Apparatus for determining exchange capacity of ion exchange resin

A technology of ion exchange resin and exchange capacity, which is applied in material analysis by observing the influence of chemical indicators, and analysis by chemical reaction of materials, etc. Easy-to-use effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

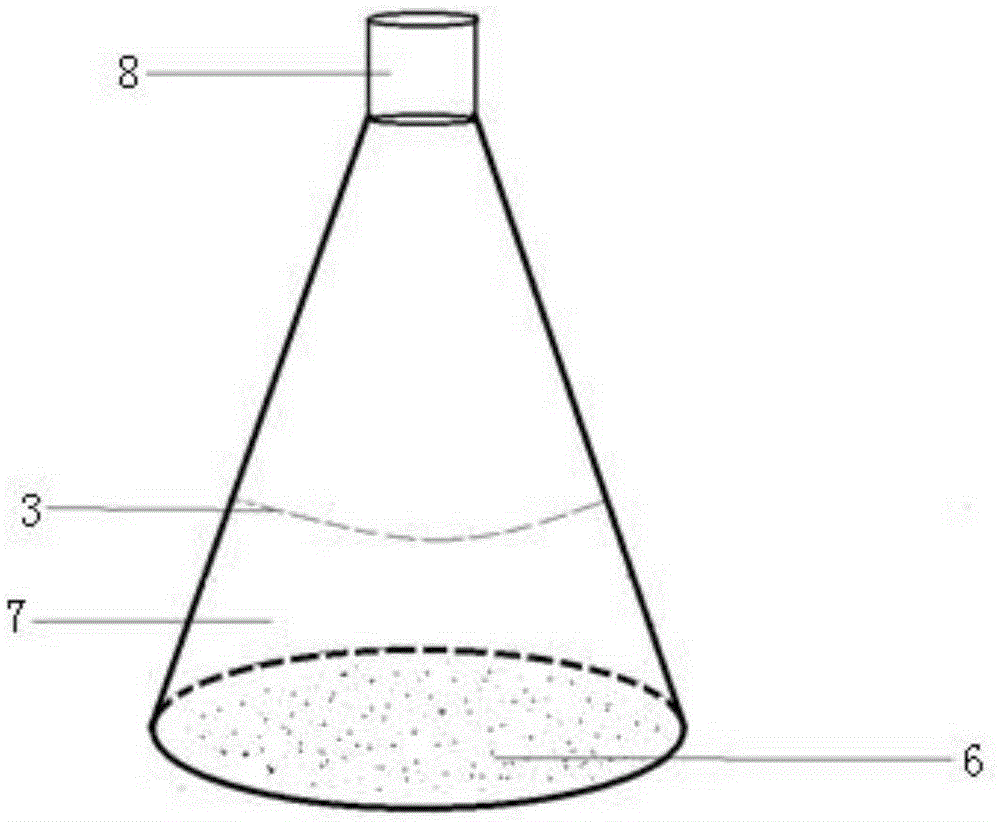

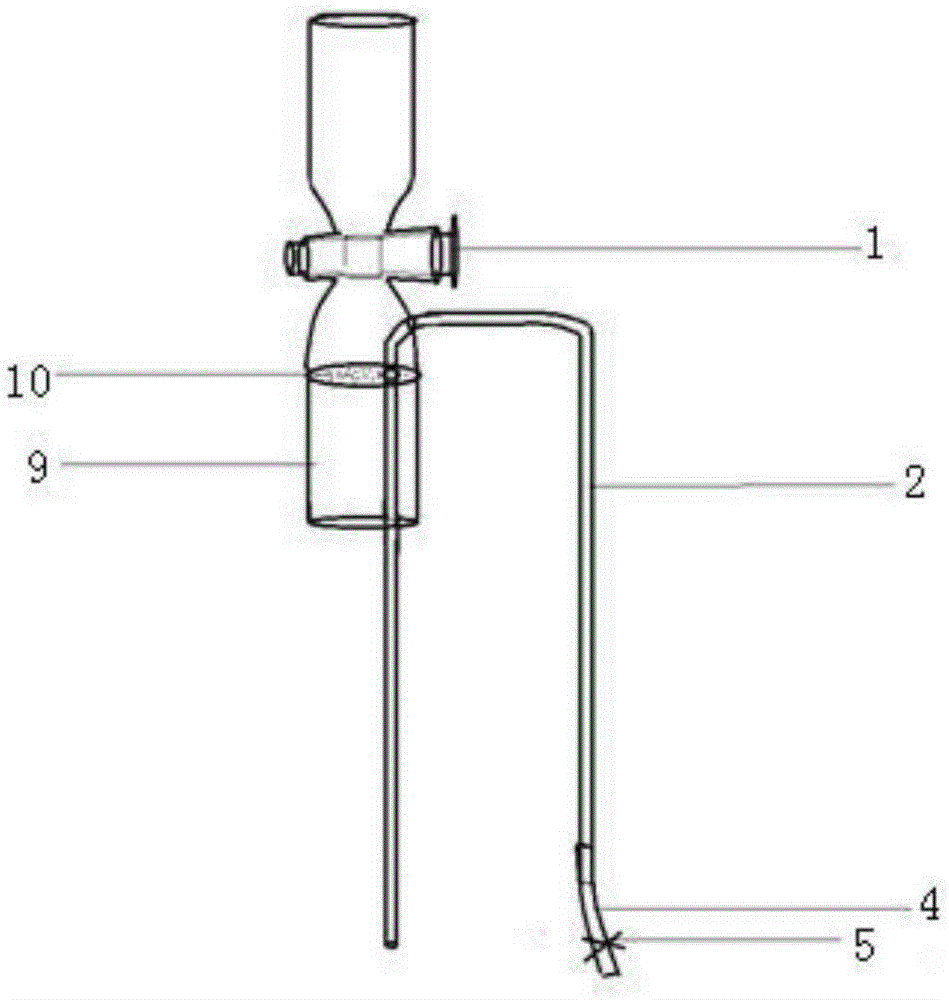

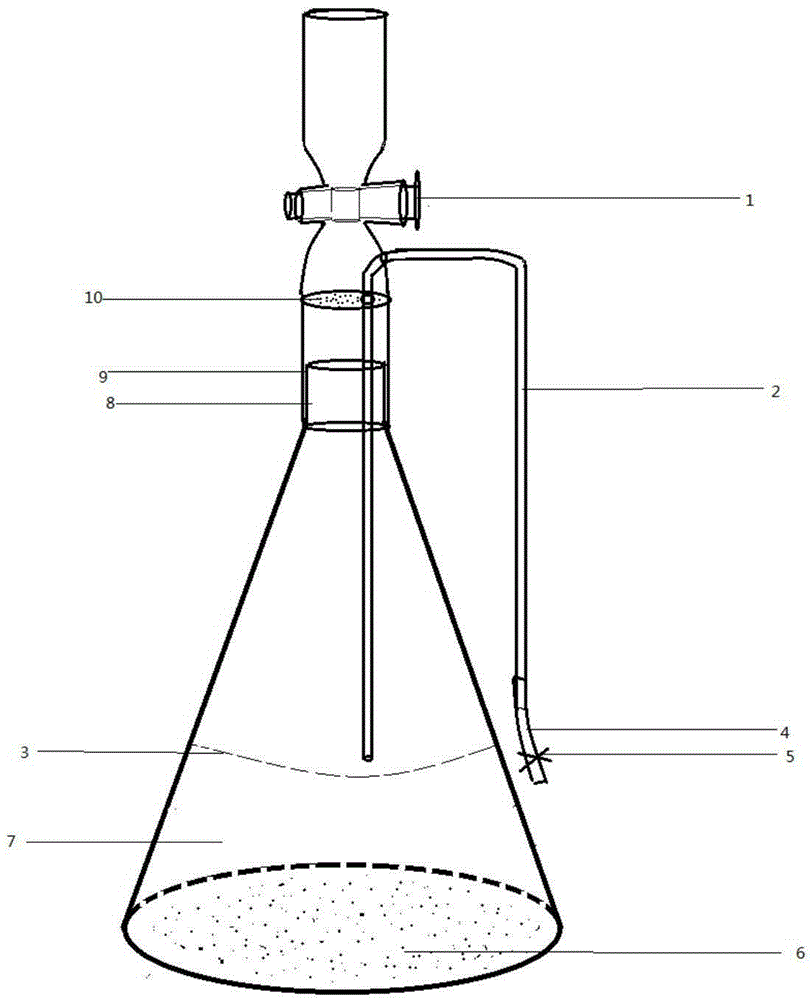

[0039]The device A of the present invention is composed of the device B and the device C, the device B and the device C are combined in a complete set, and the device C is set on the outside of the device B to form the device A. Device B is a 250mL conical flask with an external ground mouth; device C has an internal ground mouth to match with device B, and device C is equipped with a piston, a ventilation tube, and a filter element. The designed device C has a large weight and is tightly ground to the device B, which avoids the problem of being lifted and broken during the cork experiment. After soaking the resin-containing soaking solution in a water-soluble pot at 60°C for 3 hours, use device A to quickly separate the resin from the soaking solution, and the resulting soaking solution does not contain resin, thus avoiding differences in cooling time and cooling methods between the resin and the soaking solution The measurement error of the total exchange capacity of the hyd...

Embodiment 2

[0087] The difference from Example 1 is that the device B is a container with an outer grinding port, and the device C is a filter with an inner grinding port, and the inner diameter of the inner grinding port is the same as the outer diameter of the outer grinding port.

Embodiment 3

[0089] The difference from Example 1 is that the device B is a container with an inner grinding port, and the device C is a filter with an outer grinding port, and the inner diameter of the inner grinding port is the same as the outer diameter of the outer grinding port.

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com