Sulfonyl modified strong cationic hypercrosslinked resin and preparation method thereof

A technology of ultra-high cross-linked resin and strong cations, applied in the field of resins, can solve the problems of low specific surface area, low adsorption capacity, and the preparation method of strong cationic ultra-high cross-linked resin has not yet been reported, and achieves narrow particle size distribution. , the effect of good adsorption performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

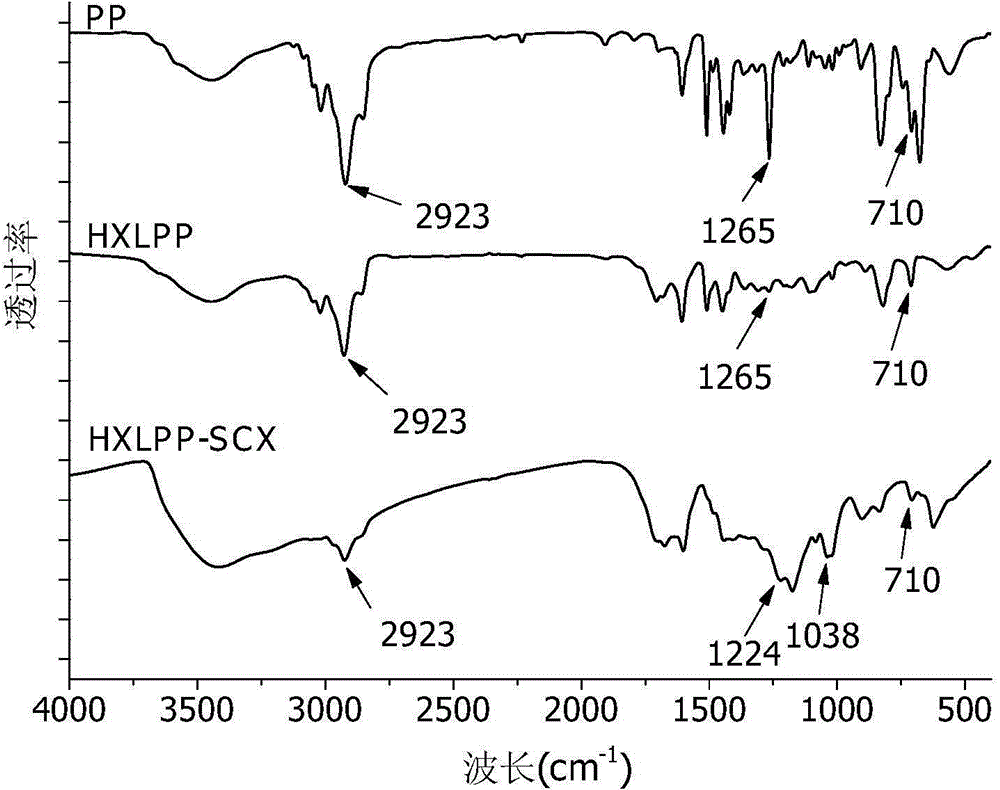

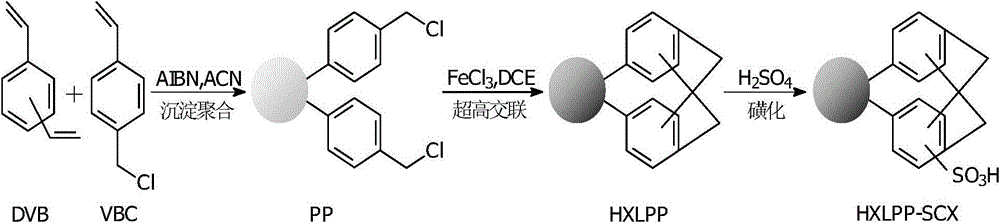

[0027] The preparation of the strong cationic super high cross-linked resin modified by sulfonic acid group comprises the following steps:

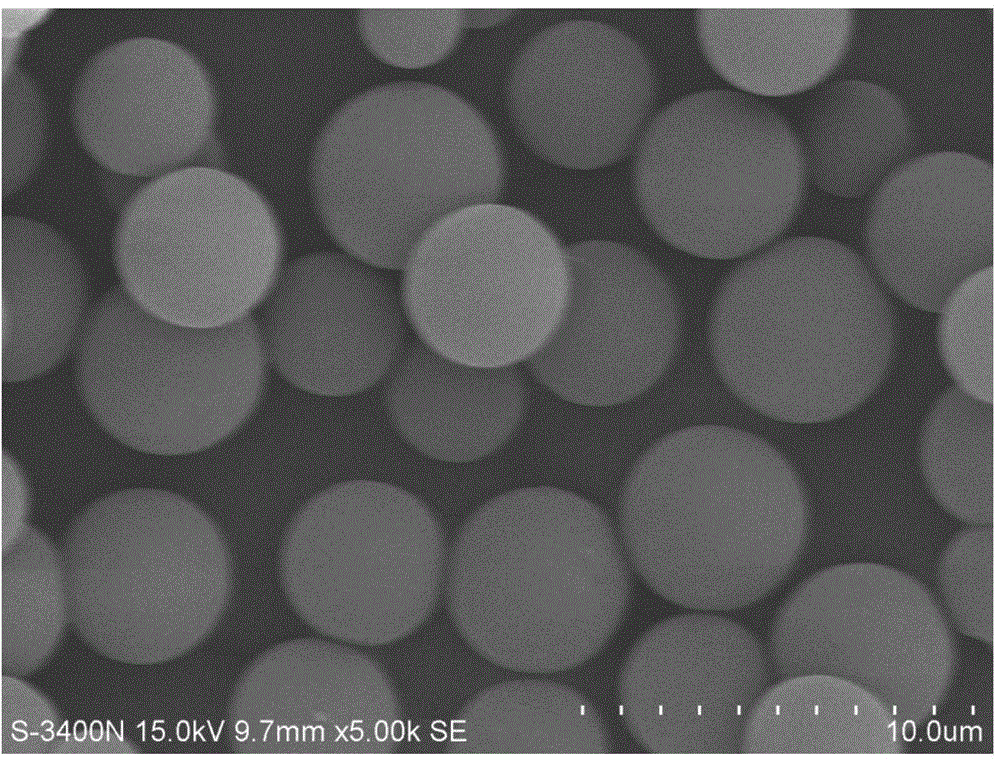

[0028] (a) In a 1000ml three-necked flask equipped with a reflux condenser, a thermometer and a nitrogen protection device, add 800ml of acetonitrile, and cool the system to 0° C. in an ice bath. Add 0.46g of azobisisobutyronitrile, 4g of divinylbenzene, and 12g of 4-chloromethylstyrene to the ice-water bath system in sequence, maintain the temperature of the system at 0°C, and blow nitrogen gas for 2 hours to remove the oxygen in the system . Then the reaction was transferred to an oil bath, the magnetic stirrer was adjusted to 200r / min, the system was slowly raised from room temperature to 60°C (according to the heating rate of 4min / °C), and the temperature was maintained to continue the reaction for 46 hours. After the reaction, cool the reaction system to room temperature, filter the reaction solution with a 0.2 μm nylon filter membr...

Embodiment 2

[0033] The strong cationic ultra-high cross-linked resin modified by sulfonic acid groups in this example is used as solid phase extraction filler to selectively adsorb basic organic compounds in aqueous solution. The steps are:

[0034](a) Preparation of stock solution: Accurately weigh 10 mg each of hippuric acid, uric acid, hypoxanthine, and xanthine, dissolve them in a small amount of 0.1 mol / L NaOH solution, and dilute to 10 mL with water. Accurately weigh 10 mg of inosine, and dilute to 10 mL with 0.13% acetic acid solution (pH=3).

[0035] (b) Prepare the solution to be tested: accurately pipette 100 μL each of the five stock solutions prepared in step (a), and dilute to 10 mL with 0.13% acetic acid solution (pH=3).

[0036] (c) Packing of solid-phase extraction column: accurately weigh 60 mg of strong cationic ultra-high cross-linked resin resin modified by sulfonic acid group, disperse it with 30 ml of anhydrous methanol, and use wet packing to pack the resin into a s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com