Clean-water-carrying petroleum proppant for petroleum production of low-permeability petroleum reservoir and preparation method thereof

A proppant and oil seepage technology, which is applied in the direction of production fluid, earthwork drilling, coating, etc., can solve the problems of unfavorable oil production increase and reduce the effect of hydraulic fracturing, so as to achieve clean fracturing, not easy to crack and empty, damage reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

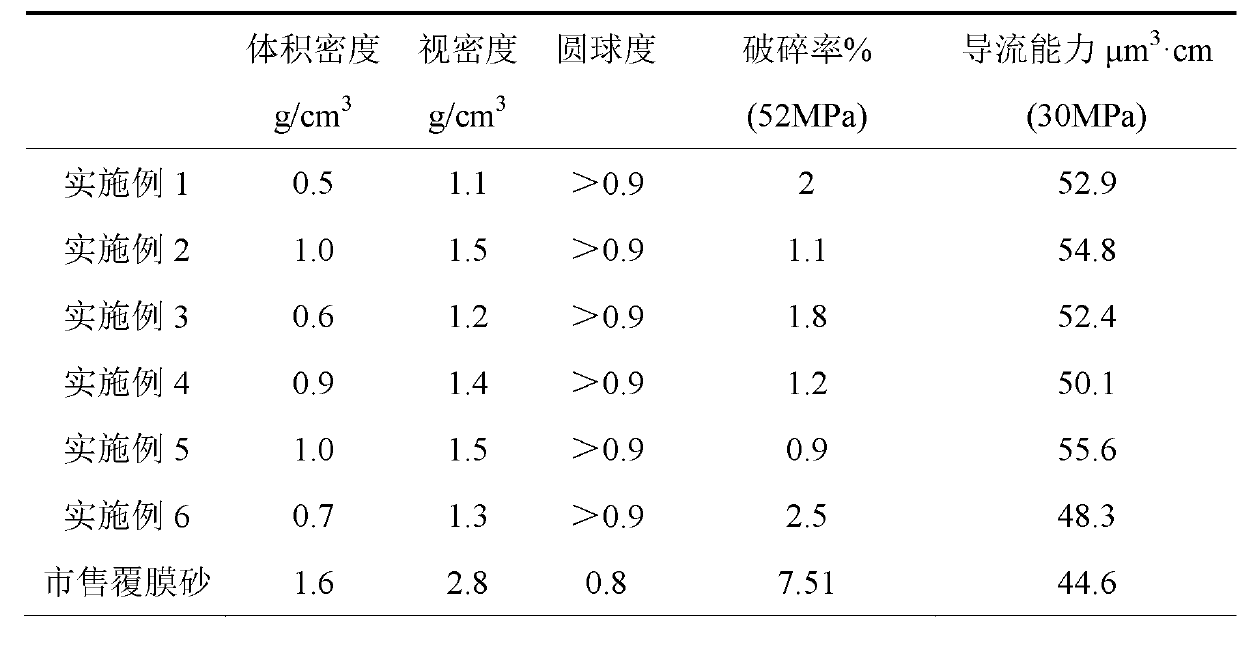

Examples

Embodiment 1

[0024] The clean water-carrying petroleum proppant provided in this example for oil recovery of low-permeability reservoirs is prepared by the following method:

[0025] (1) After mixing 10g of acrylonitrile, 0.1g of methylenebisacrylamide, 0.005g of ammonium persulfate, and 0.5g of liquid paraffin, they were dispersed into 40ml of gelatin solution with a mass percent concentration of 0.1% under stirring conditions, Then raise the temperature to 50°C for 3 hours, then raise the temperature to 80°C for 5 hours, and finally raise the temperature to 95°C for 7 hours to obtain polymer white balls with a particle size of 80-100 mesh.

[0026] (2) Weigh 10g of the above-mentioned dry polymer white ball, add it to the 10g ethanol solution dissolved with 2g phenolic resin and 0.2g hexamethylenetetramine, soak and absorb at room temperature for 0.5h, then pour out the excess solvent , and finally under the condition of stirring, gradually increase the temperature to 200°C at a rate of ...

Embodiment 2

[0028] The clean water-carrying petroleum proppant provided in this example for oil recovery of low-permeability reservoirs is prepared by the following method:

[0029] (1) Disperse 5 g of γ-aminopropyltriethoxysilane and 2.5 g of diatomaceous earth in a methanol solution, stir at room temperature for 0.5 h, then filter and dry with suction to obtain a mineral material modified by a silane coupling agent.

[0030] (2) After mixing 2g of the above-mentioned modified diatomite, 10g of acrylamide, 2g of divinylbenzene, 0.05g of potassium persulfate, and 2g of toluene, they were dispersed into 40ml of 2% by mass concentration under stirring In polyvinyl alcohol solution, then raise the temperature to 75°C for 1 hour, then raise the temperature to 90°C for 5 hours, and finally raise the temperature to 105°C for 3 hours to obtain mineral material composite polymer microspheres with a particle size of 3-10 mesh.

[0031] (3) Weigh 10 g of the above-mentioned dry polymer microspheres...

Embodiment 3

[0033] The clean water-carrying petroleum proppant provided in this example for oil recovery of low-permeability reservoirs is prepared by the following method:

[0034] (1) Mix 7g of styrene, 3g of methyl acrylate, 1g of divinylbenzene, 0.01g of benzoyl peroxide, 0.5g of liquid paraffin, and 0.5g of toluene, and then disperse to a concentration of 40ml by mass under stirring 1% gelatin solution, then heated up to 60°C for 2 hours, then heated up to 85°C for 4 hours, and finally heated up to 95°C for 6 hours to obtain polymer white balls with a particle size of 60-80 mesh.

[0035] (2) Take by weighing 10g dry above-mentioned polymer white ball, join in the 10g chloroform solution that is dissolved in 5g epoxy resin, 1g acetic anhydride that mixes uniformly, soak and absorb 12h at room temperature, then pour out excess solvent, finally in stirring Under the same conditions, the temperature is gradually raised to 200°C at a rate of 20°C / 10min for curing reaction. After curing for...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Bulk density | aaaaa | aaaaa |

| Apparent density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com