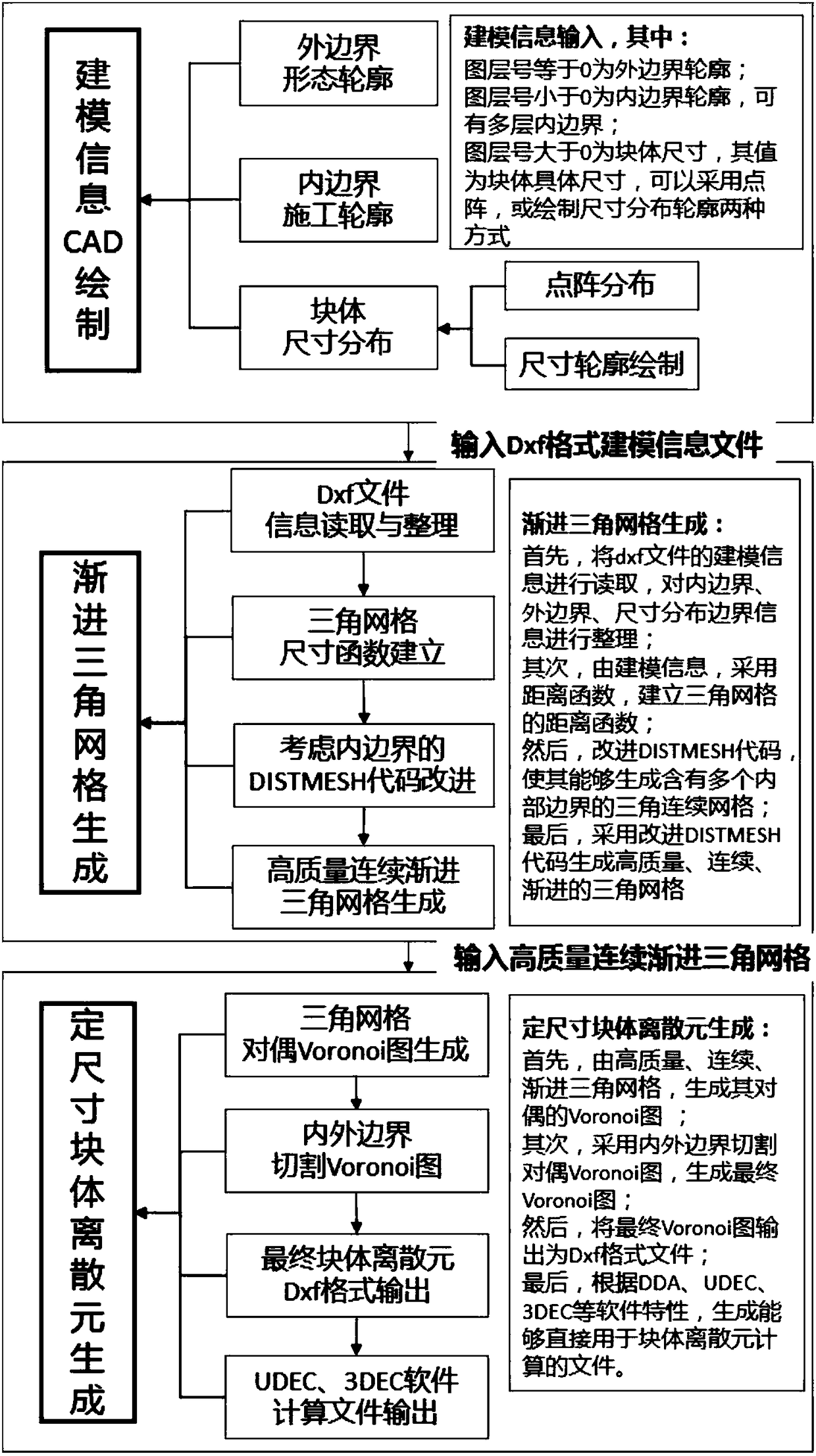

Block discrete element model generation method based on progressive finite element mesh and Voronoi segmentation method

ActiveCN108520138AEasy to operateImprove modeling efficiencyDesign optimisation/simulationSpecial data processing applicationsComputer scienceSoftware

The invention relates to a block discrete element model generation method based on a progressive finite element mesh and a Voronoi segmentation method and belongs to the field of numerical calculation. The method includes the steps of S1, drawing modeling information by using CAD; S2, reading the modeling information and generating a high-quality, continuous and progressive triangular mesh; S3, generating a discrete model and outputting a final calculation file; S4, integrating steps S1-S3 into software, so that a DDA block discrete element model, a UDEC block discrete element model and a 3DECblock discrete element model which are directly used for calculation are generated directly by only drawing CAD drawings and defining the minimum size of blocks. A specific block size distribution rule or size data can be defined, the block discrete element models which satisfy specific spatial distribution are generated, and the problem that a given size distribution rule cannot be generated according to current methods is solved.

Owner:CHONGQING UNIV +1

Semi-flexible pavement interface mesomechanics researching method under vehicle load effect

InactiveCN107563045AIncreased durabilityImprove economySpecial data processing applicationsPull forceMechanical models

The invention discloses a semi-flexible pavement interface mesomechanics researching method under a vehicle load effect, and belongs to the technical field of pavement materials. The method solves theproblems of many modeling troubles, high calculation difficulty and low result accuracy in current semi-flexible pavement interface mesomechanics researches. The method based on a discrete element method comprises the steps that firstly, discrete element numerical simulation software is adopted to generate a two-dimensional discrete element model in the same grade as an actual semi-flexible pavement bituminous-mixture framework; then, existing functions in the software and a mechanical model are combined to define properties of each constituent material and the interface connection mode of each constituent material separately; finally, simulated vehicle load is added on the basis of the existing models, the mechanical response condition of a semi-flexible pavement interface is monitored during loading, shear force, pull force, pressure stress and displacement of the interface are recorded under the load effect, and the strained condition of the interface is evaluated. The semi-flexible pavement interface mesomechanics researching method has the advantages of being visible in expression, easy and accurate in calculation, wide in application range and applicable to mesomechanics researches of bituminous pavement interfaces.

Owner:NANJING FORESTRY UNIV

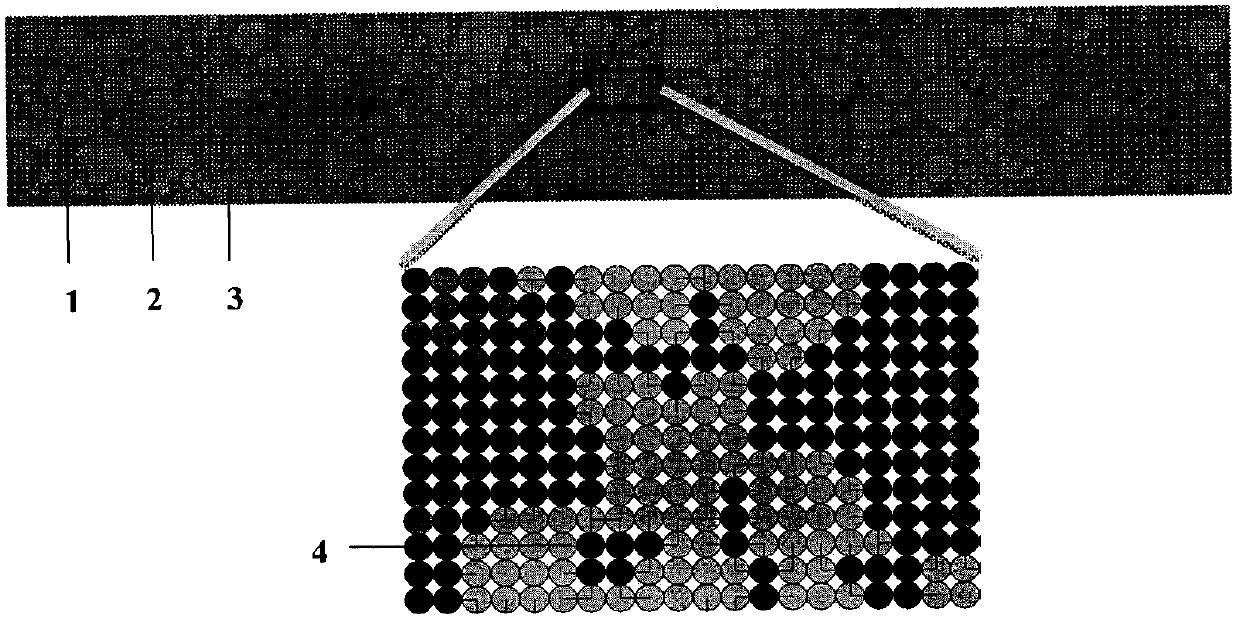

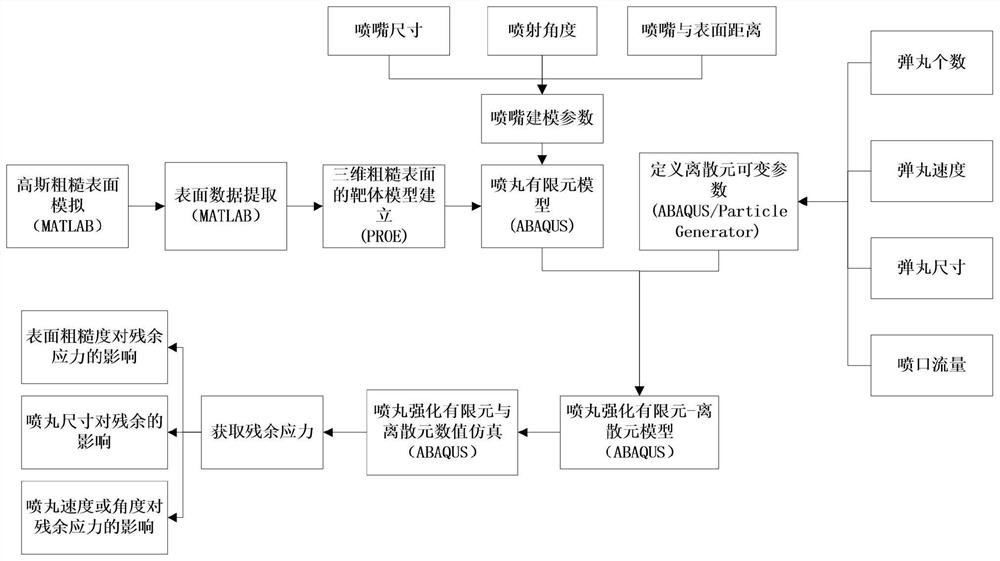

Finite element and discrete element coupled shot peening strengthening numerical simulation method considering surface roughness

PendingCN112036071AEffective simulationIn line with the reality of strengtheningDesign optimisation/simulationSpecial data processing applicationsElement modelAnalogue computation

The invention relates to a shot peening strengthening numerical simulation method considering coupling of a finite element and a discrete element of surface roughness, which comprises the following steps: (1) establishing an autocorrelation function based on Gaussian distribution to represent the real surface roughness of a part, and extracting data information of the surface roughness by using MATLAB mathematical software; (2) importing the data information of the surface roughness into PROE three-dimensional modeling software, carrying out surface smoothing treatment through fitting, and establishing a three-dimensional shell model for representing the surface roughness of the part; (3) importing the three-dimensional shell model into ABAQUS finite element software, and establishing a part finite element model considering the surface roughness on an ABAQUS / CAE platform; (4) by modifying the inp file of the ABAQUS, creating a particle generator, establishing a discrete element model of the shot flow in the shot peening strengthening process, and controlling related parameters of the shot flow according to actual shot peening working conditions; and (5) utilizing an ABAQUS / Expressexplicit dynamics algorithm to carry out shot peening numerical simulation calculation considering coupling of a finite element and a discrete element of the surface roughness in the shot peening process of the part.

Owner:ANHUI UNIV OF SCI & TECH

Method for establishing multi-scale model of medicament particles during powder compaction process of long thin metal pipe

InactiveCN103955592ARealize simulation visualizationImprove efficiencySpecial data processing applicationsThin metalScale model

The invention discloses a method for establishing a multi-scale model of medicament particles during a powder compaction process of a long thin metal pipe, and belongs to the field of computer simulation analysis. The method specifically comprises the following steps of (1) establishing a long thin metal pipe model; (2) establishing a medicament particle adding model; (3) establishing a medicament particle model; (4) establishing a long thin metal pipe compaction action model; (5) carrying out compaction simulation by utilizing discrete meta models which are established from the step (1) to the step (4). According to the method for establishing the multi-scale model of the medicament particles during the powder compaction process of the long thin metal pipe, disclosed by the invention, through establishing a multi-scale compaction model of the powder particle, the movement of the medicament particles at the inner part of the long thin metal pipe and a density changing process of the medicament particles in a compaction action are simulated by utilizing a computer, and a feasible theory basis is provided for a compaction technology of a compaction device based on impact vibration.

Owner:CHONGQING UNIV

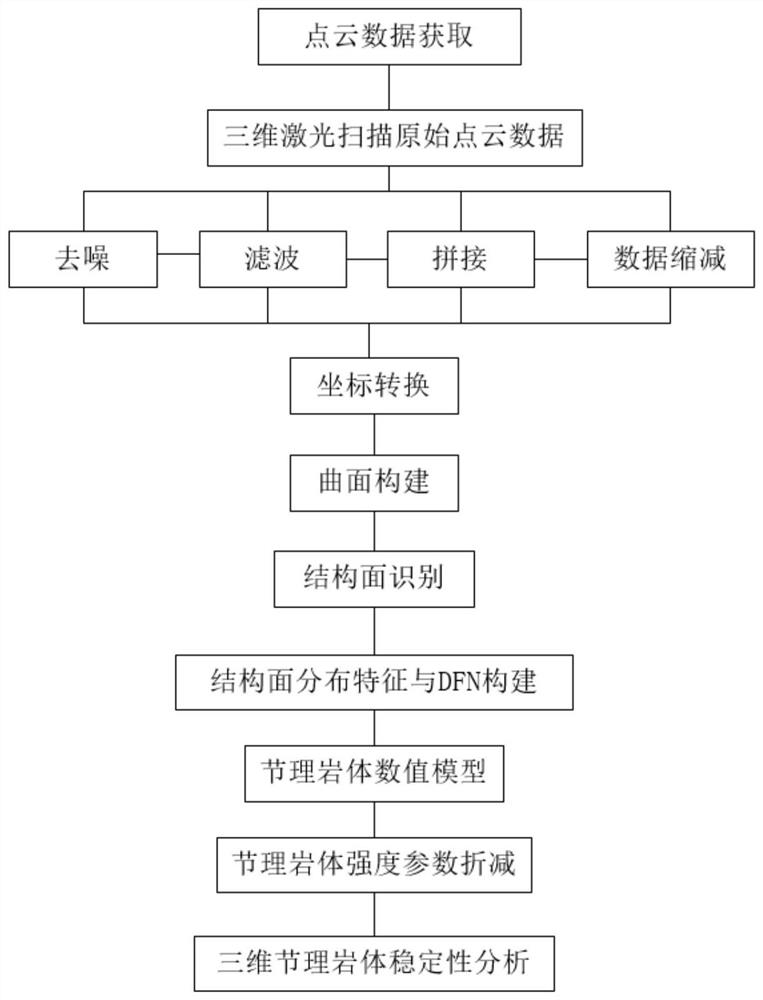

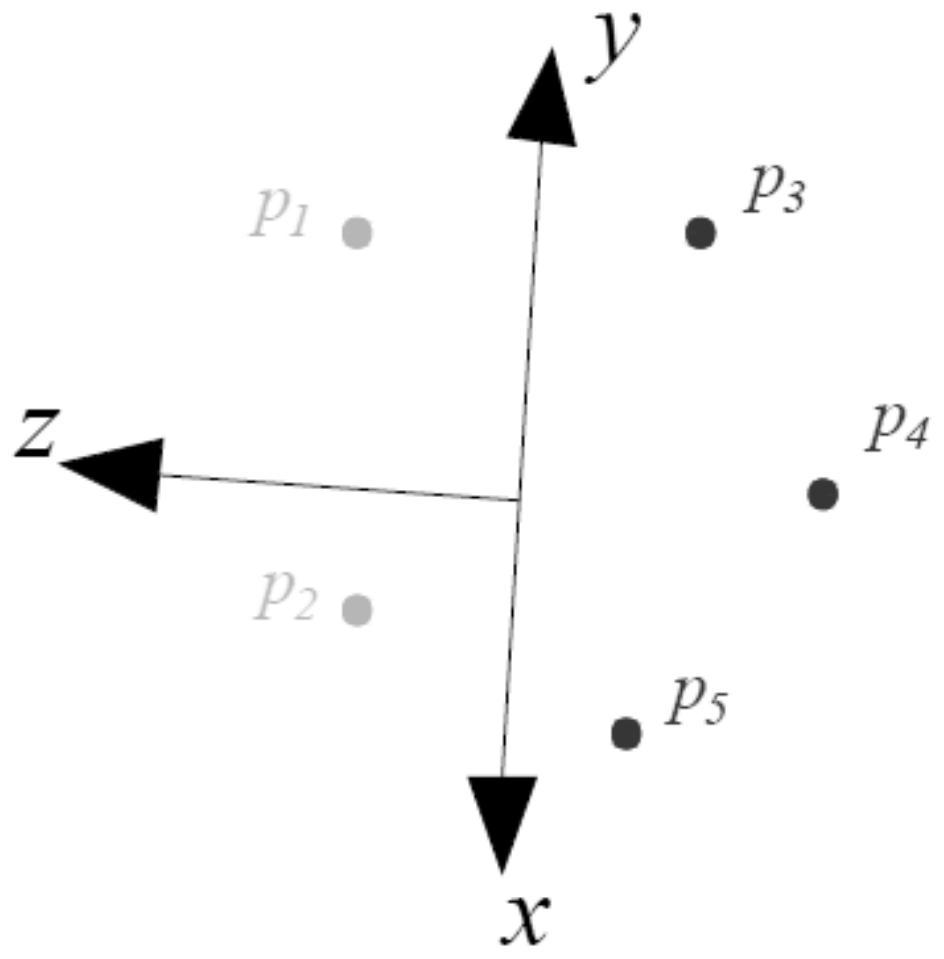

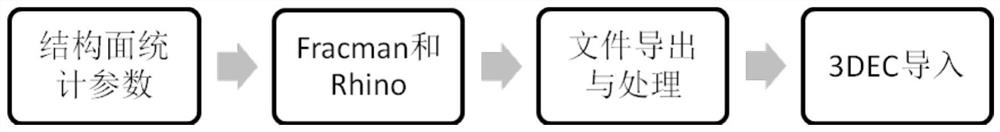

Numerical simulation method for establishing jointed rock mass discrete element model based on point cloud data

PendingCN112784403AAccurate rock conditionReal rock conditionDesign optimisation/simulationSpecial data processing applicationsComputational scienceData set

The invention provides a numerical simulation method for establishing a jointed rock mass discrete element model based on point cloud data. Firstly, a point cloud data set of a jointed rock mass is obtained, denoising and simplified filtering processing are carried out, then the occurrence of the structural plane is calculated, a three-dimensional model for recognizing the structural plane is established through the point cloud data, and discrete element software 3DEC cannot be directly imported; by means of Fracman software which has powerful structural plane modeling function and Rhino software which has complete software model processing function, the model is processed into a data file readable by 3DEC software, then the data file is imported into the 3DEC software for numerical analysis, a final three-dimensional model of the jointed rock mass is generated, the jointed rock mass model generated through the method can obtain more accurate and real rock mass conditions, and a more reliable basis is provided for an engineering site.

Owner:NORTHEASTERN UNIV

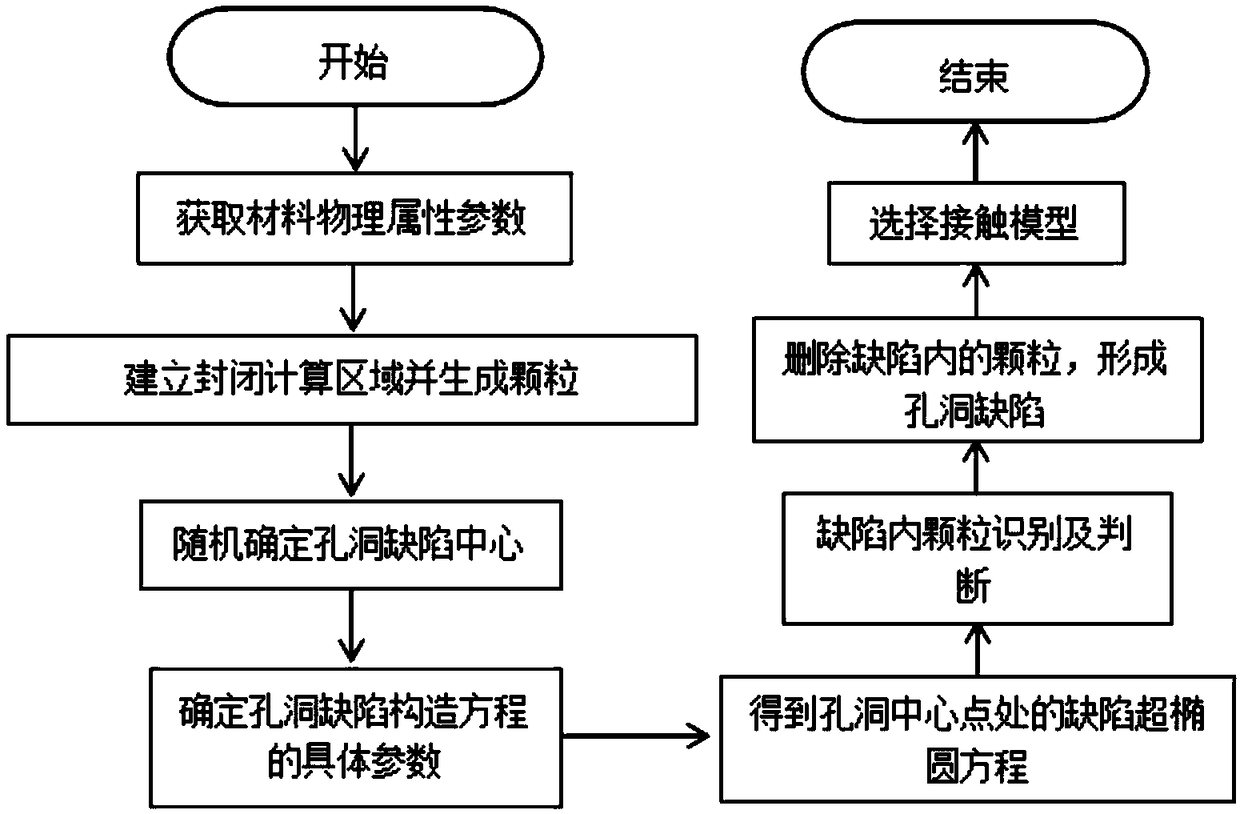

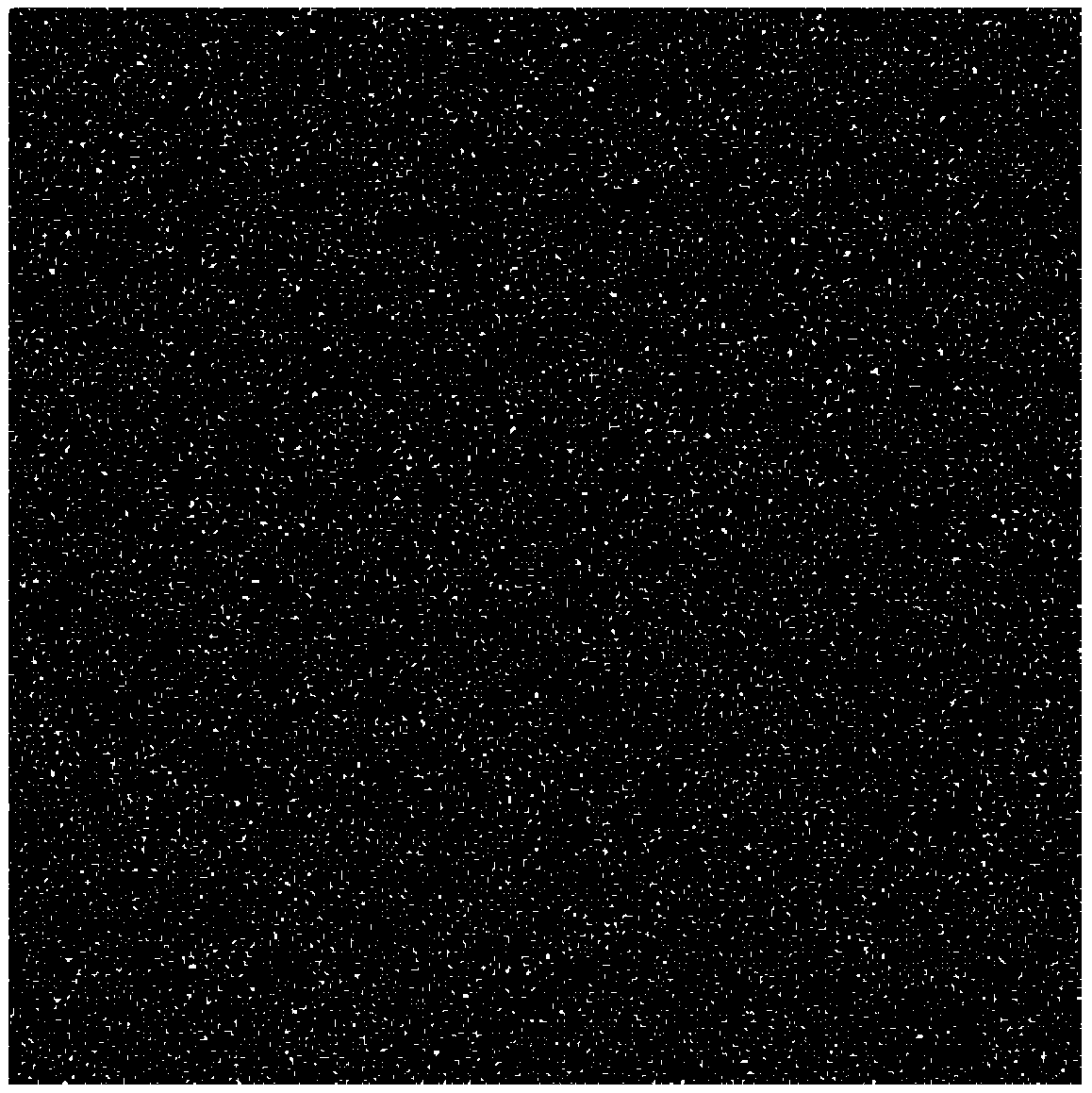

A discrete element modeling method for stochastic void defect materials based on hyperelliptic equation

ActiveCN109376454ADesign optimisation/simulationSpecial data processing applicationsDiscrete element simulationGraphics

The invention provides a discrete element modeling method for stochastic void defect materials based on hyperelliptic equation, which can randomly generate ellipse, rhombus, star or rectangular cavitydefects with different flatness by controlling parameters, and is used for discrete element simulation research of hard and brittle materials. The concrete steps are as follows: defining the main physical parameters of the material, generating particles in a closed calculation area and assigning microscopic contact property parameters to the particles, and randomly determining a certain number ofvoid defect centers with random positions; Based on the hyperelliptic equation, the hole defect patterns with different shapes are constructed at each center point. Delete the particles in each holedefect pattern, select the appropriate contact model, delete the wall of the closed area, and form the discrete element model of the hole defect. The method of the invention is simple and feasible, and the size, shape, angle and flatness of the formed hole defects are controllable, so that the generated material model is closer to the reality, so that the simulation calculation result is more accurate, and the simulation effectiveness is improved.

Owner:XIANGTAN UNIV

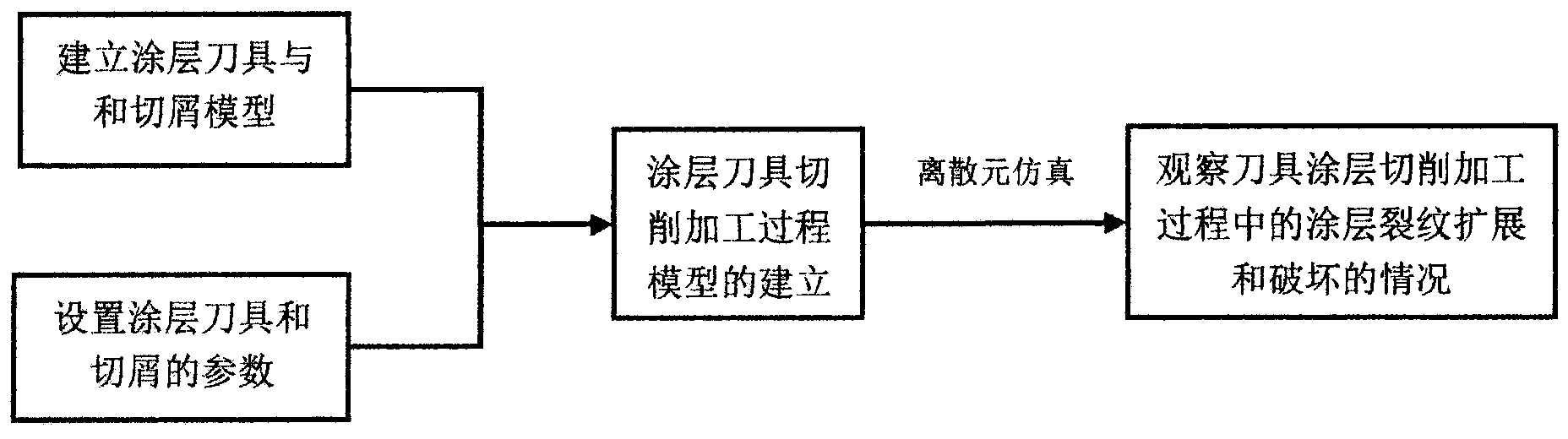

Discrete element analysis method for propagation and damage of coating crack in cutting process of coated cutting tool

InactiveCN104346498AReduce the number of unitsReduce the amount of calculationSpecial data processing applicationsElement analysisContact model

The invention discloses a discrete element analysis method for propagation and damage of a coating crack in a cutting process of a coated cutting tool. The discrete element analysis method comprises the following analysis steps of 1) establishing the coated cutting tool and a discrete element model of chips; 2) selecting a suitable contact model and calibrating microscopic parameters of the discrete element model through a mechanical property test; 3) simulating the coated cutting tool and a cutting processing process; 4) observing and recording the conditions of propagation and damage of the coating crack of the coated cutting tool. The discrete element analysis method has the following technical effect that 1, long-distance movement between the coated cutting tool and the chips is simulated by utilizing a method of a periodic boundary; the continuous long chip models are simplified to a periodic flow model of a small section of chips in contact with the coated cutting tool; the number of the units of the chip model is greatly reduced, and the calculated amount and the computation time are greatly reduced; 2, visualization of propagation and damage of the coating crack of the coated cutting tool in a cutting processing process is implemented, through the model states of several time points captured for the cutting processing process of the coated cutting tool, the conditions of propagation and damage of the coating crack of the coated cutting tool in the processing process can be directly observed.

Owner:XIANGTAN UNIV

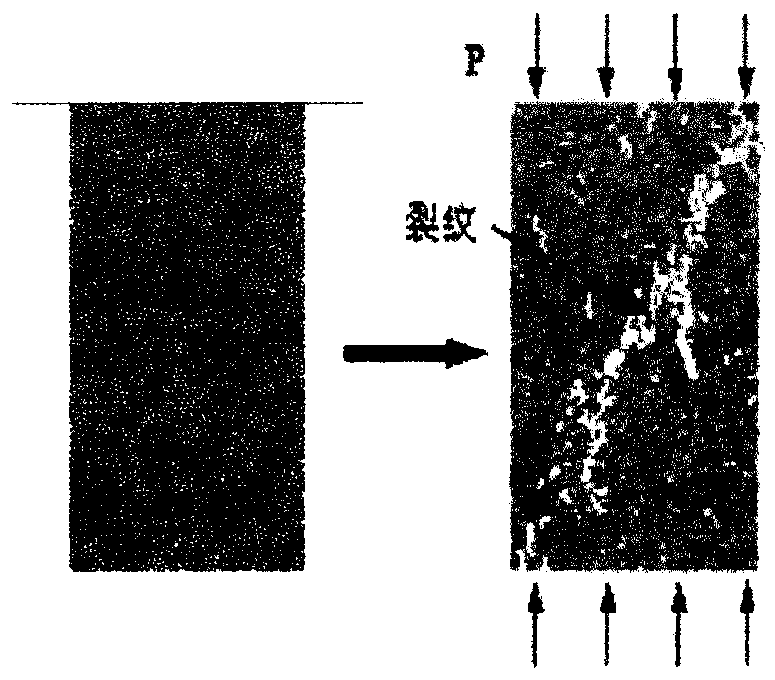

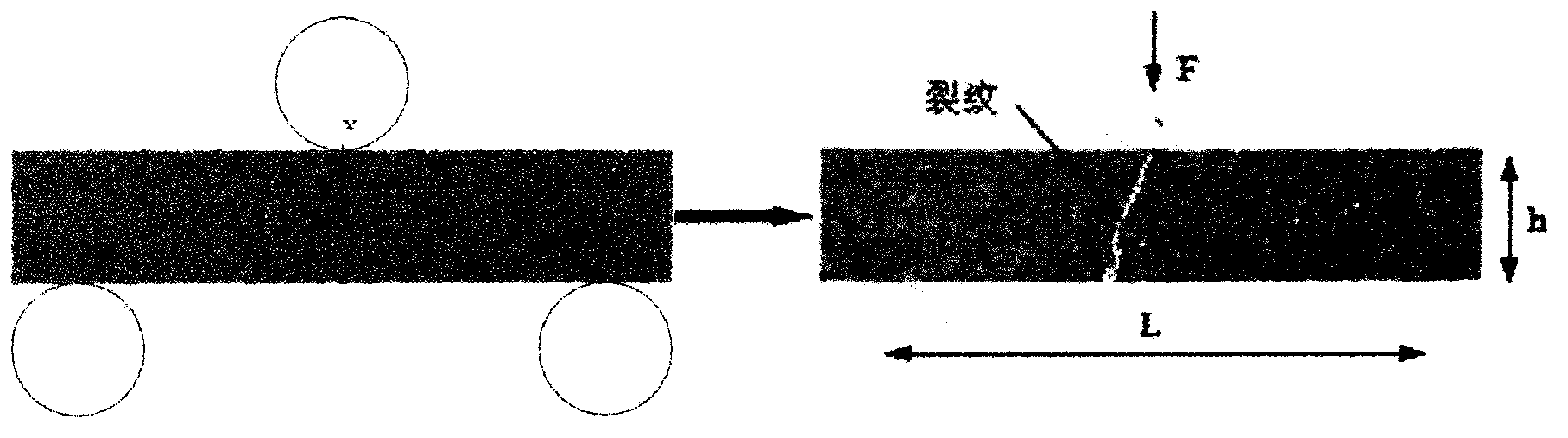

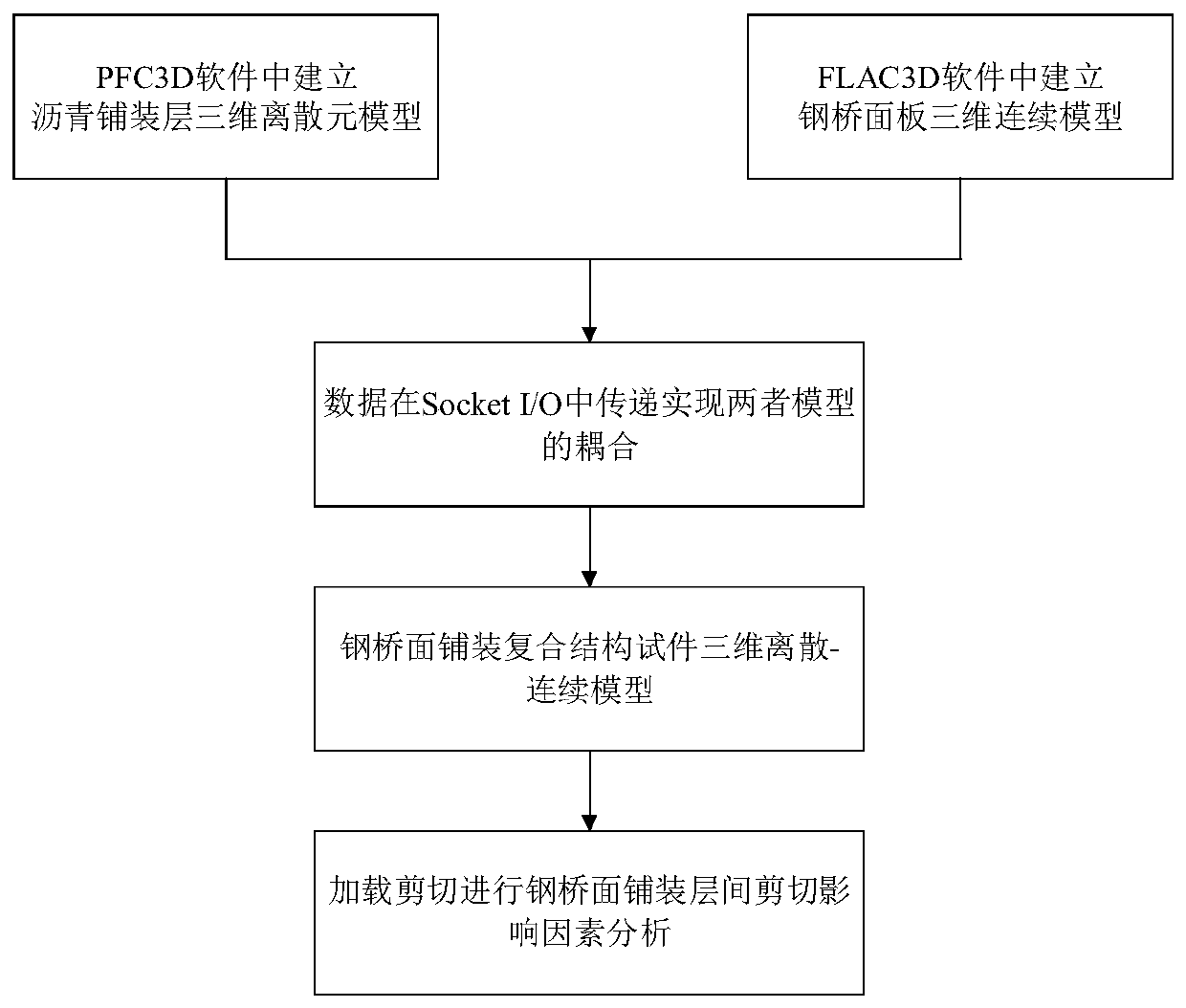

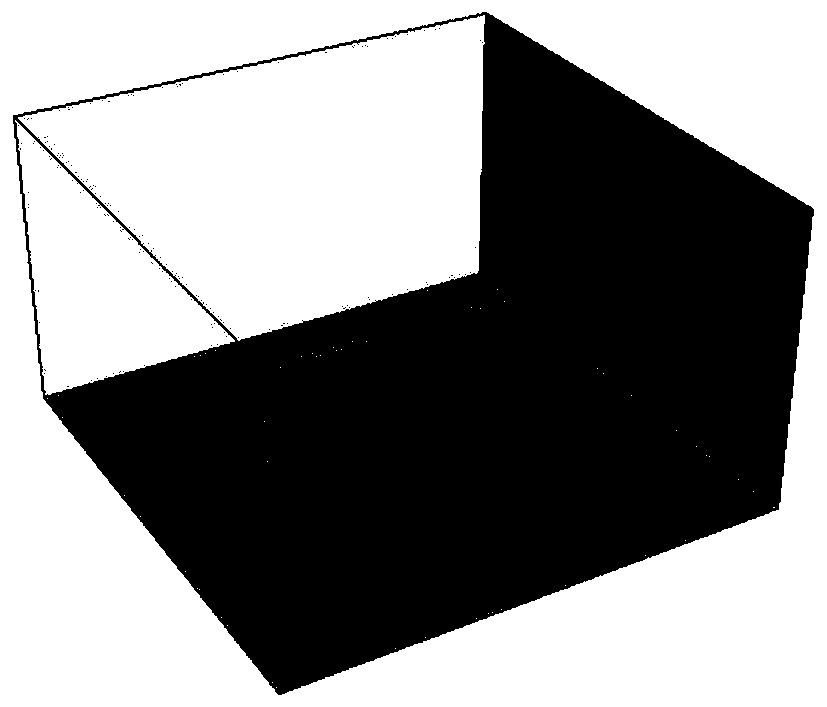

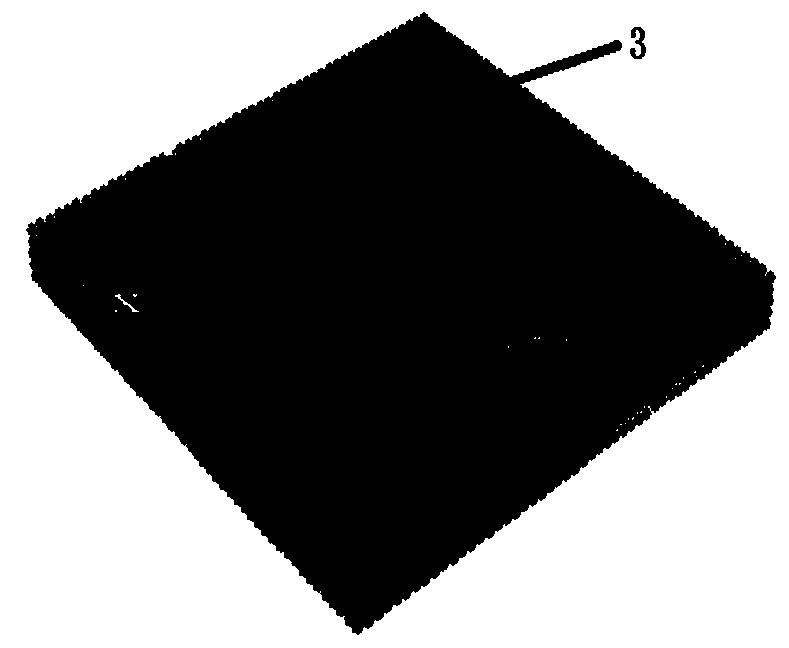

Steel bridge deck pavement interlayer shear test simulation method based on discrete-continuous coupling

ActiveCN110399661AIn line with actual engineeringSpecial data processing applicationsBridge deckEngineering

The invention discloses a steel bridge deck pavement interlayer shear test simulation method based on discrete-continuous coupling. The method comprises the following steps: firstly, carrying out themodeling in PFC3D software, and forming a three-dimensional discrete element model of a steel bridge deck pavement asphalt pavement layer; secondly, conducting the modeling in FLAC3D software, and forming a steel bridge deck slab three-dimensional continuous model; thirdly, realizing data exchange between the PFC3D model and the FLAC3D model by utilizing the Socket I / O function of the PFC3D software and the FLAC3D software; and finally, loading and shearing the model, changing the mesoscopic parameters of the three-dimensional discrete element model of the asphalt pavement layer and the material parameters of the steel bridge deck, and analyzing the influence factors of the interlayer shearing of the steel bridge deck pavement. According to the method, the advantages of a discrete elementmethod and a finite element method are integrated. The mesoscopic characteristics of asphalt concrete serving as a multi-phase composite material and the characteristics of a steel bridge deck linearelastic material are considered. The simulation result better conforms to engineering practice. The obtained data can be used for guiding the design of a composite structure of a steel bridge deck pavement system.

Owner:HOHAI UNIV

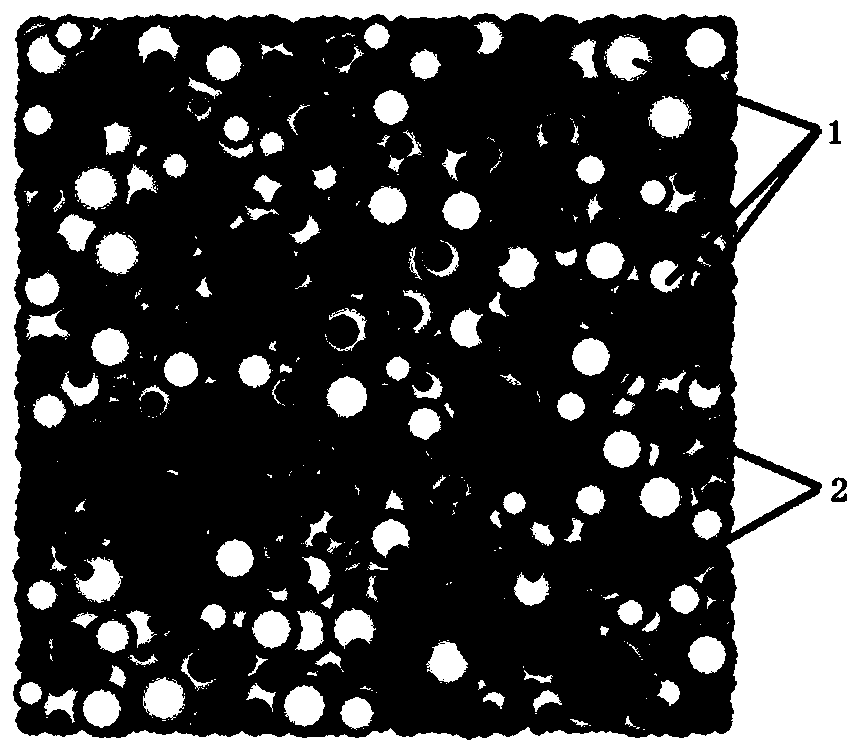

Steel bridge deck pavement interlayer shear fatigue behavior simulation method based on discrete elements

The invention provides a steel bridge deck pavement interlayer shear fatigue behavior simulation method based on discrete elements. The method comprises the following specific steps of firstly, generating the asphalt pavement layer discrete element models with the same sizes and grades according to an indoor test, then generating the steel bridge deck three-dimensional discrete element models, andcombining into a steel bridge deck pavement composite test piece model; secondly, endowing the corresponding mesomechanics parameters to the mutual contact and bonding among a generated coarse aggregate unit, an asphalt mortar unit and a steel bridge deck unit according to the macromechanics parameters; and finally, controlling a loading wall body to continuously adjust the speed by utilizing anFISH language in a PFC3D to realize different forms of periodic loads to carry out fatigue shearing, and real-timely collecting the fatigue loading frequency, the shearing deformation amount and the number and paths of the interlayer crack development in the simulation process, when the shearing deformation amount reaches a limit value, ending the simulation, exporting a data result, and analyzingthe mechanism of the steel bridge deck pavement interlayer shearing fatigue damage.

Owner:HOHAI UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com