Preparation method of macroporous weak-basicity acrylic acid series anion exchange resin

An exchange resin and weakly alkaline technology, which is applied in the direction of ion exchange, ion exchange regeneration, ion exchange treatment devices, etc., can solve the problems of rapid decline in mechanical strength, weak adsorption resin capacity, and low oxidation resistance, and achieve improved Resin exchange capacity, good anti-pollution performance, and high mechanical strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

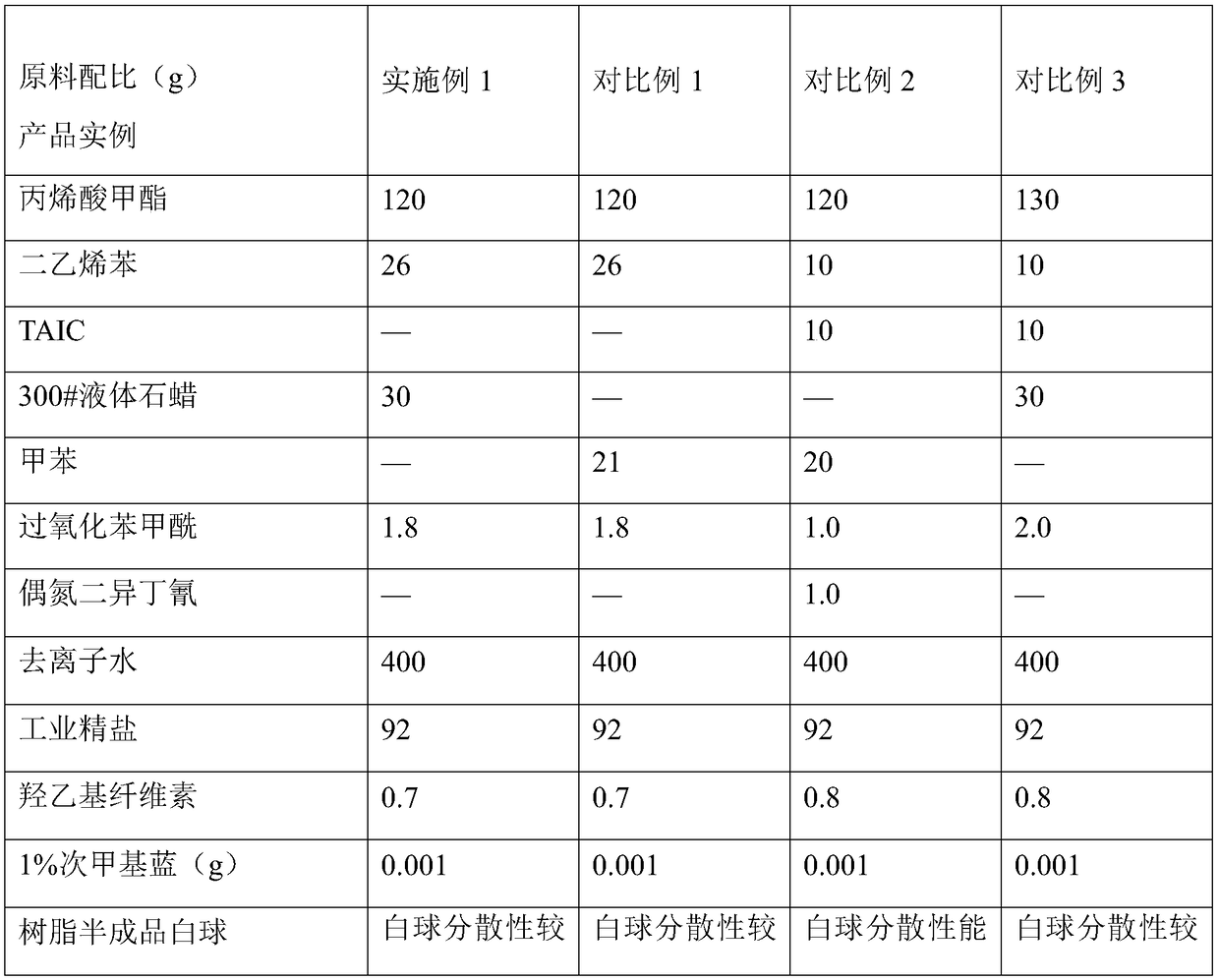

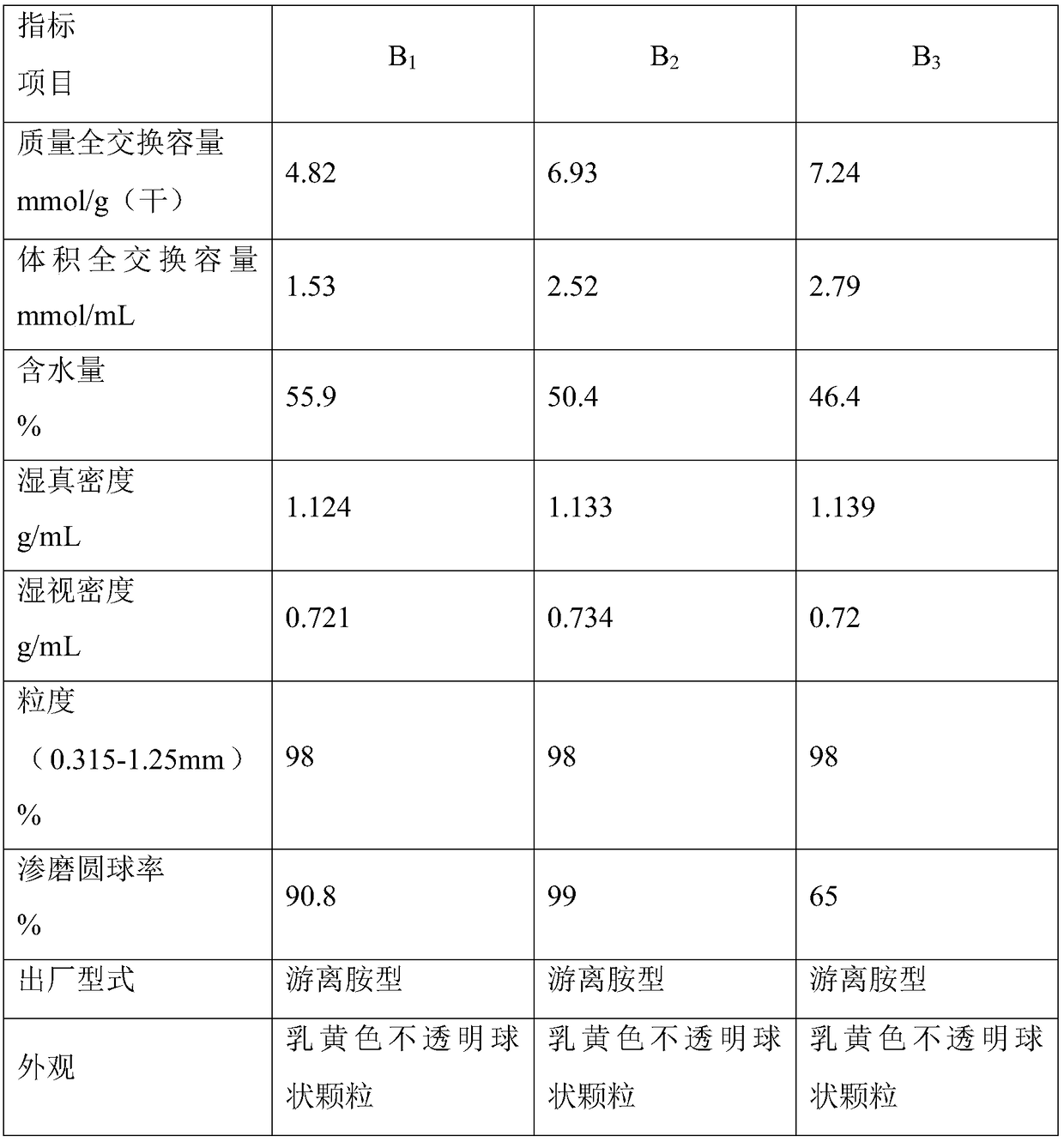

Examples

Embodiment 1

[0049](1) Prepare the water phase: add 92g of industrial refined salt to 400mL of deionized water, stir, and wait for it to fully dissolve, add 0.7g of hydroxyethyl cellulose, and then add 0.001g of methylene blue solution with a mass percentage concentration of 1%. To develop color, heat up to 50°C for later use;

[0050] (2) Prepare the organic phase, weigh 120g of methyl acrylate in a 500mL beaker, add 26g of divinylbenzene, then add 30g of liquid paraffin, heat up to 60°C, and wait until it is fully dissolved, then add 1.8g of benzoyl peroxide, Fully mix and stir for 5 minutes, set aside;

[0051] (3) Suspension polymerization reaction: Add the organic phase prepared in step (2) to the aqueous phase prepared in step (1) to obtain a mixed solution, wherein the mass ratio of the organic phase to the aqueous phase is 0.360:1, stir the mixed solution and slowly heat up To 65°C, the heating rate is 5°C / 10min, maintain for 2h, then raise the temperature to 75°C, maintain for 2h...

Embodiment 2

[0056] (1) Prepare the water phase: add 90 g of industrial refined salt to 400 mL of deionized water, stir, and wait for it to fully dissolve, then add 0.7 g of hydroxyethyl cellulose, and then add 0.001 g of methylene blue solution with a concentration of 1% by mass. To develop color, heat up to 50°C for later use;

[0057] (2) Prepare the organic phase, weigh 120g of methyl acrylate in a 500mL beaker, add 26g of divinylbenzene, then add 30g of liquid paraffin, heat up to 60°C, and wait until it is fully dissolved, then add 1.8g of benzoyl peroxide, Fully mix and stir for 5 minutes, set aside;

[0058] (3) Suspension polymerization: Add the organic phase prepared in step (2) to the aqueous phase prepared in step (1) to obtain a mixed solution, wherein the mass ratio of the organic phase to the aqueous phase is 0.36:1, and the mixed solution is stirred and heated slowly To 65°C, the heating rate is 5°C / 10min, maintain for 2h, then raise the temperature to 75°C, maintain for 2...

Embodiment 3

[0063] (1) Prepare the water phase: add 90 g of industrial refined salt to 400 mL of deionized water, stir, and wait for it to fully dissolve, then add 0.7 g of hydroxyethyl cellulose, and then add 0.001 g of methylene blue solution with a concentration of 1% by mass. To develop color, heat up to 50°C for later use;

[0064] (2) Prepare the organic phase, weigh 120g of methyl acrylate in a 500mL beaker, add 26g of divinylbenzene, then add 30g of liquid paraffin, heat up to 60°C, and wait until it is fully dissolved, then add 1.8g of benzoyl peroxide, Fully mix and stir for 5 minutes, set aside;

[0065] (3) Suspension polymerization: Add the organic phase prepared in step (2) to the aqueous phase prepared in step (1) to obtain a mixed solution, wherein the mass ratio of the organic phase to the aqueous phase is 0.36:1, and the mixed solution is stirred and heated slowly To 65°C, the heating rate is 5°C / 10min, maintain for 2h, then raise the temperature to 75°C, maintain for 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com