Resin extraction process of high-purity tea polyphenol

An extraction process and technology for tea polyphenols are applied in the field of resin extraction process of high-purity tea polyphenols, and can solve the problems of incomplete extraction of tea polyphenols, low extraction efficiency, and difficulty in obtaining high-purity tea polyphenol products.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

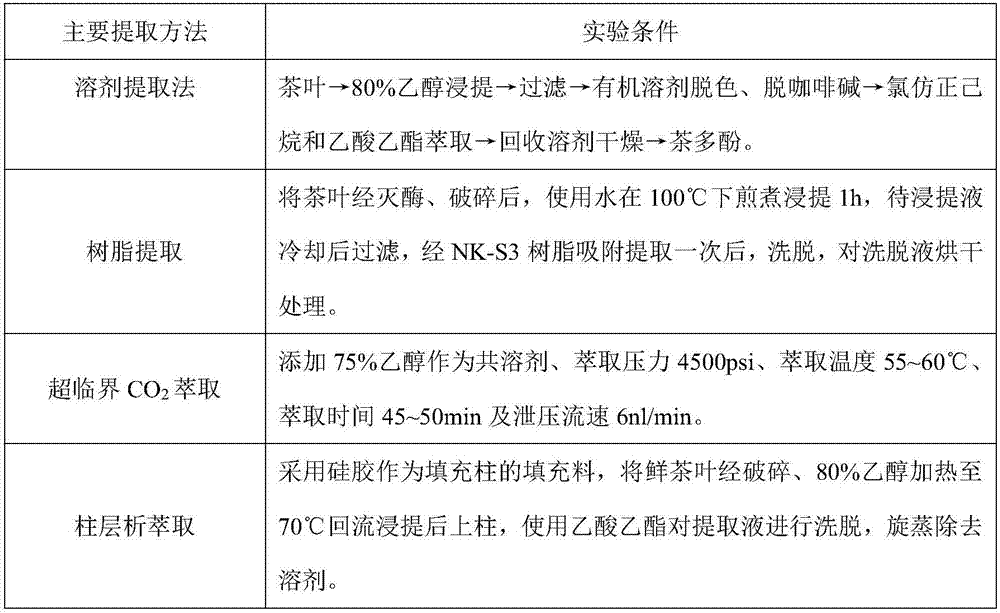

Method used

Image

Examples

Embodiment 1

[0041] A resin extraction process for high-purity tea polyphenols, comprising the following steps:

[0042] (1) Coarse separation of impurities:

[0043] A1: Heat the tea leaves to 280°C with microwave ovens and keep them for 3 minutes to inactivate the enzymes;

[0044] A2: Extract tea leaves with 70% ethanol solution, crush them with a dumb jaw crusher, cut and crush the tea leaves to a mesh size of 110-120 mesh, filter, repeat more than two times, and combine the filtrate;

[0045] A3: Maintain the temperature at 35-45°C, stir the filtrate and evaporate under negative pressure until the ethanol is basically volatilized;

[0046] A4: Hydration: add pure water to the solid-liquid mixture after step A3 until the solid is completely dissolved;

[0047] A5: Use chloroform to extract the filtrate, separate the liquid, remove the chloroform extraction layer, and keep the aqueous solution layer;

[0048] A6: Repeat step A5 more than twice, and combine the aqueous solution layer;...

Embodiment 2

[0064] A resin extraction process for high-purity tea polyphenols, comprising the following steps:

[0065] (1) Coarse separation of impurities:

[0066] A1: Heat the tea leaves to 260°C by microwave and keep for 4 minutes to inactivate the enzyme;

[0067] A2: Extract tea leaves with 70% ethanol solution, crush them with a hammer mill, cut and crush the tea leaves to a mesh size of 180-230 mesh, filter, repeat more than two times, and combine the filtrates;

[0068] A3: Maintain the temperature at 35-45°C, stir the filtrate and evaporate under negative pressure until the ethanol is basically volatilized;

[0069] A4: Hydration: add pure water to the solid-liquid mixture after step A3 until the solid is completely dissolved;

[0070] A5: Use chloroform to extract the filtrate, separate the liquid, remove the chloroform extraction layer, and keep the aqueous solution layer;

[0071] A6: Repeat step A5 more than twice, and combine the aqueous solution layer;

[0072] A7: Maint...

Embodiment 3

[0087] A resin extraction process for high-purity tea polyphenols, comprising the following steps:

[0088] (1) Coarse separation of impurities:

[0089] A1: Clean the tea leaves with a tea washing machine, then heat the tea leaves to 270°C with microwaves, and keep them for 3.5 minutes to inactivate the enzymes;

[0090] A2: Leach tea leaves with 70% ethanol solution, crush them with an ultrafine pulverizer, cut and crush the tea leaves to a mesh size of 240-280 mesh, filter, repeat more than two times, and combine the filtrates;

[0091] A3: Maintain the temperature at 35-45°C, stir the filtrate and evaporate under negative pressure until the ethanol is basically volatilized;

[0092] A4: Hydration: add pure water to the solid-liquid mixture after step A3 until the solid is completely dissolved;

[0093] A5: Use chloroform to extract the filtrate, separate the liquid, remove the chloroform extraction layer, and keep the aqueous solution layer;

[0094] A6: Repeat step A5 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

| Mesh | aaaaa | aaaaa |

| Mesh | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com