Patents

Literature

330 results about "Petroleum reservoir" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A petroleum reservoir or oil and gas reservoir is a subsurface pool of hydrocarbons contained in porous or fractured rock formations. Petroleum reservoirs are broadly classified as conventional and unconventional reservoirs. In case of conventional reservoirs, the naturally occurring hydrocarbons, such as crude oil or natural gas, are trapped by overlying rock formations with lower permeability. While in unconventional reservoirs the rocks have high porosity and low permeability which keeps the hydrocarbons trapped in place, therefore not requiring a cap rock. Reservoirs are found using hydrocarbon exploration methods.

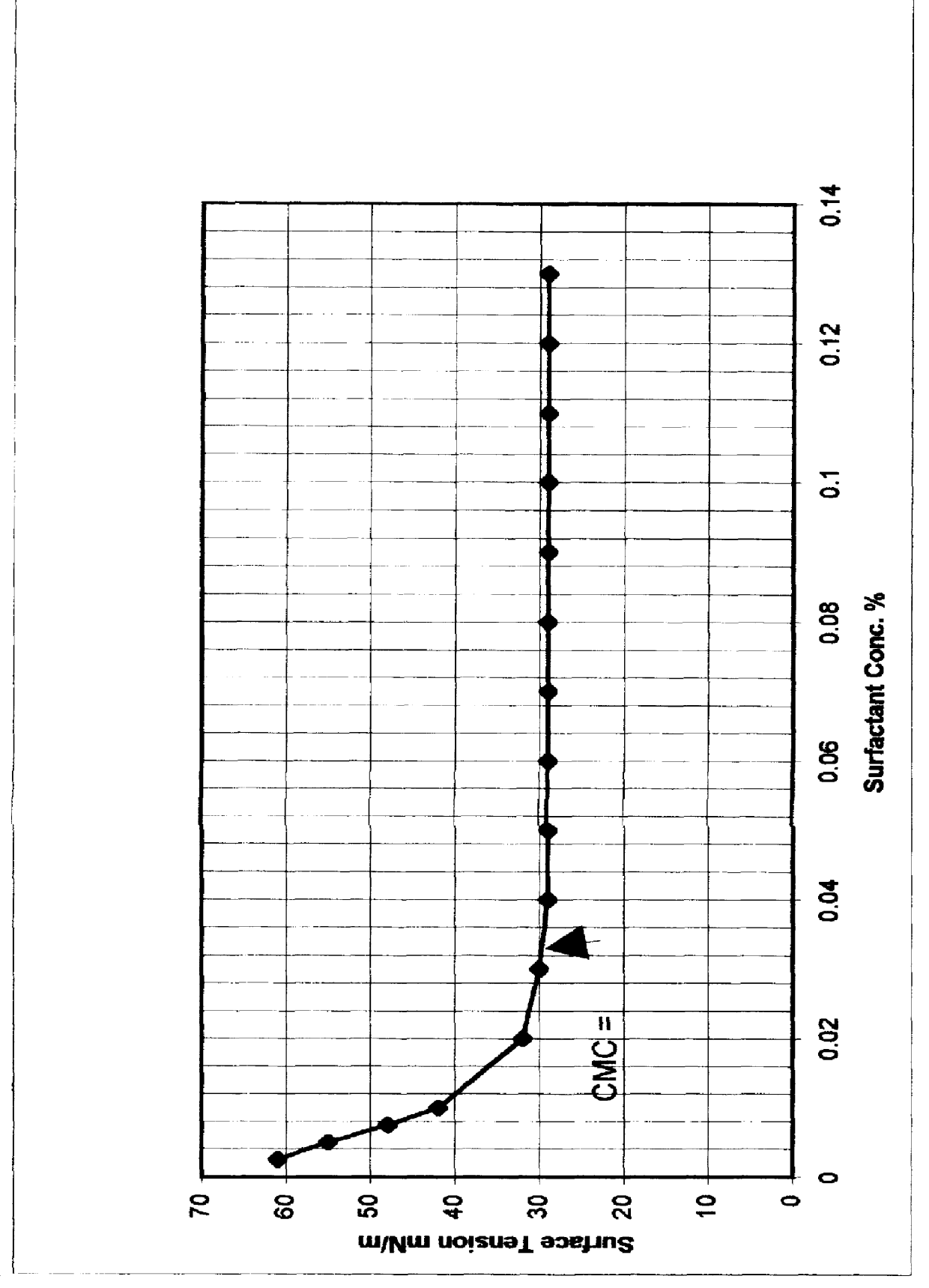

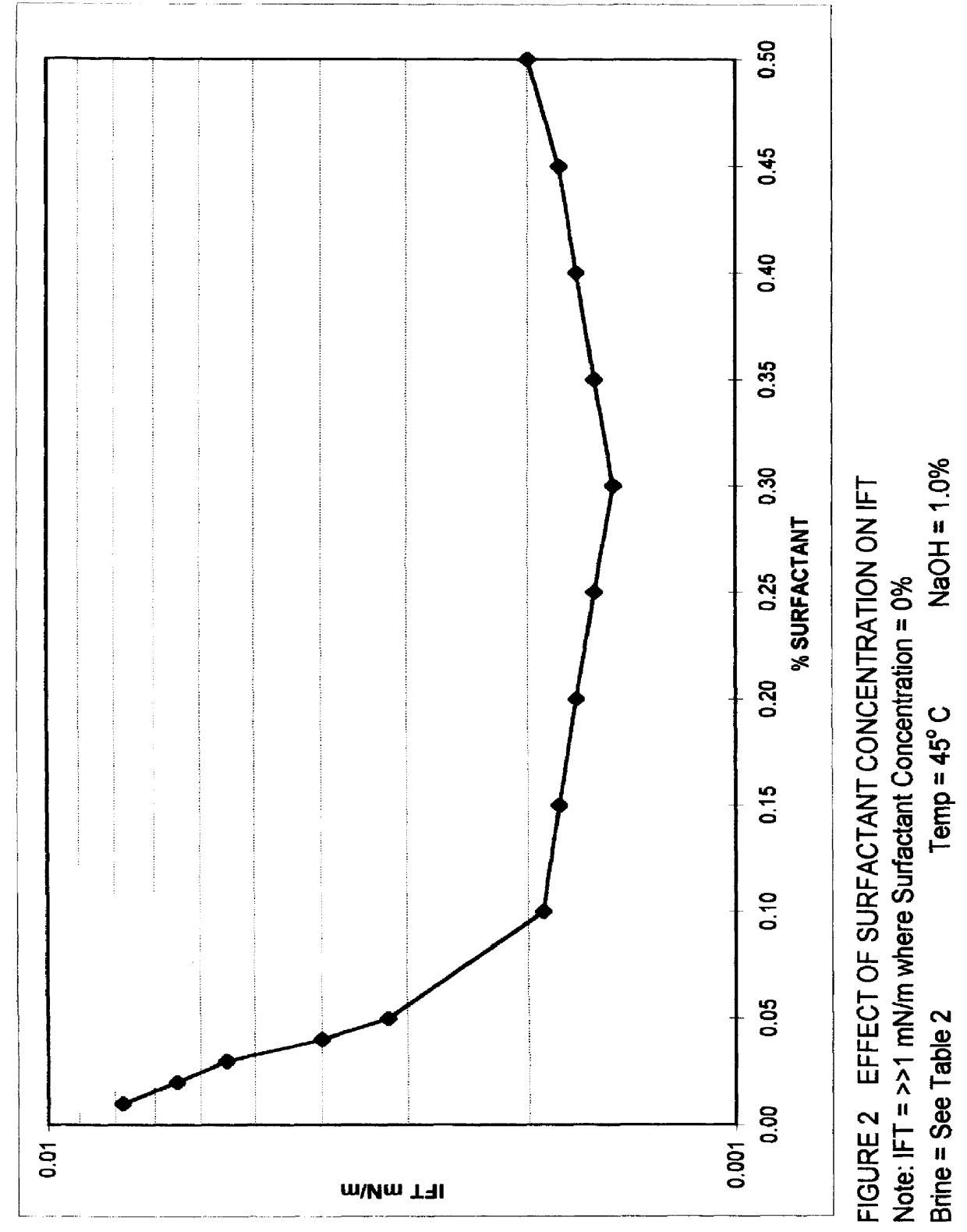

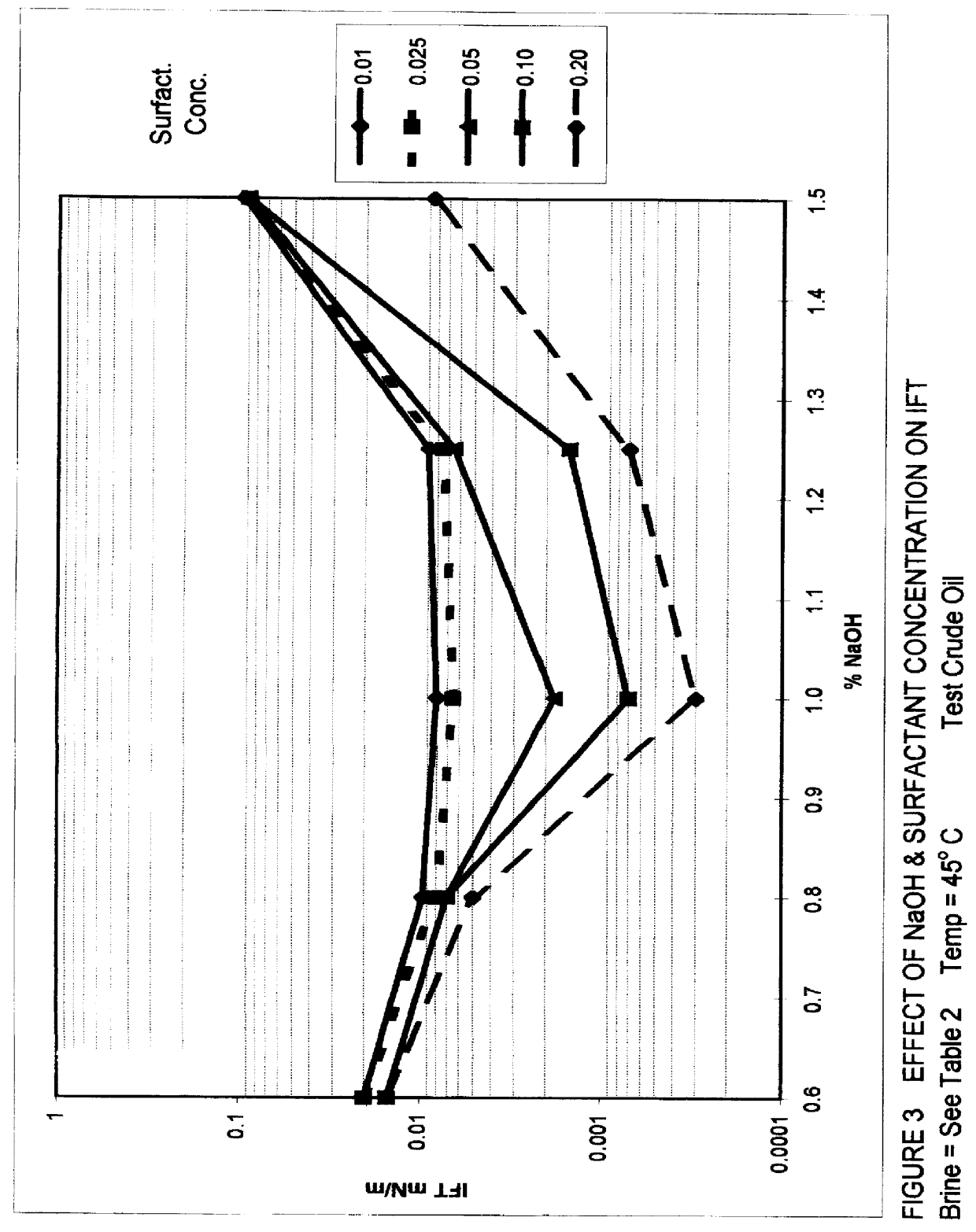

Alkaline surfactant polymer flooding composition and process

An improved concentrated surfactant formulation and process for the recovery of residual oil from subterranean petroleum reservoirs, and more particularly an improved alkali surfactant flooding process which results in ultra-low interfacial tensions between the injected material and the residual oil, wherein the concentrated surfactant formulation is supplied at a concentration above, at, or, below its CMC, also providing in situ formation of surface active material formed from the reaction of naturally occurring organic acidic components with the injected alkali material which serves to increase the efficiency of oil recovery.

Owner:OIL CHEM TECH

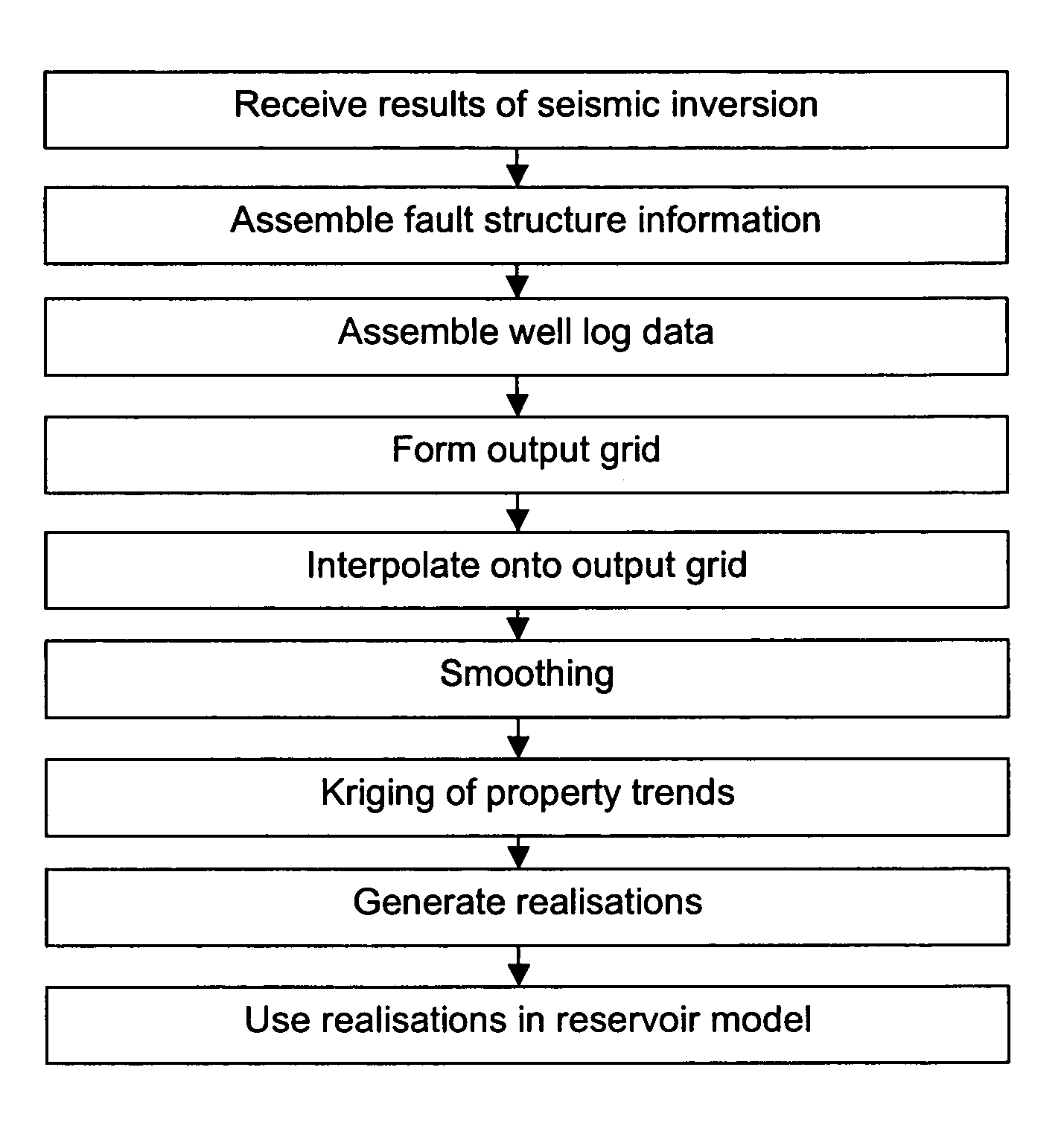

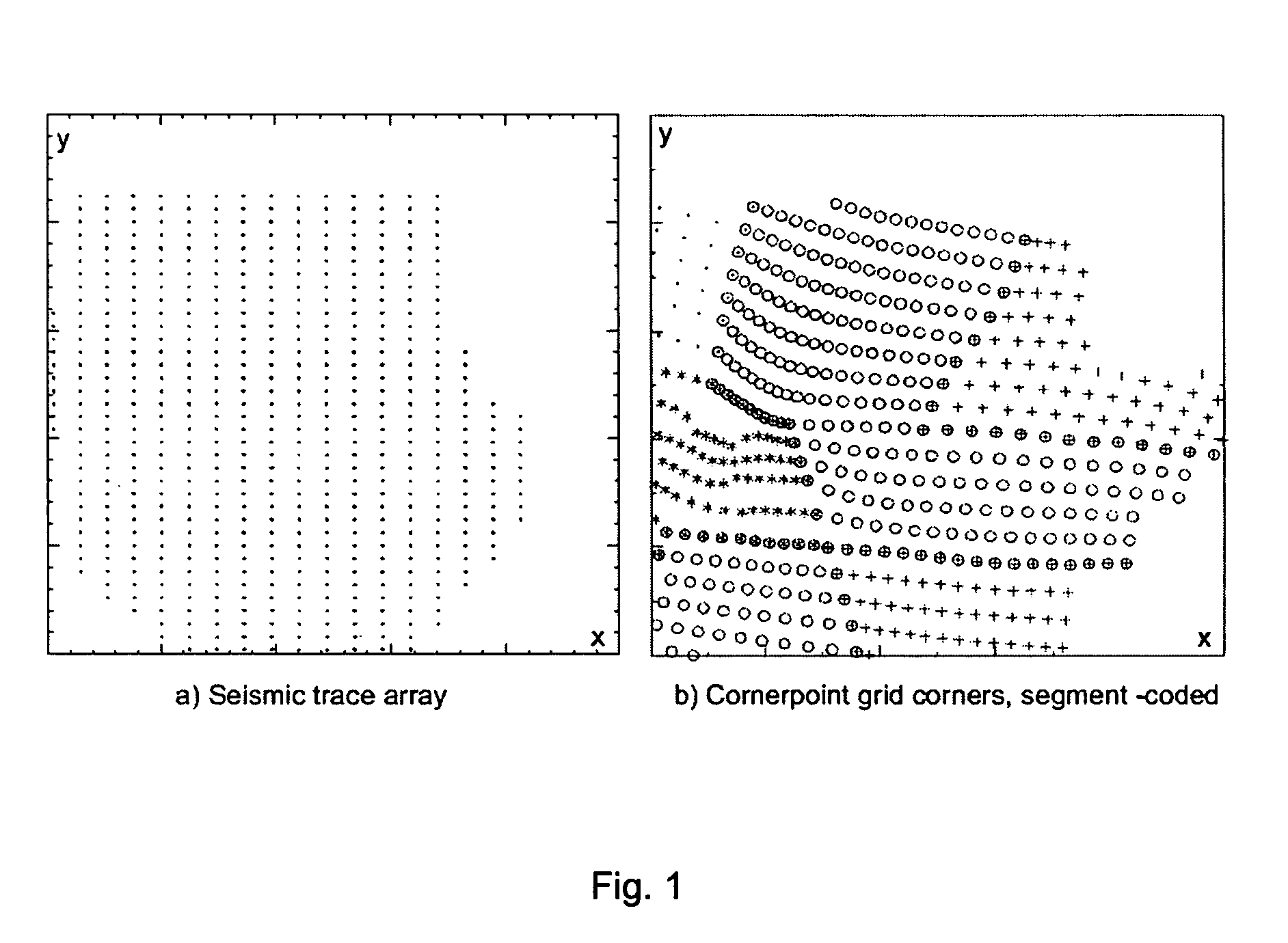

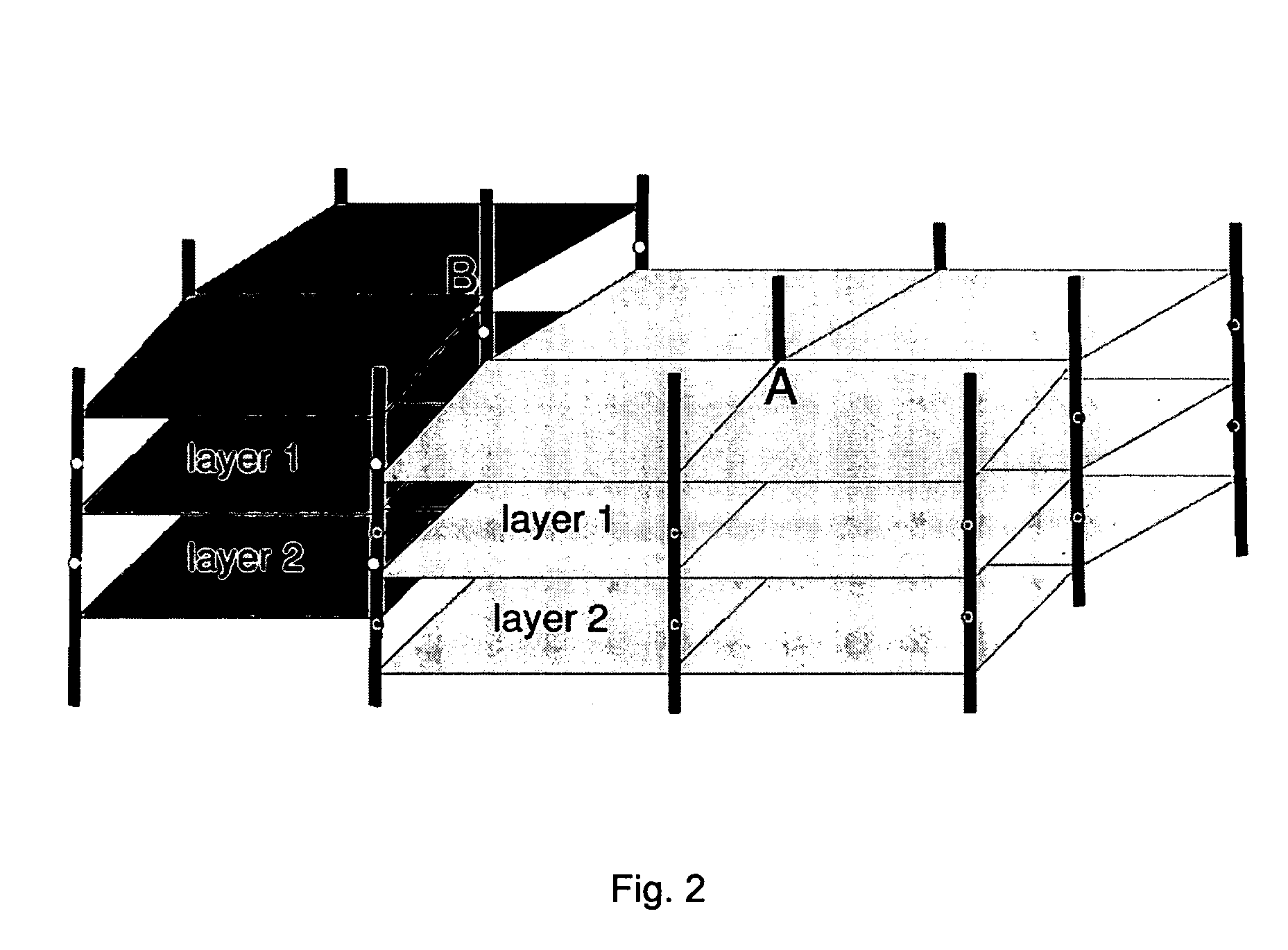

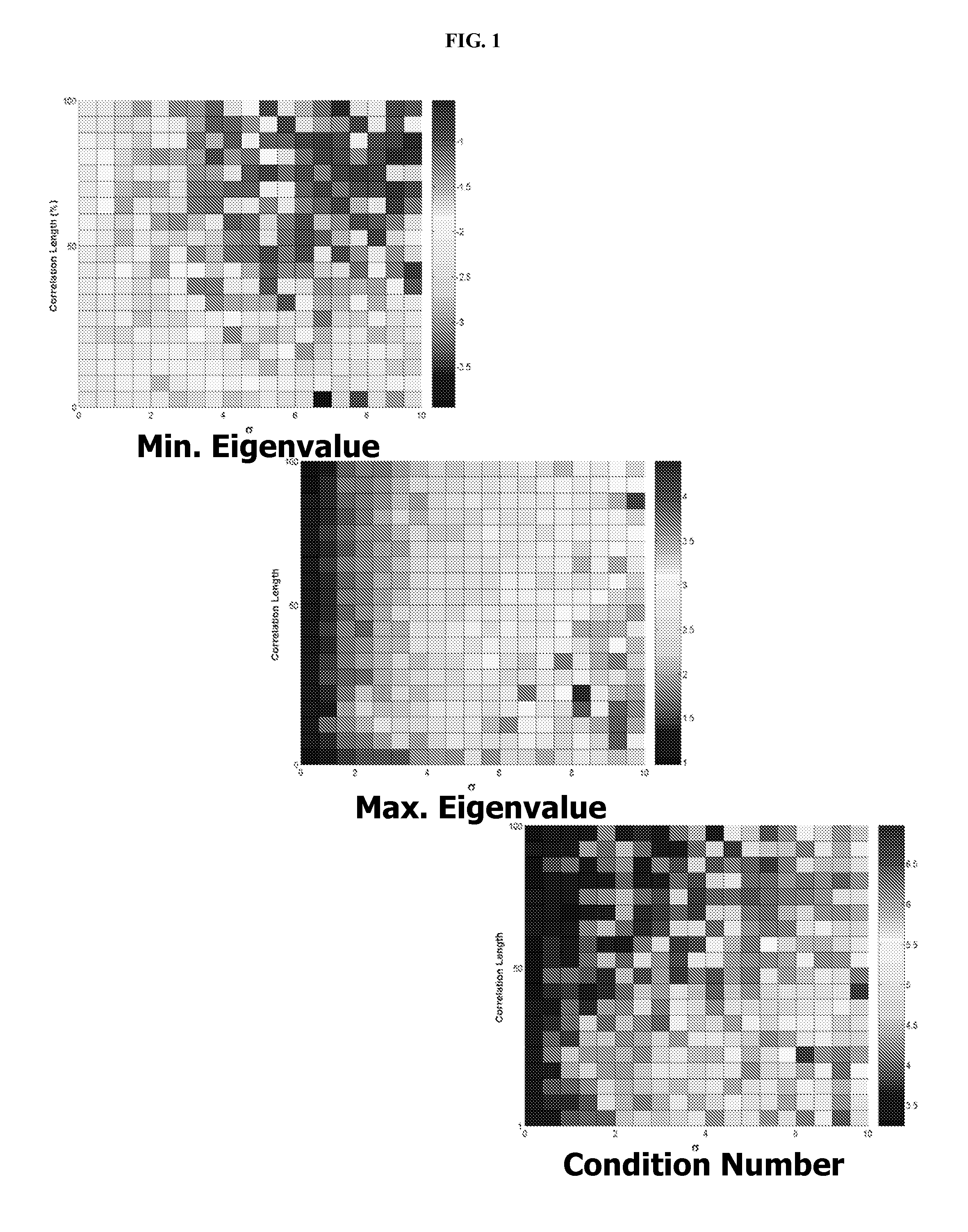

Method for estimating and/or reducing uncertainty in reservoir models of potential petroleum reservoirs

ActiveUS7254091B1Reduce uncertaintyGreat constraintSeismic signal processingSpecial data processing applicationsSoil scienceInter layer

A method for estimating and / or reducing uncertainty in reservoir models of potential petroleum reservoirs comprises receiving the results of a stochastic seismic inversion, and transforming the inversion data into a form suitable for reservoir modelling and flow simulations, while honoring inter-property and inter-layer correlations in the inversion data as well as measured well data and other geological constraints.

Owner:BHP BILLITON INNOVATION PTY LTD

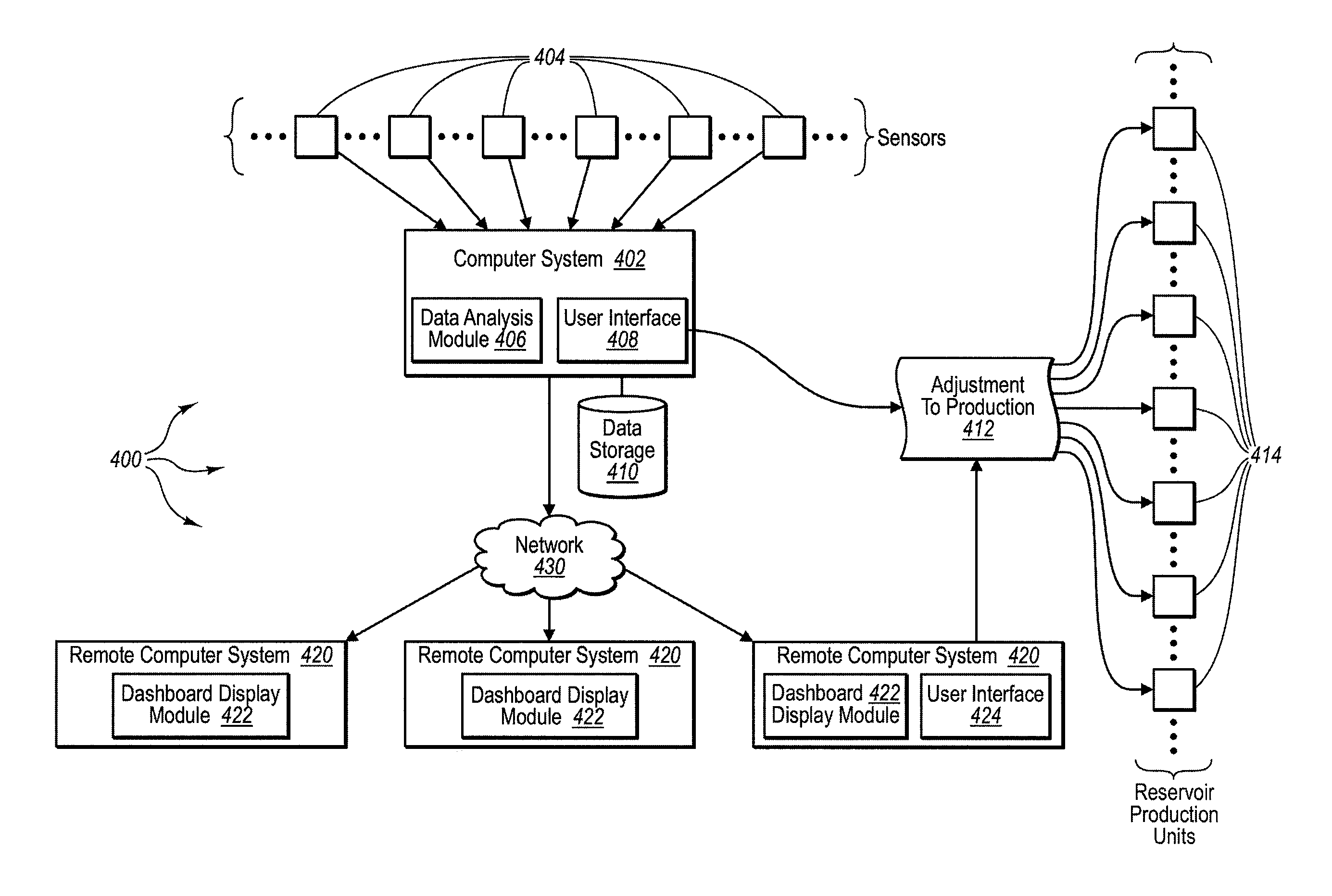

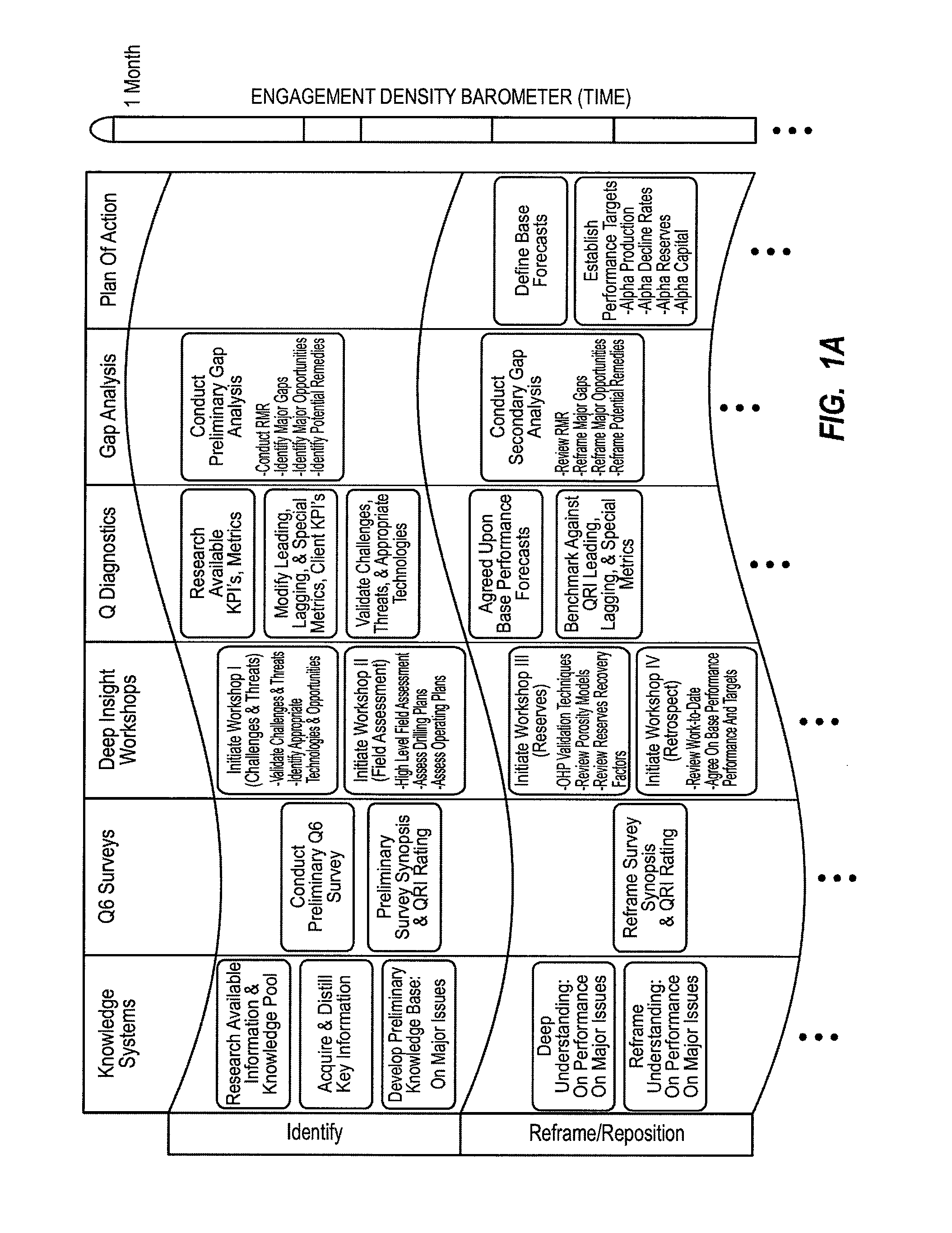

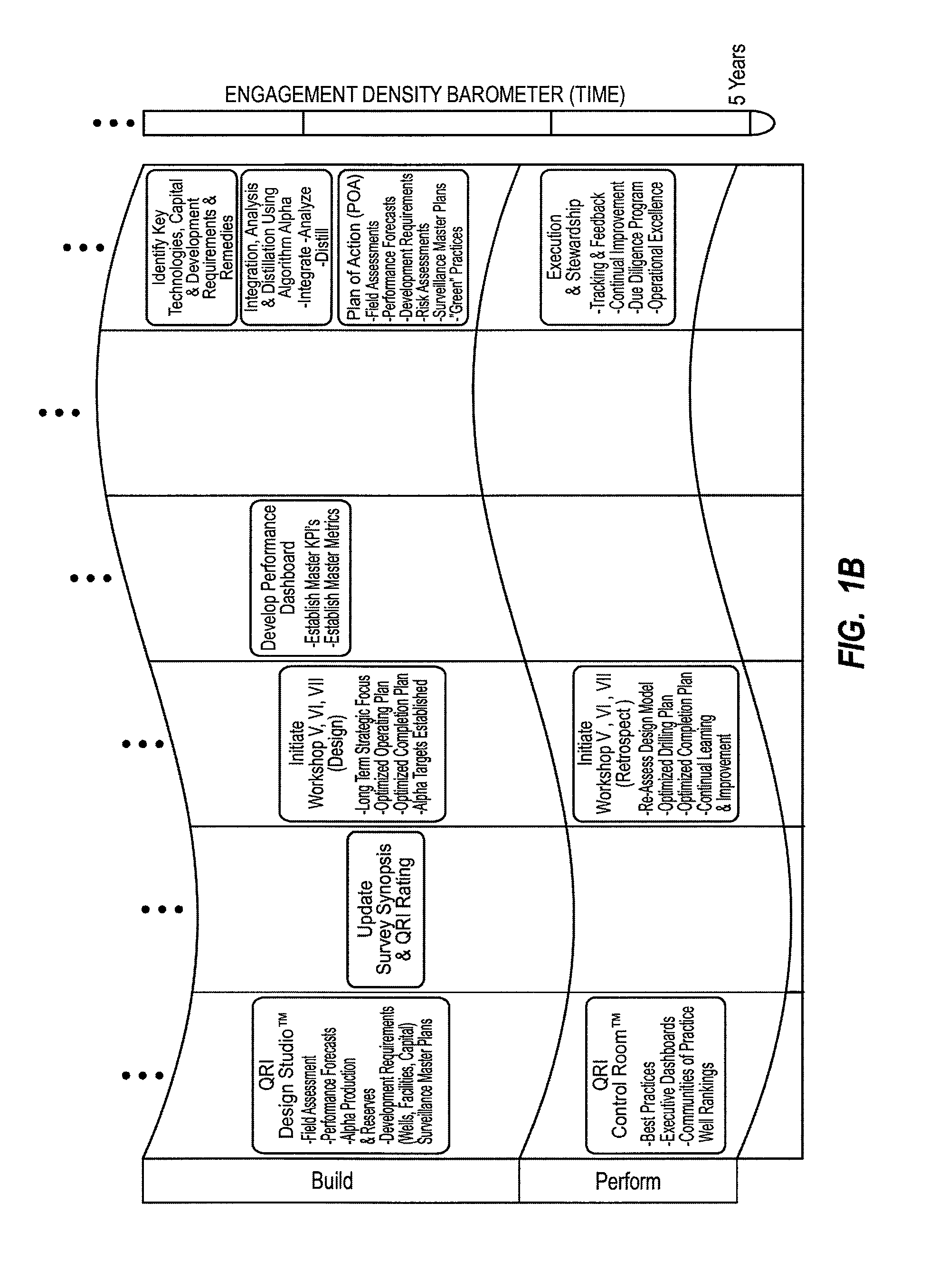

Method for dynamically assessing petroleum reservoir competency and increasing production and recovery through asymmetric analysis of performance metrics

InactiveUS7963327B1Increase short-term production rate and long-term recoveryAccurate assessmentElectric/magnetic detection for well-loggingSurveyProcess engineeringPetroleum reservoir

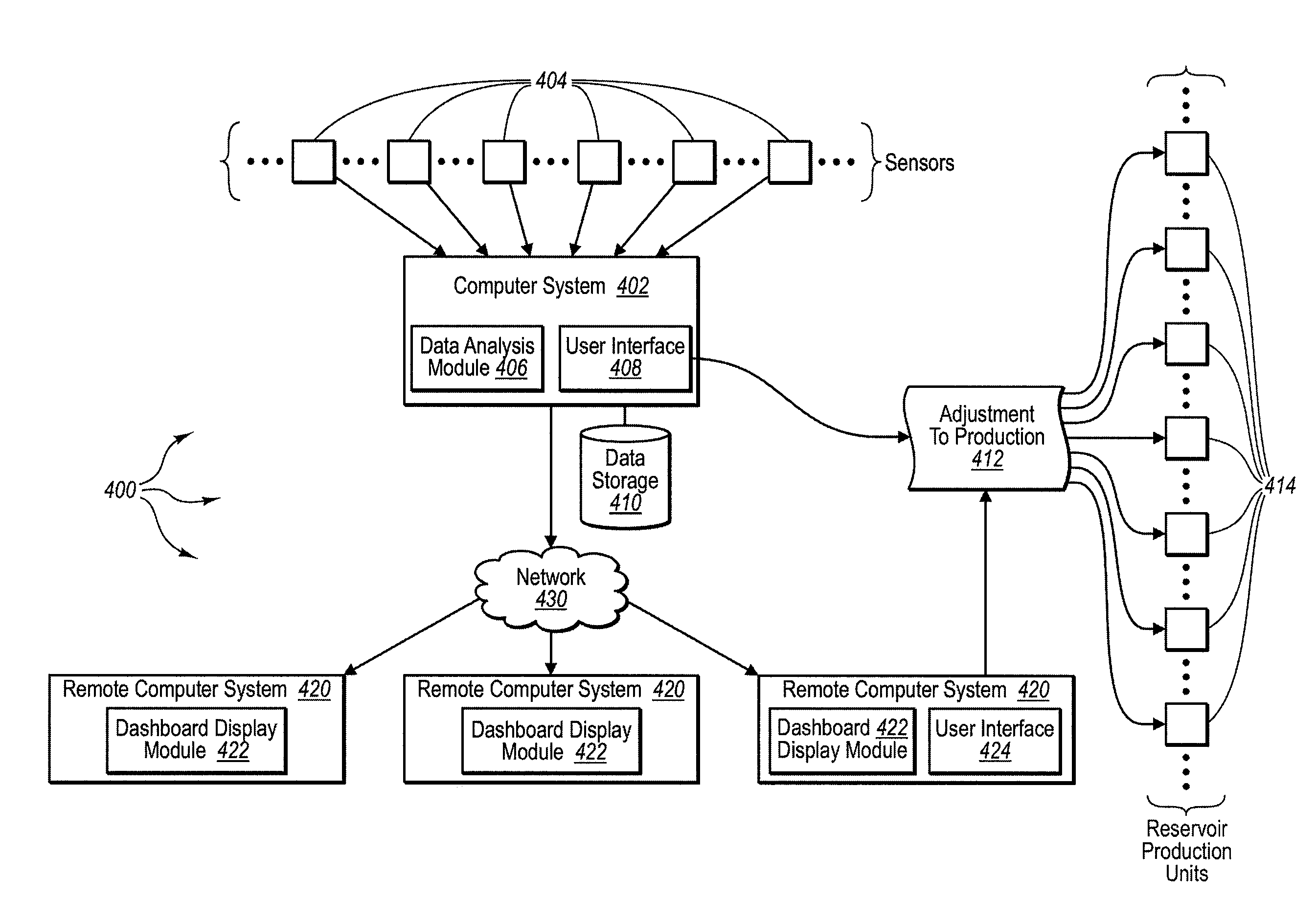

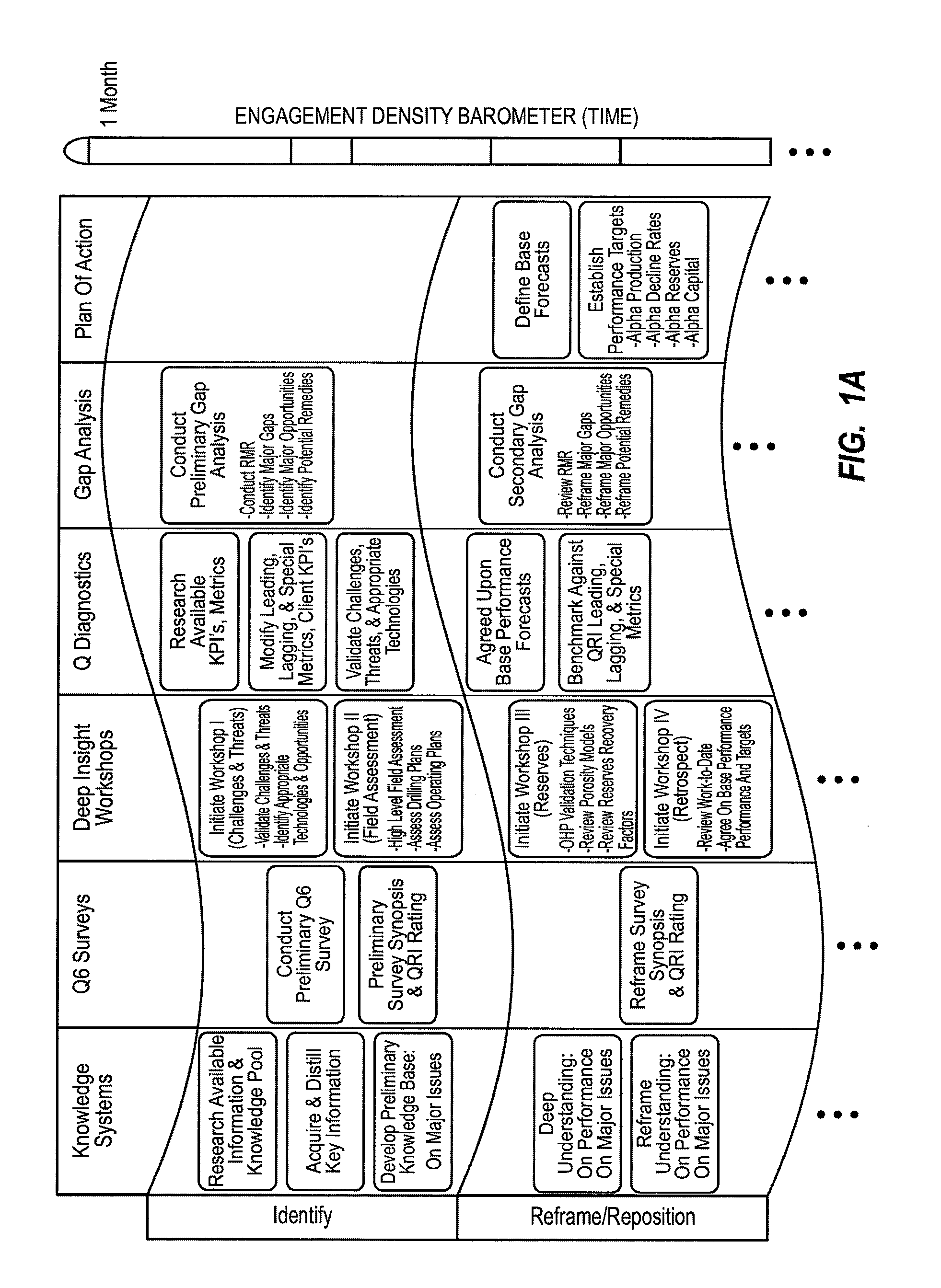

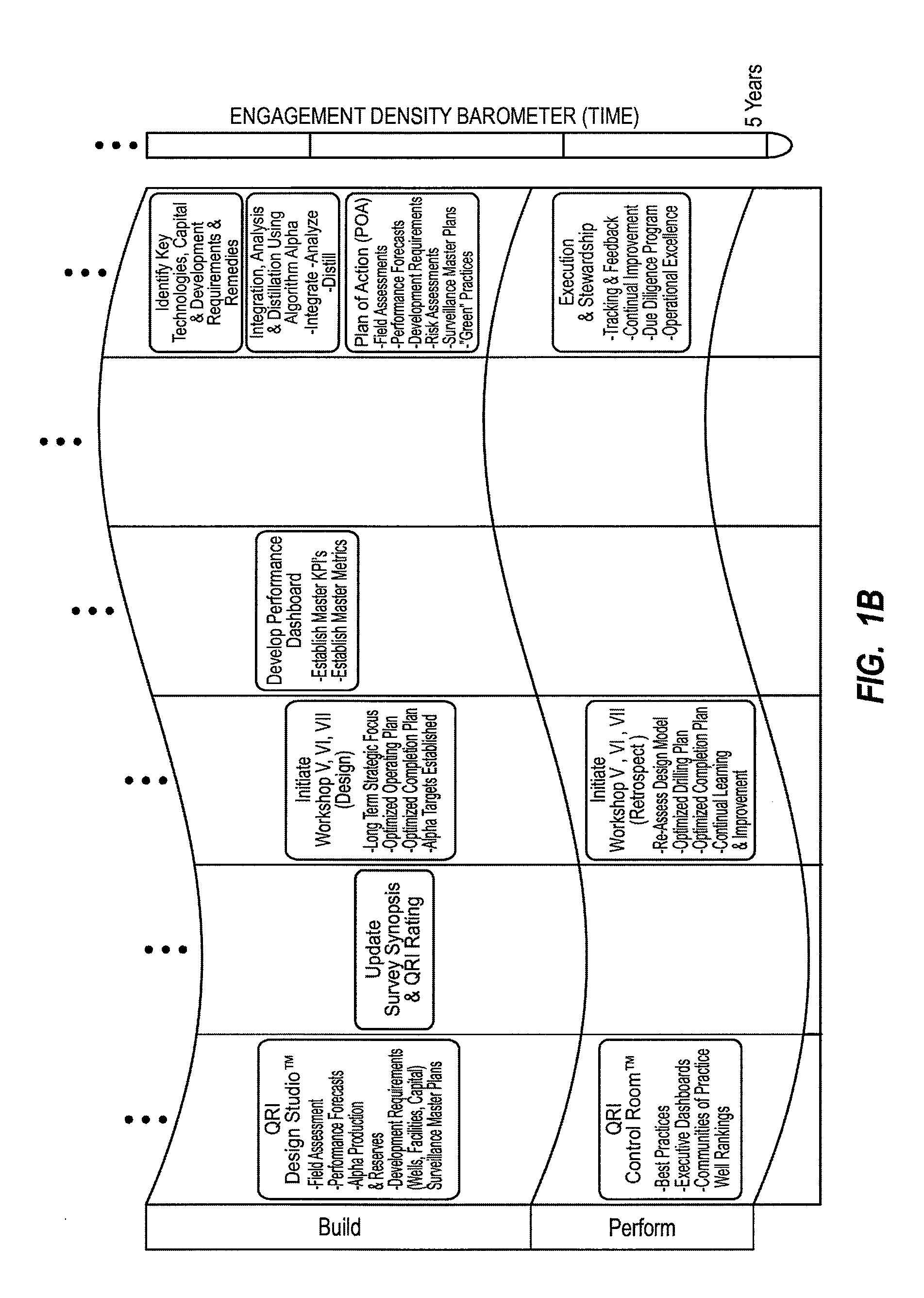

Methods for accurately assessing the condition of a petroleum reservoir and designing and implementing a plan of action to increase production and recovery of petroleum from the reservoir. Information is gathered using a unique set of metrics and information gathering techniques and analyzed in a targeted fashion by properly weighting the data in the context of the particular reservoir and goals of the producer. A reservoir rating is generated using asymmetric analysis of metrics and then used to formulate a plan of action. Production architecture (e.g., number, location and manner of constructing oil and injector wells) is then constructed according to the plan of action. Reservoir performance can be continuously monitored and used to verify production and recovery goals and / or provide triggers or alarms to alter production equipment.

Owner:QRI GROUP

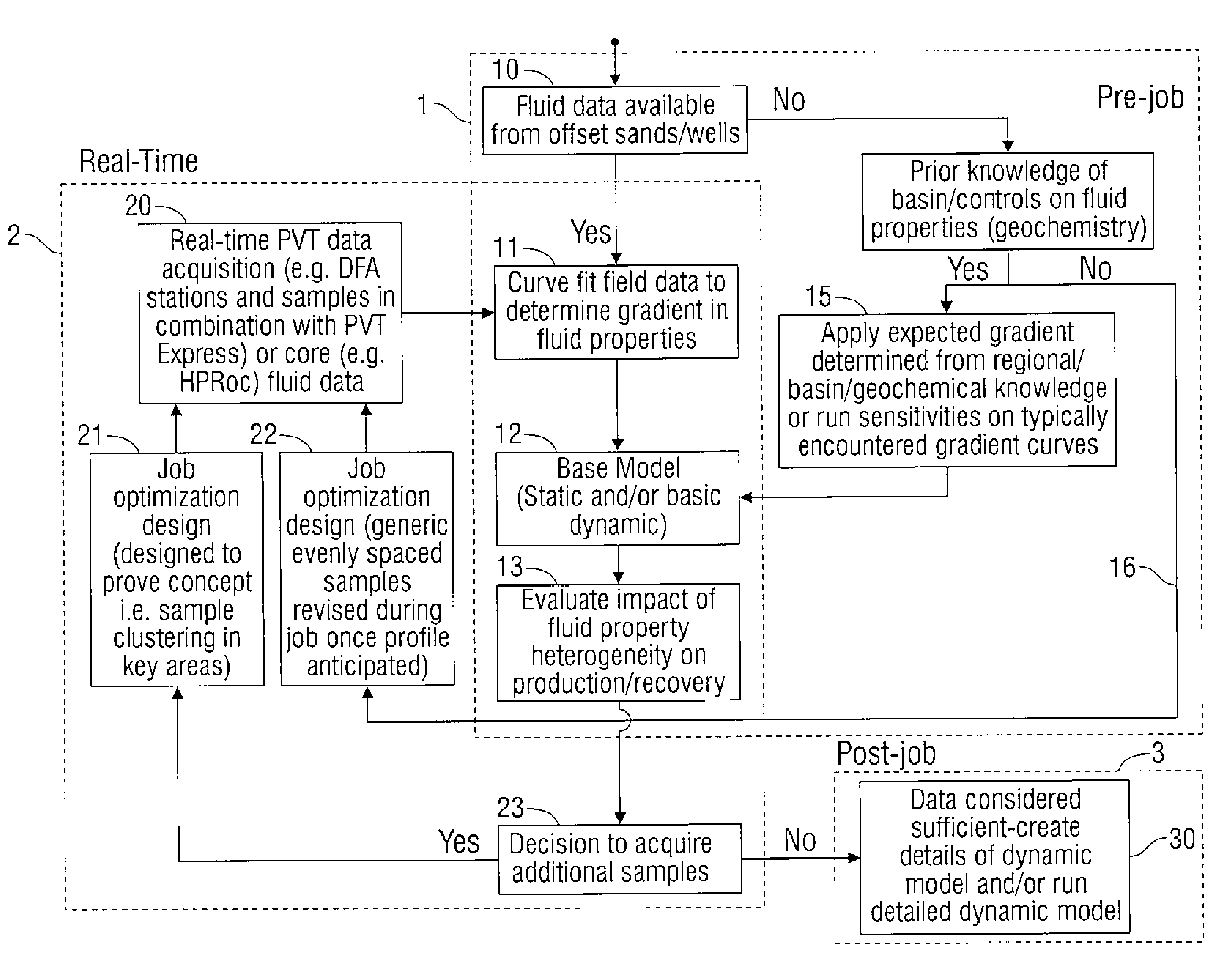

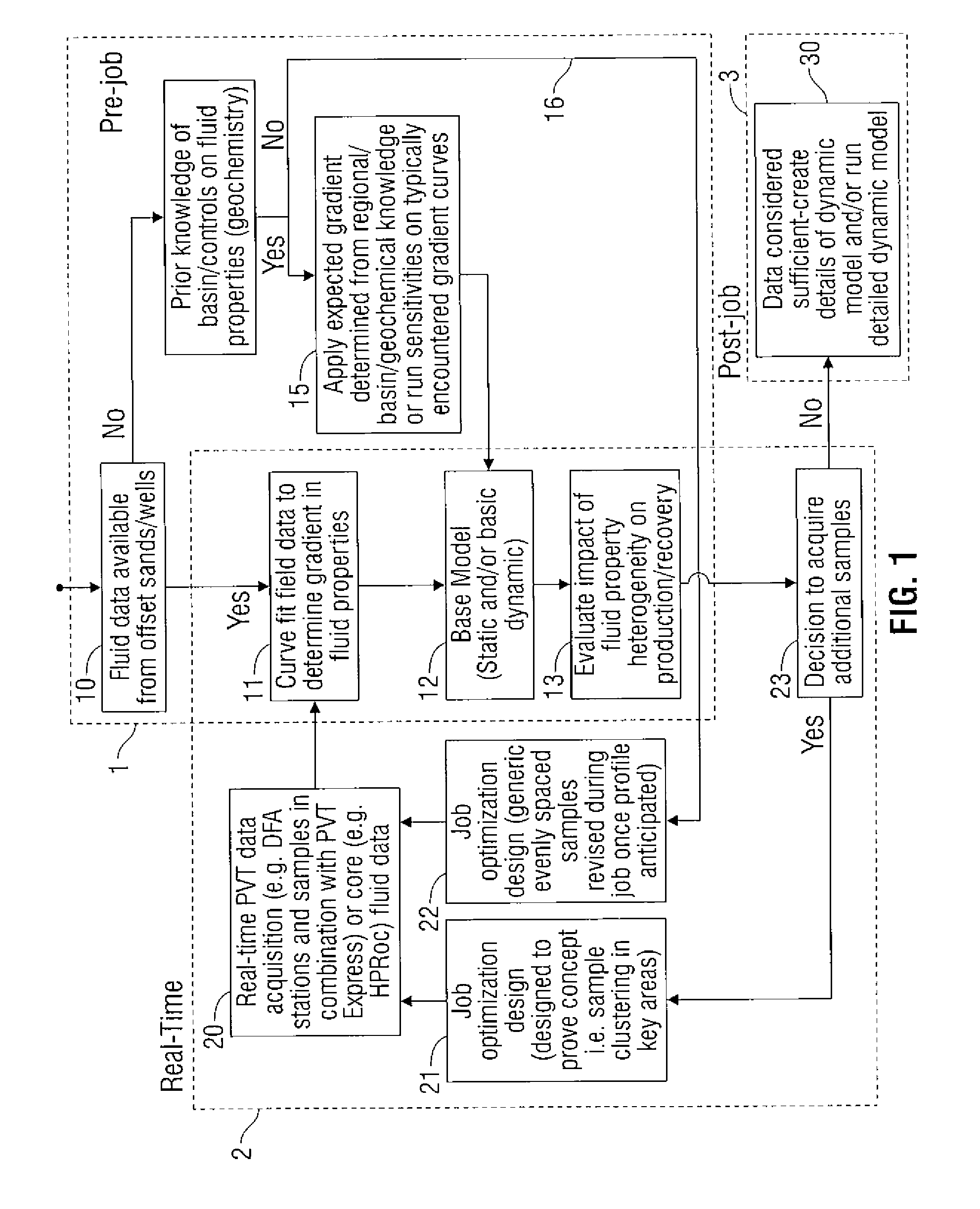

Methods for optimizing petroleum reservoir analysis

InactiveUS20090071239A1Radiation pyrometryMaterial analysis by optical meansRecovery performancePetroleum reservoir

Owner:SCHLUMBERGER TECH CORP

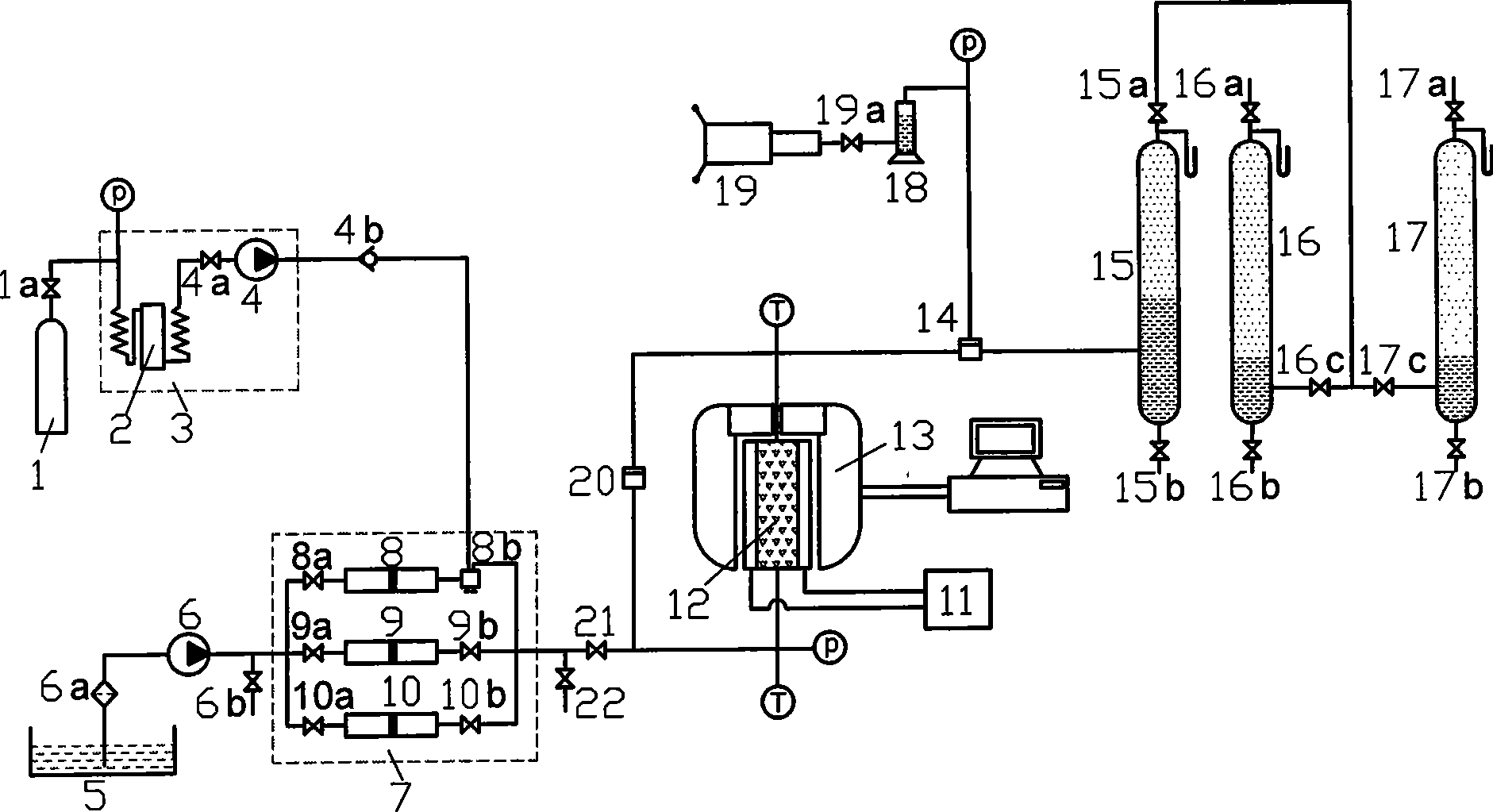

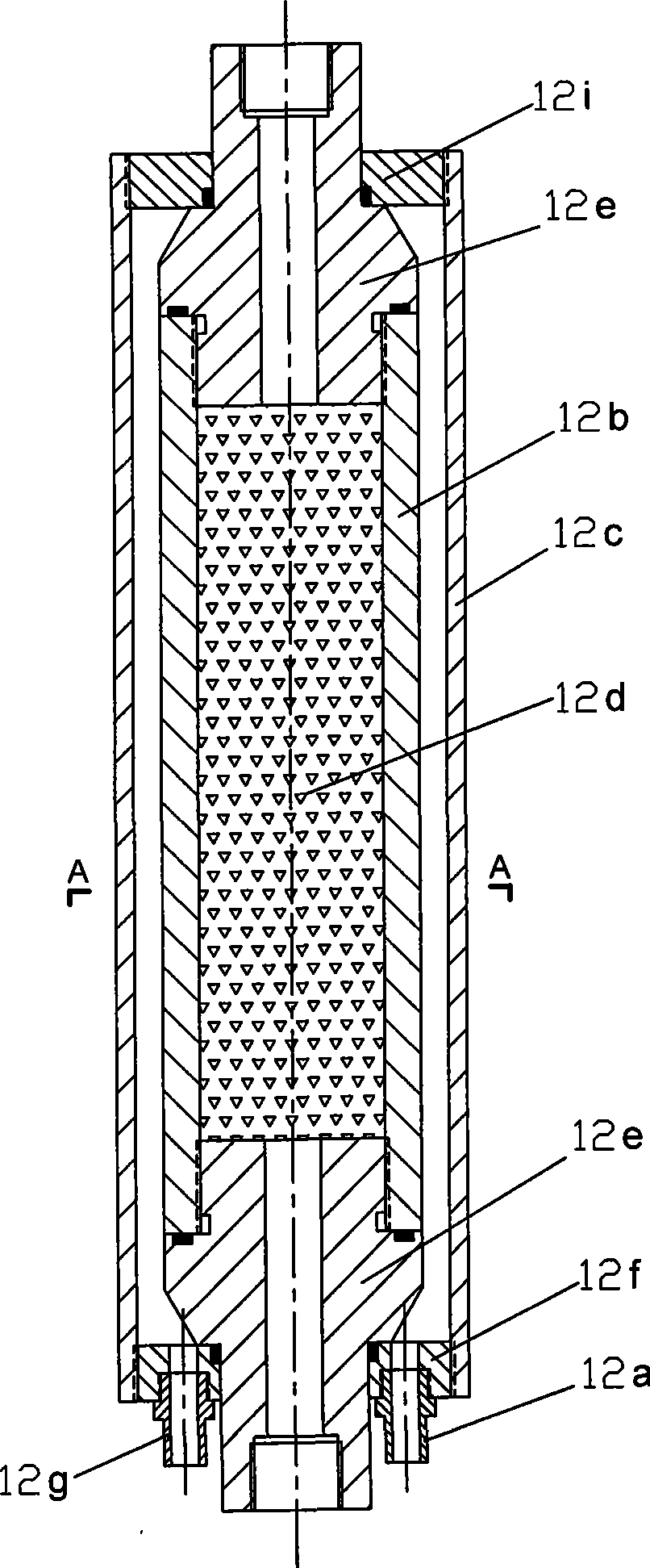

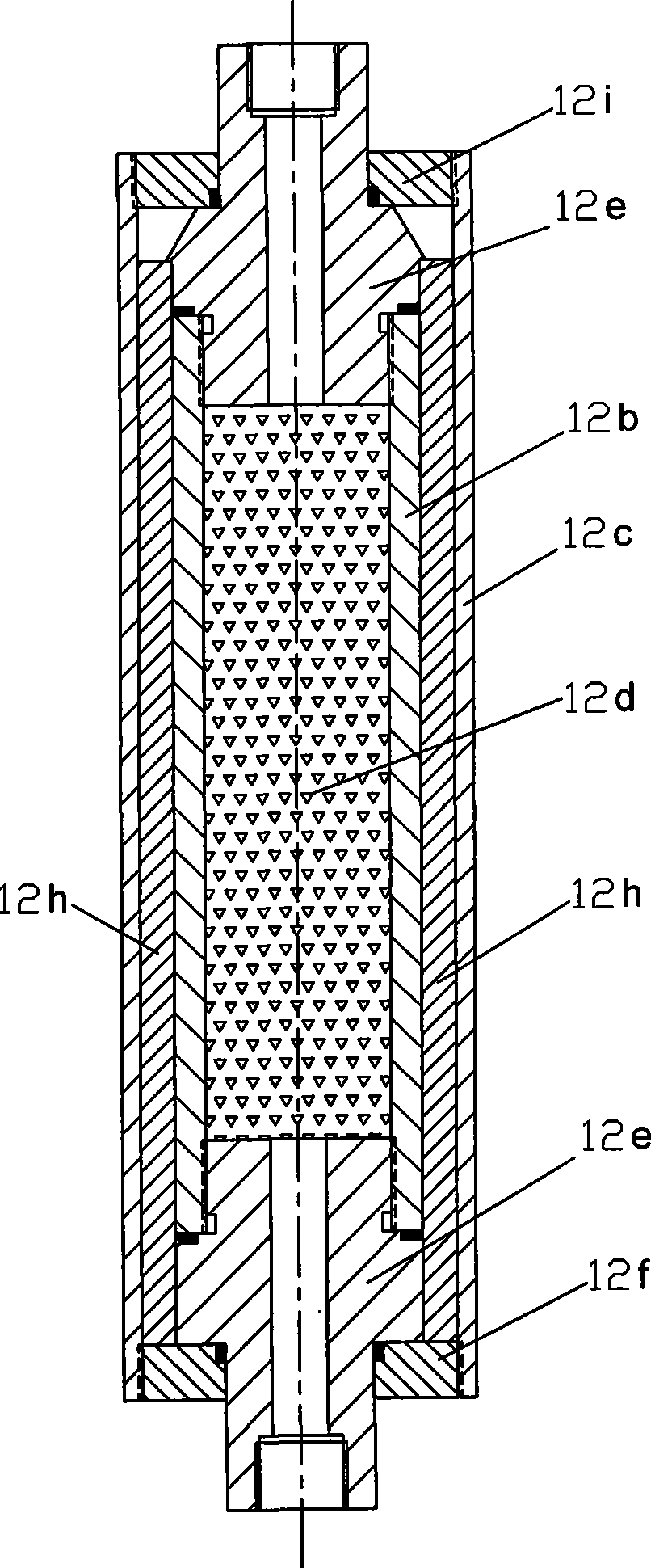

Carbon dioxide oil-displacing nmr imaging detection device

InactiveCN101458218AEasy to meet high pressure strength requirementsCompact designWater resource assessmentAnalysis using nuclear magnetic resonancePorous mediumImage detection

A carbon dioxide drive nuclear magnetic resonance imaging detection device belongs to the technical field of petroleum engineering and technology. The detection device comprises: a simulation core device which is arranged in a nuclear magnetic resonance imaging device; an injection system which sequentially injects formation water, crude oil and supercritical carbon oxide into the simulation core device; a measurement and control system which is employed to control pressure and temperature of the whole system; the nuclear magnetic resonance imaging device which is employed to detect and perform quantitative analysis on an image to be tested to obtain voidage and permeability of a porous medium, and saturation seepage parameters of the supercritical carbon oxide, the formation water and the crude oil; and an output measuring system which is employed to measure volumes of the carbon dioxide gas, the formation water and the crude oil. The detection device has a design pressure of 0-40MPa and design temperature of 0-180 DEG C, and can simulate experimental studies of different displacement schemes of the supercritical CO2 under a complex petroleum reservoir condition; the simulation core device is made of a brass material, which produces no magnetism, satisfies requirements for high pressure and strength, has a compact structure, can be recycled, is conveniently operated, simple and applicable in an experimentation.

Owner:DALIAN UNIV OF TECH

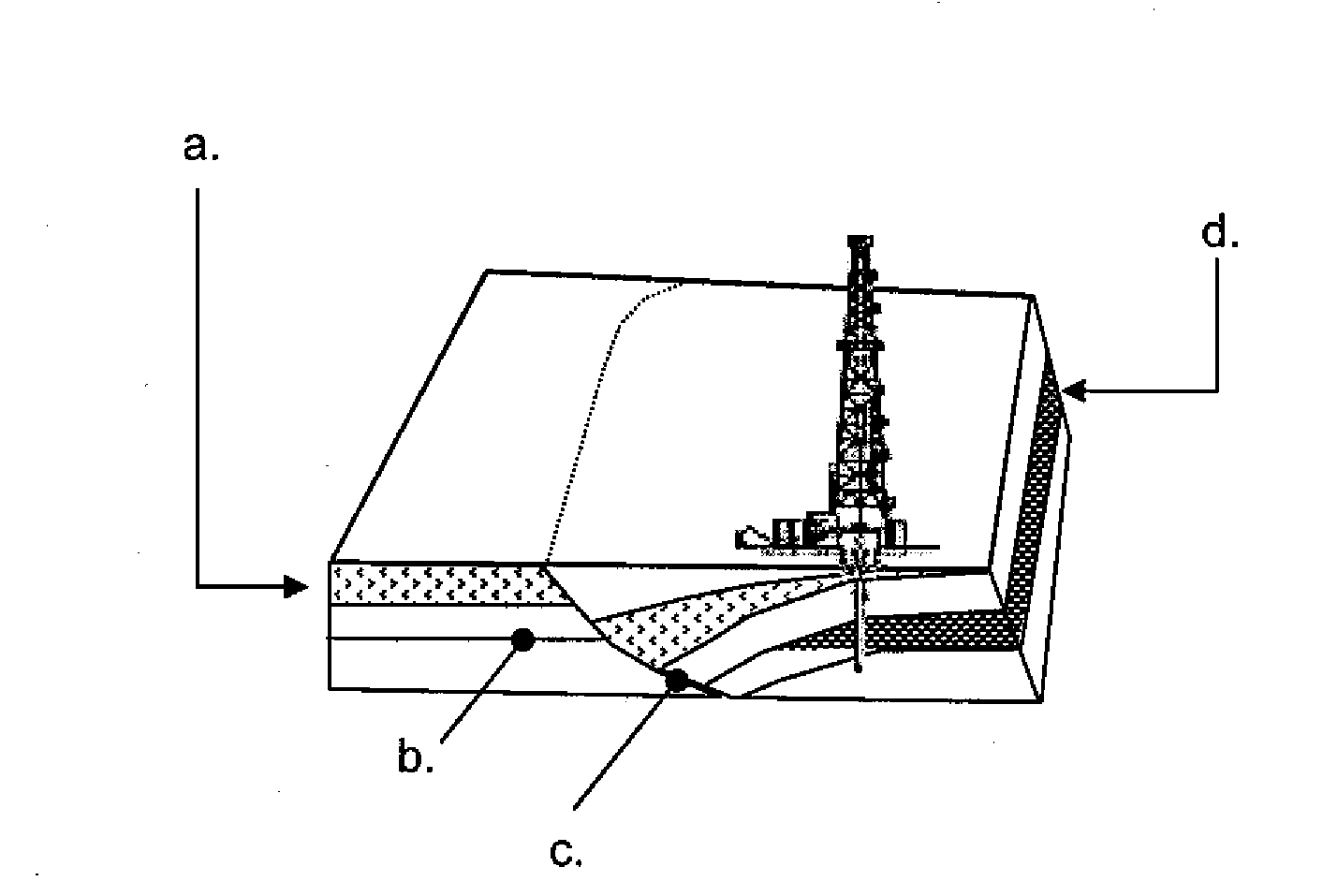

Method of seeking hydrocarbons in a geologically complex basin, by means of basin modeling

ActiveUS20090265152A1Electric/magnetic detection for well-loggingSeismology for water-loggingGeomorphologyStructure of the Earth

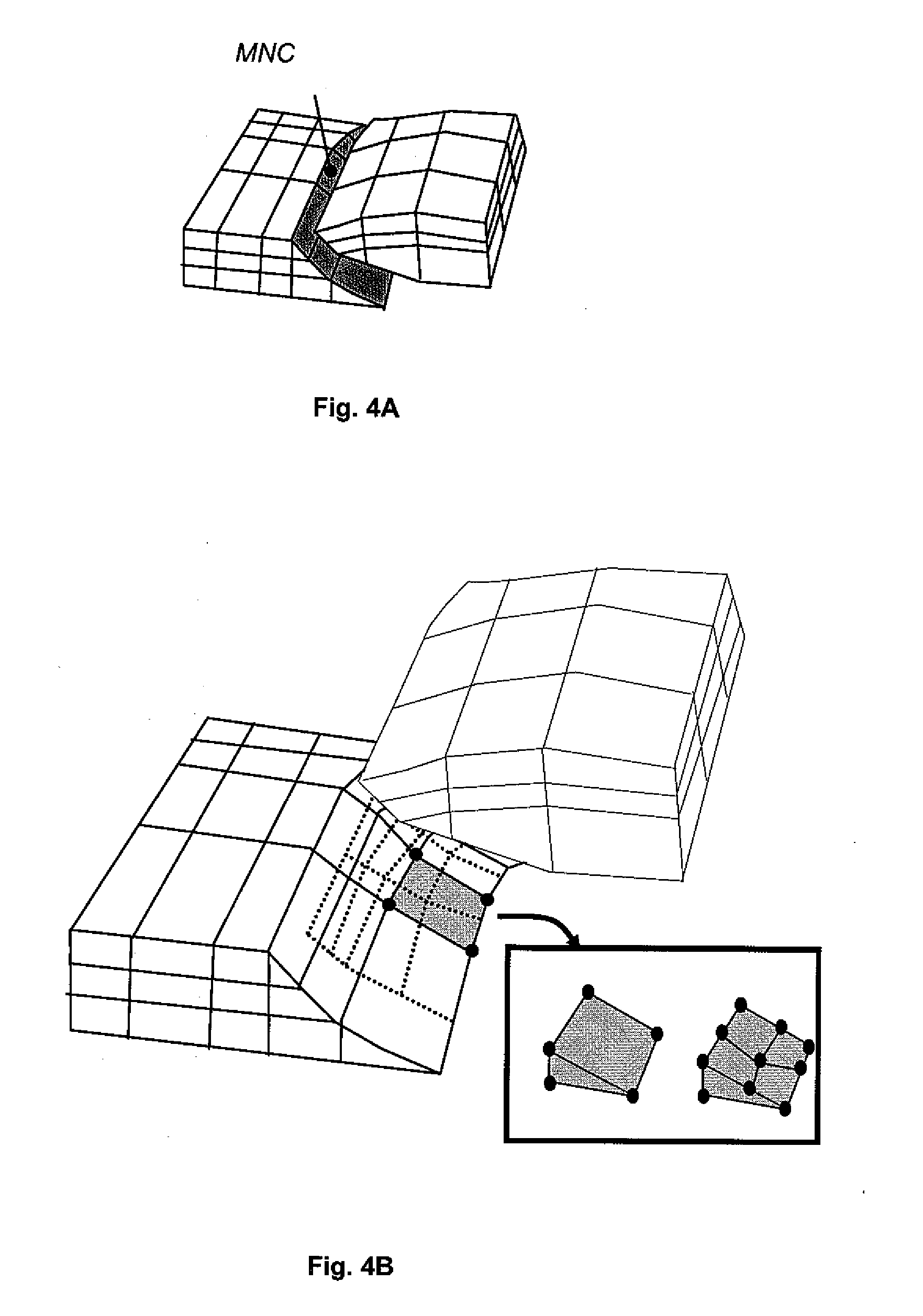

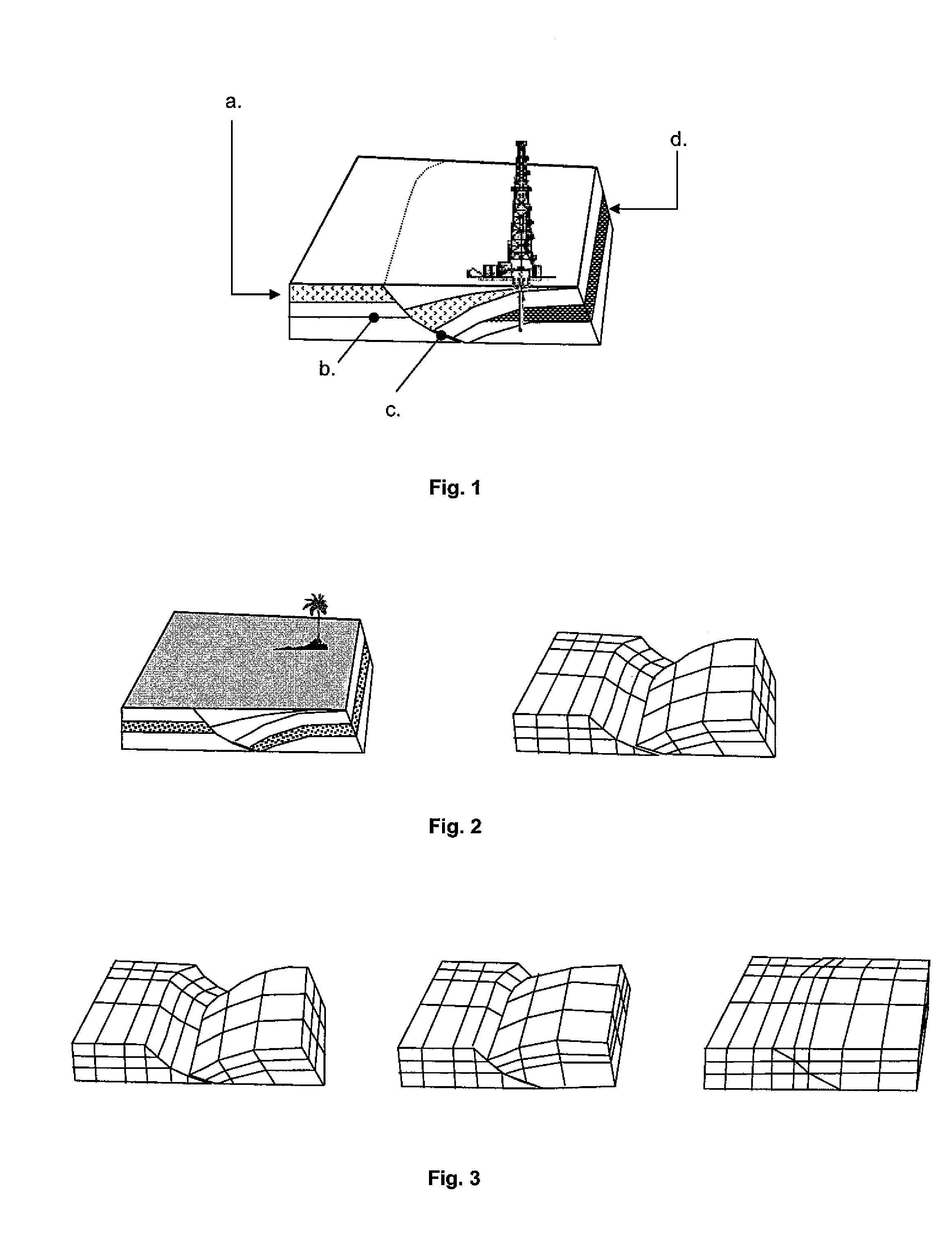

A method for mapping a complex sedimentary basin is disclosed. A grid representative of the current architecture of the basin is constructed. A mechanical structural restoration is applied in three dimensions so as to reconstruct the past architectures of the basin from the current time up to a geological time t. A simulation of the geological and geochemical processes that govern the formation of a petroleum reservoir is then carried out, directly in the grids obtained from the restoration, from the geological time t to the current one. This simulation is thereafter used for mapping the sedimentary basin so as to identify zones of the basin where hydrocarbons may have accumulated.

Owner:INST FR DU PETROLE

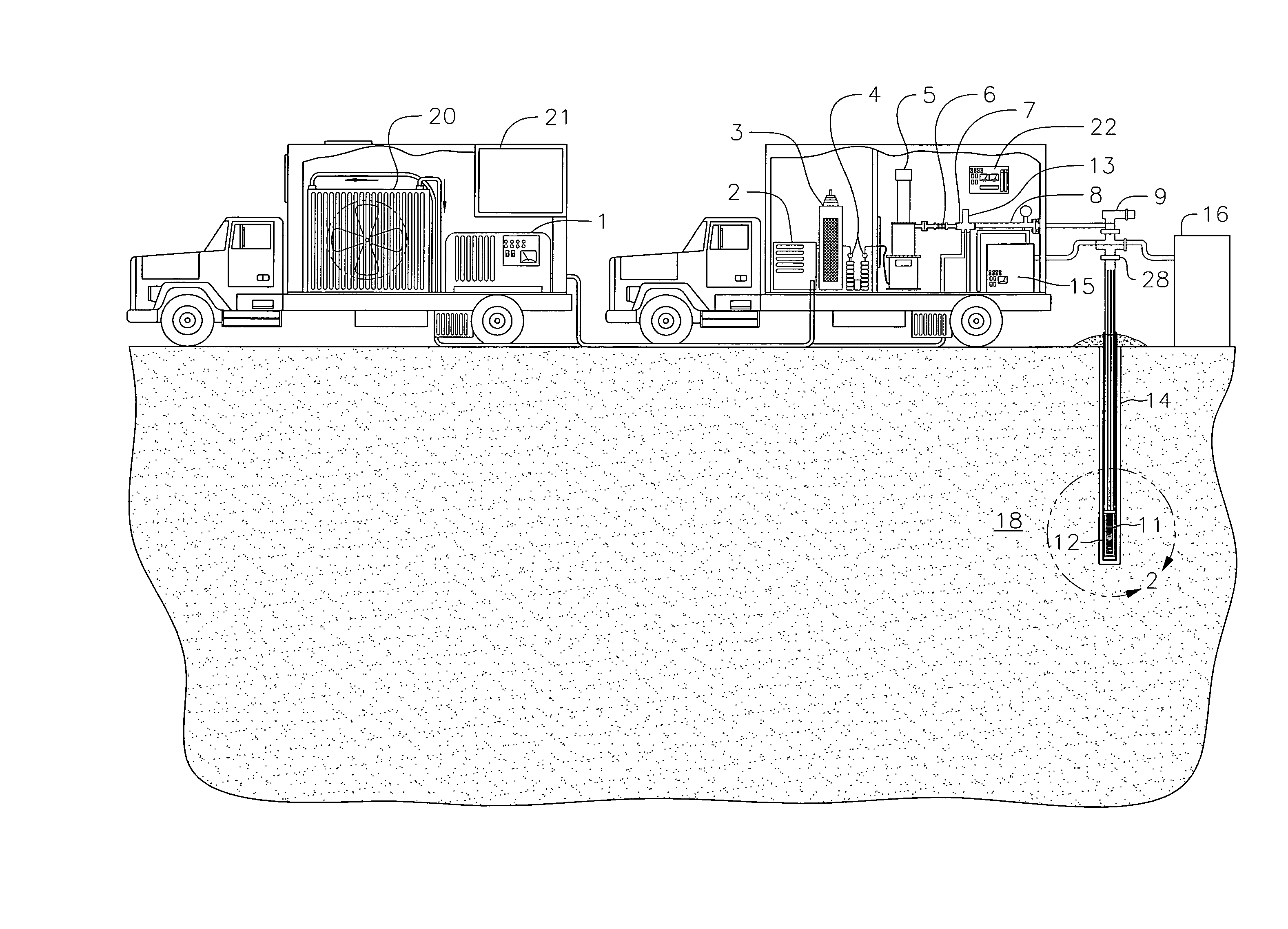

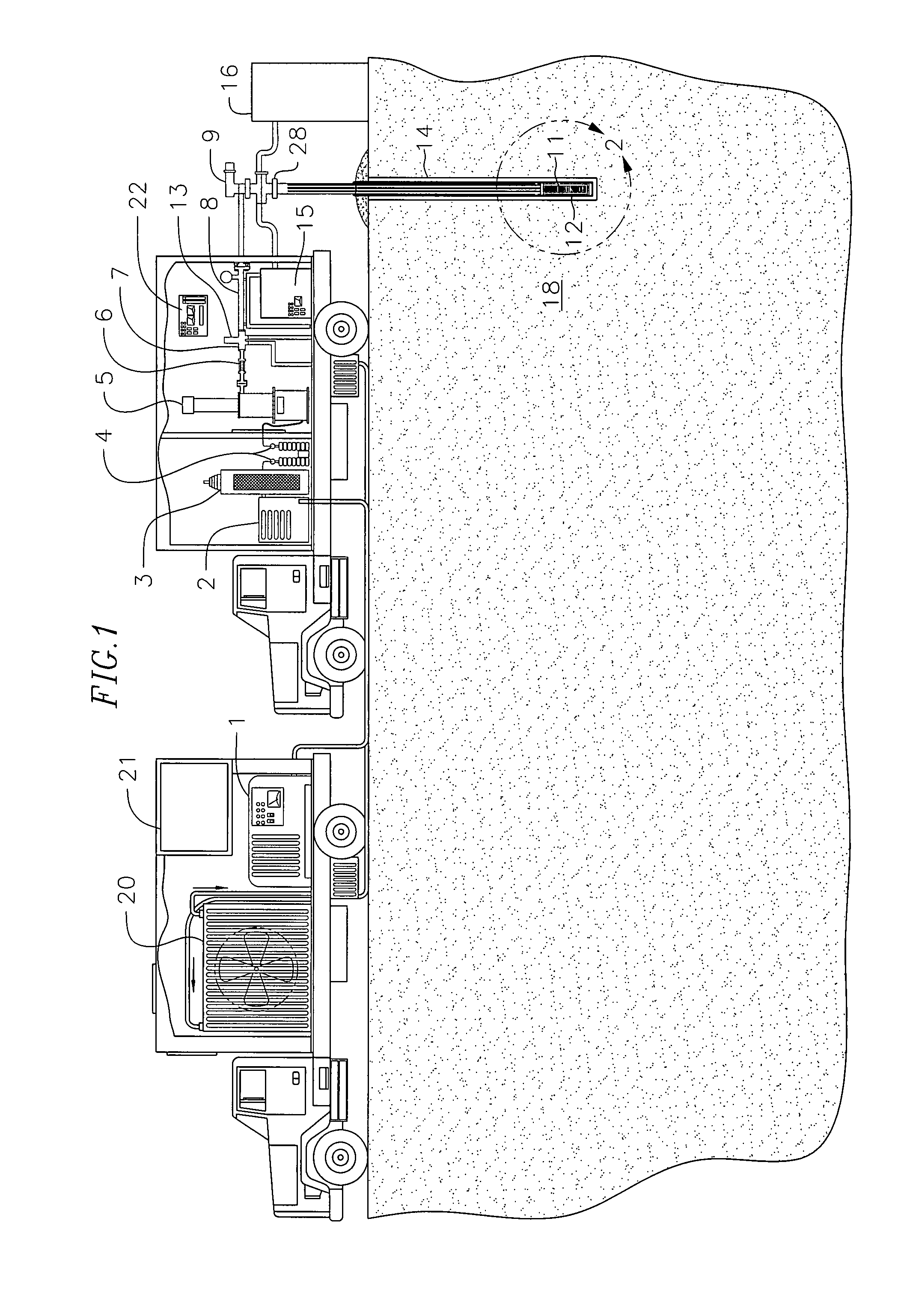

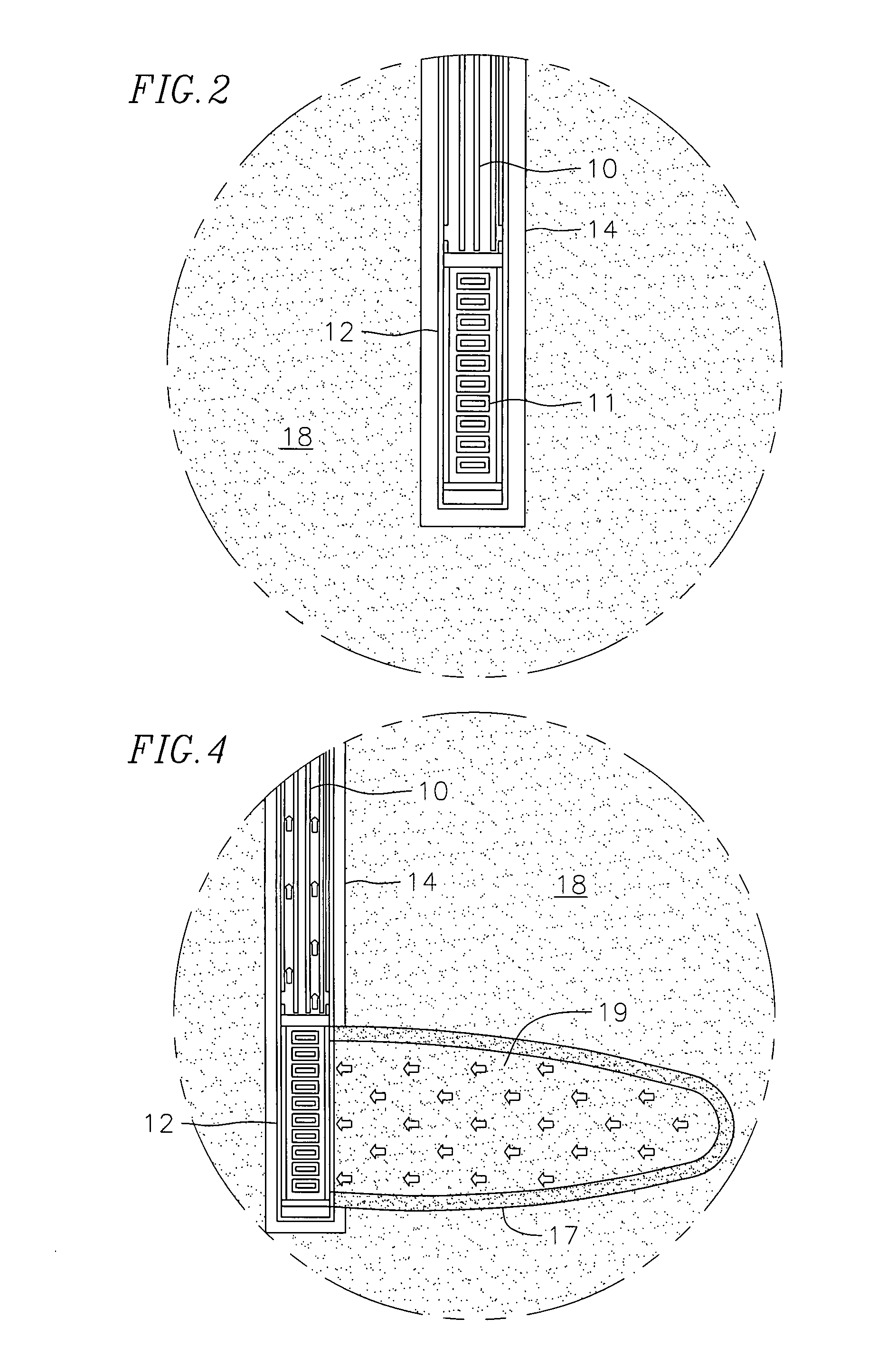

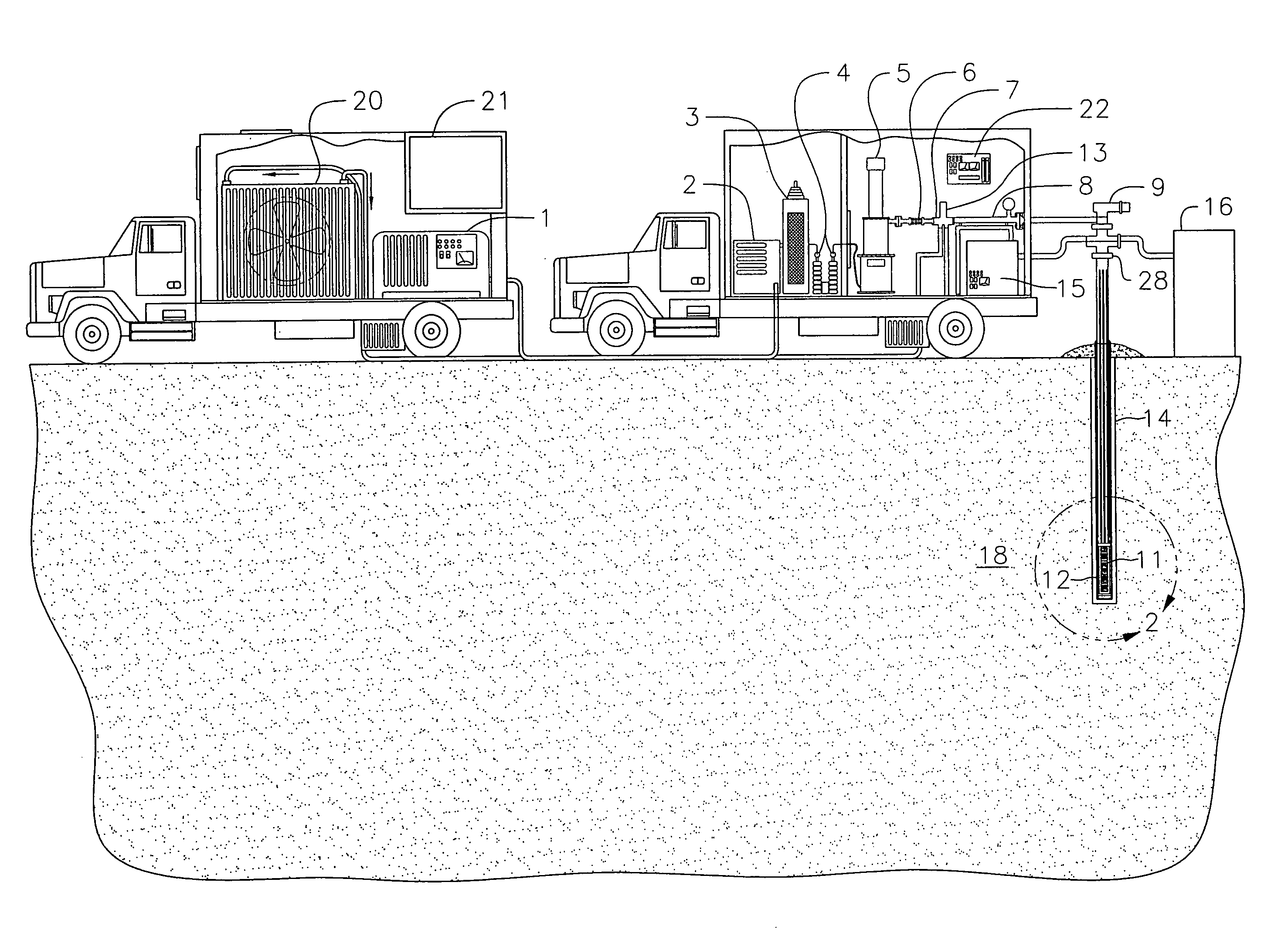

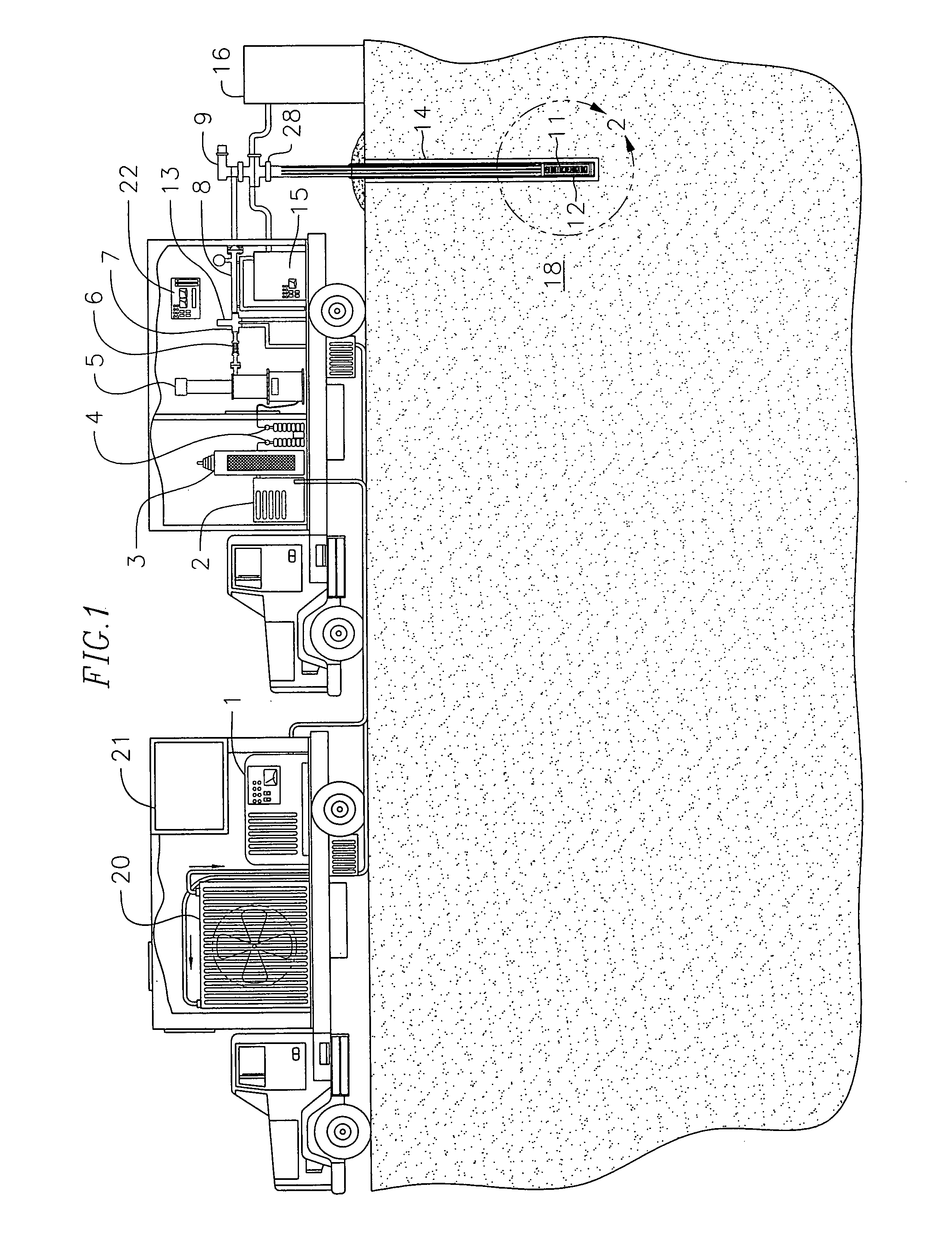

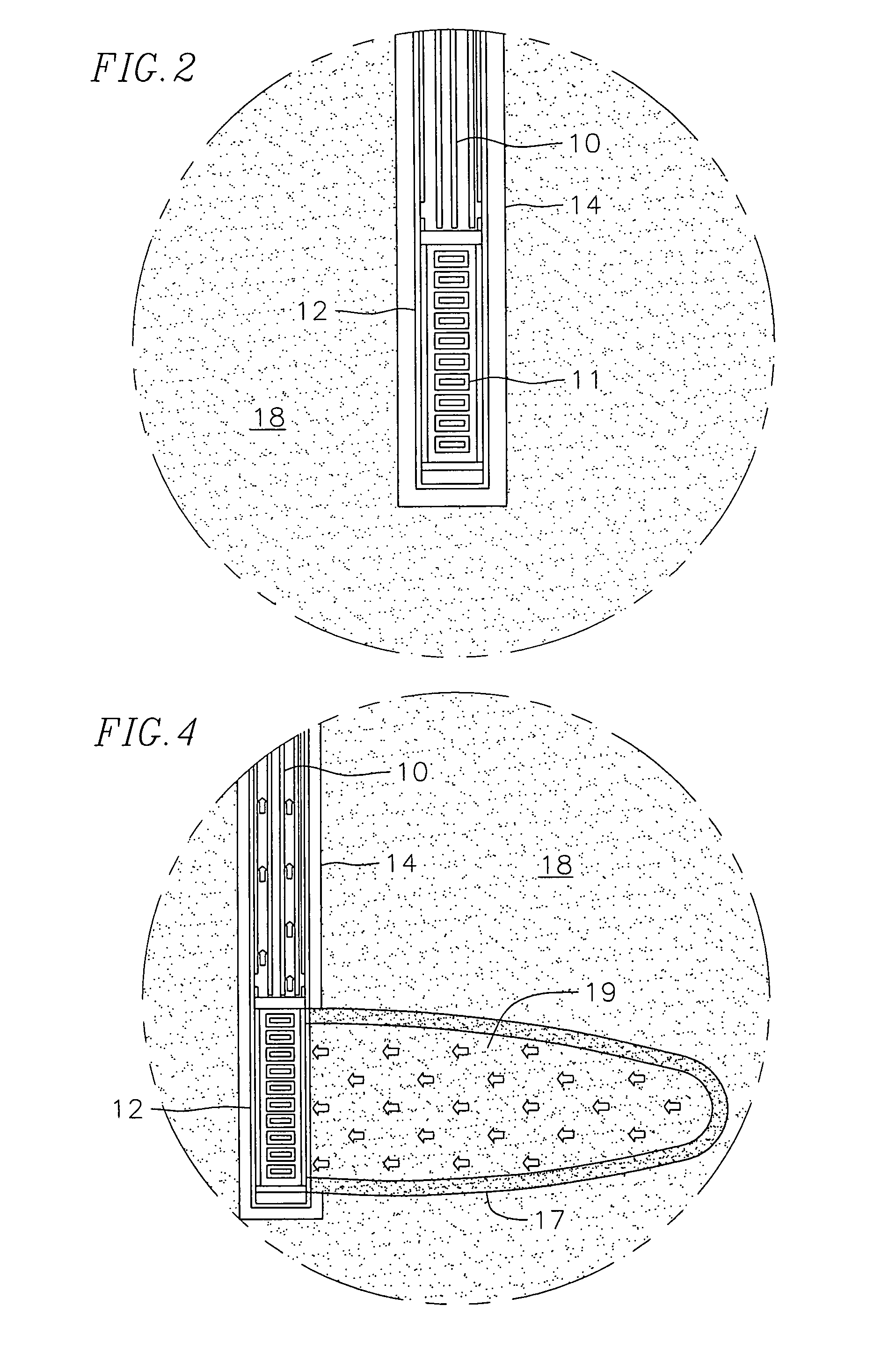

Microwave process for intrinsic permeability enhancement and hydrocarbon extraction from subsurface deposits

Hydrocarbons are extracted from a target formation, such as oil shale, tar sands, heavy oil and petroleum reservoirs, by apparatus and methods which cause fracturing of the containment rock and liquification or volatization of the hydrocarbons by microwave energy directed by a radiating antenna in the target formation.

Owner:GEOSCI SERVICES +1

Method for dynamically assessing petroleum reservoir competency and increasing production and recovery through asymmetric analysis of performance metrics

InactiveUS20110168391A1Increase short-term production rate and long-term recoveryAccurate assessmentElectric/magnetic detection for well-loggingSurveyProcess engineeringPetroleum reservoir

Owner:QRI GROUP

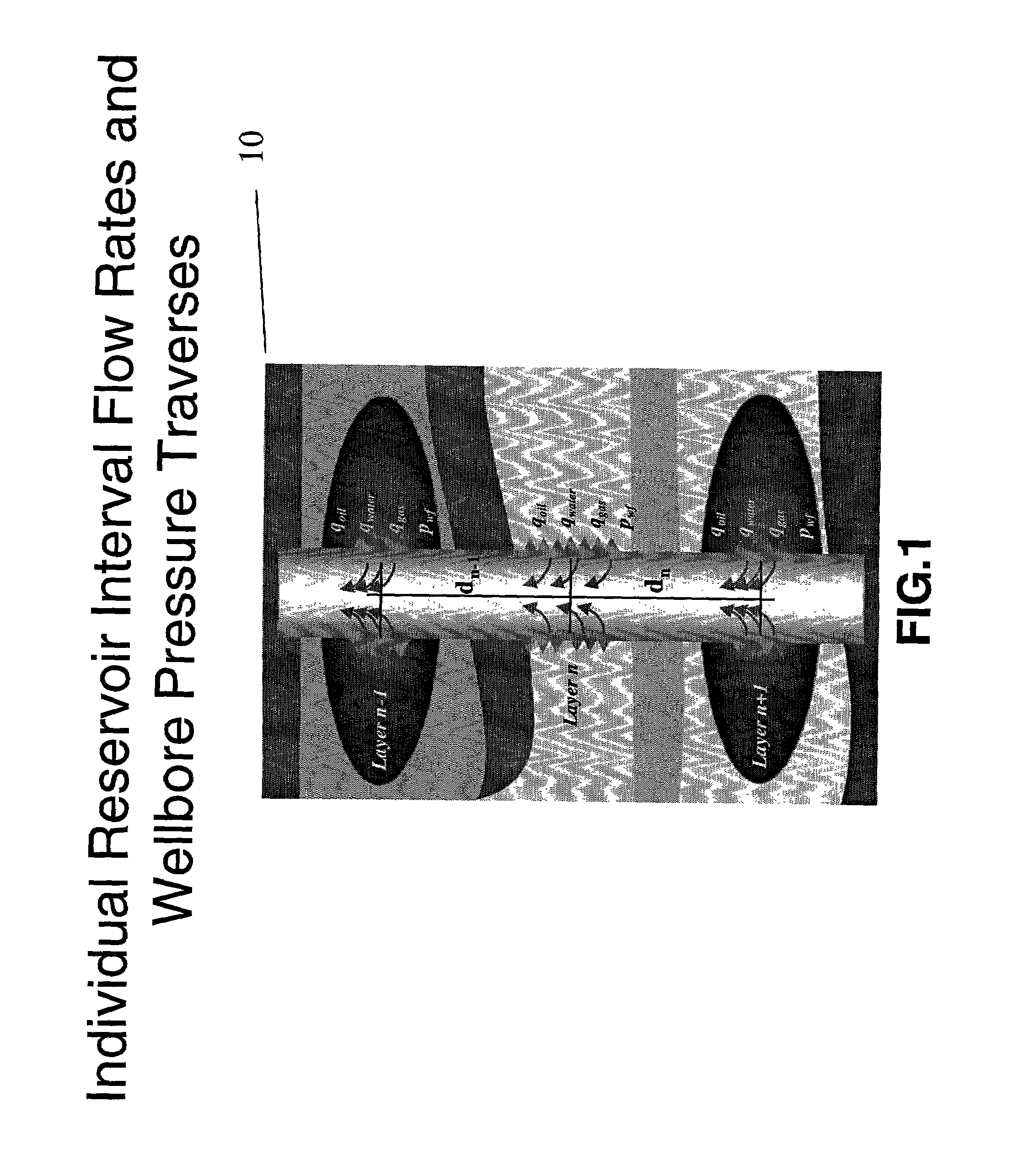

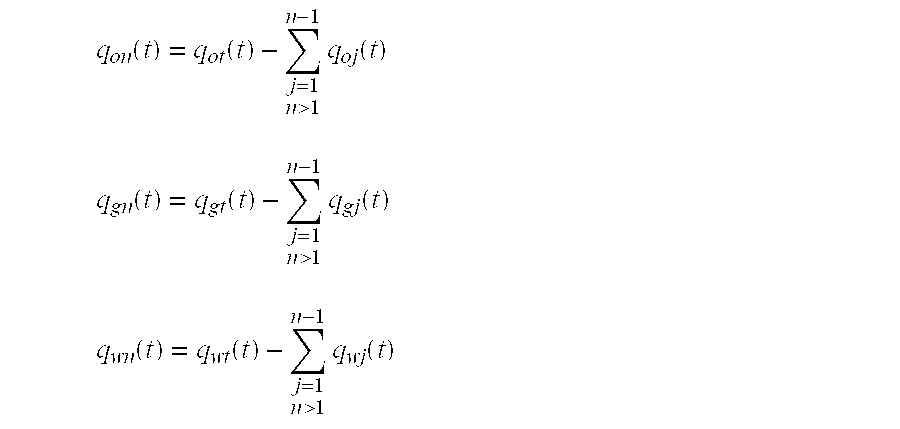

Production optimization methodology for multilayer commingled reservoirs using commingled reservoir production performance data and production logging information

InactiveUS7062420B2Improve productivityEasy to manageElectric/magnetic detection for well-loggingSurveyProduction rateProduction optimization

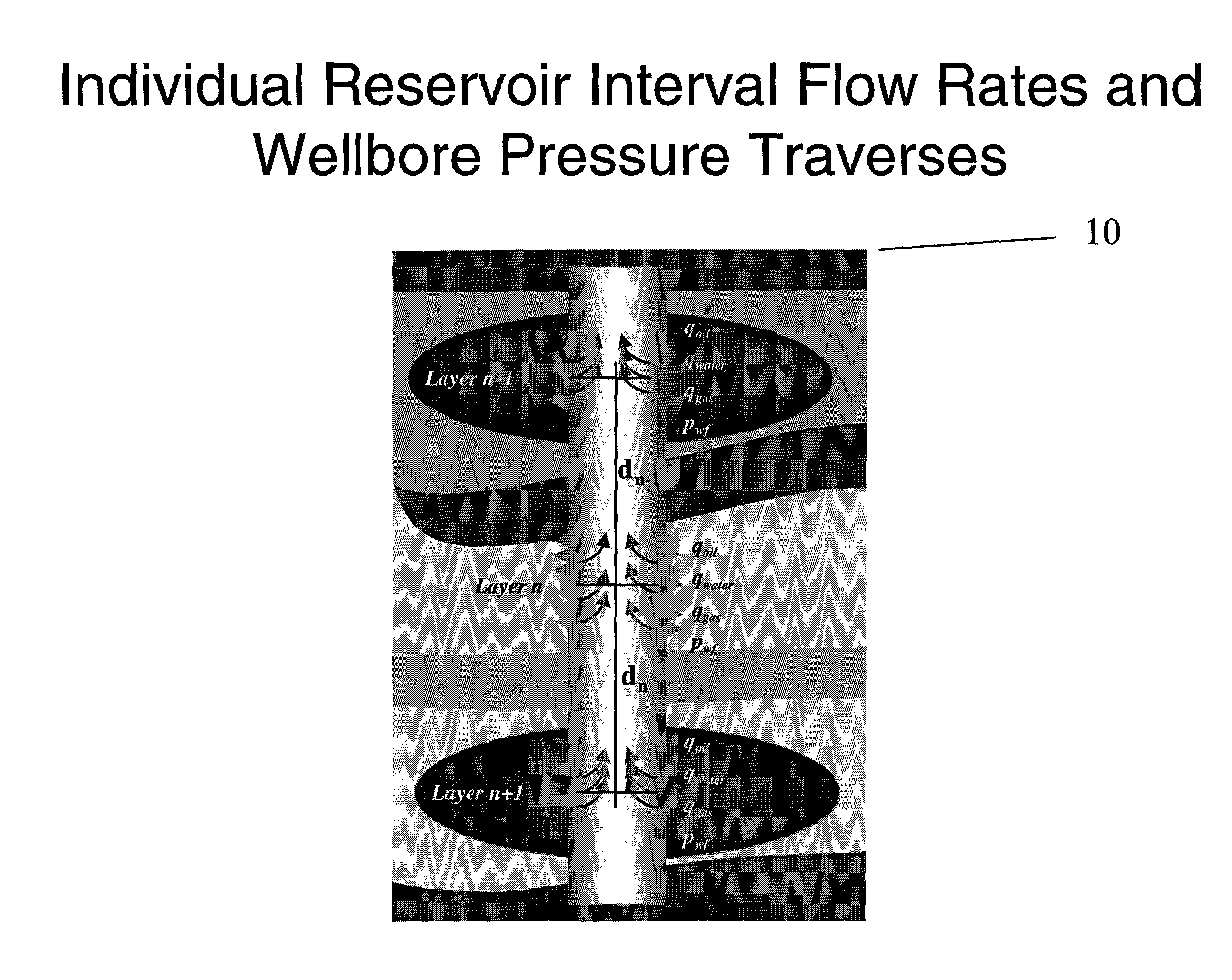

An overall petroleum reservoir production optimization methodology permits the identification and remediation of unstimulated, under-stimulated, or simply poorly performing reservoir completed intervals in a multilayer commingled reservoir that can be recompleted using any of various recompletion methods (including but not limited to hydraulic fracturing, acidization, re-perforation, or drilling of one or more lateral drain holes) to improve the productivity of the well. This provides an excellent reservoir management tool and includes the overall analysis and remediation methodology that has been developed for commingled reservoirs. The specialized recompletion techniques can be used to improve the productivity of previously completed individual reservoir intervals in a commingled reservoir.

Owner:SCHLUMBERGER TECH CORP

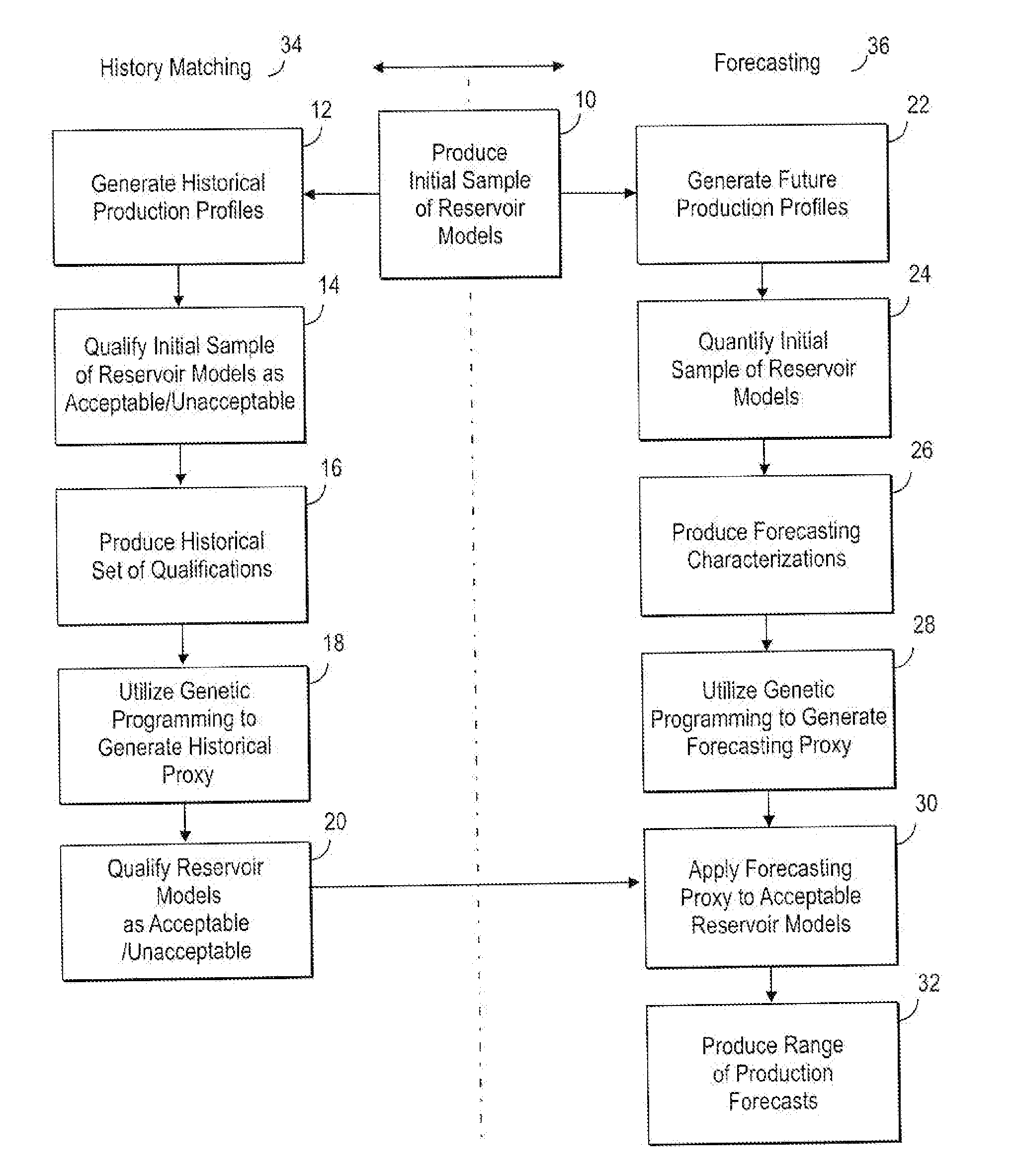

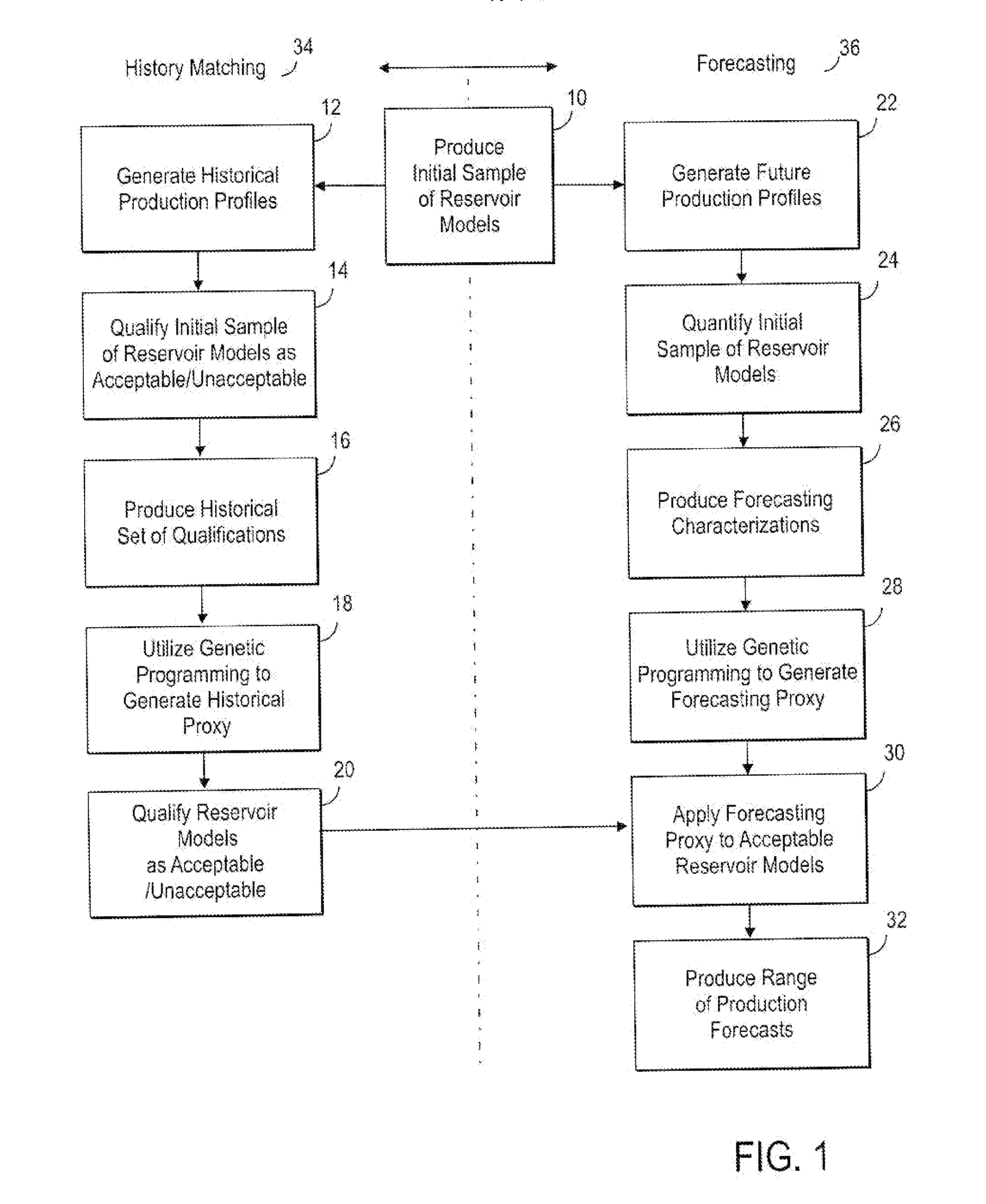

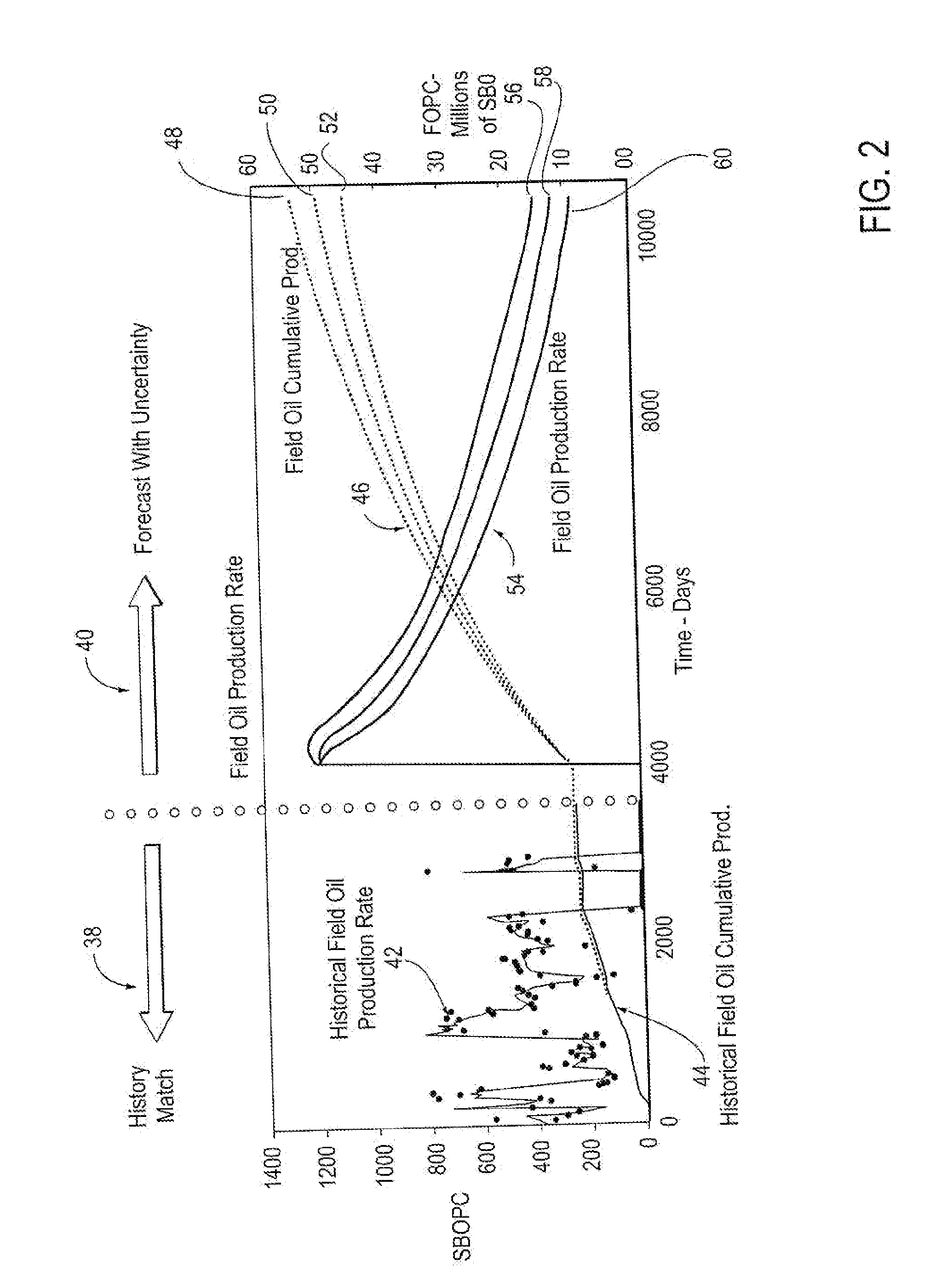

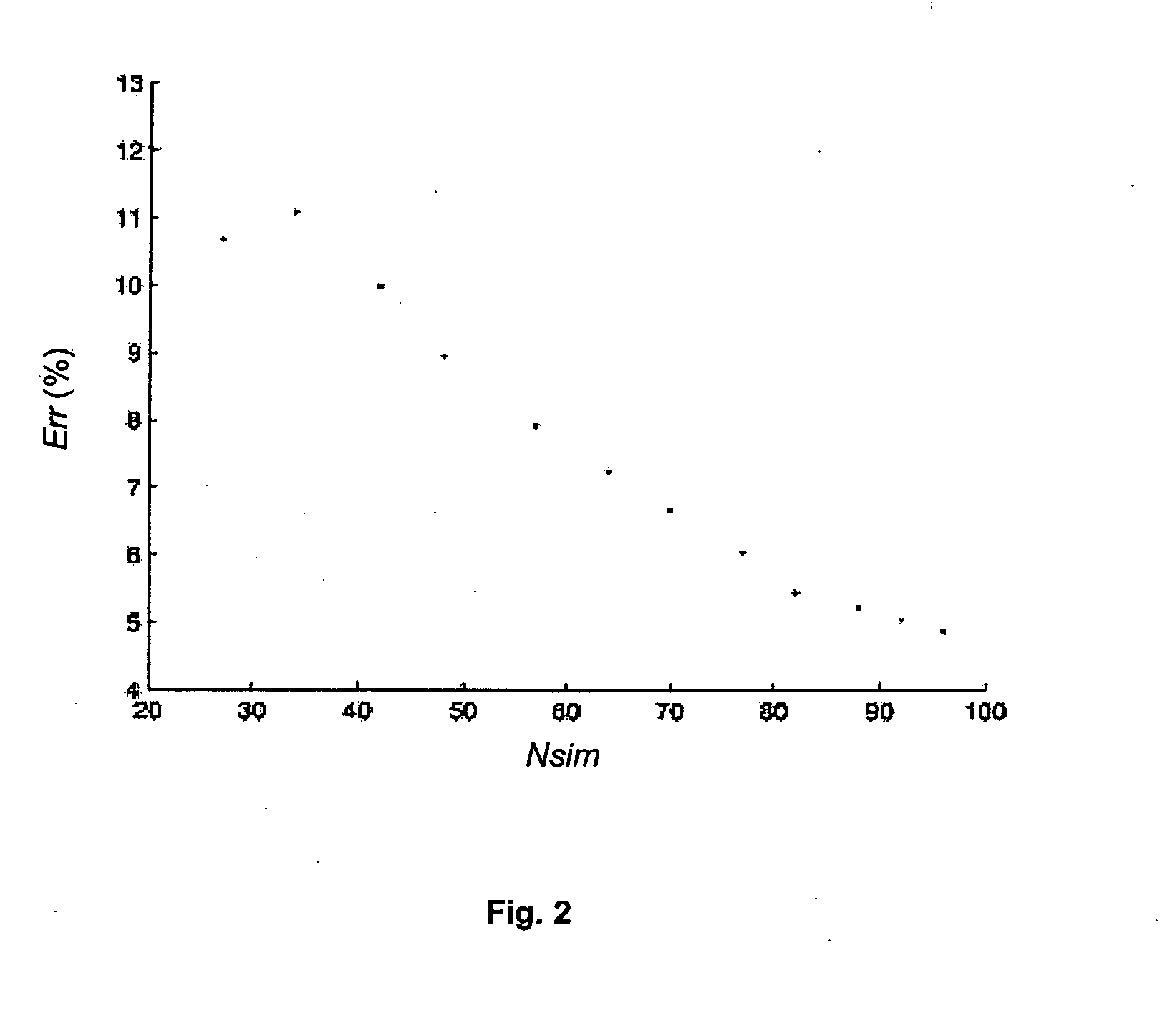

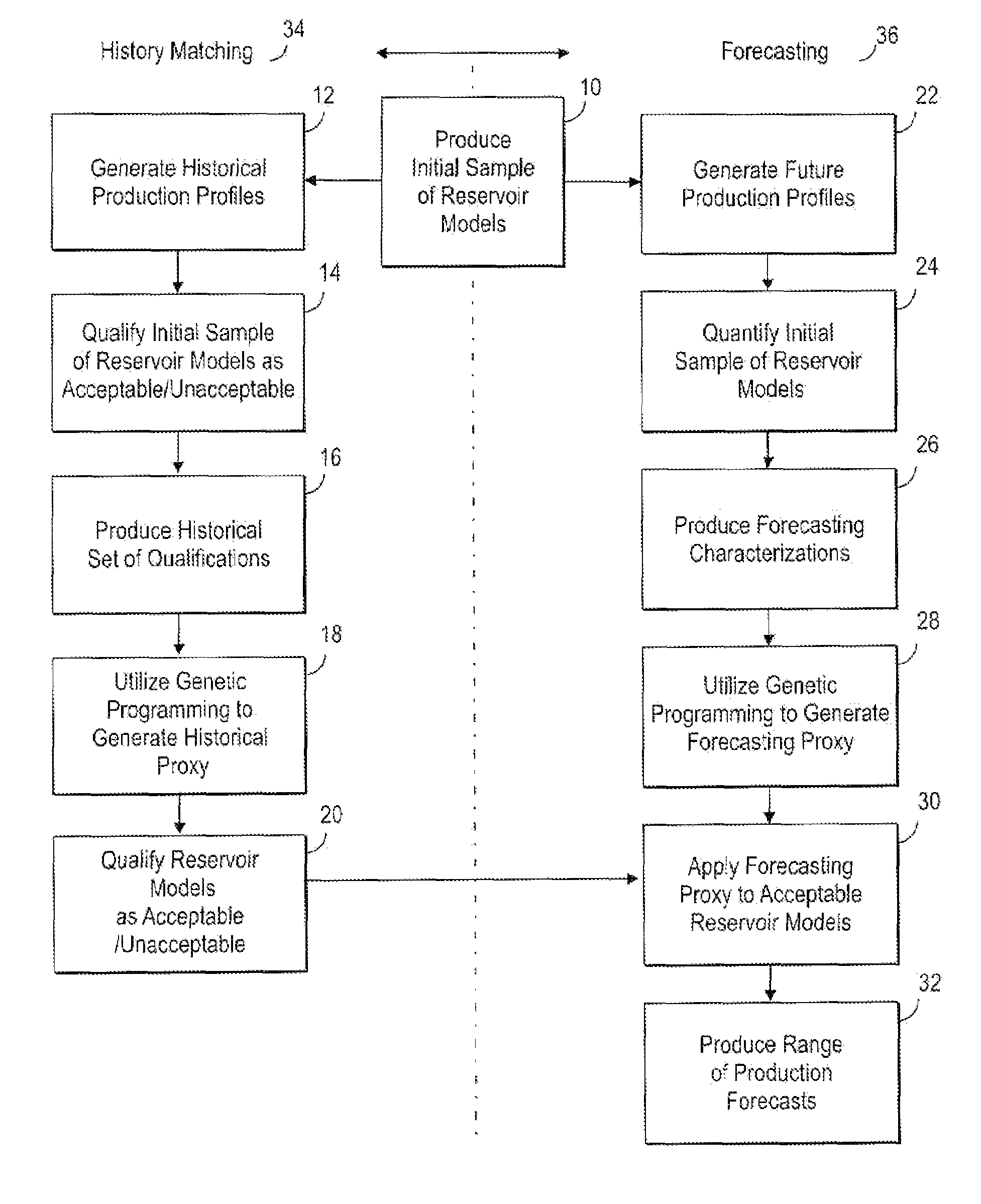

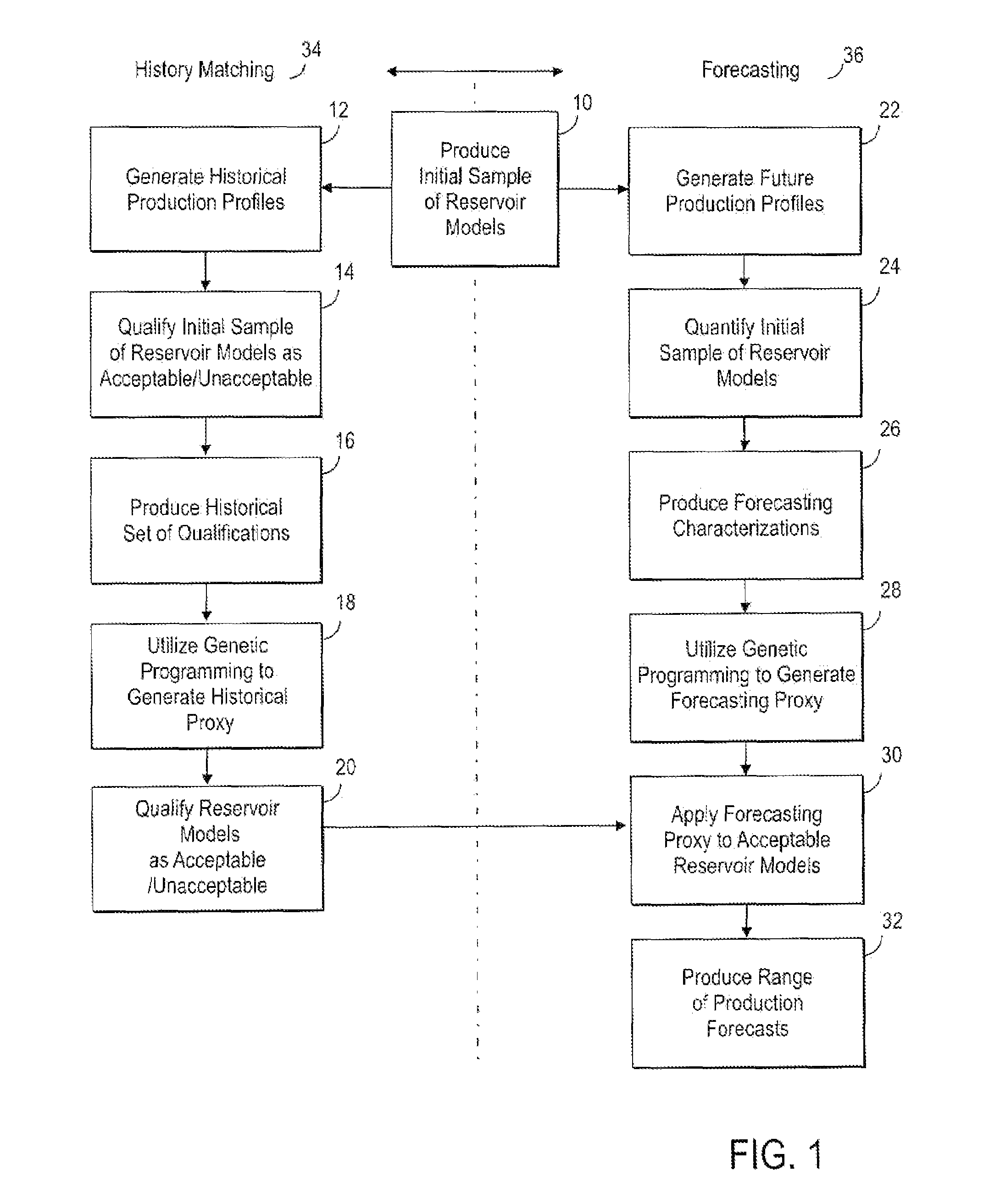

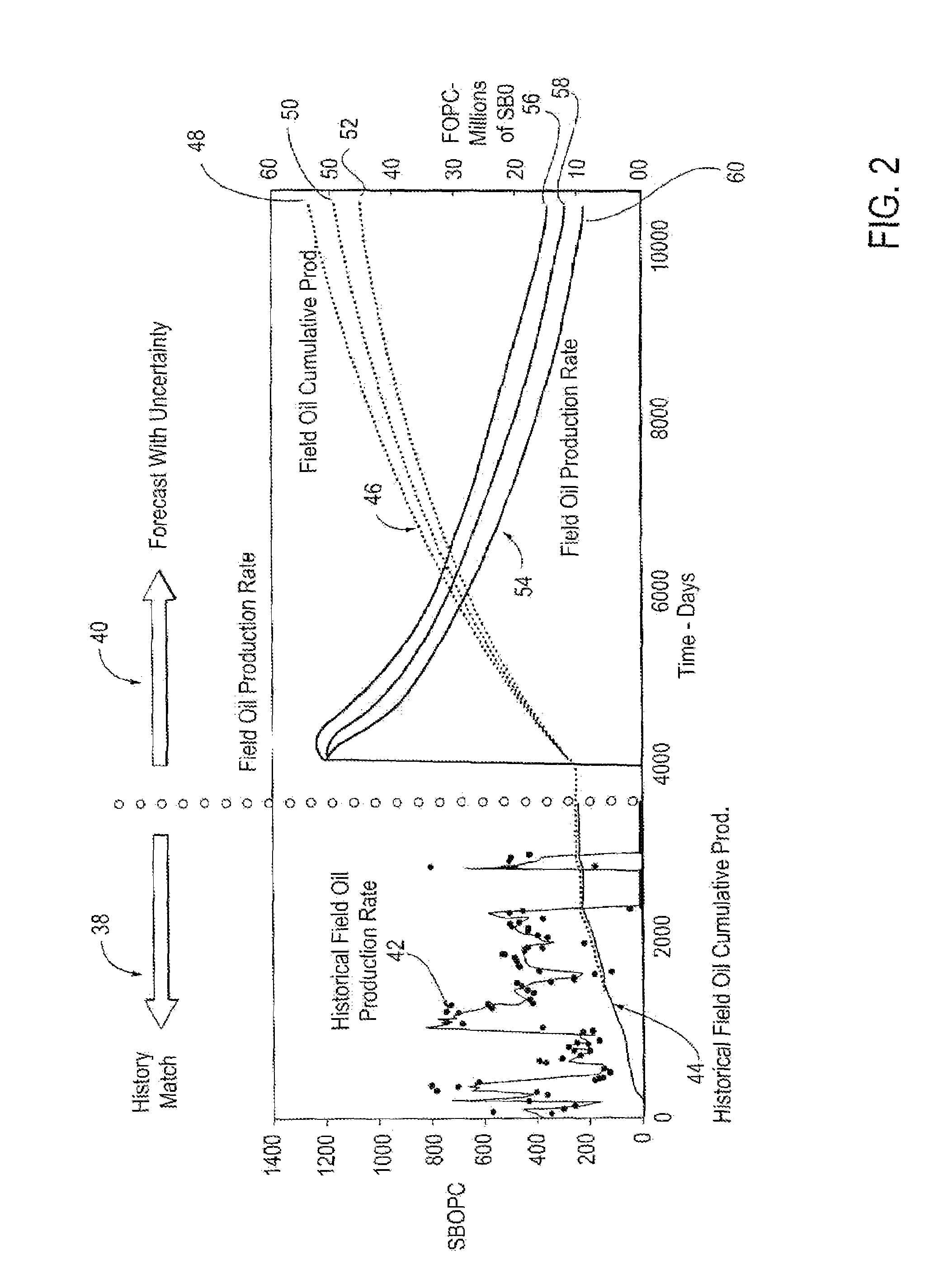

Method for forecasting the production of a petroleum reservoir utilizing genetic programming

InactiveUS20080082469A1Degree of improvementEfficient forecastingElectric/magnetic detection for well-loggingDigital computer detailsPetroleum reservoirPetroleum

A method utilizing genetic programming to construct history matching and forecasting proxies for reservoir simulators. Acting as surrogates for computer simulators, the genetic programming proxies evaluate a large number of reservoir models and predict future production forecasts for petroleum reservoirs.

Owner:CHEVROU USA INC

Microwave process for intrinsic permeability enhancement and hydrocarbon extraction from subsurface deposits

Hydrocarbons are extracted from a target formation, such as oil shale, tar sands, heavy oil and petroleum reservoirs, by apparatus and methods which cause fracturing of the containment rock and liquification or volatization of the hydrocarbons by microwave energy directed by a radiating antenna in the target formation.

Owner:GEOSCI SERVICES +1

Method for determining improved estimates of properties of a model

InactiveUS20090164186A1Reduce uncertaintyImprove accuracyComputation using non-denominational number representationGeological measurementsPetroleum reservoirPetroleum

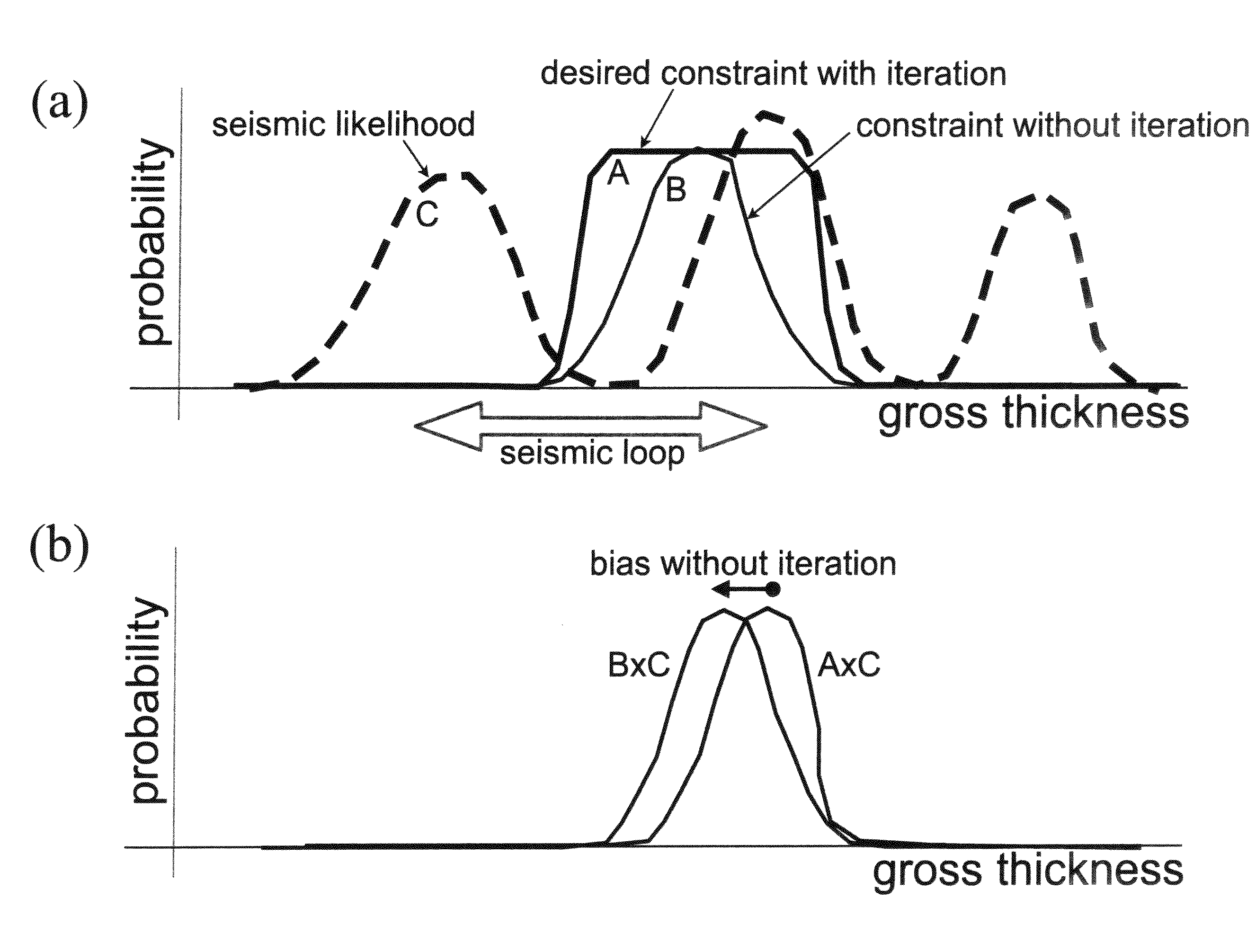

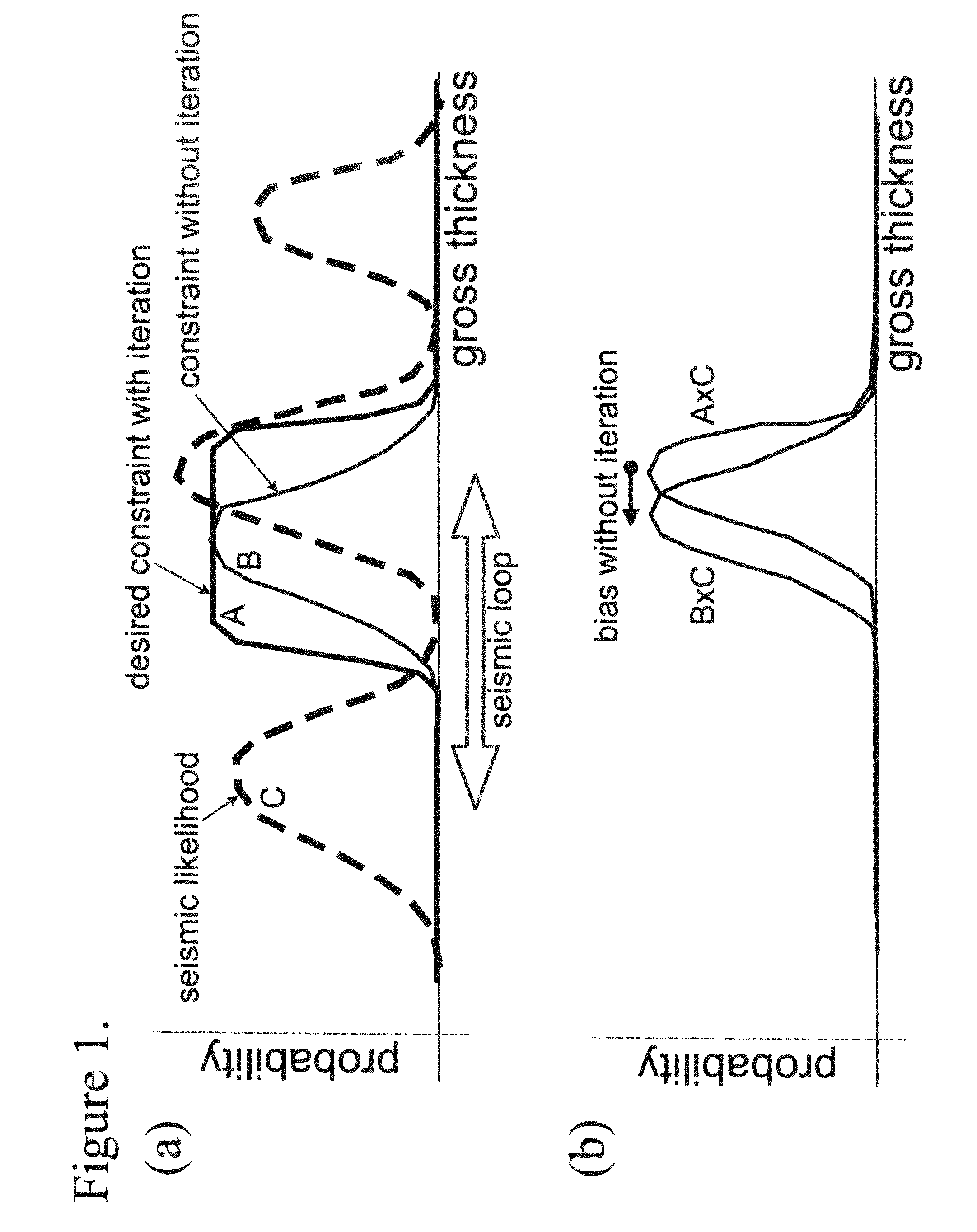

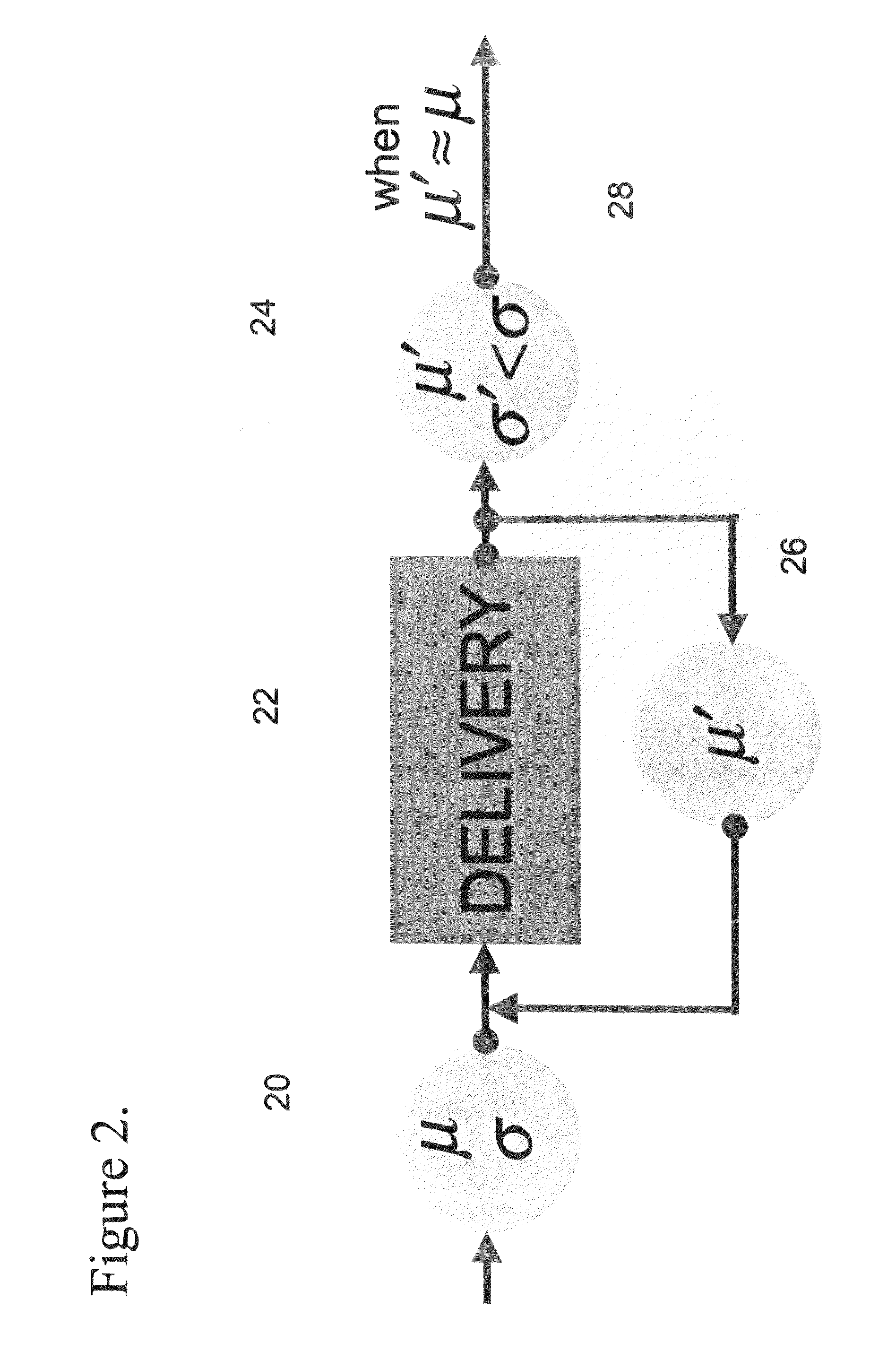

A method is disclosed for determining improved estimates of properties of a model, on the basis of estimated prior constraints, by running a mathematical inversion several times using the output posterior estimate of the previous inversion, or any of the previous inversions to provide an input for the next inversion. This iterative inversion may be repeated until the prior and posterior estimates converge to within a given threshold. The method may be applied to seismic data, using a seismic inversion, in order to improve the prediction of the viability of potential petroleum reservoirs by determining improved estimates of volumetric properties of a subsurface region.

Owner:BHP BILLITON INNOVATION PTY LTD

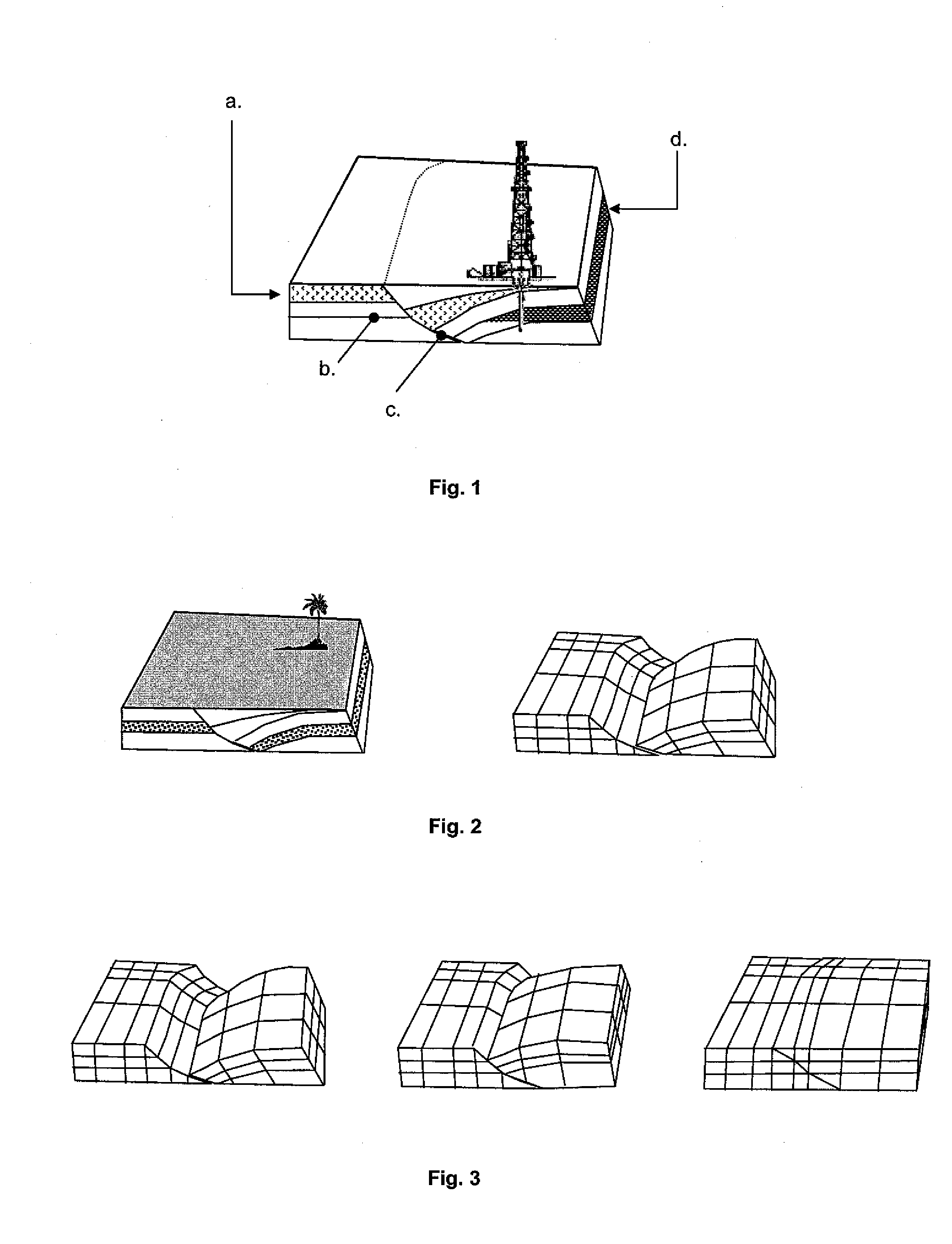

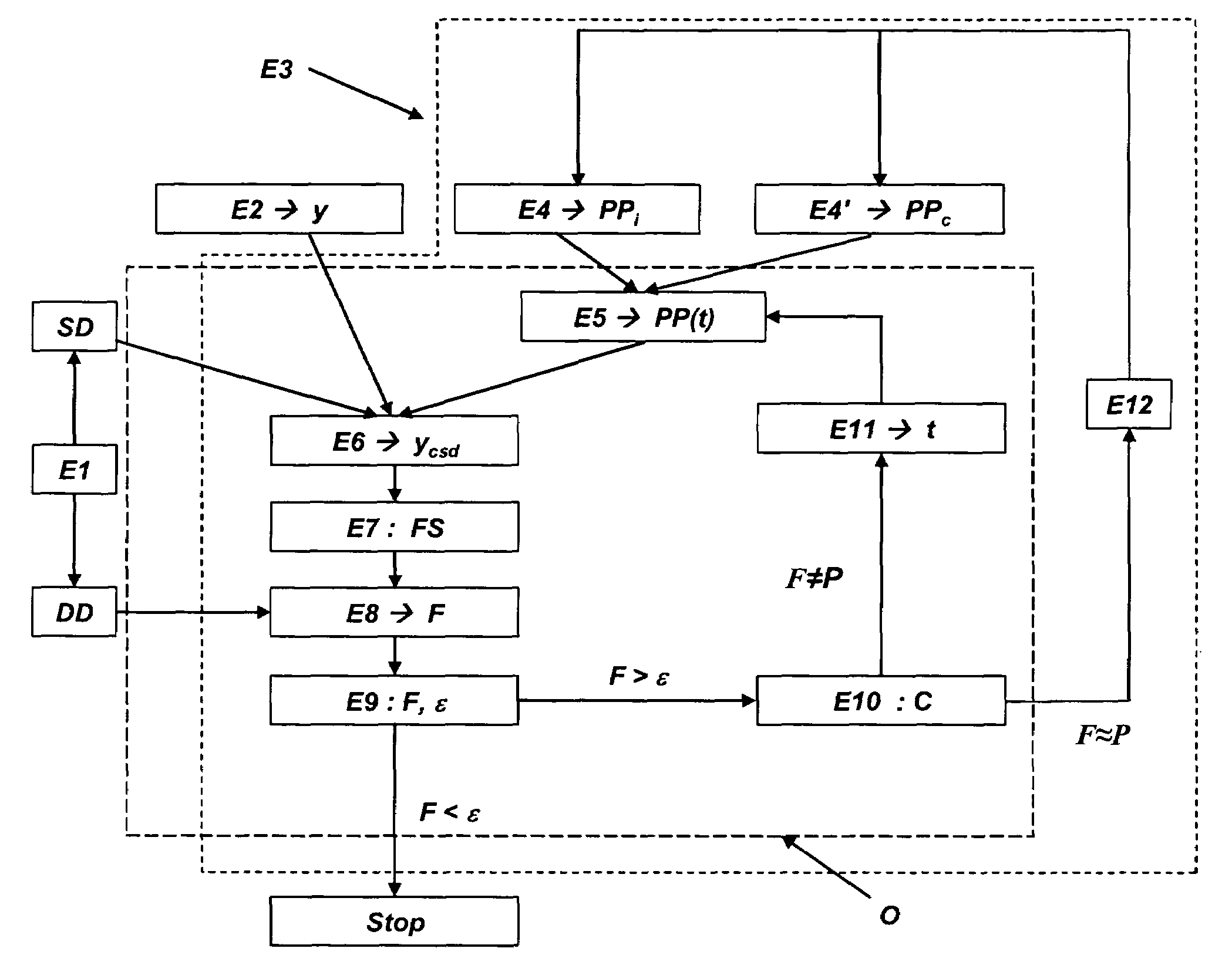

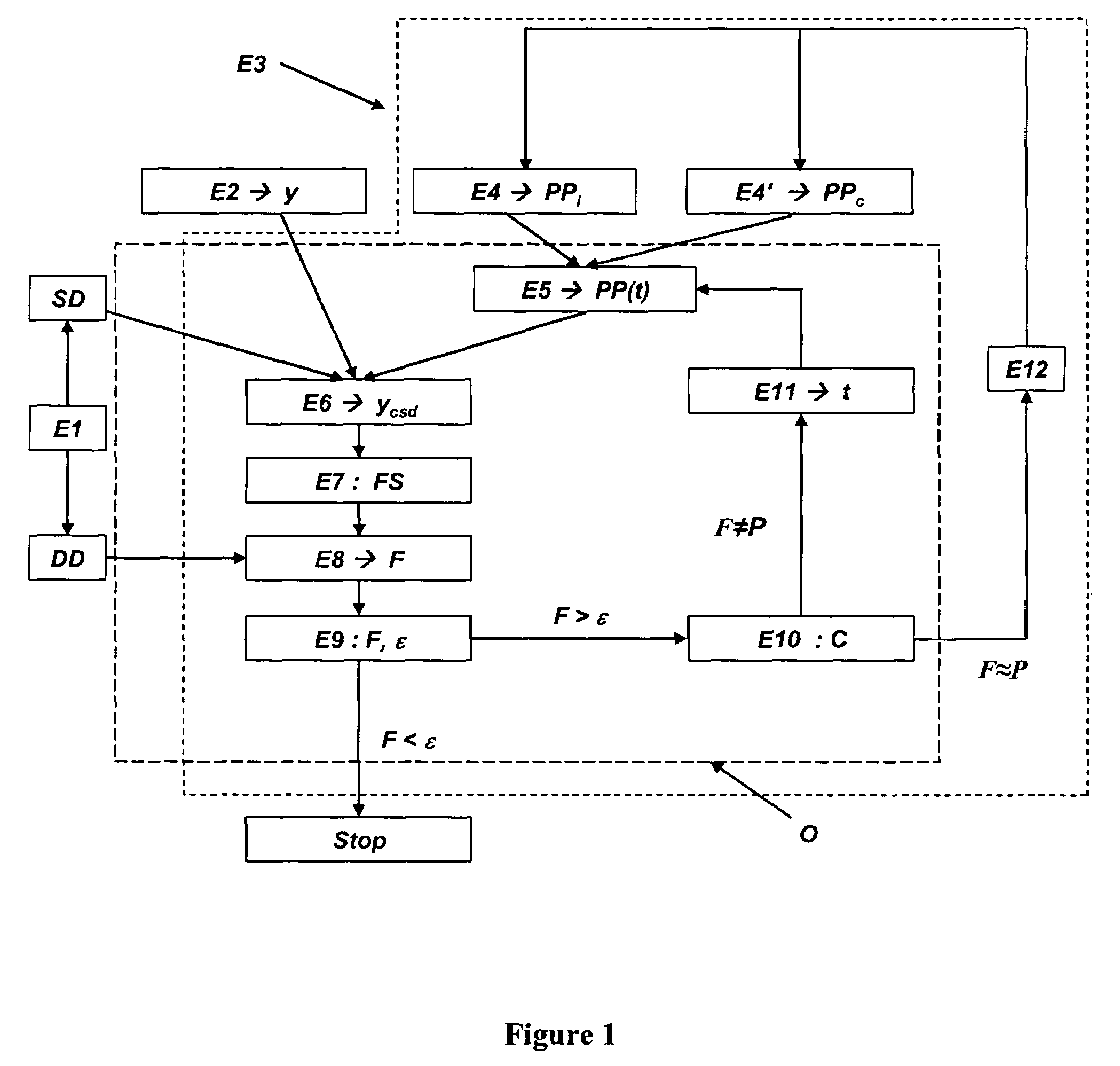

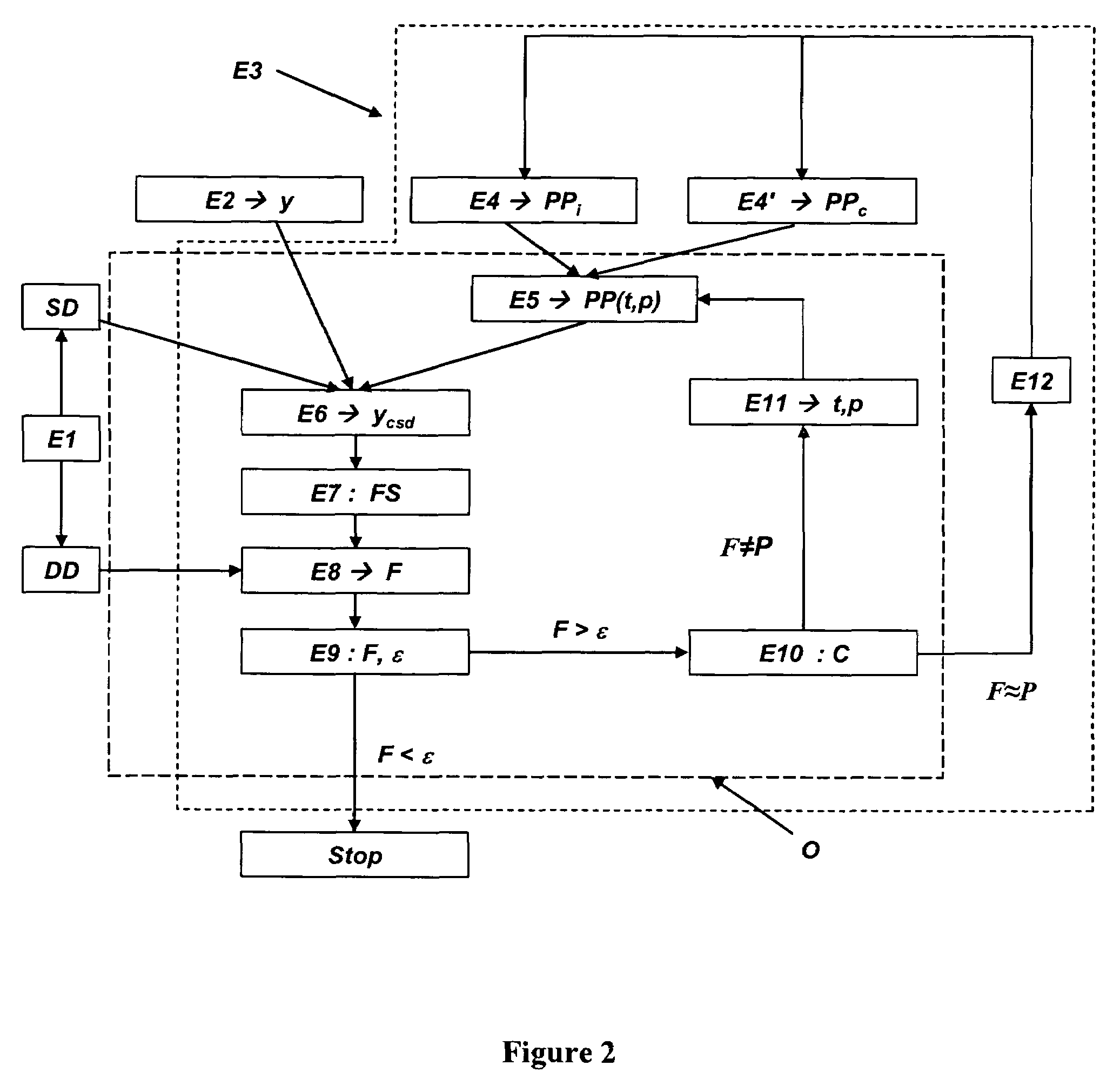

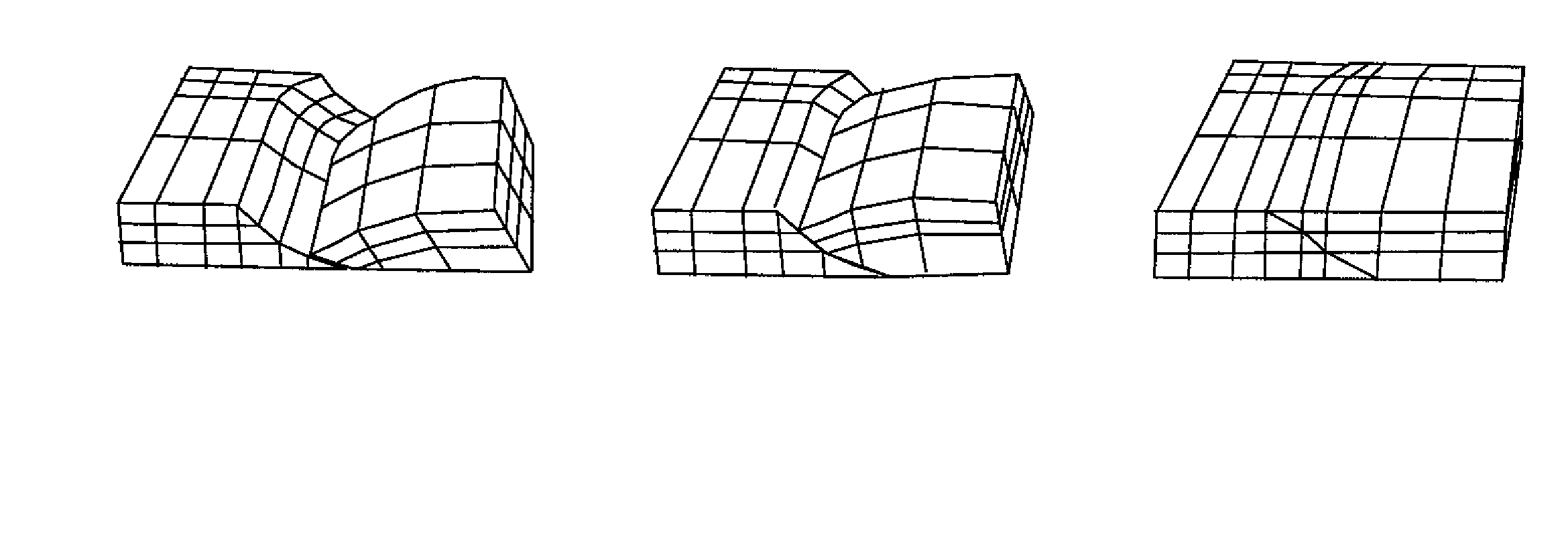

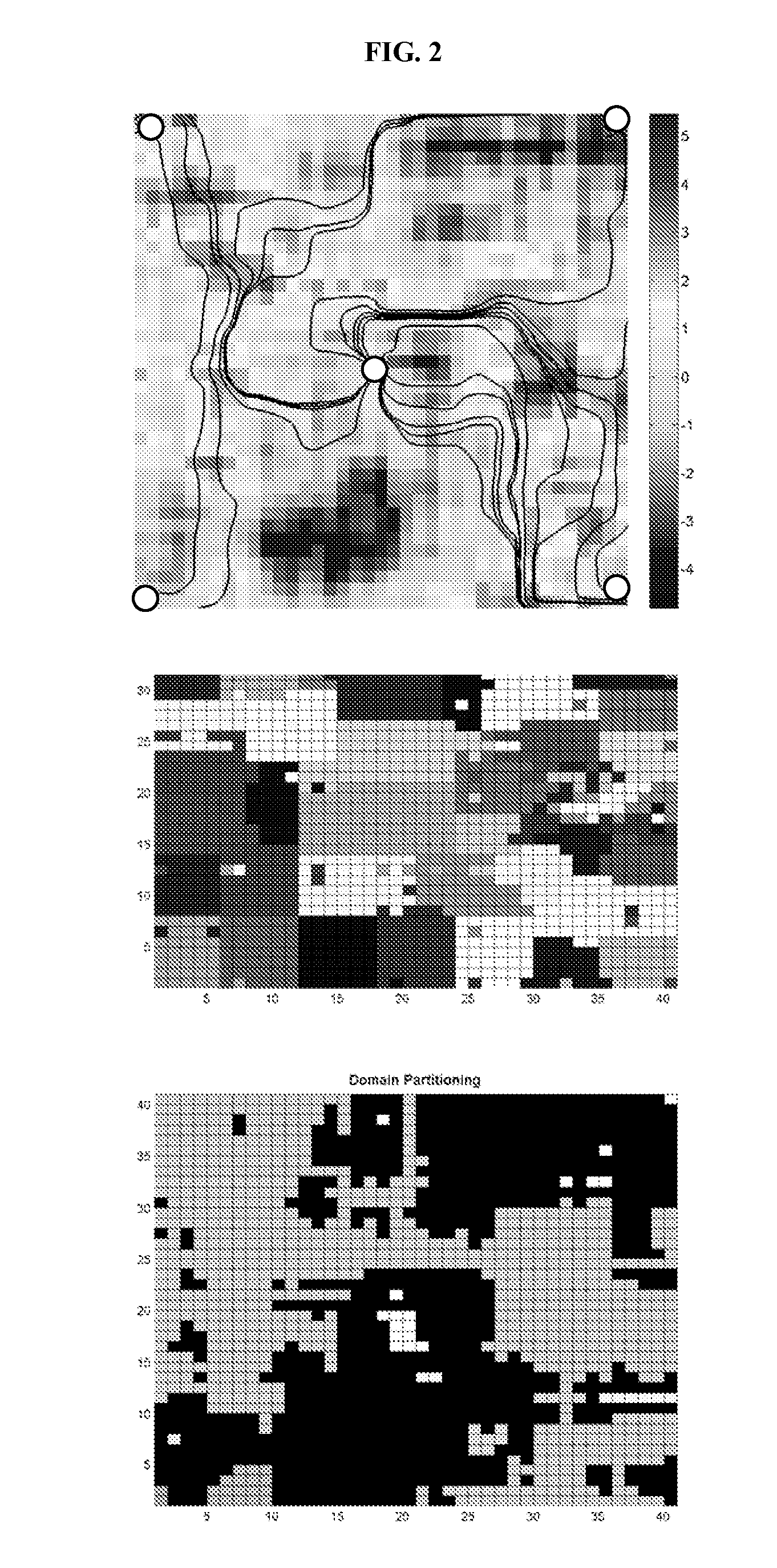

Method for updating a geological reservoir model by means of dynamic data

InactiveUS20070055447A1Electric/magnetic detection for well-loggingGeomodellingPetroleum reservoirDynamic data

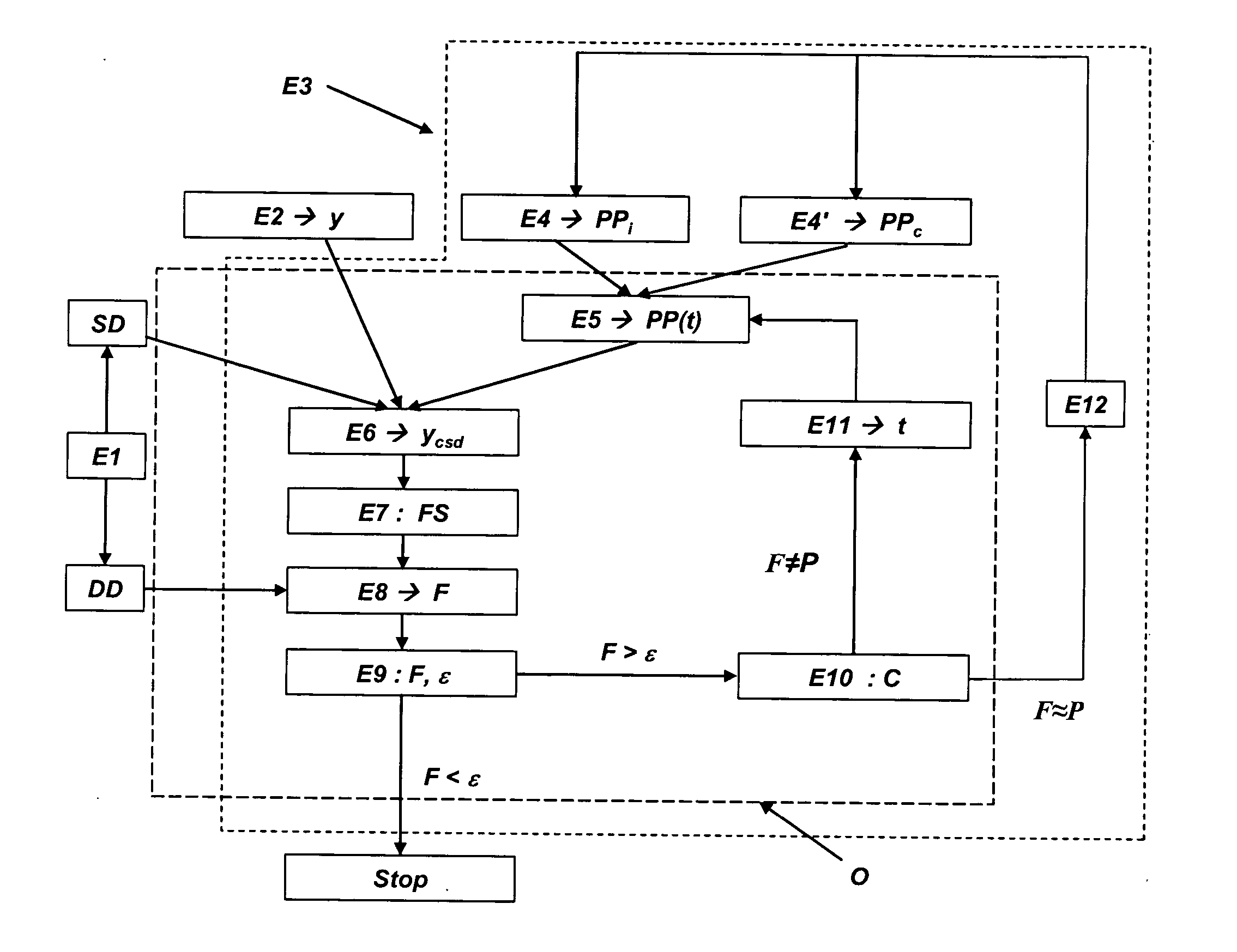

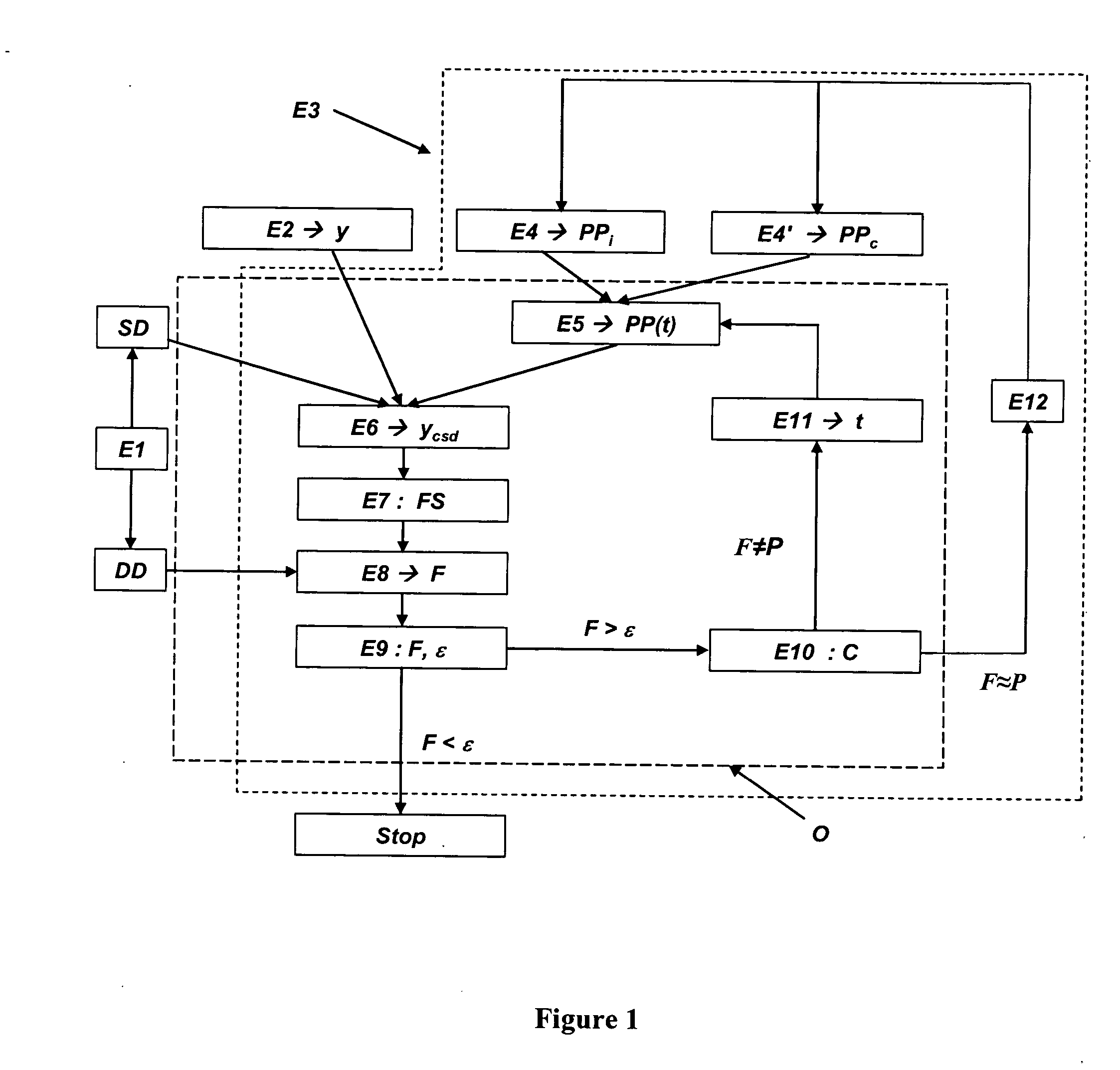

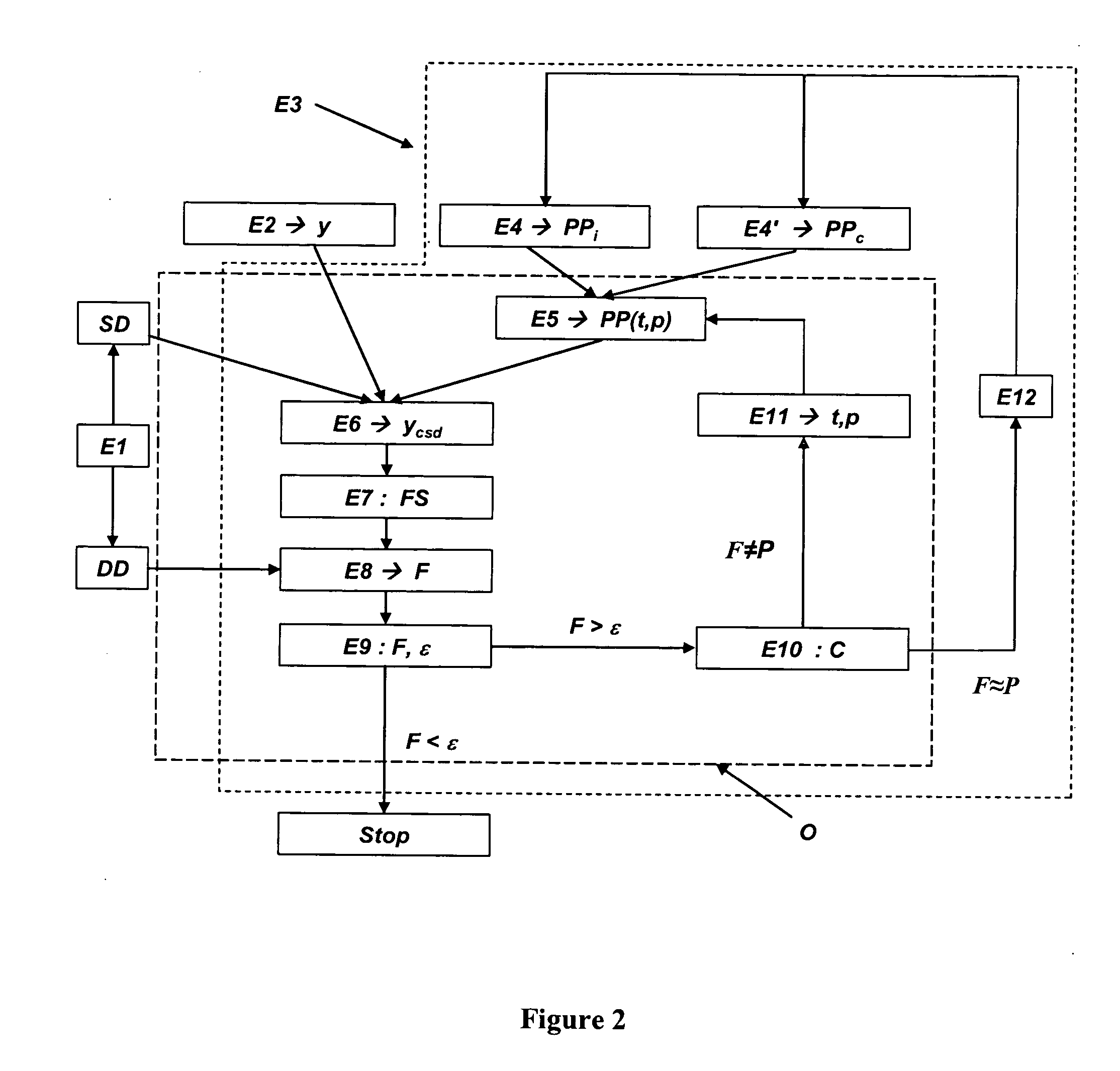

A method for updating a geological reservoir model by integration of dynamic data having application, for example, to petroleum reservoir development. An initial map (y) of petrophysical properties is constructed by means of a geostatistical simulator and of static data. Then an initial set of gradual pilot points (PPi) and at least one complementary set of gradual pilot points (PPc) are constructed. A combined set of gradual pilot points (PP(t)) is then constructed by combining these sets of gradual pilot points according to the gradual deformation method wherein at least one deformation parameter is a characteristic parameter of said pilot points (position and / or value). The initial map (y) is then modified, the deformation parameters are modified according to the dynamic data and the procedure is repeated until a stop criterion is reached and the geological reservoir model is updated by associating the map thus optimized with the grid of the model.

Owner:INST FR DU PETROLE

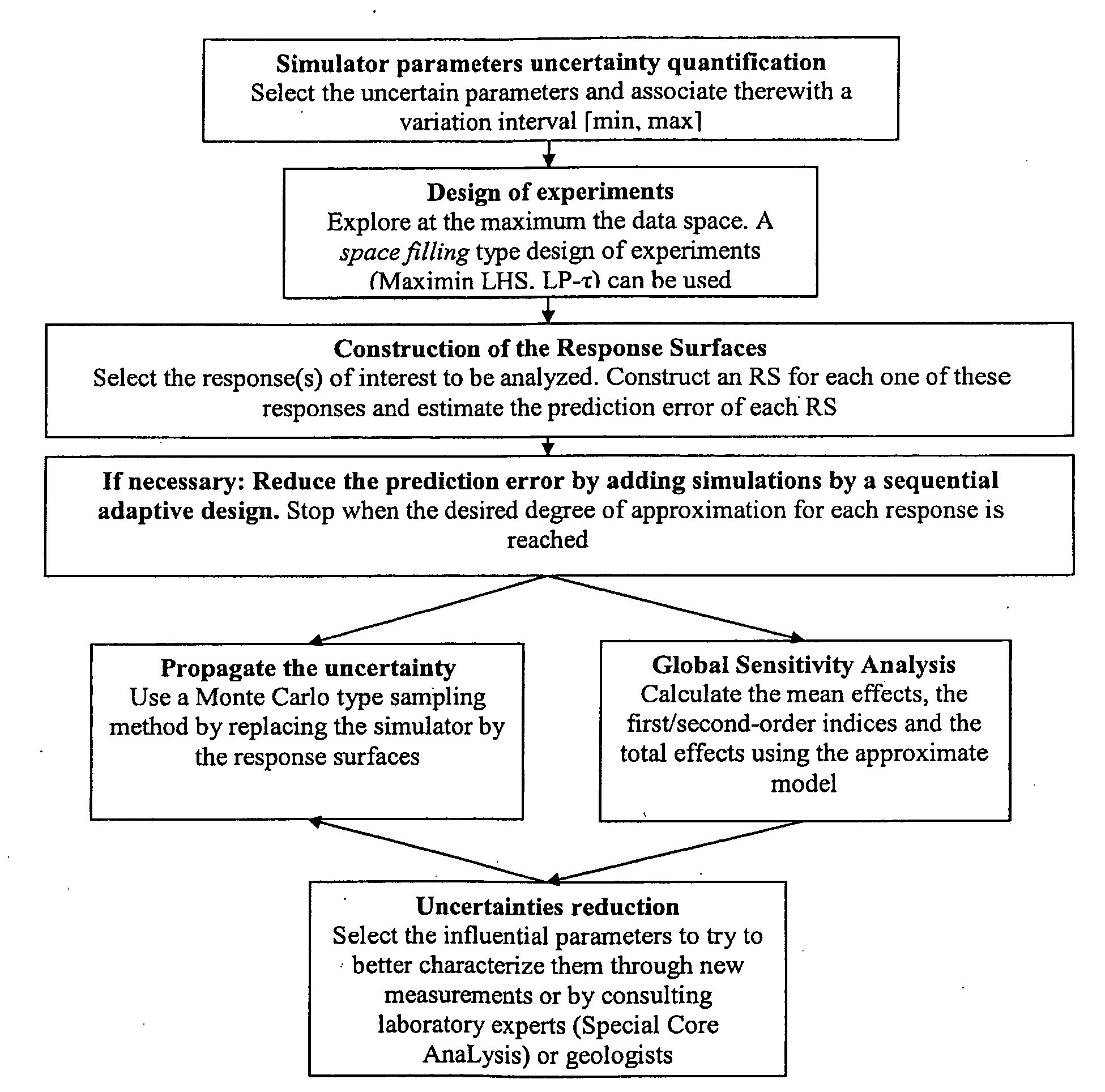

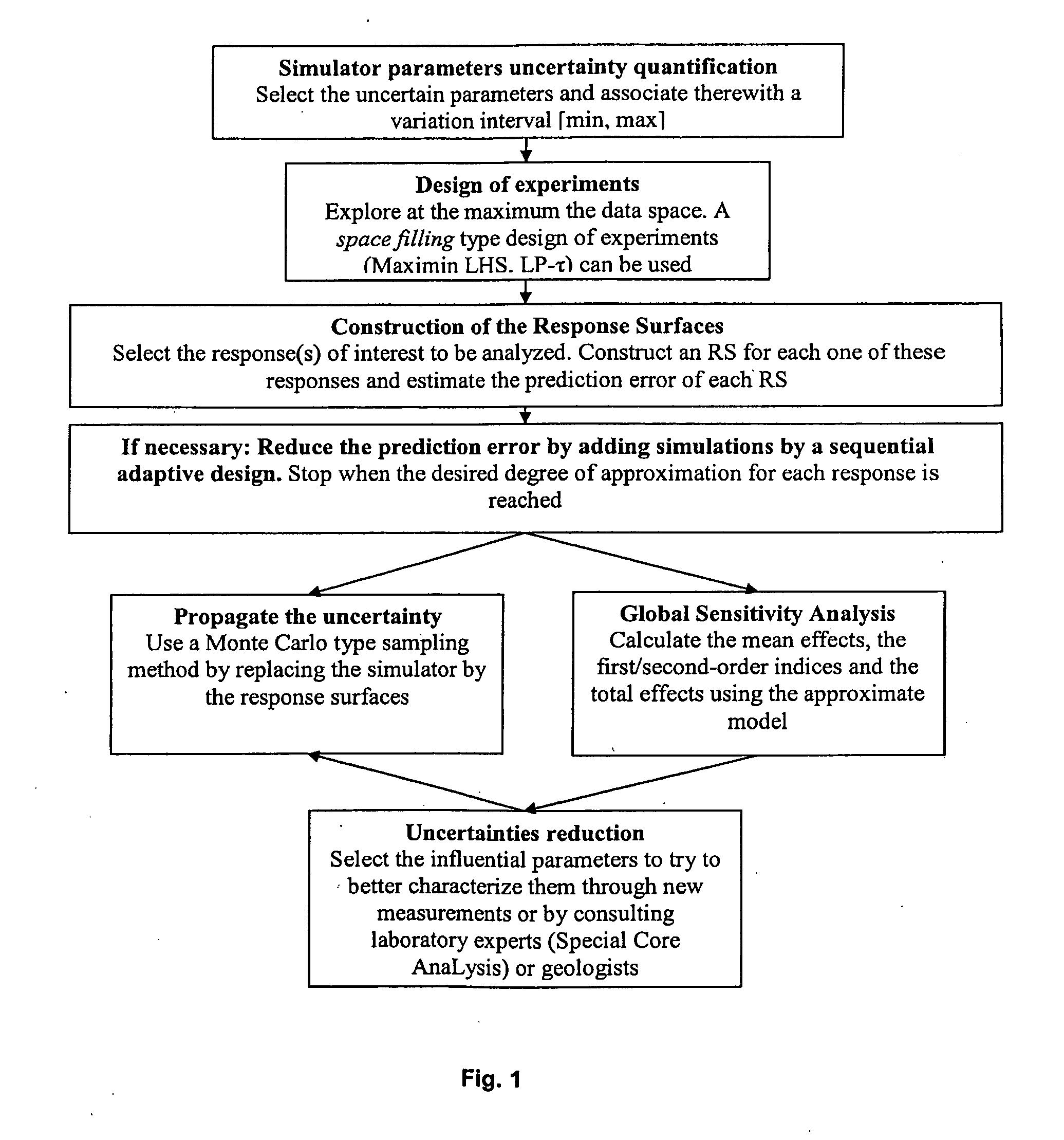

Method for Evaluating an Underground Reservoir Production Scheme Taking Account of Uncertainties

ActiveUS20090043555A1Reduce uncertaintyFluid removalComputation using non-denominational number representationComputational modelEngineering

Method for evaluating an underground reservoir production scheme taking account of uncertainties.Flow simulator input parameters characterizing the reservoir and the production scheme are selected. An approximate analytical model allowing the reservoir responses to be predicted is constructed. A desired degree of accuracy Dp is defined, this degree of accuracy Dp measuring the difference between the responses of the model and those of the simulator. The degree of accuracy Dp(M) of the predictions of the model is calculated. A design of experiments is constructed so as to select simulations to be performed, pertinent for adjustment of the model. The simulations selected by the design of experiments are carried out, then, for each response simulated by the simulator, the analytical model is adjusted by means of an approximation method. This operation is repeated until the desired degree of accuracy Dp is reached. Finally, the production scheme is evaluated by analyzing the reservoir responses predicted by the approximate analytical model.Application: notably to the development of petroleum reservoirs for example.

Owner:INST FR DU PETROLE

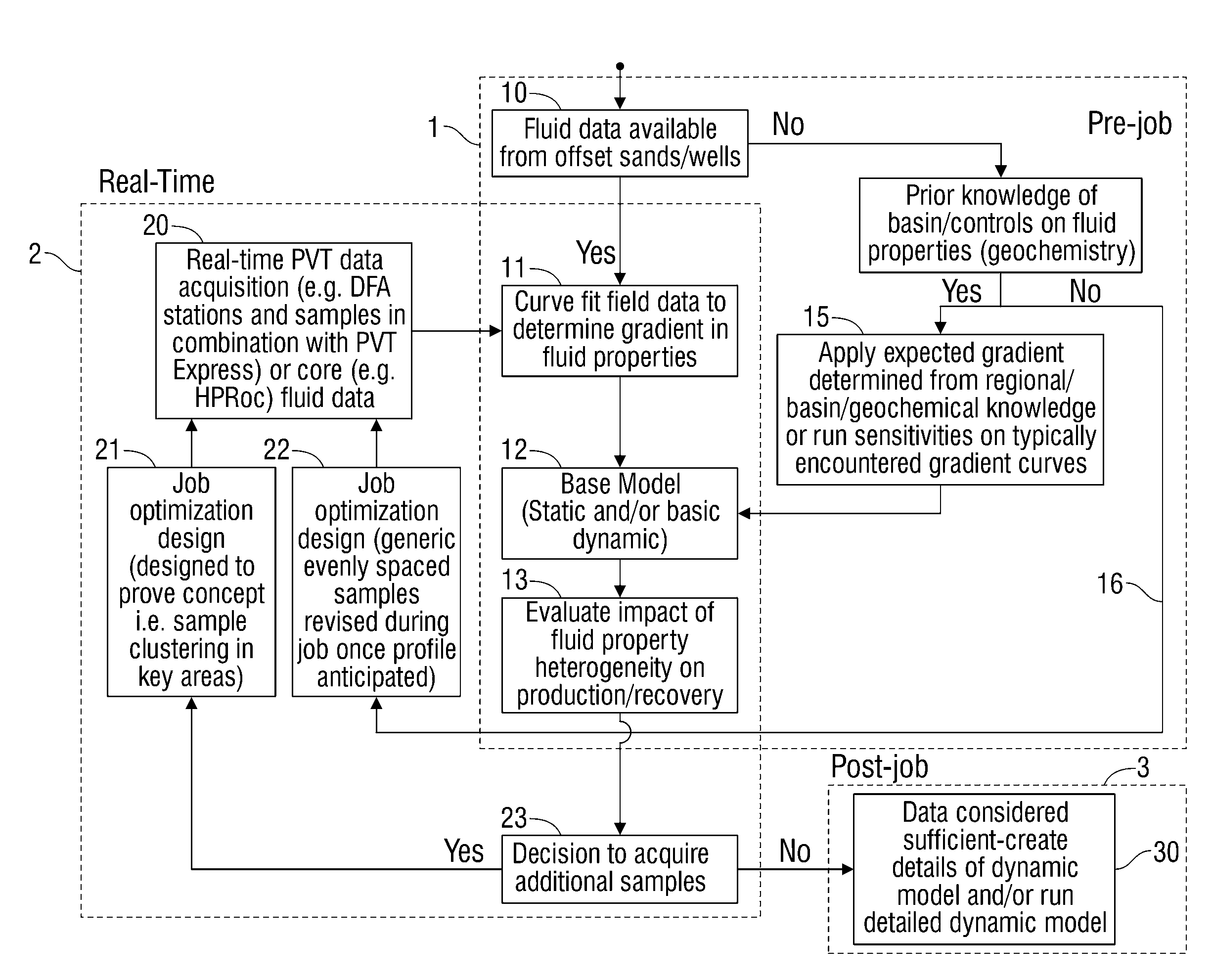

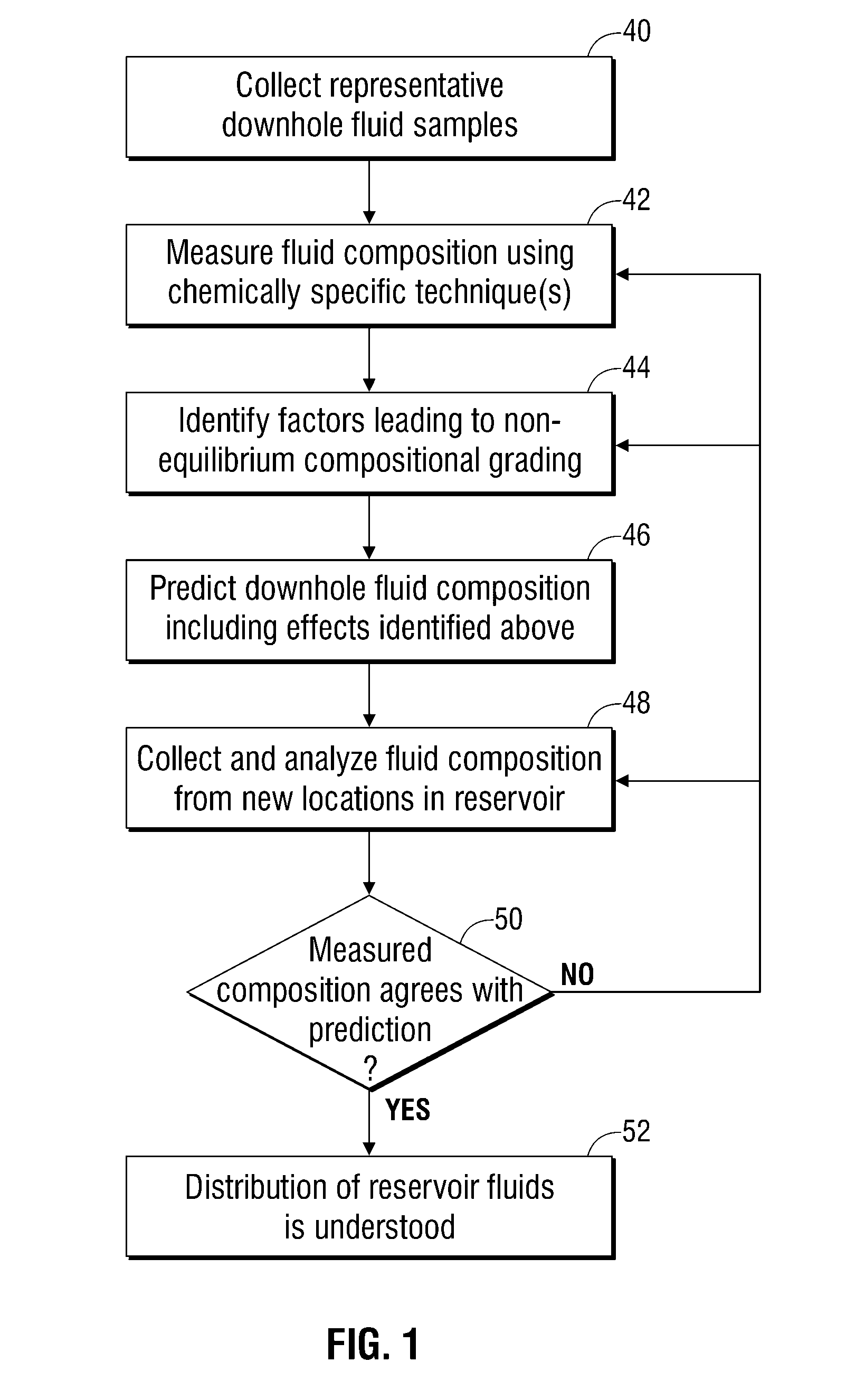

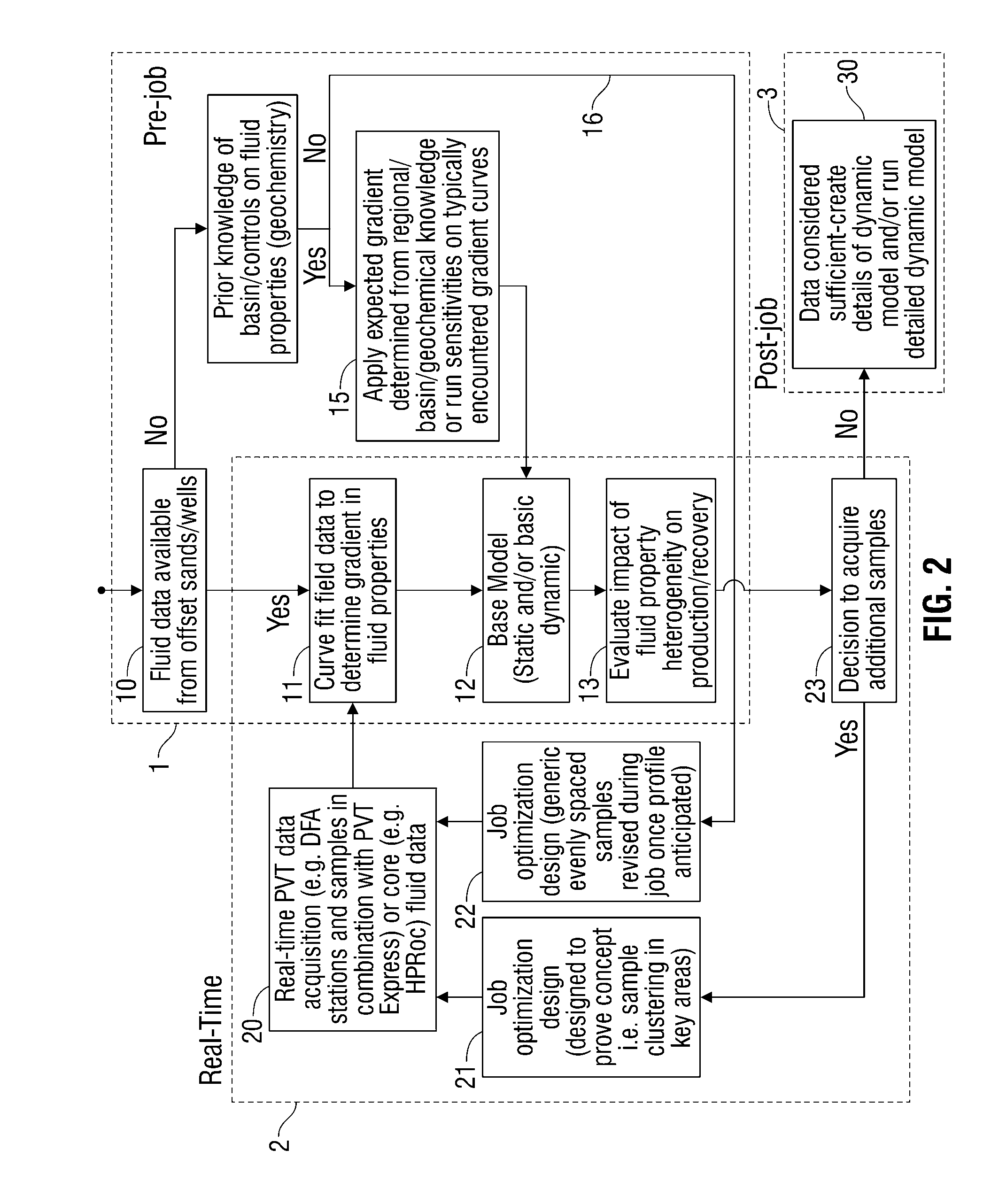

Methods for optimizing petroleum reservoir analysis

InactiveUS20100132450A1Reduce expensesImprove sampling efficiencyRadiation pyrometryComputation using non-contact making devicesReal-time dataSoil science

Methods for optimizing petroleum reservoir analysis and sampling using a real-time component wherein heterogeneities in fluid properties exist. The methods help predict the recovery performance of oil such as, for example, heavy oil, which can be adversely impacted by fluid property gradients present in the reservoir. Additionally, the methods help optimize sampling schedules of the reservoir, which can reduce overall expense and increase sampling efficiency. The methods involve the use of analytical techniques for accurately predicting one or more fluid properties that are not in equilibrium in the reservoir. By evaluating the composition of downhole fluid samples taken from the reservoir using sensitive analytical techniques, an accurate base model of the fluid property of interest can be produced. With the base model in hand, real-time data can be obtained and compared to the base model in order to further define the fluid property of interest in the reservoir.

Owner:SCHLUMBERGER TECH CORP

Method for forecasting the production of a petroleum reservoir utilizing genetic programming

InactiveUS7657494B2Degree of improvementEfficient forecastingElectric/magnetic detection for well-loggingDigital computer detailsPetroleum reservoirBiology

A method utilizing genetic programming to construct history matching and forecasting proxies for reservoir simulators. Acting as surrogates for computer simulators, the genetic programming proxies evaluate a large number of reservoir models and predict future production forecasts for petroleum reservoirs.

Owner:CHEVROU USA INC

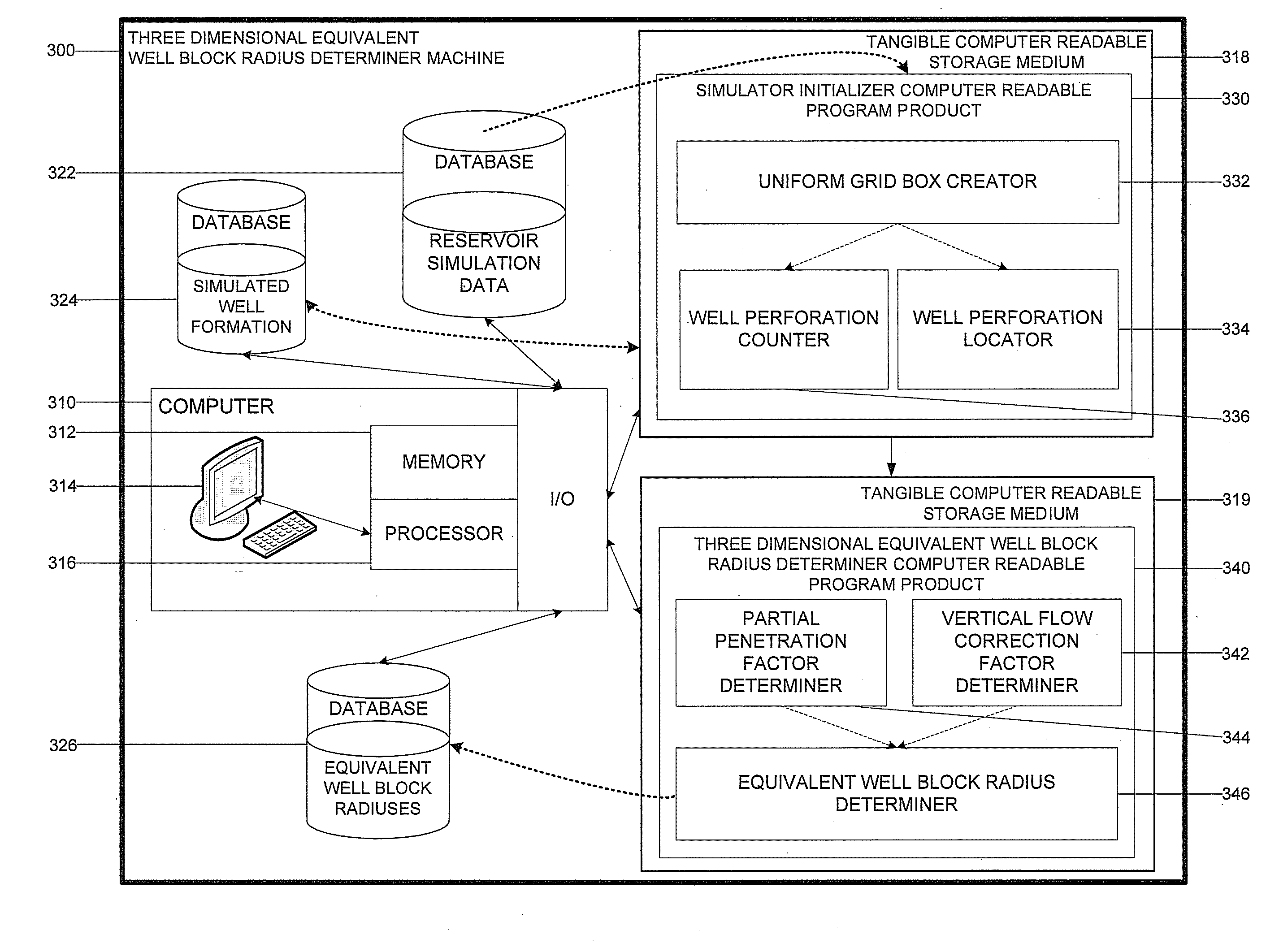

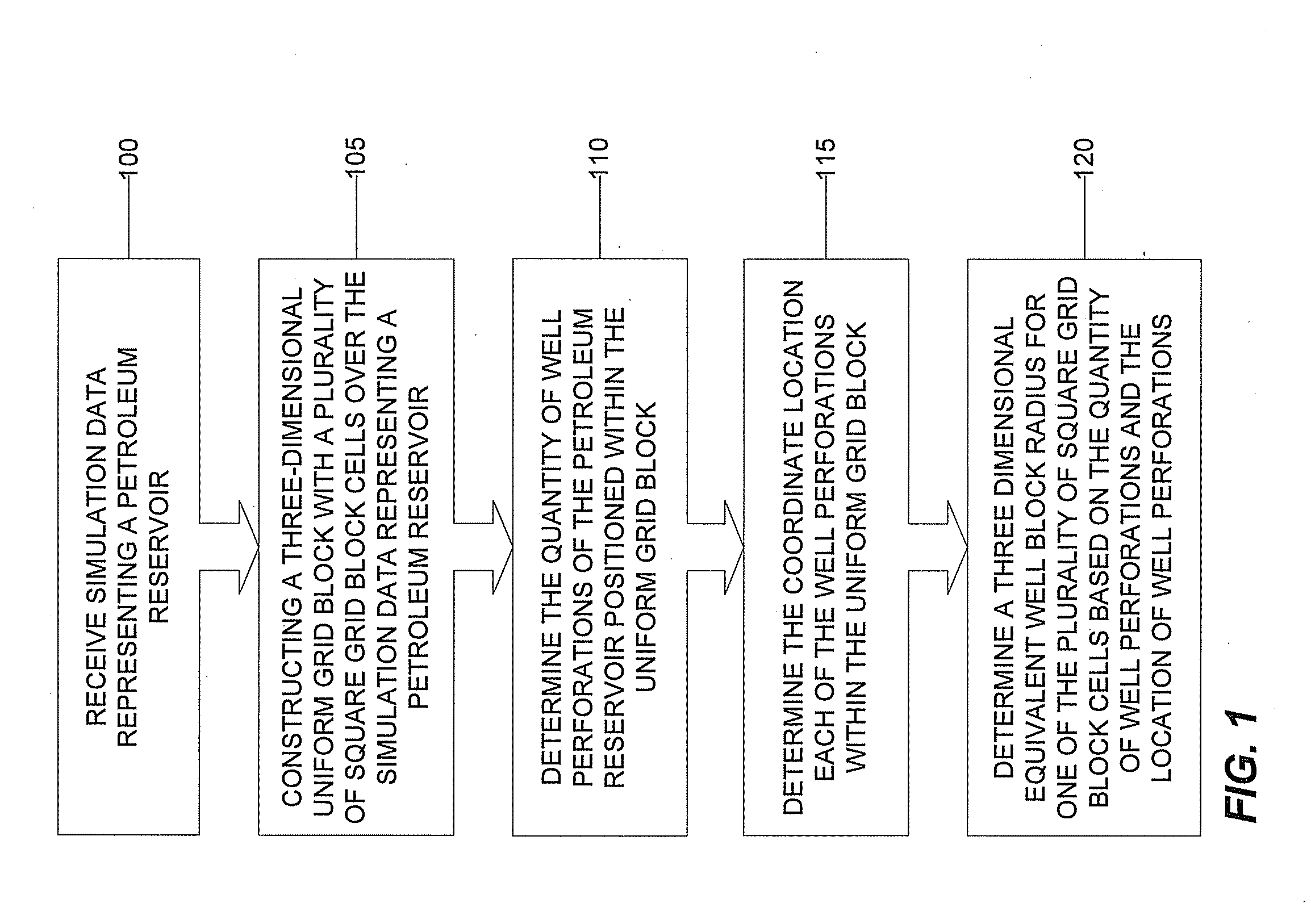

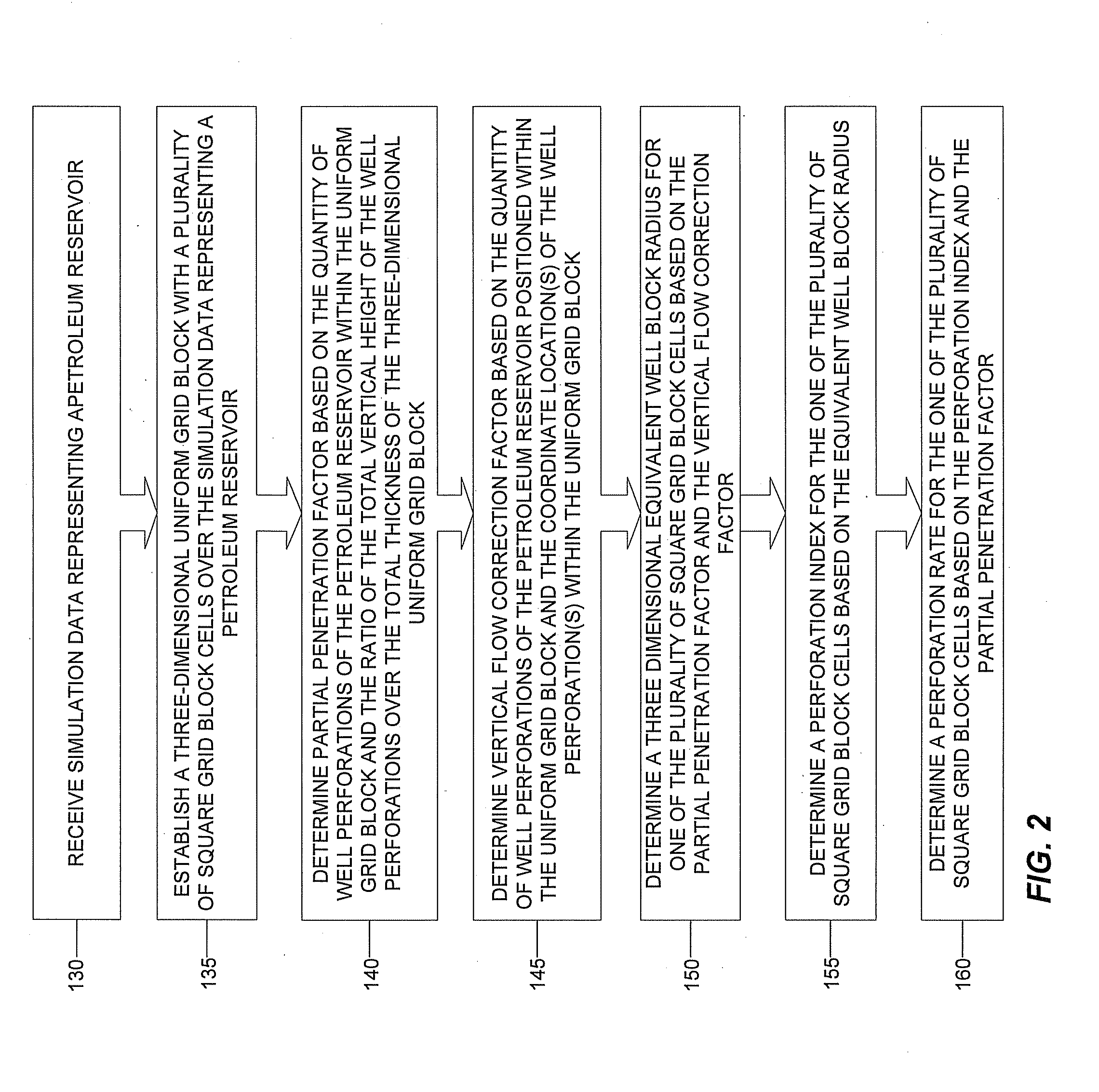

Three Dimensional Well Block Radius Determiner Machine And Related Computer Implemented Methods And Program Products

ActiveUS20100114544A1Improve accuracyLow costAnalogue computers for fluid flowGeological measurementsParallel computingPetroleum reservoir

Three dimensional well block radius determiner machines, systems, program products, and computer implemented methods are provided to determine a three dimensional equivalent well block radius of a perforated grid block cell, with three dimensional flow, of a three dimensional coordinate grid block constructed over a three dimensional simulated well formation in a finite difference petroleum reservoir simulator. Various embodiments of the invention, for example, can beneficially account for both horizontal and vertical flow of oil through a well perforation without the need for complicated, expensive, and time-consuming numerical or iterative solutions. Embodiments of the present invention, for example, can be used as a part of legacy simulators thereby providing more accurate well block radius calculations, by accounting for both horizontal and vertical perforation flow, without introducing significant implementation hurdles, development costs, or simulation runtime delays.

Owner:SAUDI ARABIAN OIL CO

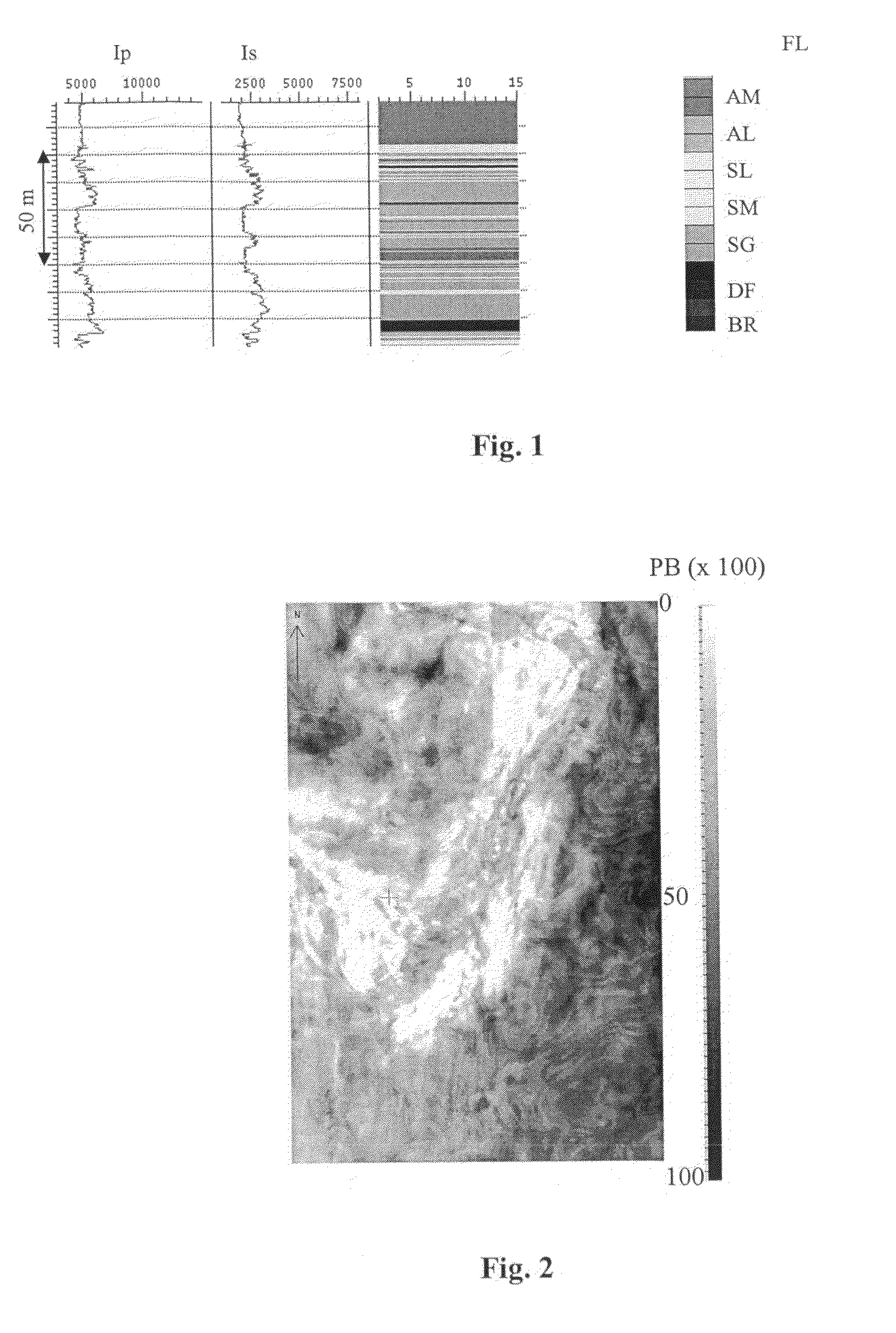

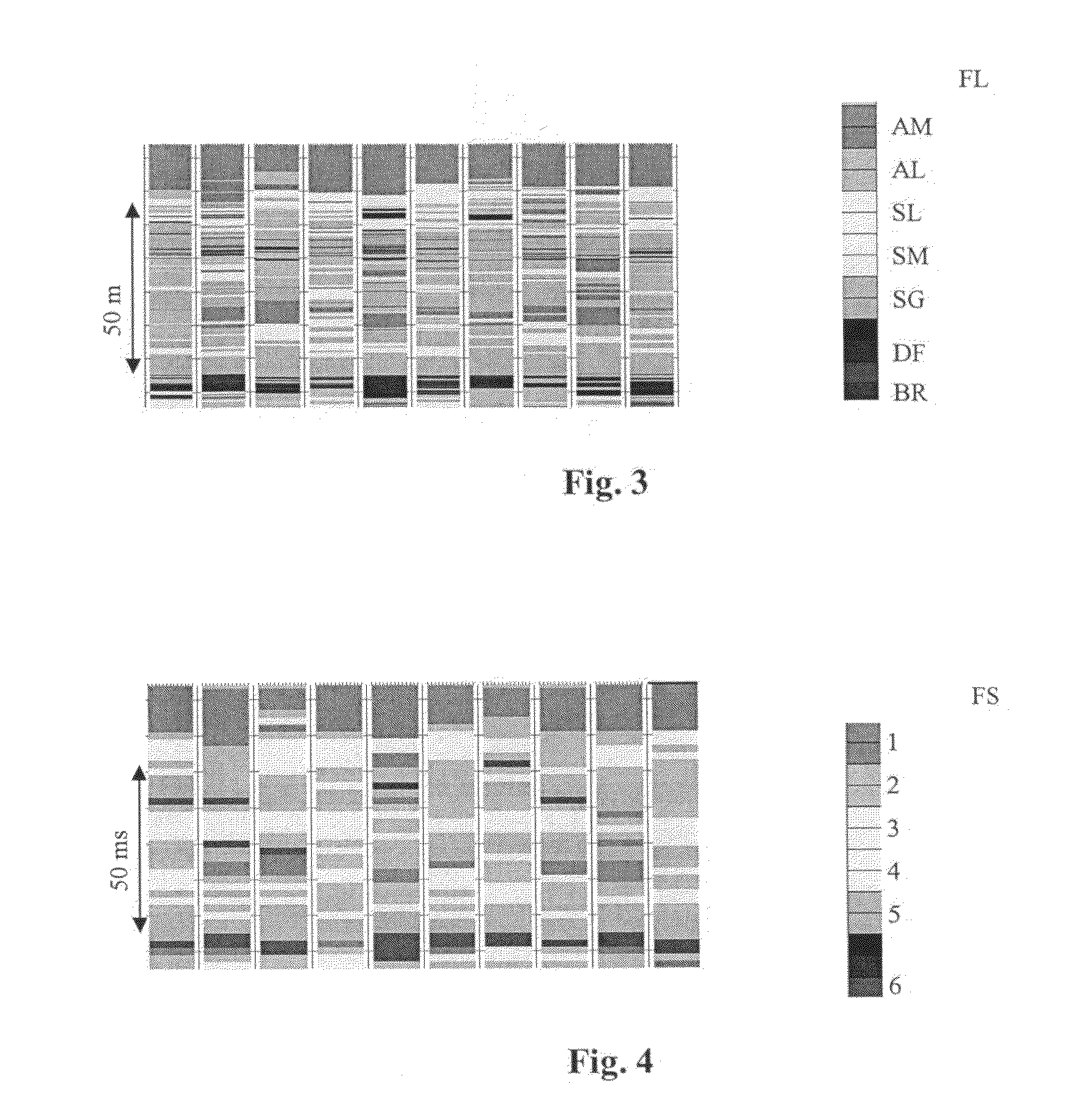

Method of constructing a geological model of a subsoil formation constrained by seismic data

InactiveUS20080162093A1Computation using non-denominational number representationSeismic signal processingLithologyGeomorphology

An method of constructing a geological model of a subsoil formation constrained by seismic data having application to petroleum reservoir development is disclosed. Logs relative to geological properties are acquired and a seismic facies cube is constructed. Logs relative to geological properties and logs relative to seismic facies are then simulated. Then distribution of proportions is estimated at any point on the subsoil by means of the acquired logs in the well and of the simulated logs. A seismic constraint is then defined by constructing a lithologic facies average proportion cube from these estimated proportion distributions. Finally, a geological model wherein the geological properties are constrained by this lithologic facies average proportion cube is constructed.

Owner:INST FR DU PETROLE

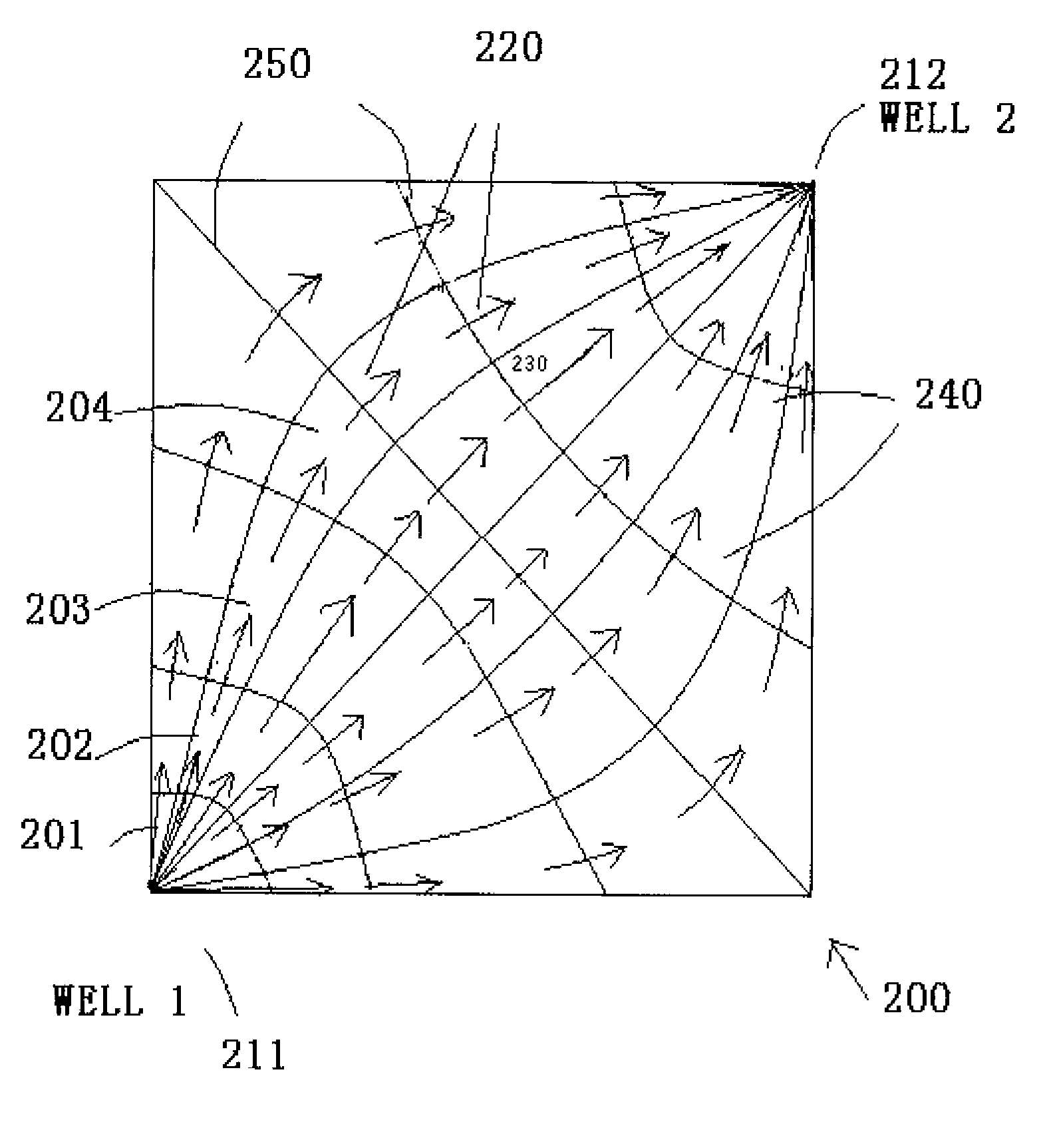

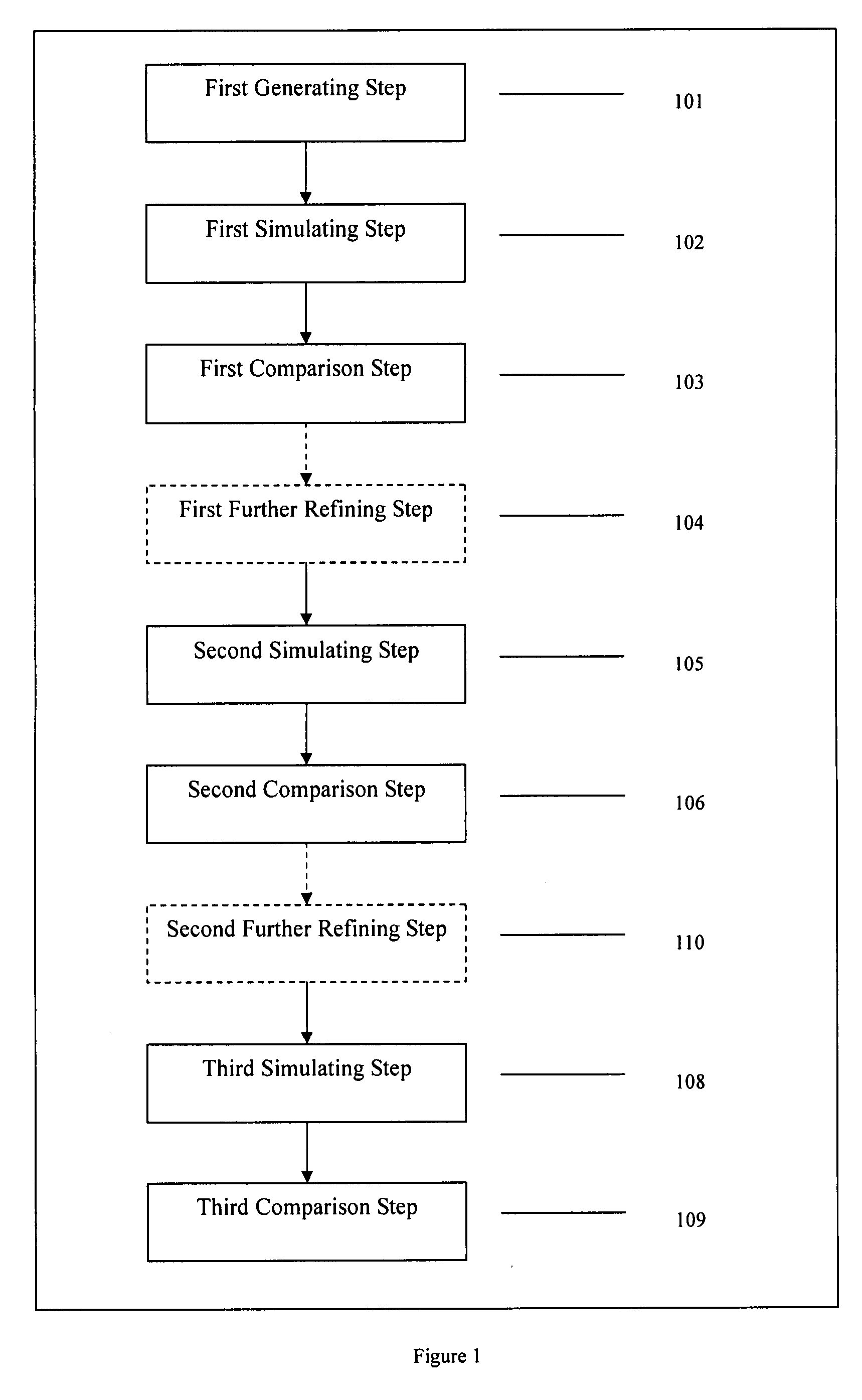

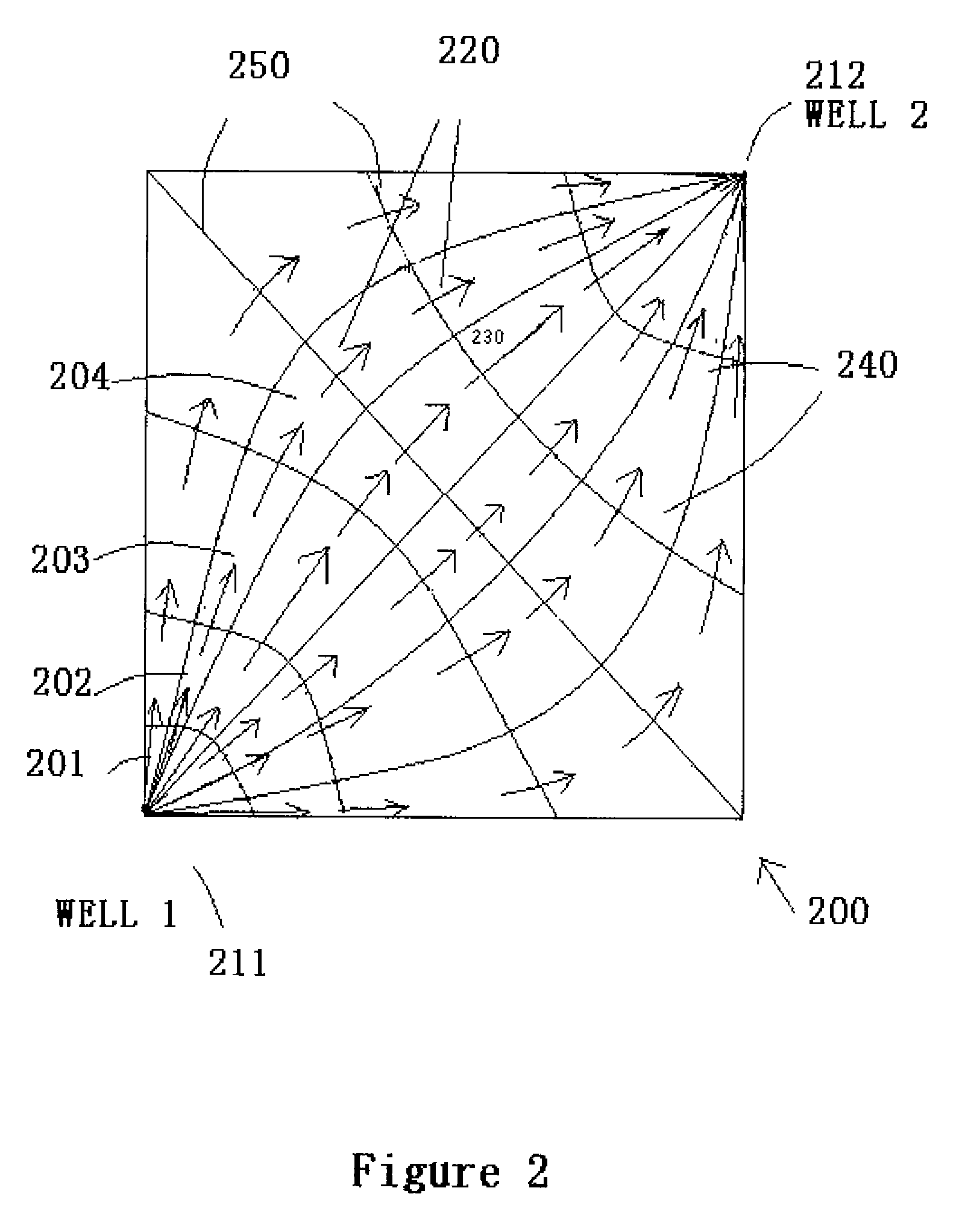

System and method for evaluating petroleum reservoir using forward modeling

InactiveUS20080255816A1Less CPU time demandingUseful propertyDesign optimisation/simulationProbabilistic CADModel systemSimulation

This invention relates to petroleum reservoir characterization. It uses a novel system and method to generate a system of reservoir models, and then use a series of simulation techniques to simulate the models. The models are refined through each simulation and comparison step by comparing the results of the simulation with the known data from the reservoir. The invention can be applied to different reservoirs which have different known properties. Simulation techniques such as EM test forward calculation, stochastic reservoir modeling, streamline forward calculation are all candidates of simulation methods disclosed in the invention.

Owner:SCHLUMBERGER TECH CORP

Method for updating a geological reservoir model by means of dynamic data

InactiveUS7363163B2Electric/magnetic detection for well-loggingGeomodellingPetroleum reservoirFeature parameter

Owner:INST FR DU PETROLE

Method of seeking hydrocarbons in a geologically complex basin, by means of basin modeling

ActiveUS8150669B2Analogue computers for chemical processesSeismologyGeomorphologyStructure of the Earth

A method for mapping a complex sedimentary basin is disclosed. A grid representative of the current architecture of the basin is constructed. A mechanical structural restoration is applied in three dimensions so as to reconstruct the past architectures of the basin from the current time up to a geological time t. A simulation of the geological and geochemical processes that govern the formation of a petroleum reservoir is then carried out, directly in the grids obtained from the restoration, from the geological time t to the current one. This simulation is thereafter used for mapping the sedimentary basin so as to identify zones of the basin where hydrocarbons may have accumulated.

Owner:INST FR DU PETROLE

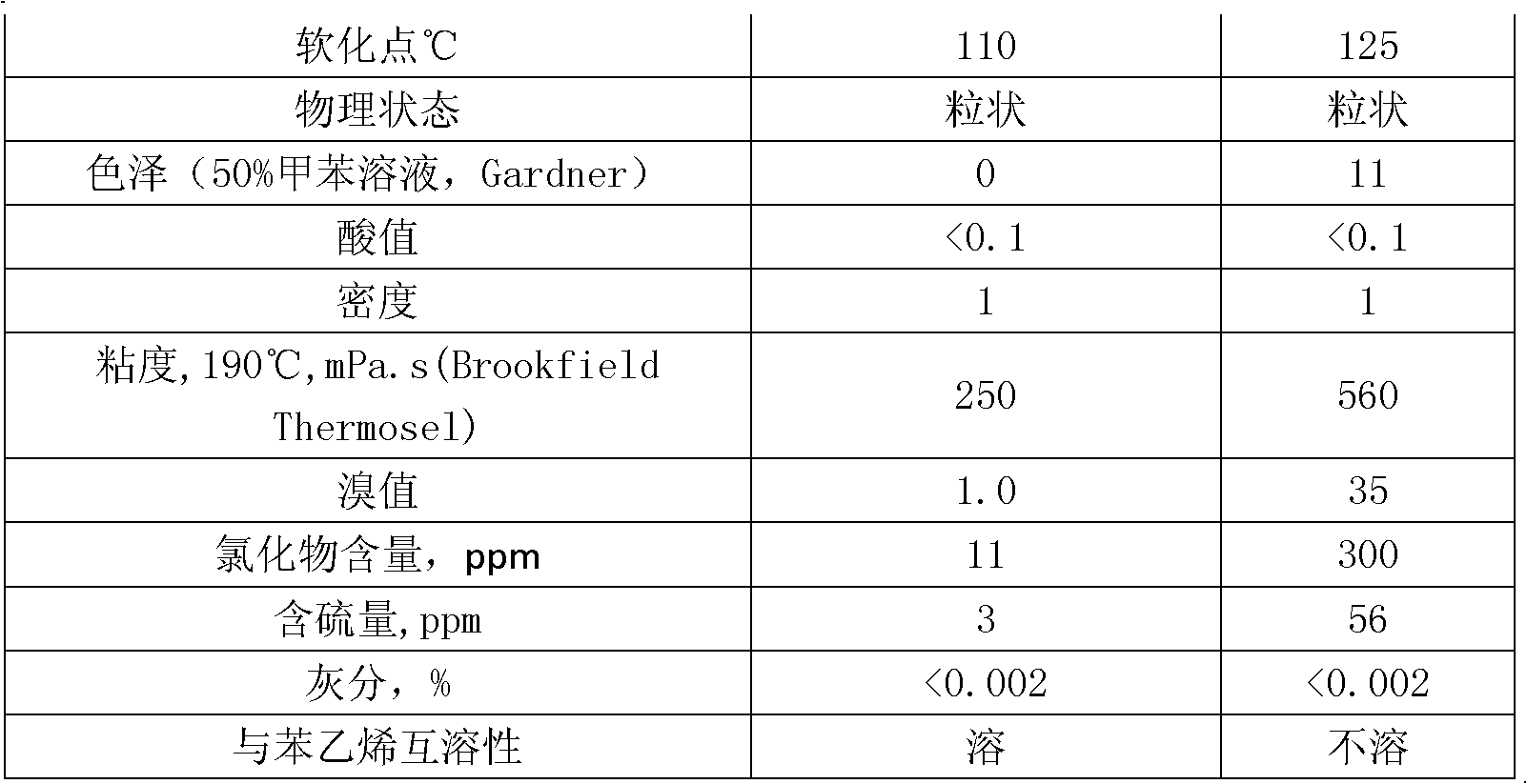

Precisive ornament casting moulding material

ActiveCN101074320AHigh hardnessLow shrinkageFoundry moulding apparatusMINERAL WAXMicrocrystalline wax

A precision-casting mold material for ornament consists of hydrogenated microcrystalline wax, paraffin, petroleum resin, high-molecular polymer, mineral wax and animal and vegetable wax. It has better bending strength, surface hardness, thermal stability, fluidity, reutilization and less linear shrinkage rate. It can be used for gold and silver ornaments.

Owner:CHINA PETROLEUM & CHEM CORP +1

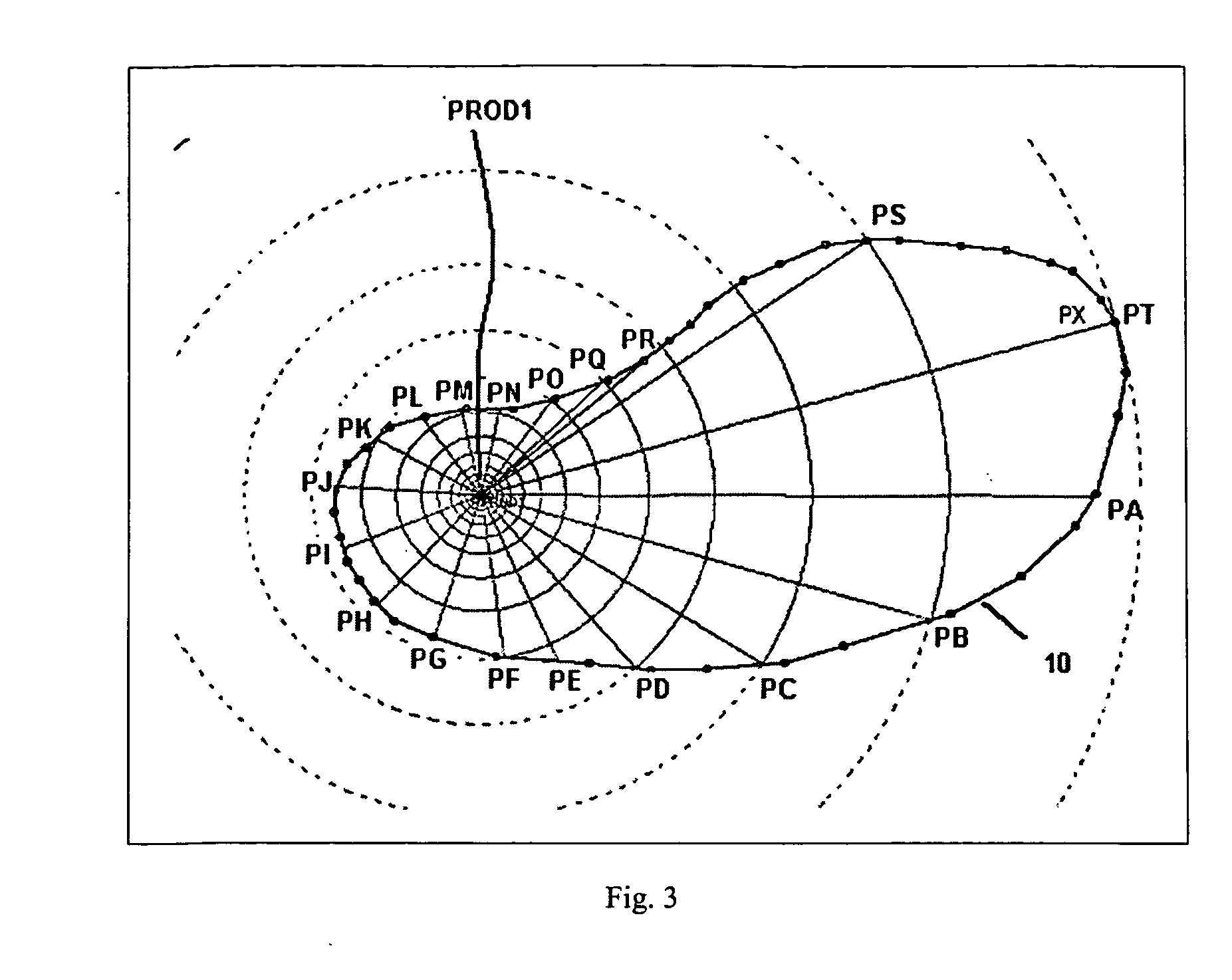

Method for producing full field radial grid for hydrocarbon reservoir simulation

InactiveUS20050021234A1Work flow easyLittle involvementElectric/magnetic detection for well-loggingGeomodellingFull fieldWork flow

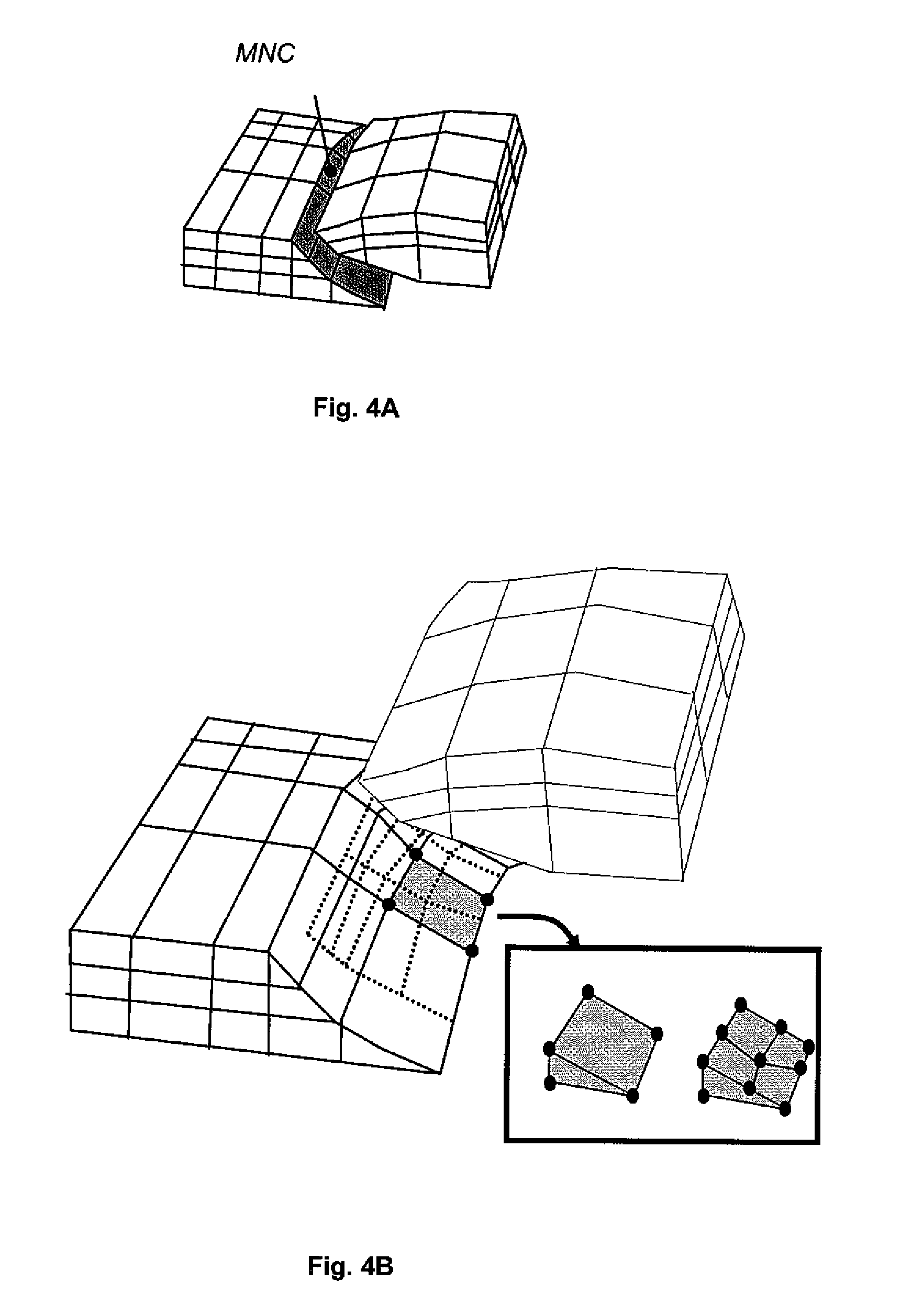

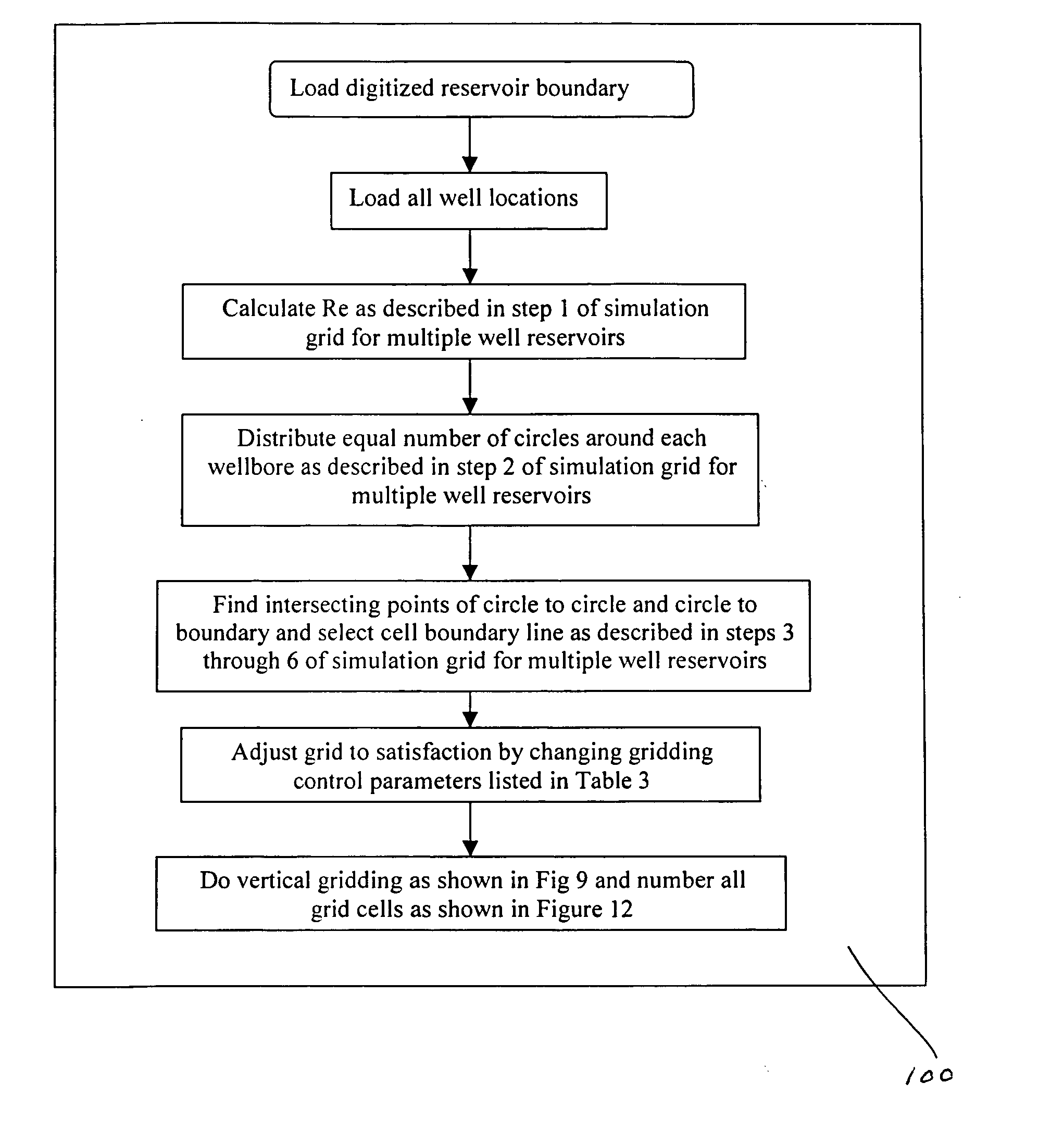

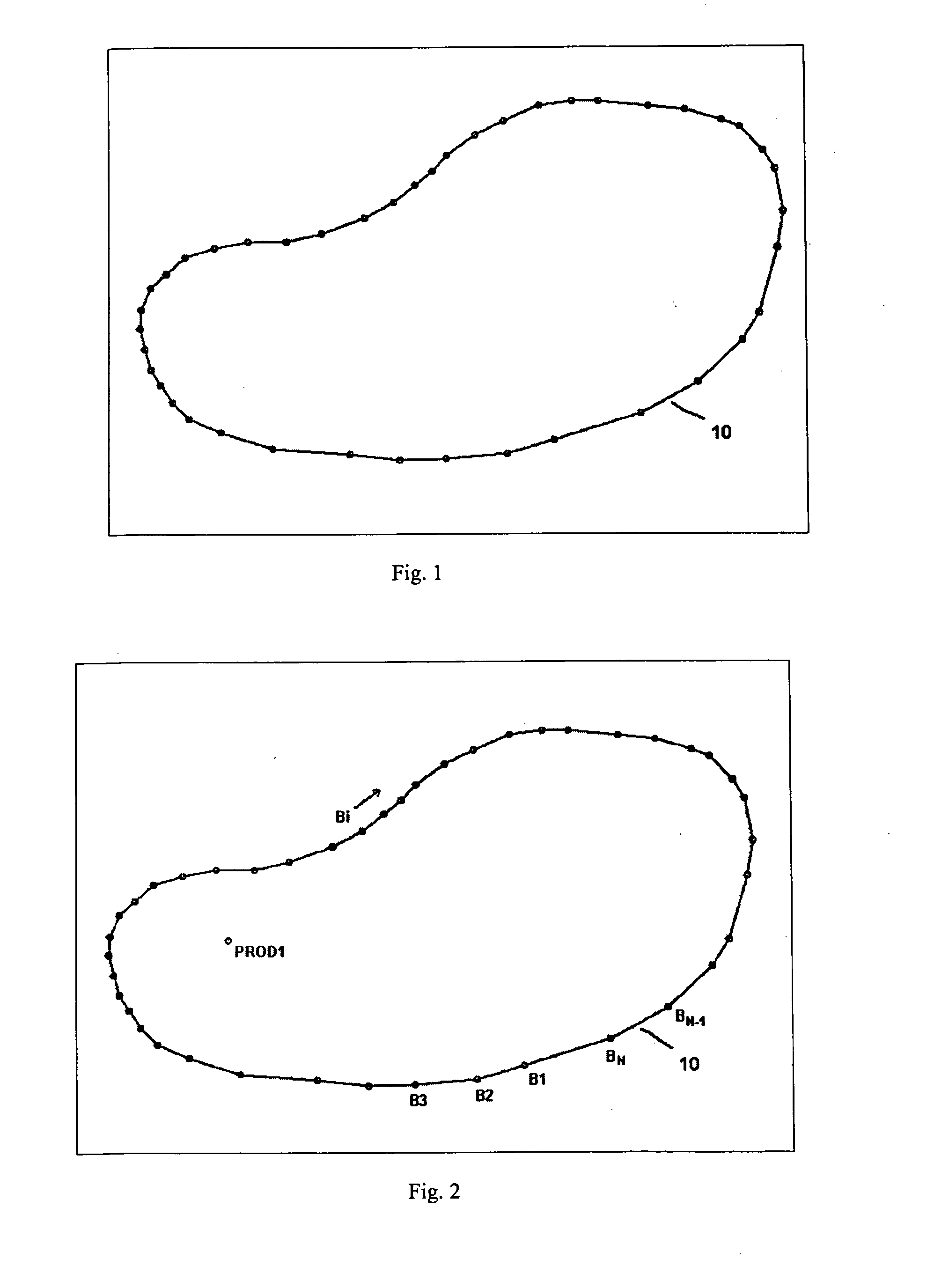

A method producing full field radial grid (called here Radial-X Grid) for more accurate and efficient reservoir simulation and improving simulation work flow. The Radial-X Grid method produces both aerial and vertical gridding to divide a reservoir structure into simulation grid cells. The aerial gridding is performed by 1) specifying a reservoir boundary (including faults) and well locations; 2) distributing a set of concentric circles around each well location; 3) determining the circle-circle and circle-boundary intersection locations of these circles; 4) forming the aerial grid by selecting circles, arc segments of intersecting circles and radial lines which connect the ends of these arc segments to the corresponding well center; 5) and forming additional grid lines by selecting the connecting lines of two wells if their circles intersect, adding additional radial lines to certain wells, and connecting end points of certain selected arc segments. Thus, the aerial boundary of each individual grid cell is formed from elements selected from the group of arc segment, well radial line, reservoir boundary, connection line of well to well, arc segment end to arc segment end. The vertical gridding is performed by casting the aerial grid vertically downwardly through all the layers defined in the reservoir structure. The Radial-X Grid method is advantageous for petroleum reservoir simulation applications because it is easy to use, runs fast, produces no grid orientation effect, provides efficient use of grid cells, provides precision modeling and provides better reservoir boundary and fault conformance.

Owner:HAN DIANLI

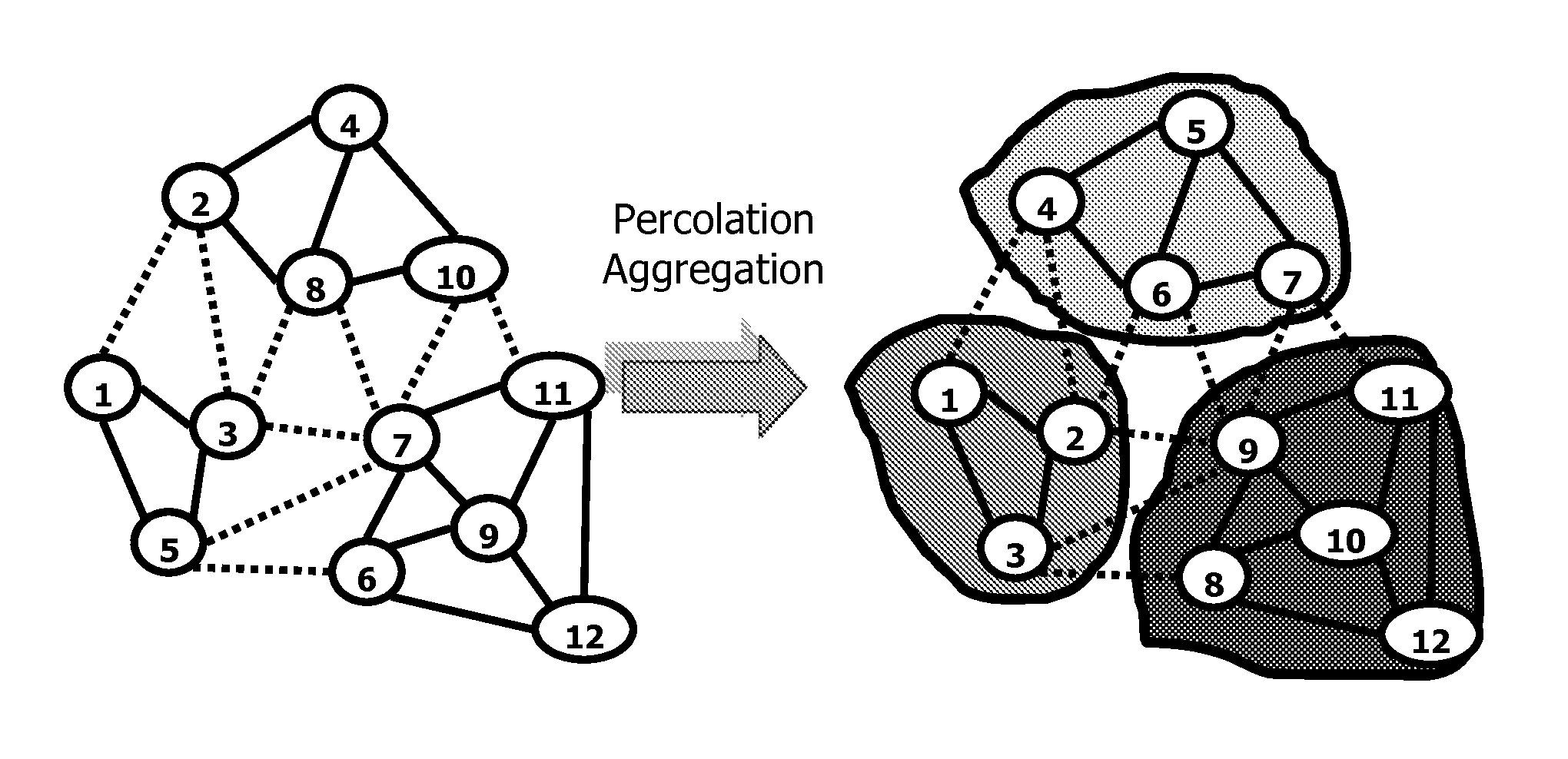

Multilevel percolation aggregation solver for petroleum reservoir simulations

InactiveUS20110191080A1Easy to solveSpecial data processing applicationsCAD numerical modellingPetroleum reservoirComputer science

An efficient percolation aggregation solver methodology captures media connectivity and continuity to reliably incorporate relevant flow solution trends in subterranean formation models. The approach allows introduction of meaningful physical information that is generally overlooked by state-of-the-art algebraic algorithms in the solution process. Percolation aggregation extends the efficiency and robustness of solution methods used to solve scientific and engineering problems.

Owner:CONOCOPHILLIPS CO

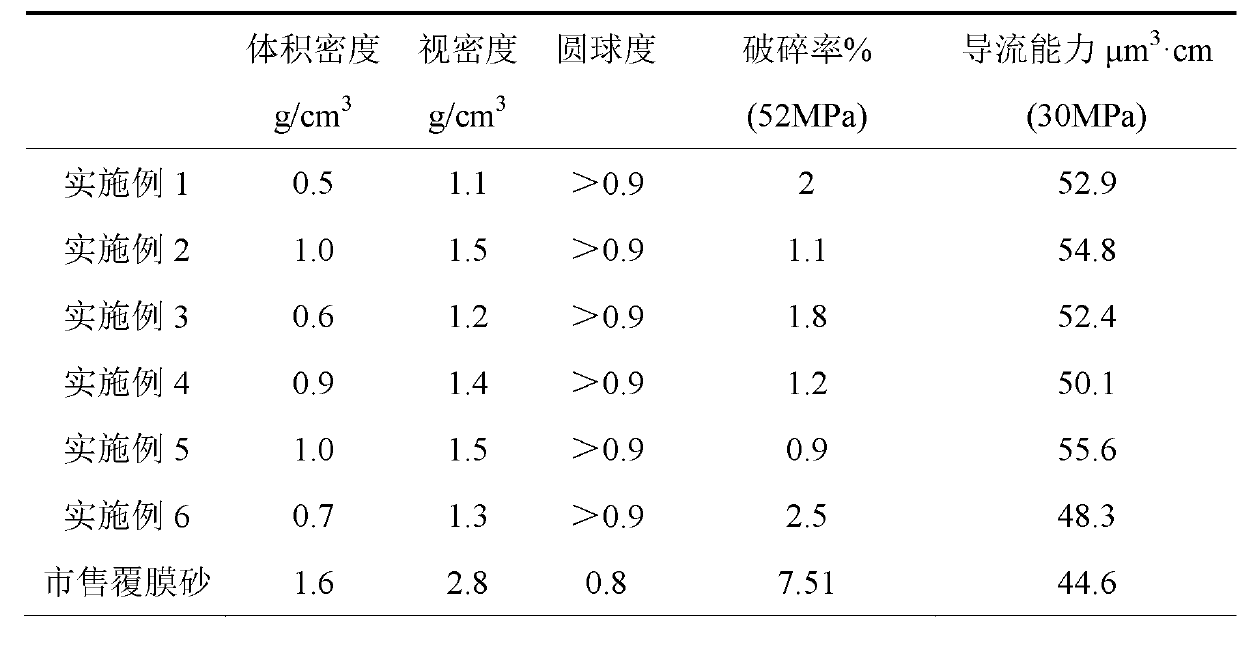

Clean-water-carrying petroleum proppant for petroleum production of low-permeability petroleum reservoir and preparation method thereof

The invention provides a clean-water-carrying petroleum proppant for petroleum production of a low-permeability petroleum reservoir. The proppant is prepared through coating macromolecular polymer particles with the particle sizes of 3-100 meshes by using macromolecular resin, wherein the macromolecular polymer particles are white polymer balls formed through polymerizing olefin monomers or polymer microspheres formed through compounding after a silane coupling agent modified mineral material is added; and the proppant has the volume density of 0.5-1.0 g / cm<3> and the apparent density of 1.1-1.5 g / cm<3>. The invention simultaneously provides a preparation method of the petroleum proppant. The clean-water-carrying petroleum proppant prepared by adopting the preparation method can greatly reduce the viscosity of sand carrying liquid, reduce the damage to strata and pumps and even realize clean fracturing. Through the low-density proppant, the entire construction cost can be reduced, and the phenomenon of proppant discharging or crack emptying is difficult to occur.

Owner:CHINA UNIV OF GEOSCIENCES (WUHAN)

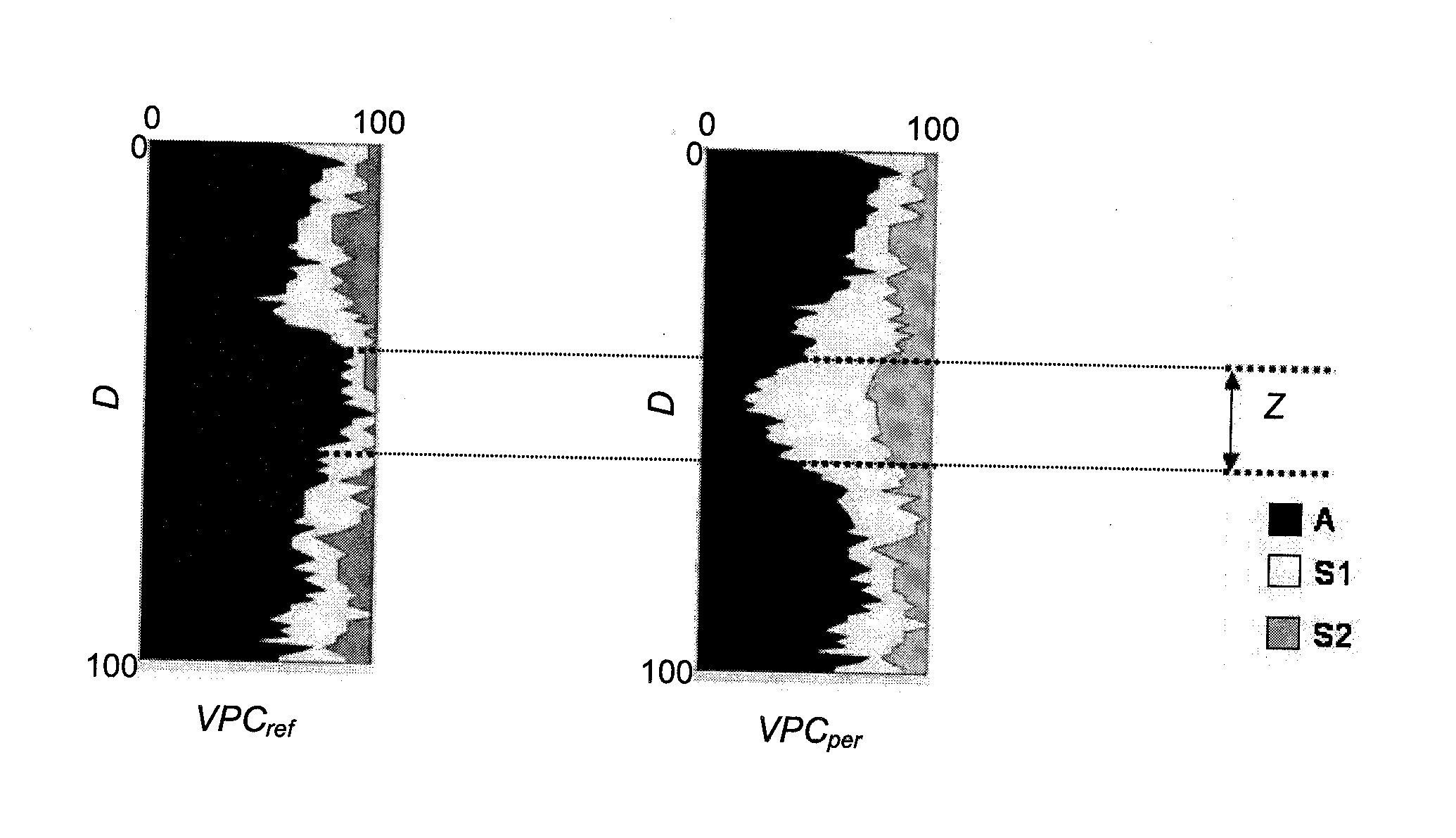

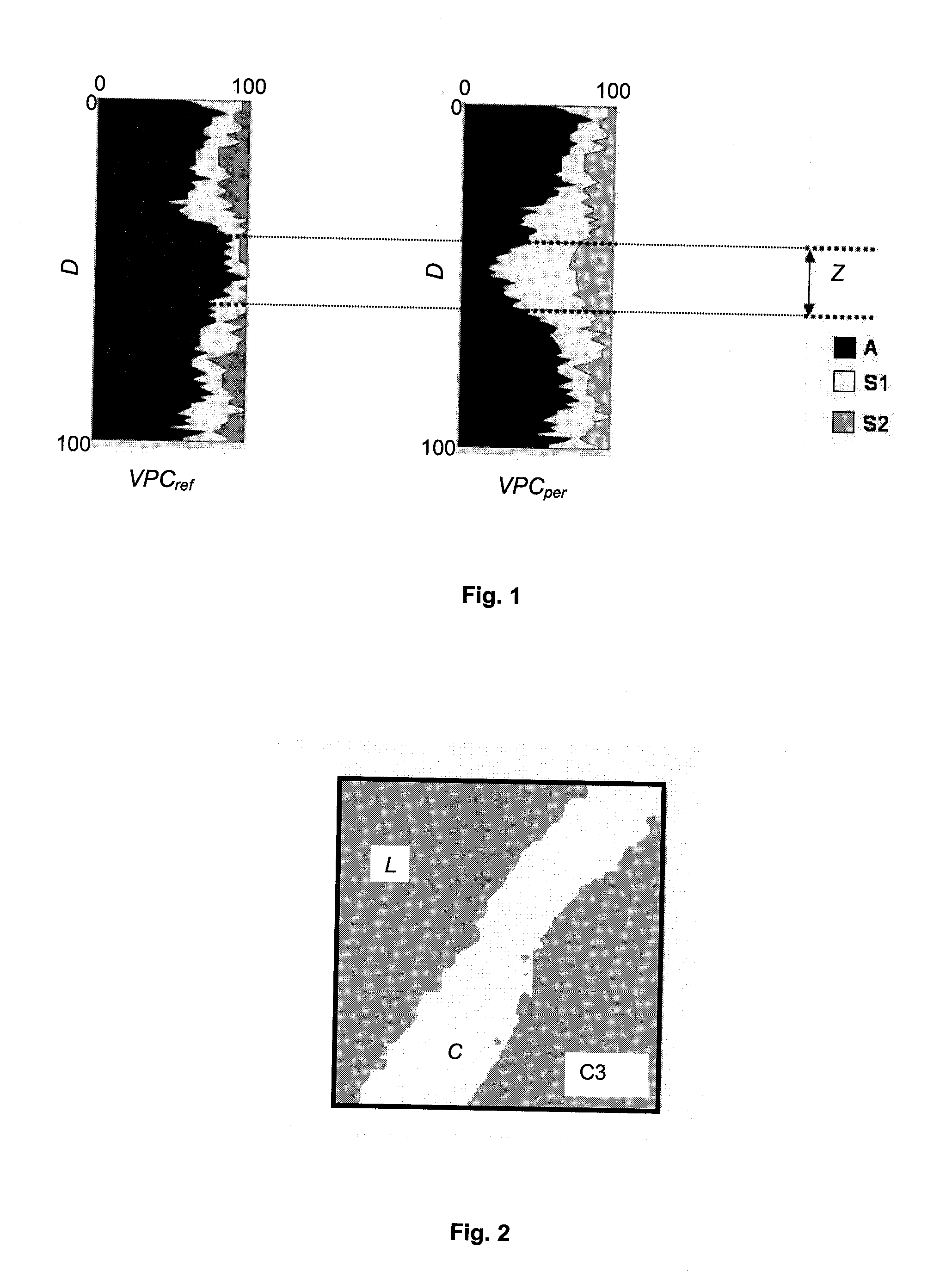

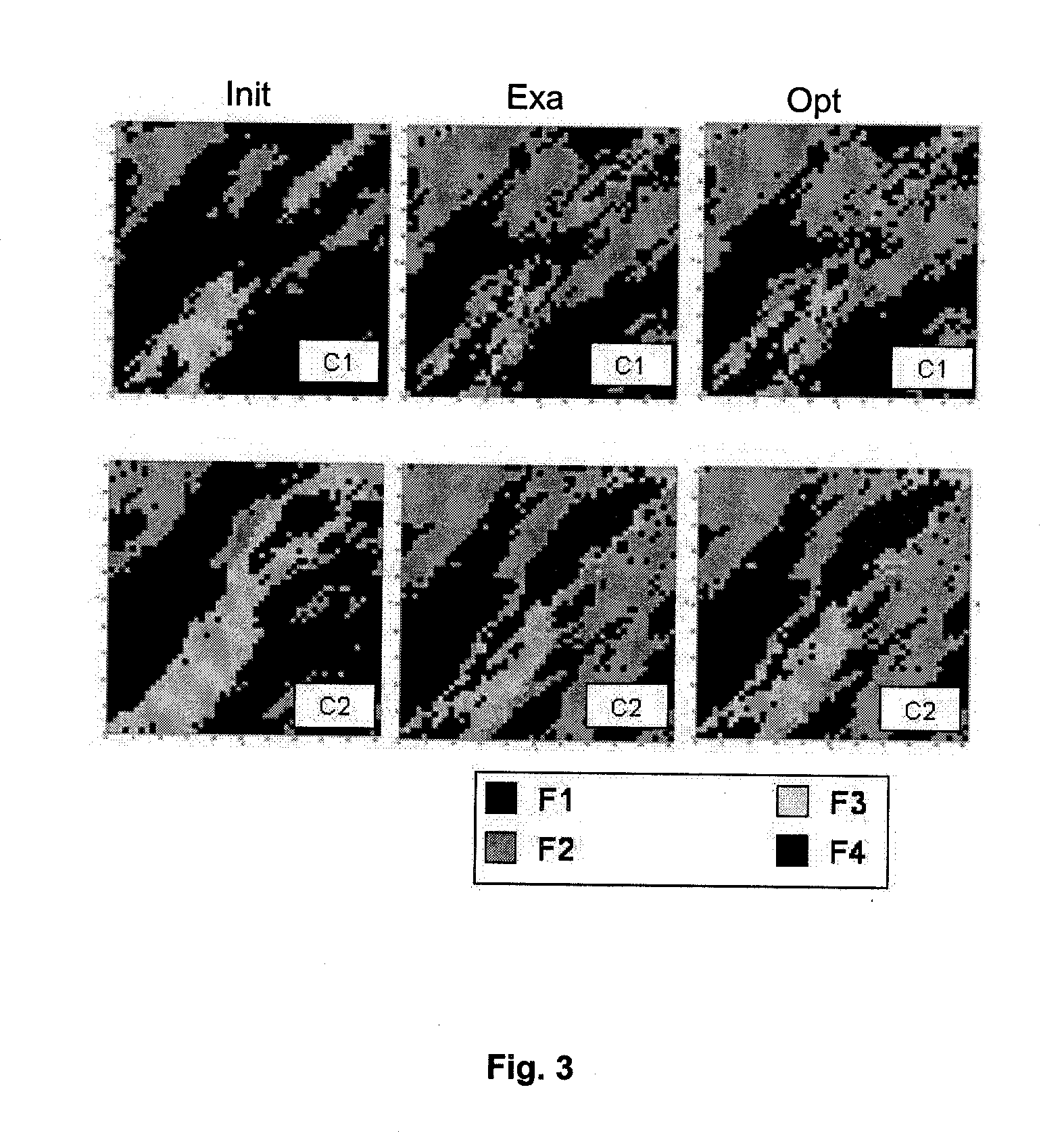

Method of modified facies proportions upon history matching of a geological model

A method of modifying a geological model representative of an underground reservoir is disclosed which respects average proportions of the lithologic facies imposed by a production data calibration process which has application to petroleum reservoir development. A geographical zone Z is defined within the geological model and an average proportion in zone Z allowing the production data to be calibrated is determined for k facies, with an optimization process. The proportions of these facies are modified using a block indicator cokriging method constrained by the average proportions to be respected. A new geological model constrained by the modified facies proportions is simulated and the development of the underground medium is optimized by the simulated model.

Owner:INST FR DU PETROLE

Inversion method for stratum elasticity constant parameter of pre-stack seismic data

ActiveCN102466816AWith noise immunityHigh resolutionSeismic signal processingSeismology for water-loggingHorizonNetwork model

The invention relates to an inversion method for a stratum elasticity constant parameter of pre-stack seismic data in geophysical prospecting for petroleum. The method comprises the following steps of: acquiring seismic data, and processing the pre-stack seismic data; obtaining logging data and extracting angle gather seismic data to form all stacked data; performing horizon calibration on the seismic data and the logging data; inverting the seismic data which is stacked at different incident angles to obtain a wave impedance parameter; calculating a corresponding reflection coefficient; generating a logging and seismic data pair; calculating a weight function and a model parameter of a function mapping network model, an impedance parameter and an elasticity constant; and drawing an elasticity constant profile for reservoir lithologic identification, petroleum-gas prediction, oil-water interface determination and petroleum reservoir description. By the method, the elasticity constant can be calculated by the conventional inversion of the seismic data and the logging data; and the method has certain adaptability to the inversion of faults and pinch-out zones, a wide application range, high resolution, high calculation speed, high stability, high calculation accuracy and the characteristic of certain anti-noise property.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

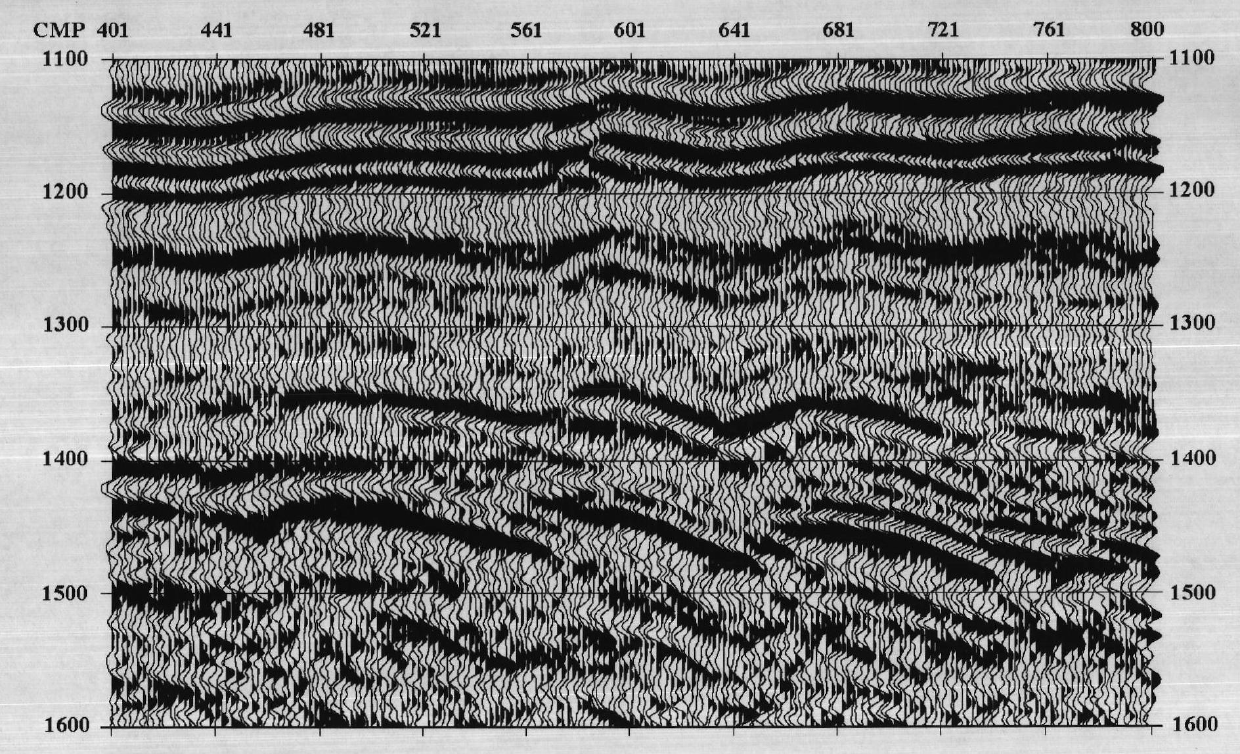

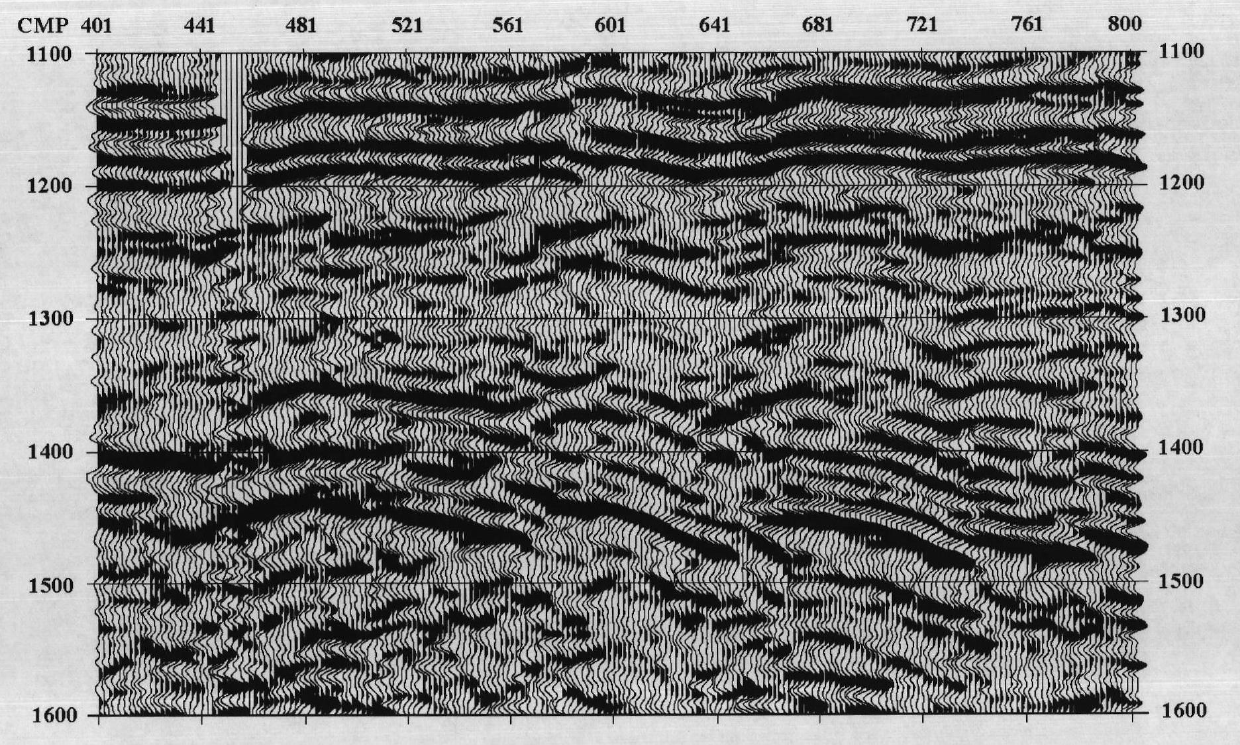

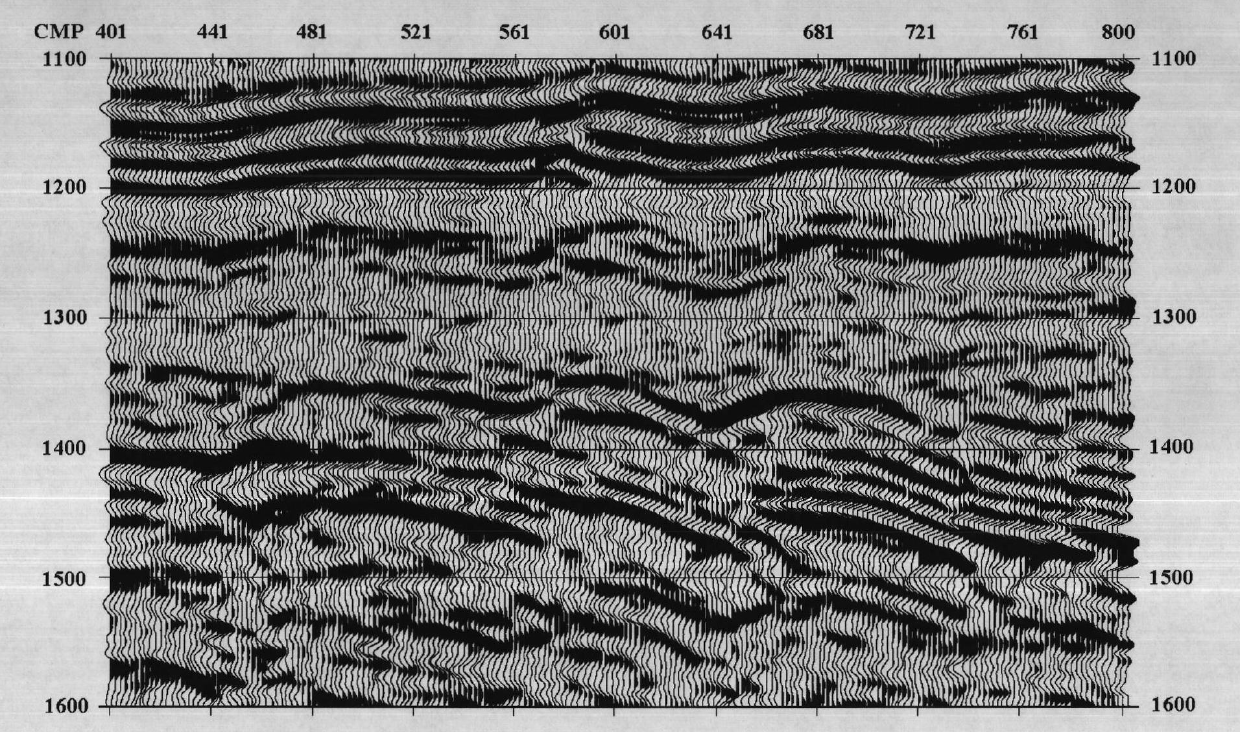

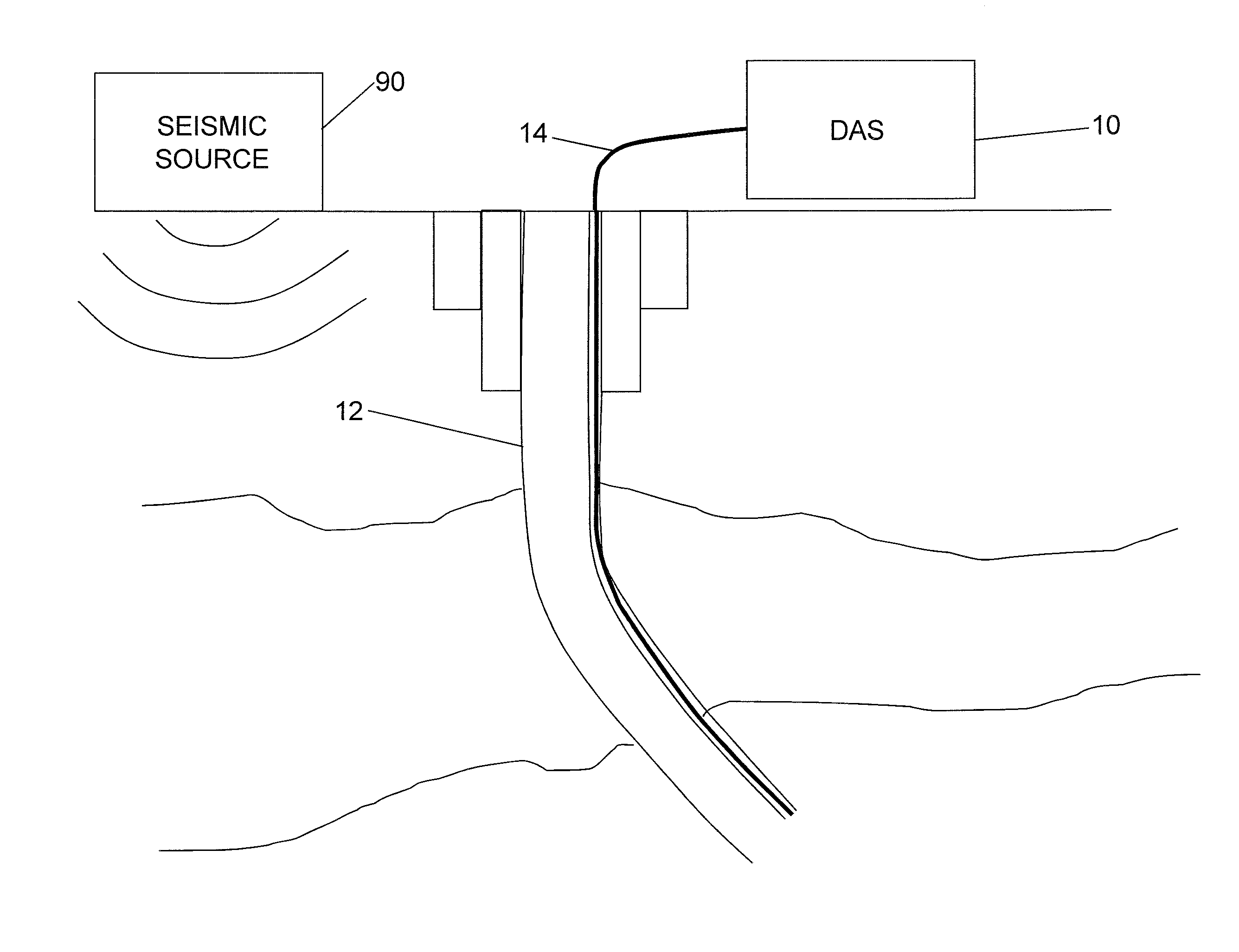

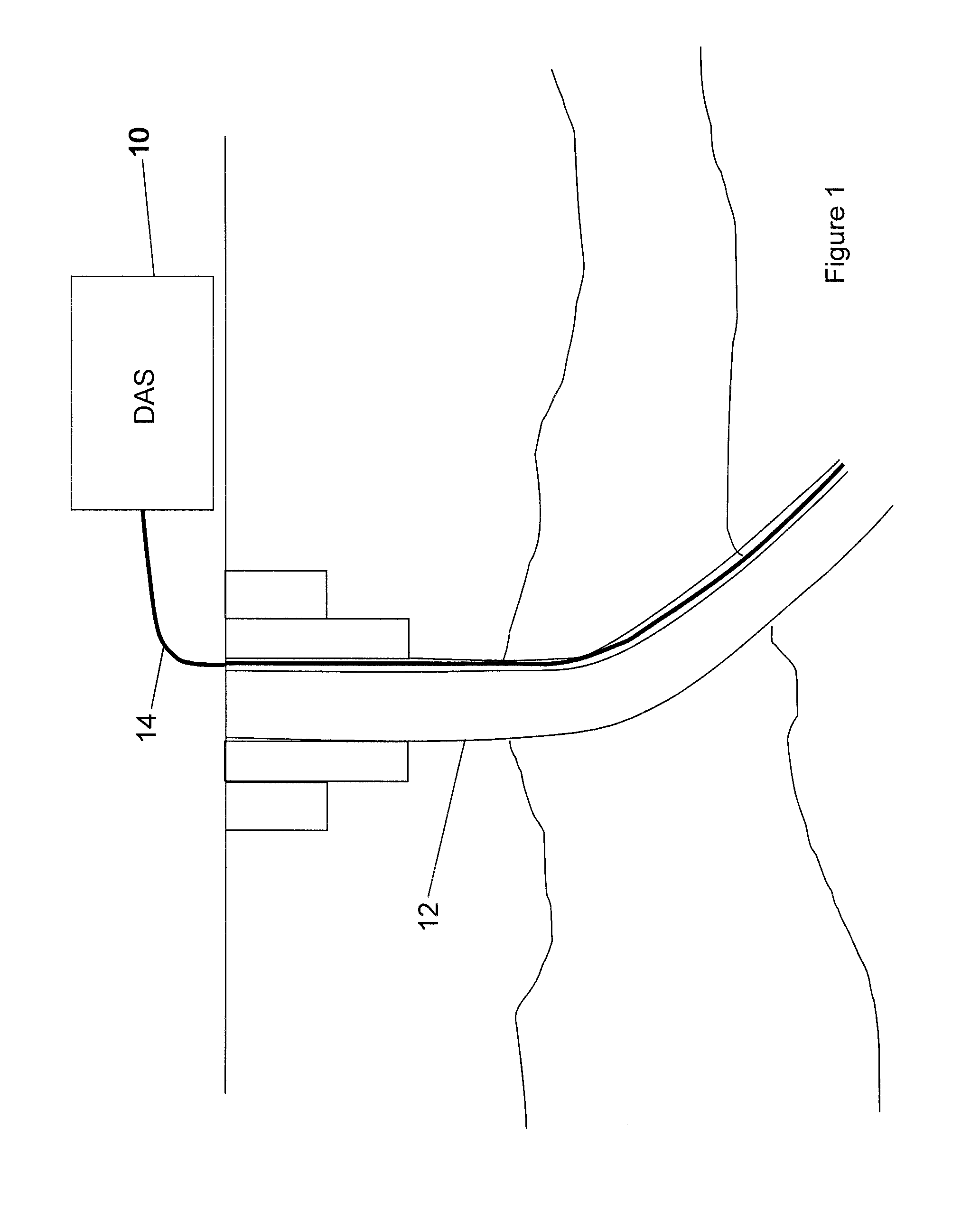

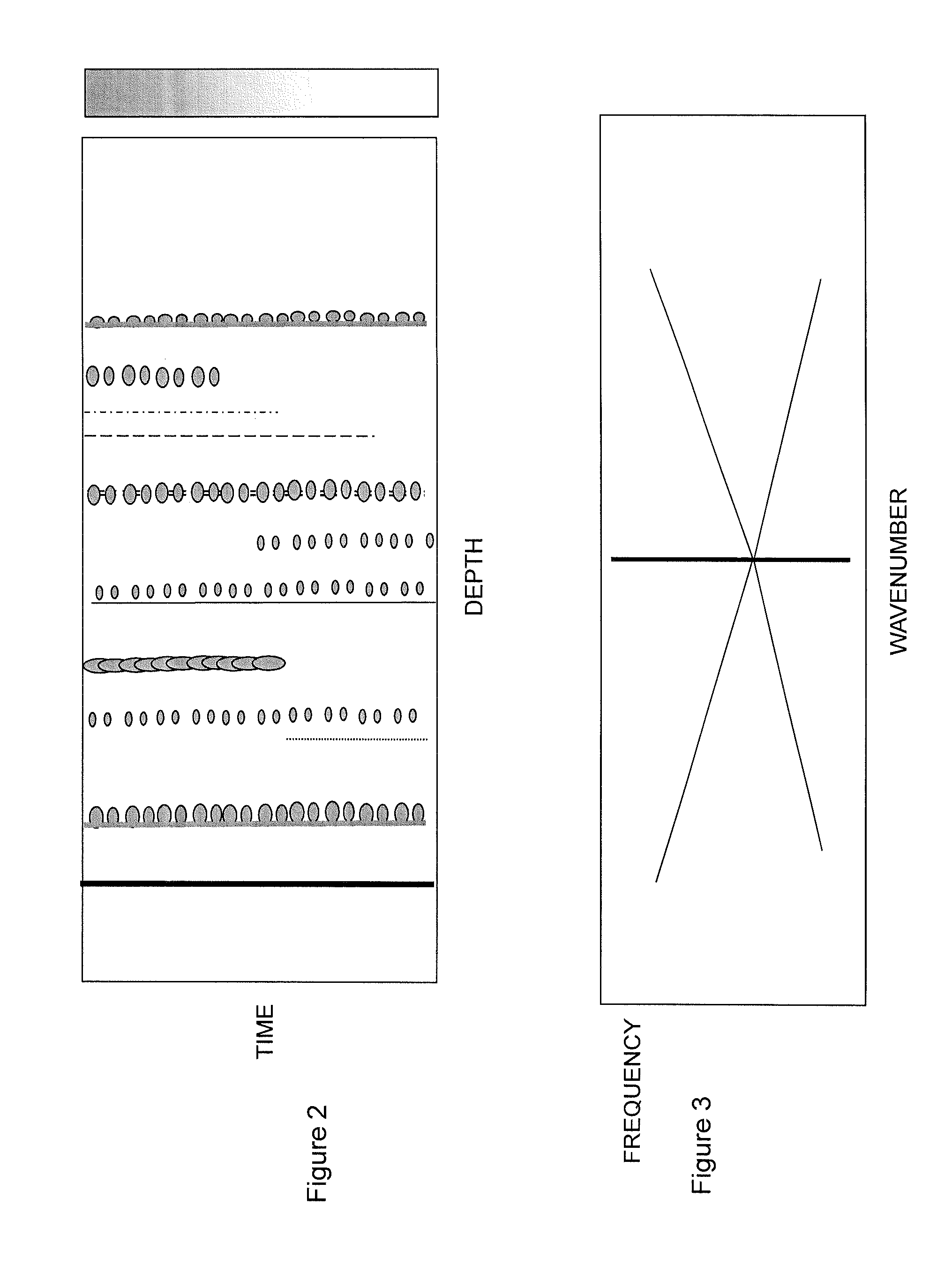

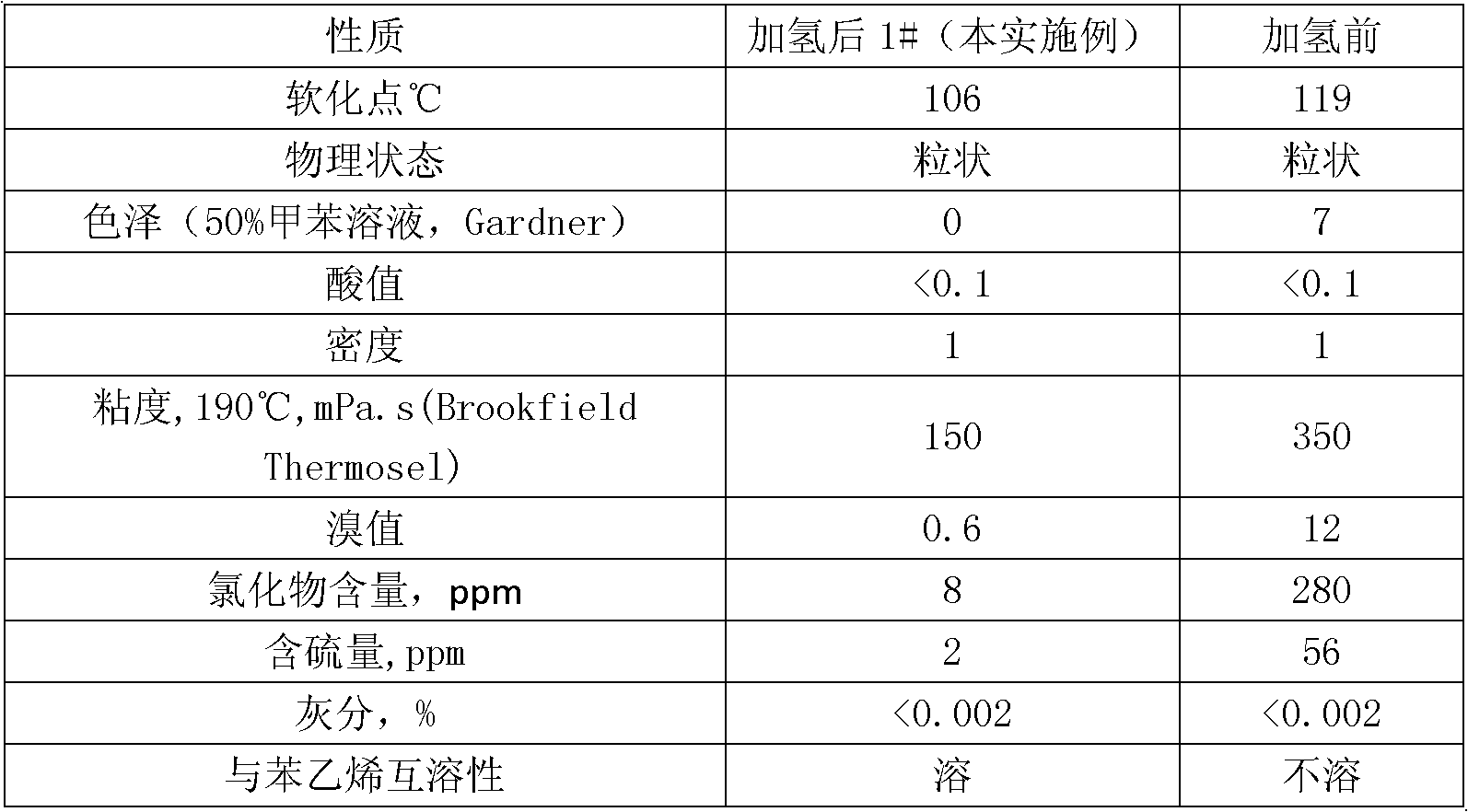

Enhanced seismic surveying

InactiveUS20140126325A1ConfidenceImprove accuracySubsonic/sonic/ultrasonic wave measurementConstructionsDistributed acoustic sensingSeismic survey

Embodiments of the present invention help in the processing and interpretation of seismic survey data, by correlating or otherwise comparing or associating seismic data obtained from a seismic survey with flow information obtained from a well or borehole in the surveyed area. In particular, embodiments of the present invention allow for flow data representing a flow profile along a well that is being monitored by a distributed acoustic sensor to be determined, such that regions of higher flow in the well can be determined. For example, in the production zone the well will be perforated to allow oil to enter the well, but it has not previously been possible to determine accurately where in the production zone the oil is entering the well. However, by determining a flow rate profile along the well using the i)AS then this provides information as to where in the perforated production zone oil is entering the well, and hence the location of oil bearing sands. This location can then be combined or otherwise correlated, used, or associated with petroleum reservoir location information obtained from the seismic survey, to improve the confidence and / or accuracy in the determined petroleum reservoir location.

Owner:SILIXA +1

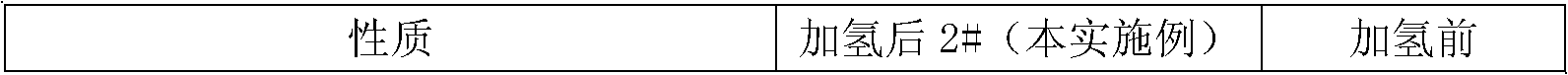

Preparation method for Carbon 5/Carbon 9 hydrogenated petroleum resin

The invention discloses a preparation method for Carbon 5 / Carbon 9 hydrogenated petroleum resin. In the existing preparation methods, certain methods have extremely high requirements on devices and high cost, and catalysts used by certain methods are not ideal for aromatic ring hydrogenation effect or easily cause intoxication. The preparation method comprises the following steps: firstly dissolving Carbon 5 / Carbon 9 petroleum resin by a dissolvent, then carrying out centrifugal sedimentation on the carbon 5 / Carbon 9 petroleum resin so as to remove most insoluble gel and asphaltenes, filtering the carbon 5 / Carbon 9 petroleum resin in an absorption tower filled with fillers so as to remove remained insoluble gel, asphaltenes and heavy metals; carrying out medium pressure hydrogenation reaction on liquid obtained through filtration in a static bed filled with secondary hydrogenation catalyst; and finally, carrying out flash evaporation and steam stripping so as to remove solvent in the product. The preparation method adopts a macroporous catalyst carrier; fluids are not easily blocked in holes, thereby greatly reducing fluid pressure drop and increasing effective catalytic area; and secondary hydrogenation can be completed in medium pressure, thereby greatly reducing requirements on devices and investment cost of the devices and obtaining hydrogenated petroleum resin with high quality.

Owner:杭州腾王网络科技有限公司

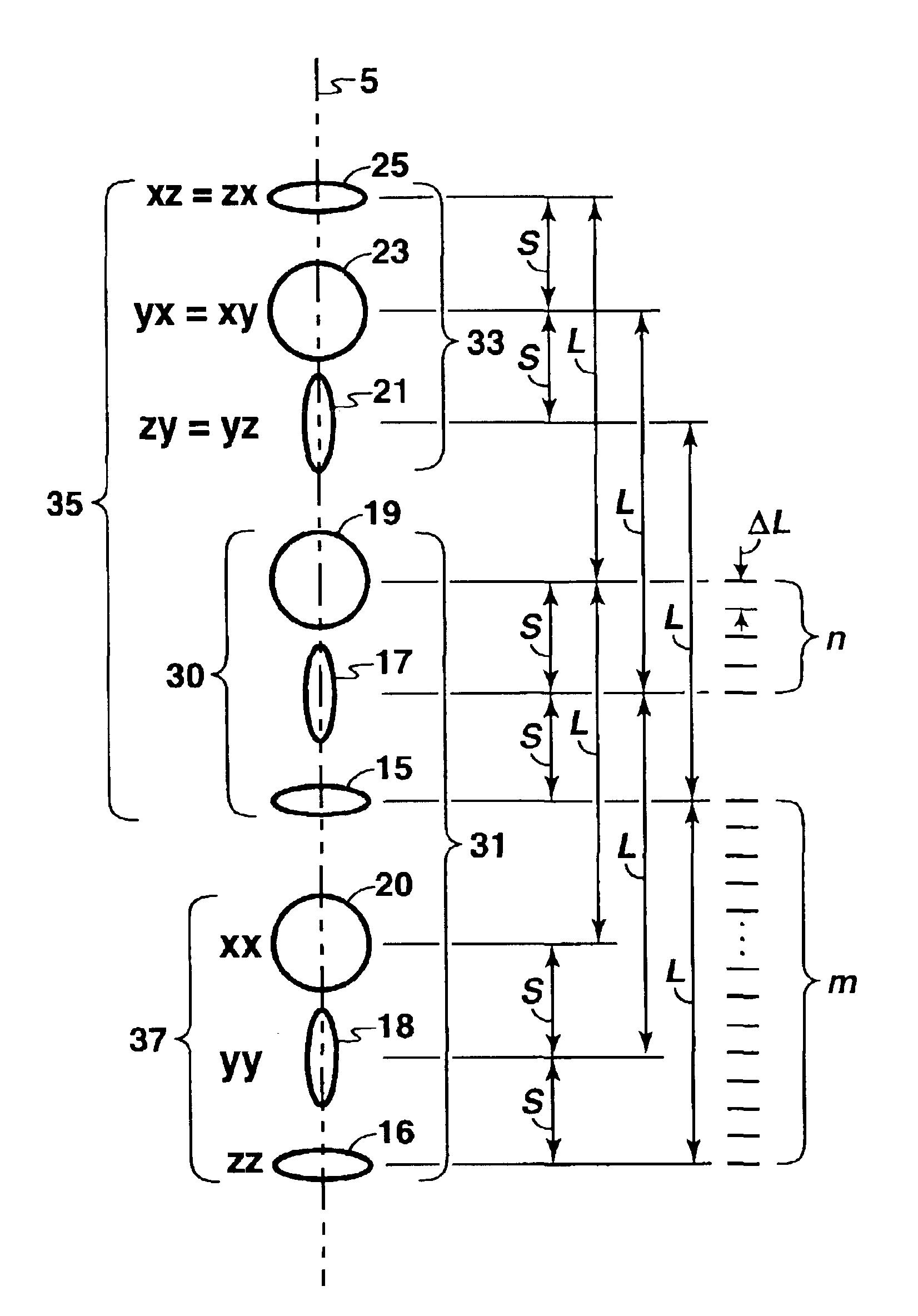

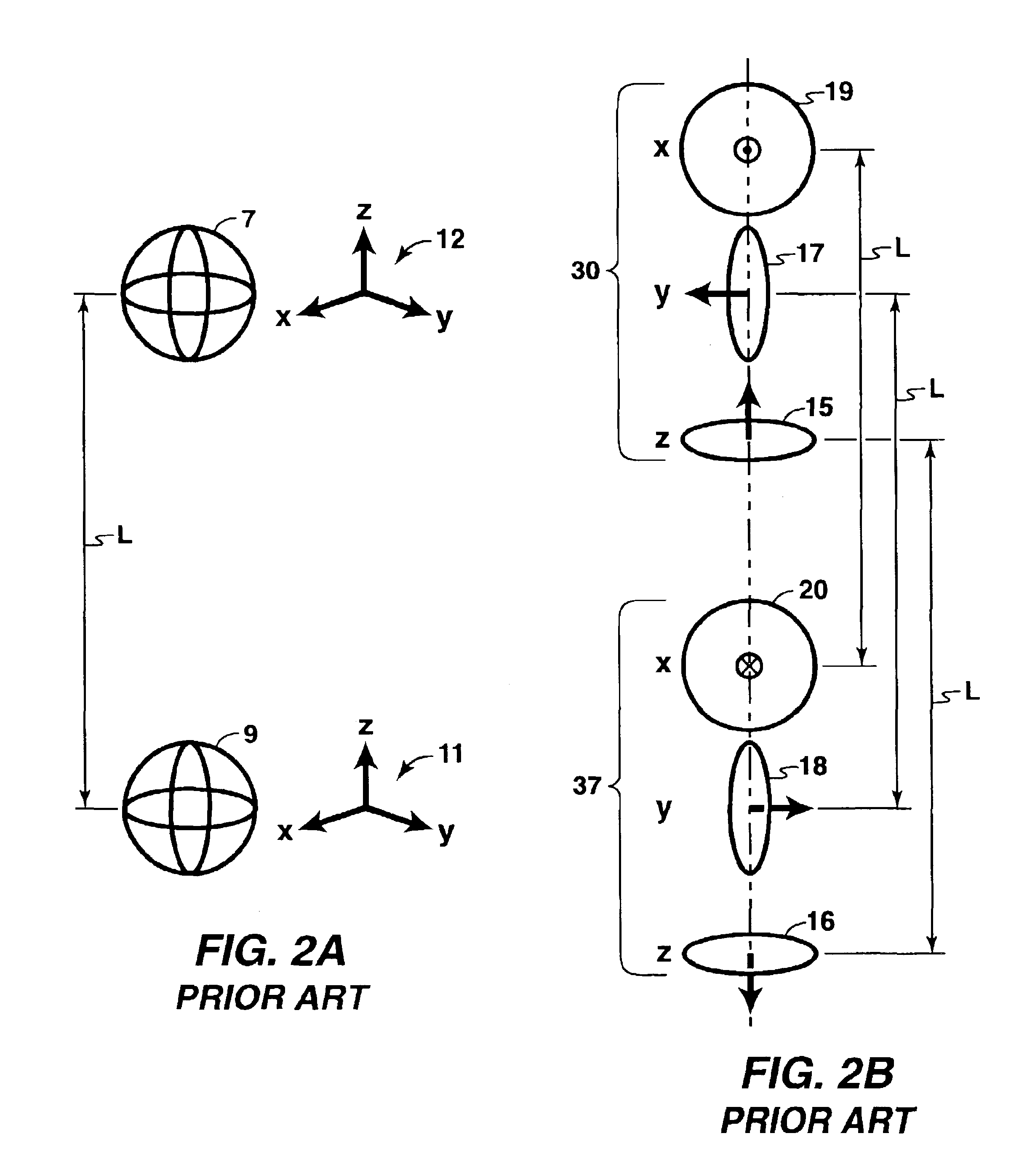

Apparatus and method for measurement of the magnetic induction tensor using triaxial induction arrays

ActiveUS6934635B2Electric/magnetic detection for well-loggingWater resource assessmentDirect couplingPetroleum reservoir

An apparatus and a method for recording the magnetic induction tensor induced in an earth formation are provided. The apparatus includes a magnetic induction device having at least three mutually orthogonal transmitter dipoles and at least three mutually orthogonal receiver dipoles that are direct-coupled, and at least three mutually orthogonal receiver dipoles that are cross-coupled. The method includes using the apparatus to sample the magnetic induction tensor components at a point. Further, samples may be taken at regularly spaced intervals using the magnetic induction device, moving the triaxial logging unit so that each transmitter and each receiver sequentially occupy the same point, repeating these steps until each transmitter and receiver array have sequentially occupied all desired points, and combining the magnetic induction tensor components to form the magnetic induction tensor. These components are useful in inferring water saturation and estimating hydrocarbon volumes in petroleum reservoirs.

Owner:EXXONMOBIL UPSTREAM RES CO

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com