Mask cutting die detection device

A detection device and die-cutting technology, which is applied in the direction of measuring devices, testing of mechanical components, testing of machine/structural components, etc., to achieve a simple and reasonable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

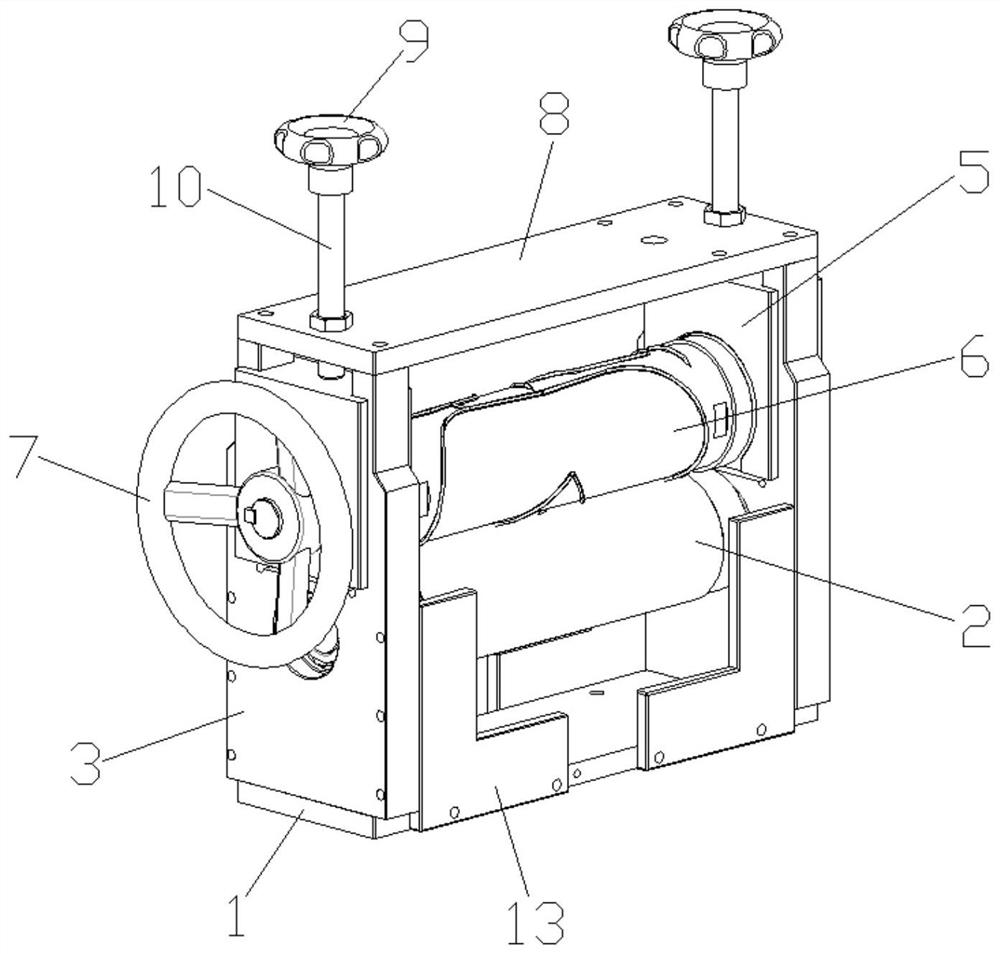

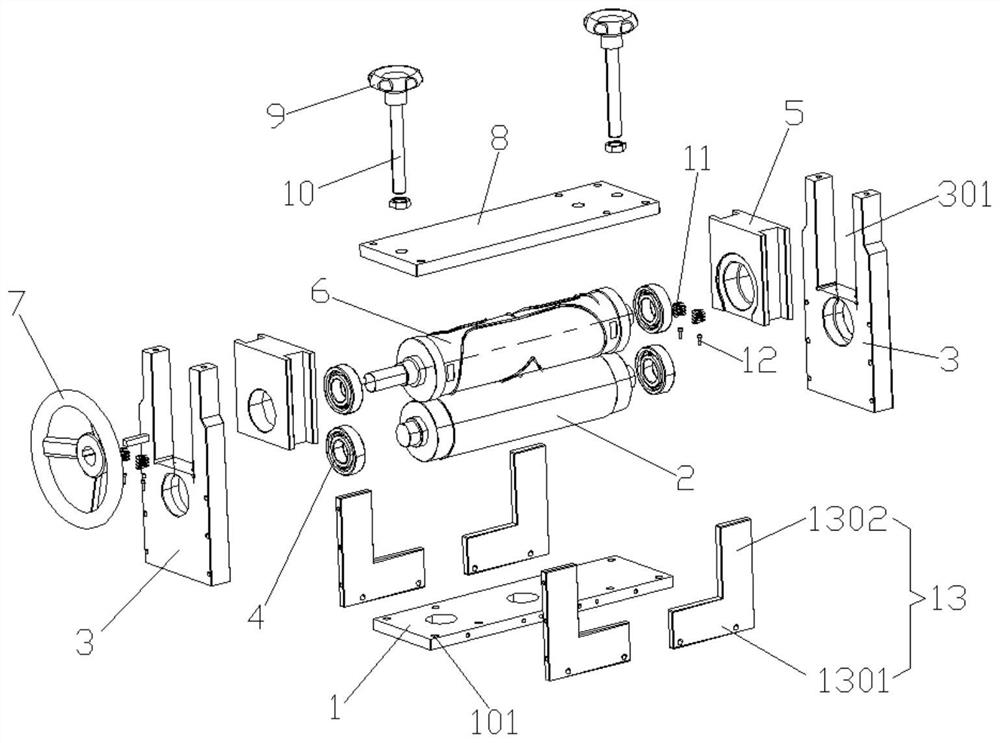

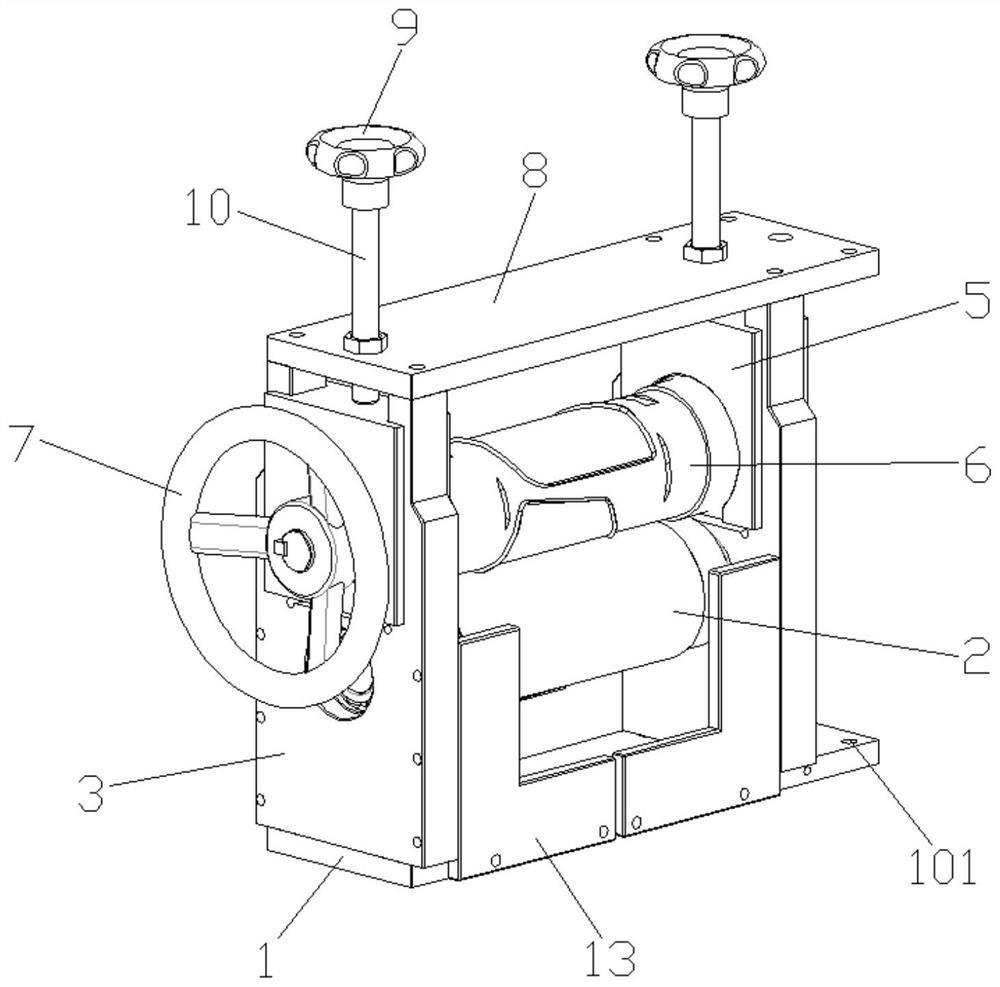

[0028] Such as Figure 1 ~ Figure 3 As shown, the present embodiment provides a mask knife mold detection device, including a base plate 1, a knife pillow 2, a movable block 5 and two support blocks 3, and the two support blocks 3 are relatively arranged on two sides of the base plate 1. Side, the gap between the two support blocks 3 is adjustable, the lower part of the support block 3 is provided with a bearing 4, and the two ends of the knife rest 2 are respectively rotatably matched with the two support blocks 3 through the bearing 4 .

[0029] The upper end of the support block 3 has an open slot 301, the movable block 5 is located in the open slot 301 and is slidably fitted with the open slot 301, and the movable block 5 is provided with a bearing 4 for installing the cutting die 6 , the die die 6 is located above the die rest 2, and the two ends of the die die 6 are rotatably matched with the two movable blocks 5 through bearings 4, and the die die 6 is connected to dri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com