Process for recovering 7-ACA (aminocephalosporanic acid) crystallization mother liquor

A technology of 7-ACA, crystallization mother liquor, applied in the direction of organic chemistry, etc., can solve the problems of rising cost, increasing processing cost, environmental pollution and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

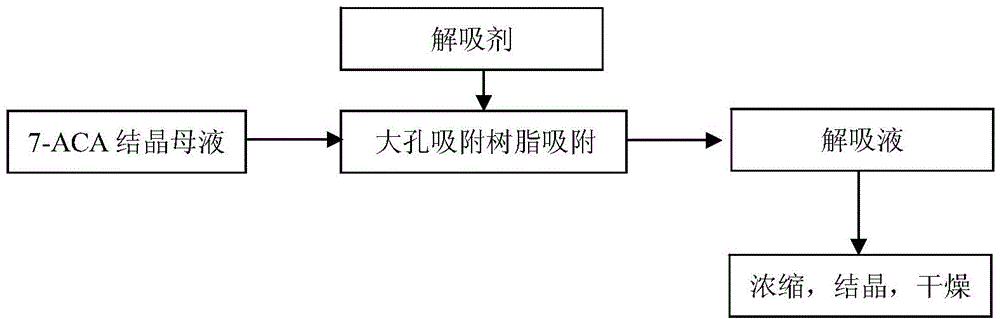

Method used

Image

Examples

Embodiment 1

[0036] 1. Resin adsorption: adjust the pH of the 7-ACA crystallization mother liquor to 4.0 with 10% hydrochloric acid (7-ACA potency in the mother liquor is 1243ug / ml, purity 64.2%), and pass through 100ml LXT at a flow rate of 1BV / h from top to bottom -032 resin bed (produced by Xi'an Lanxiao Technology New Materials Co., Ltd.), when the titer of the effluent at the bottom of the resin column is 12ug / ml, stop feeding the crystallization mother liquor into the resin column.

[0037] 2. Resin desorption: 2BV of 0.3% sodium bicarbonate desorbs the resin from top to bottom at a flow rate of 1BV / h, and collects the desorption liquid.

[0038] 3. Concentration: The desorption solution is concentrated to a titer of 32000ug / ml through an organic nanofiltration membrane with a molecular weight of 500.

[0039] 4. Crystallization drying can be carried out in accordance with the current production process, and will not be described here. Finally, 0.58 g of the 7-ACA product was obtain...

Embodiment 2

[0041] 1. Resin adsorption: adjust the pH of the 7-ACA crystallization mother liquor to 2.0 with 2% sulfuric acid (the potency of 7-ACA in the mother liquor is 1452ug / ml, and the purity is 59.5%), and pass through 100ml at a uniform speed from top to bottom at a flow rate of 2BV / h LXT-030 resin bed (produced by Xi'an Lanxiao Technology New Materials Co., Ltd.), when the titer of the effluent at the bottom of the resin column is 12ug / ml, stop feeding the crystallization mother liquor into the resin column.

[0042] 2. Resin desorption: 1.5BV of 0.4% sodium acetate desorbs the resin from top to bottom at a flow rate of 1BV / h, and collects the desorption solution.

[0043] 3. Concentration: The desorption solution is concentrated to a titer of 31050ug / ml through an organic reverse osmosis membrane with a molecular weight of 200.

[0044] 4. Crystallization drying can be carried out in accordance with the current production process, and will not be described here. Finally, 1.34 g...

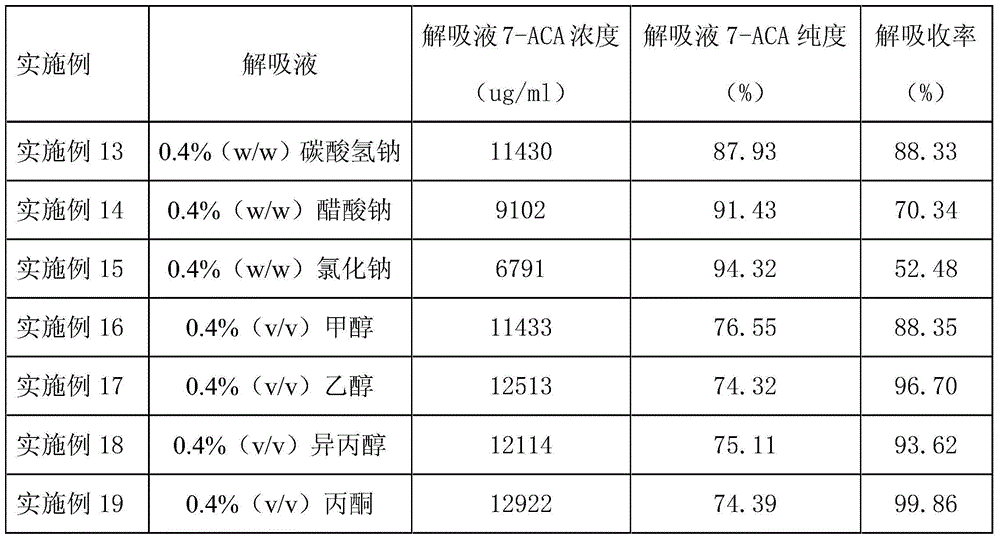

Embodiment 3- Embodiment 7

[0046] The specific embodiment is the same as that in Example 1, mainly investigating the influence of different mother liquor pHs on the adsorption capacity of the resin, desorbing and concentrating the resin, and not taking the crystallization process as an investigation factor.

[0047] The titer of 7-ACA in the mother liquor is 1376ug / ml, and the purity of 7-ACA is 60.55%. Feed volume 25BV, feed flow rate 1BV / h, prepare 5 parts of LXT-030 resin, each 100ml resin. The crystallization mother liquor was adjusted to pH 2, 3, 4, 5 with 5% hydrochloric acid, and the adsorption control test was done with the natural pH conditions.

[0048] Resin adsorption capacity = (feed 7-ACA titer - effluent 7-ACA titer) * feed volume / resin volume

[0049] Example

[0050] Example 5

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com