Bisphenol A synthetic resin catalyst and preparation method thereof

A technology for synthesizing resins and catalysts, applied in the field of high-strength bisphenol A resin catalysts and their preparation, can solve the problems of limiting the scope of use of resin catalysts, limiting the flow of reactants and products, and restricting the localization of bisphenol A technology. Anti-crushing performance, reducing differential pressure and improving service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

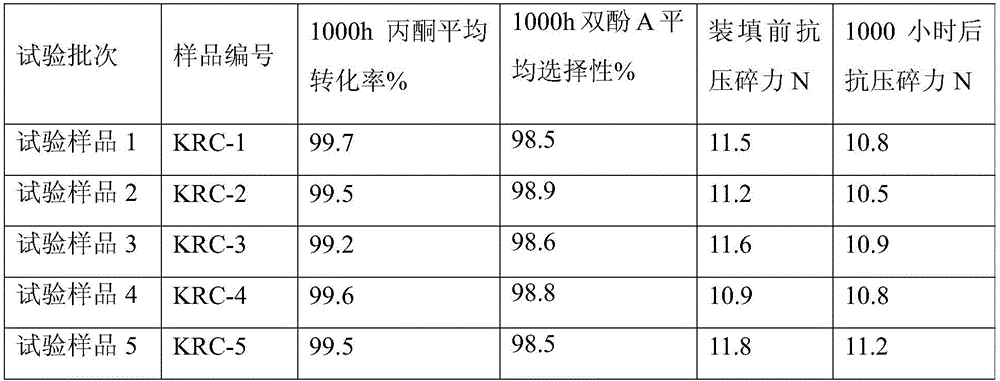

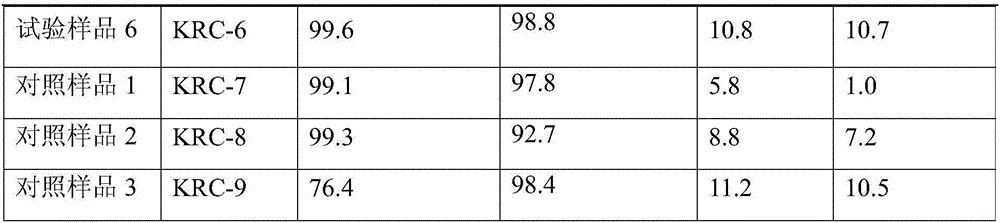

Examples

Embodiment 1

[0033] A bisphenol A synthetic resin catalyst is prepared by the following method,

[0034] 1) Polymerization reaction

[0035] In the reactor, by weight, add 100 parts of styrene, 5 parts of divinylbenzene, 1 part of diallyl bisphenol A, 20 parts of 2-methyl-1-butanol, at 78 ° C React for 4 hours, raise the temperature to 84°C for 2 hours, then raise the temperature to 96°C for 4 hours to generate polymerized white balls, after drying, extract the pore-forming agent and dry it for use;

[0036] 2) Sulfonation reaction

[0037] In the reactor, by weight, add 100 parts of white balls obtained in step 1), 1000 parts of 95% sulfuric acid, heat up to 80°C in 3h, keep warm for 10h, heat up to 86°C in 2h, keep warm for 6h, put on file according to the conventional process, Wash with water until neutral, discharge.

[0038] 3) Catalyst modification

[0039] In the reaction kettle, add 100 parts of the resin obtained in step 2) in parts by weight, add an appropriate amount of pure...

Embodiment 2

[0041] Polymerization reaction cross-linking degree is controlled at 2%, and others are the same as example 1. The resulting product number is KRC-2.

Embodiment 3

[0043]Polymerization reaction cross-linking degree is controlled at 4%, other is the same as example 1. The resulting product number is KRC-3.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com