Macroreticular resin and preparing method thereof

A technology of pore adsorption and resin, which is applied in the field of macroporous adsorption resin and its preparation, and can solve the problems of easy generation of membranes, poor force between coating materials and adsorbents, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

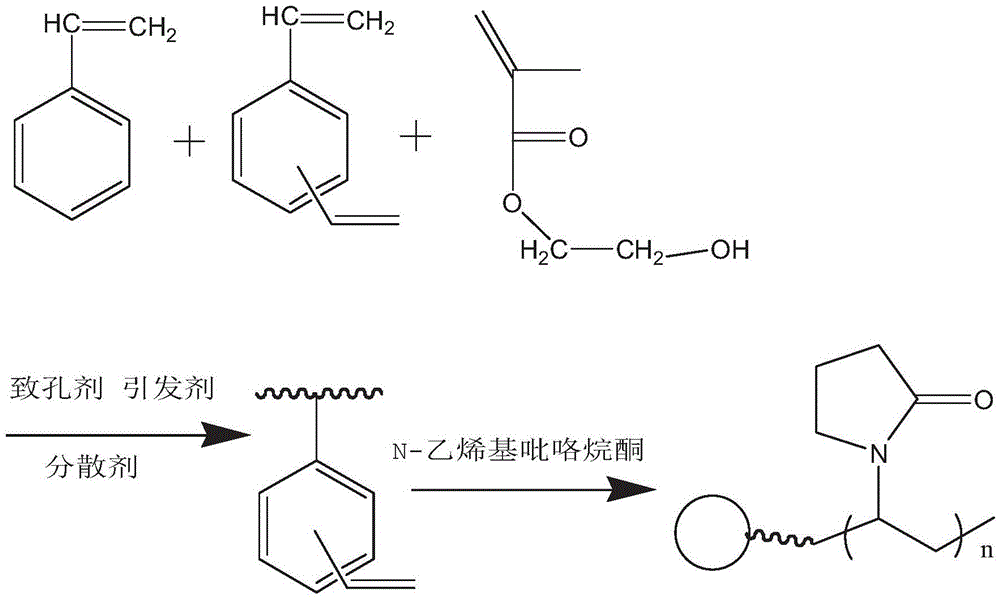

Method used

Image

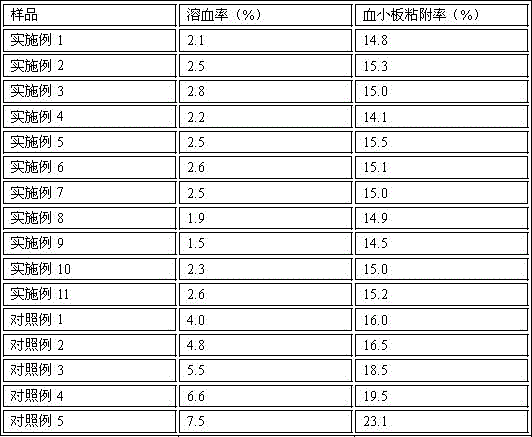

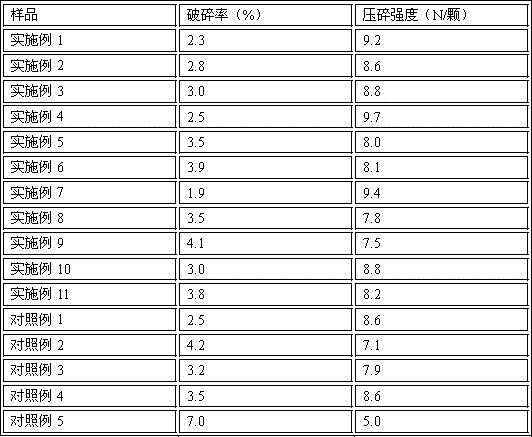

Examples

Embodiment 1

[0051] Step (1): Free radical polymerization step.

[0052] Add 500mL of aqueous solution containing 0.5wt% methyl hydroxyethyl cellulose and 15wt% NaCl to a 1000mL three-necked flask, add 15g hydroxyethyl methacrylate, 60g divinylbenzene, 45g styrene, 120g toluene, 100g Mixed organic phase of methyl isobutyl ketone, 1 g of lauryl peroxide. Under mechanical stirring, raise the temperature to 55°C to react until the setting takes about 1.5 hours (hours), and continue to keep warm for 3 hours. Then raise the temperature to 80° C. and keep the temperature for curing reaction for 1 hour. Then, the temperature was raised to 90° C. and the curing reaction was carried out for 6 hours. After the reaction, wash with water until the washing solution is clear, filter with suction, dry, and then use acetone to extract methyl isobutyl ketone until it is clean. Drying, sieving, and selecting resins with particle diameters ranging from 0.55mm to 1.25mm, the macroporous resin matrix white ...

Embodiment 2

[0060] Step (1): Free radical polymerization step.

[0061] Add 500mL of aqueous solution containing 0.5wt% methyl hydroxyethyl cellulose and 15wt% NaCl to a 1000mL three-necked flask, add 15g hydroxyethyl methacrylate, 60g divinylbenzene, 45g styrene, 120g toluene, 100g Mixed organic phase of methyl isobutyl ketone, 1 g of lauryl peroxide. Under mechanical stirring, raise the temperature to 45°C to react until the setting takes about 2.5 hours (hours), and continue to keep warm for 4.5 hours. Then raise the temperature to 80° C. and keep the temperature for curing reaction for 1 hour. Then, the temperature was raised to 90° C. and the curing reaction was carried out for 6 hours. After the reaction, wash with water until the reaction solution is clear, filter with suction, dry, and then use acetone to extract methyl isobutyl ketone until it is clean. Drying, sieving, and selecting resins with particle diameters ranging from 0.50mm to 1.20mm, the macroporous resin matrix whi...

Embodiment 3

[0064] Step (1): Free radical polymerization step.

[0065] Add 500mL of aqueous solution containing 0.5wt% methyl hydroxyethyl cellulose and 15wt% NaCl to a 1000mL three-necked flask, add 15g hydroxyethyl methacrylate, 60g divinylbenzene, 45g styrene, 120g toluene, 100g Mixed organic phase of methyl isobutyl ketone, 1 g of lauryl peroxide. Under mechanical stirring, raise the temperature to 50°C to react until the setting takes about 2.0 hours, and continue to keep warm for 3.5 hours. Then raise the temperature to 80° C. and keep the temperature for curing reaction for 1 hour. Then, the temperature was raised to 90° C. and the curing reaction was carried out for 6 hours. After the reaction, wash with water until the reaction solution is clear, filter with suction, dry, and then use acetone to extract methyl isobutyl ketone until it is clean. Drying, sieving, and selecting resins with particle diameters ranging from 0.50mm to 1.20mm, the macroporous resin matrix white balls...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com