A kind of decomposition method of double tightness chuck

A chuck and tightness technology, which is applied to the supporting components of blades, machines/engines, and leakage prevention, etc., can solve the problems that double tightness chucks cannot be disassembled, and achieve the effect of eliminating friction and interference and stabilizing the decomposition process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0051] Below in conjunction with accompanying drawing, the present invention is described in detail.

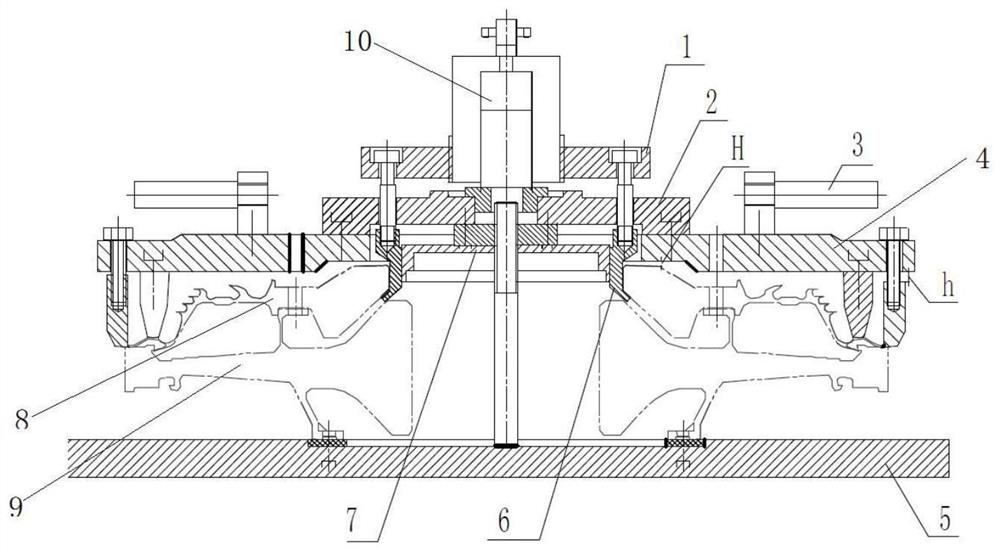

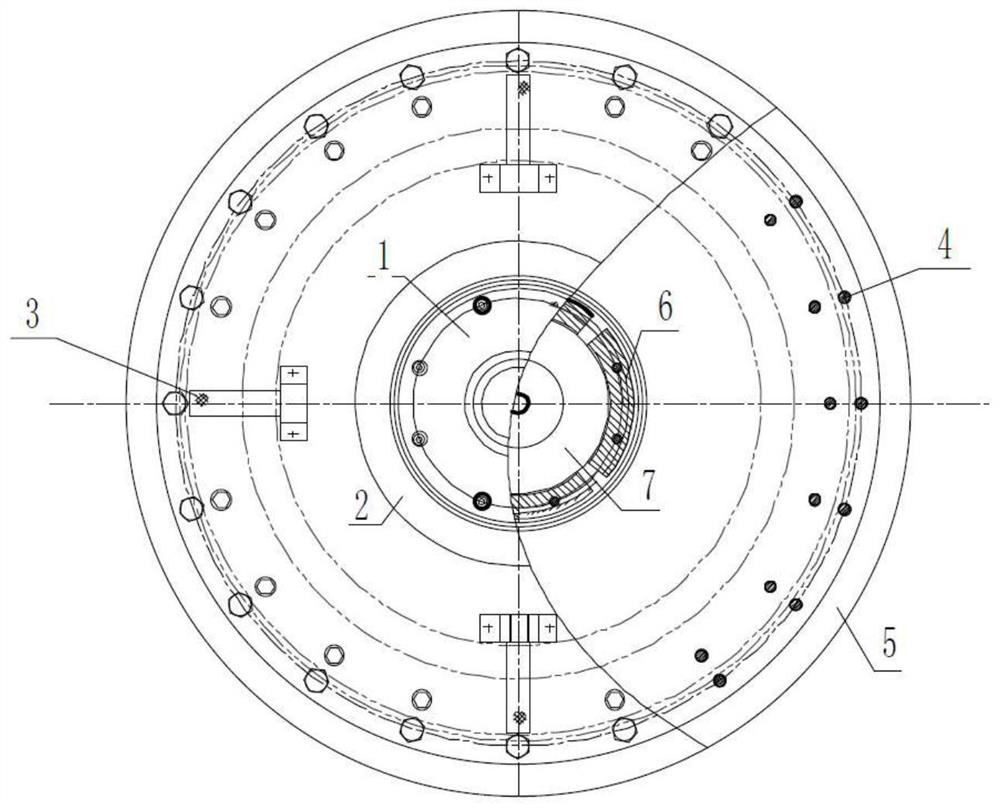

[0052] Such as figure 1 , figure 2 As shown, a disassembly device for a double-tightness chuck provided by the present invention includes a lifting mechanism 1, a body 2, a rotating mechanism 3, an outer ring lifting mechanism 4, a backing plate 5, a gripping mechanism 6 and an auxiliary gripping mechanism 7, wherein , the backing plate 5 is placed under the outer ring lifting mechanism 4, and the turbine disk to be separated is placed in the cavity between the backing plate 5 and the outer ring lifting mechanism 4; the grasping mechanism 6 and the auxiliary grasping mechanism 7 are installed outside In the central hole of the ring lifting mechanism 4, the body 2 is installed on the upper surface of the outer ring lifting mechanism 4, and the body 2 is also connected with the lifting mechanism 1.

[0053] specifically:

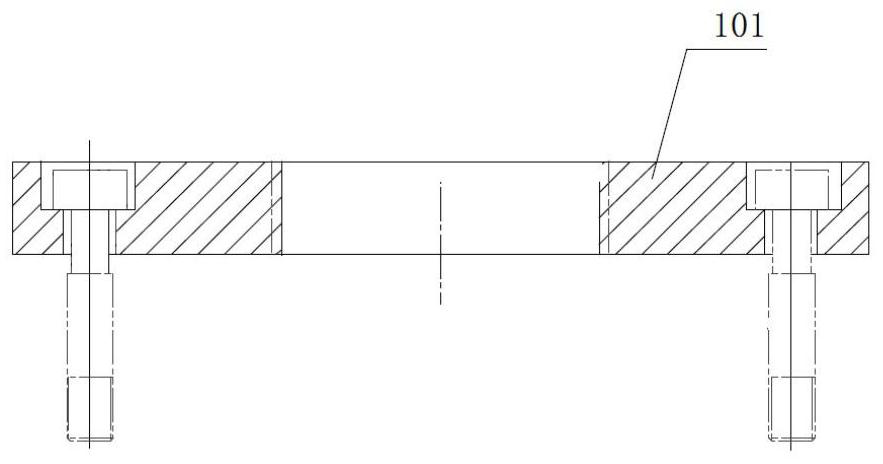

[0054] Such as image 3 As shown, the lifting mech...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com