Surface quality improving method for non-ferrous metal retainer

A non-ferrous metal and surface quality technology, applied in the field of surface quality improvement of non-ferrous metal cages, can solve the problems of scratched steel balls, non-smooth surface of the cage, cutting marks, bumps, etc., to improve application performance and surface finish. , the effect of weakening cutting marks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

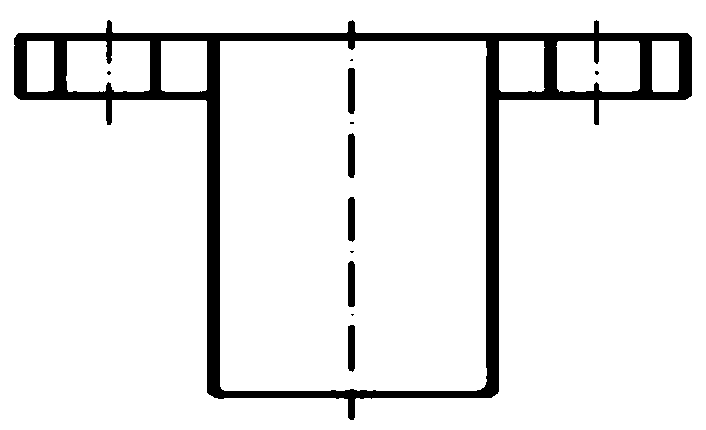

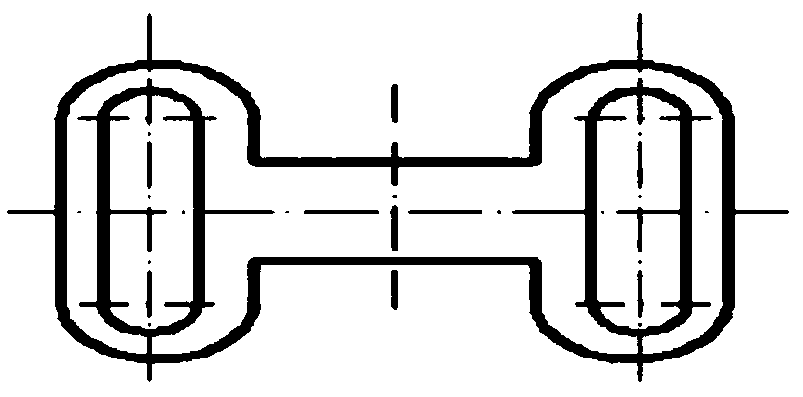

[0016] Specific Embodiment 1: In this embodiment, a method for improving the surface quality of a non-ferrous metal cage is carried out in the following steps:

[0017] 1. Select 15×15 bullet-shaped resin sintered abrasives with a particle size of 2000 mesh as the finishing material for rough finishing, and select 2000 mesh Ф2mm white spherical alumina sintered abrasive as the finishing material for fine finishing;

[0018] 2. Use baffle-type tooling to separate the non-ferrous metal cage, and then use the rough-finish finishing material to rough-finish the non-ferrous metal cage with a finishing machine. The rough-finish time is 3.5 to 4.5 hours; Then use the finishing material to finish finishing the non-ferrous metal cage with a finishing machine. The finishing time is 2.5 to 3.5 hours. After cleaning, the surface quality of the non-ferrous metal cage can be improved.

[0019] In this embodiment, the baffle-type tooling can prevent the cages from colliding with each other w...

specific Embodiment approach 2

[0020] Embodiment 2: This embodiment differs from Embodiment 1 in that: the weight of the finishing material in the rough finishing described in step 2 is 200 kg, and the amount of finishing liquid is 800-1000 mL. Others are the same as the first embodiment.

specific Embodiment approach 3

[0021] Embodiment 3: This embodiment differs from Embodiment 2 in that: the weight of the finishing material in step 2 is 200 kg, and the amount of finishing liquid is 800-1000 mL. Others are the same as those in Embodiment 1 or 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com