Patents

Literature

49results about How to "No bruises" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

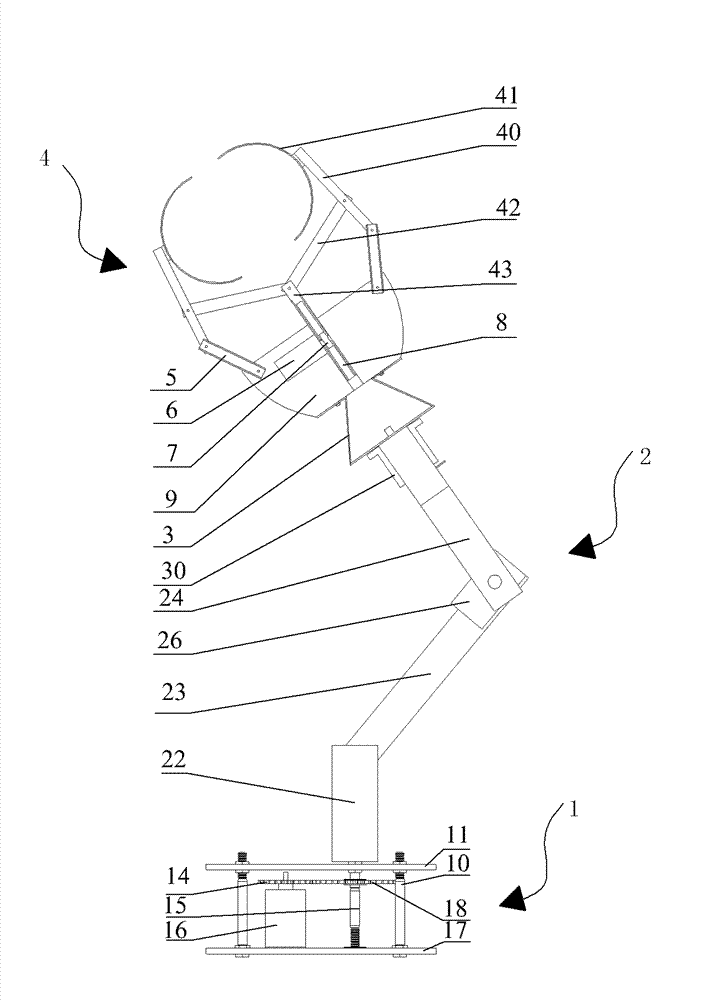

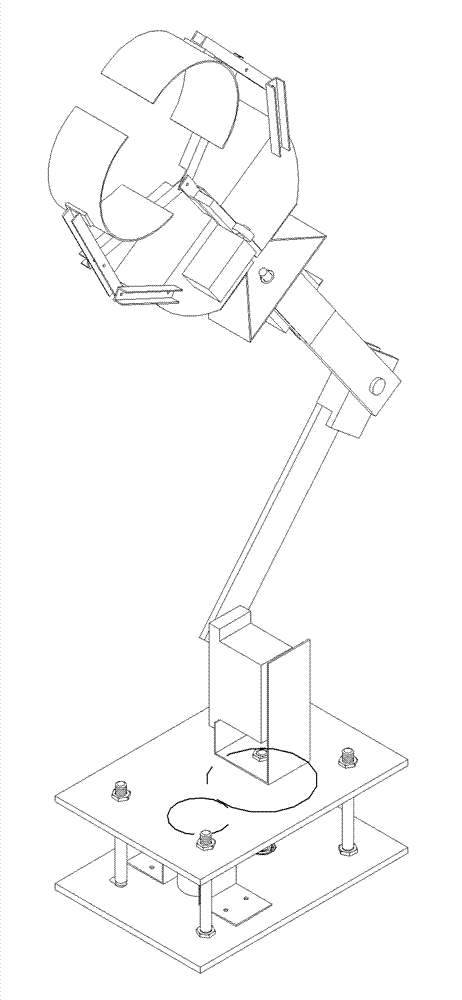

Fruit picking manipulator

InactiveCN102672712AIncrease the bearing areaEven by forceProgramme-controlled manipulatorGripping headsManipulatorEngineering

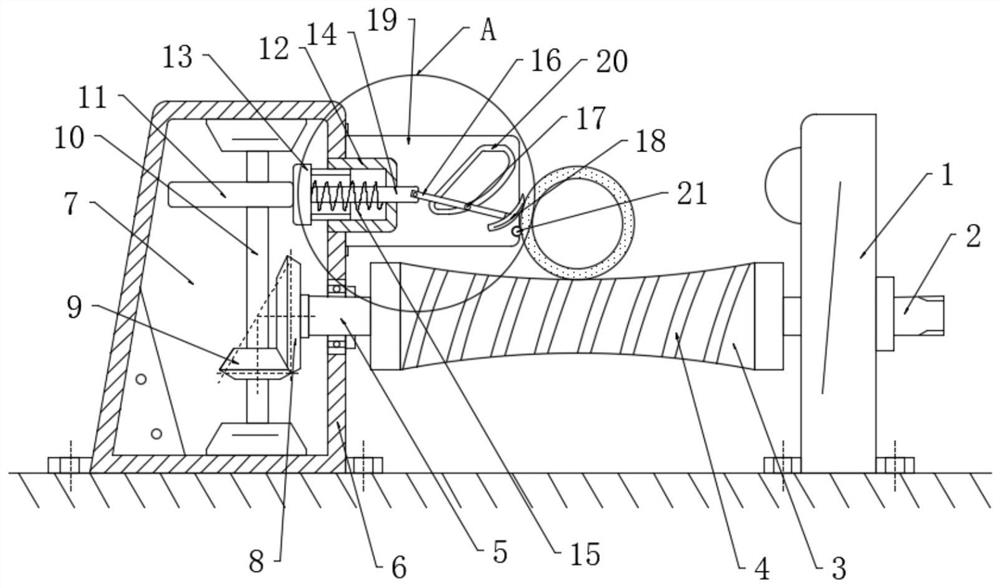

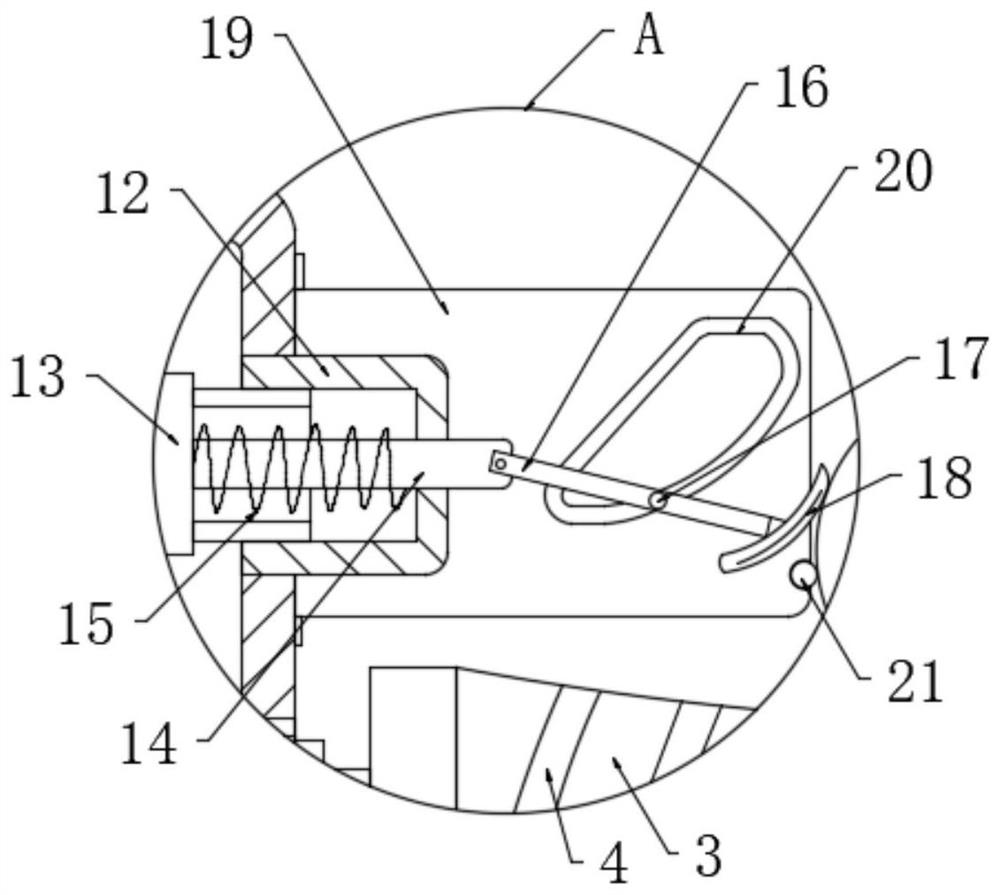

The invention discloses a fruit picking manipulator which comprises a hand portion and a tri-link spherical coordinate type arm. The hand portion comprises a supporting plate arranged on a wrist, fingers and connecting rods thereof are respectively hinged to two sides of the front end face of the supporting plate, and a draw rod for drawing the fingers to open and close is directionally and movably assembled on the supporting plate through a draw rod driving mechanism arranged on the supporting plate. The fruit picking manipulator is characterized in that the inner sides of the front ends of the fingers are provided with arc clamping plates with opposite arc directions respectively. When fruits are picked by the fingers, the arc shape of the arc clamping plates arranged in the front of the fruit picking manipulator fits shapes of fruits, so that the peripheral stressed areas of the fruits are large, the fruits are uniformly stressed, and the problem of fruit damage caused by high local stress on the fruits in the prior art can be avoided.

Owner:HENAN UNIV OF SCI & TECH

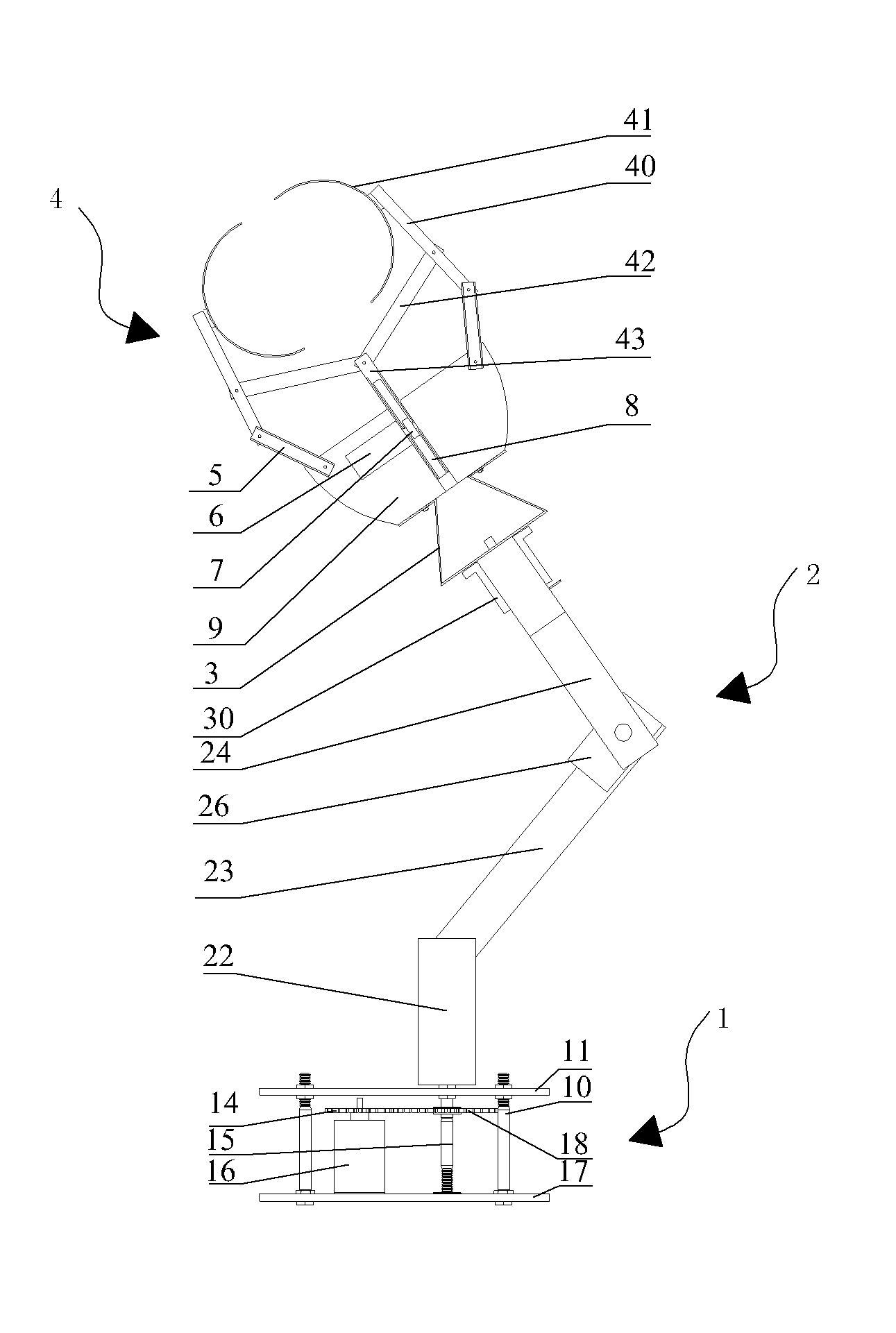

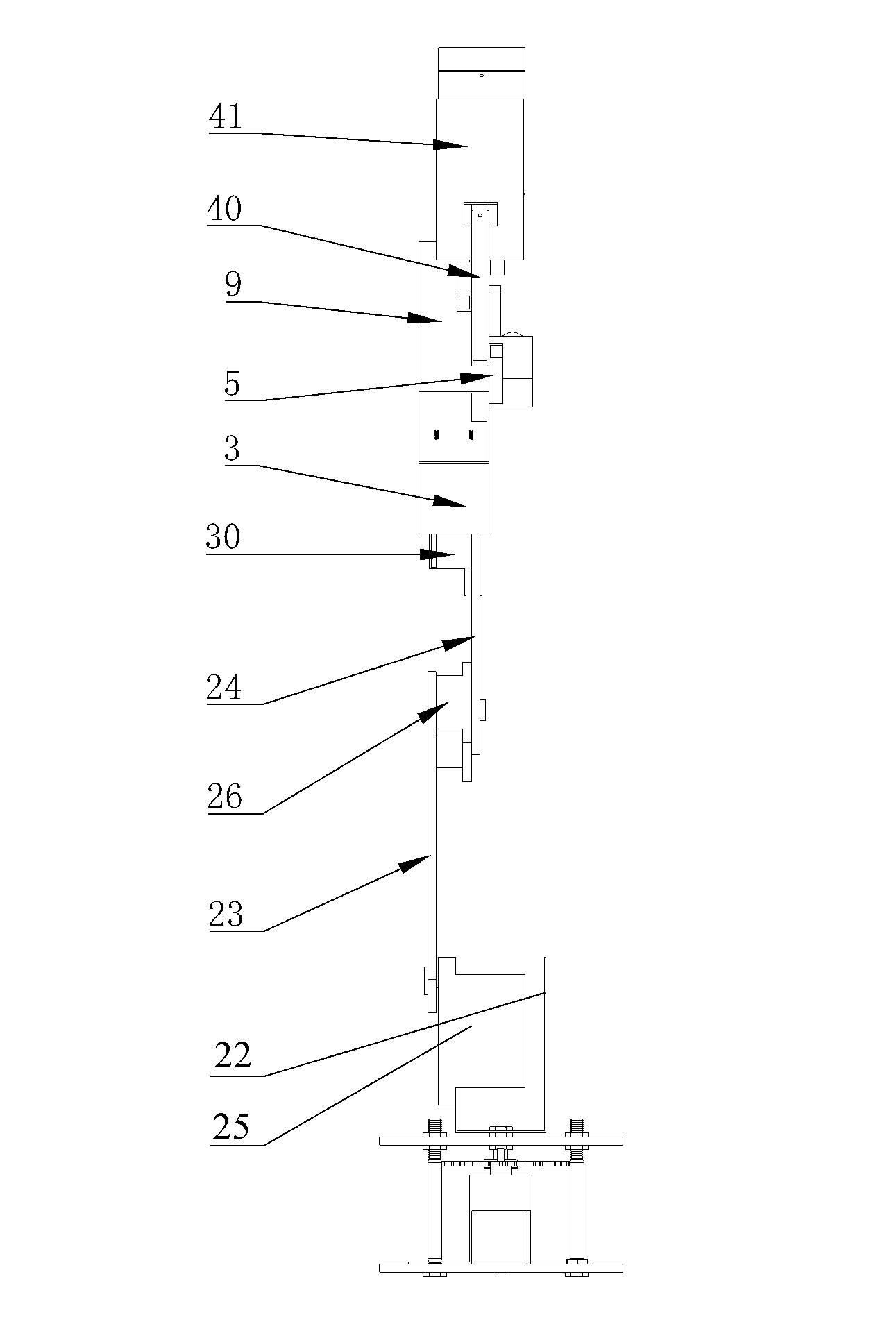

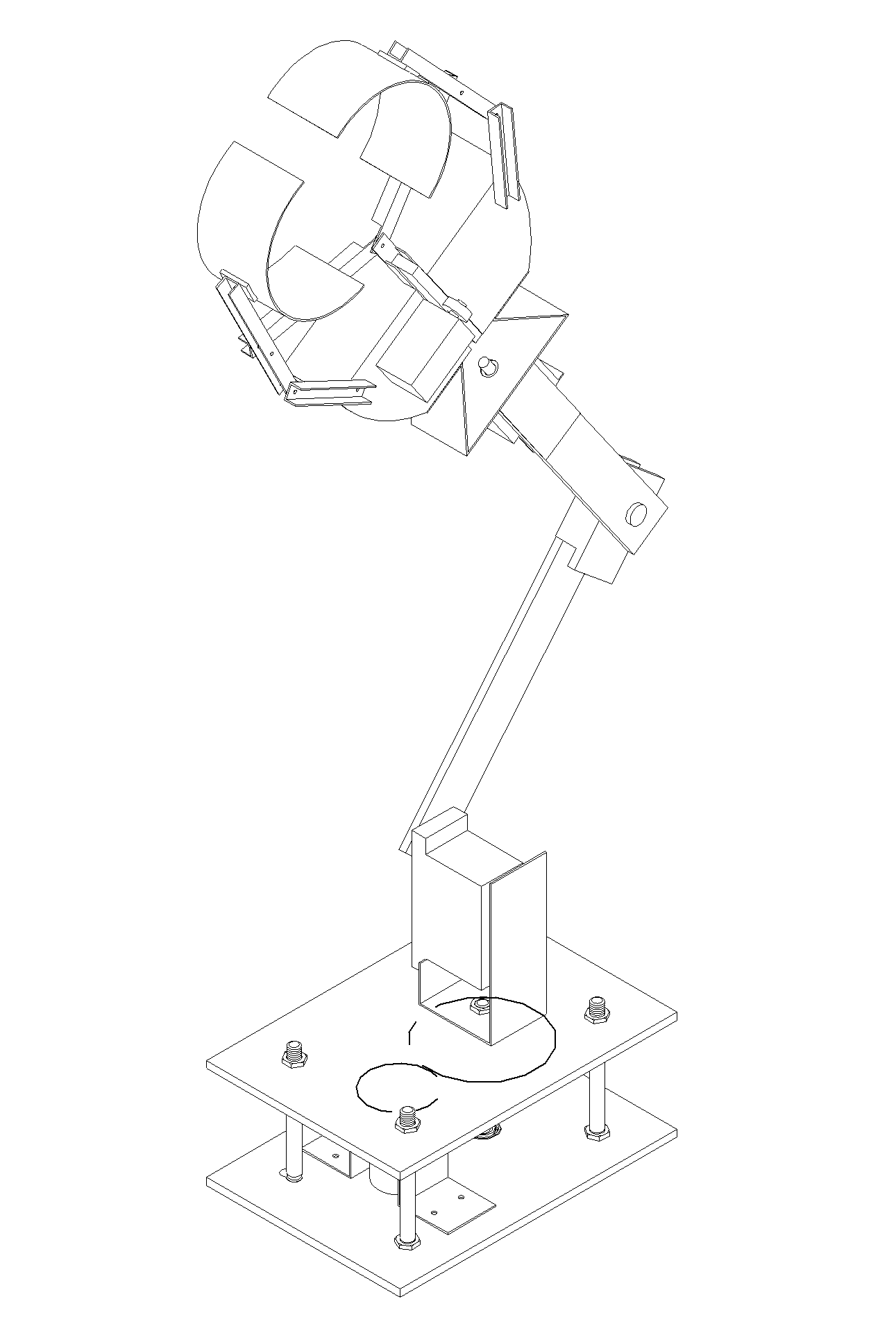

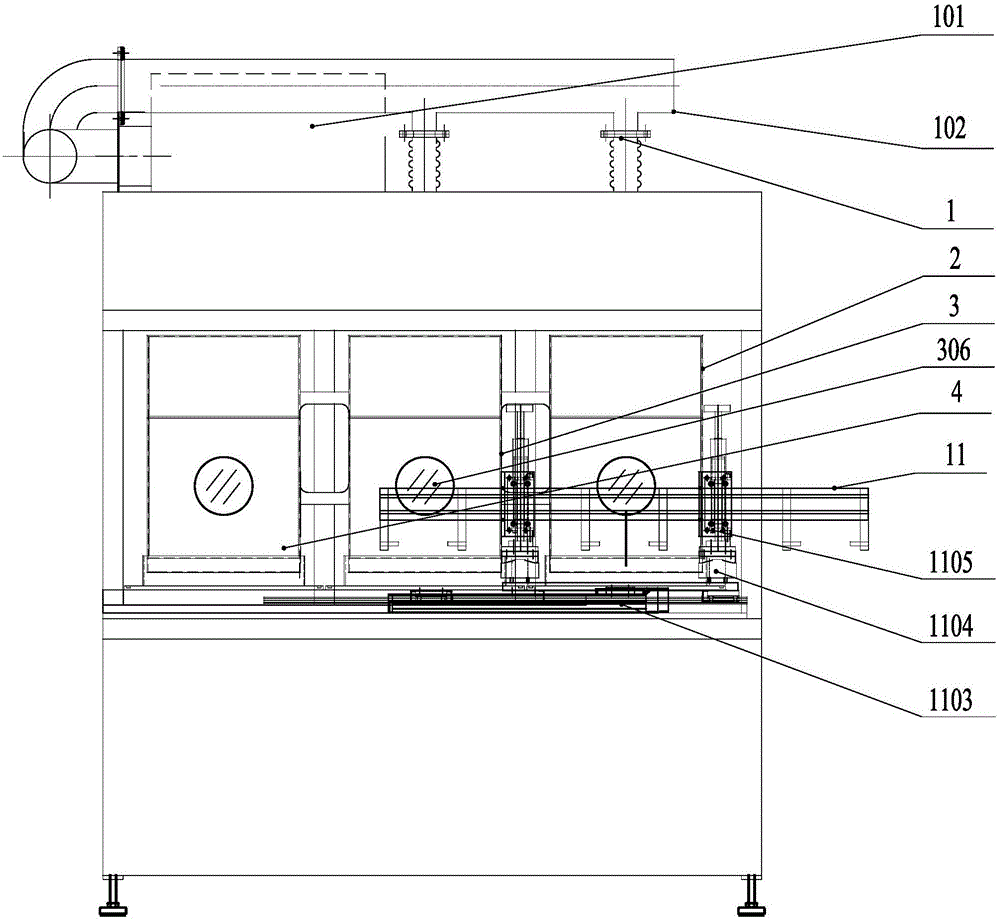

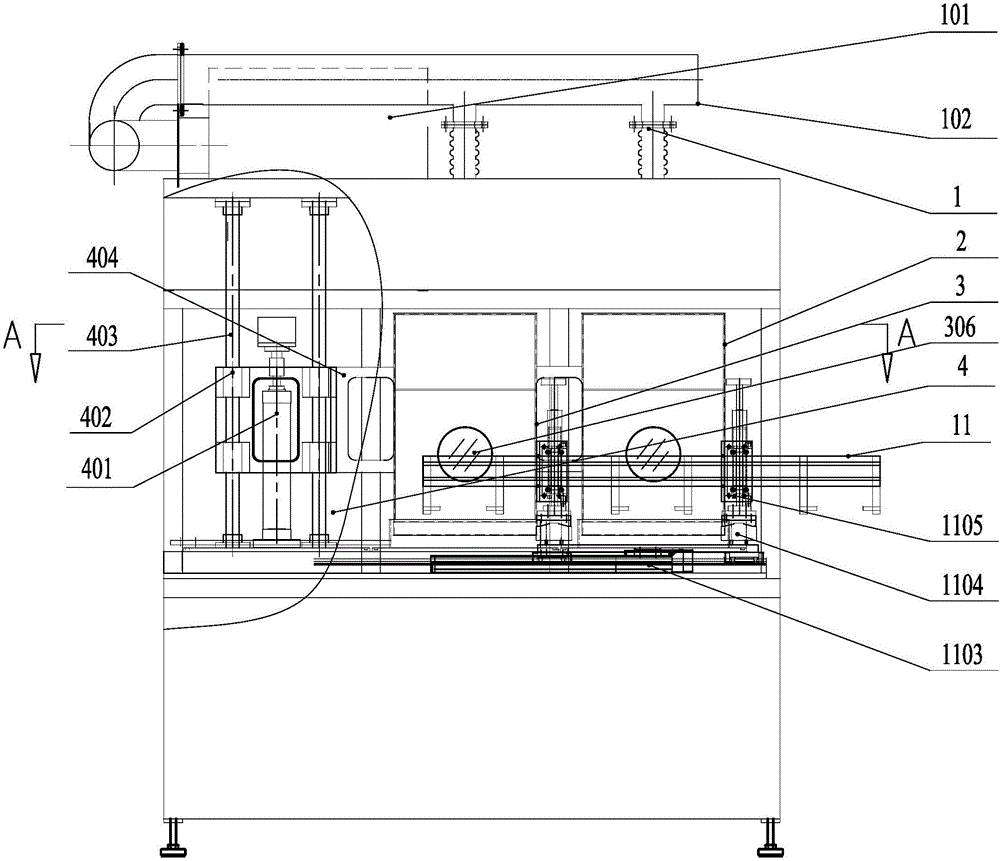

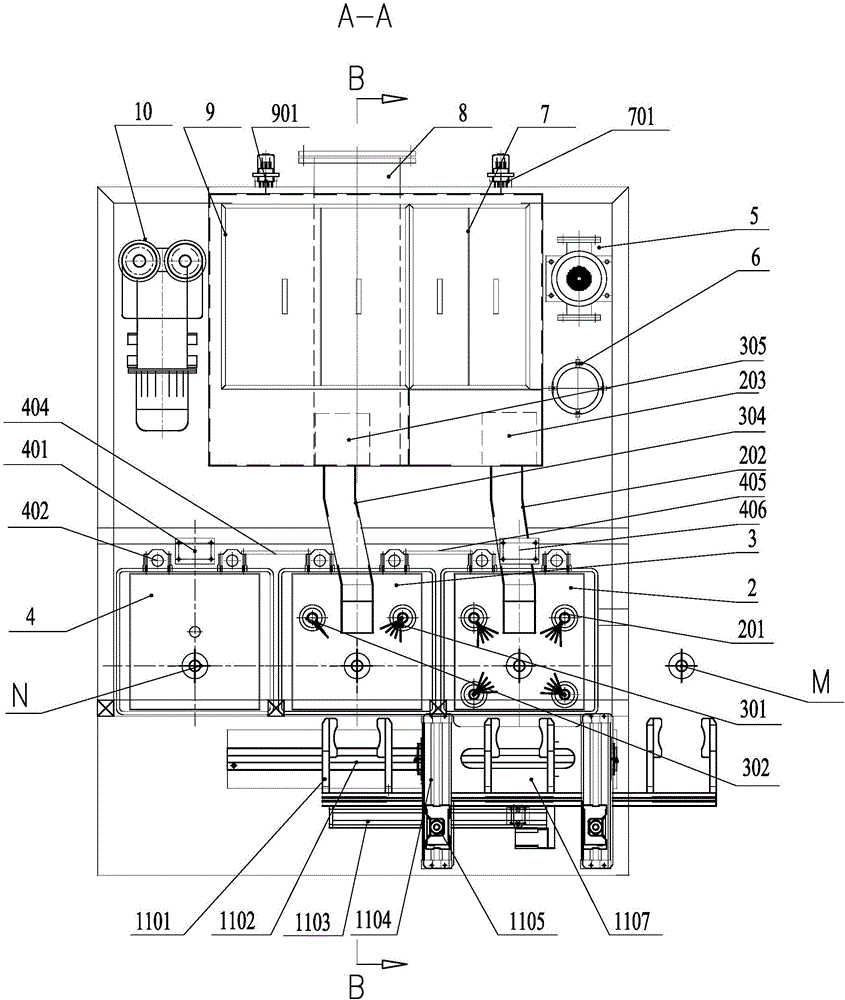

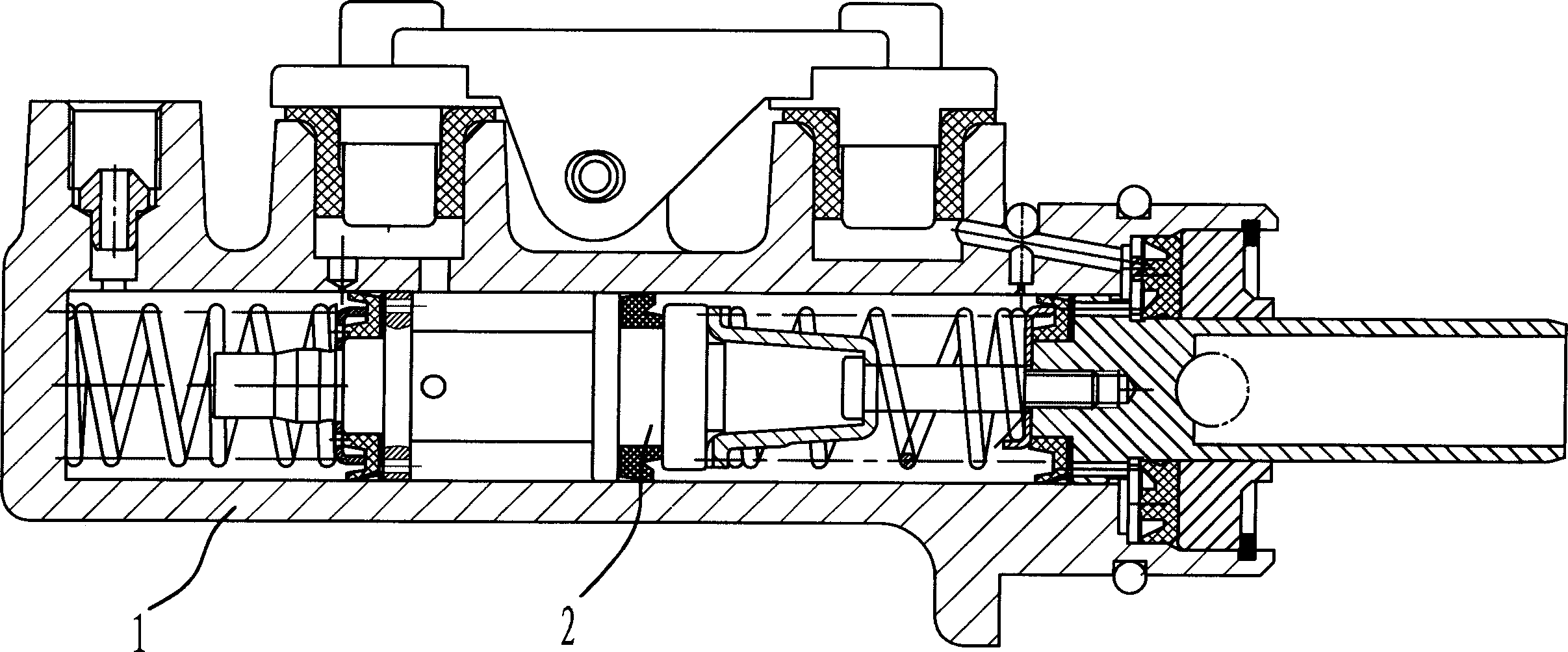

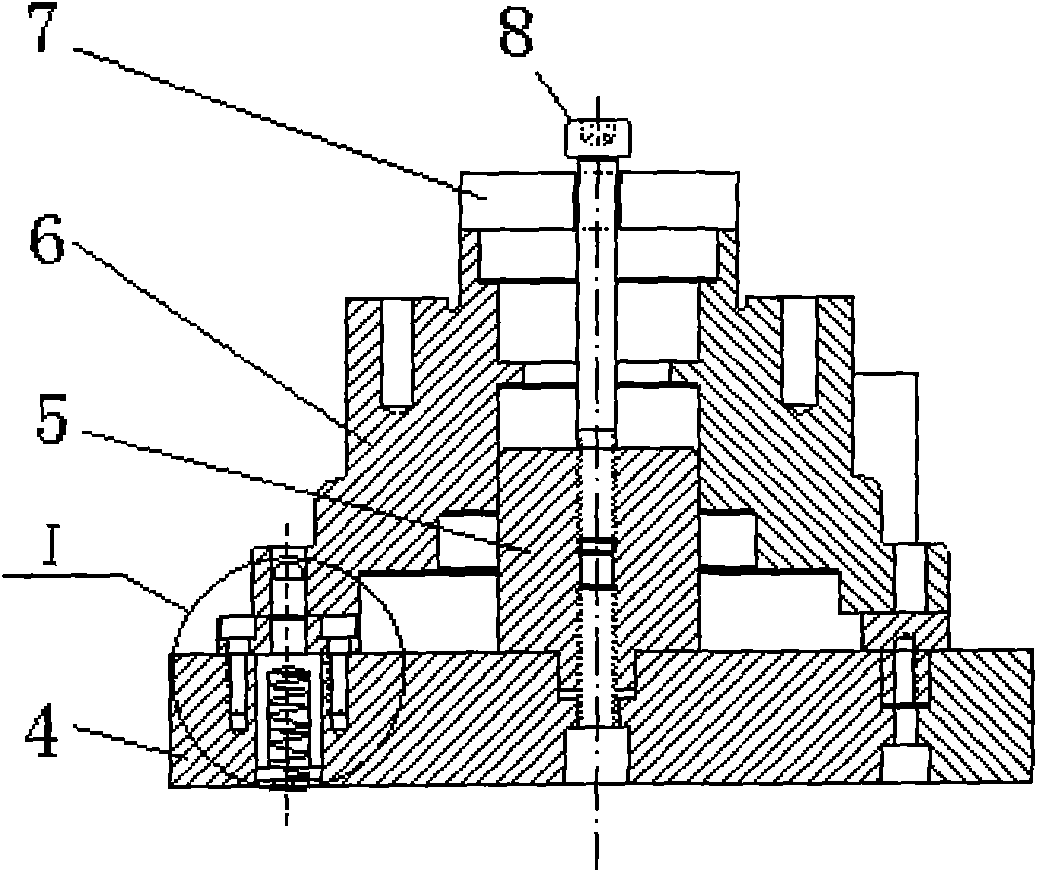

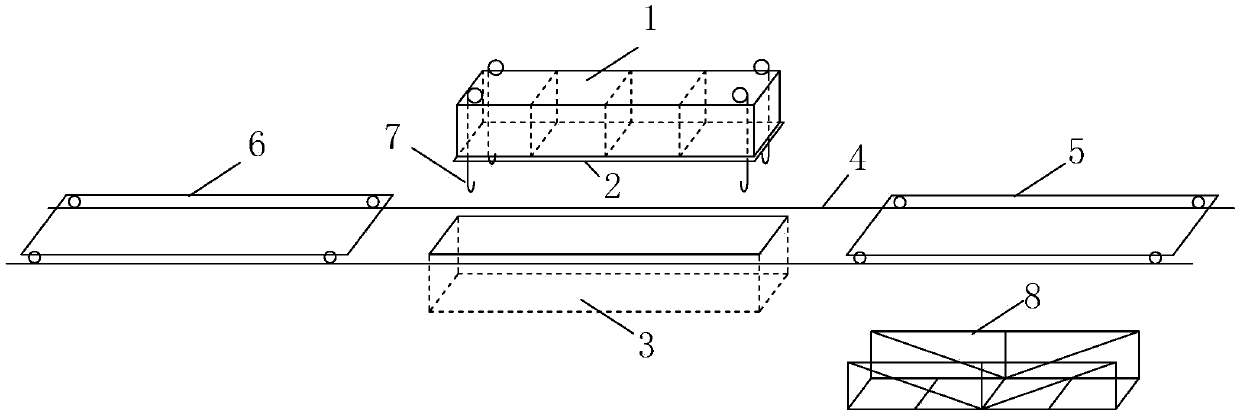

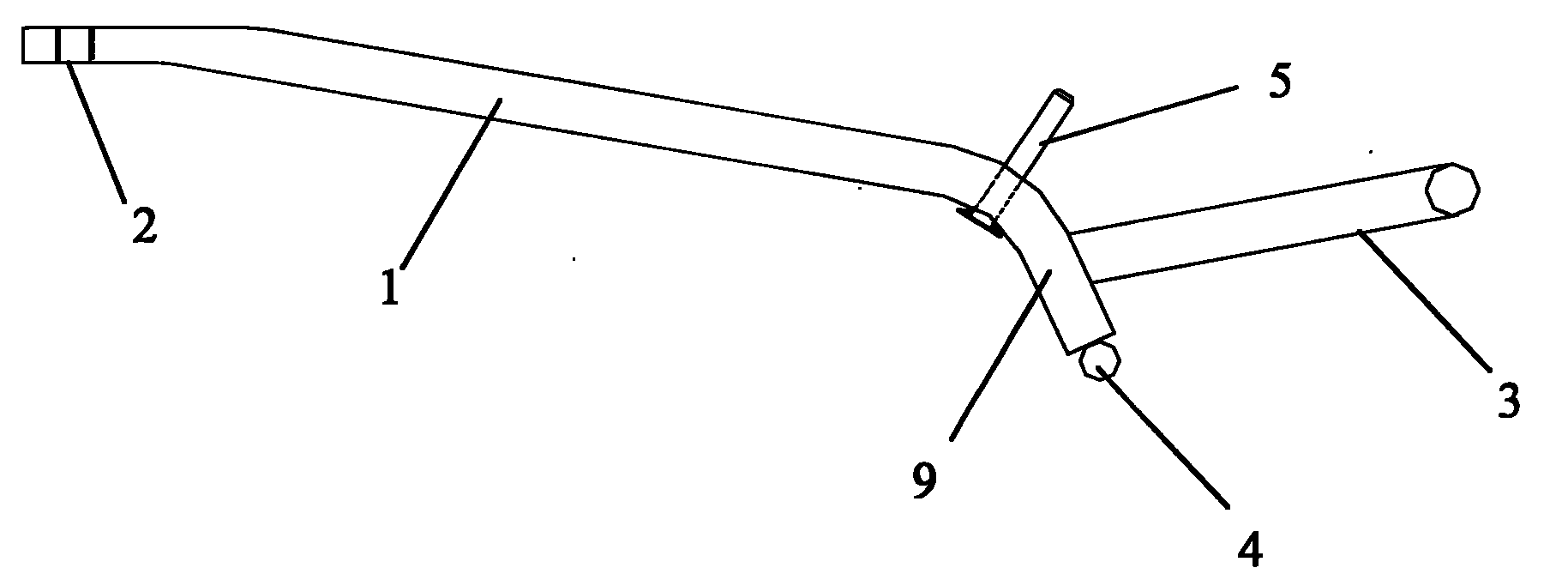

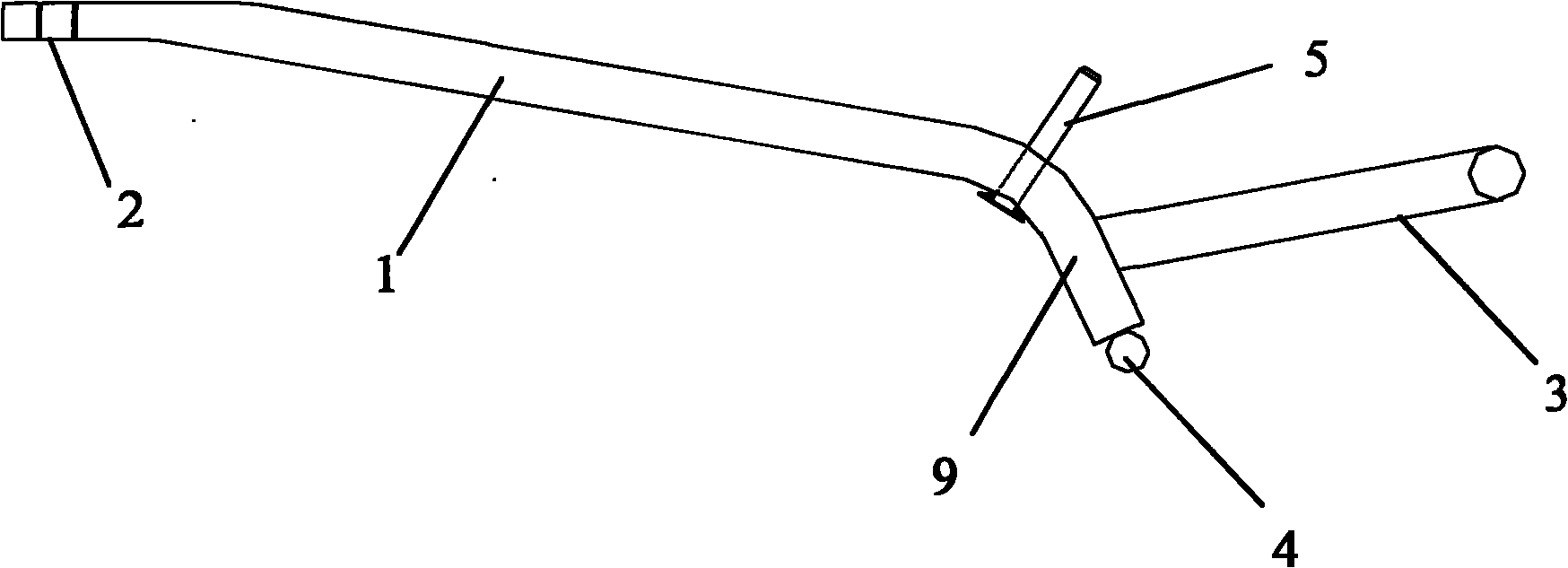

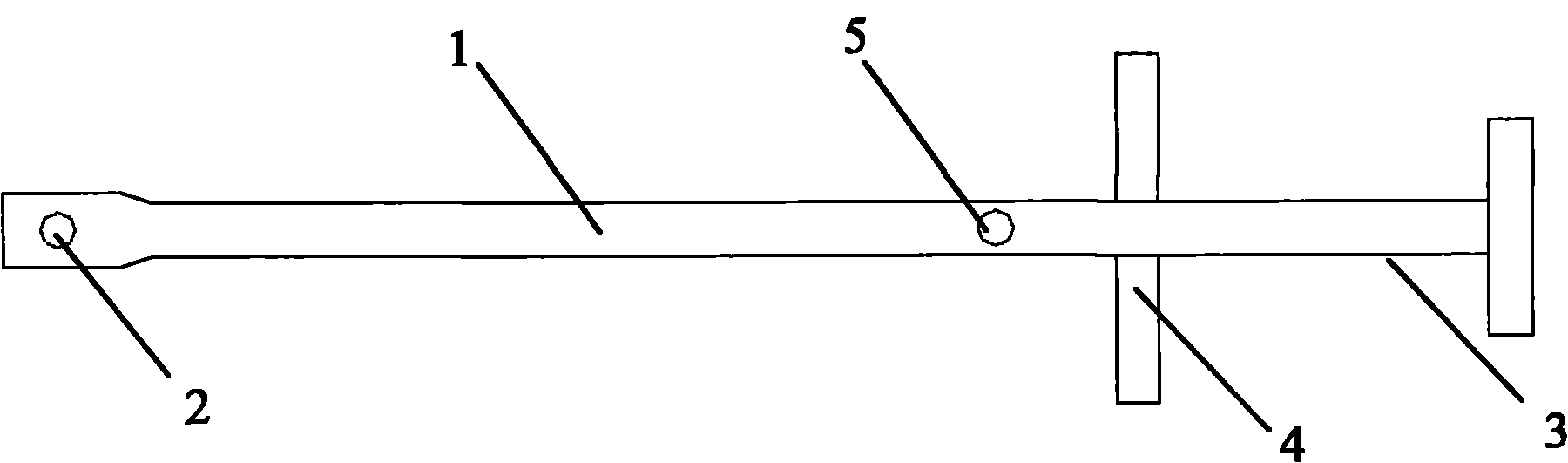

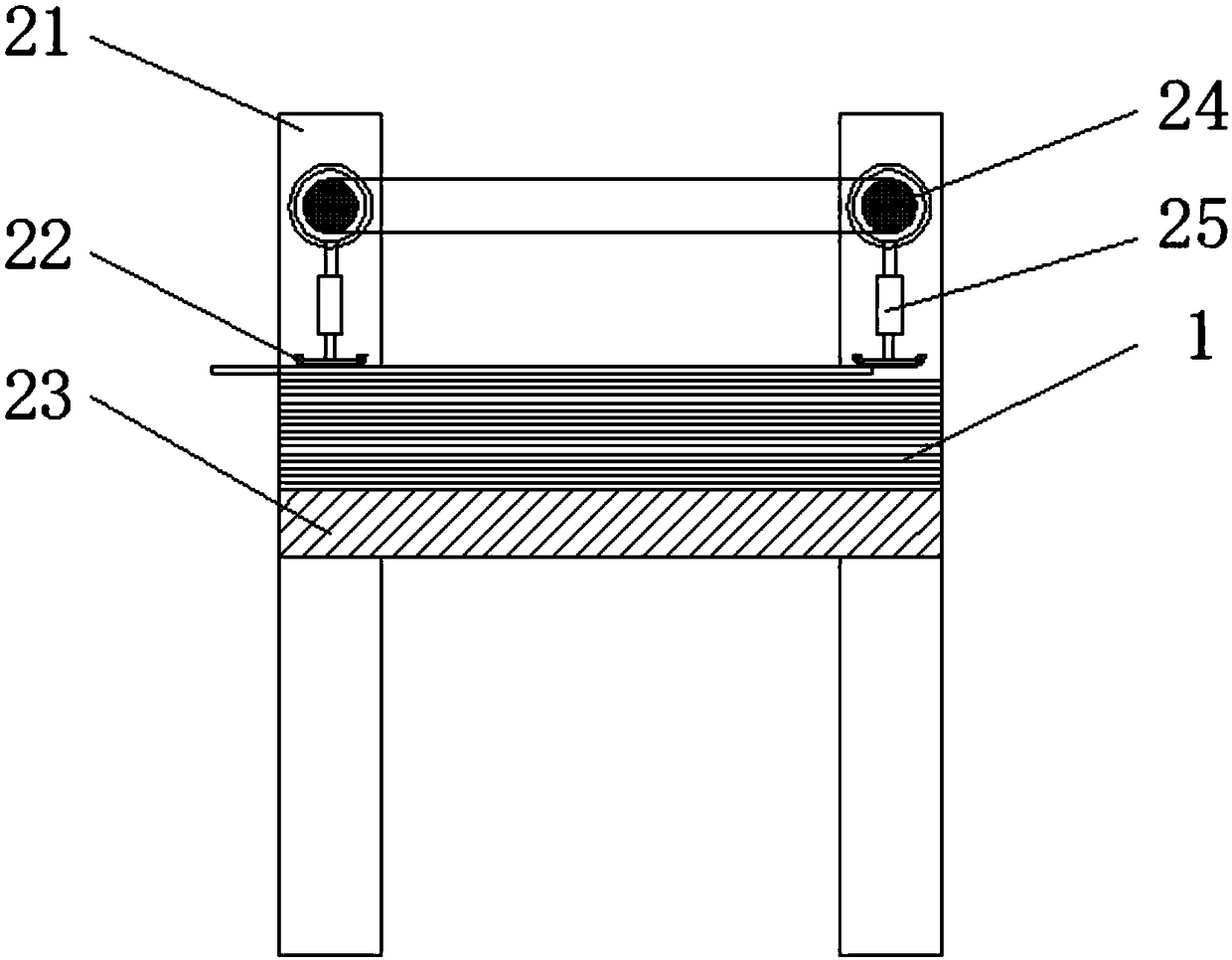

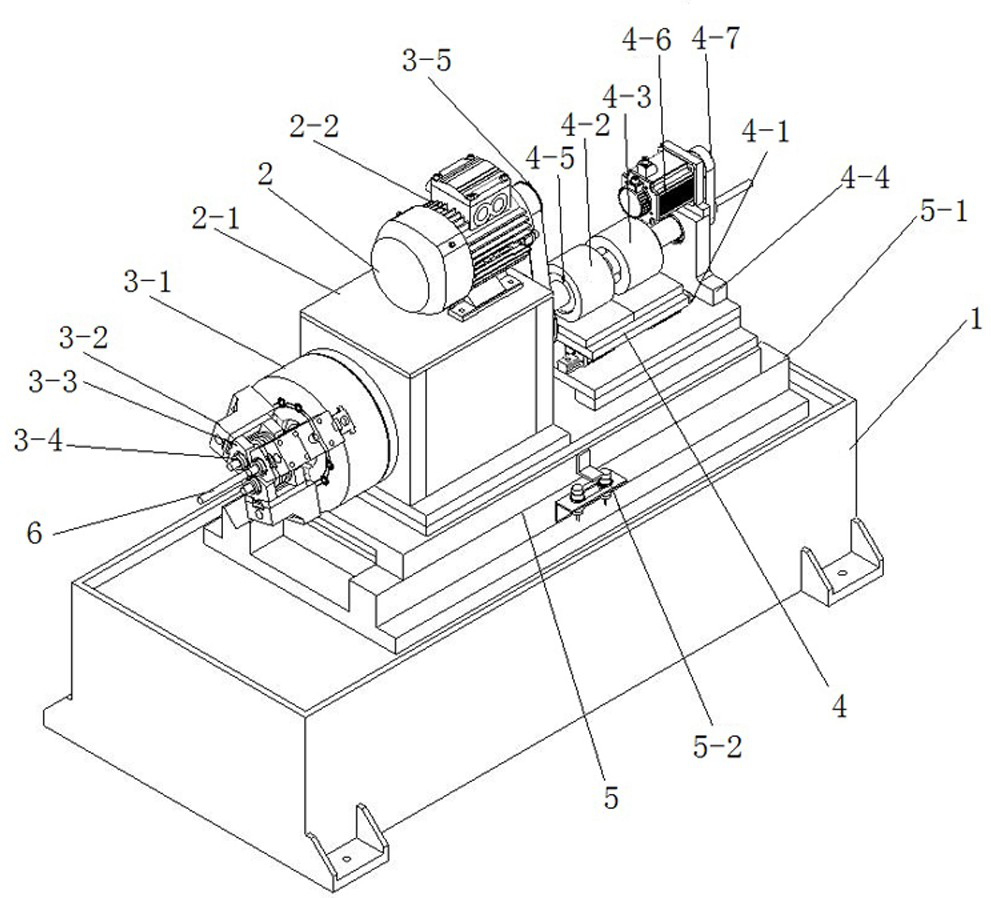

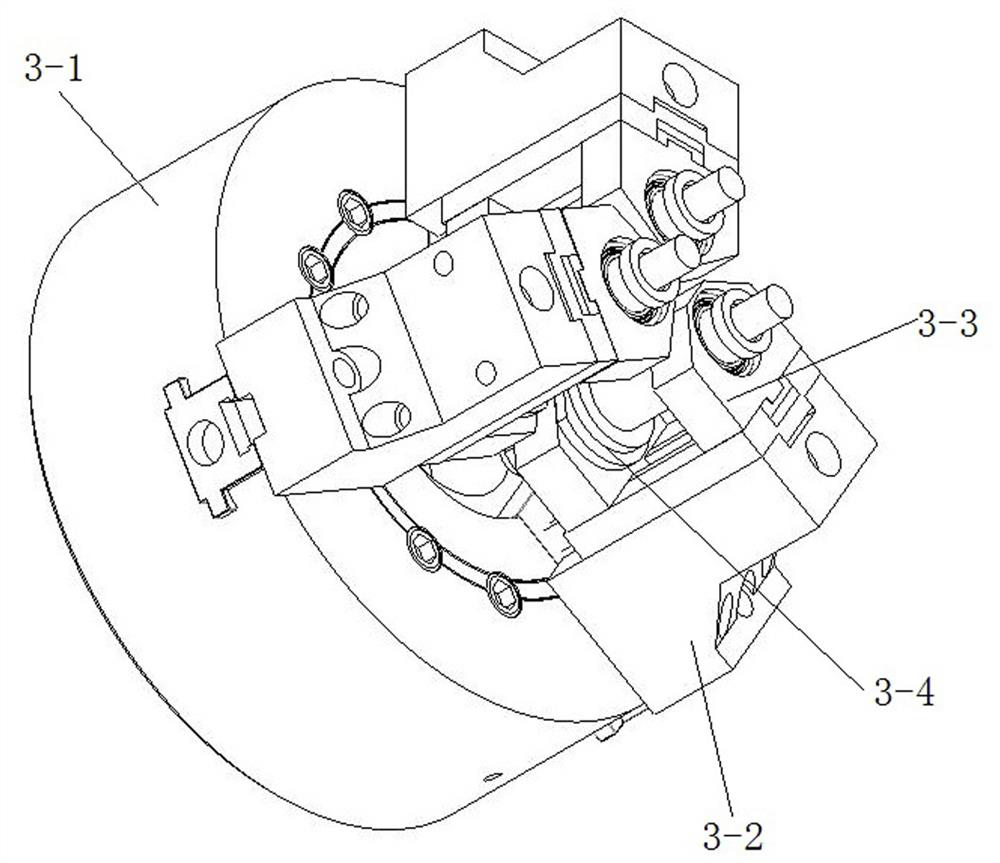

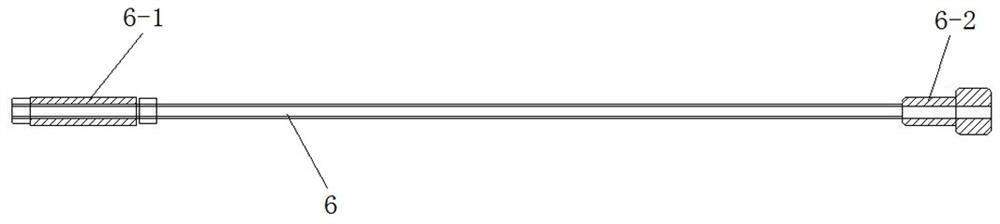

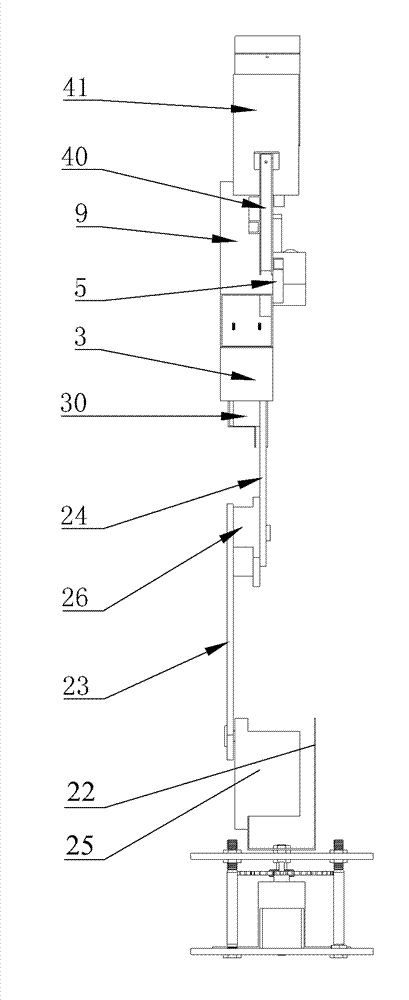

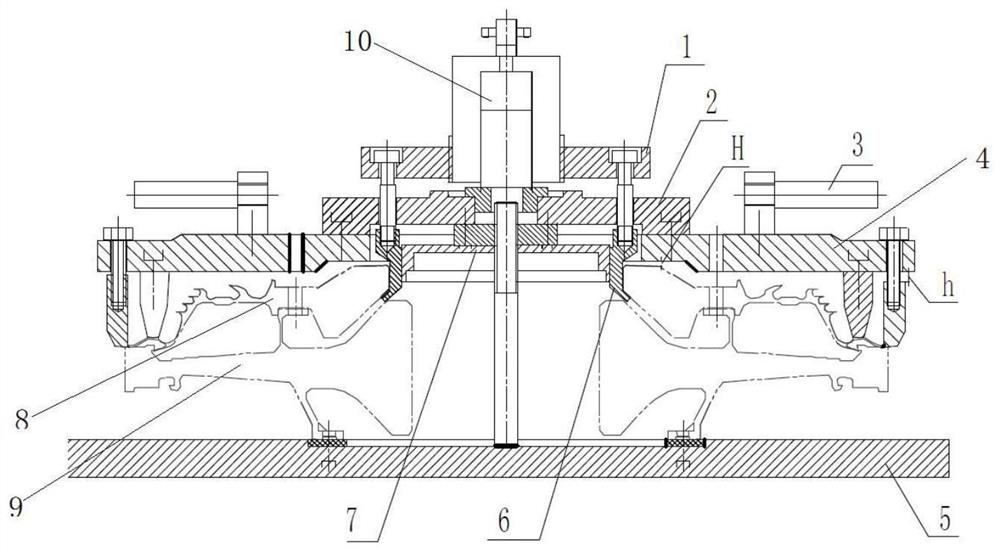

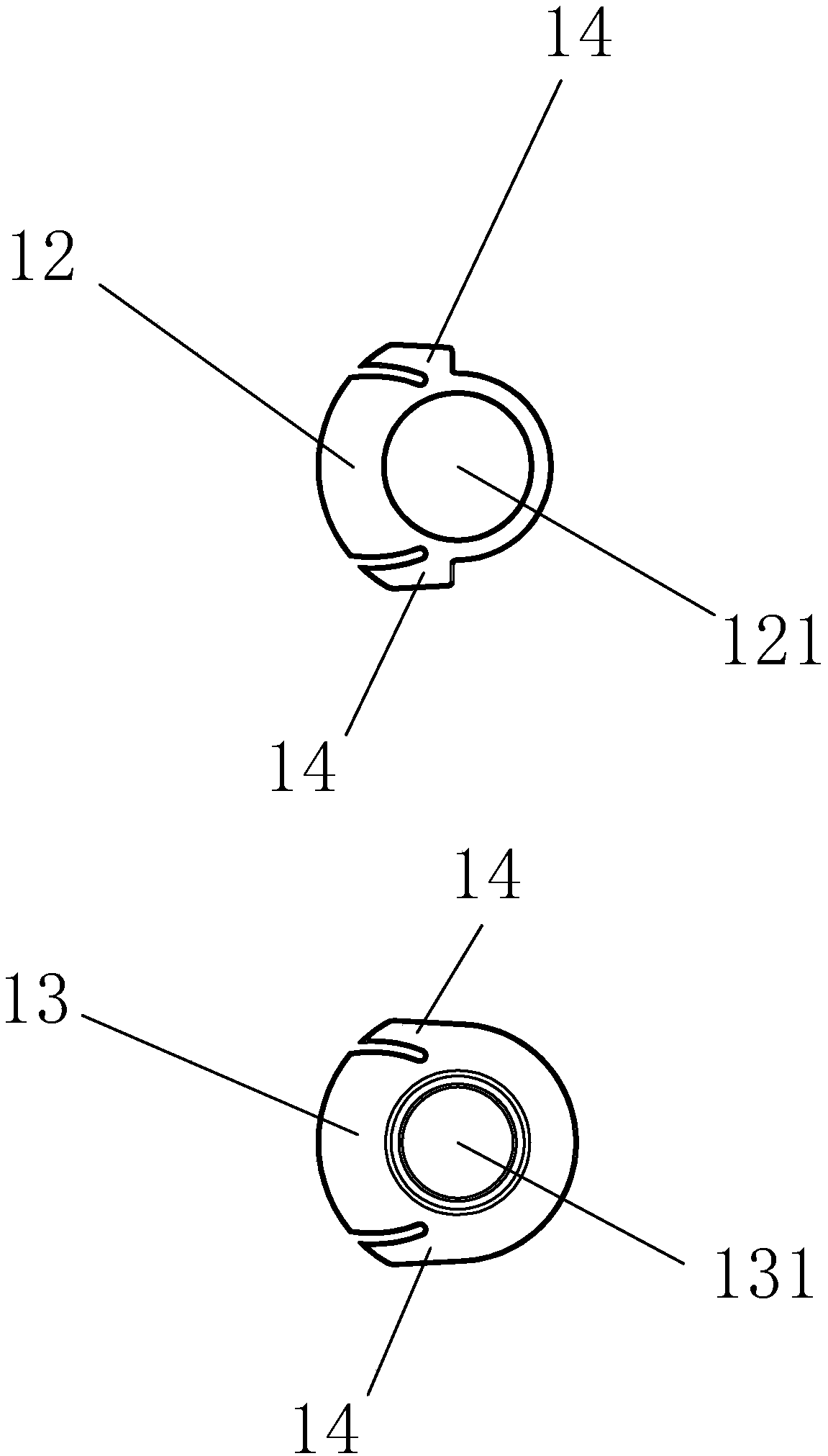

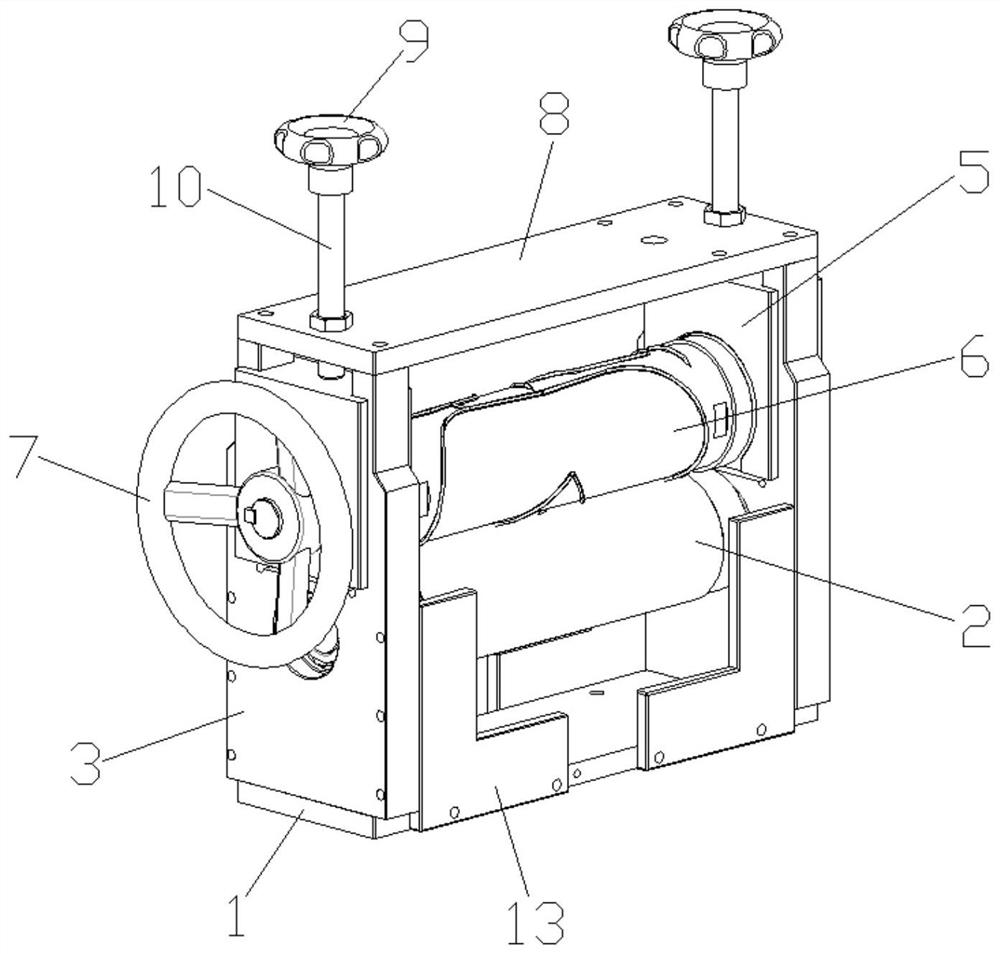

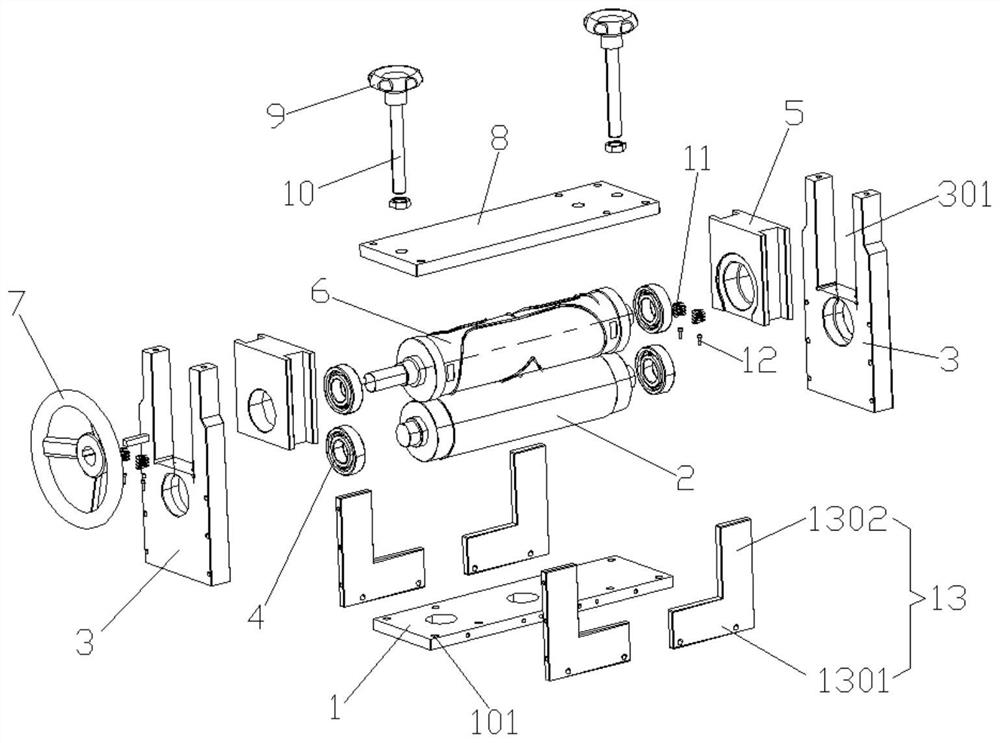

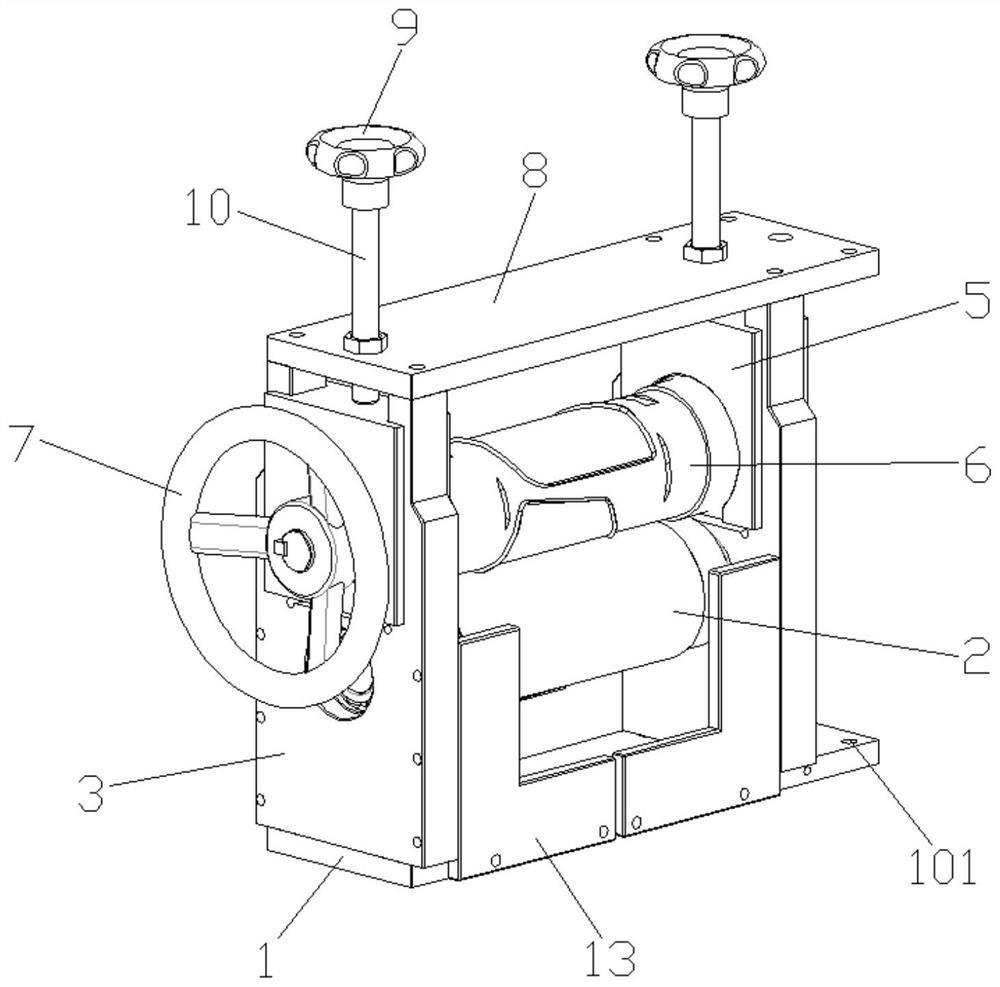

Vehicle-mounted LNG (liquefied natural gas) cylinder liner and outer cylinder sleeving device and method

InactiveCN103174931AGuaranteed verticalityNo bruisesContainer filling methodsPressure vesselsGas cylinderEngineering

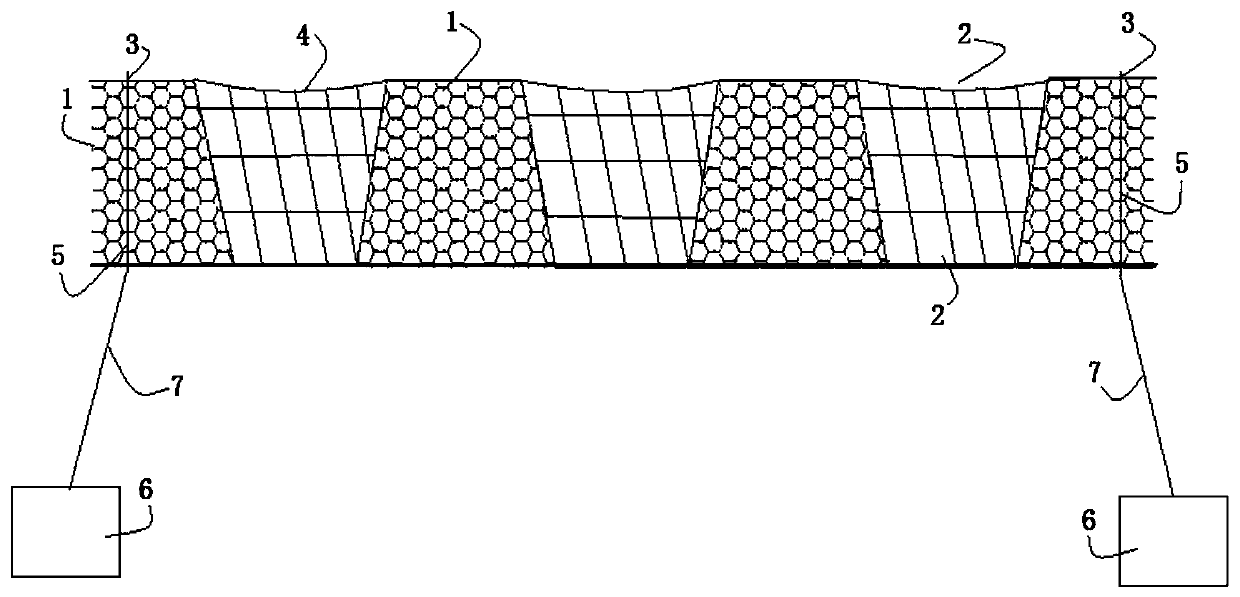

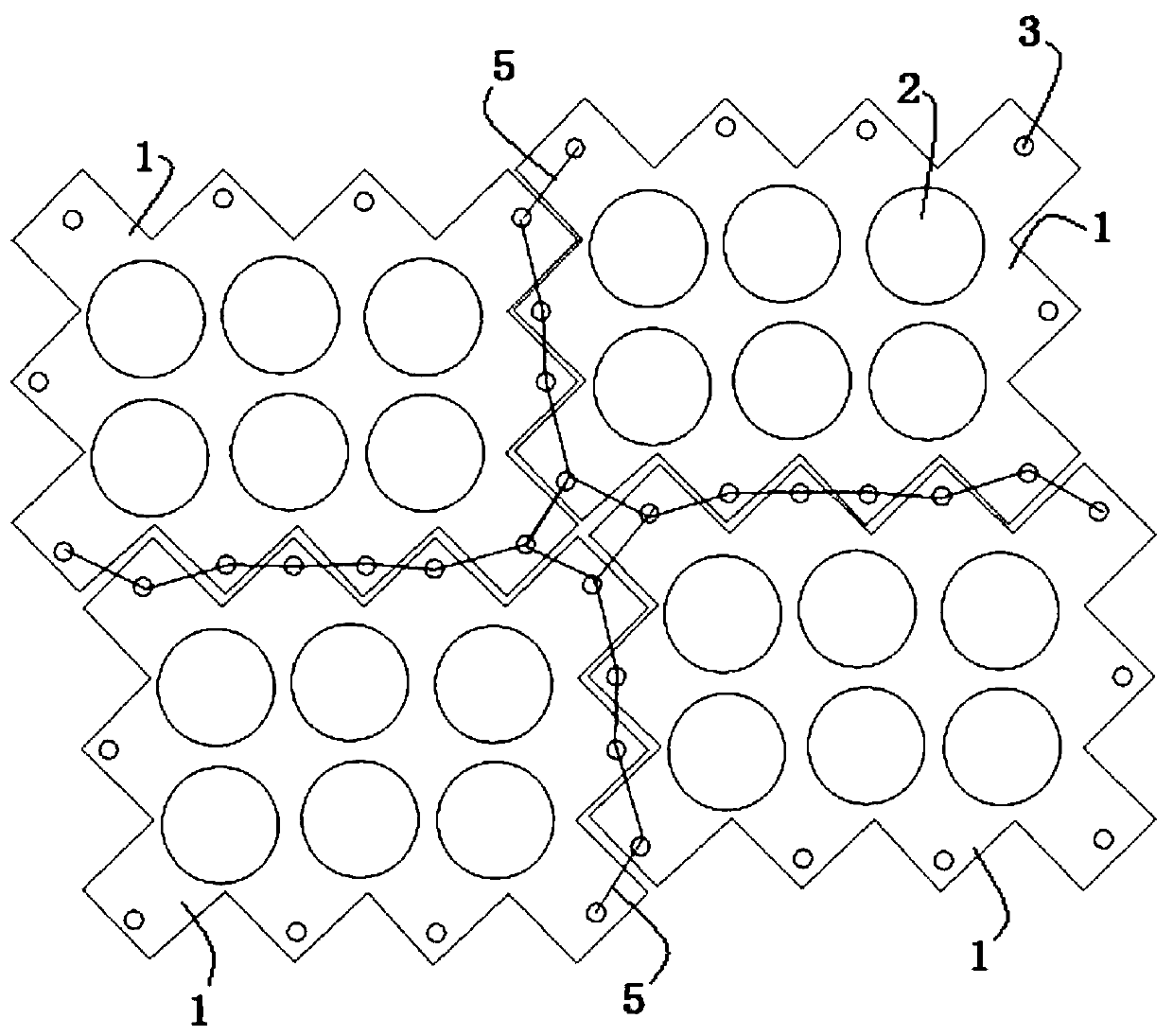

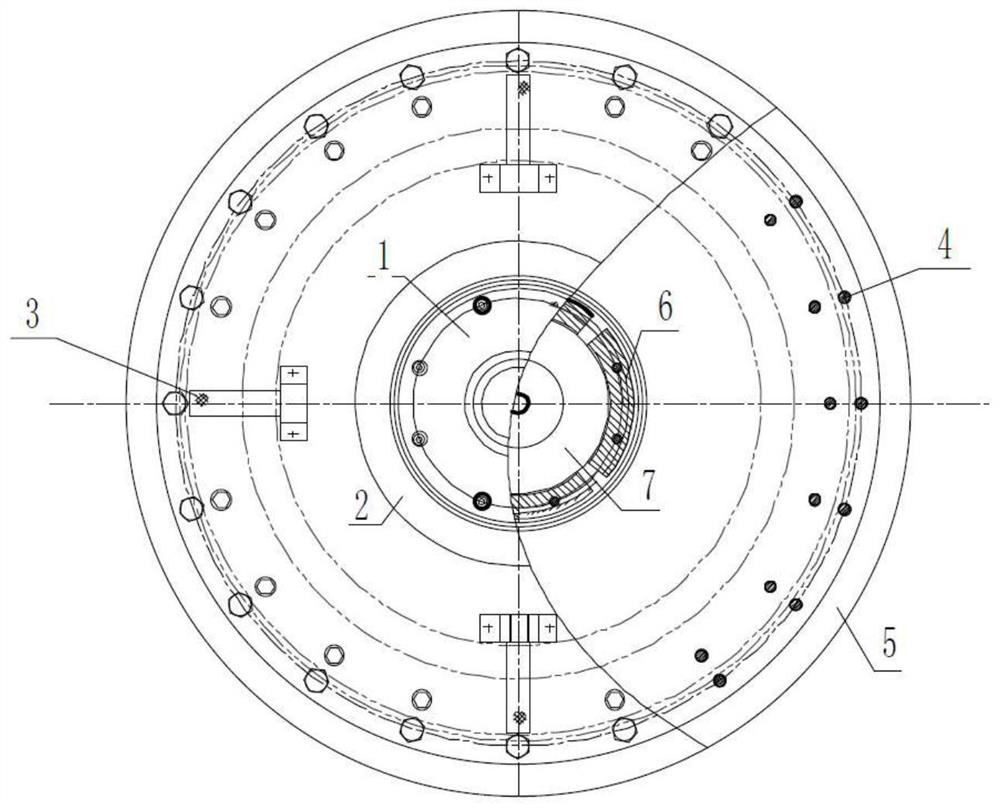

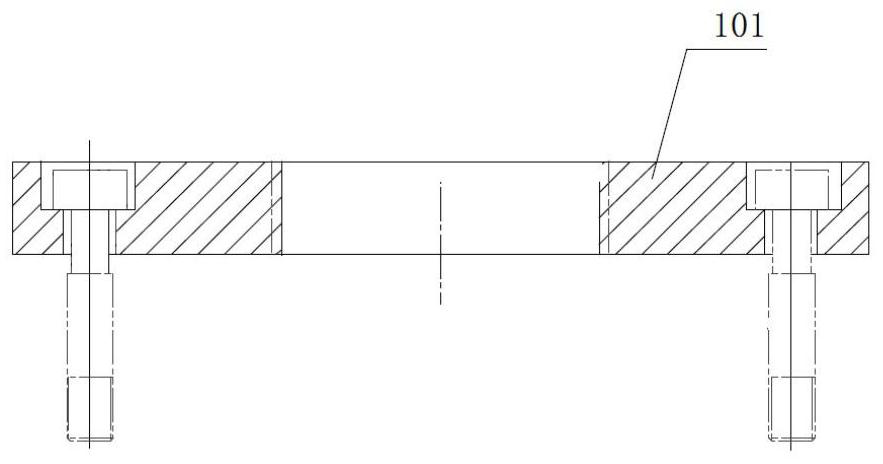

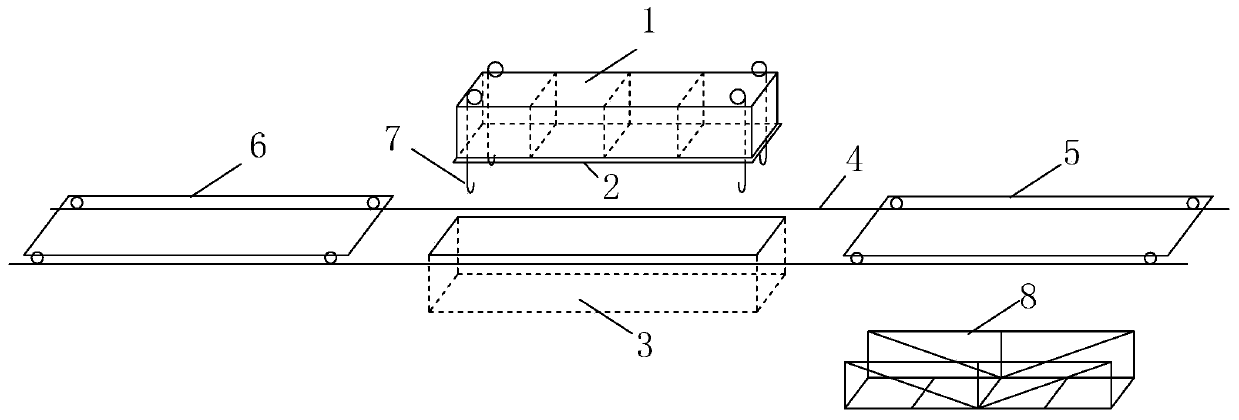

The invention discloses a vehicle-mounted LNG (liquefied natural gas) cylinder liner and outer cylinder sleeving device, which relates to the field of installation equipment and methods of vehicle-mounted gas cylinders. The vehicle-mounted LNG cylinder liner and outer cylinder sleeving device comprises a liner (1), a liner feeding device (2), an outer cylinder (3), an outer cylinder feeding device (4), an upper end socket (5), a lower end socket (6) and a clamping holding device (7), wherein the liner (1) is arranged on the liner feeding device (2), the outer cylinder (3) is arranged on the outer cylinder feeding device (4), and the clamping holding device (7) is used for clamping and holding the parts. The vehicle-mounted LNG cylinder liner and outer cylinder sleeving device is characterized in that a nylon material is embedded into the inner side of the clamping holding device (7), and the liner feeding device (2) and the outer cylinder feeding device (4) are respectively and additionally provided with two sets of semicircular guide post guide sleeves with wedged end surfaces. The vehicle-mounted LNG cylinder liner and outer cylinder sleeving device provided by the invention has the advantages that the perpendicularity of the liner can be guaranteed in the vertical hoisting of the liner under a self-supporting effect, and the sleeving is not damaged under a small gap between the liner and the outer cylinder.

Owner:XIANGTAN JIASHUN MACHINERY MFG

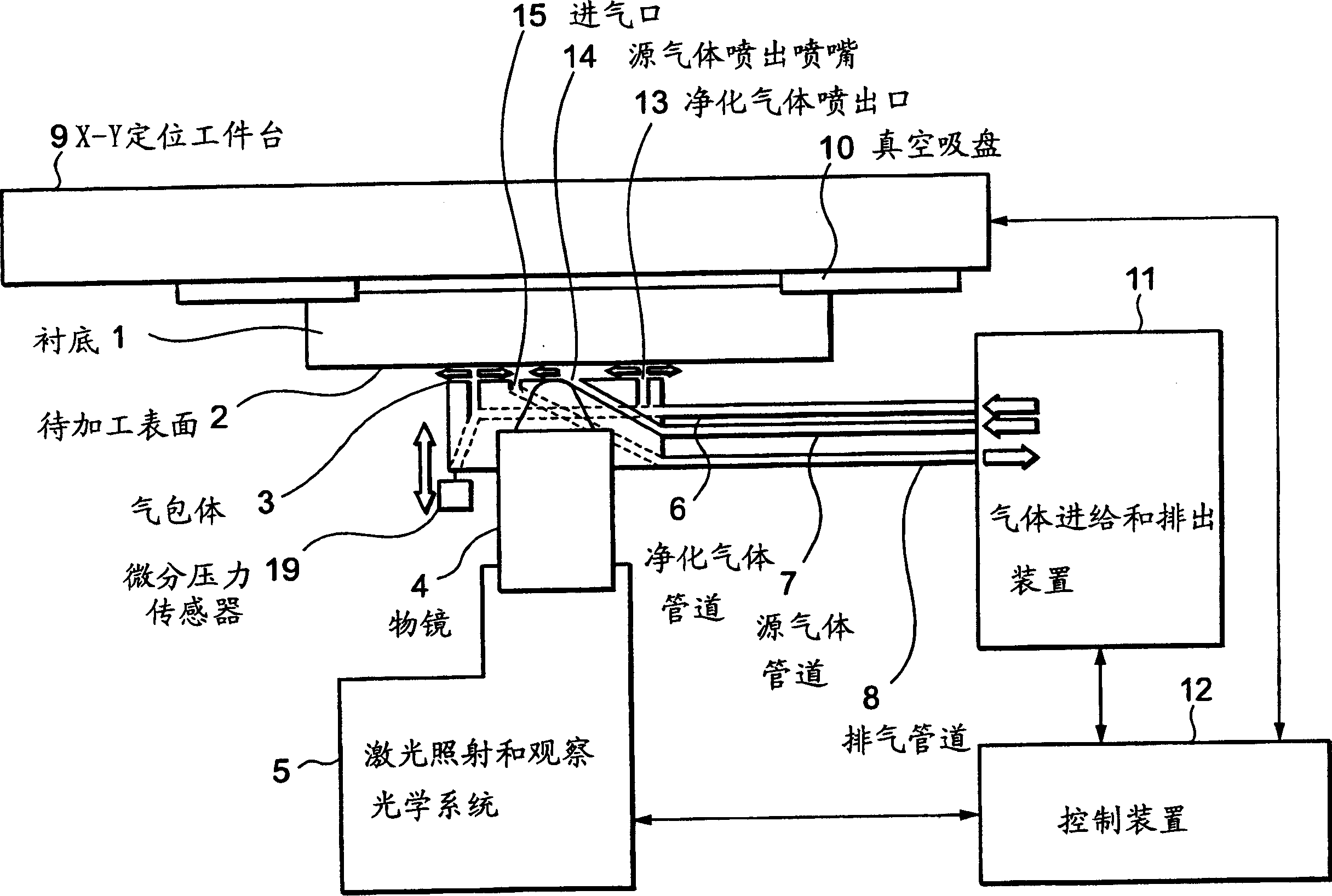

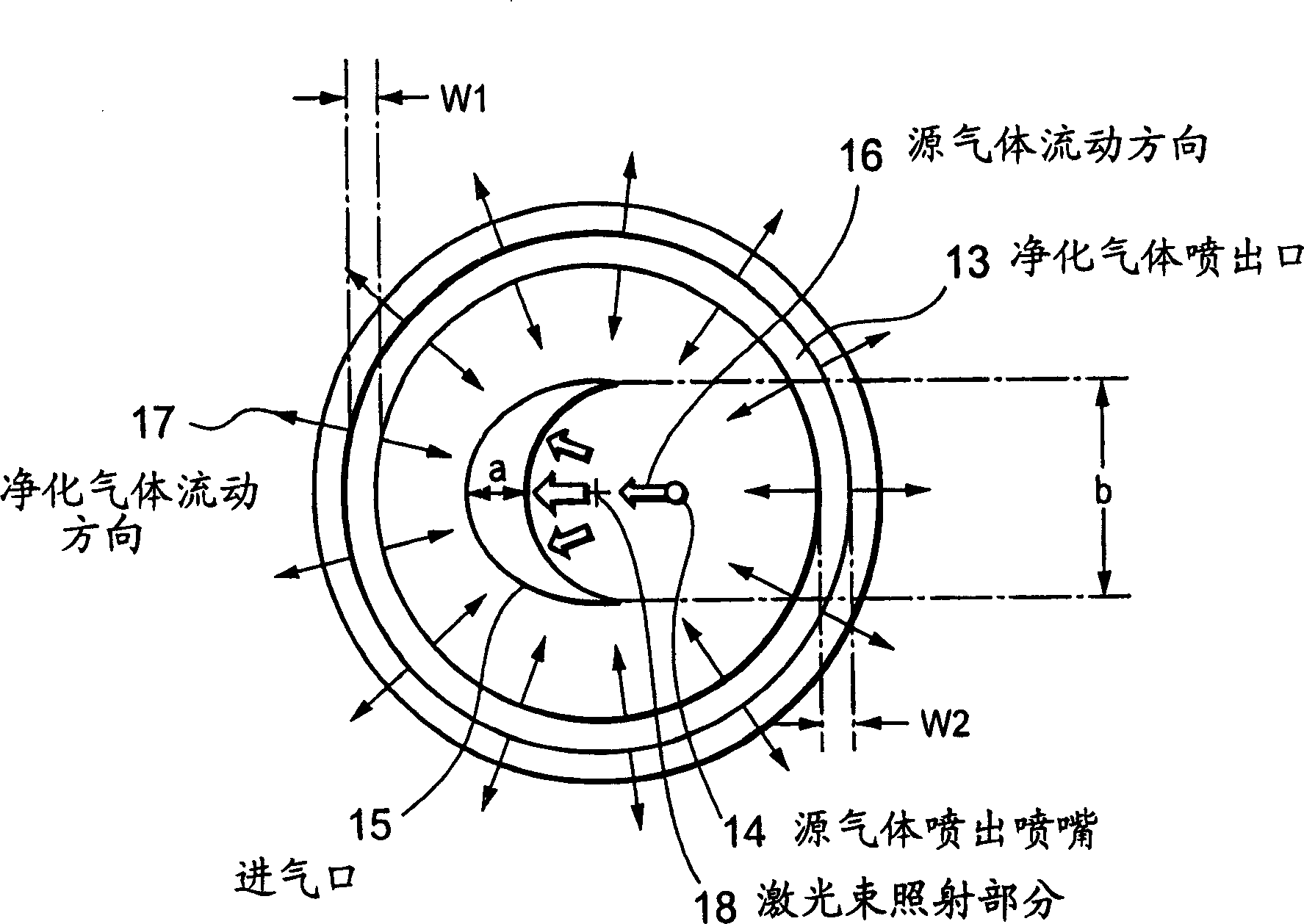

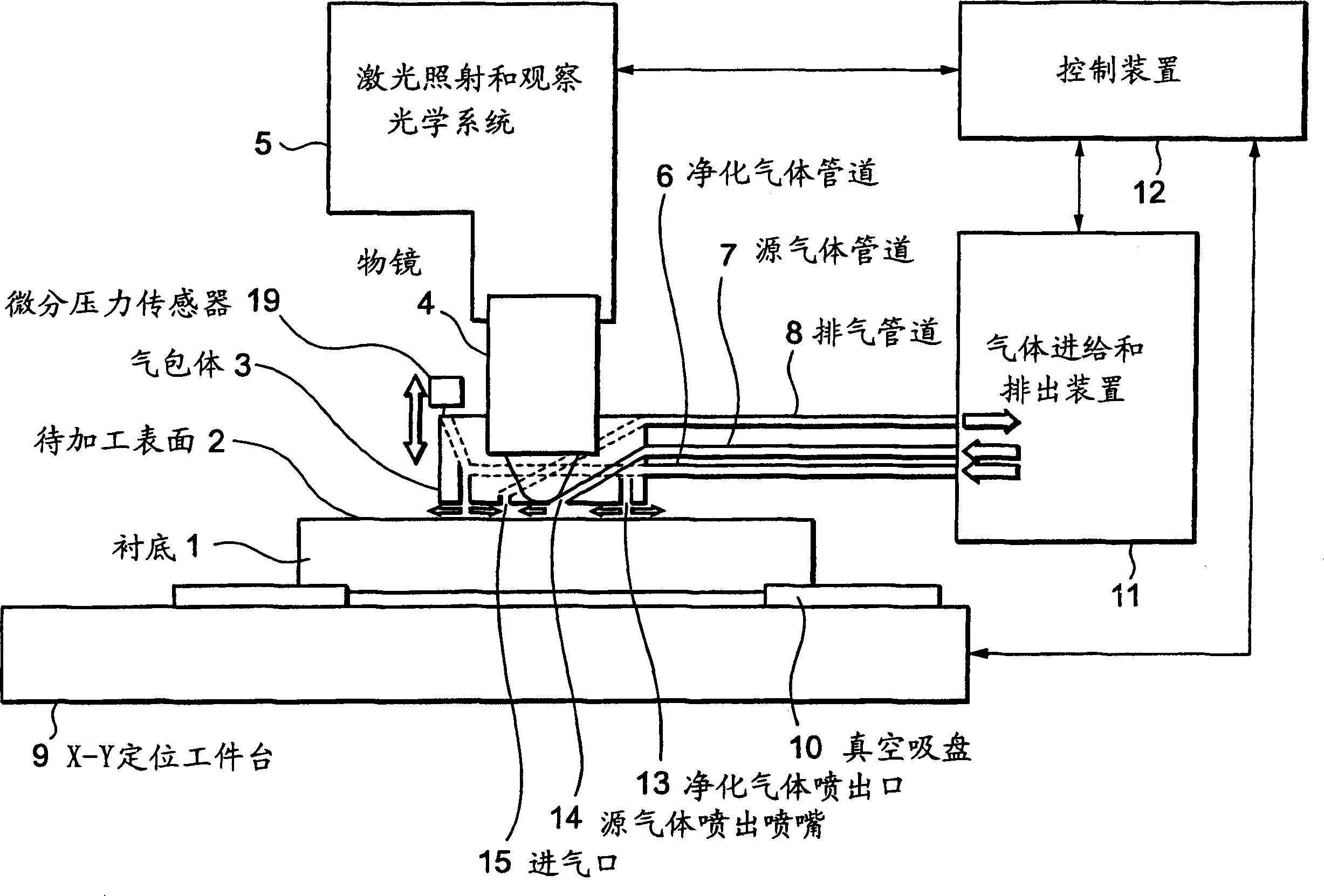

Laser processing method and equipment

InactiveCN1460892AAvoid damageImprove securitySemiconductor/solid-state device manufacturingOriginals for photomechanical treatmentLaser processingMachined surface

In a laser machining method for removing remaining defects on a photomask, there has been problems to be resolved that damage is formed at the portion of the substrate where the defect has been removed, thus resulting in degraded quality of machining. In a laser machining method for removing remaining defects on a photomask by a method of laser machining, the remaining defects are removed by using a configuration in which irradiation with a laser beam is performed from below with a to-be-machined surface directed downward, and irradiation with a laser beam in an atmosphere containing a halogenated hydrocarbon gas (as an example, ethyl iodide).

Owner:V TECH CO LTD

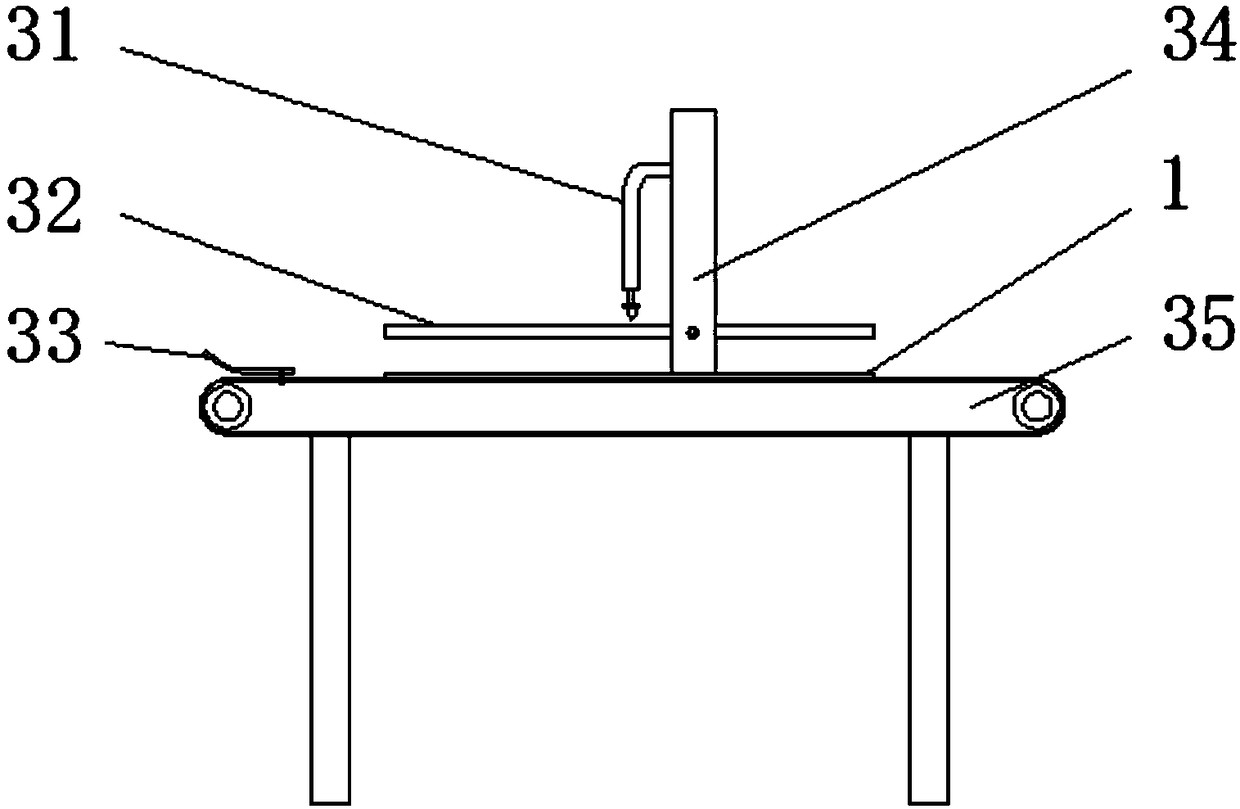

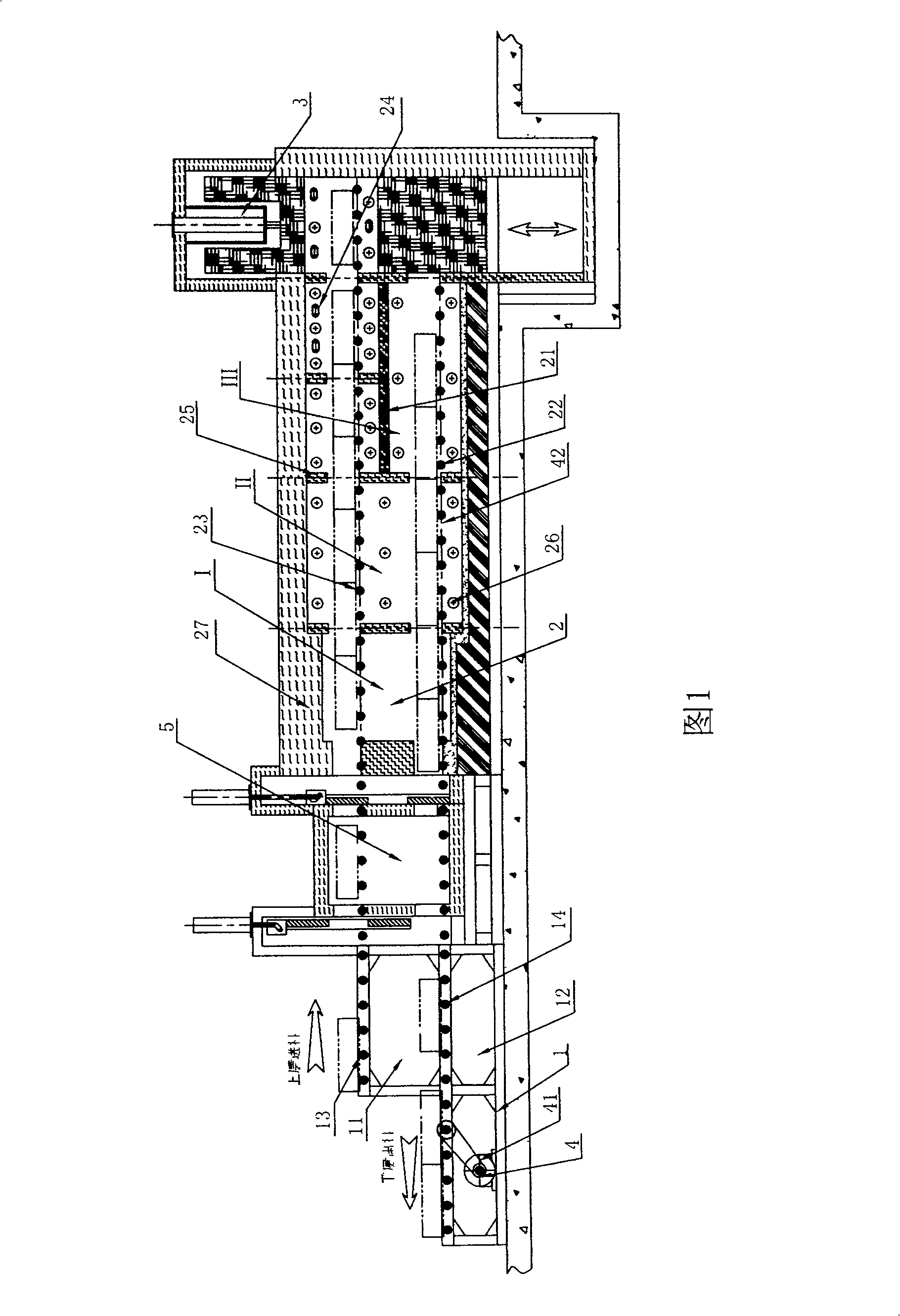

Multi-station spraying cleaning and drying machine

InactiveCN106429410AImprove cleaning and drying efficiencyGood cleaning and drying efficiencyDrying solid materials without heatCleaning using liquidsEngineeringCleaning station

The invention relates to industrial cleaning equipment, in particular to a multi-station spraying cleaning and drying machine. The multi-station spraying cleaning and drying machine comprises a cleaning station arranged on a rack worktable. The cleaning station comprises a fixed-point positioning spraying cleaning cavity, a rotary spraying rinsing wind shear cavity and a vacuum drying cavity, wherein the fixed-point positioning spraying cleaning cavity, the rotary spraying rinsing wind shear cavity and the vacuum drying cavity are arranged in a simultaneous vertical opening or closing manner. A mechanical arm is arranged at the position, corresponds to the cleaning station, of the front portion of the rack worktable. The mechanical arm is used for simultaneously carrying workpieces in a feeding position, the fixed-point positioning spraying cleaning cavity and the rotary spraying rinsing wind shear cavity to the next corresponding station. A vacuum pump, a rinsing liquid storage box, a cleaning liquid storage box, a spraying pump and a pressure tank are arranged at the rear portion of the rack worktable. The cleaning liquid storage box is connected with a first spraying pipeline in the spraying cleaning cavity through the spraying pump. According to the cleaning and drying machine, space can be effectively saved, the problems about cleaning, rinsing, drying and the like are solved in the limited space, and high-efficiency cleaning is achieved.

Owner:无锡新弘田环保技术有限公司

Use of plastic to produce automobile brake main cylinder piston and process

InactiveCN1425546ADimensionally stableNo bruisesPlungersTrunk pistonsManufacturing technologyMaster cylinder

The present invention relates to automobile manufacture technology. Plastic, preferably BPTP, is used in manufacturing piston of main automobile brake cylinder, and the manufacture process includes mixing material, stoving injecting in injecting machine andfinal water setting. The present invention has the advantages of high material utilization, simple technological process, high product quality, light weight and prolonged service life of brake cylinder.

Owner:玉环市金峰实业有限公司

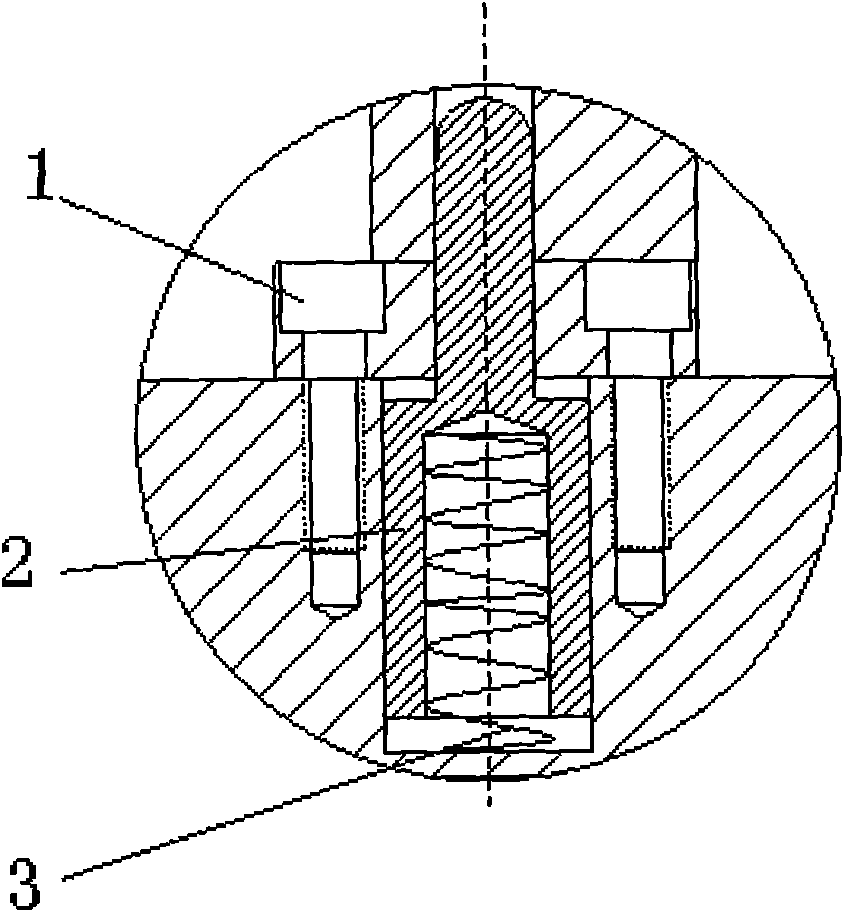

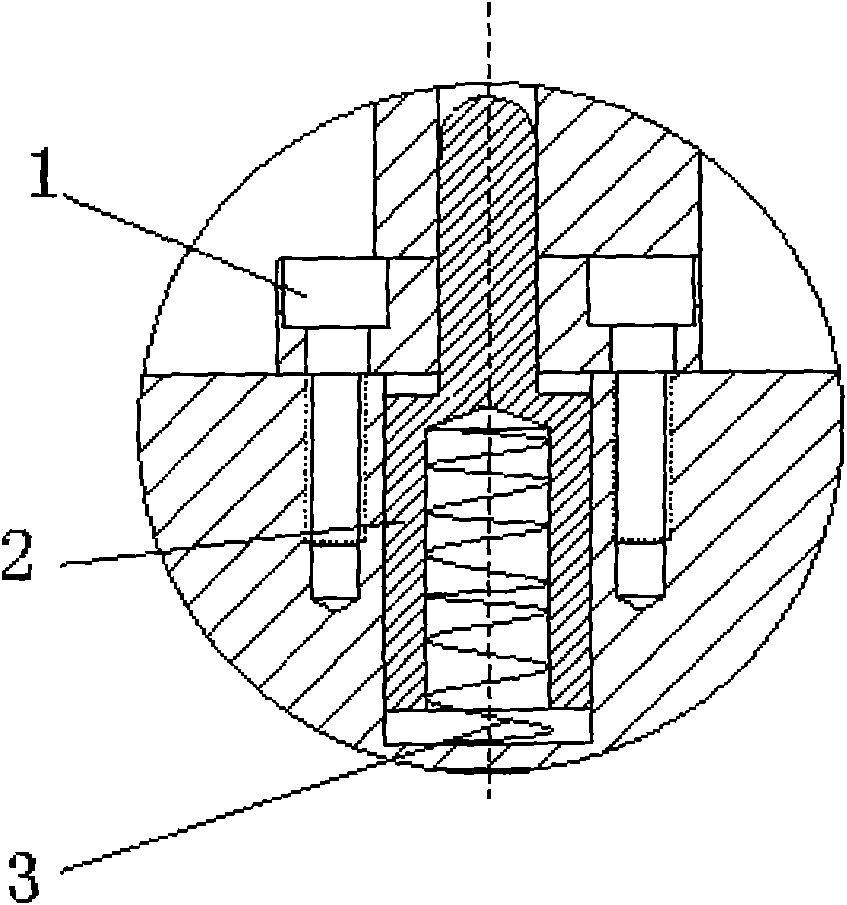

Floating pin positioning device for use in product processing

InactiveCN101885149AExtensive Process Improvement MeasuresGood value for moneyPositioning apparatusMetal-working holdersState of artSize change

The invention relates to a floating pin positioning device for use in product processing, which comprises a gland, a positioning pin, a spring and a processing fixture basic hole. The gland is arranged on two shoulders of the positioning pin; the spring is arranged in the positioning pin; and the positioning pin is arranged in the processing fixture basic hole. Compared with the prior art, the floating pin positioning device for use product processing has the advantages of wide application range, flexibility, high cost performance, convenient and quick maintenance, convenient and quick clamping for a product, automatic correction, eliminating the influence of the size changes (moderate) of a blank on the size after the product is processed, and the like.

Owner:SHANGHAI CENSI AUTOMOBILE PARTS

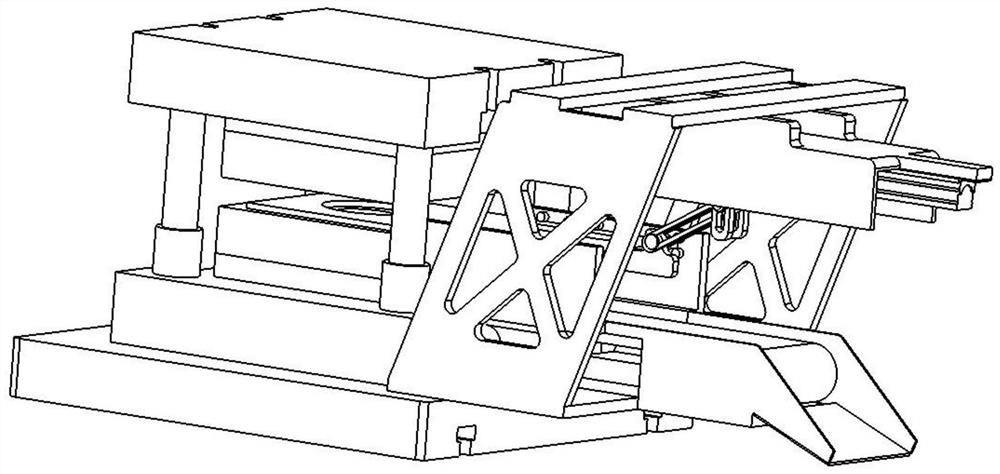

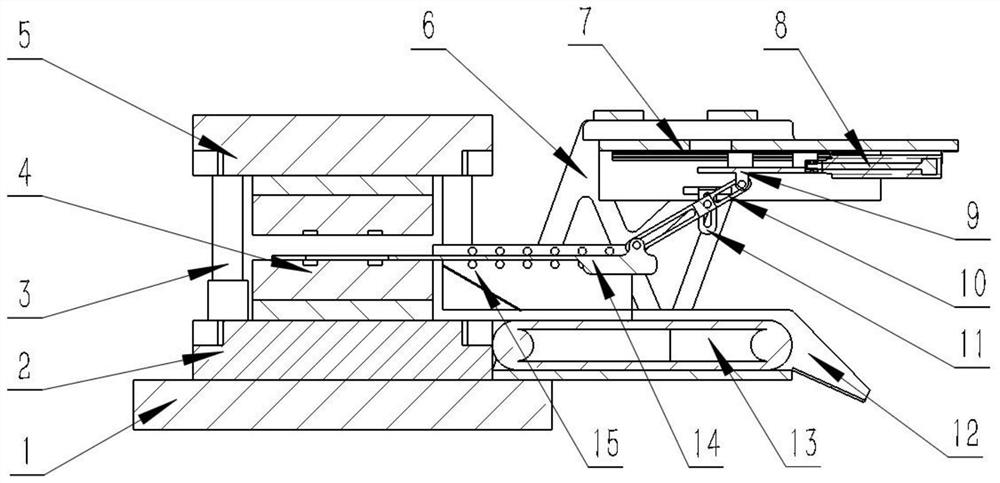

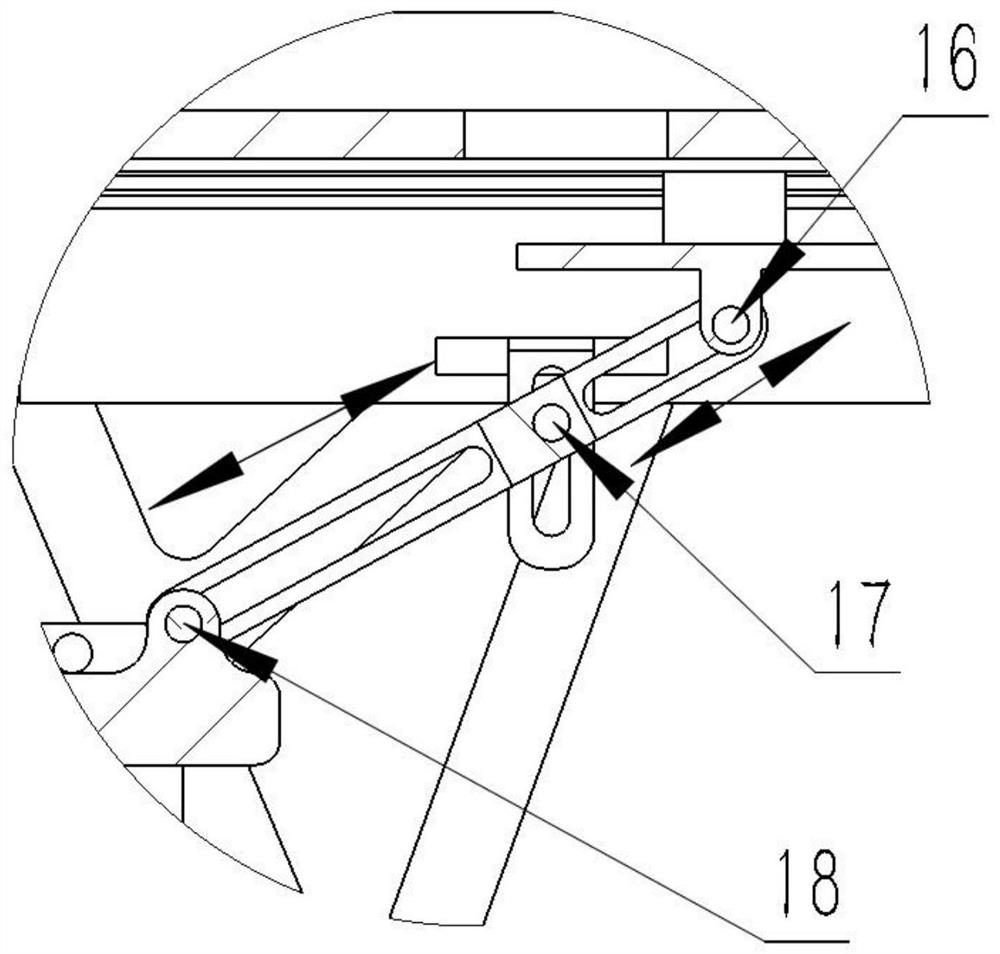

Thermal treatment device and thermal treatment technology of ultra-long aluminum extrusion

ActiveCN109536683AAchieving solution quenchingAchieve annealingFurnace typesHeat treatment furnacesMaterials processingHeating furnace

The invention discloses a thermal treatment device and a thermal treatment technology of an ultra-long aluminum extrusion, and belongs to the technical field of material processing. The thermal treatment device comprises a heating furnace, a quenching water well, a feeding and discharge rail, a feeding trolley, a discharge trolley, a lifting device and a material basket, wherein a furnace body isan ultra-long horizontal furnace composed of a plurality of regions of which the temperature is independently controlled; and a product is horizontally stacked in the material basket, and enters the furnace body or the quenching water well through the feeding trolley, the discharge trolley and the lifting device to be subjected to thermal treatment. According to the thermal treatment device and the thermal treatment technology, horizontal furnace horizontal heating and inclined descend soaking quenching technologies are adopted to replace traditional vertical quenching and roller hearth type quenching technologies, the quenching cooling speed is high and uniform, quenching deformation of the product is low, surface quality is good, and performance is uniform; solid-solution quenching, annealing and ageing functions can be achieved, production scheduling is flexible, length of a biggest product of thermal treatment is large, charge batch is large, production efficiency and heat utilization rate are high, and operation is safe and reliable; and besides, deep well, heat-resistant roller, spraying devices, and the like are not required, basic requirements on equipment are low, and investment is low.

Owner:广西百矿冶金技术研究有限公司

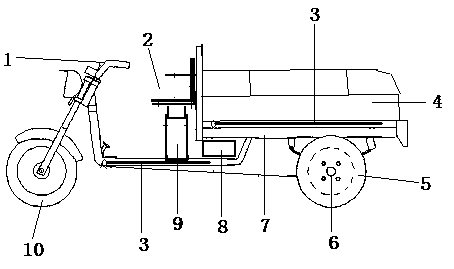

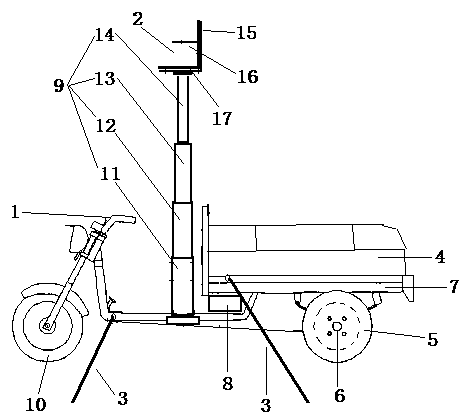

Special electric tricycle for fruit industry

The invention discloses a special electric tricycle for the fruit industry. The special electric tricycle comprises a tricycle frame, a handlebar rotationally connected to the front end of the tricycle frame, a front wheel arranged at the lower end of the handlebar, a transmission shaft arranged at the lower portion of the rear end of the tricycle frame, two rear wheels arranged at the two ends ofthe transmission shaft, a motor in transmission connection with the transmission shaft, a controller electrically connected with the motor, a storage battery electrically connected with the controller, a carriage arranged at the upper portion of the rear end of the tricycle frame, a saddle arranged at the upper portion of the middle portion of the tricycle frame and an electric spraying device, wherein the saddle is an electric lifting saddle, the lifting height of the electric lifting saddle enables a fruit farmer sitting on the saddle to pick fruits on fruit trees, the tricycle is safe andcapable of saving labor and time, and the picked fruits are not damaged; the electric spraying device can spray pesticide on the fruit trees, so that a pesticide cylinder does not need to be carried on the back, and the labor intensity of the fruit farmer is greatly reduced.

Owner:任磊

Auxiliary paint spraying device for front cover of sedan

ActiveCN101811112ASimple structureEasy to operateLiquid surface applicatorsSpraying apparatusEngineeringFront cover

The invention aims to provide an auxiliary paint spraying device for a front cover of a sedan, which can lighten the labor intensity of operators and prevent the paint on the inner surface of the front cover from being bumped so as to improve the production efficiency and paint spraying quality and reduce the production cost. The device comprises a main rod, the front end of the main rod is provided with a fixed part matched with a circular hole at the rear end of the front cover of the sedan, the rear part of the main rod is provided with a handle extending backwards, and the rear end of the main rod is downwards bent to form a support part. During use, the auxiliary paint spraying device for the front cover of the sedan can be fixed with the front cover of the body, and then the front cover of the body is easily lifted by using the handle to spray paint; and after the paint spraying is finished, the front cover of the body is suspended above a front bumper beam of the sedan by using the support part of the auxiliary paint spraying device for the front cover of the sedan so as to avoid paint bumping caused by the contact between the inner surface of the front cover of the body and the front bumper beam. The auxiliary paint spraying device for the front cover of the sedan has the advantages of greatly reducing the labor intensity of workers, improving the production efficiency and paint spraying quality, saving the production cost, along with simple structure and convenient operation.

Owner:CHERY COMML VEHICLE ANHUI

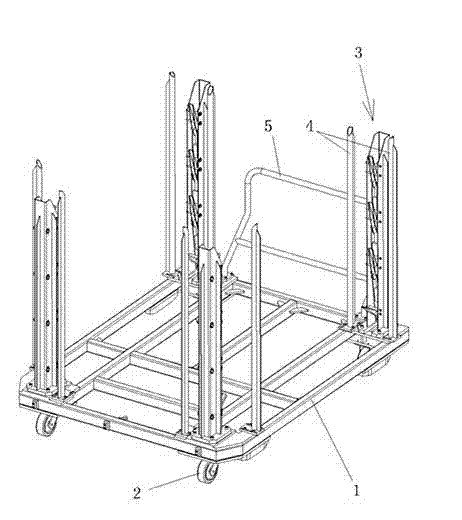

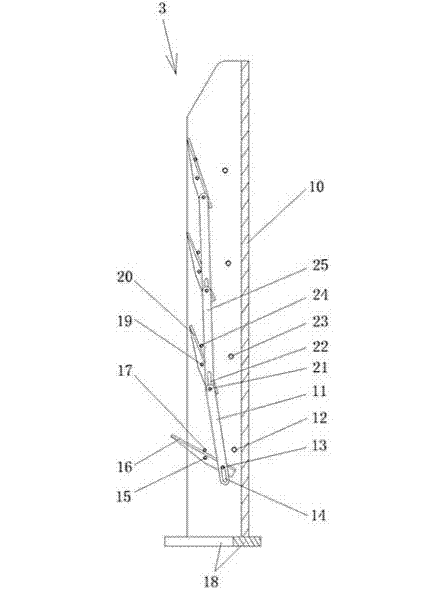

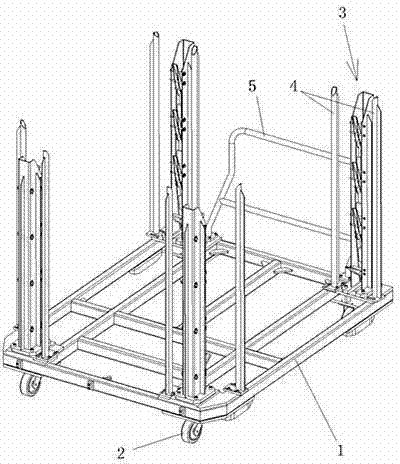

Feeding carriage capable of holding multi-layer workpieces

InactiveCN102514816AEffective protectionNo collisionPackaging vehiclesContainers for machinesVehicle frameEngineering

A feeding carriage capable of holding multi-layer workpieces is characterized in that trundles are arranged below a frame, vertical link workpiece releasing mechanisms are arranged at four corners above the frame, each link workpiece releasing mechanism comprises a support, a first workpiece supporting plate is connected to the lower portion of each support through a first workpiece supporting plate shaft, a first upper limiting shaft is arranged on each support and positioned in front of a position above the first workpiece supporting plate shaft, a first lower limiting shaft is arranged on each support and positioned behind a position above the first workpiece supporting plate shaft, a first link slot hole is arranged at the lower end of a first link, the first link is connected with the first workpiece supporting plate through a first link pin shaft and the first link slot hole, and at least two groups of workpiece supporting plate structures are sequentially arranged on each support from bottom to top. By the aid of the feeding carriage, the multi-layer workpieces can be conveyed simultaneously without contact and collision.

Owner:大连奥托股份有限公司

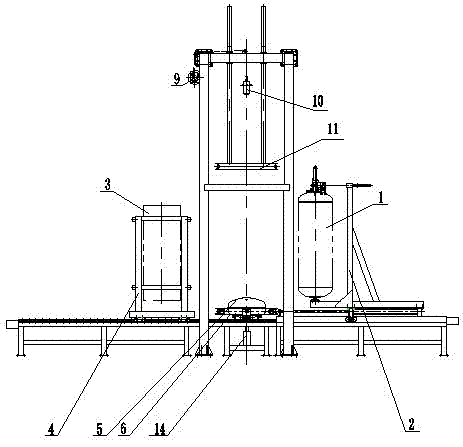

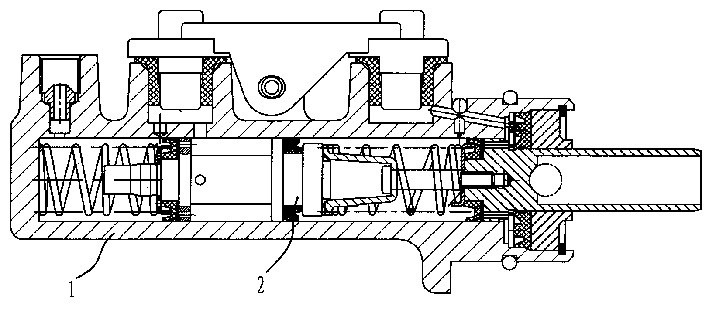

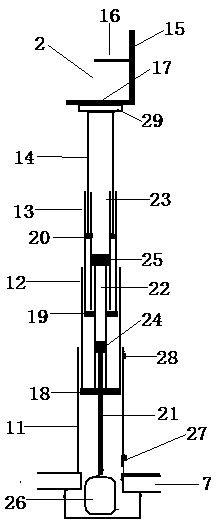

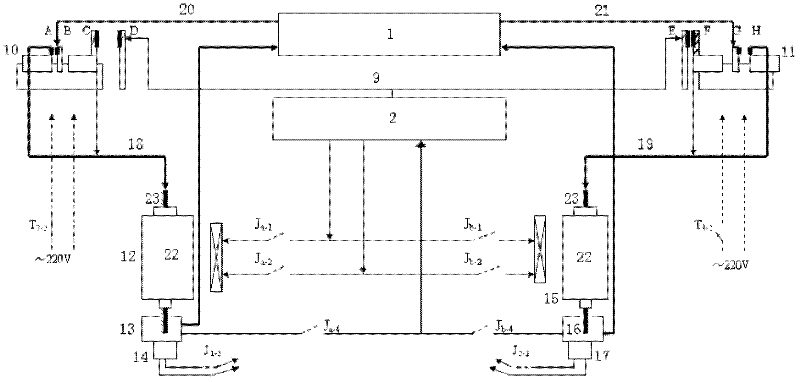

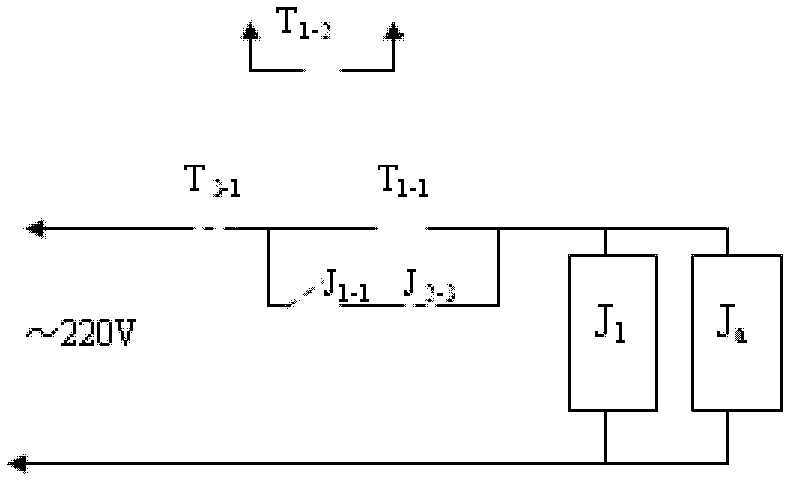

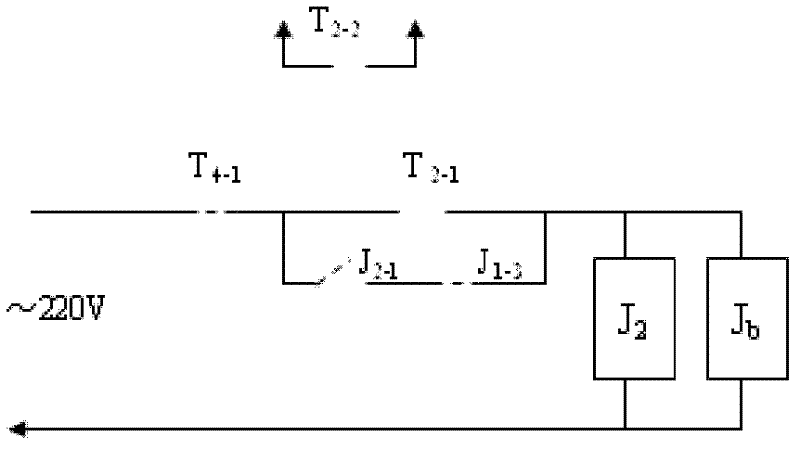

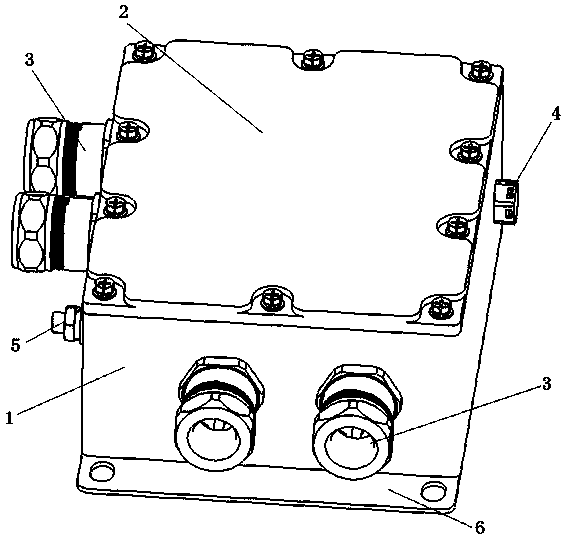

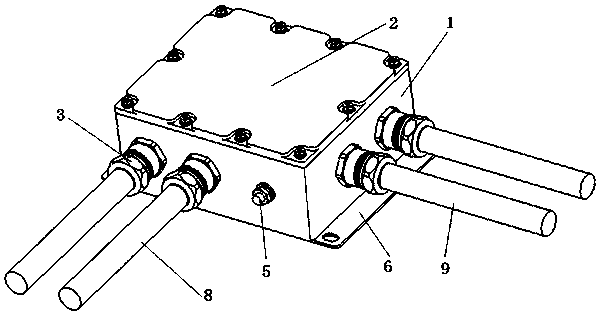

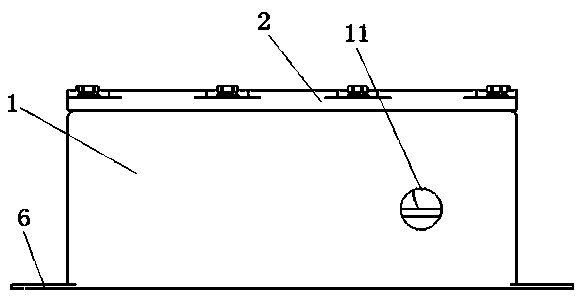

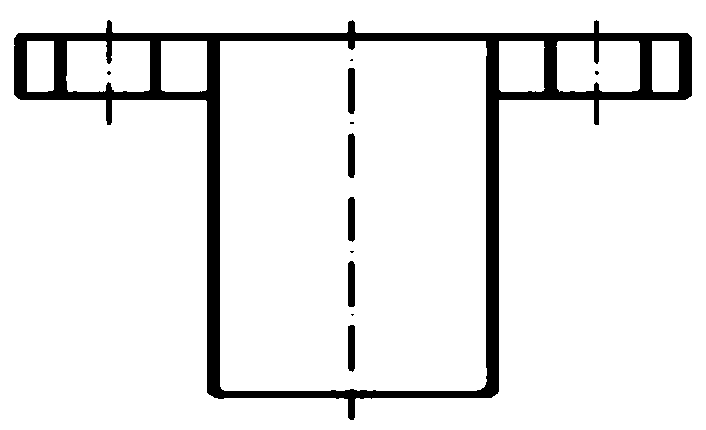

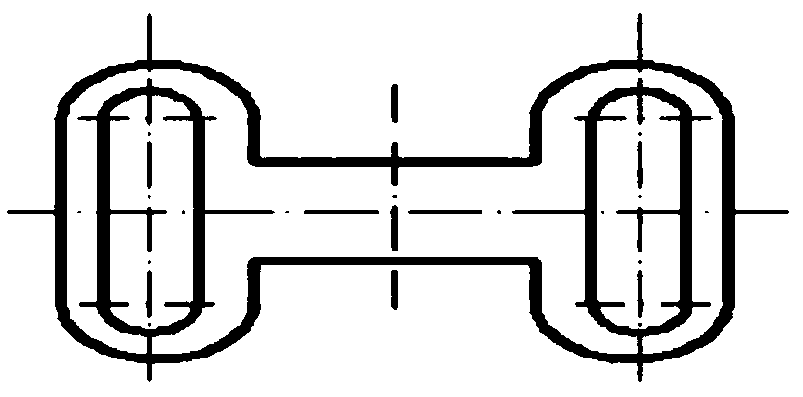

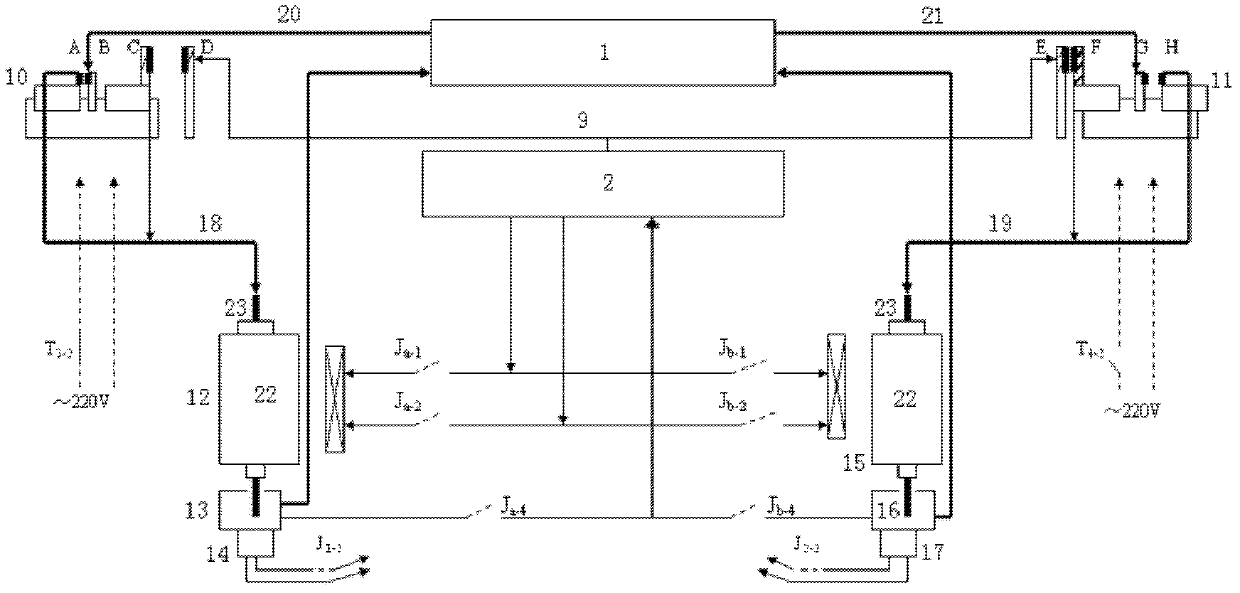

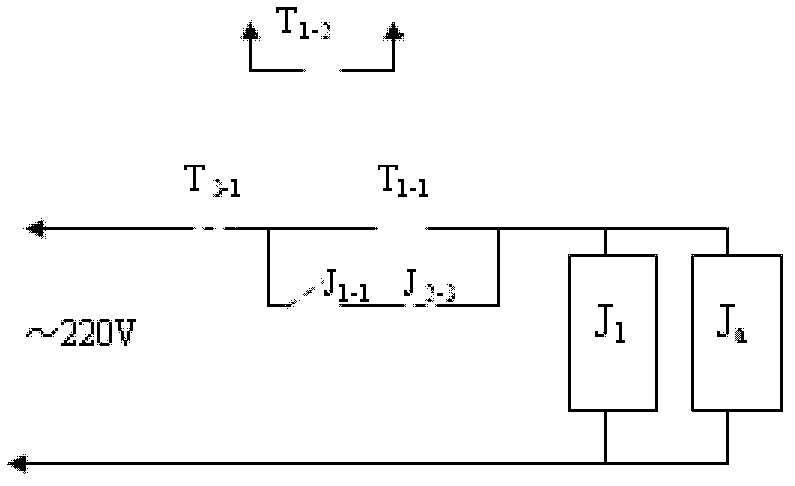

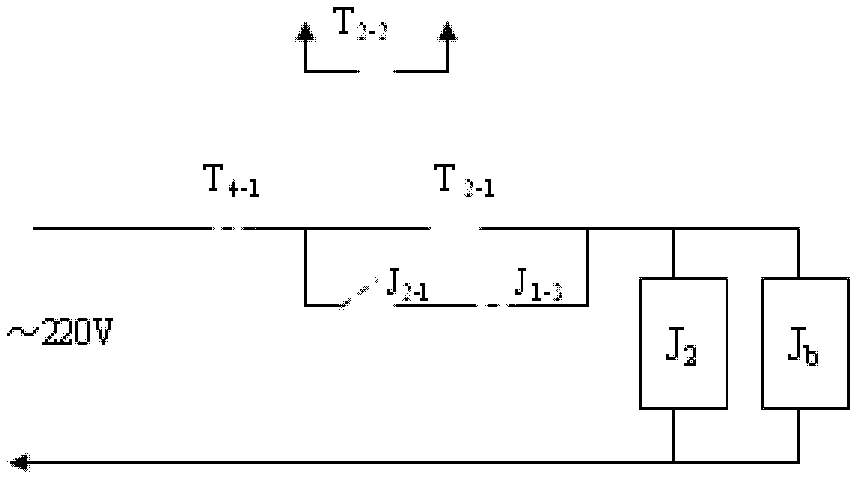

Combination device for testing large current aging and vacuum degree of a vacuum arc extinguish chamber

ActiveCN102332366AAvoid bumpingReduce labor intensityHigh-tension/heavy-dress switchesAir-break switchesHigh tension lineEngineering

The invention discloses a combination device for testing large current aging and vacuum degree of a vacuum arc extinguish chamber. An aging switch of an aging bench (1) is connected with a conversion cylinder (6); a pneumatic switch of the aging bench (1) is connected with a clamping cylinder (4) and a pull-down cylinder (5); a pair of conductive blocks A and B and another pair of conductive blocks C and D are arranged on the conversion cylinder (6); the conductive A is connected with an aging clip line (7); the conductive B is connected to the aging bench (1) through an aging line (8); the conductive C is connected with the aging clip line (7); the conductive D is connected to a vacuum gauge (2) through a high-voltage line (9); and the vacuum gauge (2) is connected with a contact Ja-1, acontact Ja-2 and a contact Ja-4 of an alternating current contactor Ja respectively. In the invention, test functions of large current aging and vacuum degree are combined, so the conductive blocks at a static end are prevented from being collided in an original test process, the labor intensity of an operator is reduced, the working time is shortened, and the production efficiency is improved.

Owner:中国振华电子集团宇光电工有限公司(国营第七七一厂)

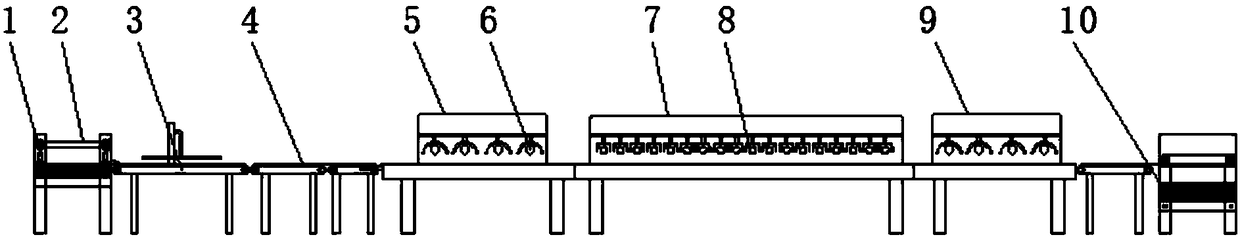

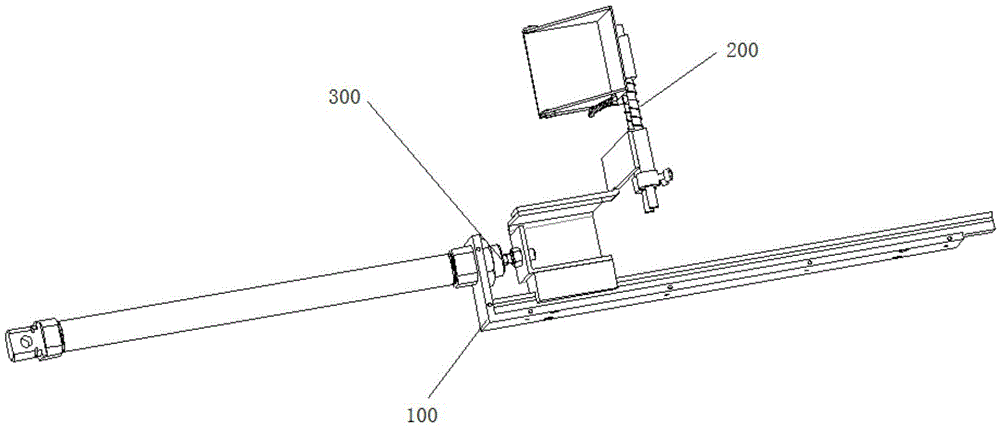

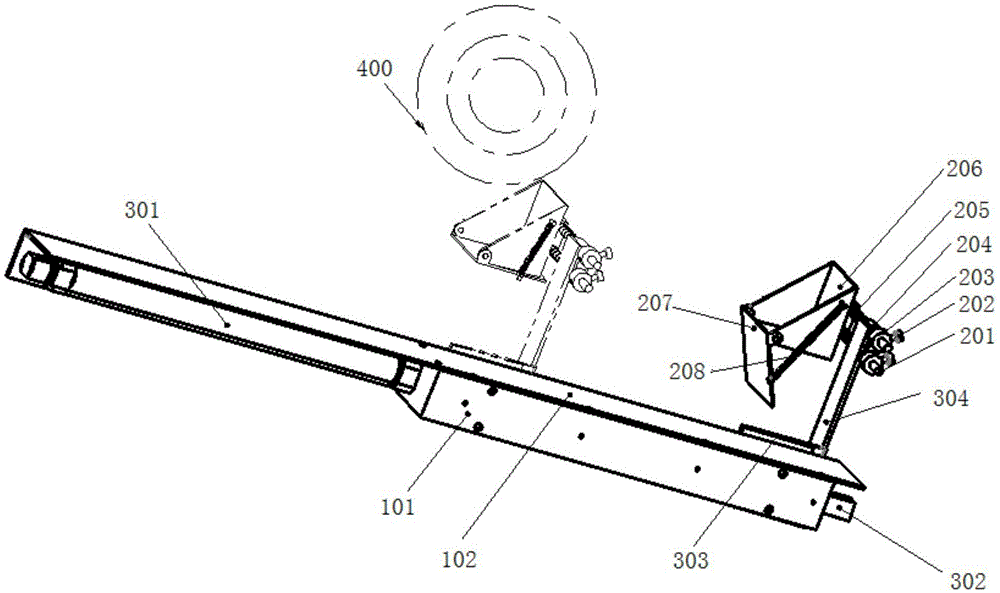

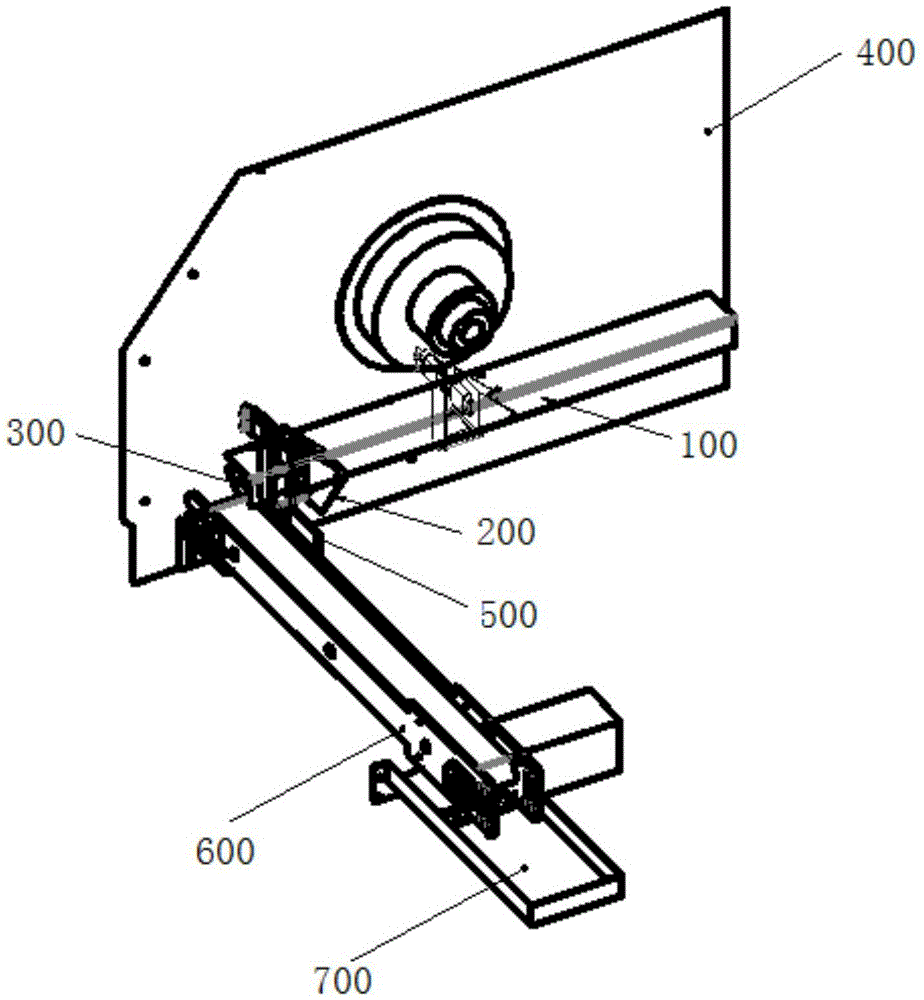

Integrated screen printing device for tinplates and screen printing technology

InactiveCN108501507AAvoid scratchesNo bruisesScreen printersOther printing apparatusScreen printingTransmission belt

The invention discloses an integrated screen printing device for tinplates. The integrated screen printing device comprises the tinplates, a feeding assembly, a screen printing assembly, a transportation assembly, a first UV drying and curing machine, an infrared heating and drying machine, a second UV drying and curing machine and a discharging assembly. The invention further discloses a screen printing technology of the integrated screen printing device for the tinplates. According to the device and the technology, four attraction guns are changed into two attraction guns currently, the twoattraction guns are adjusted to be in an electromagnetic attraction mode, and meanwhile, relatively soft flannelette coats the ends, to be in contact with the tinplates, of the attraction guns, so that the problems of scratching or attraction gun marking and the like on the surfaces of the tinplates caused in the processes of attracting and supplying a part of the tinplates with surfaces coated with films are prevented from generating; the speed of a transmission belt is adjusted, a deceleration belt is arranged by taking the phenomenon that the tinplates do not slip after deceleration as thestandard, a section of differential belt is additionally arranged, and a deceleration sliding block is additionally arranged so that the tinplates can be conveyed to a drying room without collision damage, the product quality is effectively improved, and the rejection rate is reduced.

Owner:宜兴市华丽印铁制罐有限公司

Automatic receiving device of numerical control lathe

ActiveCN105562723ASave human effortAvoid accumulationAutomatic workpiece supply/removalMetal working apparatusNumerical controlButt joint

The invention discloses an automatic receiving device of a numerical control lathe. The device comprises a connecting part, a receiving part, a moving part and a controller; the connecting part includes a machine tool connecting plate; the machine tool connecting plate is fixedly mounted in a preset position of the numerical control lathe through a fastening piece; the receiving part includes a buffer base, and a receiver arranged on the buffer base and with the bottom capable of being automatically opened and closed; the moving part includes a linear slide rail and a driving piece; a fixed rail of the linear slide rail is fixedly mounted on the machine tool connecting plate; a slide block of the linear slide rail is driven by the driving piece to slide along the fixed rail, and is provided with a slide bracket; and the slide bracket is connected with the buffer base of the receiving part. The automatic receiving device overcomes the defect that a traditional automatic receiving device is only suitable for a fixed cutter tower type numerical control lathe and not suitable for a slide plate type cutter arrangement lathe, and is additionally provided with the receiver to replace a traditional receiving tipping bucket to finish seamless butt joint of transporting products to a conveying belt.

Owner:SHENZHEN KING TEAM PRECISION TECH

Vehicle and electrical piece wiring method of vehicle

InactiveCN110386086AGuaranteed sealing effectImprove waterproofElectrical apparatusElectric/fluid circuitElectric vehicleElectricity

Owner:ZHENGZHOU YUTONG BUS CO LTD

Novel finned tube machining method without rotation of workpiece

The invention discloses a novel finned tube machining method without rotation of a workpiece, which comprises the following steps: a tube blank is rolled to obtain a prefabricated coil tube; one end of the prefabricated coil tube is introduced into a straightening machine, and the prefabricated coil tube is straightened through the straightening machine; the prefabricated coil tube is subjected to continuous reducing drawing through a drawing machine, the diameter and the wall thickness of the prefabricated coil tube are controlled, and a to-be-machined tube is obtained; a long and thin core rod is sleeved with the to-be-machined tube, a first servo motor drives a hydraulic chuck to rotate, blades revolve around the to-be-machined tube, a second servo motor drives a pull rod to move axially, the blades conduct radial feeding and retracting, and outer fins of the to-be-machined tube are machined; and an internal thread core head is arranged at the position, located at the intersection point of extension lines of the blades, of the long and thin core rod, and the internal thread core head is extruded through blade spinning and deformation of the to-be-machined tube and driven to rotate to machine internal threads. The blades are installed on the hydraulic chuck, the hydraulic chuck rotates to enable the blades to revolve around the to-be-machined tube, and meanwhile the blades rotate to extrude threads of the to-be-machined tube.

Owner:TAIZHOU CHIJUN INTELLIGENT EQUIP CO LTD

Surface quality improving method for non-ferrous metal retainer

The invention relates to a surface quality improving method for a non-ferrous metal retainer, and solves problems that the surface of a current retainer after polishing is not smooth and a chipping mark reserved by machining is still apparent, and surface smoothness is not apparently improved; bumping damage frequently occurs on the surface of the retainer, especially a sharper chamfering part, and damage repairing treatment is needed later; and the sharp edge of a locking point part of the retainer cannot meet circular and smooth technological requirements after polishing, a phenomenon that asteel ball is scratched by a locking point of the retainer occurs unavoidably in a using process of a bearing, and the sharp edge needs to be further removed by using a manual burr knife. A bullet-like resin polishing material in 2000 meshes of a granularity and 15X15 of a standard and a white ball-like aluminum oxide polishing material in Phi 2 mm of a standard are used for completing coarse polishing and fine polishing. Polishing time is optimized. The method is used for surface quality improvement of the non-ferrous metal retainer.

Owner:AVIC HARBIN BEARING

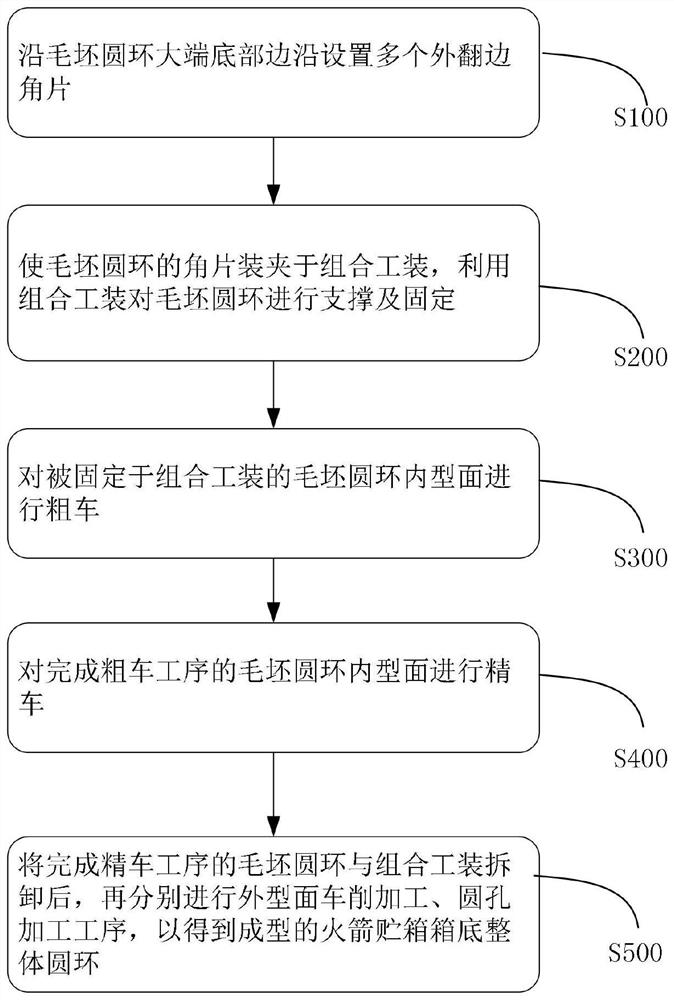

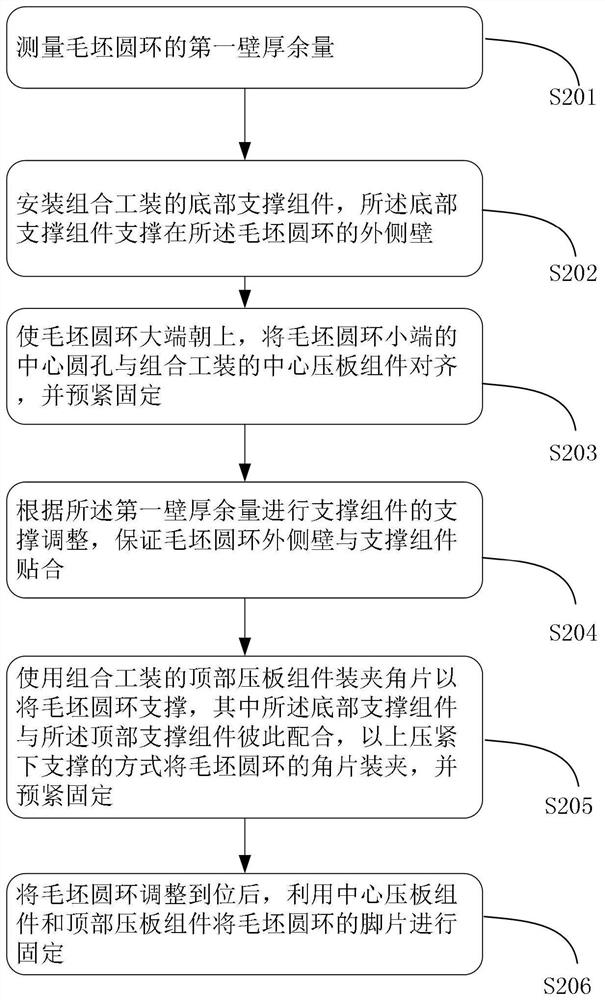

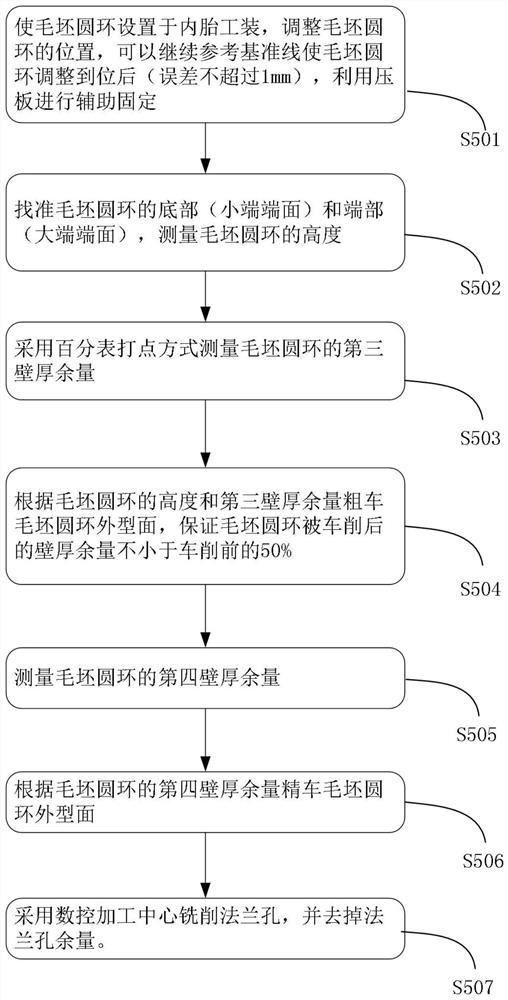

Rocket storage tank bottom integral circular ring forming method

ActiveCN113319300ANo bruisesFree from scratchesAuxillary equipmentTurning machinesStructural engineeringRocket

The invention provides a rocket storage tank bottom integral circular ring forming method. The rocket storage tank bottom integral circular ring forming method at least comprises the following steps that a plurality of outwards-turned corner pieces are arranged along the edge of the bottom of a large end of a blank circular ring, the corner pieces of the blank circular ring are clamped to a combined tool, the blank circular ring is supported and fixed through the combined tool, an inner molded surface of the blank circular ring fixed to the combined tool is subjected to rough turning, then finish turning is conducted on the inner molded surface of the blank circular ring subjected to the rough turning procedure, after the blank circular ring subjected to the finish turning procedure is detached from the combined tool, an outer molded surface turning procedure and a circular hole machining procedure are conducted respectively, and finally the formed rocket storage tank bottom whole circular ring is obtained. According to the rocket storage tank bottom integral circular ring forming method, irregular deformation in the product inner molded surface machining process can be effectively avoided, the subsequent turning difficulty of an outer molded surface is reduced, the same reference is adopted in the product machining process, and high-efficiency, high-precision and high-quality manufacturing of the box bottom integral circular ring is achieved.

Owner:浙江蓝箭航天空间科技有限公司

Stress relief and deformation control device for titanium alloy heat treatment

ActiveCN112323003AReduce distortionReduce the possibility of deformationFurnace typesHeat treatment furnacesDrive shaftEngineering

The invention relates to the technical field of material processing, and particularly relates to a stress relief and deformation control device for titanium alloy heat treatment. The stress relief anddeformation control device comprises a bearing seat, wherein a driving shaft is rotatably mounted in the bearing seat, and a supporting roller is fixedly mounted on the driving shaft; a spiral threadis formed in the supporting roller, and a balance shaft is fixedly mounted on the supporting roller; the balance shaft is rotatably mounted on a supporting block, and a cavity is formed in the supporting block; a driving bevel gear is fixedly mounted on the balance shaft, and a driven bevel gear is mounted on the driving bevel gear in an engaged mode; and the driven bevel gear is fixedly mountedon a vertical shaft, and a cam is fixedly mounted on the vertical shaft. A titanium alloy pipe is slowly pushed through the supporting roller mounted in an annealing furnace, and the titanium alloy pipe is continuously moved and rotated in the cooling process; and no fixed contact point exists between the pipe and a roller way, so that a workpiece is heated more uniformly without being damaged, and the possibility of pipe deformation is effectively reduced.

Owner:INNER MONGOLIA UNIV OF TECH

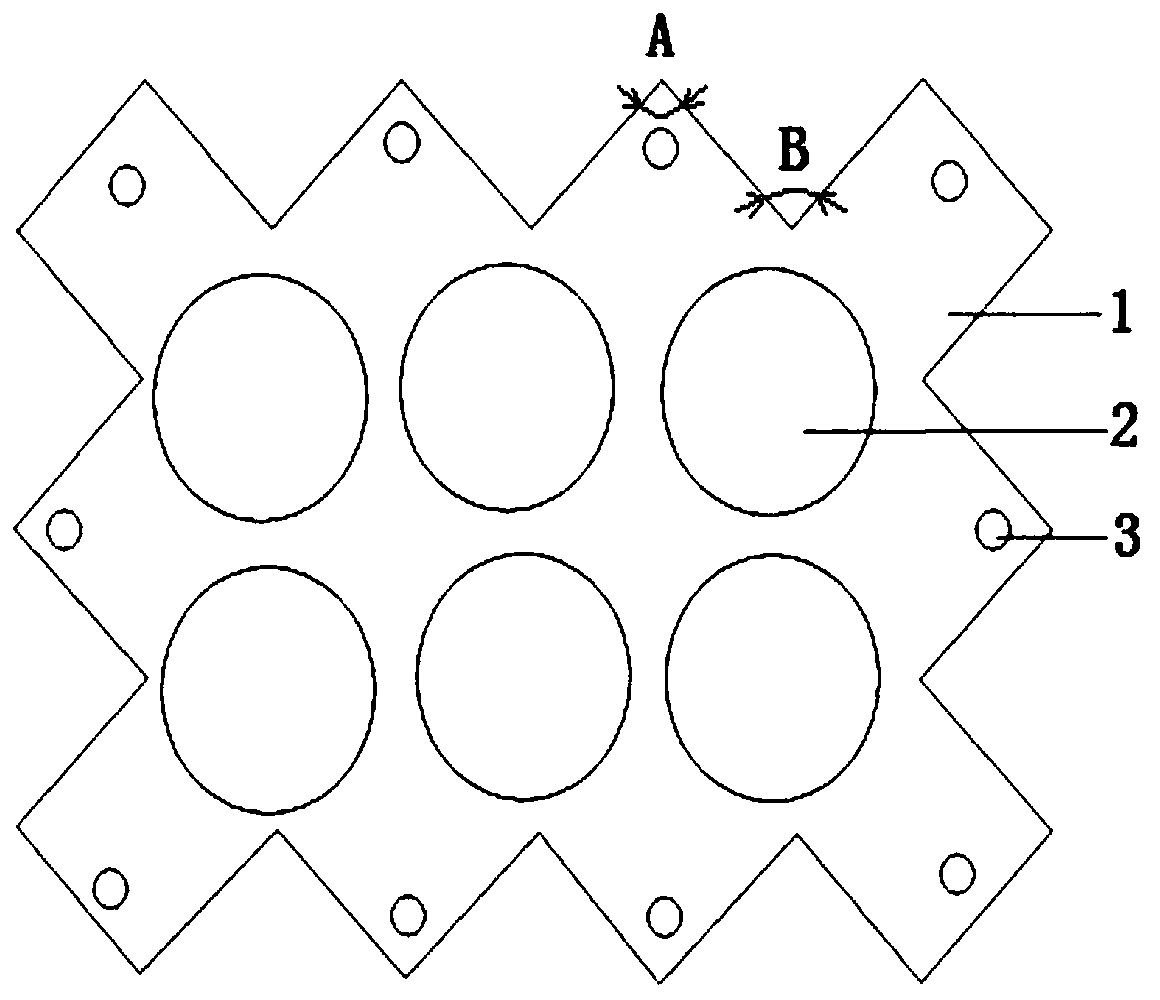

Artificial ecological floating bed based on foamed polypropylene material

InactiveCN111115828AWon't hurtReduce manufacturing costBiological water/sewage treatmentPolypropylenePollution

The invention discloses an artificial ecological floating bed based on a foamed polypropylene material. A foamed polypropylene floating plate is arranged, and planting holes are formed in the foamed polypropylene floating plate, so that the characteristics that the foamed polypropylene material is nontoxic, odorless, free of secondary pollution, simple and convenient to recycle and regenerate, high in adsorption rate to bacteria in water, high in impact resistance, stable and reliable in floatability, and the using temperature difference range is -30-130 DEG C can be fully played.

Owner:北京爱尔斯生态环境工程有限公司

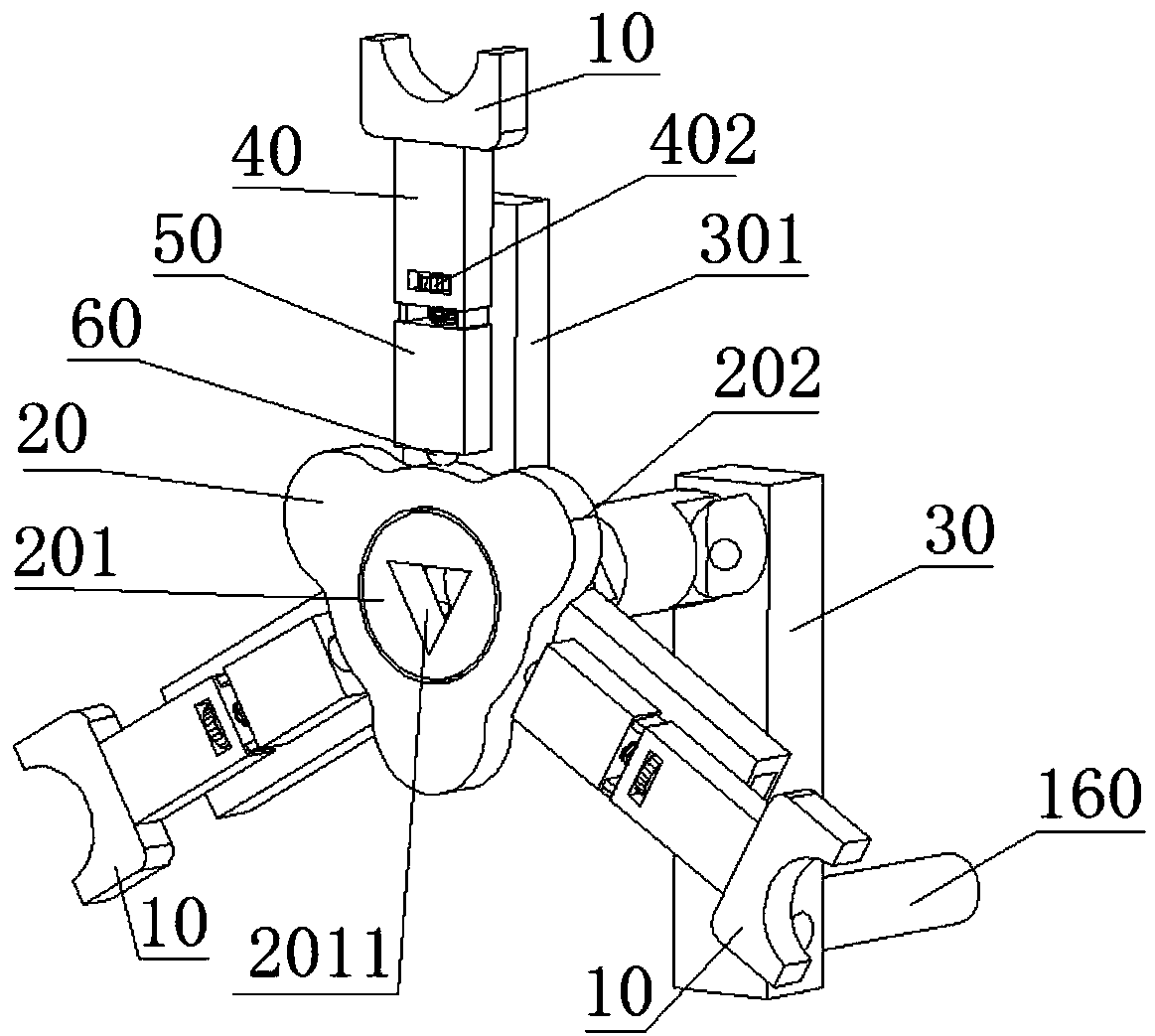

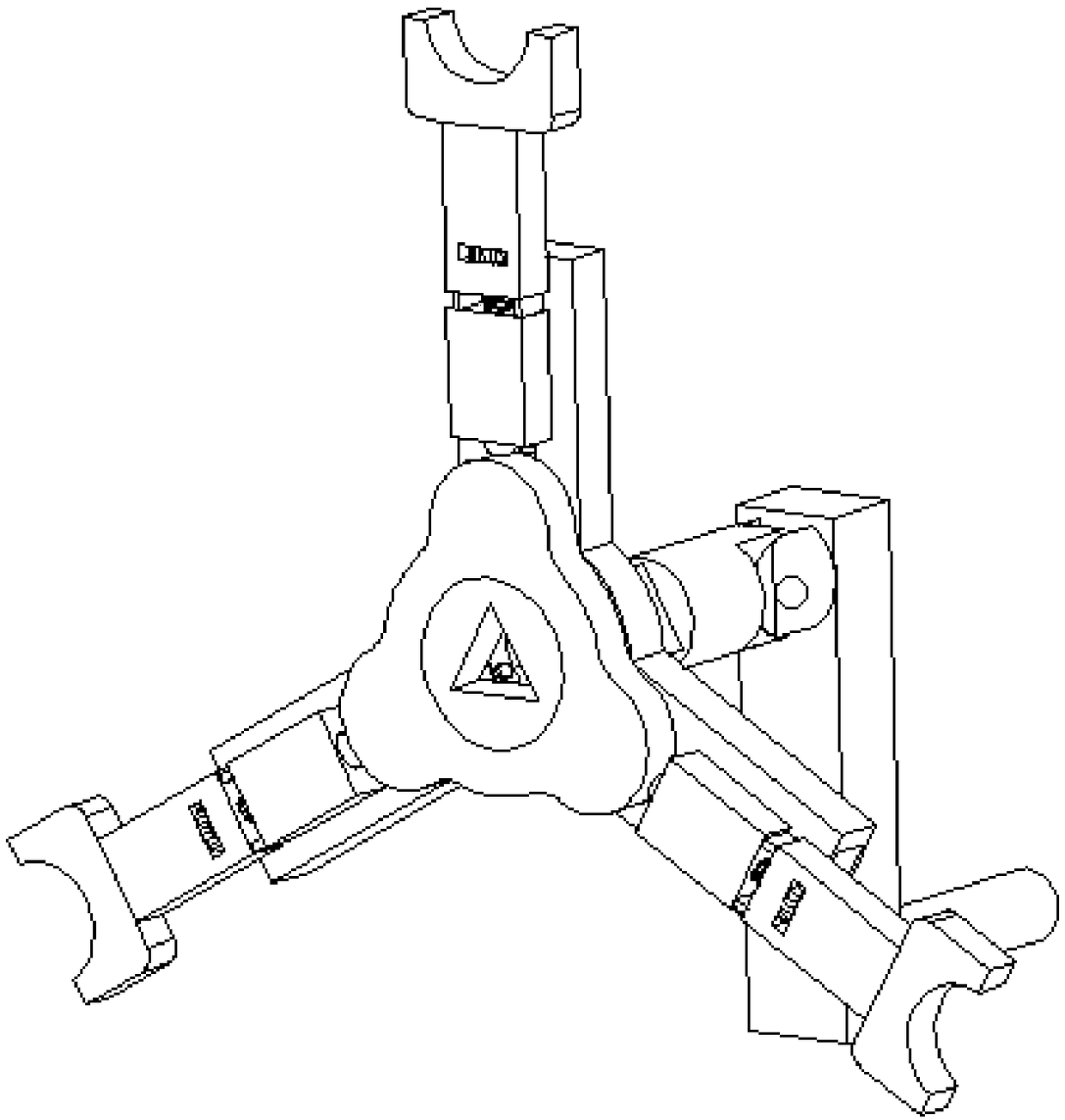

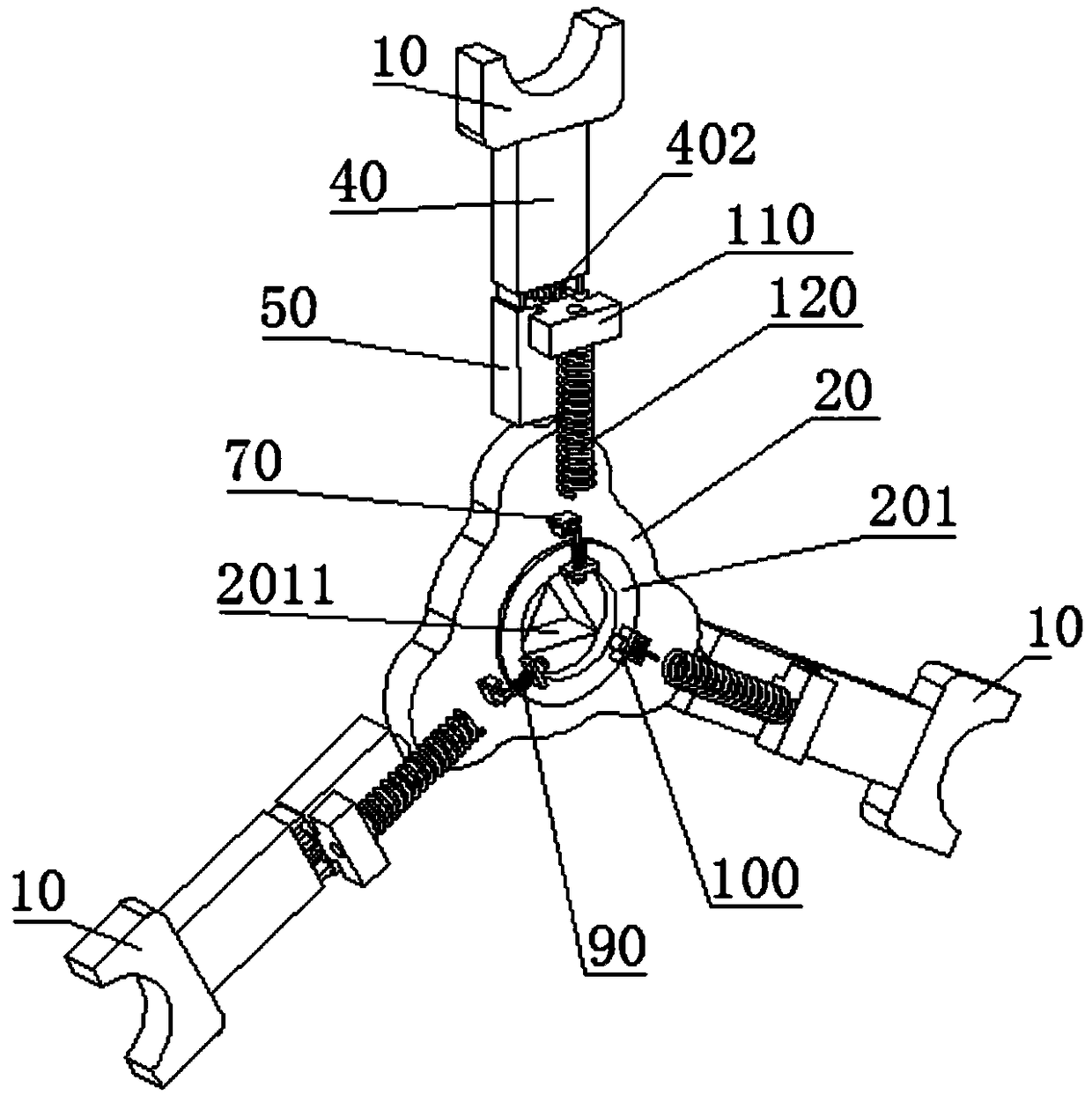

Pipe type bus bar mounting bracket

PendingCN109245000AGuaranteed to be relatively fixedNo bruisesTotally enclosed bus-bar installationsEngineeringElectric power

The invention provides a pipe type bus bar mounting bracket, which relates to the technical field of electric power. The pipe bus bar mounting bracket comprises a pipe bus bar bracket, a connecting piece, a rotary table and a fixed plate. The turntable is rotatably mounted on the fixed disk, and the fixed disk is radially extended with three extending arms along the centerline, and the connectingmembers are respectively slidably arranged on the three extending arms, one end of the connecting member faces the outer edge of the turntable, and the other end is connected with the tube mother bracket; -three protrusions are arranged on the outer edge of the turntable, - a distance between the three protrusions on the outer edge of the turntable and the central line is longest. As that turntable is rotate relative to the fixed disk, one end of the three connection pieces can abut on the three protrusions simultaneously.- The pipe type bus bar mounting bracket alleviates the technical problems of the prior art that the installation difficulty of the tube parent mounting bracket when the tube bus bar is installed is great and the hidden danger of the staff in the installation process is great.

Owner:MAINTENANCE CO STATE GRID QINGHAI ELECTRIC POWER

Fruit picking manipulator

InactiveCN102672712BLarge peripheral stress areaEven by forceProgramme-controlled manipulatorGripping headsEngineeringManipulator

The invention discloses a fruit picking manipulator which comprises a hand portion and a tri-link spherical coordinate type arm. The hand portion comprises a supporting plate arranged on a wrist, fingers and connecting rods thereof are respectively hinged to two sides of the front end face of the supporting plate, and a draw rod for drawing the fingers to open and close is directionally and movably assembled on the supporting plate through a draw rod driving mechanism arranged on the supporting plate. The fruit picking manipulator is characterized in that the inner sides of the front ends of the fingers are provided with arc clamping plates with opposite arc directions respectively. When fruits are picked by the fingers, the arc shape of the arc clamping plates arranged in the front of the fruit picking manipulator fits shapes of fruits, so that the peripheral stressed areas of the fruits are large, the fruits are uniformly stressed, and the problem of fruit damage caused by high local stress on the fruits in the prior art can be avoided.

Owner:HENAN UNIV OF SCI & TECH

U-shaped afterheat utilizing annealing furnace below roller

ActiveCN100419095CEvenly heatedNo bruisesFurnace typesHeat treatment furnacesAir convectionUtilization rate

Owner:HANGZHOU JINZHOU TECH CO INC

Combination device for testing large current aging and vacuum degree of a vacuum arc extinguish chamber

ActiveCN102332366BAvoid bumpingReduce labor intensityHigh-tension/heavy-dress switchesAir-break switchesEngineeringHigh tension line

The invention discloses a combination device for testing large current aging and vacuum degree of a vacuum arc extinguish chamber. An aging switch of an aging bench (1) is connected with a conversion cylinder (6); a pneumatic switch of the aging bench (1) is connected with a clamping cylinder (4) and a pull-down cylinder (5); a pair of conductive blocks A and B and another pair of conductive blocks C and D are arranged on the conversion cylinder (6); the conductive A is connected with an aging clip line (7); the conductive B is connected to the aging bench (1) through an aging line (8); the conductive C is connected with the aging clip line (7); the conductive D is connected to a vacuum gauge (2) through a high-voltage line (9); and the vacuum gauge (2) is connected with a contact Ja-1, acontact Ja-2 and a contact Ja-4 of an alternating current contactor Ja respectively. In the invention, test functions of large current aging and vacuum degree are combined, so the conductive blocks at a static end are prevented from being collided in an original test process, the labor intensity of an operator is reduced, the working time is shortened, and the production efficiency is improved.

Owner:中国振华电子集团宇光电工有限公司(国营第七七一厂)

Method for skin beauty

InactiveCN106730314ARelieve painGuaranteed skin beauty effectCosmetic preparationsToilet preparationsBiomedical engineeringIndividual based

The invention relates to a method for skin beauty. The method comprises the steps of detecting the skin; drawing blood; centrifuging the blood; deploying a blood medicine; injecting the blood medicine into the body; repairing; cleaning; conducting further consultation; conducting secondary repairing, wherein the step of deploying the blood medicine comprises the procedures of adding a corresponding medicine into serum in a targeted mode according to skin data obtained through skin detection, and uniformly mixing the medicine and the serum to obtain the blood medicine; the step of injecting the blood medicine into the body comprises the procedures of adding the blood medicine into water light needling equipment, and utilizing the water light needling equipment to inject the blood medicine into the skin which needs to be beautified; the step of repairing comprises the procedures of utilizing red blue light therapeutic equipment to irradiate the part of the human body which is inserted with the blood medicine after the blood medicine is injected, wherein the irradiating time is 5-10 minutes. The method for skin beauty has the first advantage that the painful feeling in the operational process can be obviously reduced; the second advantage that a product can be uniformly and effectively flat laid on the skin by adopting the water light needling equipment to operate; the third advantage that an operational scheme is customized, an individual-based treatment scheme is matched according to the skin problems of each person, and the skin beautify effect is guaranteed; the fourth advantage that the operational time is short, and there are no untoward effects of swelling, bruise and the like after the operation.

Owner:袁梦瑶

A kind of processing method of high precision U-shaped titanium nail

The invention relates to a processing method for a high-precision U-shaped titanium nail. The method comprises the following steps that a straightening mechanism is manufactured by utilizing cork materials; titanium wires are conveyed in the straightening mechanism, the rotating speed of a straightening raw is controlled to be 2800-3200 revolutions / min, the wire discharging speed is 2-3.5 circles / min, the wire winding speed of a wire winding mechanism is controlled to be 6-7circles / min for wire winding; and the titanium wires wound by the wire winding mechanism are convoyed into a cutter die,a die core is attached to cutters, after a forming mechanism presses down, a pressure spring and a pre-pressing block press the titanium wires tightly, then double cutters on the two sides act to cuttitanium wires on the two sides of the cutter die at the same time, the titanium wires are bent and formed, and a titanium nail with a U-shaped structure is formed. Compared with the prior art, the process of one-time punching forming has the advantages that the process is greatly simplified, the production efficiency is improved, and the processing mode is unique, so that products are greatly improved in terms of quality, performance and processing flexibility.

Owner:上海亚尔精密零件制造有限公司

A kind of decomposition method of double tightness chuck

ActiveCN109184807BEliminate interferenceStable decompositionBlade accessoriesLeakage preventionEngineeringRelative motion

A disassembly device and method for a double-tightness chuck provided by the present invention includes a lifting mechanism, a body, a rotating mechanism, an outer ring lifting mechanism, a backing plate and a gripping mechanism, wherein the body is arranged below the lifting mechanism, and the gripping mechanism is placed It is under the body, and the three are fixedly connected; the outer ring lifting mechanism is set on one end of the grasping mechanism and connected to the body, and the other end of the grasping mechanism is in contact with the chuck in the double-tightness chuck to be separated; the backing plate is placed Below the lifting mechanism of the outer ring, the turbine disk in the double-tightness chuck to be separated is placed in the cavity between the backing plate and the lifting mechanism of the outer ring, and fixed on the backing plate; the rotating mechanism is set on the lifting mechanism of the outer ring The upper surface of the upper surface; the present invention uses the decomposing hydraulic device to make the chuck pre-deformed, and decomposes the synchronous double-tight over-positioning chuck step by step, eliminating the friction and interference between the parts during the relative motion of the decomposition, and the decomposing process is stable and accurate , Reliable, no bump damage.

Owner:AECC AVIATION POWER CO LTD

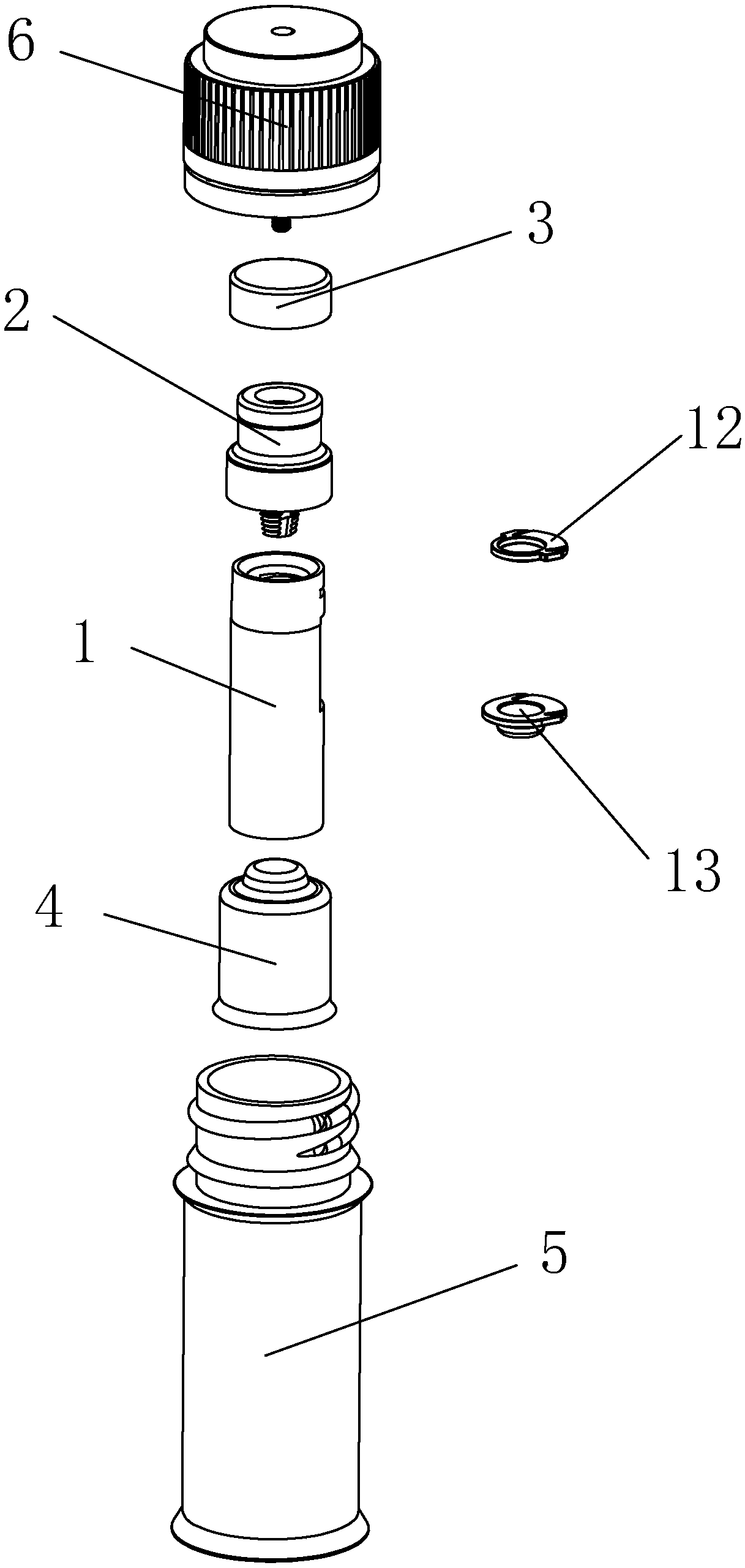

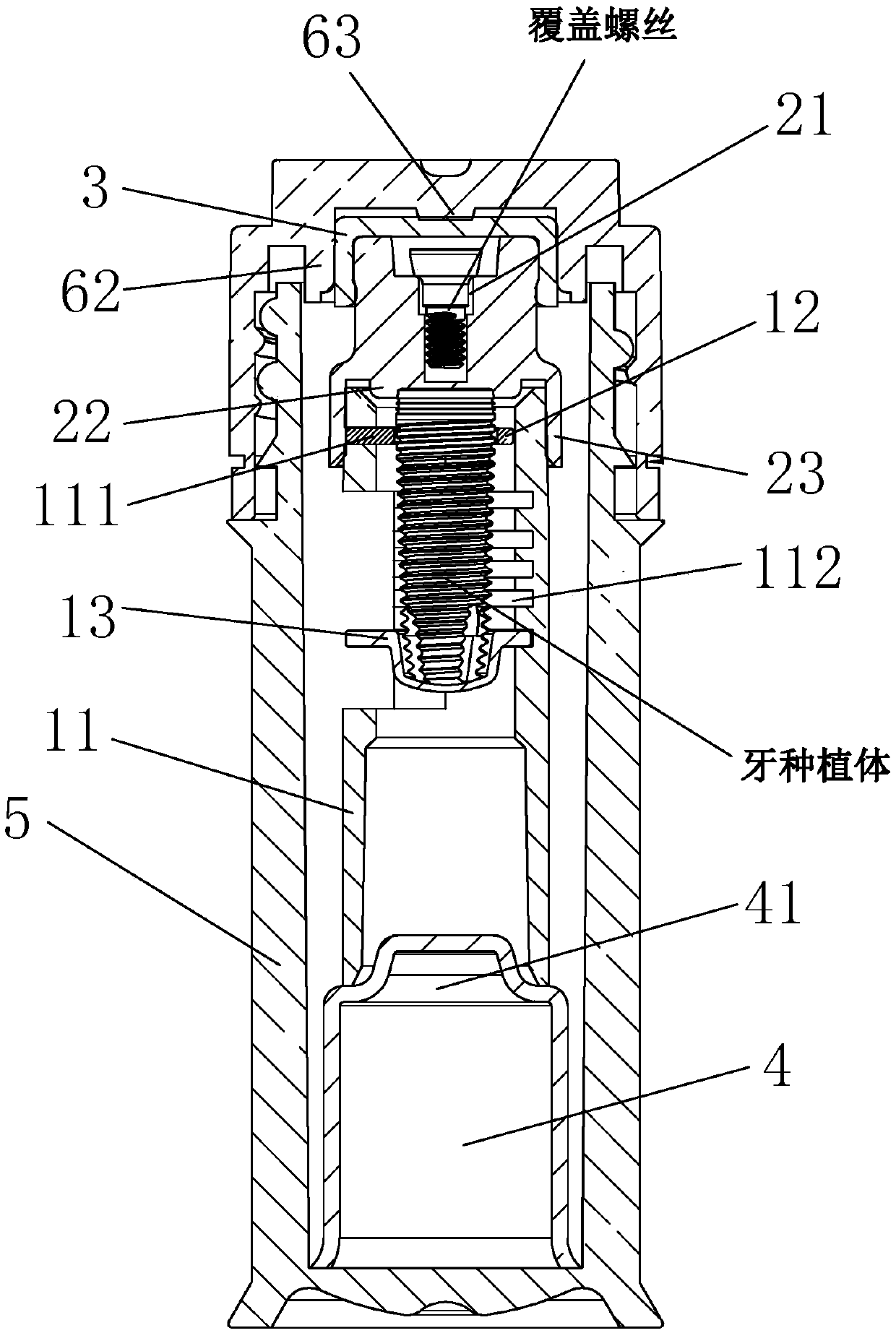

Dental implant packaging assembly

The invention discloses a dental implant packaging assembly. The dental implant packaging assembly comprises an outer packaging bottle and an inner packaging structure. The inner packaging structure comprises a dental implant protective sleeve, a cover screw bottle, a cover screw bottle cap and an elastic cushion. The dental implant sleeve comprises a sleeve body, a first titanium sheet and a second titanium sheet, a hole is formed in the middle of the first titanium sheet, a concave hole is formed in the middle of the second titanium sheet, the sleeve body is provided with an upper clamping groove into which the first titanium sheet can be inserted and fixed and at least one lower clamping groove into which the second titanium sheet can be inserted and fixed. According to the dental implant packaging assembly, a dental implant is limited to the middle of the sleeve through the first titanium sheet and the second titanium sheet in the dental implant protective sleeve, meanwhile, the upper clamping groove, the lower clamping grooves and the cover screw bottle can jointly form a structure which can carry out fixing and clamping according to the length and the diameter of the dental implant so that the dental implant cannot make contact with the dental implant sleeve in the assembling, transporting and taking processes, and therefore the situation that the dental implant is polluted by foreign substances or collided and damaged is avoided.

Owner:广东健齿生物科技有限公司

Mask cutting die detection device

PendingCN111678685ASimple structureCertifiedMachine part testingStructural engineeringMechanical engineering

The invention belongs to the technical field of mask production, and particularly relates to a mask cutting die detection device. The device comprises a bottom plate, a tool rest, a movable block andtwo supporting blocks. The two supporting blocks are oppositely arranged on the two sides of the bottom plate. The two ends of the tool rest are in running fit with the two supporting blocks respectively; an open groove is formed in the upper end of the supporting block, the movable blocks are slidably arranged in the open groove, the two ends of the cutting die are rotatably matched with the twomovable blocks correspondingly, the cutting die is connected with a first hand wheel, the top of the supporting block is connected with a top plate, a pushing mechanism for pushing the movable blocksto move is arranged on the top plate, and an elastic reset mechanism is arranged in the supporting block; the cutting die is pushed by the pushing mechanism to move towards the tool rest, when the cutting die is close to the tool rest, mask cloth is placed between the cutting die and the tool rest, the hand wheel is rotated for trial cutting, if the mask cloth is cut off by the cutting die, the cutting die is provided to be qualified, and when cutting dies with different lengths need to be tested, only the gap between the two supporting blocks needs to be adjusted and corresponding cutters arereplaced.

Owner:英诺莱比(北京)科技有限公司

Heat treatment device and heat treatment process for ultra-long aluminum extrusion

ActiveCN109536683BAchieving solution quenchingAchieve annealingFurnace typesHeat treatment furnacesEngineeringHeating furnace

Owner:广西百矿冶金技术研究有限公司

Automatic material taking device of fine blanking machine and material taking method of automatic material taking device

PendingCN113458269AReclaiming speed is fastVersatileStripping-off devicesLocking plateIndustrial engineering

The invention discloses an automatic material taking device of a fine blanking machine and a material taking method of the automatic material taking device. The automatic material taking device of the fine blanking machine comprises a supporting support, a driving mechanism, a material taking arm, a sliding rail seat and a conveying mechanism,wherein the supporting support is fixed to the discharging side of a lower die locking plate, the driving mechanism is installed on the supporting support, the material taking arm is installed on the sliding rail seat, the driving mechanism is connected with the material taking arm so as to drive the material taking arm to linearly slide relative to the sliding rail seat, the driving mechanism drives the free end of the material taking arm to stretch into a mold cavity so as to take out a fine blanking part, and a conveying mechanism is located below the sliding rail seat so as to convey out the fine blanking part taken out by the material taking arm. According to the automatic material taking device of the fine blanking machine, compressed air is not needed during material taking, and meanwhile noise and oil mist cannot be generated.

Owner:武汉华夏精冲技术有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com