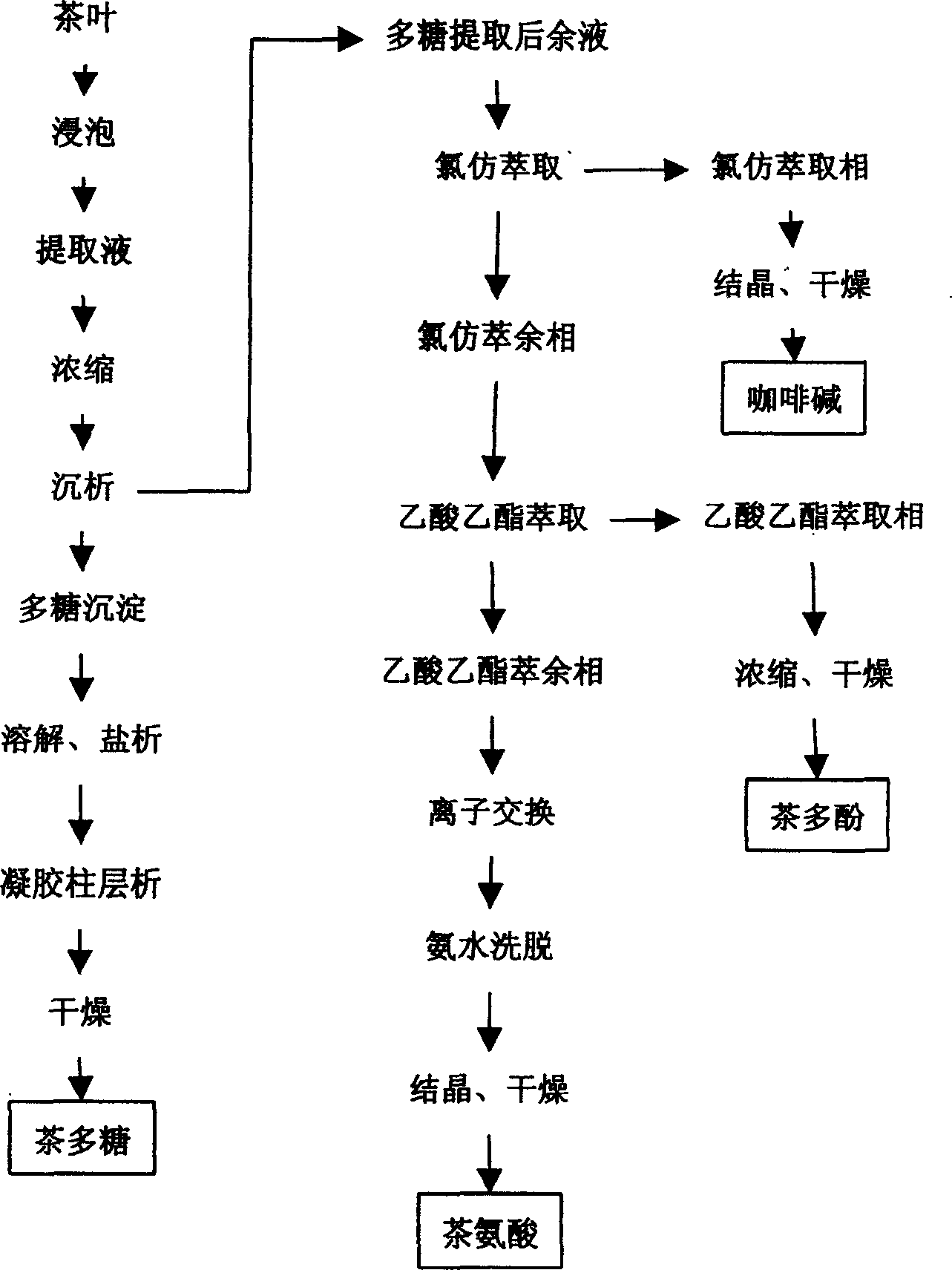

Process for synthetic extraction of polysaccharides, tea-polyphenol, theanine, caffeine from tea

A technology of comprehensive extraction and tea extraction, which is applied in the field of caffeine, comprehensive extraction of tea polysaccharides, tea polyphenols, and theanine, can solve the problems of reducing the economic benefits of tea deep processing, extraction and separation of theanine, and the inability to make full use of it. The effect of less loss of active substances, short extraction time, and high content of tea polysaccharides

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] 1) 1 kg of tea powder, under the action of microwave, use 5 times of ethanol aqueous solution, soak and extract repeatedly at 60 ° C for 4 times, each time for 5 minutes, and separate by filtration to obtain the tea extract, which is concentrated and concentrated. Edible ethanol was added to the mixture, and the dosage was twice the volume of the concentrated solution. After filtration, the tea polysaccharide precipitate and the residual liquid after polysaccharide extraction were obtained. After the polysaccharide precipitate was dissolved in water, 1% zinc acetate was added to remove the protein, and the polysaccharide solution was subjected to gel G75 column chromatography. , the eluate was dried to obtain tea polysaccharide, the total sugar content in the tea polysaccharide reached 65.00%, and the yield was 0.5%.

[0030] 2) After polysaccharide extraction, the residual liquid is extracted with chloroform, the amount of chloroform is 1 times the volume of the liquid ...

Embodiment 2

[0034] 1) 1 kg of tea powder, under microwave action, use 10 times of 30% ethanol aqueous solution, soak and extract repeatedly at 40°C for 3 times, each time for 20 minutes, filter and separate to obtain tea extract, the tea extract is concentrated, Add edible ethanol to the concentrated solution, the dosage is 3 times the volume of the concentrated solution, filter to obtain the tea polysaccharide precipitate and the residual liquid after polysaccharide extraction, dissolve the polysaccharide precipitate in water, add 1% zinc acetate to remove protein, and pass the polysaccharide solution through the gel G25 column Chromatography, drying the eluent to obtain tea polysaccharide, the total sugar content in the tea polysaccharide reaches 66.10%, and the yield is 0.51%.

[0035]2) After the polysaccharide is extracted, the residual liquid is extracted with chloroform, the amount of chloroform is 5 times the volume of the liquid phase, mixed evenly, and the two phases are separate...

Embodiment 3

[0039] 1) 1 kg of tea powder, under microwave action, use 15 times of 10% ethanol aqueous solution, soak and extract repeatedly at 40°C for 3 times, each time for 15 minutes, obtain tea extract through filtration and separation, and concentrate the tea extract. Edible ethanol is added to the concentrated solution, the dosage is 5 times the volume of the concentrated solution, and the tea polysaccharide precipitate and the residual liquid after polysaccharide extraction are obtained by filtration. After the polysaccharide precipitate is dissolved in water, 1% zinc acetate is added to remove the protein, and the polysaccharide solution is passed through the gel Bio- Gel P-6 column chromatography, the eluate was dried to obtain tea polysaccharide, the total sugar content in the tea polysaccharide reached 67%, and the yield was 0.55%.

[0040] 2) After the polysaccharide is extracted, the residual liquid is extracted with chloroform, the amount of chloroform is 3 times the volume o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com