Finite element and discrete element coupled shot peening strengthening numerical simulation method considering surface roughness

A technology of surface roughness and shot peening, applied in the field of aerospace surface engineering, can solve the problems of not considering the influence of residual stress, not considering the influence of projectile residual stress, not establishing the surface roughness of the target body, etc., to achieve easy operation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] In the following, a numerical simulation method of shot-peening strengthening considering surface roughness coupled with finite element and discrete element will be further described by way of example in conjunction with the accompanying drawings.

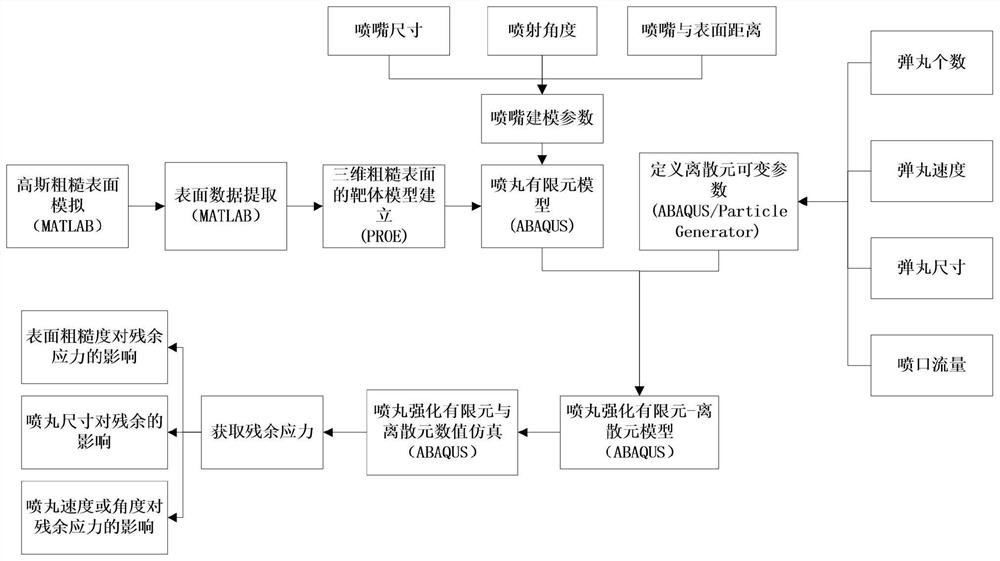

[0025] Such as figure 1 Shown, the realization process of the present invention is as follows:

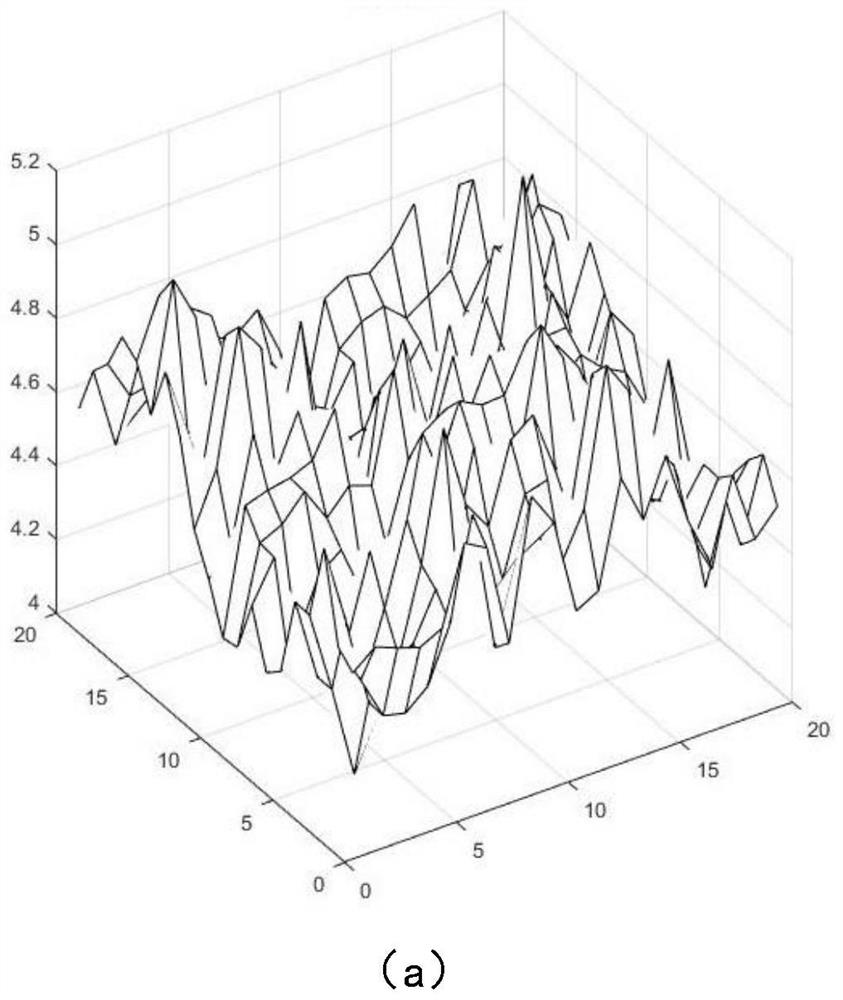

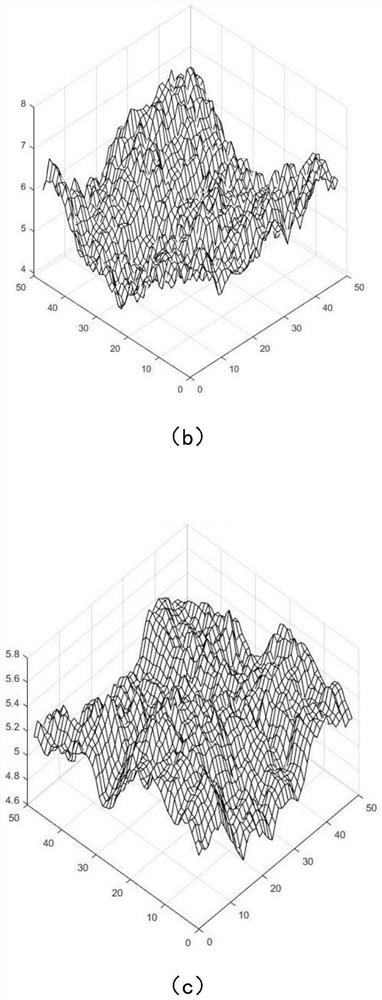

[0026] The first step is to obtain and extract target surface data based on rough surface simulation with autocorrelation function under Gaussian distribution conditions; use probability distribution function and autocorrelation function to generate Gaussian random rough surface values; autocorrelation function simulation under Gaussian distribution conditions is different Rough surface extraction graphics display as figure 2 shown. The function model for simulating a Gaussian surface is as follows:

[0027]

[0028] where τ x =1,···,N;τ y =1,...,N. η(x+τ x ,y+τ y ) is a random sequence of Gaussian distribution; h(τ ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com