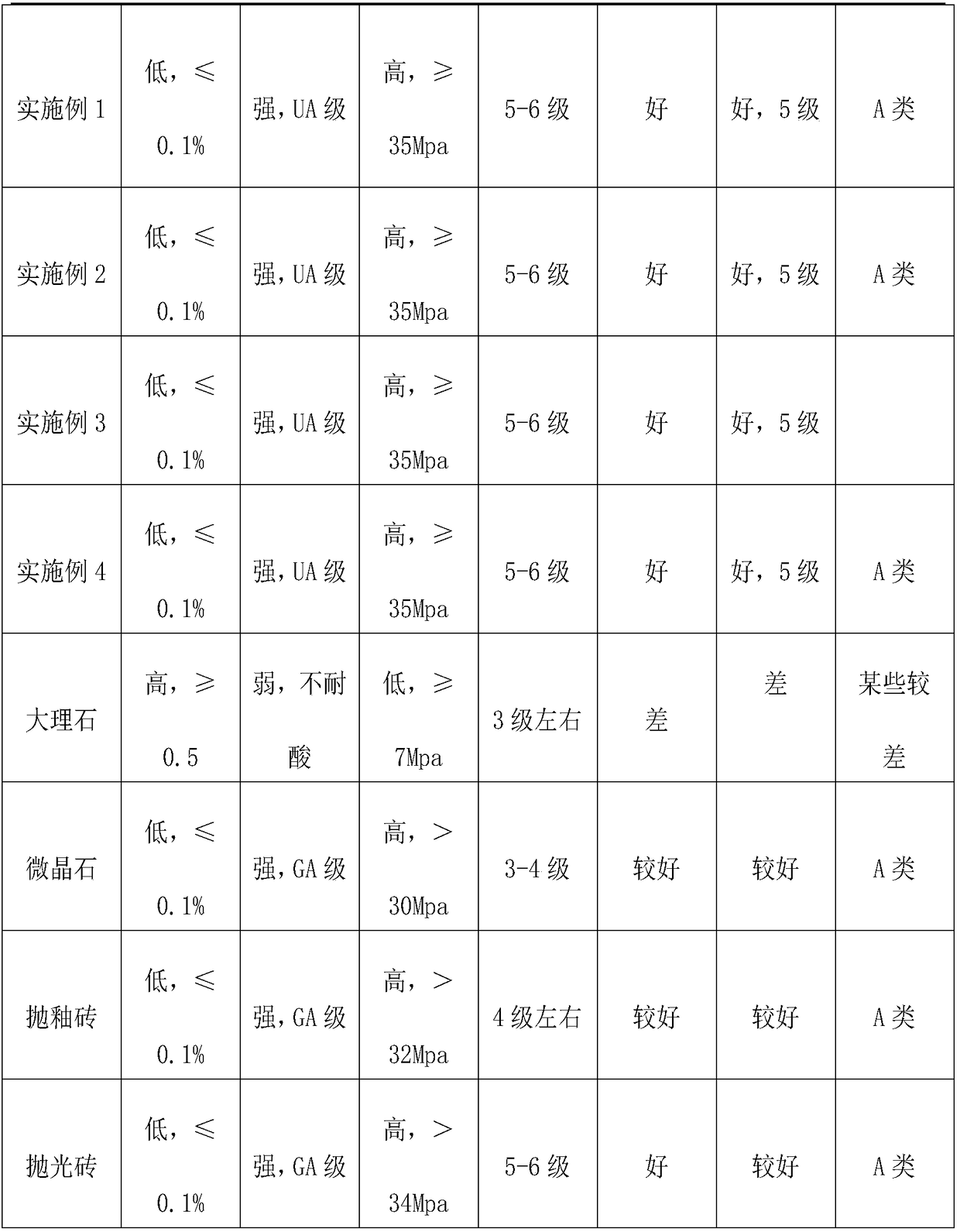

Patents

Literature

75 results about "White ball" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

The ball, held in a tent outside Tavern on the Green, was a charity event that raised $1.4 million for the Alzheimer's Association. In anticipation of selling the contents of the Plaza Hotel, Christie's Auction House recreated the Black and White Ball in 2006 at Rockefeller Center.

Novel chelate resin and production method and application thereof

ActiveCN101735372AHigh removal rateSimple process controlOther chemical processesMetal impuritiesChloroacetic acids

The invention provides a chelate resin and a production method and the application thereof, and the novel chelate resin can effectively remove impurities in trichlorosilane; the preparation method provided by the invention comprises the following steps: (1) zinc chloride is used as catalyzer, a white ball and chloromethyl ether are reacted to obtain chloromethylate white ball; (2) the chloromethylate white ball and hexamine are reacted, and then concentrated hydrochloric acid-ethanol mixing solution is used for decomposing, so as to obtain primary amine resin; (3) the primary amine resin is added in the chloroacetic acid aqueous solution, and the reaction is carried out for 10-30 hours at 55-70 DEG C to obtain the chelate resin; the chelate resin can effectively remove the metal impurities such as boron, phosphorus, calcium, magnesium, copper, ferrum and other impurities in trichlorosilane, the removal rate can reach more than 99 percent; the chelate resin has high processing capacity with 200t per cube and is the optimal choice for improving the product quality.

Owner:SUNRESIN NEW METERIALS CO LTD XIAN

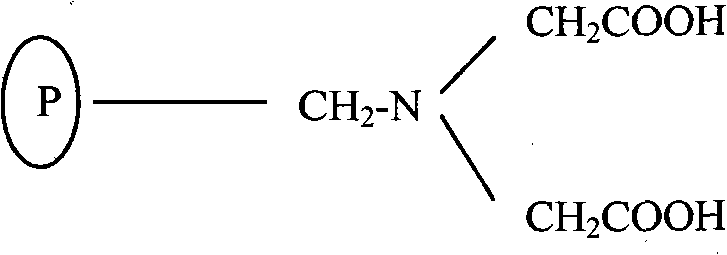

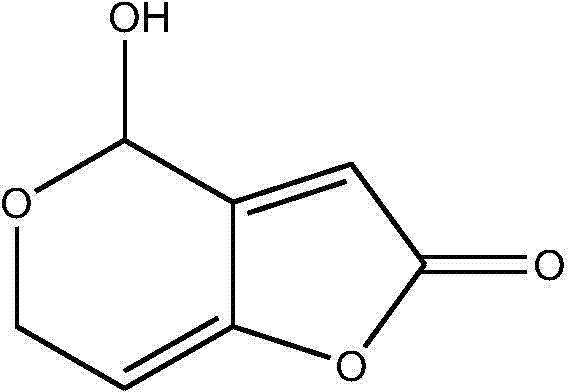

Ultrahigh cross-linked macro-porous adsorption resin applicable to removal of patulin

ActiveCN103772573ADense channelsUnique Pore Size DistributionIon-exchange process apparatusOther chemical processesCross-linkFunctional monomer

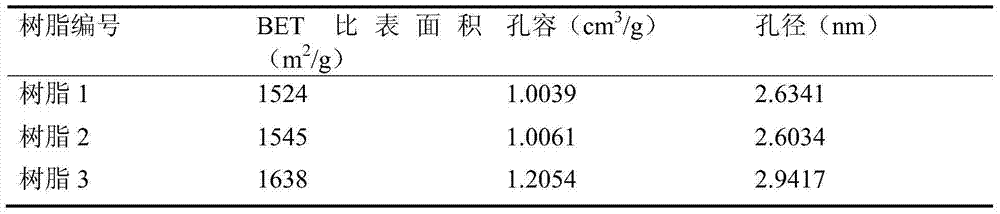

The invention provides ultrahigh cross-linked macro-porous adsorption resin which is obtained by taking a styrene monomer as a functional monomer, taking a multi-vinyl monomer as a cross-linking agent, suspending and polymerizing in the presence of a pore forming agent to obtain low-cross-linked macro-porous polystyrene white ball, reacting the obtained white ball with chloromethyl ether under the catalysis of lewis acid to obtain chloromethylation macro-porous polystyrene resin, and carrying out a Friedel-Crafts alkylation reaction on the obtained chloromethylation macro-porous polystyrene resin in the presence of a swelling agent by taking the lewis acid as a catalyst. Through adopting a novel cross-linking agent and pore forming agent system, the obtained resin has the advantages of high specific surface area and uniform pore diameter; the specific surface area is up to 1500-1800m<2> / g, the pore diameter distribution is uniform, a pore channel is dense and the average pore diameter is small; the pore diameter of the obtained macro-porous resin is rightly applicable to removal of patulin in juice and the removing efficiency is high; the resin can be used for pointedly removing the patulin which stably exists in the juice and the potential hazards on the human health, caused by the patulin in the juice, are solved; the ultrahigh cross-linked macro-porous adsorption resin has great social and economic benefits.

Owner:AMICOGEN CHINA BIOPHARM CO LTD

Macroreticular resin and preparing method thereof

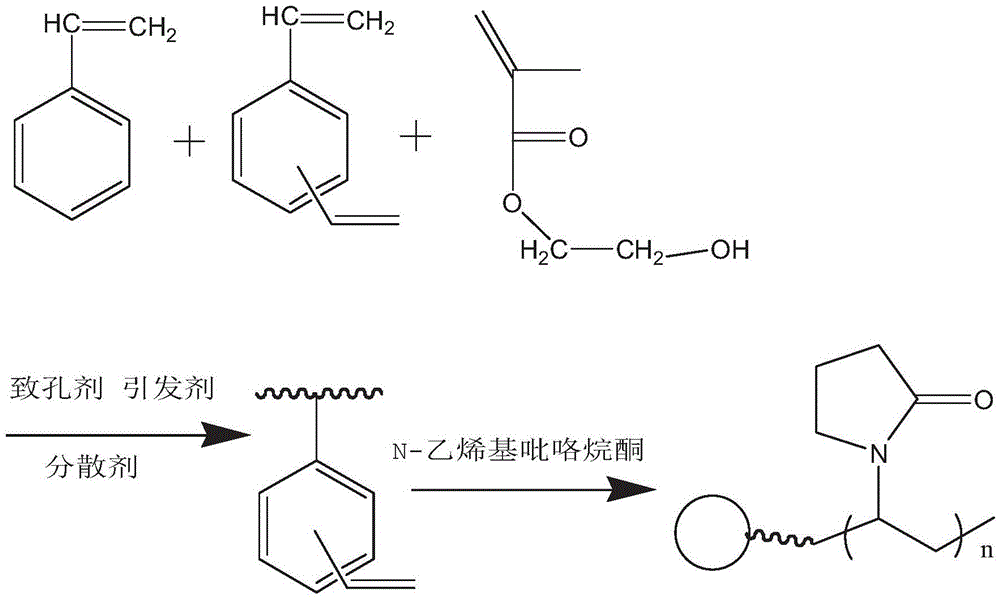

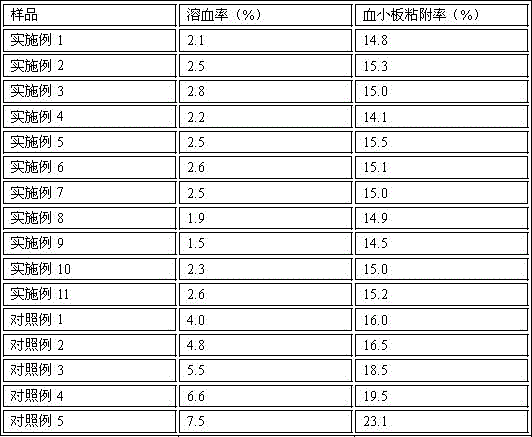

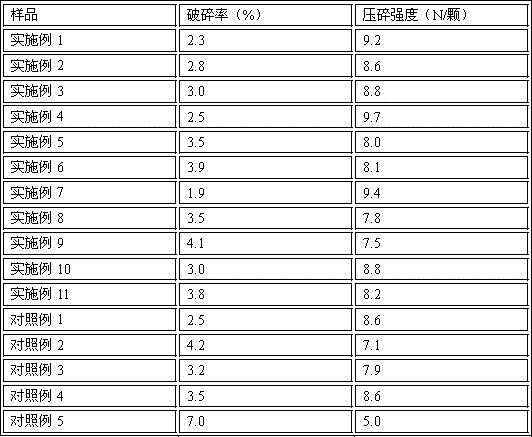

The invention relates to macroreticular resin and a preparing method thereof. The preparing method comprises the steps of a radial polymerizing step in step (1), a surface grafting step in step (2) and a postcrosslinking step in step (3) in sequence. The macroreticular resin as a blood perfusion adsorbent is used for uremia treatment, the macroreticular resin comprises matrix white balls formed by styrene class monomer, multivinyl class monomers and acrylics monomers containing hydroxyl groups, polyvinylpyrrolidone is grafted to the surface of the matrix white balls, and suspension double bonds on the matrix white balls form ultrahigh crosslinking macroreticular resin after postcrosslinking reaction. The macroreticular resin is improved in aspects of mechanical strength, adsorption performance and hemolysis effect.

Owner:JAFRON BIOMEDICAL

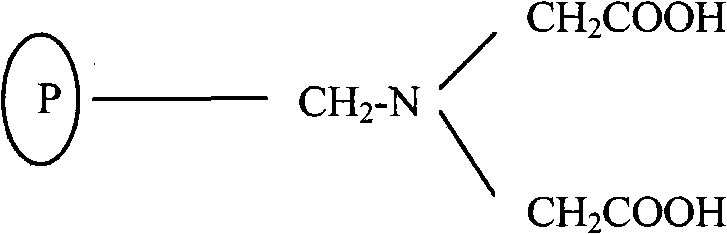

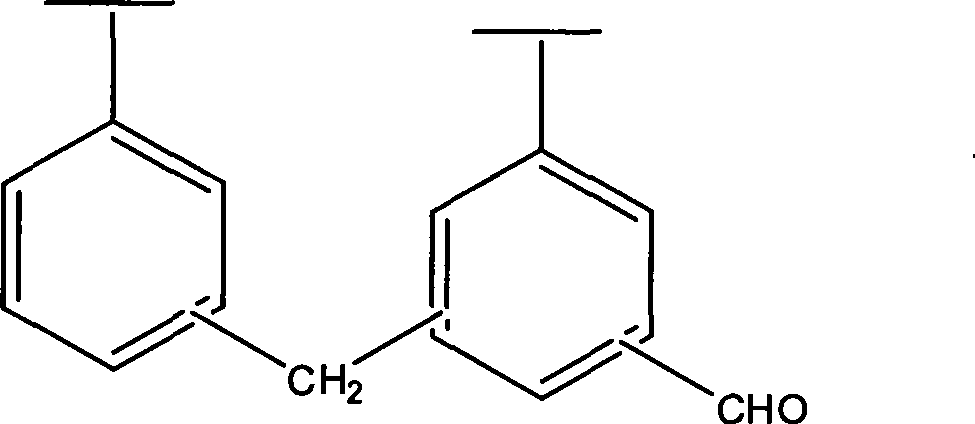

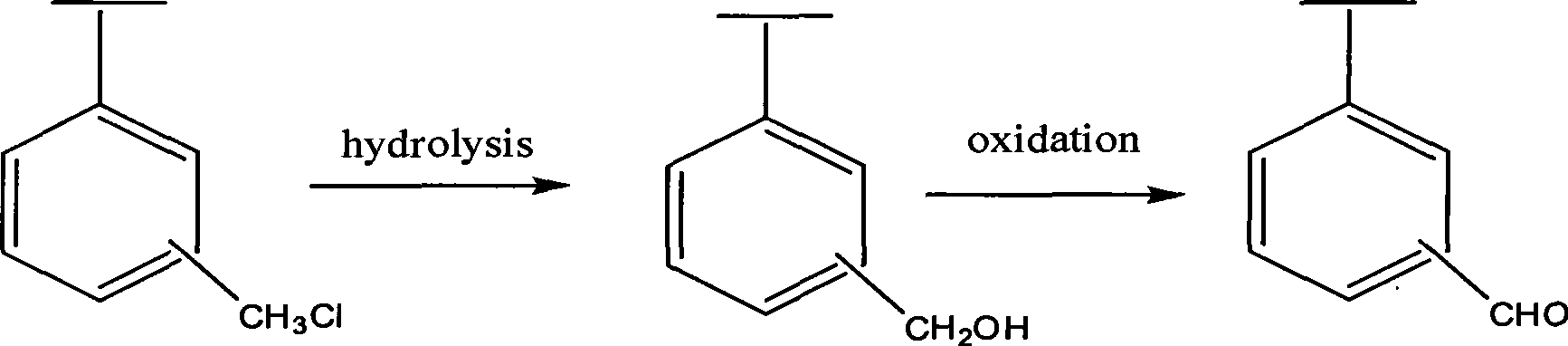

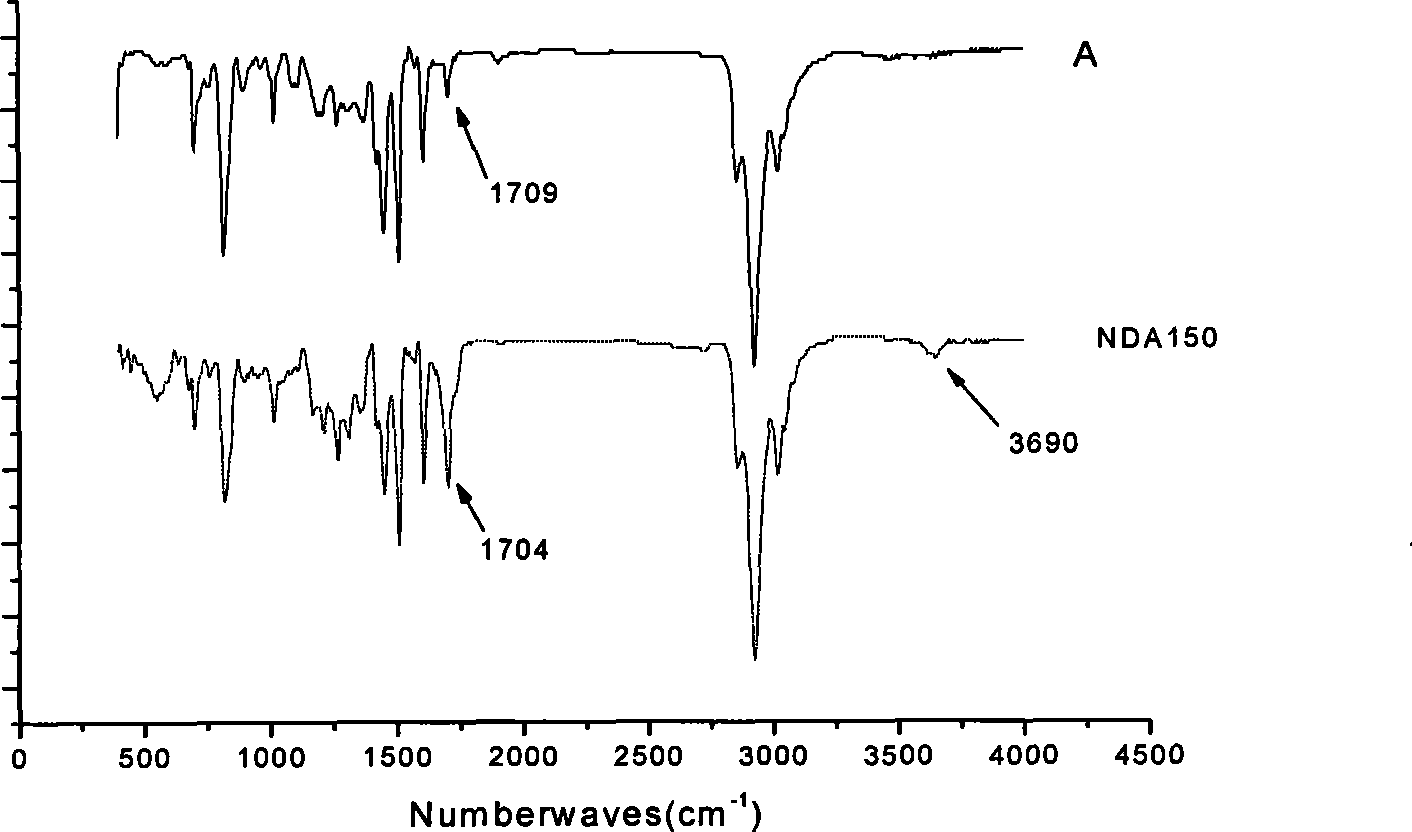

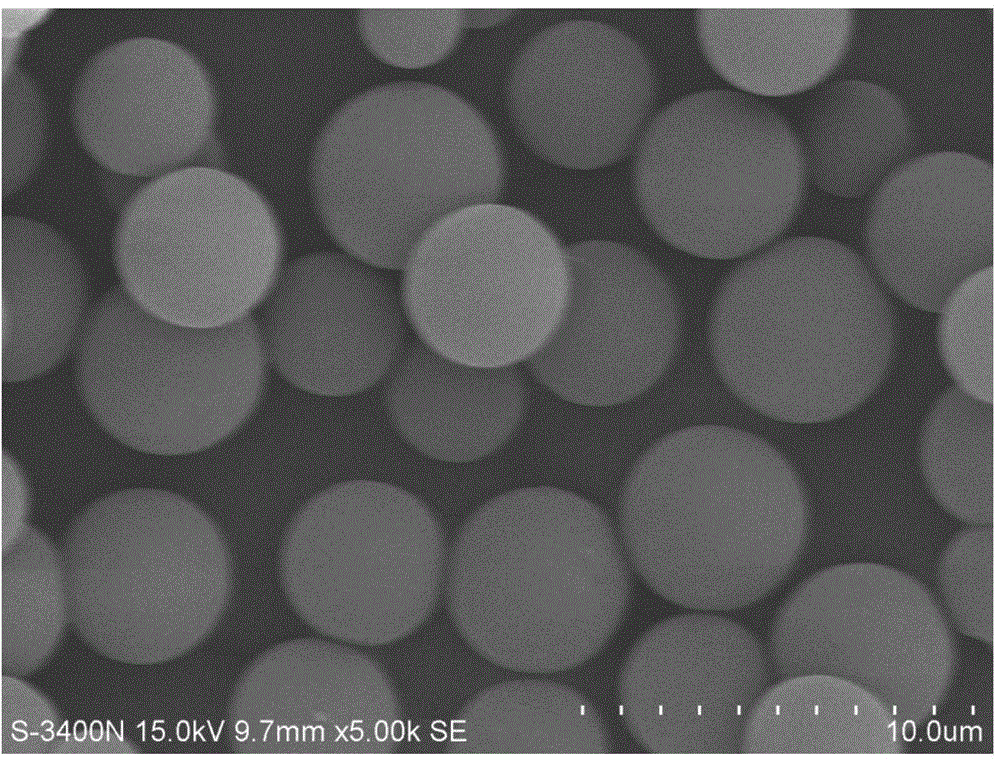

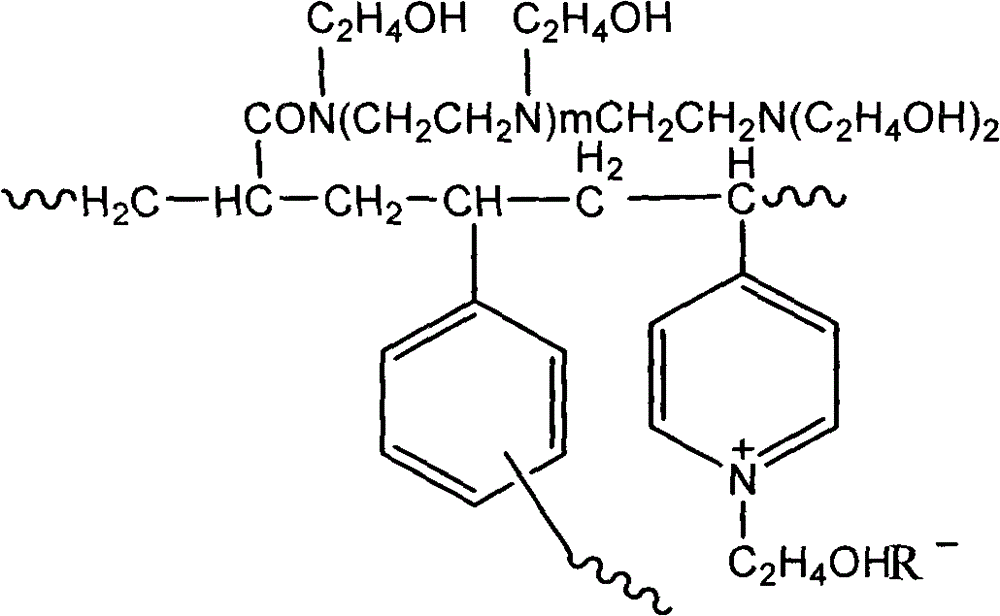

Hydrophobic carbonyl modified superhigh crosslinked adsorption resin as well as synthetic method and application thereof

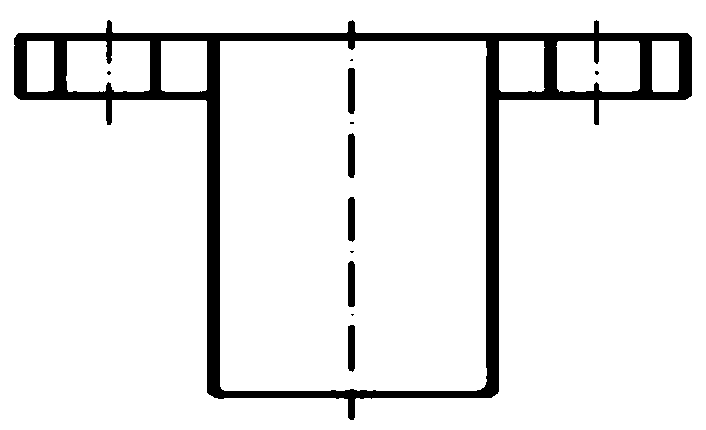

InactiveCN101543764ALarge specific surface areaImprove hydrophobicityOther chemical processesIron chlorideHydrophobe

The invention discloses a hydrophobic carbonyl modified superhigh crosslinked adsorption resin as well as a synthetic method and an application thereof. The hydrophobic carbonyl modified superhigh crosslinked adsorption resin has a basal structure as the right drawing. The synthetic method of the hydrophobic carbonyl modified superhigh crosslinked adsorption resin includes the following steps: preparing a white ball; preparing a chlorine ball by the white ball; swelling the chlorine ball into a dichloroethane liquid or ortho-dichlorobenzene solution, adding iron chloride as a catalyst, stirring at normal temperature and reacting at a raising temperature to obtain the hydrophobic carbonyl modified superhigh crosslinked adsorption resin. The resin obtained by the invention contains no hydroxyl group, has strong hydrophobic nature, high specific surface and large adsorption capacity and can be applied to the adsorption and the separation of original waste gas and non-polar organic substances. The invention has simple and easy synthetic process and simple needed equipment.

Owner:NANJING UNIV

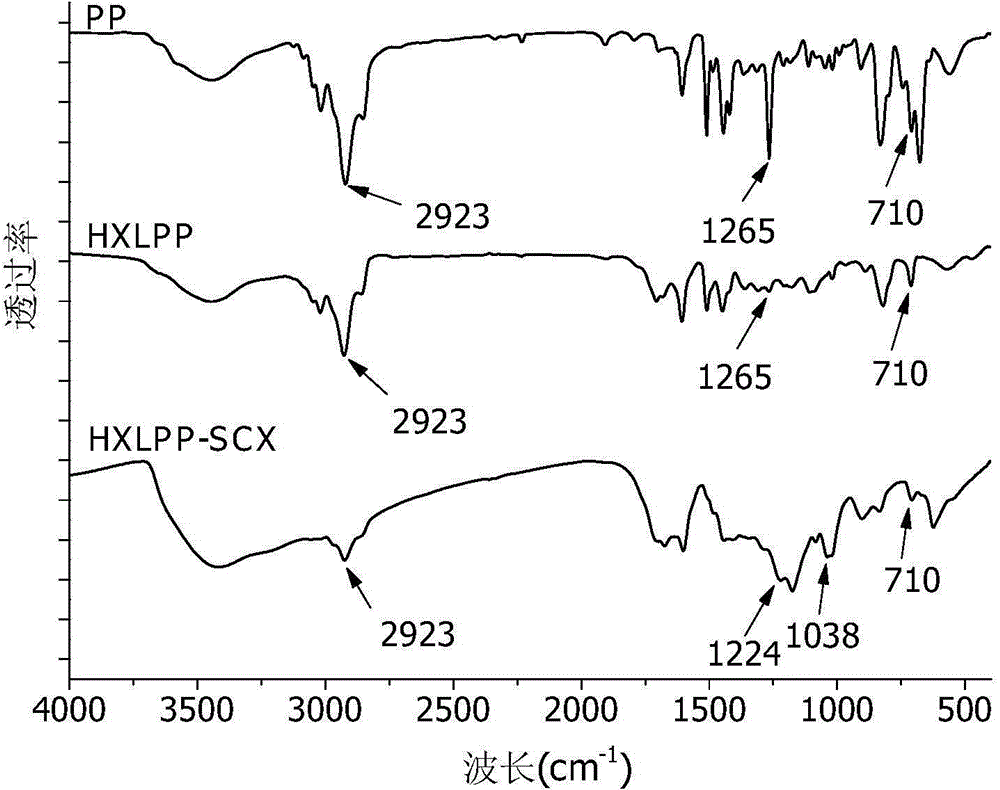

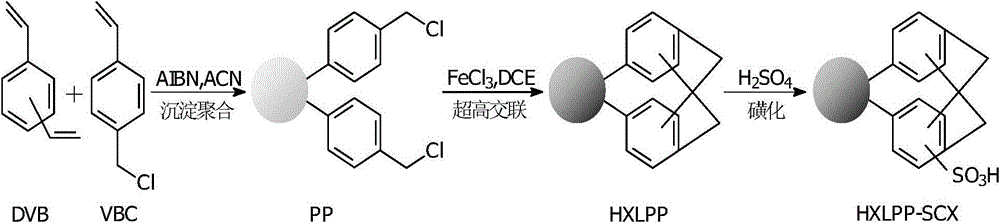

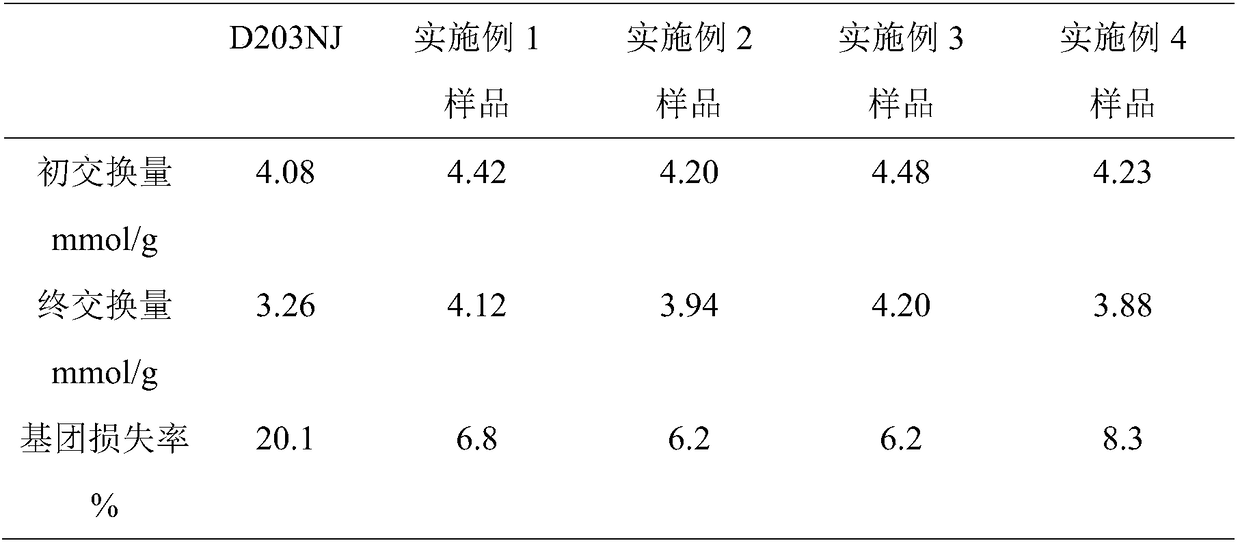

Sulfonyl modified strong cationic hypercrosslinked resin and preparation method thereof

InactiveCN104693336AImprove adsorption capacityNarrow particle size distributionIon-exchange process apparatusOther chemical processesPolymer resinSolid phase extraction

The invention relates to a sulfonyl modified strong cationic hypercrosslinked resin and a preparation method thereof. The performance of the resin serving as a solid-phase extraction filler is evaluated. The preparation method comprises the following steps: by taking chloromethyl styrene and divinyl benzene as reaction raw materials and taking azodiisobutyronitrile as an initiator, synthesizing a resin white ball by virtue of a non-aqueous precipitation polymerization reaction; by taking ferric trichloride as a catalyst, synthesizing a hypercrosslinked resin by virtue of a Fourier crosslinking reaction; and finally, sulfonating by using concentrated sulfuric acid, and synthesizing the sulfonyl-containing strong cationic hypercrosslinked resin. The strong cationic hypercrosslinked resin disclosed by the invention belongs to a new generation of porous polymer resins, has the complex functions of strong cationic exchange interaction and non-polar interaction and serves as a solid-phase extraction filler, the performance of the resin is obviously superior to that of a commercial Oasis MCX solid-phase extraction column, and the resin can be used for separation and enrichment of alkali compounds in complex samples and has good application prospects in the fields of biology and environments.

Owner:EAST CHINA UNIV OF SCI & TECH

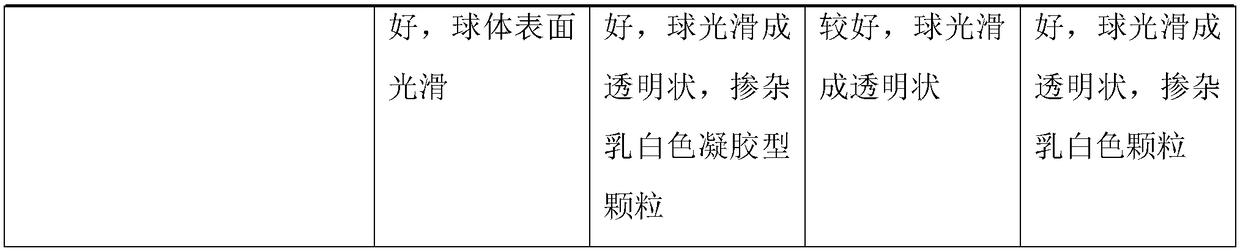

Contamination-resistant large-capacity macroporous weak-acid resin synthesis method

ActiveCN105884967AIncrease capacityPollution-resistant large capacity for high and complicated water qualityCation exchanger materialsDistillationSynthesis methods

The invention discloses a contamination-resistant large-capacity macroporous weak-acid resin synthesis method. The synthesis method comprises the steps that an acrylonitrile monomer, a divinyl benzene crosslinking agent, a pore-foaming agent and an initiator are adopted according to a certain proportion to prepare an oil phase, and water, a dispersing agent and NaCI are adopted to prepare a water phase in a polymerization kettle, then the oil phase is added to the water phase, heat release reaction occurs in the polymerization kettle, and the temperature of released heat is as high as 95 DEG C; cooling is performed with prepared saturated salt water, the temperature of the polymerization kettle is kept at 95 DEG C, then heating is performed to reach 100 DEG C, and heat-preservation distillation is performed; after temperature reduction, discharging, washing, drying, screening and cooling, contamination-resistant large-capacity acrylic acid type cation exchange resin white balls are obtained, the white balls are subjected to dissolving and swelling and then are mixed with 60 wt% sulphuric acid to perform hydrolysis reaction, heat preservation is performed for 10 hours, then discharging is performed, the discharge is washed with water to be neutral, alkali regulation is performed to reach pH = 12, and standing is performed for 2 hours; then, the discharge is washed with water to be neutral, acid regulation is performed to reach pH = 2, and standing is performed for 2 hours; the discharge is washed with pure water to be neutral and then is converted into sodium resin by using NaOH with the concentration of 30%, namely the contamination-resistant large-capacity macroporous weak-acid resin is obtained.

Owner:TONGJI UNIV +1

Method for performing positioning sulfonation on cation exchange resin by using sulfur trioxide

ActiveCN102641751ANot easy to fall offNo pollution in the processCation exchanger materialsIon-exchanger modification/after-treatmentReaction temperatureIon-exchange resin

The invention provides a method for performing positioning sulfonation on cation exchange resin, which comprises the following steps of: firstly, forming a complex by using sulfur trioxide and organic amine; and then, mixing the complex with an organic solvent, and feeding the mixture into a stationary bed to perform polymerization white ball reaction with styrenic cation exchange resin for 1-8 hours at the reaction temperature of between 60 and 90 DEG C and the airspeed of between 0.5 and 4 / h. Relative to a general sulfonation method for ion exchange resin, the method provided by the invention is high in reaction selectivity, less in side reaction, low in unit consumption of raw materials and cost and small in usage amount, and has no pollution problem of a large amount of waste acid; moreover, sulfonic groups are difficultly dropped.

Owner:KAIRUI ENVIRONMENTAL PROTECTION TECH

High temperature resistance anion exchange resin preparation method

InactiveCN108164622AIncrease softnessReduced post-crosslinking reactionAnion exchangersOil phaseTemperature resistance

The invention discloses a high temperature resistance anion exchange resin preparation method which comprises the step 10) of mixing hydroxyethyl cellulose, sodium chloride and deionized water, heating and stirring to be transparent to obtain water-phase reaction liquid; the step 20) mixing an initiator, a pore foaming agent and polymerization monomer and stirring to obtain oil-phase reaction liquid; the step 30) of mixing the water-phase reaction liquid with the oil-phase reaction liquid, stirring and warming to 70 to 75 DEG C and stopping heating after reaction; cooling to 50 to 55 DEG C, adding divinyl benzene, stirring, warming to 70 to 75 DEG C to react, warming to 80 to 85 DEG C to react and finally warming to 90 to 95 DEG C to react; utilizing methylbenzene to remove the pore foaming agent and drying and sieving to obtain resin white balls; the step 40) of mixing the resin white balls with chloromethyl ether, stirring and reacting, filtering to obtain chloromethylation resin andperforming amination treatment to obtain anion exchange resin. The method can be used for preparing anion exchange resin with good temperature resistance.

Owner:JIANGSU SUQING WATER TREATMENT ENG GROUP +1

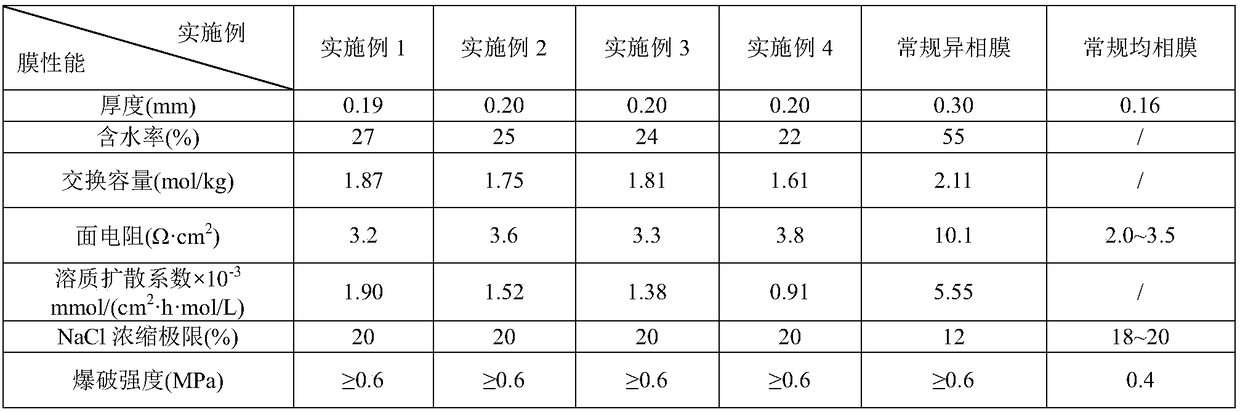

Continuous preparation method of high-density polystyrene cation exchange membrane

ActiveCN109316979AUniform and continuous microstructureImprove the shortcomings of membrane performance declineSemi-permeable membranesMembranesPolystyreneVolumetric Mass Density

The invention discloses a continuous preparation method of a high-density polystyrene cation exchange membrane. The method comprises the steps of evenly mixing styrene, a crosslinking agent, an initiator and a solvent for dissolving polyvinylidene fluoride to obtain a homogeneous mixed solution, and then thermally initiating the polymerization to obtain jelly having an interpenetrating network structure; extruding and granulating to obtain polystyrene / polyvinylidene fluoride white ball granules, and then preparing cation exchange resin granules by using functionalization of cation exchange resin as reference; mixing the prepared cation exchange resin granules with a composite crosslinking agent, and extruding into a membrane piece by using a twin-screw extruder; enabling the product to enter a four-roll calendering unit for calendering into a pre-formed film, covering with a net and then enabling the product to enter a flat belt drum type vulcanizer for hot-pressing so as to obtain thehigh-density polystyrene cation exchange membrane. The cation exchange membrane prepared by the method has the interpenetrating network structure, thus eliminating the microscopic phase separation structural defect; the compactness density of the membrane is further improved after a secondary crosslinking reaction is carried out; the concentration ability and surface resistance of the high-density polystyrene cation exchange membrane are the same as those of a homogeneous cation exchange membrane, and industrialized continuous production can be realized.

Owner:绿邦膜分离技术(江苏)有限公司 +2

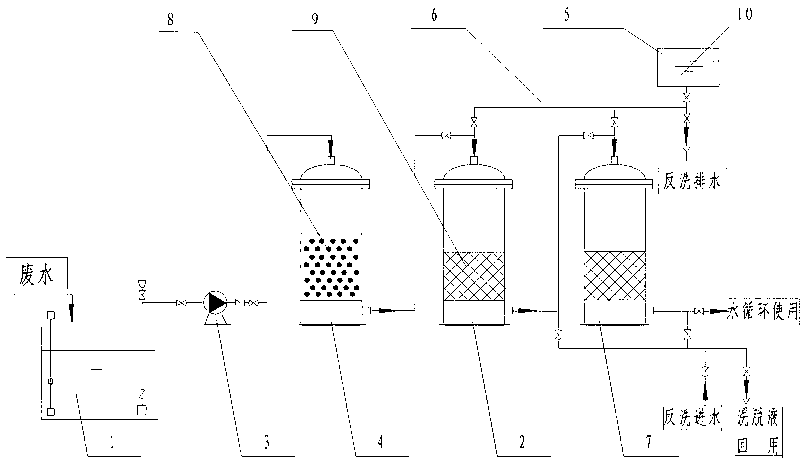

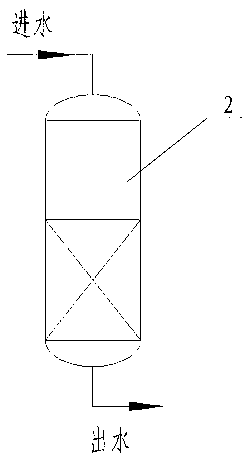

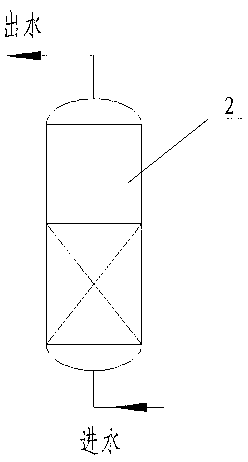

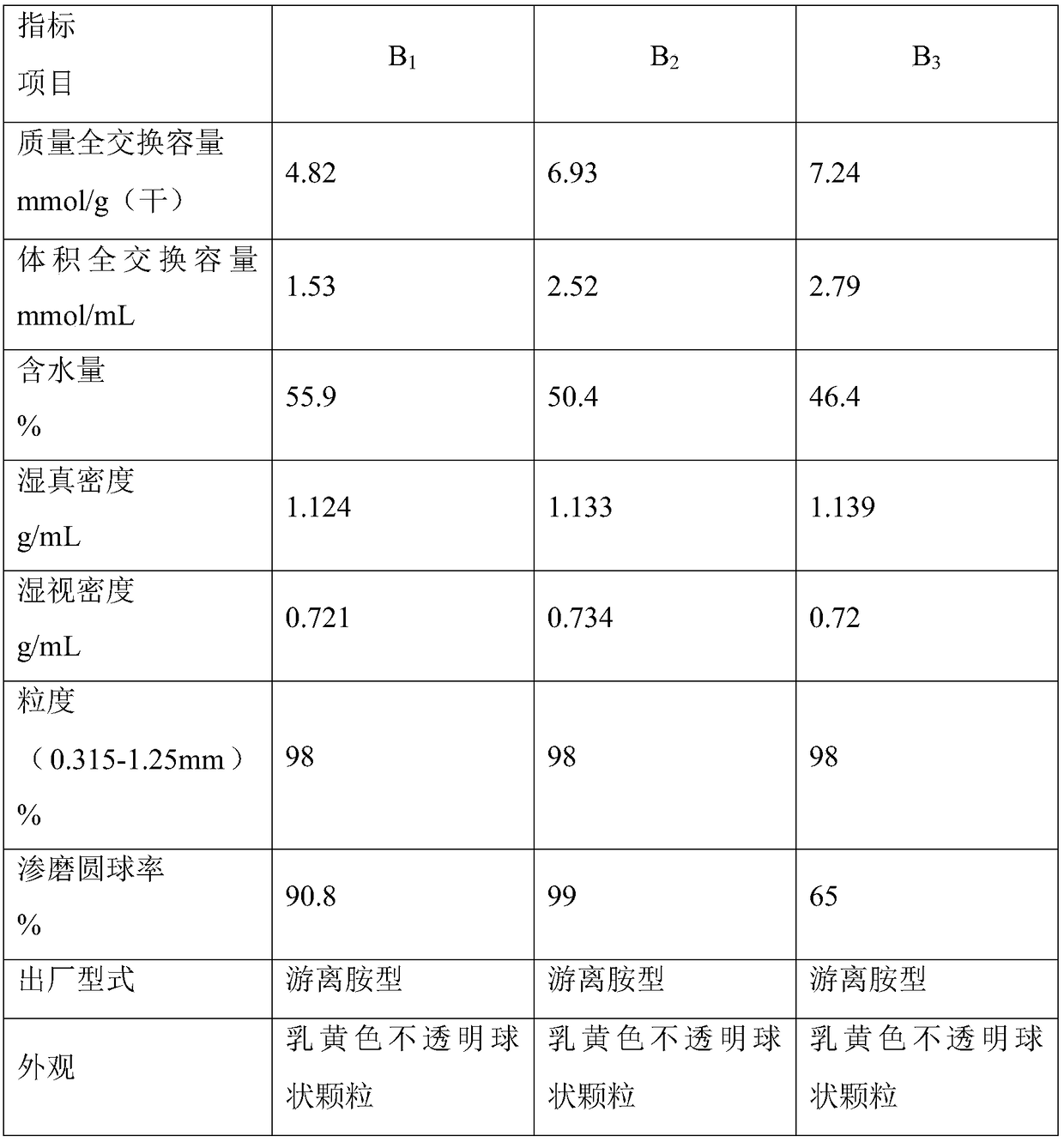

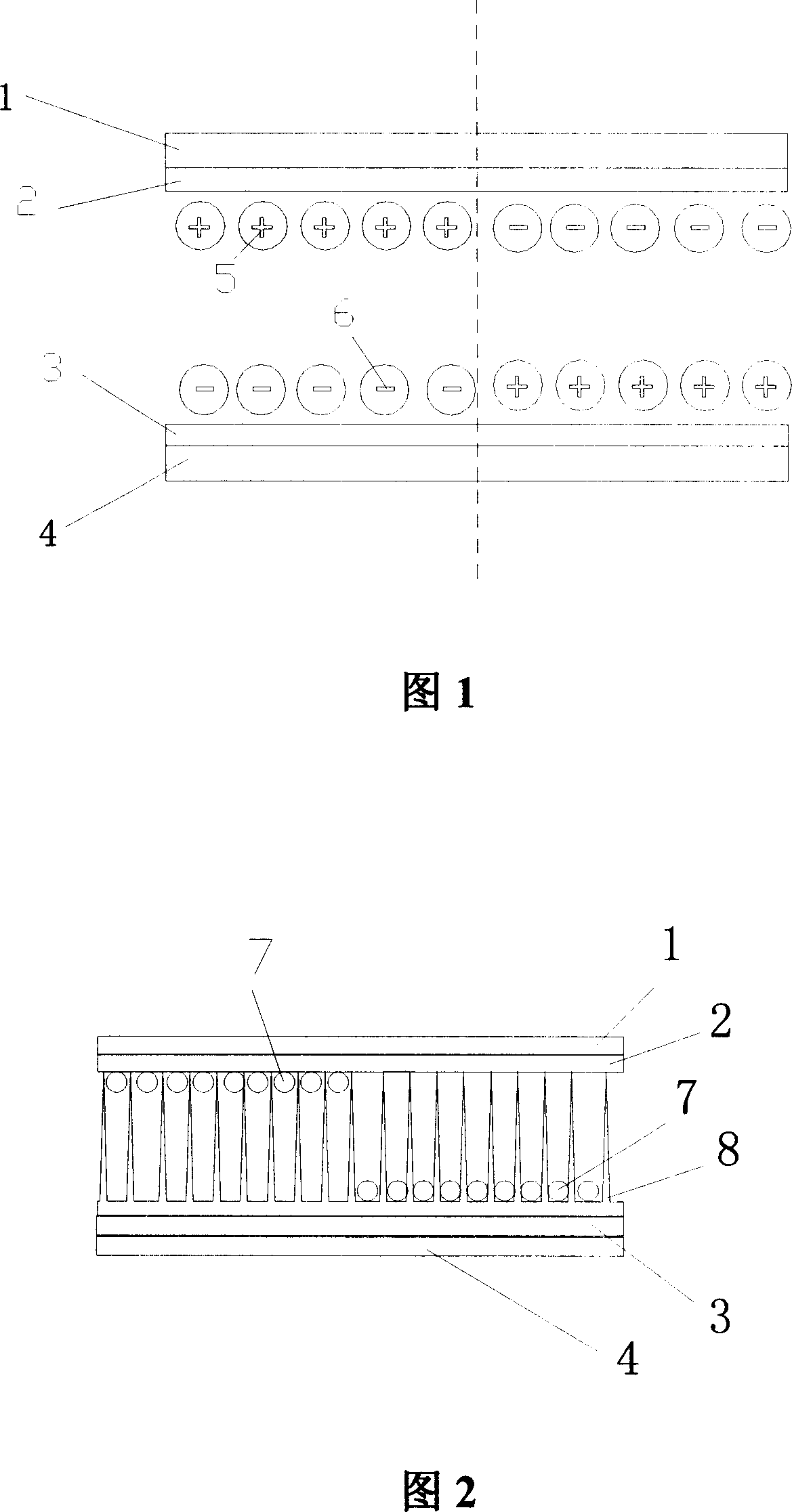

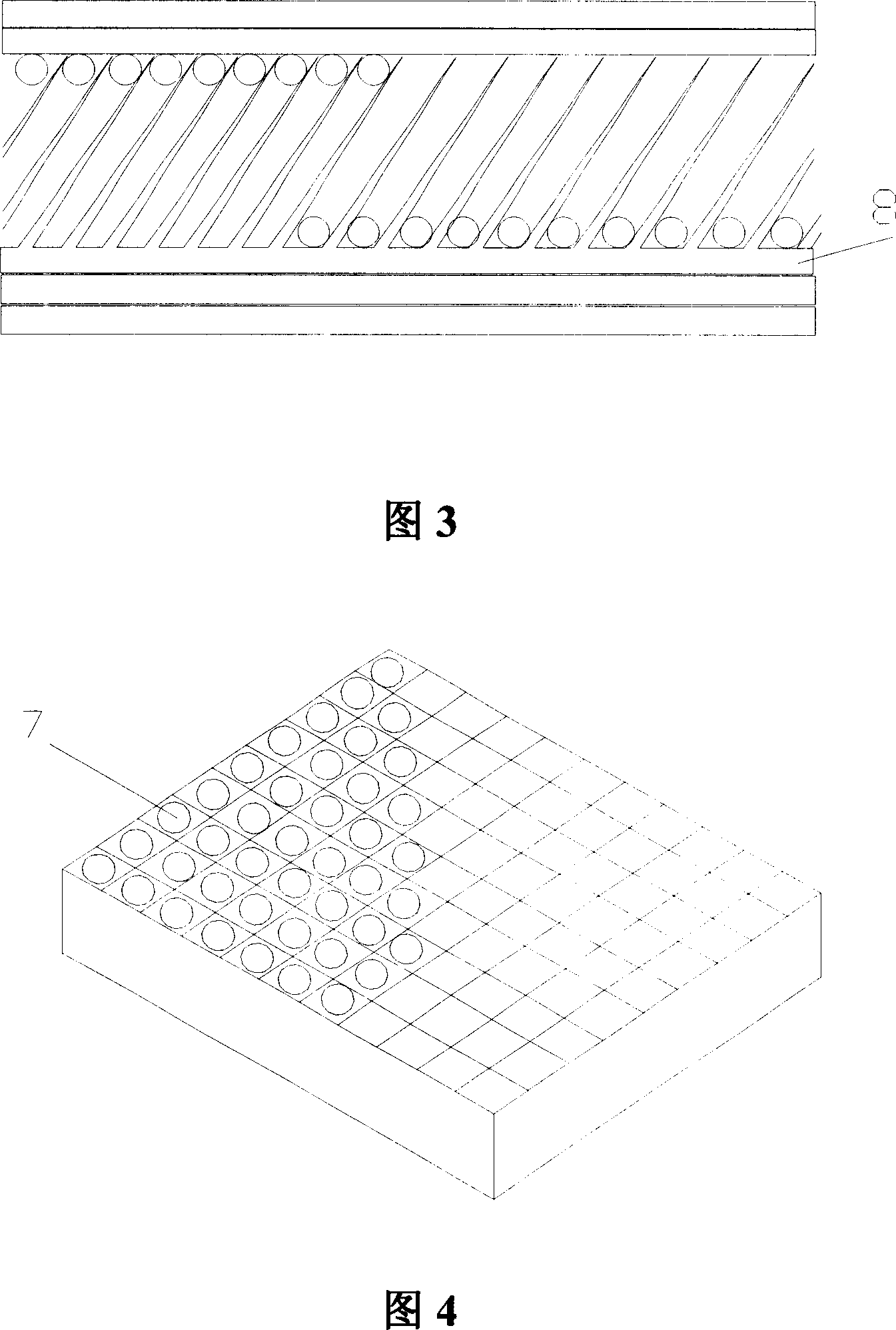

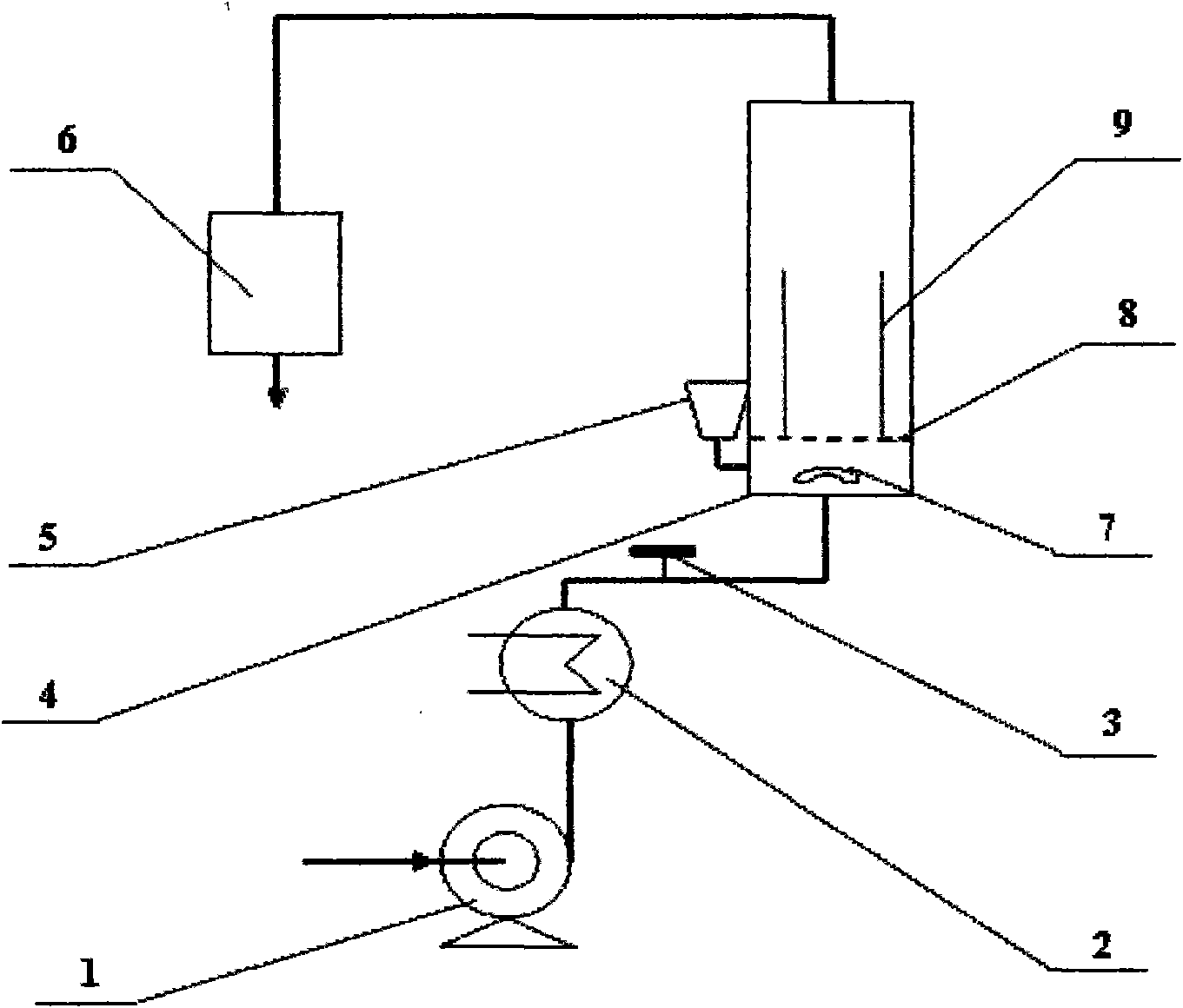

Industrial wastewater treatment system

InactiveCN103058420AAvoid pollutionSave resourcesWater/sewage treatment by ion-exchangeMultistage water/sewage treatmentIon exchangeIon-exchange resin

The invention discloses an industrial wastewater treatment system comprising a wastewater storage groove (1), a corrosion resisting water pump (3), a filtering column (4), a first exchanging column (2) and a second exchanging column (7), which are connected in sequence according to a treatment flow, wherein the filtering column (4) is filled with resin white ball filtering mediums (8); the first exchanging column (2) and the second exchanging column (7) are internally provided with ion exchange resin filtering devices (9); and water inlets of the first exchanging column (2) and the second exchanging column (7) are connected with a regenerated liquid groove (5) through a combined valve pipeline (6). According to the industrial wastewater treatment system disclosed by the invention, opposite ions on active genes of ion exchange resin and same ions in a solution are subjected to position displacement, and heavy metals including chromium, copper, cadmium, zinc, gold, silver, palladium, platinum, rhodium, nickel and the like in electroplating wastewater and substances with greater toxin can be treated; and resin can be repeatedly used so that a lot of cost is saved.

Owner:永兴鑫裕环保镍业有限公司

Preparation method for resin used for antibiotics purification

The invention discloses a preparation method for resin used for antibiotics purification. The preparation method comprises the following steps that 1) an oil phase is prepared; 2) a water phase is prepared; 3) the oil phase reacts with the water phase to make mixed liquid gradually solidified into milk white particles, and white balls are obtained; 4) the obtained white balls are swelled by usingchloromethylation solvent, under the effect of a ferric chloride catalyst, the reaction lasts for 6 hours, after washing and drying, chlorine balls are obtained; 5) residual pore-foaming agent in thechlorine balls is eluted, and macropore cationic resin semi-finished products are prepared; 6) 100 ml of wet resin is added into 300 ml of caustic soda liquid with the concentration of 20-25%, the reaction lasts for 8-12 hours at 75-80 DEG C, after the reaction is finished, packing is conducted, the resin is washed with deionized water with the volume same with that of the resin, column chromatography isolation by using hydrochloric acid lasts for 4-5 hours, the resin is washed with deionized water to neutral, the macropore weakly acidic cation exchange resin is prepared, and by adopting the method, the purification rate of the prepared resin used for antibiotics purification is significantly improved.

Owner:安徽皖东树脂科技有限公司

Preparation method of 2-chloro trityl chloride resin

The invention discloses a preparation method of 2-chloro trityl chloride resin in the fields of medicine, biological chemistry and chemical engineering, which comprises the following steps that: 2-chlorobenzophenone is adopted as the raw material to synthesize 1-chlorine-2- dichloro-diphenyl benzene, and the 1-chlorine-2- dichloro-diphenyl benzene is chemically coupled with low cross-linked polystyrene (PS) white balls to obtain the 2-chloro trityl chloride (2-CTC) resin. The method overcomes the defects of a traditional 2- chloro trityl chloride resin preparation method that the steps are complicated and organic metal reagent must be used, is simple and feasible, does not need to use the organic metal reagent, the uploading level of the first amino acid, swelling property and peptide solid-phase synthesis efficiency of the prepared 2-CTC resin are better than those of similar commodities 2-CTC resin, and the mass quality is stable, the repeatability is good and the industrial production is easy.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

Preparation method of ion exchange resin for removing thermostable salt in alcohol amine solution

ActiveCN104725541ALarge strong base exchange capacityThermal stability and high salt removal efficiencyCation exchanger materialsAlcoholIon exchange

The invention provides a preparation method of ion exchange resin for removing thermostable salt in an alcohol amine solution. The preparation method comprises the steps that styrene, divinyl benzene, deionized water, a disperse system and an auxiliary agent are added to a polymerization kettle, and react at certain polymerization temperature; the time and speed are controlled; fine particle polystyrene white balls (particle size of 0.1-0.3mm) are obtained, cleaned, dried, and then subjected to chloromethylation; chloromethylation polystyrene resin is obtained and reacts with trimethylamine; and qualified fine particle resin is obtained. The ion exchange resin prepared by the method is small in particle size and high in specific surface area; the strong base exchange capacity is 2.9-4.7meq / g (dry agent); the efficiency of removing thermostable salt in the alcohol amine solution is improved significantly; and the elution and regeneration of the resin are easy to conduct.

Owner:HANGZHOU DUONENG ENVIRONMENTAL PROTECTION TECH

Resin catalyst for polyoxymethylene dimethyl ether DMM3-8 synthesis and preparation method thereof

InactiveCN106944135AModerate pore sizeEvenly distributedOrganic-compounds/hydrides/coordination-complexes catalystsCatalytic reactionsOrganic chemistryDivinyl benzene

The application of the patent provides a resin catalyst for polyoxymethylene dimethyl ether DMM3-8 synthesis and a preparation method thereof. The resin catalyst for polyoxymethylene dimethyl ether DMM3-8 synthesis is prepared by the following steps: carrying out suspension copolymerization on styrene and divinyl benzene in the presence of a pore forming agent and a dispersant to obtain a copolymer white ball, carrying out pore structure purification and carrying out sulfonation. The resin catalyst obtained by the technical scheme is especially suitable for etherification catalytic reaction technological production of polyoxymethylene dimethyl ether. As the swelling pore-broadening process is omitted in the polymerization stage, production efficiency is raised and production cost is lowered. The resin catalyst of the invention has advantages of moderate pore size, uniform distribution, large pore volume and specific surface area, high exchange capacity, high reaction activity and long usage period.

Owner:丹东明珠特种树脂有限公司

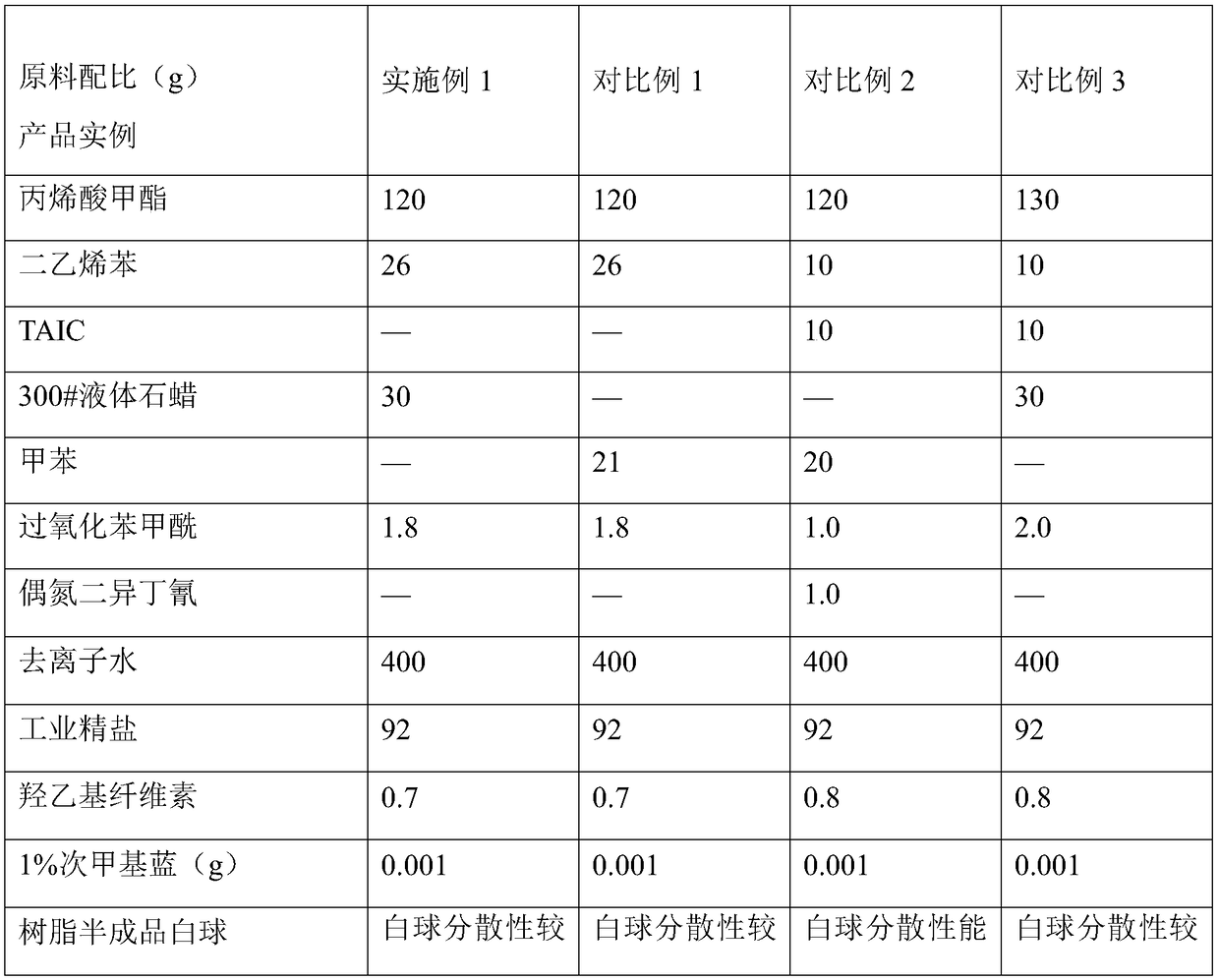

Preparation method of macroporous weak-basicity acrylic acid series anion exchange resin

ActiveCN109320650AUniform pore sizeHigh selectivityIon-exchange process apparatusIon-exchanger regenerationBenzoyl peroxideIon exchange

The invention belongs to the technical field of ion exchange resin, and relates to a preparation method of macroporous weak-basicity acrylic acid series anion exchange resin. The preparation method comprises the following steps: adding industrial refined salt into deionized water and stirring; adding hydroxyethyl cellulose and methylene blue, and heating to obtain a water phase; mixing methyl acrylate, divinylbenzene and liquid paraffin, heating and adding benzoyl peroxide, and stirring to obtain an organic phase; mixing the organic phase with the water phase, stirring and heating for reaction; cooling and filtering to obtain a high-molecular polymer; soaking the polymer in toluene, heating and stirring; thoroughly filtering out the toluene; cleaning, drying and screening to obtain a semi-finished product white ball of resin; after amination and methylation, taking out the resin and rinsing, and filtering out moisture to obtain the macroporous weak-basicity acrylic acid series anion exchange resin. The resin prepared by the invention has the advantages of simple technology, fast exchange velocity, high regeneration efficiency, good anti-pollution property, environmental friendliness, no pollution and broad application prospect.

Owner:扬州金珠树脂有限公司

High-temperature-resistant fluorine-containing resin catalyst and preparation method thereof

InactiveCN102228841AReduce processing costsLow water conductivityOrganic-compounds/hydrides/coordination-complexes catalystsPreparation by hydroxy group additionHalogenReaction temperature

The invention provides a high-temperature-resistant fluorine-containing resin catalyst which is prepared by the steps of: with polymerized white balls of the resin catalyst as raw materials, fully swelling the white balls with a solvent, acylating with an acylating agent, adding a halogen element for halogenating, and finally introducing sulfo groups through sulfonation of a sulfonating agent. The high-temperature-resistant fluorine-containing resin catalyst is suitable for a reaction process with a reaction temperature of higher than 150 DEG C, and can be used for a long time at a temperature of below 200 DEG C. The invention also provides a preparation method of the high-temperature-resistant fluorine-containing resin catalyst.

Owner:KAIRUI ENVIRONMENTAL PROTECTION TECH

Electronic-paper display screen with black light-absorbing grid channel

The invention relates to an electronic paper display screen with black light absorbing cell, comprising: transparent glass, transparent electrode, electrode and baseplate, where there is positively charged white powder between the transparent electrode and the electrode; there is a black light absorbing cell to separate the white powder; when displaying graphics and texts, the transparent electrode acts as a negative pole so that the white powder rises; when needing to turn pages, the transparent electrode acts as a positive pole so that the white powder falls; and its beneficial effects: because the powder is composed of positively charged white small balls, the white balls in the places in need of displaying graphics and texts will be attracted onto the display screen and those in the rest which are black need not move so as to be able to save power all the more and the distortion ratio is low, the contrast high and the characters are clearer. And it is a desired tool suitable for users to read.

Owner:TOPRET IND DESIGN(SHANGHAI) CO LTD

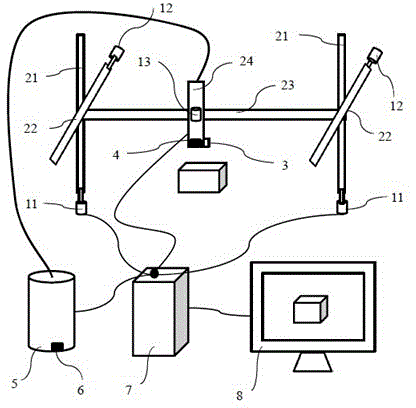

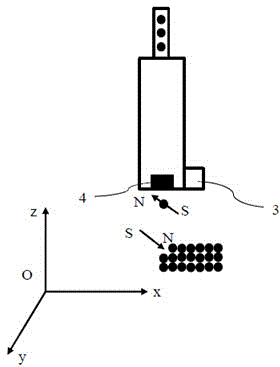

3D printing mechanism based on magnetic ball and printing method

ActiveCN104626580AIncrease the sense of 3DReduce financial burdenAdditive manufacturing apparatusEngineering3d printer

The invention discloses a 3D printing mechanism based on a magnetic ball and projection. The 3D printing mechanism is not only capable of magnetizing the magnetisable white ball of a certain size according to a certain magnetic field intensity and direction and placing the ball at a position to be printed, but also capable of projecting visual information, such as the colour, of a practical object on a 3D printing object according to a certain requirement, so that the visual effect of the 3D object is displayed according to design requirements. By utilizing the 3D printing mechanism based on the magnetic ball and projection, a 3D model object can be printed very rapidly and efficiently according to the design requirements; when a 3D model is not used, the magnetized ball is demagnetized, and then the ball also can be continuously used for other 3D printing tasks; the 3D printing mechanism is particularly suitable for displaying a sand table model, a development house and the like; the manufacturing time and the manufacturing cost of the 3D model can be greatly reduced; and complete cyclic utilization of printing materials is realized.

Owner:GUANGZHOU DABO INTELLIGENT TECH CO LTD

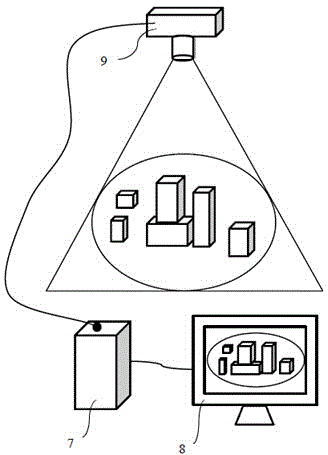

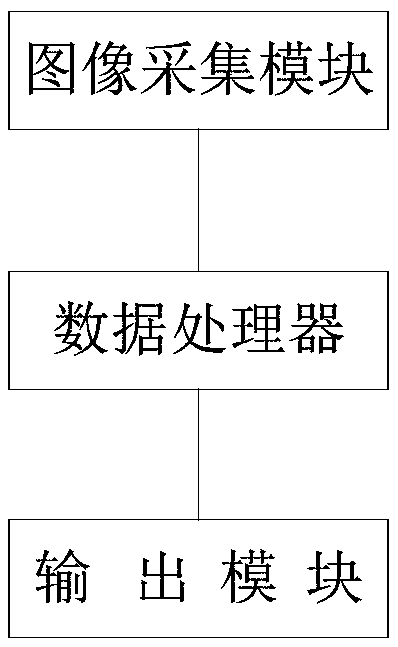

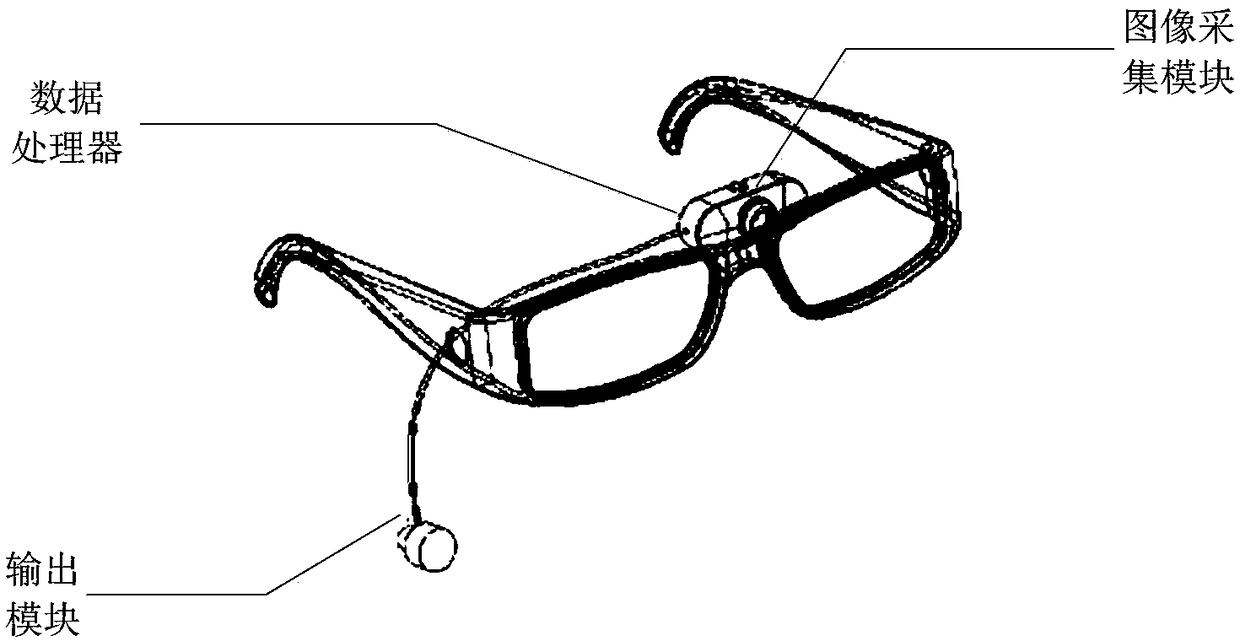

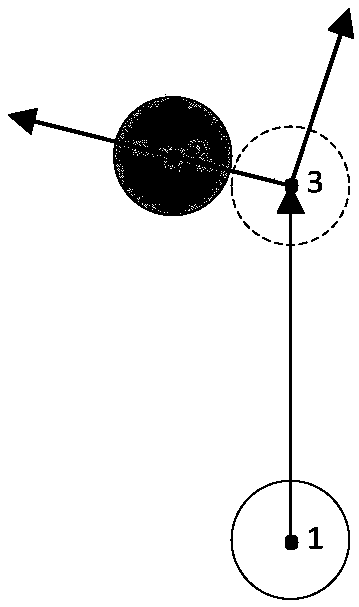

Intelligent glasses and billiard photograph positioning and aiming method

ActiveCN108905182AImprove hitting experienceMake up for the high cost of trainingBilliardsSituated computingEngineering

The invention discloses a pair of intelligent glasses and a billiard photograph positioning and aiming method. The pair of intelligent glasses comprises an image collection module, a data processor and an output module, wherein the image collection module is used for collecting position images of a white ball, target balls, pocket openings and clubs before conducting hitting in real time; the dataprocessor, in accordance with the collected position images, is used for calculating positions of the white ball, the target ball, the pocket openings and the clubs, calculating collision positions of the target balls collided by the white ball under a circumstance that the target balls are collided into the pocket openings, calculating hitting directions corresponding to the collision positions,calculating adjusting angles of the clubs in accordance with the hitting directions and the positions of the clubs and generating adjusting angle prompting information in accordance with the adjusting angles; and the output module is used for outputting the adjusting angle prompting information, so that users can refer to the adjusting angle prompting information. According to the intelligent glasses provided by the invention, it can prompt a practicer to adjust an aiming direction in accordance with relations of the white ball, the target balls and the pocket openings, so as to effectively improve a hitting experience and to improve a hitting level.

Owner:BOE TECH GRP CO LTD

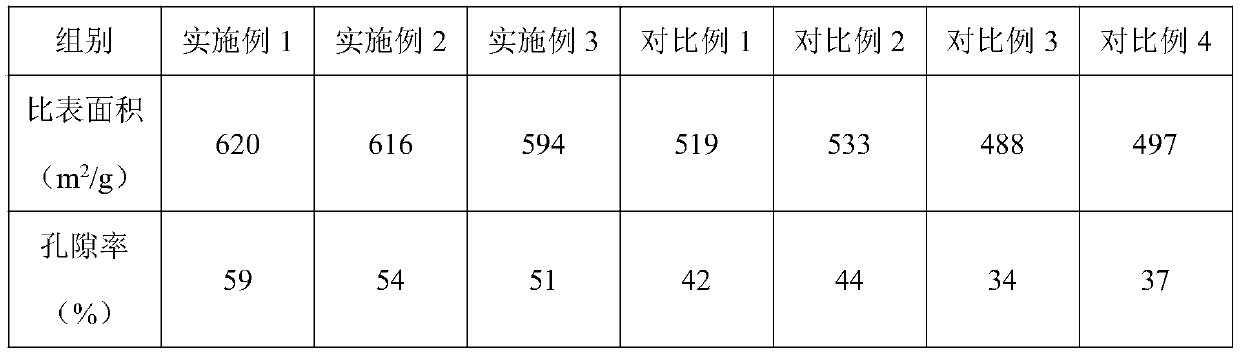

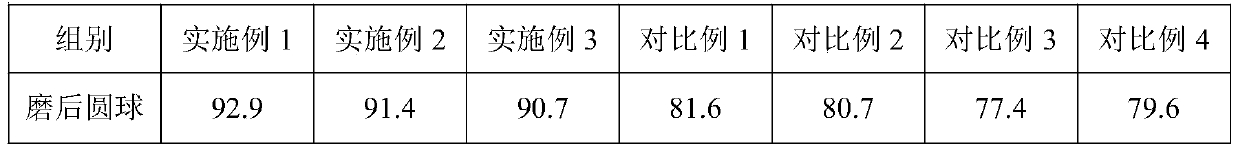

Macroporous adsorption resin and preparation method thereof

ActiveCN109833854AIncrease the areaHigh mechanical strengthOther chemical processesAlkali metal oxides/hydroxidesPorosityPolymer science

The invention provides macroporous adsorption resin which is prepared from the following raw materials: water, gelatin, styrene, divinylbenzene, white oil, an initiator, a pore-foaming agent, solventoil, 1,2-dichloroethane, zinc chloride and chloromethyl ether by the the following steps: carrying out white ball polymerization, white ball drying and screening, carrying out wax extraction, wax balldrying and screening, chlorination, chlorine ball drying and post-crosslinking reaction. The prepared resin is relatively large in specific surface area and porosity and has relatively good mechanical strength, high temperature resistance, simple preparation process and easy industrial production.

Owner:蚌埠市天星树脂有限责任公司

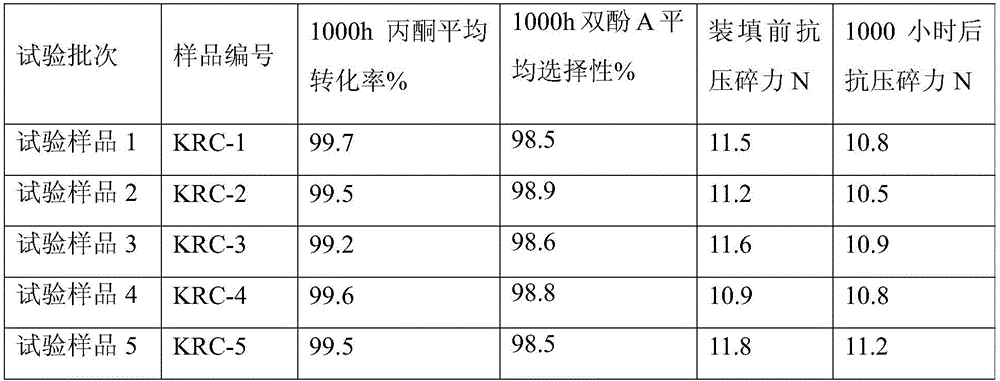

Bisphenol A synthetic resin catalyst and preparation method thereof

ActiveCN106563502AHigh selectivityStable internal cross-linked structureOrganic chemistryOrganic compound preparationStrong acidsDouble bond

The invention provides a bisphenol A synthetic resin catalyst and a preparation method thereof. According to the method, the crosslinking degree being 2 to 8 percent is used; third monomers with unsaturated double bonds are introduced to participate in copolymerization; mesoporous white balls with the pore diameter being 1 to 20 nm are obtained and are used as parent matrixes; then, a mild sulfonation process is used for sulfonation; finally, the resin is modified; and a high-intensity strong acid and mesoporous cation resin catalyst with the pore diameter being 2 to 10nm can be obtained. The pressure difference of the materials on the catalyst can be reduced by mesopores formed in the catalyst; the mesopores are favorable for the generation of bisphenol A; byproducts are few; the third monomers of diallyl bisphenol A are added into the catalyst in polymerization, the inside crosslinking structure of the resin is more stable; the pressure-resistant intensity is improved; the affinity of the resin on phenol is improved; the swelling property of materials of the phenol, acetone and the like on the resin is reduced; the damage of the materials to the resin is reduced. The catalyst provided by the invention has the advantages that through the addition of modifying agents, the effects of a cocatalyst are achieved; and the phenol and acetone conversion rate of the reaction raw materials is improved and is high.

Owner:KAIRUI ENVIRONMENTAL PROTECTION TECH

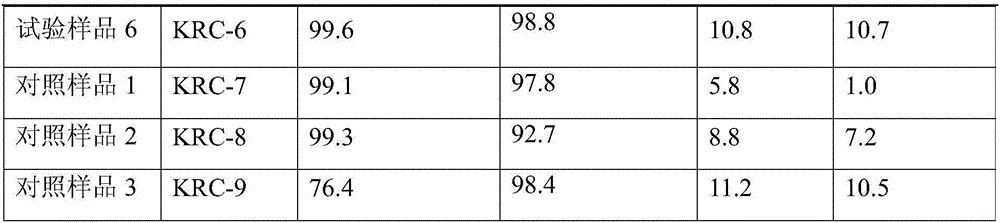

Ecological rock and method for preparing same

The invention discloses ecological rock. The ecological rock is prepared from surface materials and base materials. The surface materials are prepared from raw materials including, by weight, 8-10% ofball clay, 8-10% of super-white ball clay, 25-30% of transparent powder, 40-60% of mixed sand and 1-3% of bentonite; the sum of the weight percentage contents of the raw materials is 100%. The invention further discloses a method for preparing the ecological rock. The method includes steps of proportioning, ball-milling and ageing, spray-drying, compression molding, drying, green brick printing and permeating, burning and polishing. The ecological rock and the method have the advantages that the method is low in energy consumption and pollution, the ecological rock can be prepared by the aidof the method, good decoration effects can be realized by the ecological rock, and the ecological rock is low in water absorption, good in acid and alkali resistance, abrasion resistance and pollutionresistance and high in mechanical strength and Mohs hardness.

Owner:GUANGDONG BODE FINE IND CONSTR MATERIAL

Surface quality improving method for non-ferrous metal retainer

The invention relates to a surface quality improving method for a non-ferrous metal retainer, and solves problems that the surface of a current retainer after polishing is not smooth and a chipping mark reserved by machining is still apparent, and surface smoothness is not apparently improved; bumping damage frequently occurs on the surface of the retainer, especially a sharper chamfering part, and damage repairing treatment is needed later; and the sharp edge of a locking point part of the retainer cannot meet circular and smooth technological requirements after polishing, a phenomenon that asteel ball is scratched by a locking point of the retainer occurs unavoidably in a using process of a bearing, and the sharp edge needs to be further removed by using a manual burr knife. A bullet-like resin polishing material in 2000 meshes of a granularity and 15X15 of a standard and a white ball-like aluminum oxide polishing material in Phi 2 mm of a standard are used for completing coarse polishing and fine polishing. Polishing time is optimized. The method is used for surface quality improvement of the non-ferrous metal retainer.

Owner:AVIC HARBIN BEARING

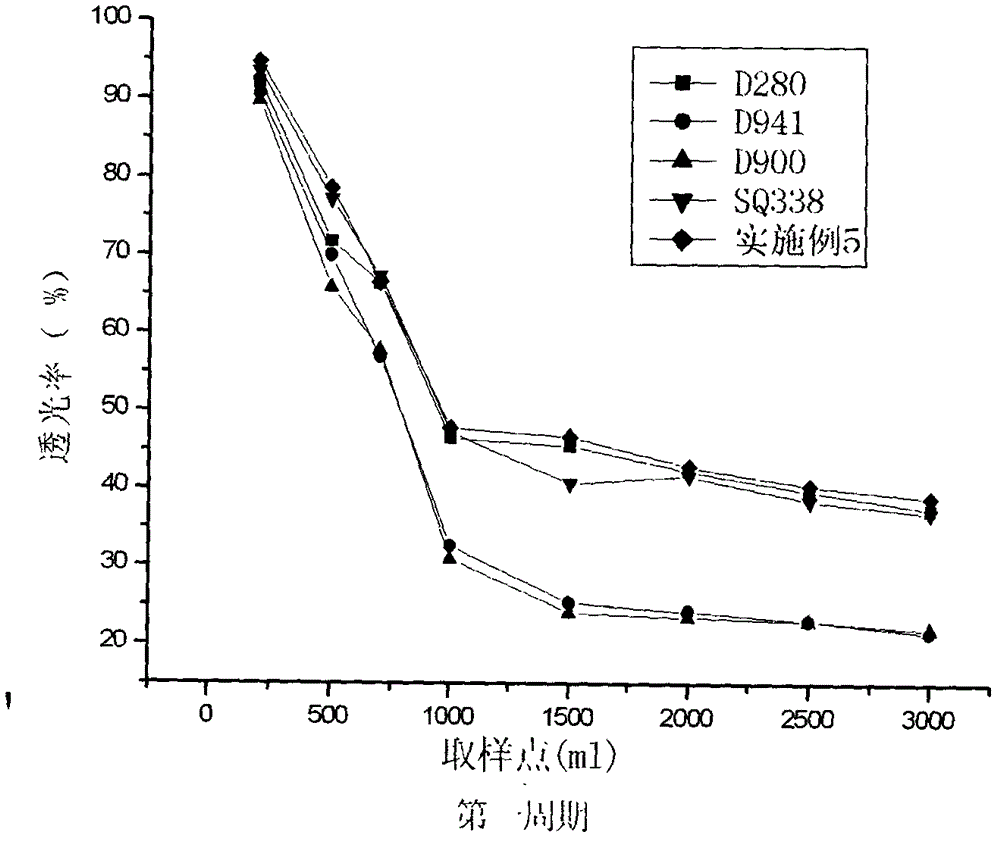

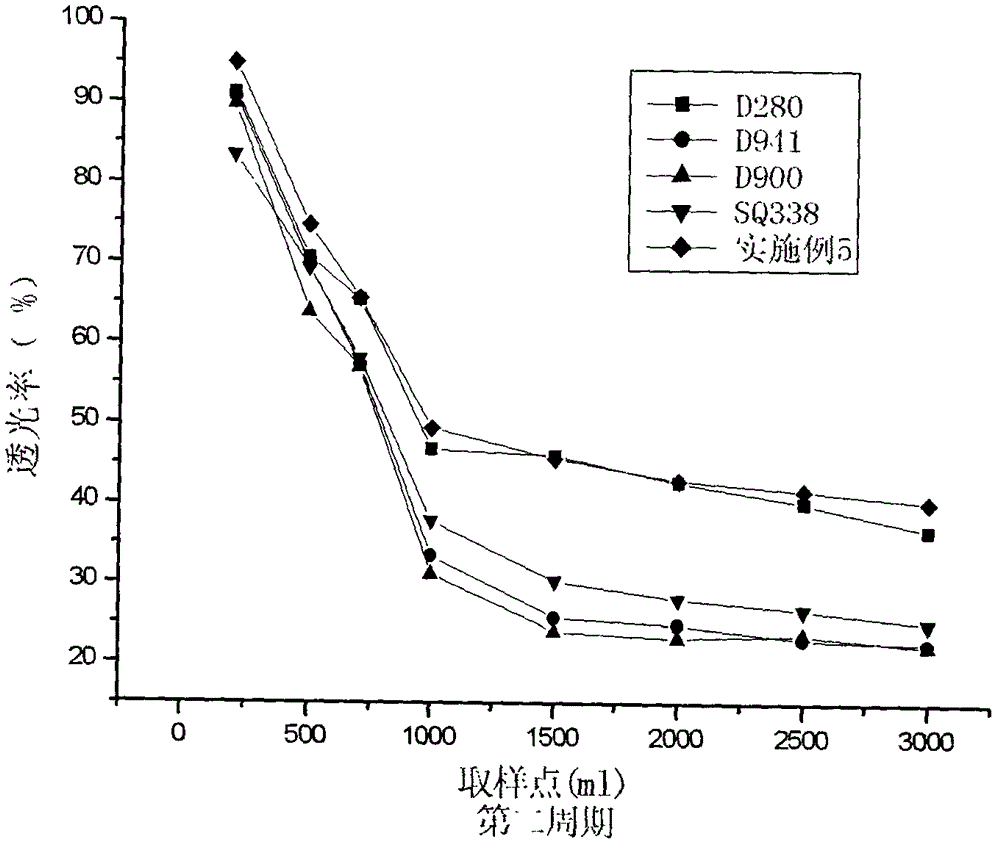

Acrylic decolorization resin and preparation method thereof

ActiveCN102020745BStrong decolorization abilityHigh content of functional groupsAnion exchangersCross-linkPolymer science

The invention relates to the field of polymer chemistry, in particular to a novel acrylic decolorization resin and a preparation method thereof. The preparation method comprises the following steps: by taking a polyvinyl monomer as a cross-linking agent, carrying out suspension polymerization on a vinylpyridine monomer and an aliphatic unsaturated ester monomer in the presence of a pore forming agent to obtain white balls; carrying out aminolysis reaction on the obtained white balls and polyethylene polyamine to introduce amine groups; and reacting the obtained amine balls with a monomer containing an alcoholic hydroxyl group under an alkaline condition to obtain the acrylic ion exchange decolorization resin. The resin has the properties of a strong-base resin and a weak-base resin containing pyridine groups at the same time; and compared with the commercially available common strong or weak-base ion exchange resin, the obtained target product in the invention has the advantages of high functional group content, strong decolorization capability, good contamination resistance, long service life, greater social benefit and economic benefit and the like during the decolorization process.

Owner:AMICOGEN CHINA BIOPHARM CO LTD

Adsorbent used for adsorbing formaldehyde in rooms and automobiles and preparation method thereof

ActiveCN105080494AStrong ability to absorb formaldehydeLarge saturated adsorption capacityOther chemical processesDispersed particle separationSlagSorbent

The invention relates to an adsorbent used for adsorbing formaldehyde in rooms and automobiles and a preparation method thereof and belongs to the technical field of air purification. According to the invention, aluminum slag is used as a carrier, and a mixed solution of triethylene tetramine and sodium hydroxide is sprayed on the carrier; the adsorbent takes the shape of a white ball, the carrier comprises aluminum slag powder and alumina powder with the mass ratio of (1-2):(1-3) and the adsorbent used for adsorbing formaldehyde in rooms and automobiles is obtained through mixing, preparing seeds, pelleting, screening, polishing, carrying out standing, drying, preparing a citric acid solution and spraying. Raw materials used in the preparation process are derived from aluminum slag generated from automobile hub production, the cost is low, the purpose of controlling hazardous substances by waste is realized and an important effect on environment protection is realized.

Owner:JIANGSU AIER ENVIRONMENTAL PROTECTION TECH CO LTD

High temperature resistant guanidine-based strong alkali resin and preparation method thereof

ActiveCN109180851AGood particle size uniformityHigh reaction conversion rateAnion exchangersPolystyreneMacroporous resin

The invention discloses a high temperature resistant guanidine-based strong alkali resin and a preparation method thereof. The resin material is a core-shell structure compound. A core is a surface cubic phase delta-Bi2O3 and an outer shell is a guanidine-based strong alkali resin. The invention also provides a preparation method of the guanidine-based strong alkali resin. The preparation method comprises: preparing a surface cubic phase delta-Bi2O3 through a microwave reaction, carrying out surface hydrophobic modification on delta-Bi2O3 through KH570, coupling delta-Bi2O3 through KH570, carrying out suspension polymerization to obtain a polystyrene macroporous resin so that the delta-Bi2O3 resin white ball core-shell compound is prepared, the compound undergoes a chloromethylation reaction and the product undergoes a reaction with guanidine hydrochloride to produce the high temperature resistant guanidine-based strong alkali resin. The strong alkali resin has a large strong alkali exchange capacity and strong high temperature resistance and has potential application prospects in high temperature environments such as condensing water precision treatment and a catalytic reaction ofan air cooling unit.

Owner:NANJING INST OF TECH +1

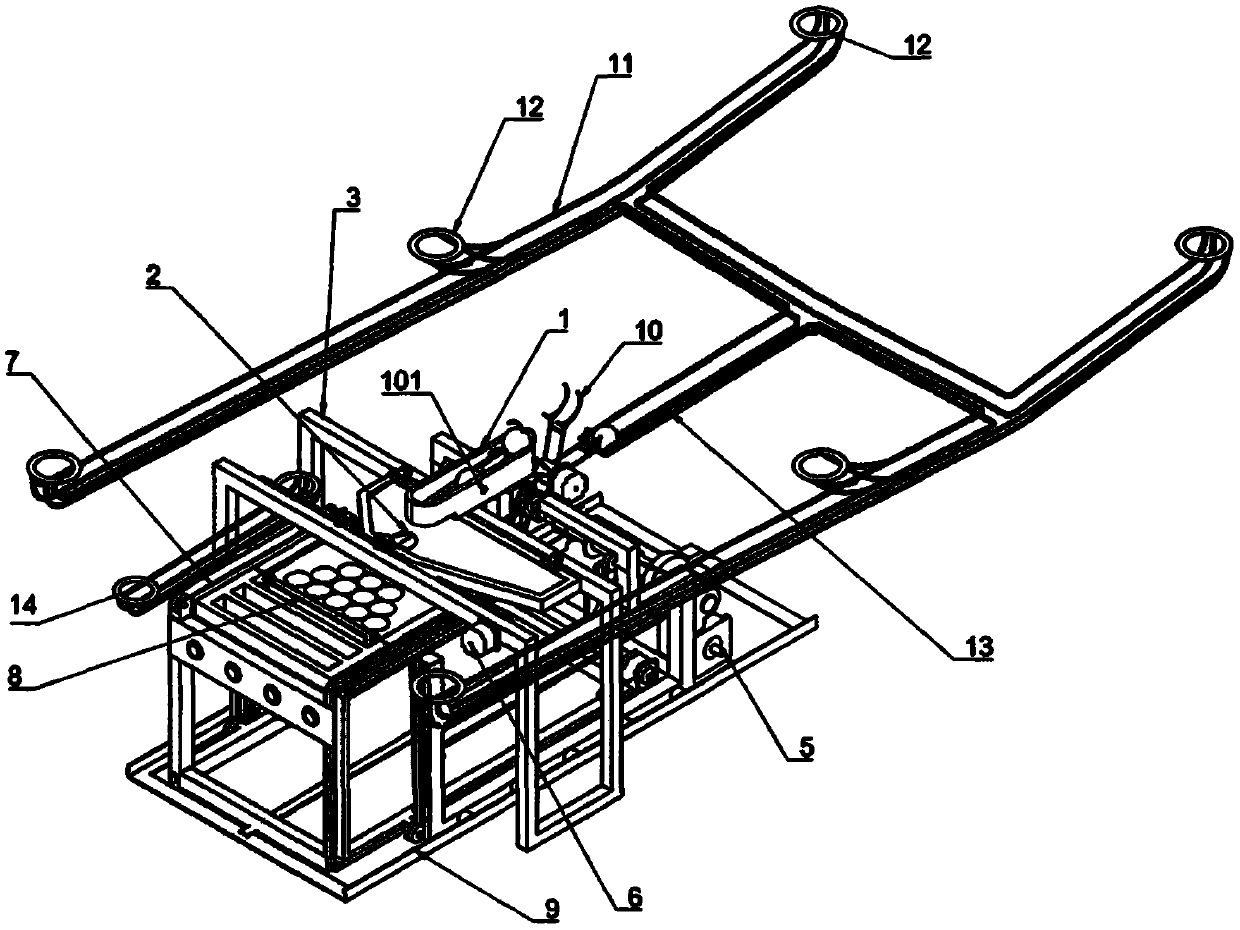

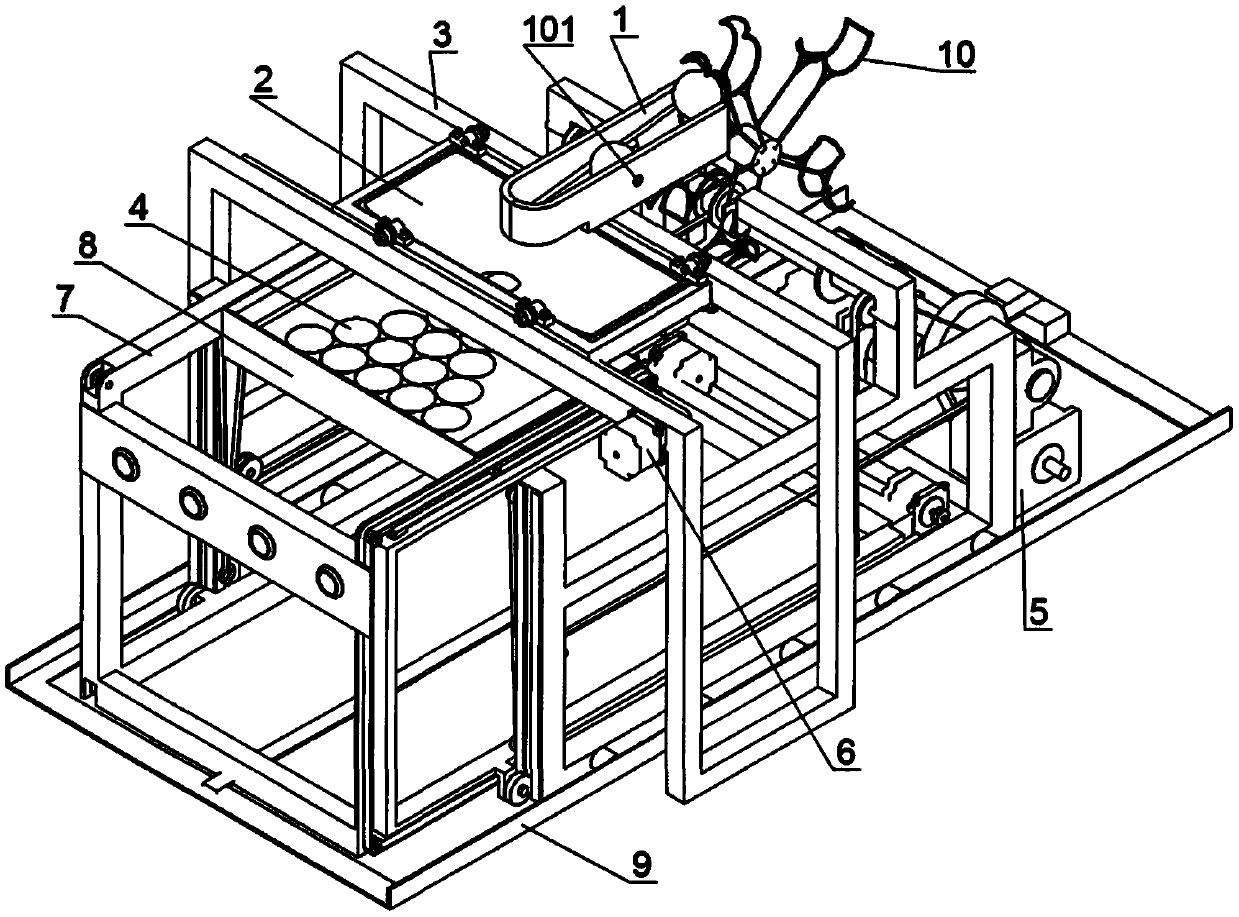

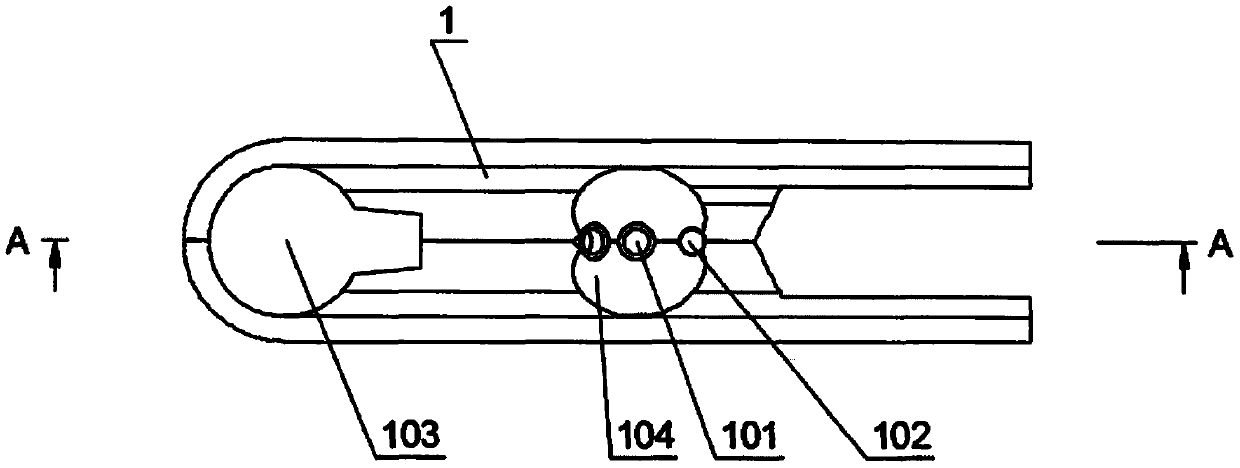

Automatic Chinese billiard ball placing and feeding device

InactiveCN111013122AHigh degree of automationRealization of automatic deliveryBilliardsColor recognitionElectric machinery

The invention discloses an automatic billiard ball placing and feeding device comprising a module identification table, a ball leaking hopper, a transverse advancing device, a longitudinal advancing device, a height advancing device, a secondary longitudinal device, a white ball collecting device and a control unit. A color recognition module recognizes colors of balls; the control unit confirms the serial number of a ball after processing a signal and determines the position where the ball should be located; and then a motor drives the billiard ball to fall into a certain specific position hole of a ball groove in a ball pushing frame to complete ball placement; and the placed balls are conveyed through the longitudinal advancing device, the height advancing device and the secondary longitudinal device. On the basis of the structure, the color of the billiard ball can be identified the position can be determined and automatic ball placing and feeding can be realized, so that the automation degree of billiard games is improved and the billiard table is convenient and fast to use.

Owner:丁希文

Method for preparing floating bed white ball resin with uniform density

A method for preparing floating bed white ball resin with uniform density which is used for a water treatment ion exchanger comprises the steps of: throwing a water phase consisting of a styrene oil phase, dispersant and water into a reactor for suspension polymerization, with the polymerization temperature for a first section of 60-85 DEG C and the time of 3 hours to 8 hours, and the polymerization temperature for a second section of 86-95 DEG C and the time of 4 hours to 10 hours; after reaction, adding foaming agent with the styrene quality of 1 percent to 5 percent under 105-115 DEG C for 3 hours to 8 hours for preparing spherical particles with the particle diameter of 0.5-2.0mm; adjusting the air volume of a suspension reactor to be 0.2-10kPa, under the temperature of 90-110 DEG C, with the residence time of spherules of 20 seconds to 300 seconds, for preparing the white ball resin with the particle diameter of 0.8-3.0mm and the bulk density of 0.10-0.55g / ml. The polystyrene sphere prepared by the invention has uniform particle size and density and good strength. By adjusting the air volume and the temperature for controlling the density of the sphere, homogeneous materials of different density levels can be prepared, thereby being capable of meeting the technical requirements of water treatment exchangers, foam plastic filter layers and styrene polymers with high foaming multiplying power.

Owner:LIAONING GEOLOGY ENG VOCATIONAL COLLEGE

Chonghua No.2 cauliflower cross breeding technology

The present invention provides a kind of Chonghua No. 2 cauliflower cross breeding technology. The Chonghua No. 2 cauliflower cross breeding process with selfing line D8 as female parent and selfing line W12 as male parent includes mechanical castration, colony pollination, and coordinate hybridization. The obtained Chonghua No. 2 cauliflower breed has the advantages of compact plant form, short and wide leaf stem, pure white ball flower, high pest resistance, high yield and other advantages.

Owner:上海崇明花菜研发中心

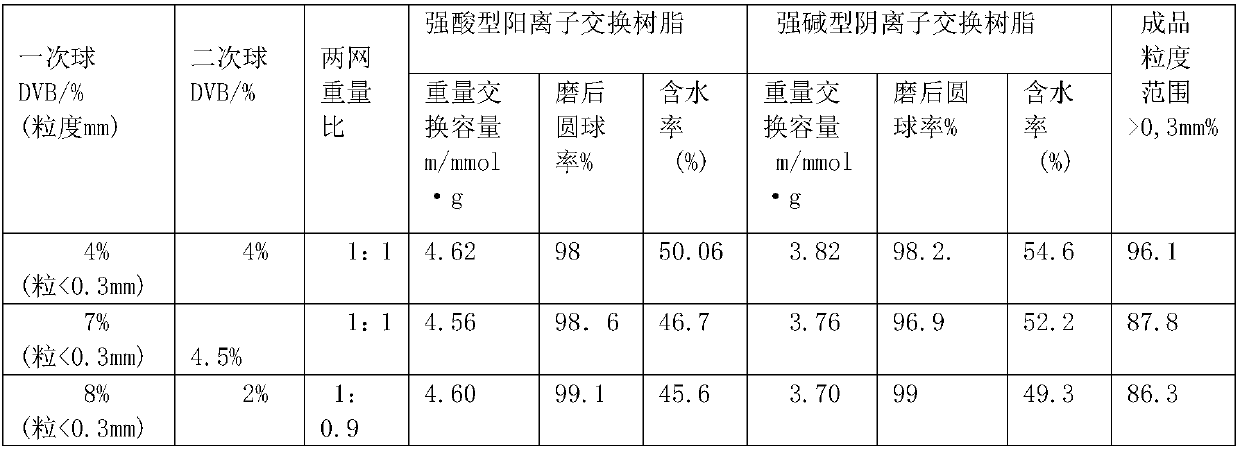

Method for improving resin performance in suspension polymerization production resin through interpenetrating method

InactiveCN107641166AImprove performanceIncrease lossCation exchanger materialsAnion exchangersCross-linkPolymer science

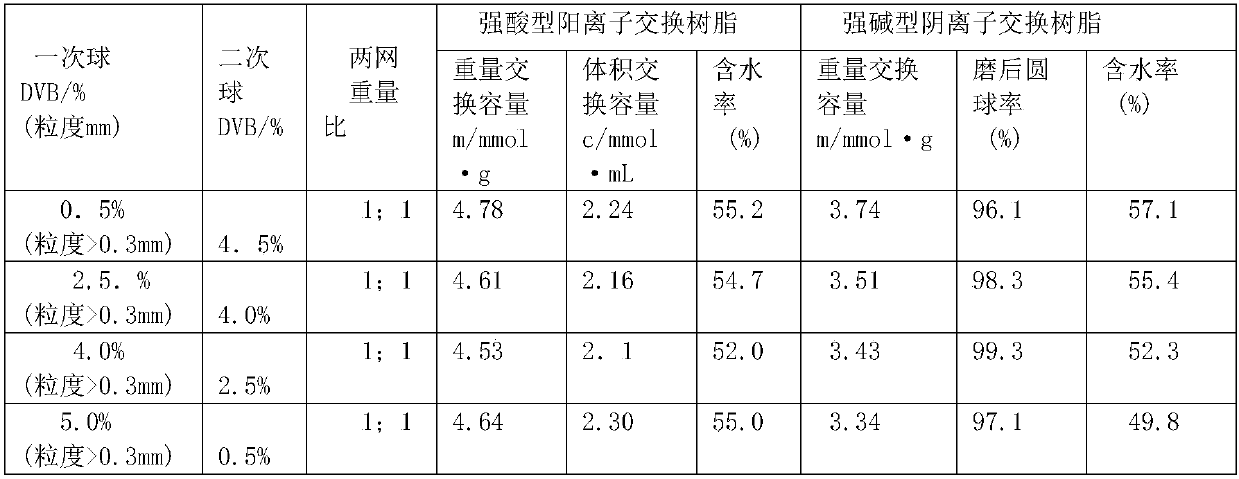

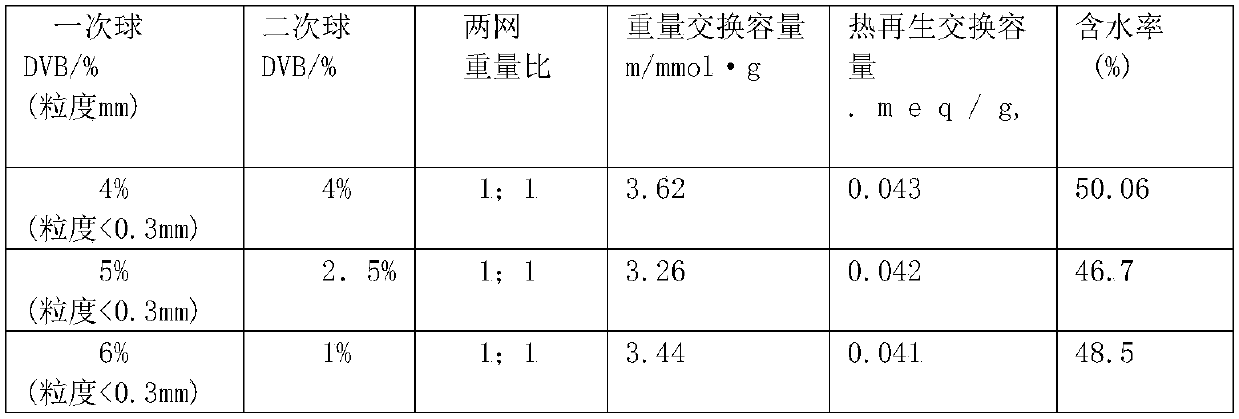

The invention relates to a method for improving resin comprehensive performances by producing an ion exchange resin framework white ball through an interpenetrating, cross-linking, suspending and polymerizing process, and the specific range involved comprises similar interpenetrating and cross-linking of styrene / divinyl benzene and styrene / divinyl benzene, heterogeneous interpenetrating and cross-linking of styrene / divinyl benzene and divinyl benzene or triallyl isocyanurate as well as heterogeneous interpenetrating and cross-linking of styrene / divinyl benzene and chloroethylene / divinyl benzene. According to the method disclosed by the invention, a white ball (smaller than 0.3 mm) with an unqualified once polymerized ball body is polymerized again under the same condition through secondary polymerization, so that the grain size is increased, and the white ball which meets standard grain size range (greater than 0.3mm-0.8mm); under the special condition, various resins prepared by performing secondary polymerization on a same monomer cross-linking agent of different concentrations can effectively reduce heterogeneity, in the polymerized ball body, of the cross-linking agent.

Owner:JIANGSU JIANYA ENVIRONMENTAL PROTECTION TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com