Macroporous adsorption resin and preparation method thereof

A pore adsorption and resin technology, applied in the field of macroporous adsorption resin and its preparation, can solve the problems of limited development and application, low extract purity, poor mechanical strength, etc., and achieves easy industrial production, simple preparation process, and good mechanical strength. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

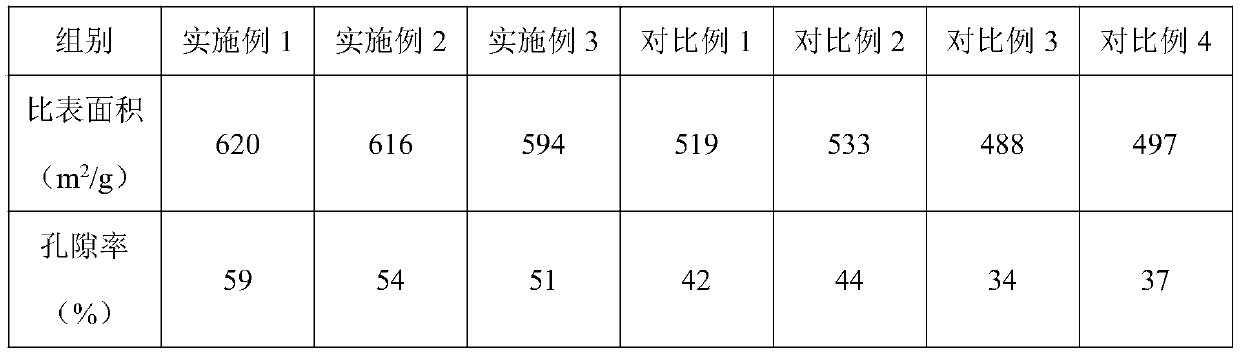

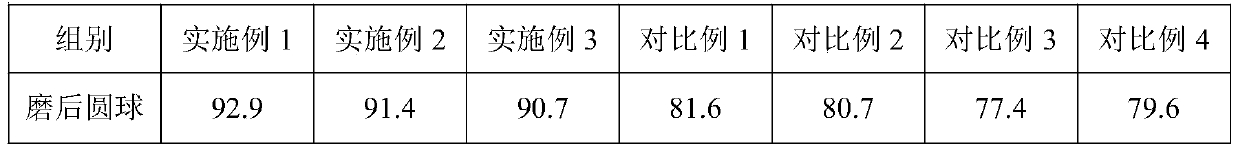

Examples

Embodiment 1

[0037] Raw material composition: 200 parts of water, 10 parts of gelatin, 10 parts of styrene, 50 parts of divinylbenzene, 10 parts of white oil, 5 parts of azobisisobutyronitrile, 2 parts of toluene, 100 parts of No. 120 solvent naphtha, 5 parts of 1 , 2-dichloroethane, 10 parts of zinc chloride, 150 parts of chloromethyl ether.

[0038] Preparation:

[0039] (1) Polymerization of white balls: Heat water to 50°C, add gelatin, stir for 1 hour, then add styrene, divinylbenzene, white oil, toluene and azobisisobutyronitrile, heat up to 70°C to set the shape, and keep warm for 2 hours after setting , then raise the temperature to 85°C for the second time, keep warm for 6 hours for the second time, wash with water at 60°C for 5 times after keeping warm, and obtain white balls;

[0040] (2) Drying and screening of white balls: dry the white balls at a drying temperature not exceeding 80°C until the weight loss rate is less than 8.0%, and then sieve the dried white balls to obtain ...

Embodiment 2

[0047] Raw material composition: 300 parts of water, 5 parts of gelatin, 20 parts of styrene, 20 parts of divinylbenzene, 10 parts of white oil, 2 parts of initiator, 5 parts of porogen, 50 parts of mineral spirits, 10 parts of 1,2-di Ethyl chloride, 5 parts of zinc chloride, 200 parts of chloromethyl ether.

[0048] Preparation:

[0049] (1) Polymerization of white balls: Heat water to 60°C, add gelatin, stir for 2 hours, then add styrene, divinylbenzene, white oil, toluene and azobisisovaleronitrile, heat up to 85°C to set the shape, and keep warm for 3 hours after setting , and then raise the temperature to 92°C for the second time, keep warm for 9 hours for the second time, and wash 6 times with water at 60°C after keeping warm to obtain white balls;

[0050] (2) Drying and screening of white balls: dry the white balls at a drying temperature not exceeding 80°C until the weight loss rate is less than 8.0%, and then sieve the dried white balls to obtain white balls with a ...

Embodiment 3

[0057] Raw material composition: 250 parts of water, 8 parts of gelatin, 15 parts of styrene, 35 parts of divinylbenzene, 20 parts of white oil, 4 parts of benzoyl peroxide, 3 parts of porogen, 80 parts of mineral spirits, 7 parts of 1, 2-dichloroethane, 8 parts of zinc chloride, 170 parts of chloromethyl ether.

[0058] Preparation:

[0059] (1) Polymerization of white balls: Heat water to 55°C, add gelatin, stir for 2 hours, then add styrene, divinylbenzene, white oil, toluene and benzoyl peroxide, heat up to 80°C to set the shape, keep the temperature for 3 hours after setting, Then heat up to 90°C for the second time, keep warm for 7 hours for the second time, wash 6 times with water at 60°C after keeping warm, and get white balls;

[0060] (2) Drying and screening of white balls: dry the white balls at a drying temperature not exceeding 80°C until the weight loss rate is less than 8.0%, and then sieve the dried white balls to obtain white balls with a particle size of 0....

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com