Patents

Literature

95 results about "Resin extraction" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Resin extraction consists of incising the outer layers of a pine tree in order to collect the sap or resin.

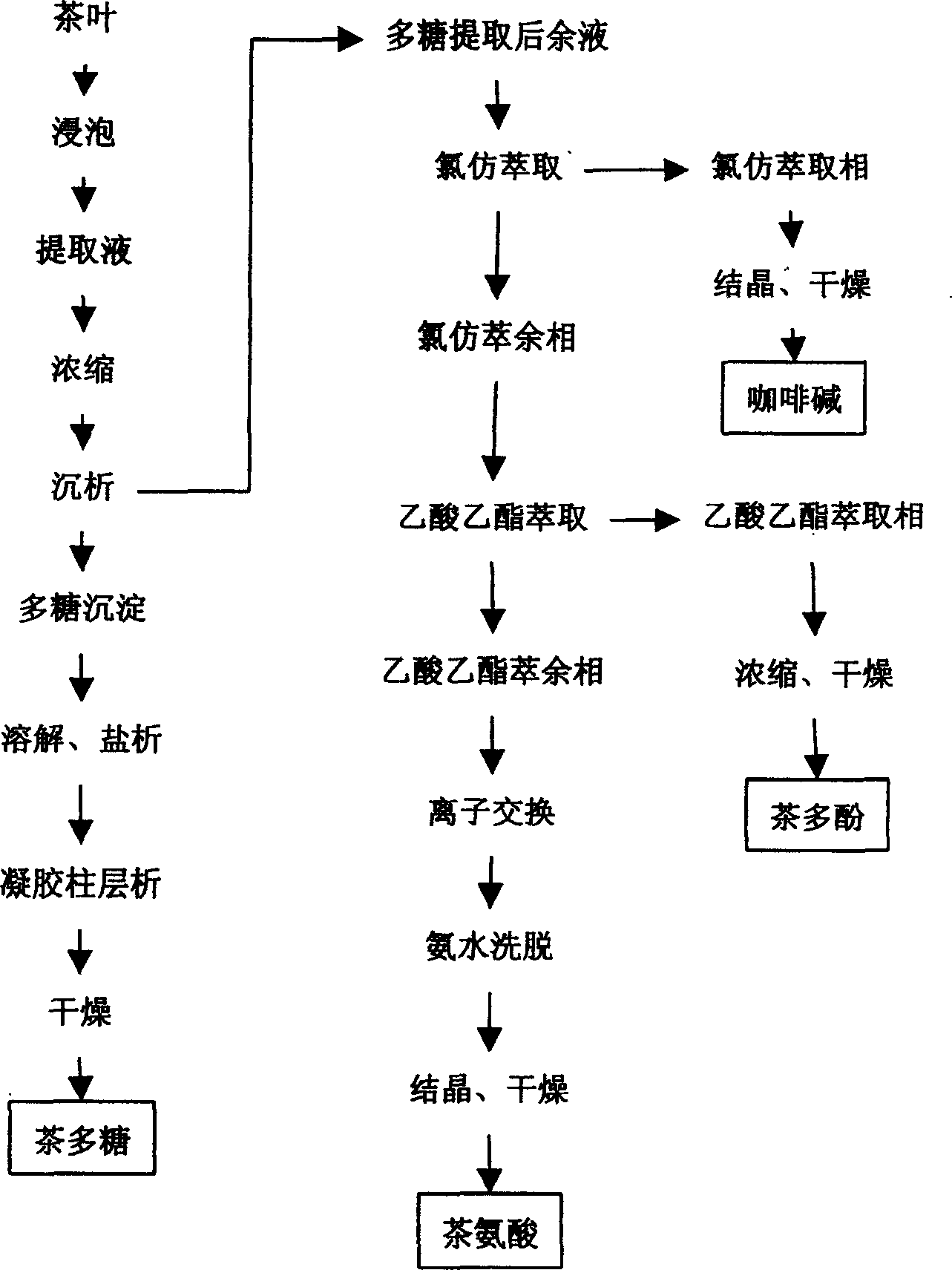

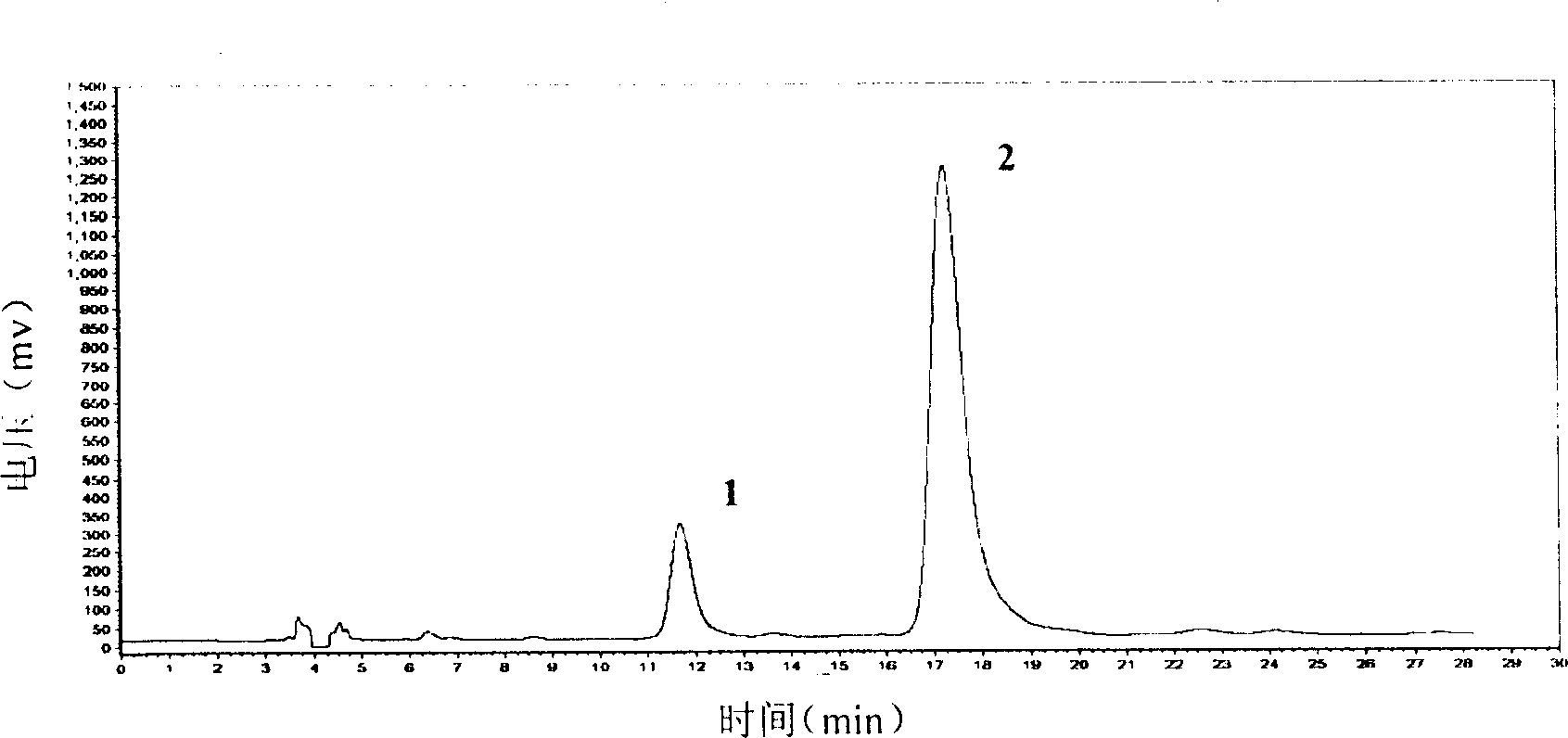

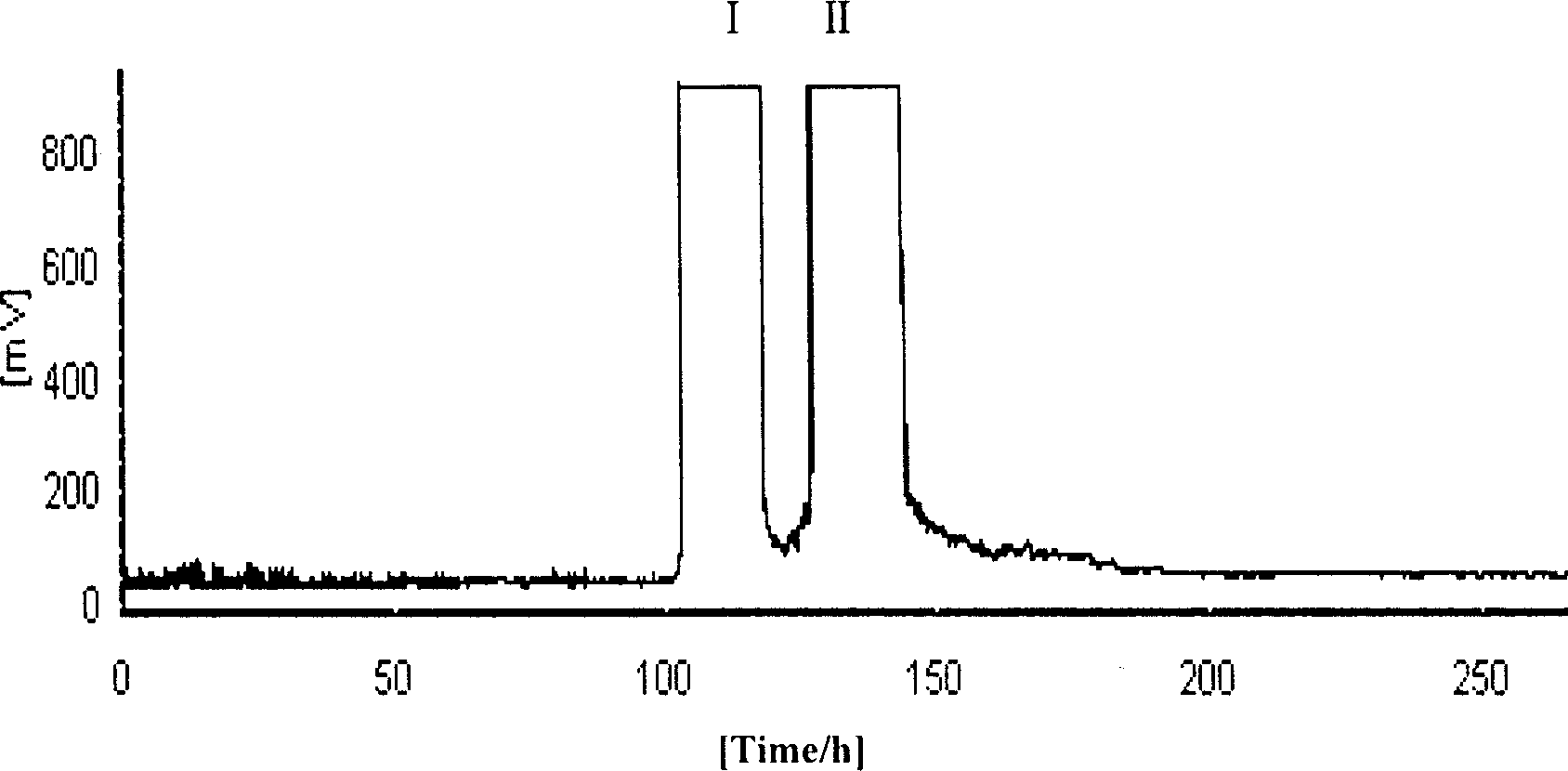

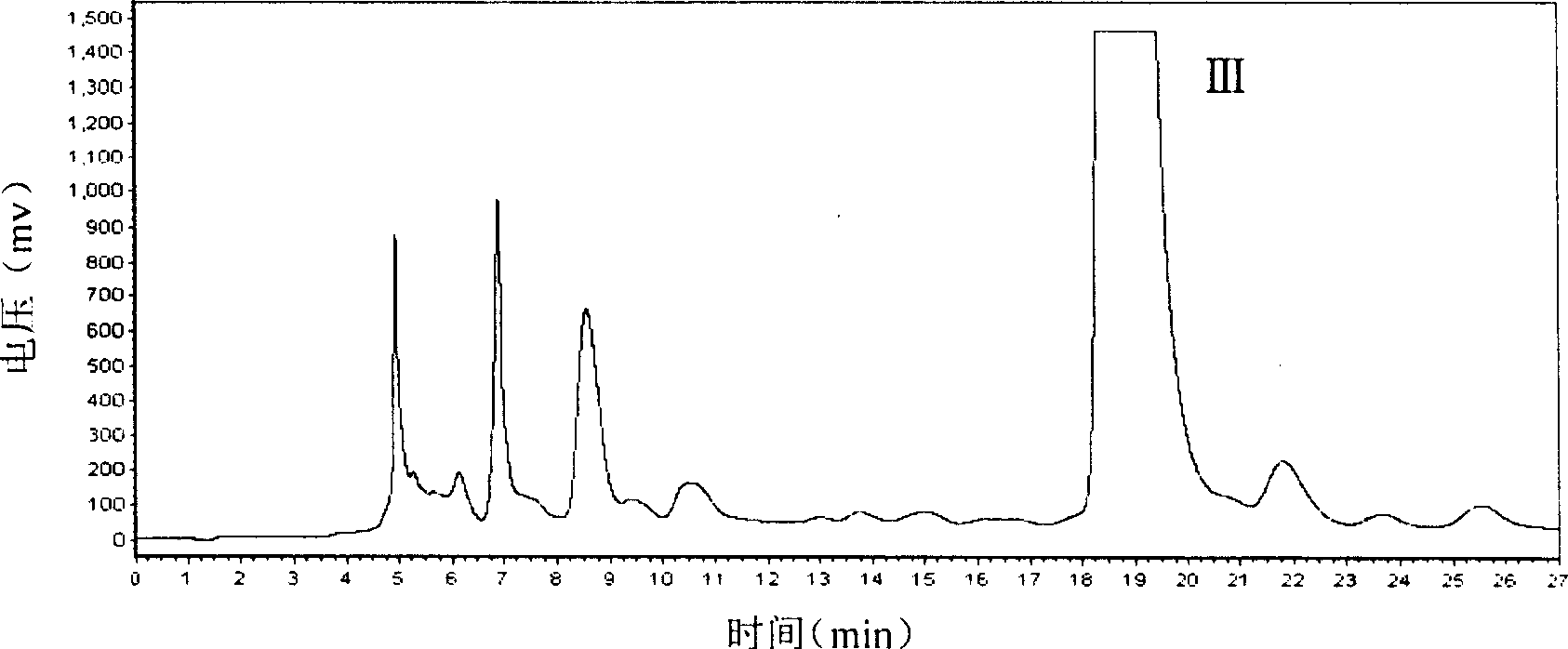

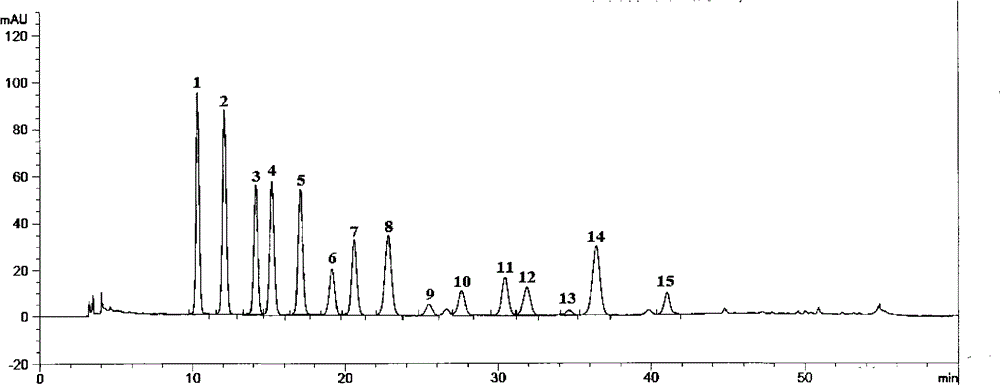

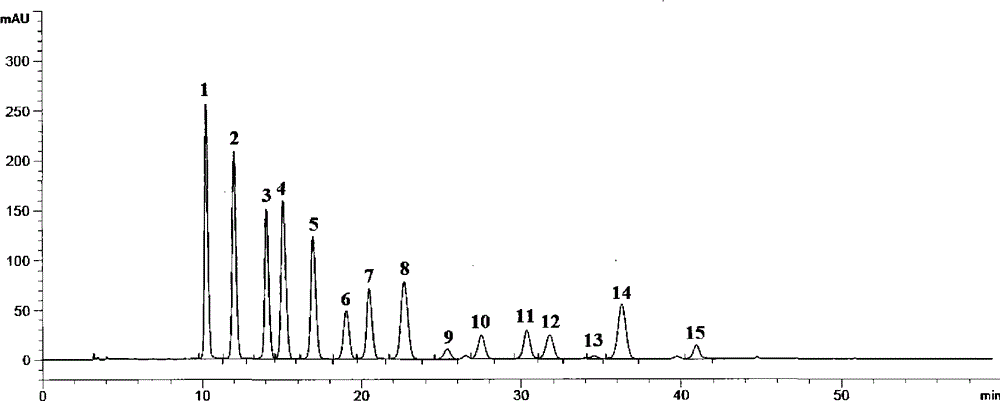

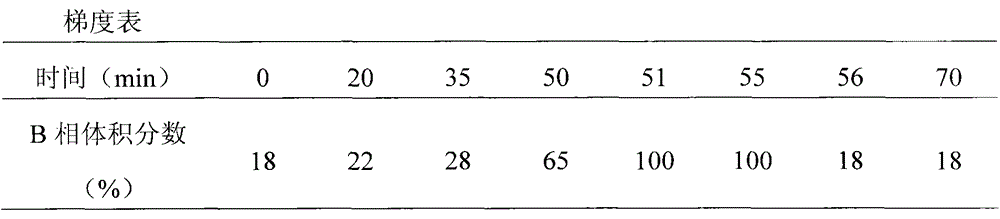

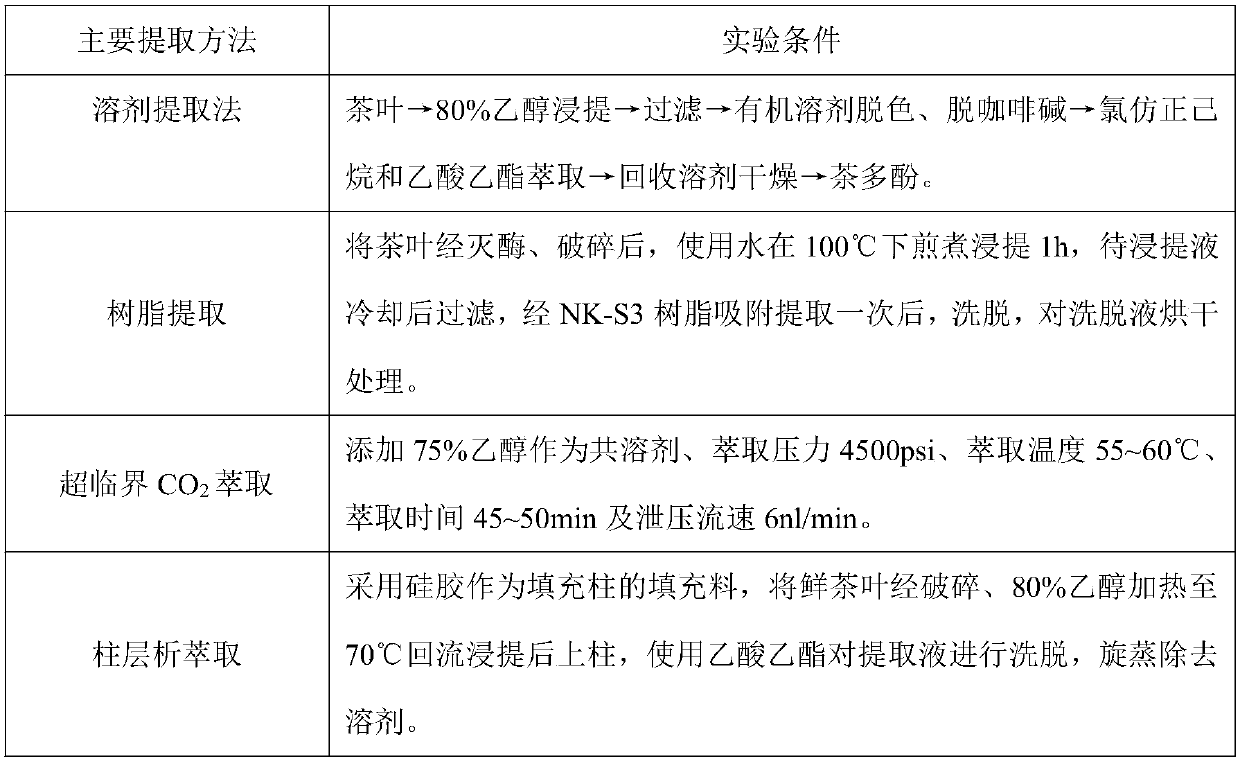

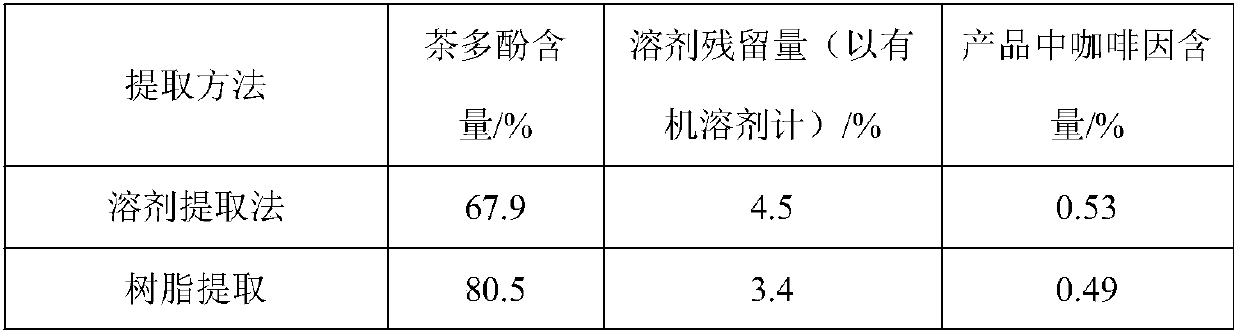

Process for synthetic extraction of polysaccharides, tea-polyphenol, theanine, caffeine from tea

InactiveCN1557841AReduce lossesNo structural damageOrganic chemistrySolid solvent extractionTheanineEthyl acetate

The comprehensive process of extracting tea polysaccharide, tea polyphenol, theanine and coffine from tea includes the following steps: water or organic solvent extraction of tea powder under the action of microwave, concentration, precipitation and water dissolving the extract liquid, salt separating to eliminate protein and separation in gel column and drying to obtain tea polysaccharide; chloroform extraction of the raffinate, ethyl acetate extraction of the chloroform raffinate and drying to obtain tea polyphenol; No. 732 cationic exchange resin extraction of the ethyl acetate raffinate, concentration, crystallization and drying to obtain theanine; and crystallizing and drying the chloroform extract liquid to obtain coffine. The present invention has the advantages of short extraction time, high extraction rate, less loss of active matter, etc.

Owner:TEA RES INST CHINESE ACAD OF AGRI SCI

Resin process of extracting proanthocyanidin from graup seed

The present invention relates to the extraction of proanthocyanidin from plant material, and is especially the resin extraction process of proanthocyanidin from grape seed. Grape seed as material is extracted with water and / or alcohol as solvent at normal temperature or heating condition; the extractive liquid is filtered, concentrated while recovering alcohol solvent, re-filtered while adding water, the filtrate is adsorbed with macroporous adsorptive resin, the saturated resin is eluted with water solution of alcohol and the eluent is dried while recovering solvent to obtain the product. The process has yield of 3-10 %, and the product has proanthocyanidin content of 38-90 %. The present invention has the advantages of low cost and no residual solvent in the product, and is environment friendly and suitable for industrial production.

Owner:沈阳中科药业有限责任公司

Process for preparing jasminodin and genipin-1-beta-D-gentiobioside with cape jasmine fruit

InactiveCN1706858ANo pollutionOvercome operabilitySugar derivativesChromatographic separationGenipin

The present invention relates to medicine technology, and is especially the preparation process of preparing high purity jasminodin and genipin-1-beta-D-gentiobioside through separating and purifying cape jasmine fruit. The preparation process includes soaking or refluxing cape jasmine fruit with water or water solution of ethanol to obtain coarse extract; eluting in macroporous adsorbing resin first with great amount of water and then with low concentration ethanol solution; decompression concentrating to obtain the macroporous adsorbing resin extract of cape jasmine fruit; and final high speed liquid phase chromatographic and preparing liquid phase chromatographic separation to purify and obtain high purity jasminodin and genipin-1-beta-D-gentiobioside. The preparation process of the present invention has high separation efficiency, high product purity and simple operation, and is suitable for industrial production.

Owner:SECOND MILITARY MEDICAL UNIV OF THE PEOPLES LIBERATION ARMY

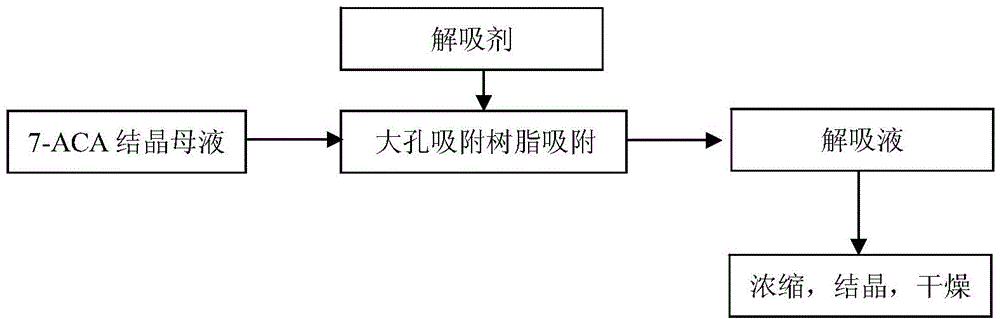

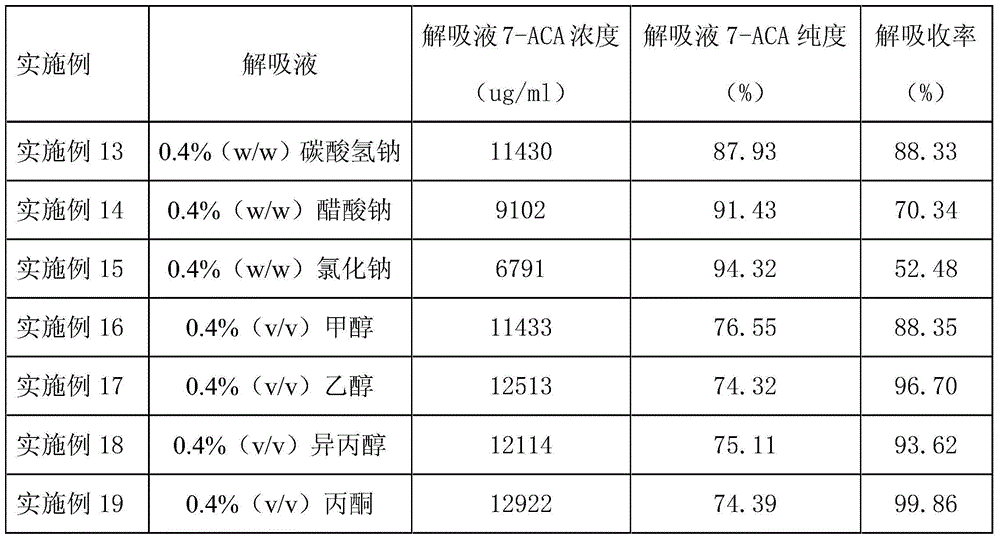

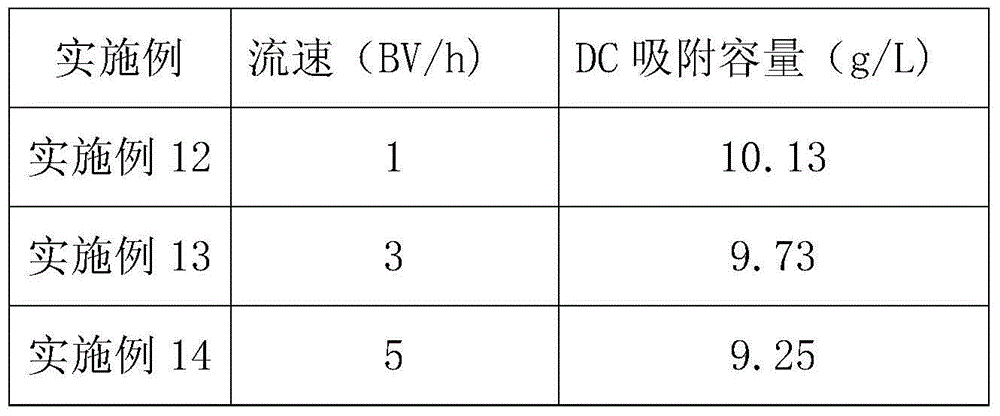

Process for recovering 7-ACA (aminocephalosporanic acid) crystallization mother liquor

The invention provides a process for recovering a 7-ACA (aminocephalosporanic acid) product from mother liquor through macroporous adsorption resin. The process mainly comprises the following steps: performing resin adsorption, performing resin desorption, concentrating and the like, wherein in the resin absorption step, the pH value of 7-ACA crystallization mother liquor is adjusted, the crystallization mother liquor passes through a macroporous adsorption resin layer from top to bottom at a certain flow speed, and when the valence of 7-ACA contained in effluent of a resin column is 1% of that of the crystallization mother liquor at an inlet, resin adsorption is stopped. According to the method, the qualified 7-ACA product with the purity of greater than or equal to 98% and the color grade of greater than 4 can be obtained; the extraction yield of the resin is greater than or equal to 90% and the total process yield is greater than or equal to 40%; based on estimation of 200t of the mother liquor produced each day, the economic benefit of a year can reach more than ten million yuan.

Owner:SUNRESIN NEW METERIALS CO LTD XIAN

Preparation method of mecobalamin

InactiveCN102391340ALow costImprove conversion rateSugar derivativesSugar derivatives preparationAlcoholFiltration

The invention discloses a preparation method of mecobalamin. The preparation method includes the steps: A.dissolving cyanocobalamine, cobalt chloride and trimethylsulfoxonium iodide in deionized water to obtain a liquid to react; B. dissolving sodium borohydride in absolute ethyl alcohol and adding the liquid to react which is obtained from the step A so as to generate reaction; C. adjusting the PH of the solution to 5.0-7.0; D. conducting centrifugation to obtain filtrate; E. conducting vacuum evaporation on the filtrate to obtain a concentrate; and F. absorbing the concentrate with a macroporous resin column and then conducting washing, layer developing and resolution, thus obtaining crystallization stock solution; adding acetone in the crystallization stock solution; and after dynamic and static crystallization, conducting filtration, washing and drying, thus obtaining the finished product of the mecobalamin. In the invention, low-concentration reaction liquid is adopted and by the steps of centrifugation, resin extraction, crystallization and the like, the mecobalamin with high yield, high purity and low cost is obtained; and the preparation method belongs to an industrial preparation method.

Owner:HEBEI YUXING BIO ENG

Natural resin extracting process and apparatus

InactiveCN101024754AHeated evenly and thoroughlyHigh purityNatural resin processNatural resinEngineering

The invention discloses a technology and device for distilled natural resin like san-mou oil and cedar oil. It includes the following steps: passing through steam into the barrel containing the slice of cunninghamia sinensis stump and coniferles vstump, taking oil-water separation to the natural resin, gathering natural resin. The device includes distilling barrel and steam boiler. The natural resin distilling technology and device could distil resin and have good quality. It has good economic and environment protection benefits.

Owner:粟国江

Bilberry extract and preparation method thereof

InactiveCN105287690ASimple and fast operationSuitable for industrial productionOrganic active ingredientsFood preparationLingonberry extractDivinylbenzene

The invention relates to a plant extract, in particular to a bilberry extract and a method for preparing the extract. The content of the bilberry extract is 55%-95%, and the bilberry extract is consistent to finger-print specified in European Pharmacopoeia. The invention also relates to the method for preparing the extract. The method comprises the following steps of extracting the bilberry extract by using macroporous adsorption resin; and concentrating and performing spraying drying on collected extracting solution. According to the method, rate of charge of divinylbenzene to esters monomers of the macroporous adsorption resin used in the method is 19:1-7:3, and a desorption agent used in a desorption process is ethanol or an acid aqueous solution of methyl alcohol or acetone.

Owner:TIANJIN NANKAI SHARE PHARMA SCI & TECH

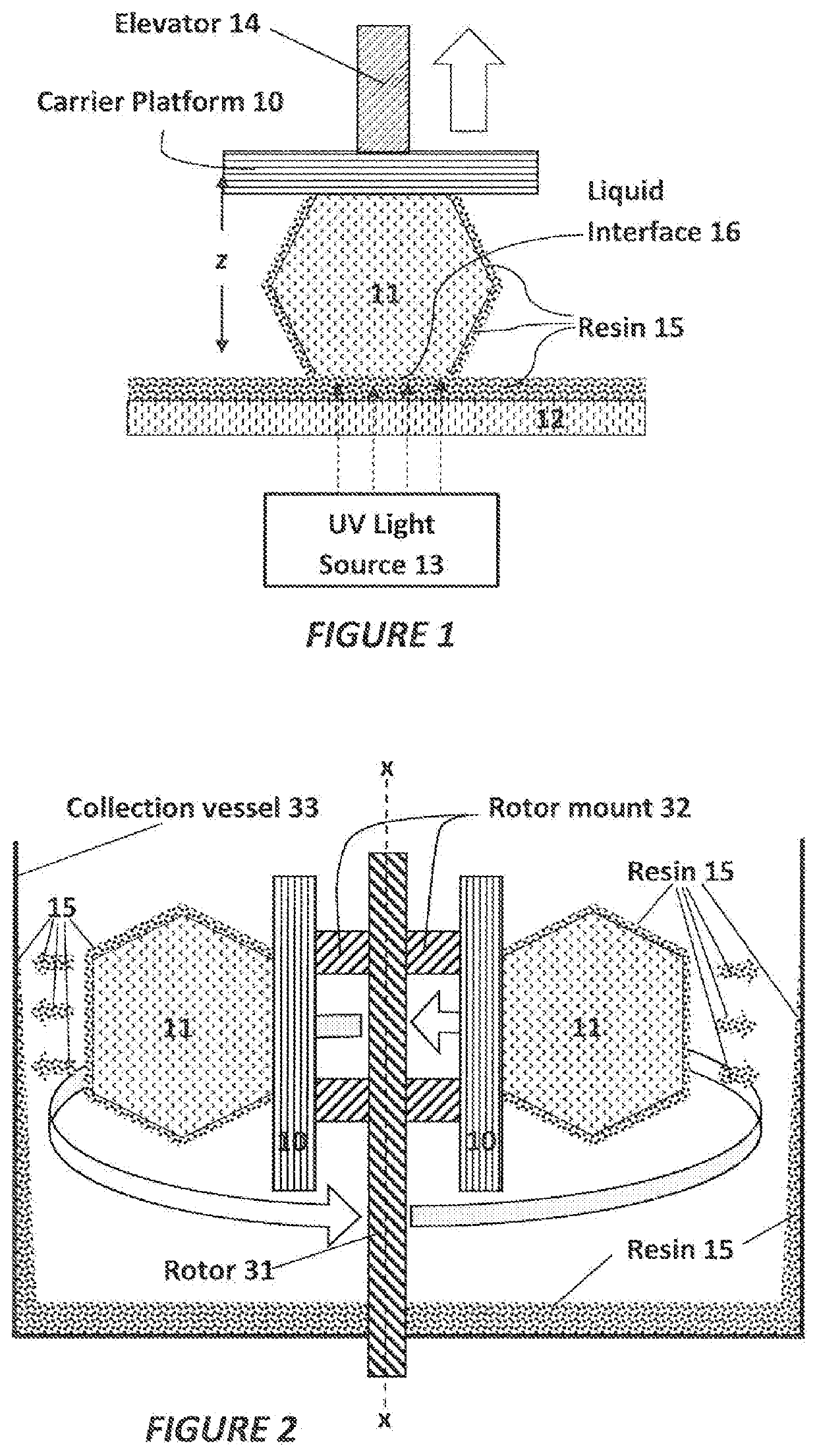

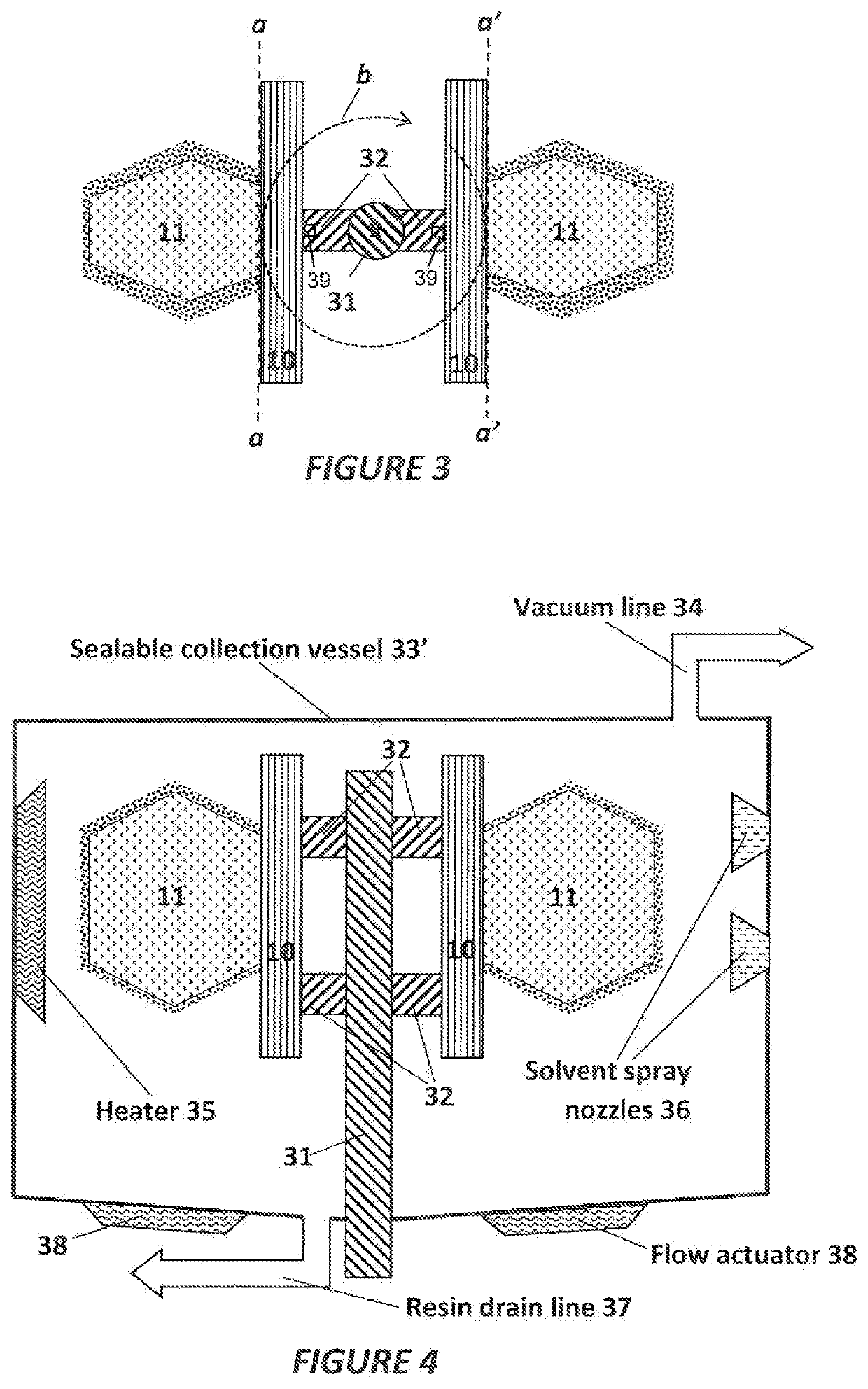

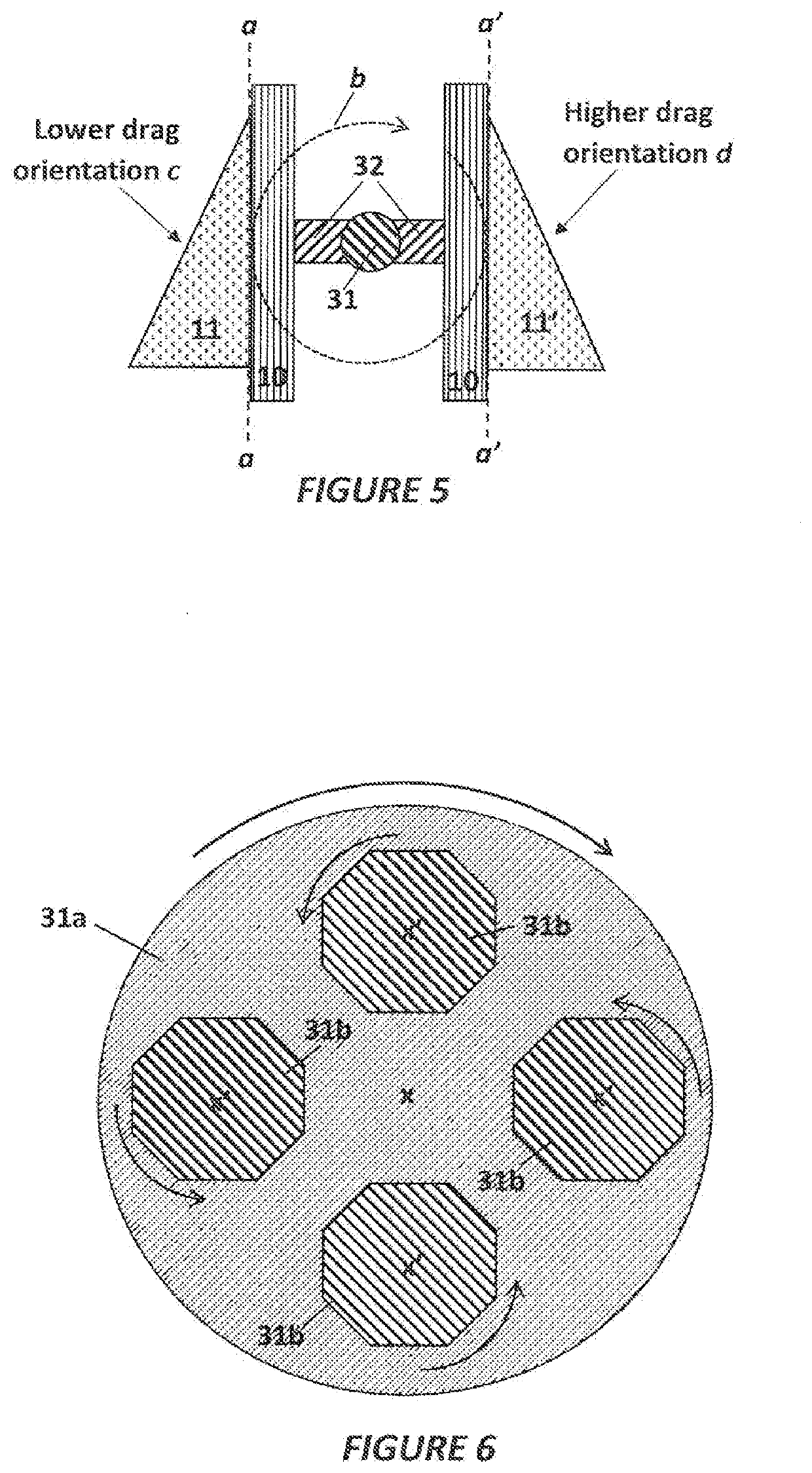

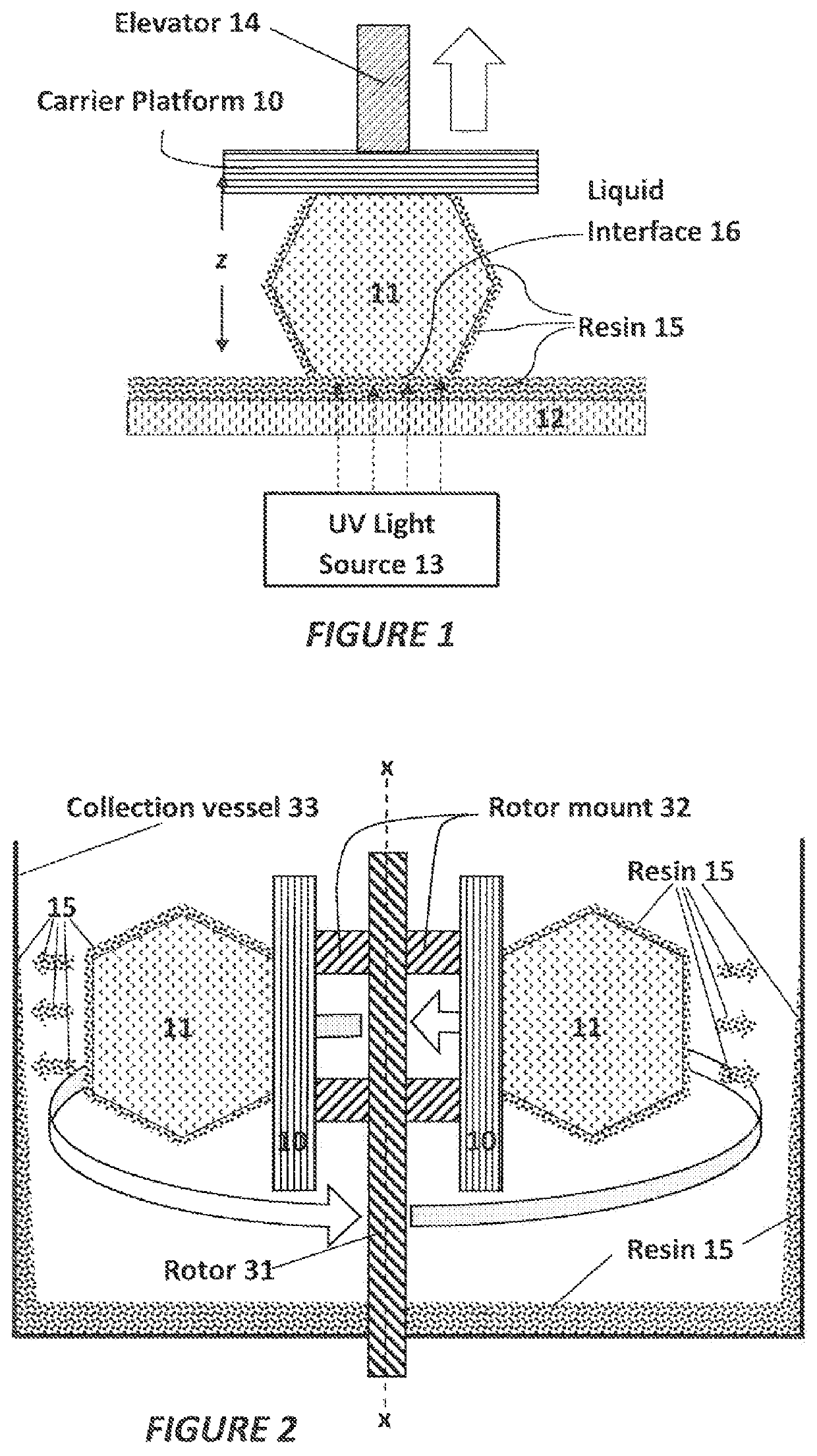

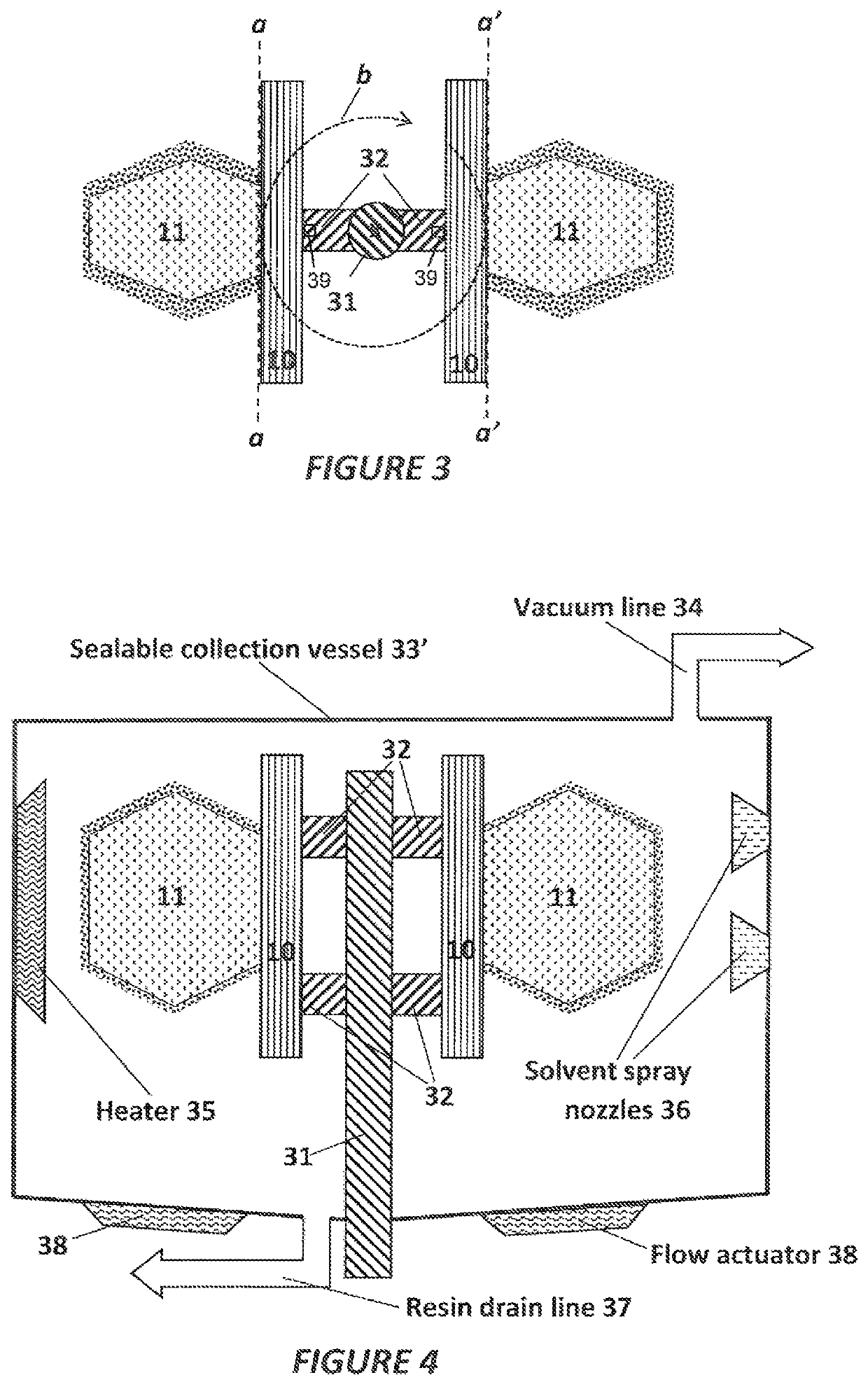

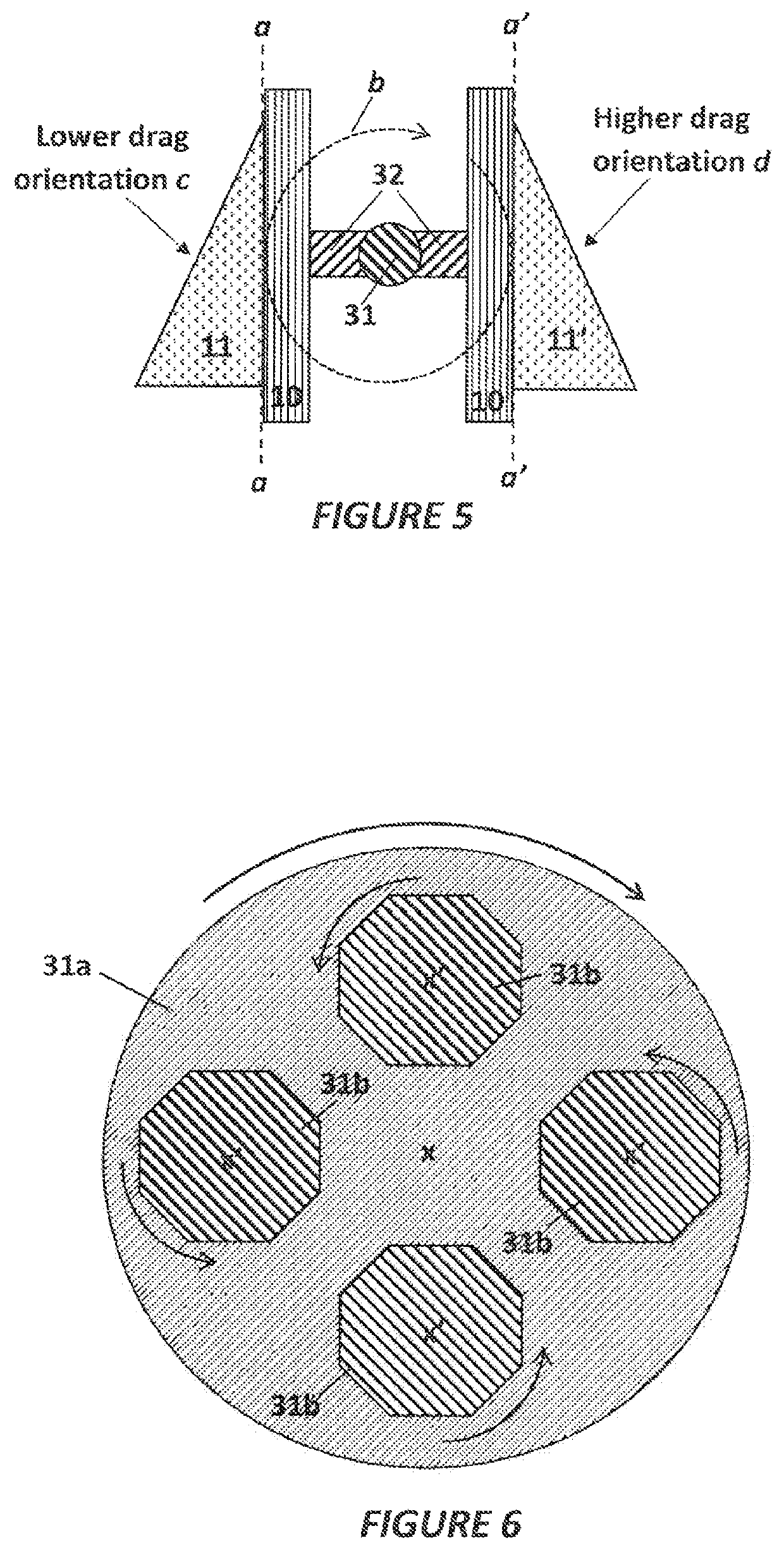

Resin extractor for additive manufacturing

ActiveUS20210086450A1Low viscosityReduce resistanceManufacturing platforms/substrates3D object support structuresStereolithographiesResin extraction

A method of separating excess resin (15) from at least one object (11), includes: (a) stereolithographically producing at least one object (11) on at least one carrier platform (10), each carrier platform (10) having a planar build surface to which at least one object (11) is connected, each object (11) carrying excess resin (15) on a surface thereof; then (b) mounting each carrier platform (10) to a rotor (31); (c) centrifugally separating excess resin (15) from each object (11) by spinning the rotor (31) with each carrier platform (10) connected thereto while each object (11) remains connected to each carrier platform (10); and then (d) removing each carrier platform (10) from the rotor (31) with each object (11) thereon, with excess resin (15) separated therefrom.

Owner:CARBON INC

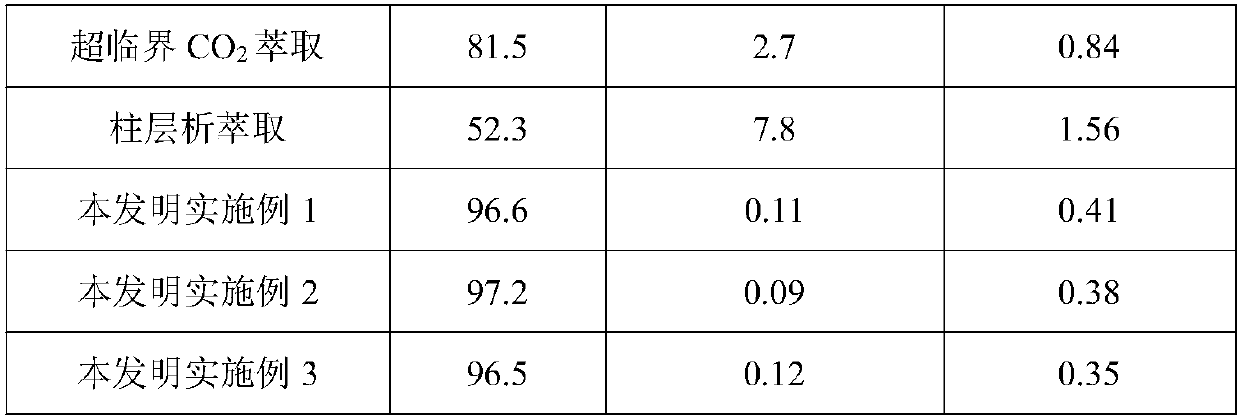

Polycondensation bead type macroporous resin extraction agent and preparation method thereof

InactiveCN104017151AExtended service lifeHigh mechanical strengthSolvent extractionFoaming agentResin extraction

The invention relates to a polycondensation bead type macroporous resin extraction agent and a preparation method thereof, belonging to the technical field of high polymer materials. The polycondensation bead type macroporous resin extraction agent disclosed by the invention comprises the following raw materials in parts by weight: 15-25 parts of melamine, 35-50 parts of formaldehyde, 5-10 parts of polyphenol, 20-30 parts of solid extraction agent, 5-10 parts of pore-foaming agent, 5-10 parts of distilled water, 300-500 parts of dispersion medium, and 3-5 parts of Barafluro. A plurality of types of solid extraction agents can be embedded in polycondensation bead type macroporous resin disclosed by the invention; melamine is directly used as the synthesis raw material of the polycondensation bead type macroporous resin extraction agent disclosed by the invention; the mechanical strength of resin is effectively increased; the service life of the resin extraction agent is increased; in addition, due to application of the pore-foaming agent, the prepared resin extraction agent has macroporous property; and the extraction efficiency of the resin extraction agent is increased.

Owner:CHINA BLUESTAR CHENGRAND CO LTD

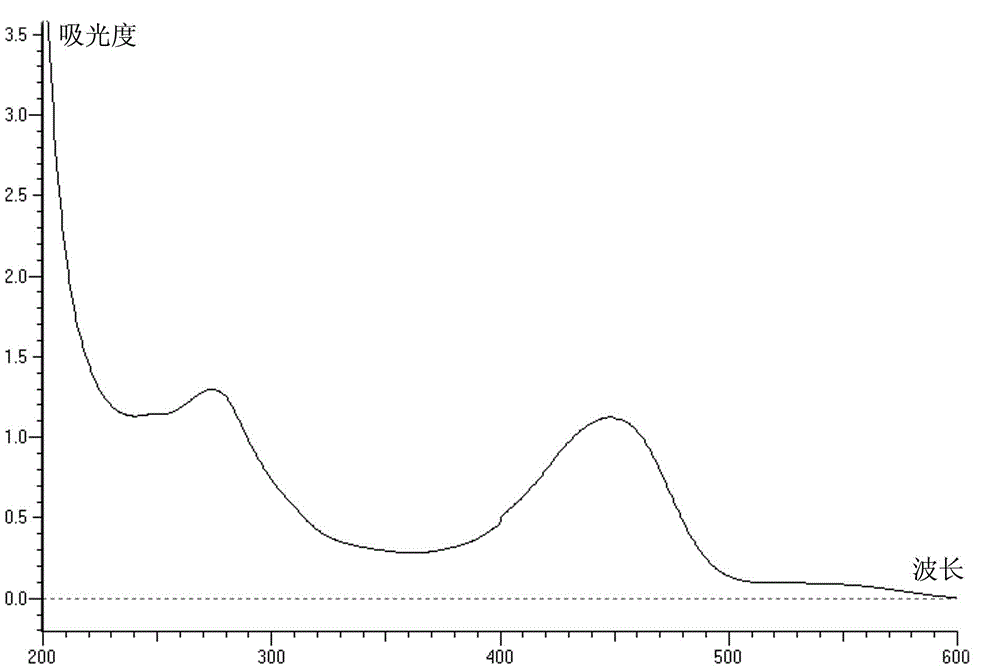

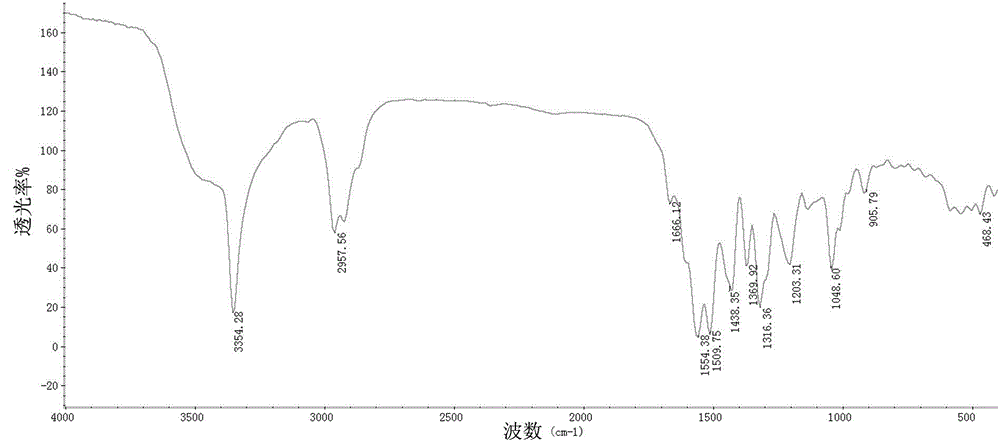

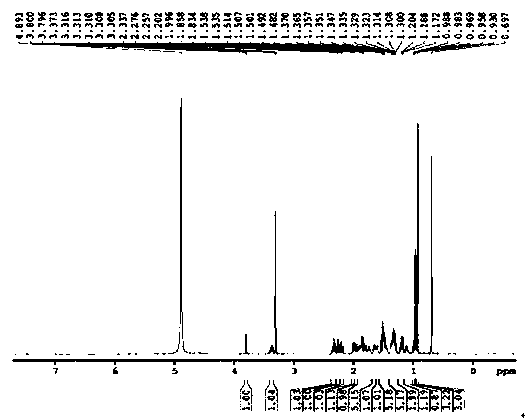

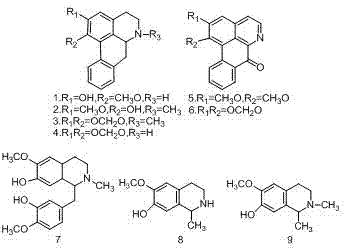

Novel skeleton alkaloid compound and extraction separation method thereof

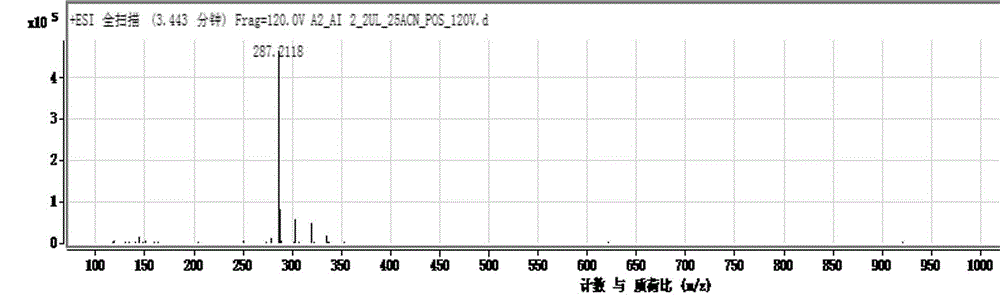

ActiveCN105085534AEasy to separate and extractFast extraction and separationOrganic chemistryAntipyreticSephadexResin extraction

The invention discloses a novel skeleton alkaloid compound. The novel skeleton alkaloid compound has a molecular formula of C18H26N2O, is named as Oleracimine and is shown in the chemical structural formula (I). The invention provides an extraction separation method of the novel skeleton alkaloid compound. The extraction separation method orderly comprises water decoction extraction, macroporous adsorption resin extraction, ethyl acetate extraction, silica gel column chromatography, ODS medium-pressure column treatment and Sephadex LH-20 treatment. The extraction separation method realizes simple and fast extraction separation of the novel skeleton alkaloid compound with a unique skeleton. The novel skeleton alkaloid compound has the effect of easing pain and can be used for preparation of pain easing drugs. The novel skeleton alkaloid compound is shown in the formula (I).

Owner:LIAONING UNIV OF TRADITIONAL CHINESE MEDICINE

Resin extractor for additive manufacturing

ActiveUS11084216B2Low viscosityReduce resistanceManufacturing platforms/substrates3D object support structuresStereolithographiesResin extraction

A method of separating excess resin (15) from at least one object (11), includes: (a) stereolithographically producing at least one object (11) on at least one carrier platform (10), each carrier platform (10) having a planar build surface to which at least one object (11) is connected, each object (11) carrying excess resin (15) on a surface thereof; then (b) mounting each carrier platform (10) to a rotor (31); (c) centrifugally separating excess resin (15) from each object (11) by spinning the rotor (31) with each carrier platform (10) connected thereto while each object (11) remains connected to each carrier platform (10); and then (d) removing each carrier platform (10) from the rotor (31) with each object (11) thereon, with excess resin (15) separated therefrom.

Owner:CARBON INC

Method for separating and purifying chenodeoxycholic acid from goose bile

The invention provides a method for separating and purifying chenodeoxycholic acid from goose bile. Specifically, fresh goose bile is subjected to saponification, calcium precipitation, roughing and macro-porous resin purification to obtain a chenodeoxycholic acid pure product. The method has the advantages that (1) the raw material source of the chenodeoxycholic acid is expanded and the method for separating and purifying the chenodeoxycholic acid from the goose bile is provided, (2) compared with the conventional extraction process, ethyl acetate is not used any longer, the repeatability of experiments is increased, the environmental pollution is reduced and the recovery rate of the chenodeoxycholic acid is improved, and (3) compared with other macro-porous resin extraction methods, the operation is simplified and the recovery rate of the chenodeoxycholic acid is improved.

Owner:四川新功生物科技集团有限公司

Edible and medicinal fungal polysaccharide low-temperature normal-pressure plasma extraction method

An edible and medicinal fungal polysaccharide low-temperature normal-pressure plasma extraction method includes the first step of adsorption resin preprocessing, the second step of fungal polysaccharide primary extraction, the third step of low-temperature normal-pressure plasma extraction, the fourth step of porous adsorption resin extraction, the fifth step of alcohol precipitation and the sixth step of drying. The fungal polysaccharide prepared through extraction is prepared from lentinula edodes, hericium erinaceus, ganoderma lucidum, black fungi, grifola frondosa, white fungi, flammulina velutipes and any one or combination of edible and medicinal fungi containing polysaccharide compounds. According to the edible and medicinal fungal polysaccharide low-temperature normal-pressure plasma extraction method, the extraction period is shortened, the use amount of solvents is small, production efficiency is high, energy is saved, consumption is reduced, and extraction purity is high.

Owner:HEILONGJIANG JOHNSUN BIOLOGICAL ENG CO LTD

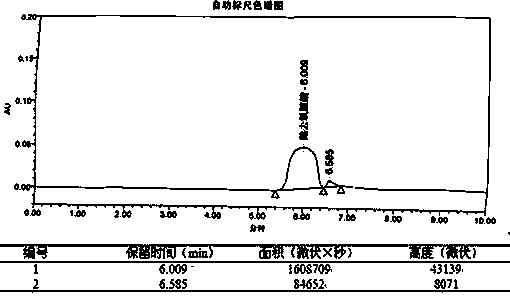

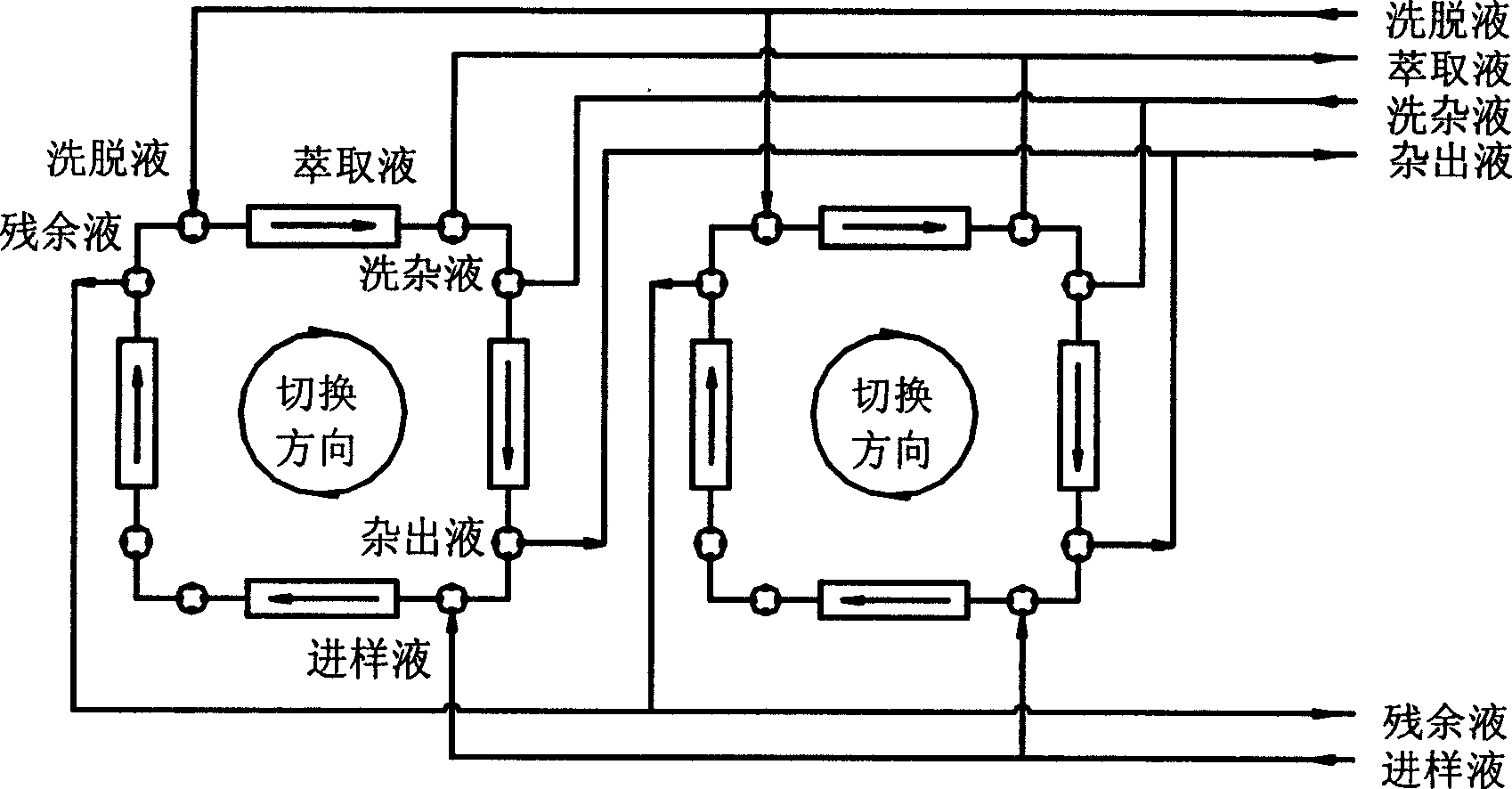

Continuous ion exchage extracting process for L-phenylalanine

InactiveCN1616415AEasy to operateHigh extraction yieldOrganic compound preparationAmino-carboxyl compound preparationElutionIon exchange

The present invention relates to the continuous ion exchange extracting process of L-phenylalanine as medicine intermediate. Continuous ion exchange process is utilized in realizing the high efficiency extraction of L-phenylalanine; and includes centrifugal filtering to eliminate microbe cell and segment with the column liquid, continuous ion exchange system to adsorb L-phenylalanine, elution with eluent, and concentrating crystallization. The specific technological parameters includes feeding the material liquid into the continuous ion exchange system with 10-20 g / L column liquid in the speed of 1-5 cu m / hr, adsorption pH of 1-3, eluent amount of 2-4 cu m / hr, etc. The present invention has extraction yield over 97 %, product purity over 99 %, 30 % raised resin utilization, 80 % lowered acid and alkali consumption and 3-5 times raised unit resin extraction capacity.

Owner:NANJING UNIV OF TECH

Method for safely and efficiently extracting high-purity tea polyphenols

ActiveCN107617025AEfficient extractionAvoid lostAntinoxious agentsDermatological disorderWater bathsPhenolic content in tea

The invention discloses a method for safely and efficiently extracting high-purity tea polyphenols. The method has the advantages that solvent purification processes and resin adsorption processes arecombined with one another, and accordingly the tea polyphenols can be efficiently extracted; impurities can be ultimately removed to the greatest extent by the aid of impurity crude separation, water-bath and ultrasonic crude extraction, resin extraction, solvent impurity removal and low-temperature still standing residue removal processes and the like, accordingly, the available content of the tea polyphenols can be obviously increased, the purity of the tea polyphenols can be obviously improved, effects of reducing the residual quantities of harmful solvents can be realized, and the processes are safe.

Owner:雅安市云茶供应链管理有限公司

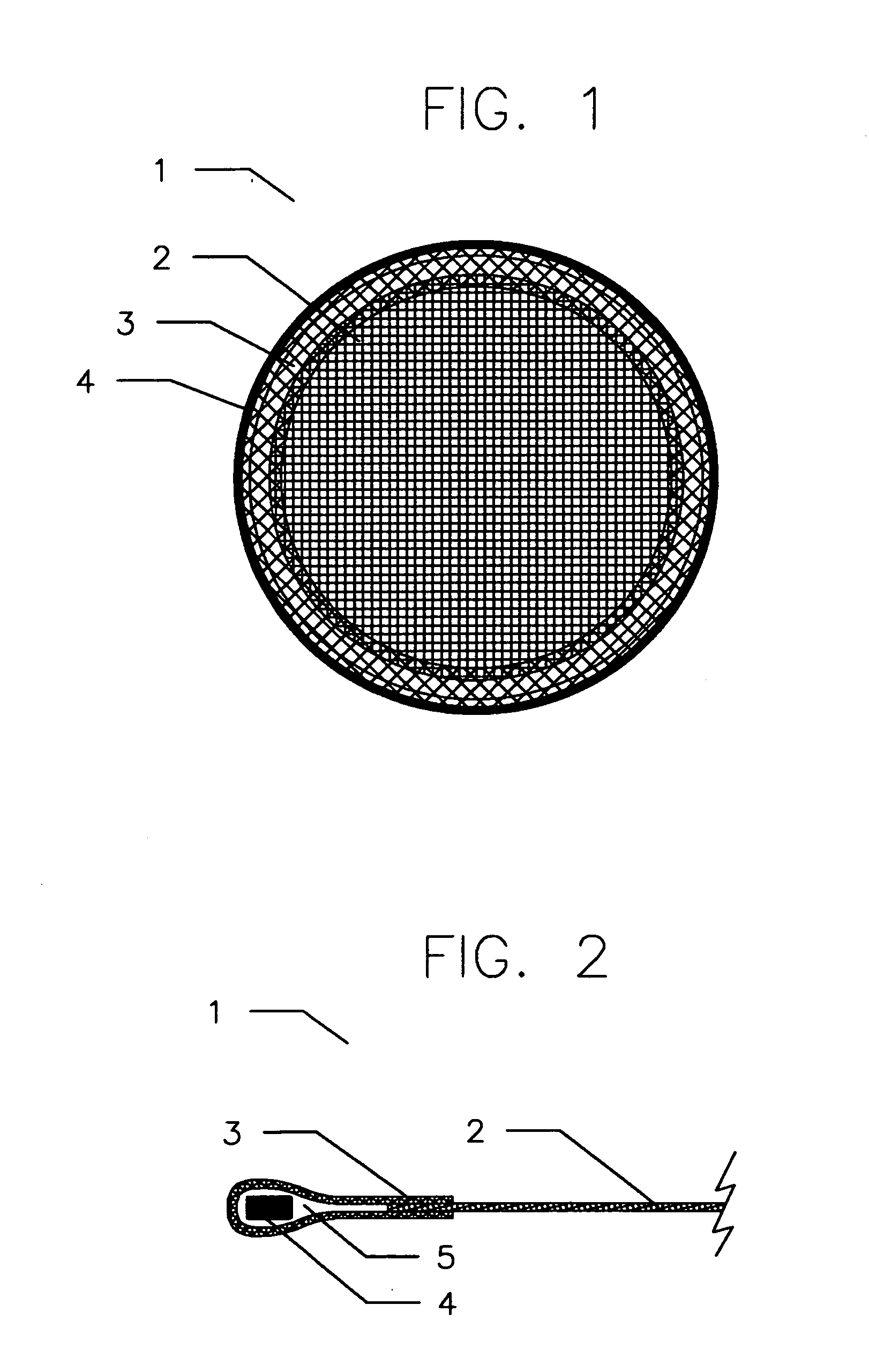

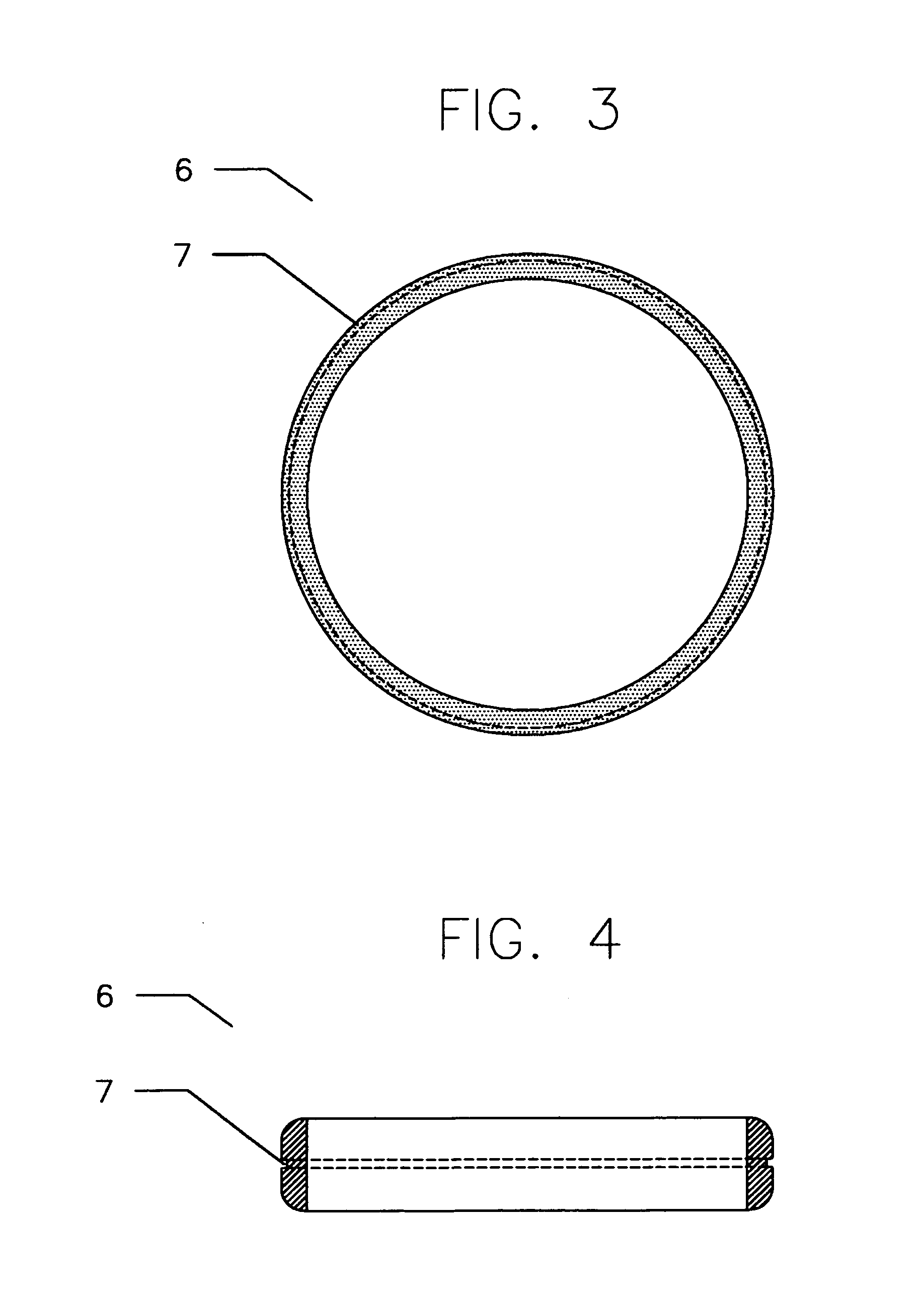

Apparatus and method for plant resins extraction

Apparatus and method for extracting plant resin particulates by sifting plant materials using micron mesh filter media that can be quickly and easily installed and replaced.

Owner:TUCKER RICHARD ASHLEY +1

Modification method of polystyrene resin for adsorbing flavones

InactiveCN104610473AImprove adsorption capacityReaction conditions require mildOther chemical processesWater bathsFiltration

The invention discloses a modification method of a polystyrene resin for adsorbing flavones, which comprises the following steps: adding the polystyrene resin and chloromethyl ether into a three-neck flask which is provided with a stirrer, a thermometer and a reflux condenser, carrying out chloromethylation reaction under the action of a catalyst zinc chloride, carrying out vacuum filtration on the chloromethylation resin obtained by reaction, separating from the reaction solution, cleaning with ethanol, and swelling; and adding a chloromethylated resin and an amino reagent methylamine into the three-neck flask which is provided with the stirrer, thermometer and reflux condenser, and heating in a water bath to 45 DEG C to react for 12 hours, thereby obtaining the amino modified resin. When the modified resin is used for extracting total flavones in the ethanol extract, the adsorption capacity of every gram of modified resin reaches 58.776mg. The modification method has the advantages of mild reaction conditions, high practicality and the like, and is widely applicable to the polystyrene resin.

Owner:BEIHAI HESI TECH

Technique method of extracting heparin sodium by virtue of macroporous polymeric adsorbent

The invention discloses a technique method of extracting heparin sodium by virtue of a macroporous polymeric adsorbent, wherein the technique method comprises: adding an adsorption step in the traditional refining procedure, utilizing AmberliteXAD16 polymeric adsorbent using polystyrene as a base material to absorb a rough product heparin sodium acid solution, desorbing by use of a sodium hydroxide eluent, and finally, performing alcohol precipitation and drying treatment to obtain heparin sodium with titer larger than 160 U / mg, wherein residual heteropolymeric protein in the rough product can be completely removed.

Owner:JIANGSU LIANZHONG CASING

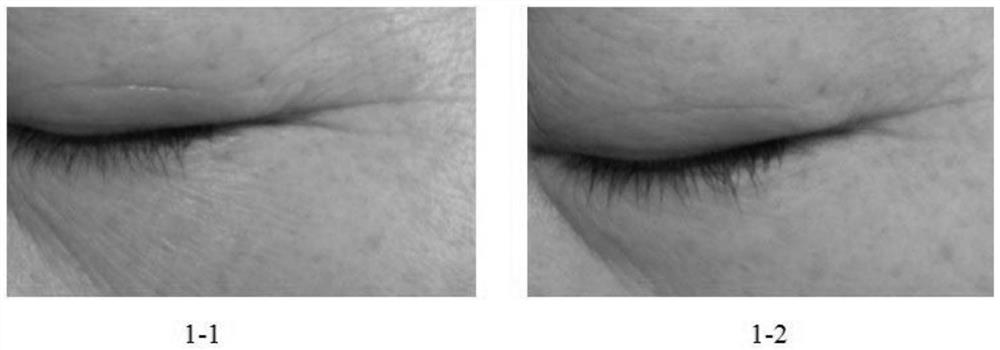

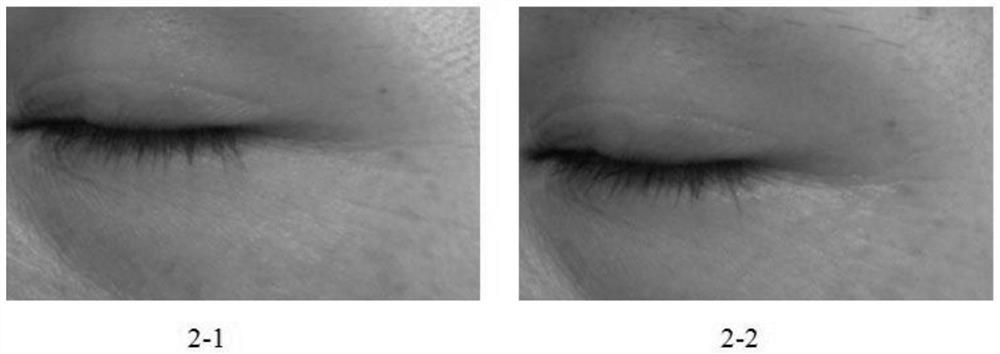

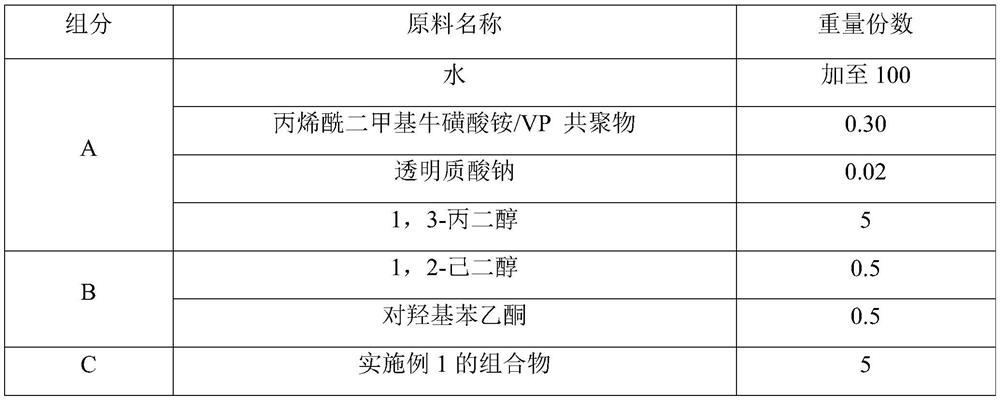

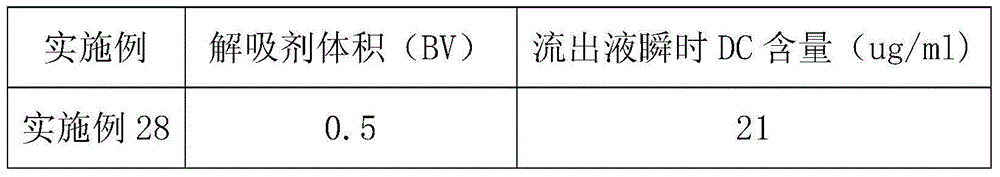

Composition with tightening and anti-aging effects as well as preparation method and application thereof

PendingCN114099393AGive full play to the firming effectQuality improvementCosmetic preparationsToilet preparationsBiotechnologyPolyol

The invention provides a composition with tightening and anti-aging effects. The composition is prepared from the following components in parts by weight: 0.1 to 12 parts of hydrolyzed vegetable protein, 0.1 to 20 parts of resin extract, 1 to 50 parts of polyhydric alcohol and 30 to 90 parts of water. The invention belongs to the technical field of cosmetics, the specific hydrolyzed vegetable protein and the resin extract are combined according to a proper mass ratio, the skin can be rapidly smoothed and wrinkles can be reduced at a low dosage, the skin firming effect capable of being perceived by the skin is remarkable, and meanwhile, the skin firming effect can be achieved. The composition also has long-acting moisturizing, anti-oxidation, skin elasticity enhancing and anti-aging effects.

Owner:广州宏众生物科技有限公司

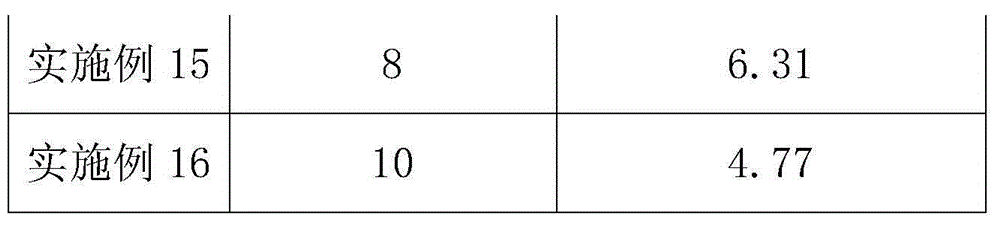

Method for recycling DCPC (deacetyl cephalosporin C) from cephalosporin C resin adsorption waste liquor

The invention provides a method for recycling DCPC from cephalosporin C resin adsorption waste liquor. According to the method, an anion exchange resin 1 is firstly used for removing residual inorganic anions, particularly sulfate ions, in the adsorption raffinate; and the remaining feed liquid is adsorbed by a macroporous adsorption resin, a salt solution is used as desorption agent, the elutriant is directly concentrated by nanofiltration after being decolored through an anion exchange resin 2, further, after the processes of splitting decomposition, crystallization, drying, and so on, a D-7ACA qualified product with purity of not less than 98% and color grade of more than 4 is obtained. Resin extraction yield is not less than 85%, and total yield of the process is not less than 45%.

Owner:SUNRESIN NEW METERIALS CO LTD XIAN

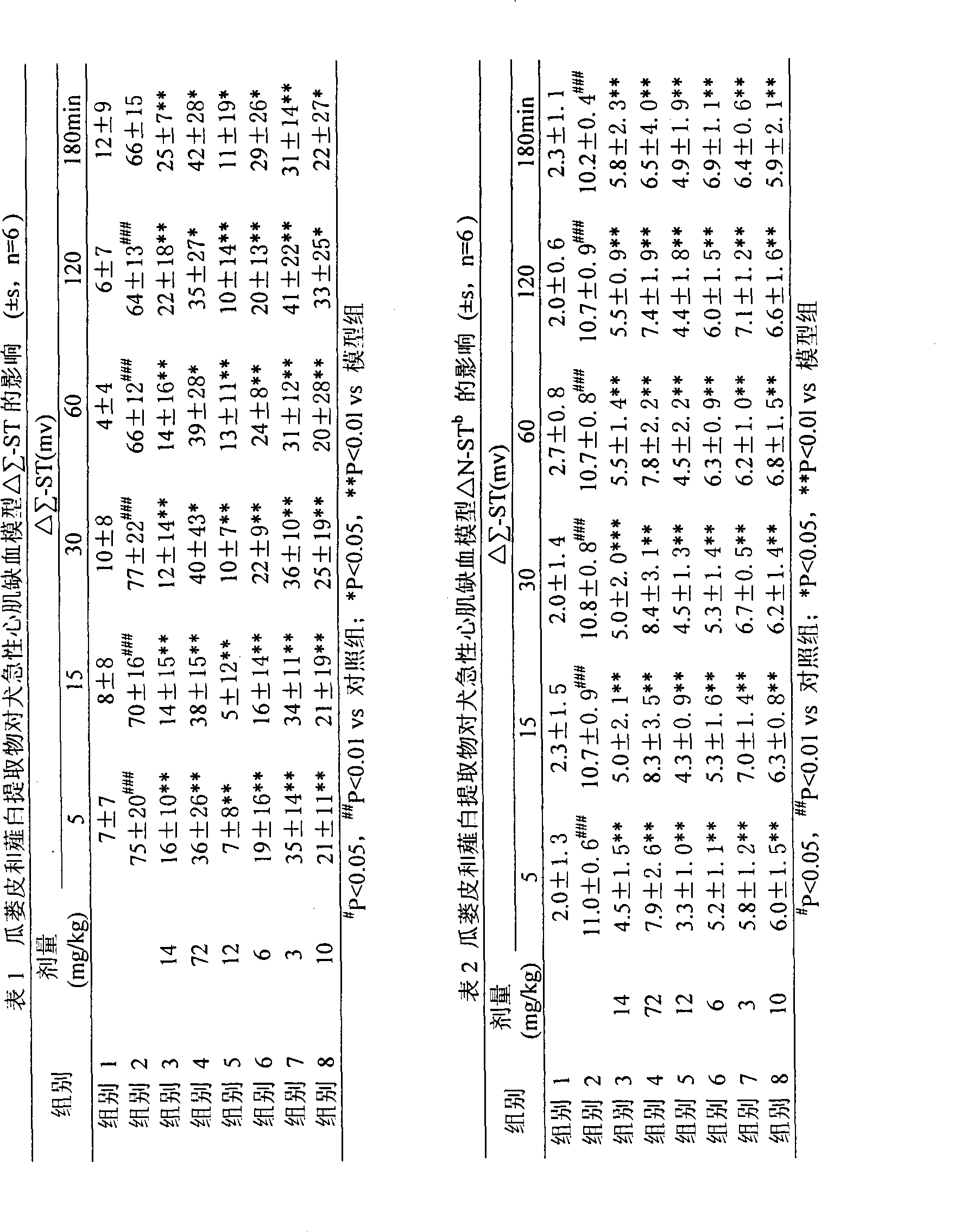

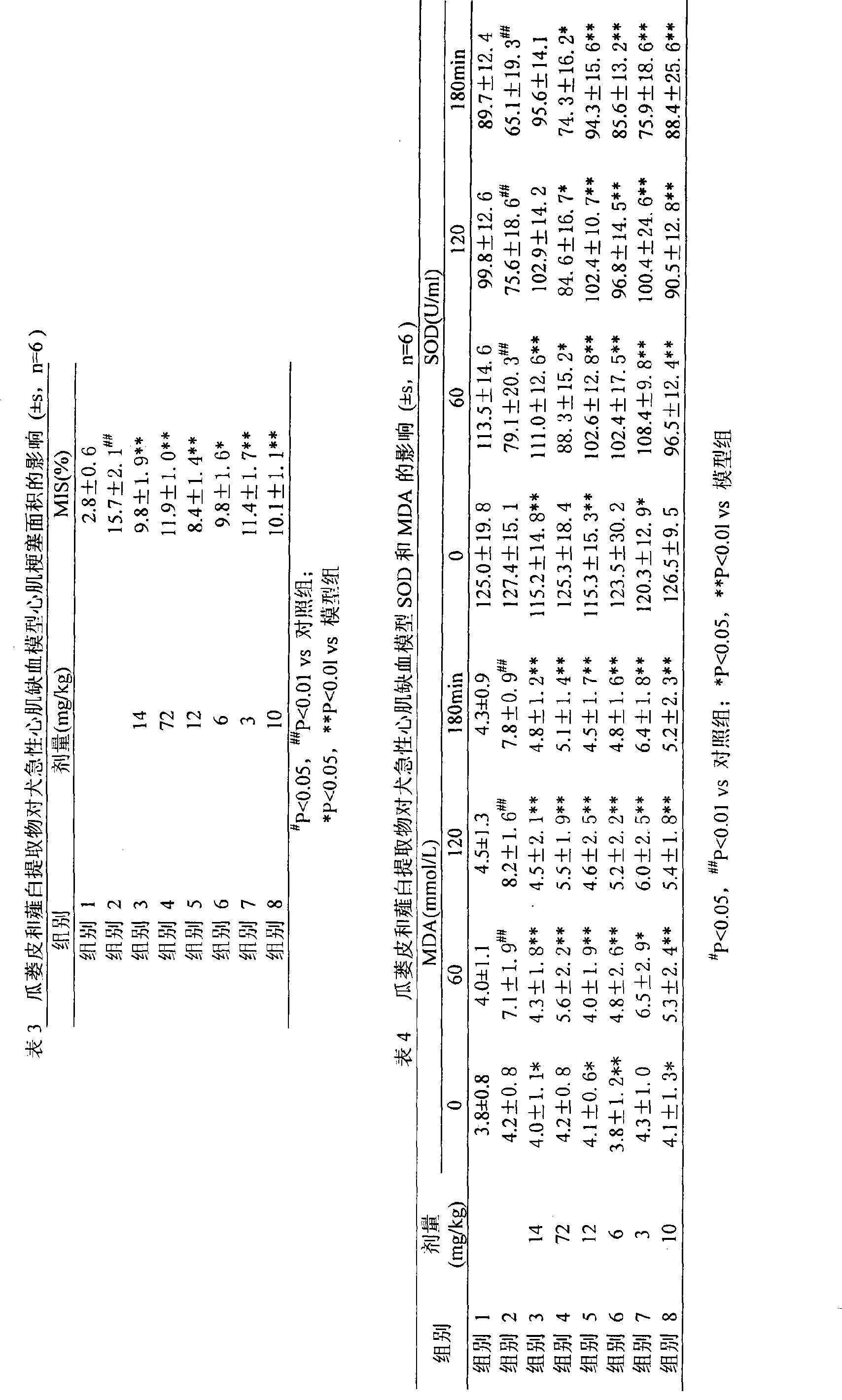

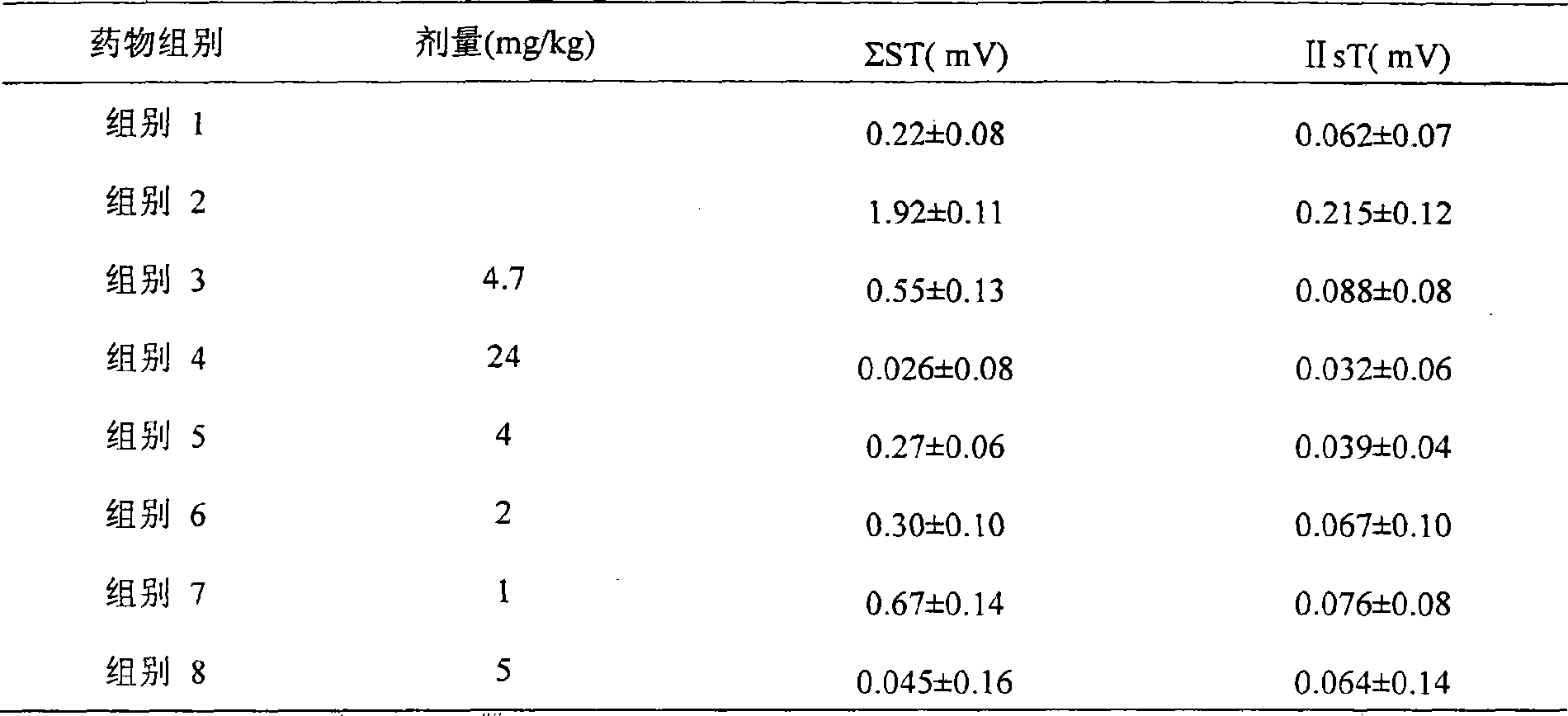

Extract of Pericarpium trichosanthis and Allium macrostemon, and preparation method thereof

InactiveCN101461882AQuality improvementProcess stabilityCardiovascular disorderPlant ingredientsPL ExtractDisease

The invention discloses a trichosanthes bark and allium macrostemon extract and a preparation method thereof. The composition is prepared by adopting the following steps: mixing trichosanthes bark with allium macrostemon in the weight proportion of 2:1 to 1:1; adding water or C1-3 ethanol with the concentration less than 50 percent for extraction; extracting an extracted solution by ion exchange resin and macroporous absorbent resin; extracting 50 to 90 weight portions of components from trichosanthes bark and the ion exchange resin of allium macrostemon; extracting 10 to 50 weight portions of components from the trichosanthes bark and macroporous resin of the allium macrostemon; mixing the two components; and obtaining the extract. The extract is applied to preparing medicines for treating diseases of cardiovascular system, and has determined curative efficacy; moreover, the extract reaches the goal of reducing dose without reducing medicine efficacy and has an extensive application prospect.

Owner:江苏吴中苏药医药开发有限责任公司

Method for recovering perfluorosulfonic acid resin from waste membrane

InactiveCN110066421AEnvironmental advantages are obviousSufficient sourcePlastic recyclingChemical treatmentProton

The invention relates to the field of proton exchange membranes and resins thereof, in particular to a method for recovering a perfluorosulfonic acid resin from a waste membrane. The waste ion exchange membrane containing the perfluorosulfonic acid resin is taken as a core raw material for preparing the perfluorosulfonic acid resin. Firstly, the raw material is physically cleaned and then chemically treated and biologically treated to remove dirt and various impurities on the surface of the raw material, drying and crushing are conducted, and a solvent is adopted for resin extraction. According to the method, with the waste proton exchange membrane as the raw material, on one hand, the problem of difficult treatment of the raw material as dangerous solid waste is solved; on the other hand,the problem of high cost of the ion exchange membrane is solved. The performance of the prepared product is comparable to that of similar products on the market, the cost is far lower than that of the similar products, composition and structural design are conducted according to target demands, and the method has great significance for the wider application of the ion exchange membrane.

Owner:CHAOYANG HUADING ENERGY STORAGE TECH

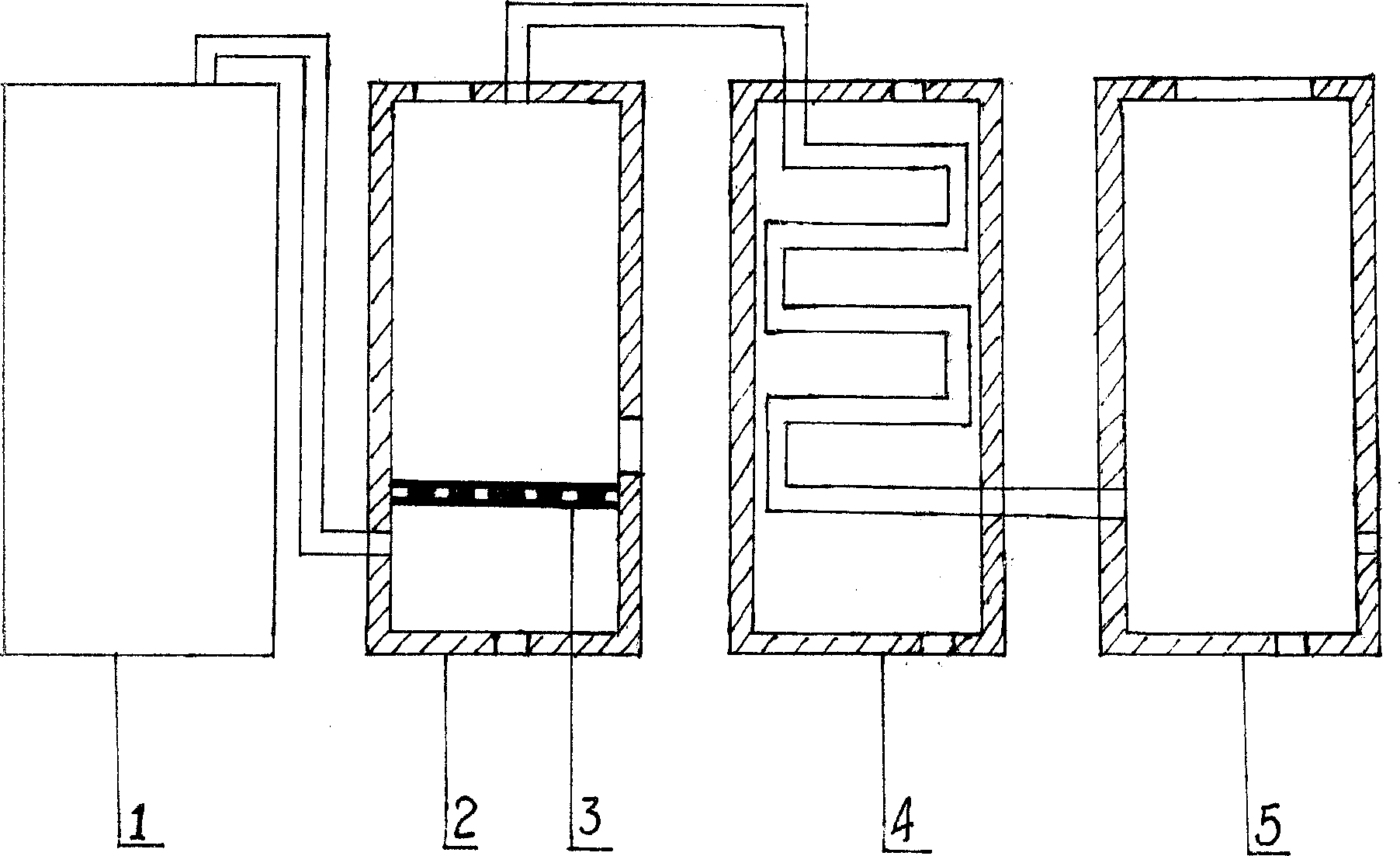

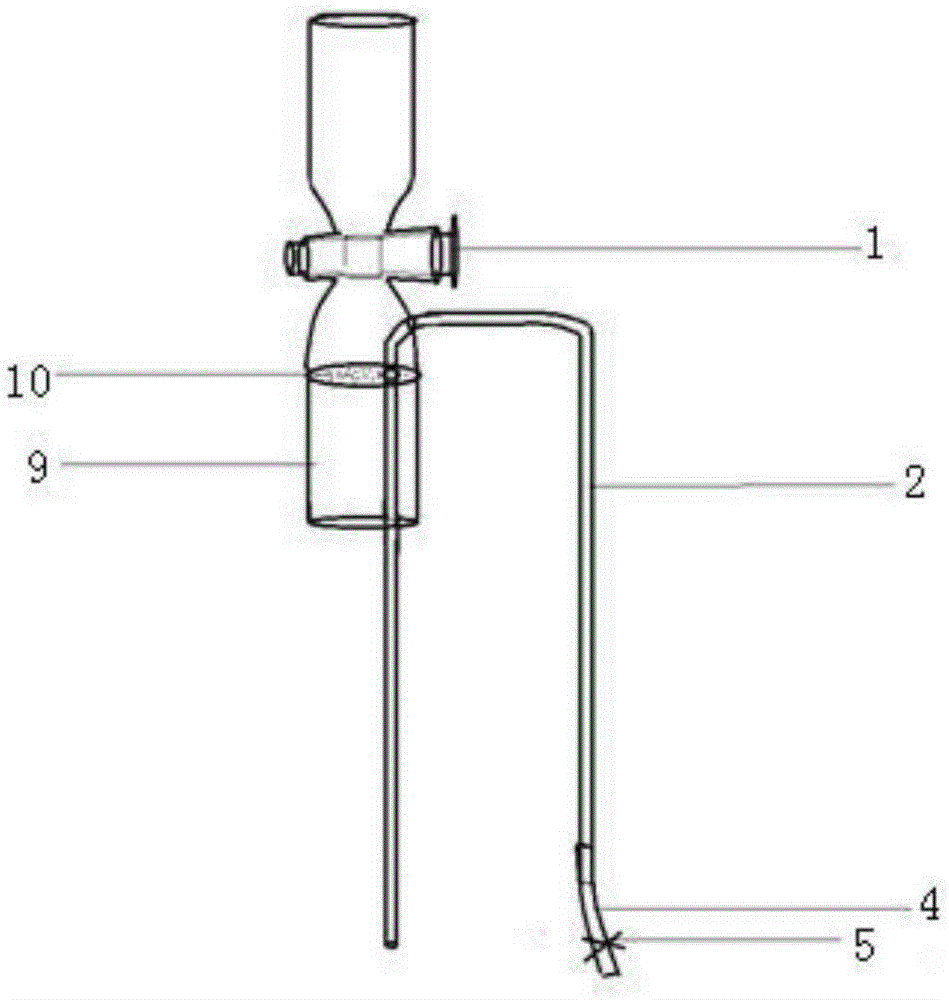

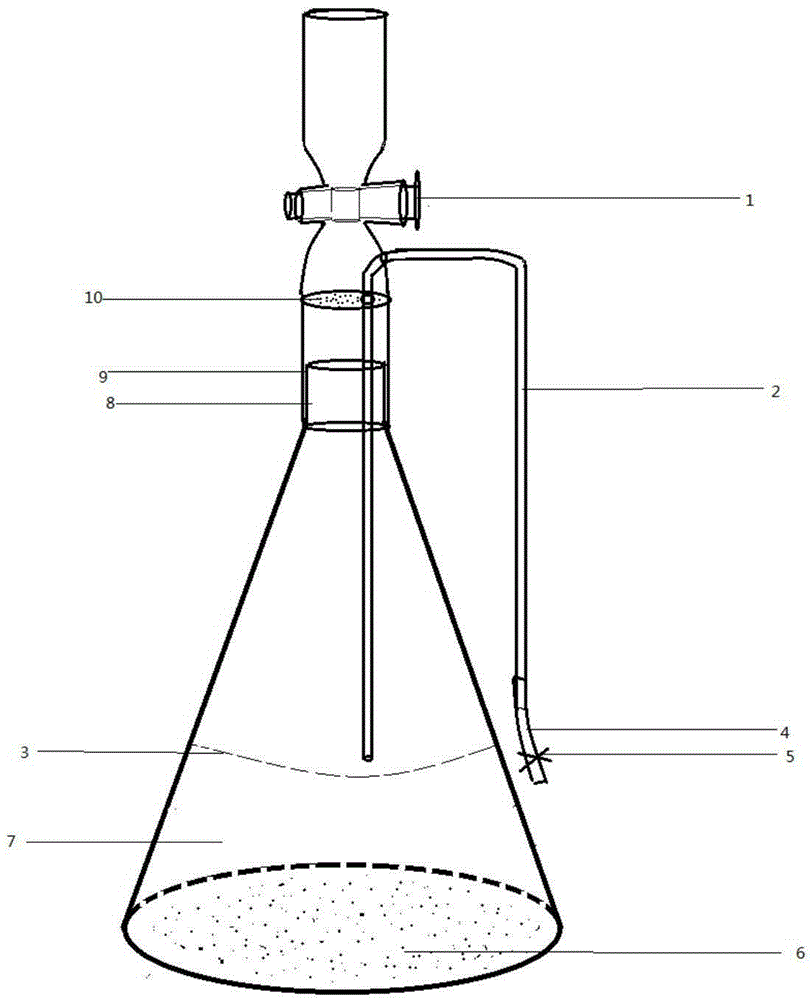

Apparatus for determining exchange capacity of ion exchange resin

InactiveCN105277544AEasy to separateGuaranteed accuracyMaterial analysis by observing effect on chemical indicatorIon exchangeEngineering

The invention discloses an apparatus for determining the exchange capacity of ion exchange resin. The apparatus is composed of a device B and a device C, the device B is an open-ended container, the device C comprises a filter, the outlet pipeline of the device C is provided with a flow control device, and the opening of the device B is connected with the inlet end of the device C; when the flow control device is closed, a closed cavity is formed between the device C and the device B, and the volume of the cavity is kept unchanged; the device C is provided with a gas change tube, the bottom end of the gas change tube extends into the device B, the top end of the gas change tube extends to the outside of the device B, and the top end of the gas change tube is provided with a gas flow control device; and when in a stationary state, the bottom end of the gas change tube is positioned above the liquid level of a reaction liquid. The problems of influences of resin and immersion liquid cooling time difference, cooling mode difference and resin extraction in the immersion liquid removal process on the determination of the exchange capacity of ion exchange resin and on avoiding of bottle stopper breaking in test are solved.

Owner:ELECTRIC POWER RESEARCH INSTITUTE OF STATE GRID SHANDONG ELECTRIC POWER COMPANY +2

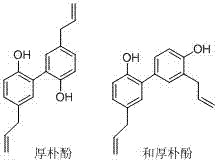

Process for preparing magnolia officinalis total phenol extract by adsorptive separation

The invention provides a process for extracting two isomeride components in magnolia officinalis, namely honokiol and magnolol. The process comprises the steps of preparing an adsorption liquid, adsorbing by macroporous resin, balancing after adsorption, desorbing magnolia officinalis total phenol and post-treating the desorption solution. The process can be used for overcoming the interference of co-existing alkaloid when the magnolia officinalis total phenol extract is prepared by adsorptive separation, a method for preparing the adsorbent which is extracted from an organic solvent by acid-alkali isolation is provided, a continuous process for pre-separating alkaloid and extracting high-purity magnolia officinalis total phenol adsorptive resin is established, and the magnolia officinalis total phenol extract with purity higher than 70 percent is obtained by an 'adsorption-elution' process flow. The adsorptive resin method extraction process is convenient to operate, the resin can be recycled, and the process is applicable to large-scale industrial production.

Owner:NANKAI UNIV

Continuous extraction method of pepper oil resin

ActiveCN108148677AEasy extractionLess loss of active ingredientsEssential-oils/perfumesNatural resin purificationResin extractionSolvent

The invention relates to a continuous extraction method of pepper oil resin, and belongs to the technical field of natural pepper oil resin extraction. The continuous extraction method of the pepper oil resin includes the process steps: crushing pepper and extracting essential oil from the crushed pepper; pretreating pepper powder after essential oil extraction; performing continuous extraction onthe pretreated pepper powder through extraction solution by a rotocel extractor to obtain pepper oil resin extracting solution; continuously concentrating the pepper oil resin extracting solution andremoving solvents to obtain the pepper oil resin. The extraction solution is mixed solution of extraction solvents, diluting solvents and stabilizers. The continuous extraction method of the pepper oil resin can realize continuous extraction, continuous concentration and solvent removal of the pepper oil resin, is good in extraction effect, high in effective component content, less in extractionsolvent dosage, high in automation degree and low in production and can realize large-scale industrial production.

Owner:CHENGUANG BIOTECH GRP CO LTD

Method for extracting rhodioside in purification fermentation liquid by using macroporous absorbent resin

InactiveCN107686492AHigh purityEasy to operateSugar derivativesSugar derivatives preparationRhodiosideAbsorption column

The invention discloses a method for extracting rhodioside in purification fermentation liquid by using macroporous absorbent resin. The method comprises the following steps of (1) performing centrifugation on bacillus coli fermentation liquid producing rhodioside to obtain supernatant fluid being sampling liquid; (2) adding the sampling liquid into a large pore resin absorption column; (3) addingwater into the large pore resin absorption column; removing remained supernatant fluid and polar impurities in the large pore resin absorption column; (4) adding an ethanol water solution with the volume concentration being 10 to 20 percent into the large pore resin absorption column for elution; collecting elution liquid accounting for 20 to 80 percent of the volume of the ethanol water solution(5) concentrating and drying elution liquid to obtain a rhodioside crude product; (6) dissolving the rhodioside crude product by the 90-percent ethanol water solution; performing crystallization; (7)repeating the step (6) to obtain the rhodioside with the purification being 98 percent or higher. The rhodioside is obtained through extraction and purification from the bacillus coli fermentation liquid producing rhodioside; the method has the advantages that the operation is simple, the yield is high, and the environment-friendly effect is achieved. The obtained rhodioside has high purity and is suitable for industrial production.

Owner:TIANJIN INST OF IND BIOTECH CHINESE ACADEMY OF SCI

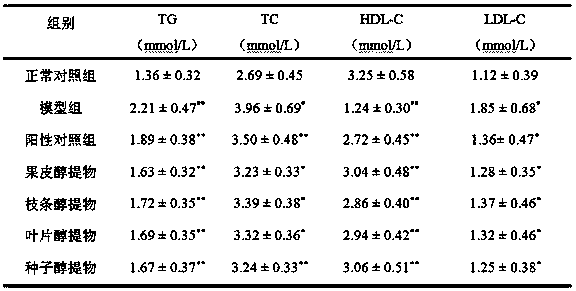

Application of euscaphis konishii hayata extract to preparation of hypolipidemic drugs

InactiveCN110201011AControl abnormal increaseReduce contentMetabolism disorderPlant ingredientsLow density lipoprotein cholesterolTG - Triglyceride

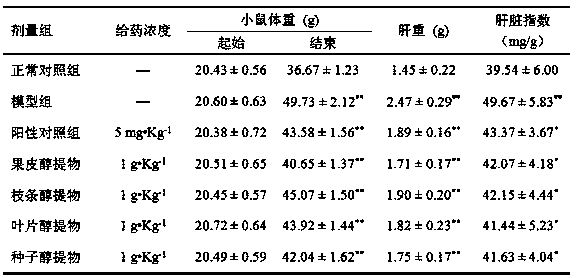

The invention relates to application of euscaphis konishii hayata extract to preparation of hypolipidemic drugs. According to an ethanol extraction and macroporous adsorption resin extraction preparation method, the euscaphis konishii hayata extract is obtained and capable of effectively inhibiting abnormal weight increase of hyperlipidemia model mice, reducing contents of TC (total cholesterol),TG (triglyceride) and LDL-C (low-density lipoprotein cholesterol) in serum of the hyperlipidemia mice and increasing the content of HDL-C (high-density lipoprotein cholesterol). By observation of liver tissue pathological sections of each group of mice, the euscaphis konishii hayata extract is capable of improving hepatic adipose tissue and cell morphology changes, so that the euscaphis konishii hayata extract has a remarkable hypolipidemic function and can be applied to preparation of medicines for prevention and treatment of hyperlipidemia.

Owner:FUJIAN AGRI & FORESTRY UNIV

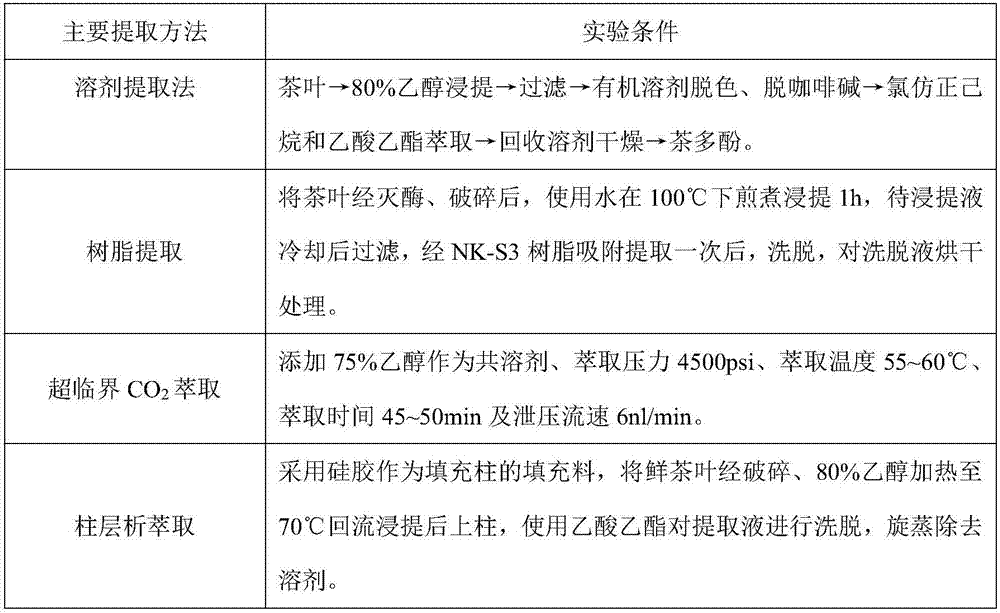

Resin extraction process of high-purity tea polyphenol

InactiveCN107468822AEfficient extractionAntinoxious agentsPlant ingredientsPhenolic content in teaResin extraction

Owner:广西克鲁尼茶叶生物科技有限公司

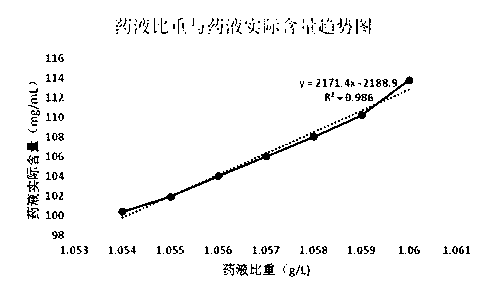

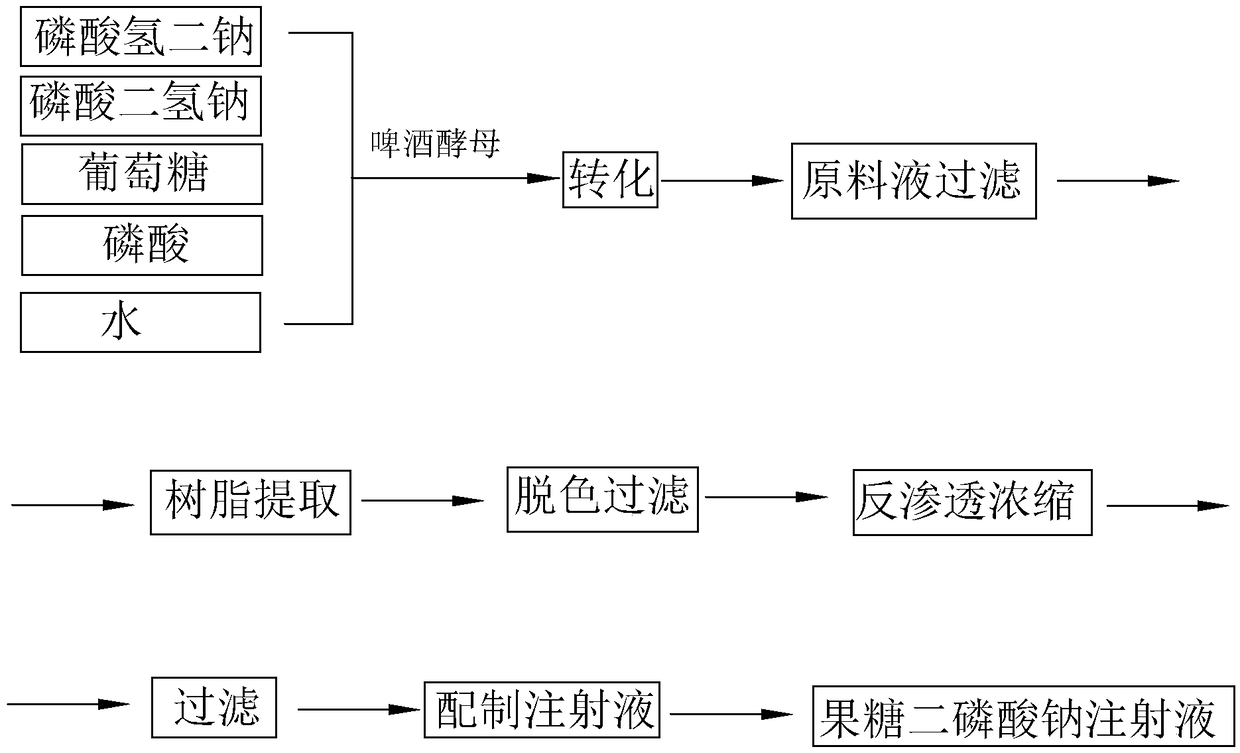

Preparation method of fructose sodium diphosphate injection

ActiveCN109223709ALess impuritiesReduce usageOrganic active ingredientsMetabolism disorderDrugs solutionPhosphoric acid

The invention discloses a preparation method of fructose sodium diphosphate injection, which comprises the following steps: S1, dissolving disodium hydrogen phosphate, sodium dihydrogen phosphate, glucose and phosphoric acid in water to prepare a reaction liquid, mixing with beer yeast, stirring and reacting to obtain a raw material liquid containing fructose sodium diphosphate; 2, filter that rawmaterial liquid plate frame; S3, adsorbing and purifying the solid-liquid separated raw liquid in S2 by anionic resin to obtain resin extract containing fructose sodium diphosphate; 4, decolorizing and filtering, decolorize that resin extract solution by activated carbon, and filtering and decarburizing; 5, carrying out initial concentration on that decolorization filtrate in S4, washing and desalinate the decolorization filtrate with water, and finally pressurizing the decolorization filtrate to concentrate the specific gravity of the decolorization filtrate to more than 1.05 g / ml; 6, filterthat concentrated drug solution to obtain RO solution; 7, filter that RO solution in S6, diluting, filter, and filling to obtain sterile fructose sodium diphosphate injection. The invention has the advantages of greatly reducing the use amount of the organic solvent in the preparation process and reducing the production cost.

Owner:BEIJING HUAJIN PHARM CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com