Natural resin extracting process and apparatus

A technology of natural resin and extraction process, which is applied in the direction of natural resin technology, chemical instruments and methods, etc., can solve the problems of many impurities, large environmental pollution, and low resource utilization, and achieve high quality, no pollution to the environment, and full utilization of wood. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

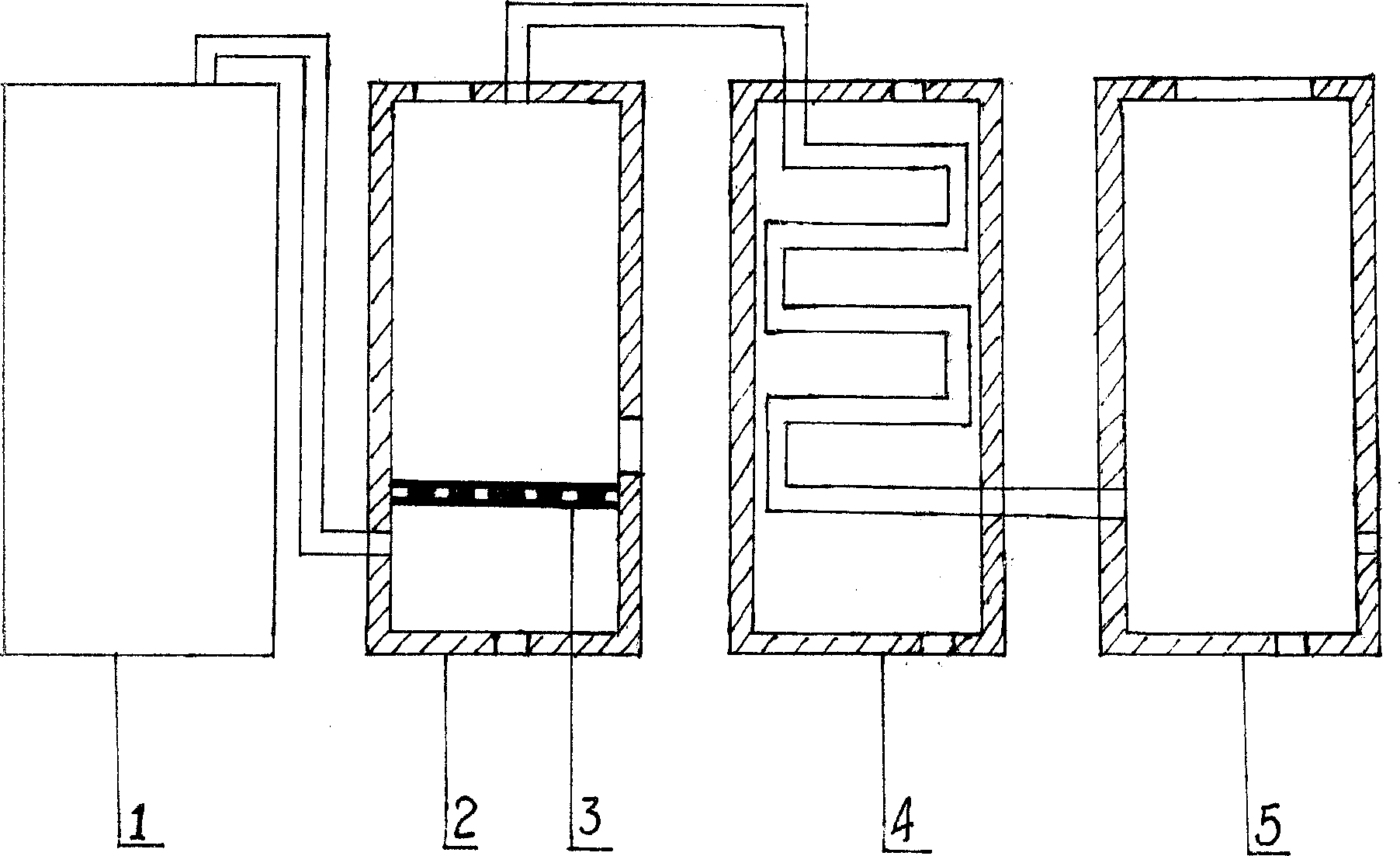

[0015] The specific implementation of the natural resin extraction process and device of the present invention will be described below using discarded fir bushes or pine and cypress bushes as raw materials. Its process is carried out as follows:

[0016] ①Cut or plane the collected fir or cypress shrubs into thin slices;

[0017] ②Put the flaky fir or pine and cypress wood that has been processed through step ① into the charging cavity of the distillation barrel [2], close the charging port, feed water steam and steam for 7-8 hours, the temperature of the steam that feeds At least 100°C until almost all the natural resin contained in the wood is evaporated together with the moisture. ;

[0018] ③The fir oil or cedar oil containing water vapor steamed in step ② is imported into the cooling barrel [4] and flows through the curved pipe for cooling treatment to make it liquid;

[0019] ④Introduce the water-containing fir oil or cedar oil cooled in step ③ into the oil-water sepa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com