Rocket storage tank bottom integral circular ring forming method

A forming method and ring technology, applied in the field of aerospace launch vehicles, can solve the problem that the blank parts cannot be directly applied to the bottom of the tank of the launch vehicle, and achieve the effects of reducing stress deformation, improving adaptability, and improving quality stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and through specific implementation methods. Spatially relative terms such as "below", "beneath", "under", "lower", "above", "on", "higher", etc. are used to facilitate description to explain the relative The orientation of two elements means that these terms are intended to encompass different orientations of the device in addition to orientations other than those shown in the figures. In addition, for example, "one element is on / under another element" may mean that two elements are in direct contact, or that there are other elements between the two elements. In addition, terms such as "first", "second", etc. are also used to describe various elements, regions, sections, etc. and should not be taken as limitations. Similar terms refer to similar elements throughout the description.

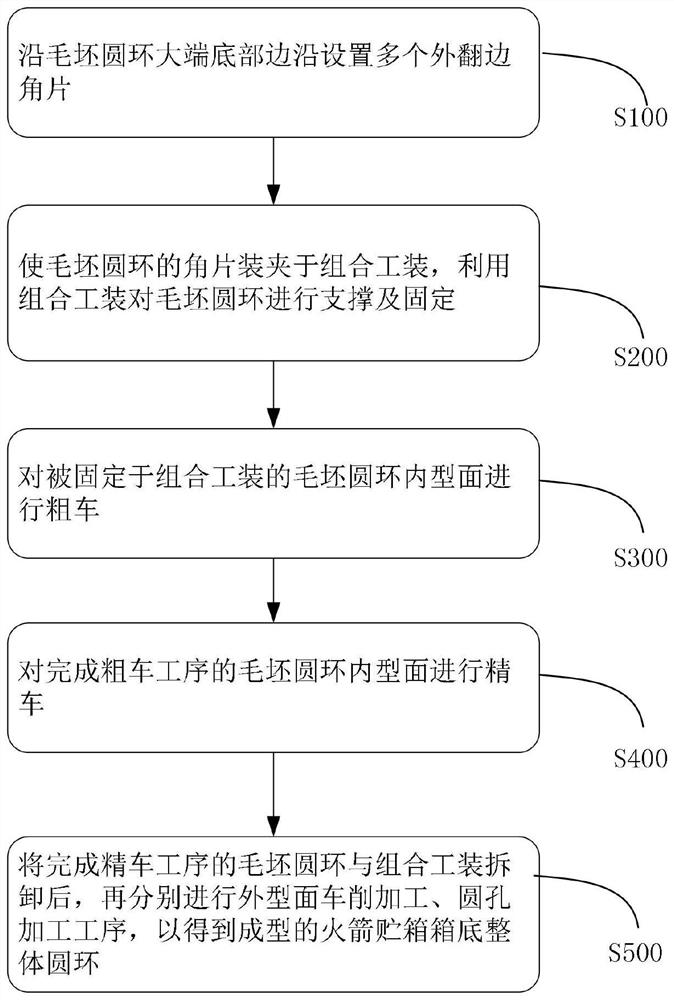

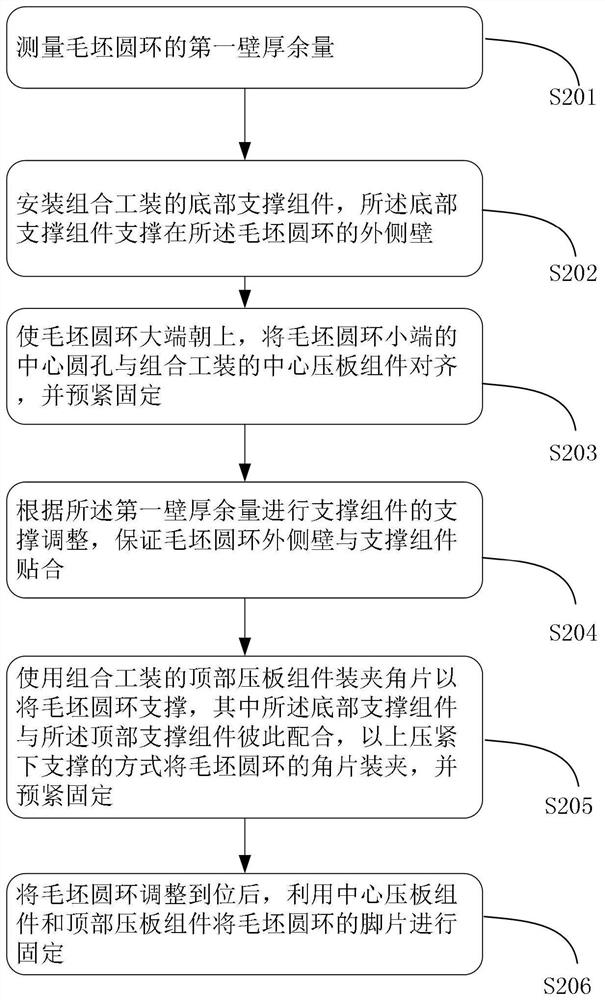

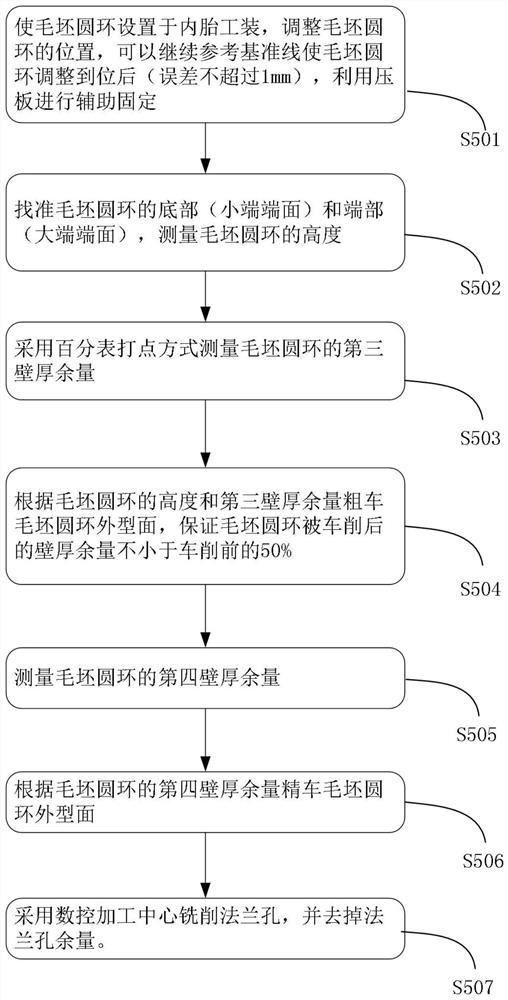

[0047] The machining of the overall circular ring at the bo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com