Hydrophobic carbonyl modified superhigh crosslinked adsorption resin as well as synthetic method and application thereof

A technology of ultra-high cross-linking and adsorption resin, applied in chemical instruments and methods, other chemical processes, etc., to achieve the effects of strong hydrophobicity, simple equipment, and simple control process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

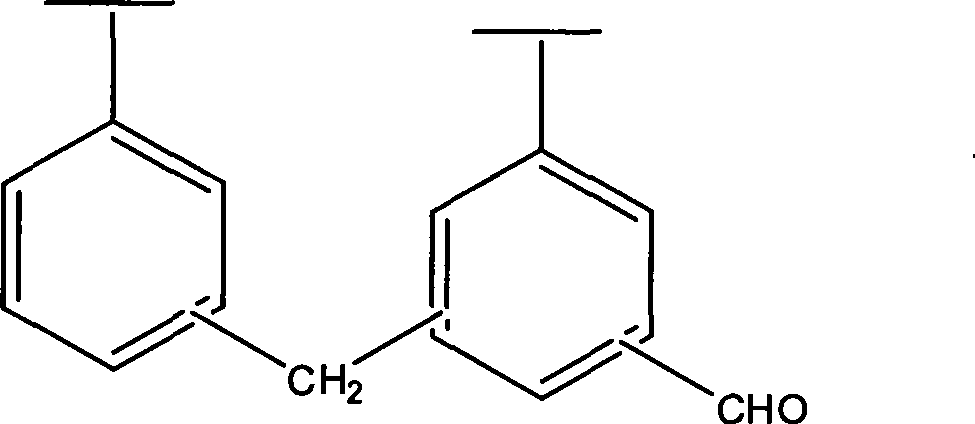

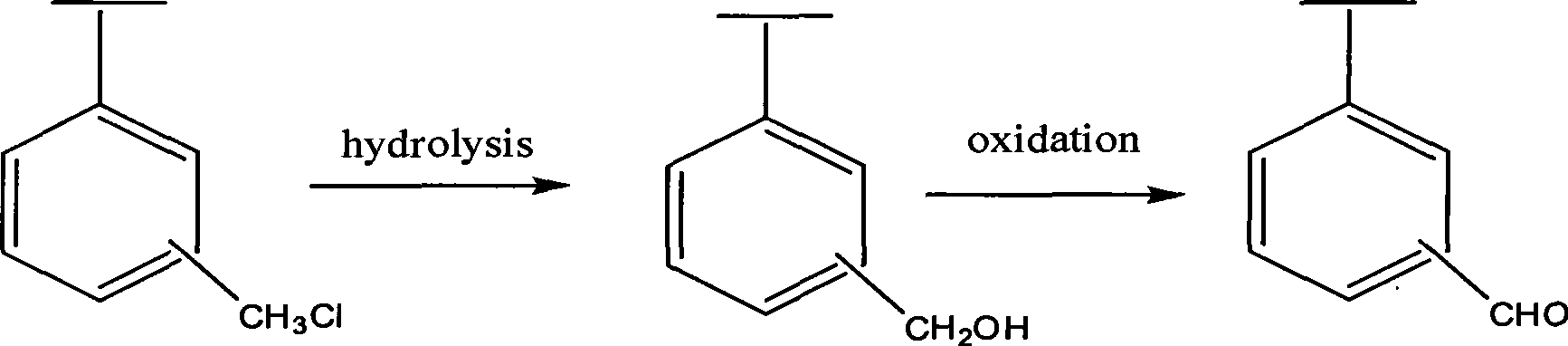

Method used

Image

Examples

Embodiment 1

[0025] A Suspension polymerization: The synthesis of low-crosslinked polystyrene resin adopts the suspension polymerization method. In the water phase (500g), 3g of gelatin should be added as a dispersant, 7g of sodium carbonate and 23g of magnesium sulfate should be added. The oil phase (150g) comprises: 89.7g of styrene, 7.5g of divinylbenzene (80% purity), 50g of 200# solvent naphtha, and 3g of initiator benzoyl peroxide. Carry out the water phase for a period of time until the gelatin is completely dissolved, add 2ml of methylene blue, then add the oil phase, control the speed of the stirrer at 300rpm, and the polymerization reaction temperature is 78°C. After 10 hours of reaction, keep warm at 85°C for 6 hours, and then Heat up to 90°C and boil the balls for 4 hours, and finally heat up to 95°C and cook the balls for 4 hours, after cooling, you can get milky white linear polymer balls, white balls. After filtration, wash with hot water and cold water for several times, p...

Embodiment 2

[0033] The specific operation steps are the same as in Example 1, except that in step A, the solvent oil is changed to toluene, styrene is changed to 80g, divinylbenzene is changed to a purity of 65%, and the weight is changed to 15g, and the reaction obtains a hydrophobic carbonyl-modified ultra-high cross-linked adsorption resin C, the basic structure is the same as in Example 1.

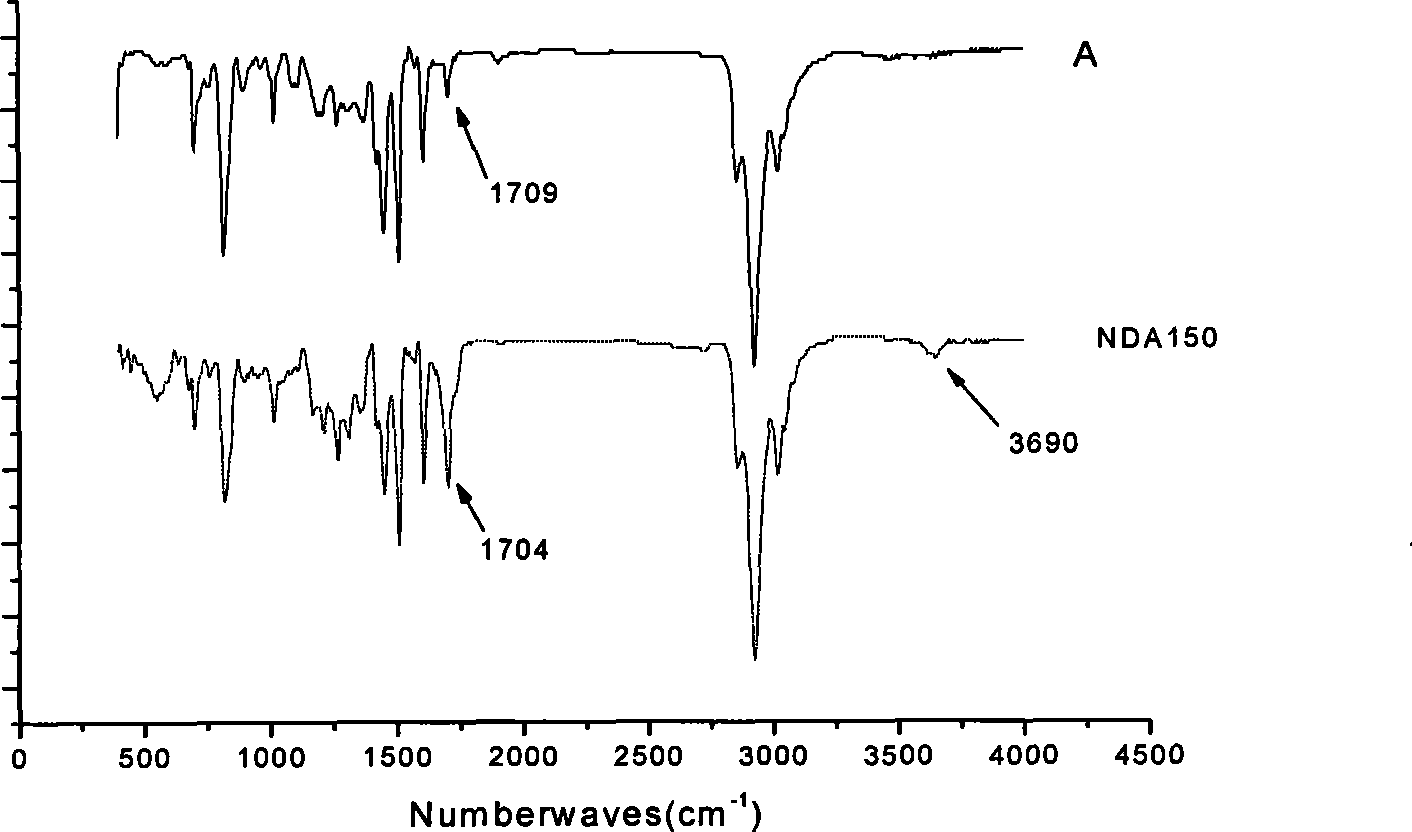

[0034] The performance of the adsorption resin B prepared by the above synthesis: the BET specific surface area is as high as 1401m 2 The average pore size per g is 1-2nm, and the saturated adsorption capacity of butanone gas at 20°C is 493mg / g. As a comparison, the saturated adsorption capacity of the commodity ultra-high cross-linked adsorption resin NDA150 to butanone gas under the same conditions is 367mg / g.

Embodiment 3

[0036] The specific operation steps are the same as in Example 1, except that in step C, dichloroethane is changed to o-dichlorobenzene, and the heating program is changed to 80°C and then kept for 2 hours, and then heated to 110°C for 10 hours to obtain a hydrophobic carbonyl Modified ultra-high cross-linked adsorption resin C, the basic structure is the same as that of Example 1.

[0037] The adsorption performance of the adsorption resin C prepared by the above synthesis: the BET specific surface area is 1073m 2 / g, the average pore size is 1-2nm, and the saturated adsorption capacity of butanone gas at 20°C is 412mg / g. As a comparison, the saturated adsorption capacity of commercial super-crosslinked adsorption resin NDA150 is 367mg / g for butanone gas under the same conditions.

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com