Patents

Literature

34results about How to "Achieve annealing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

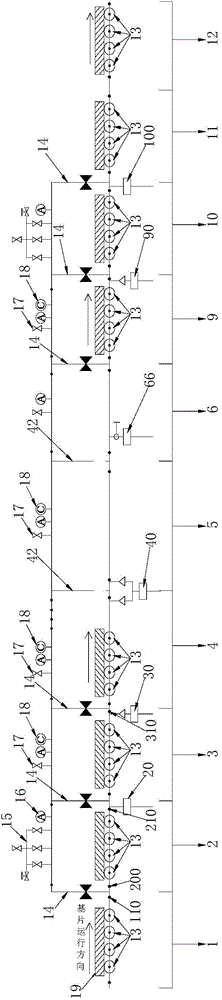

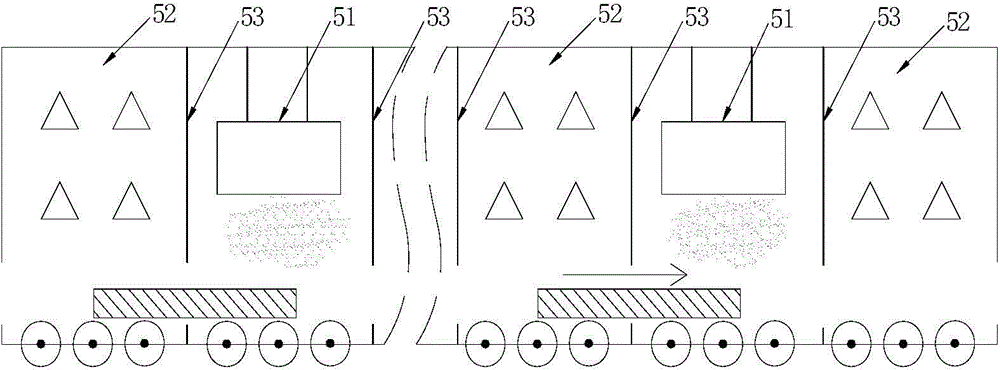

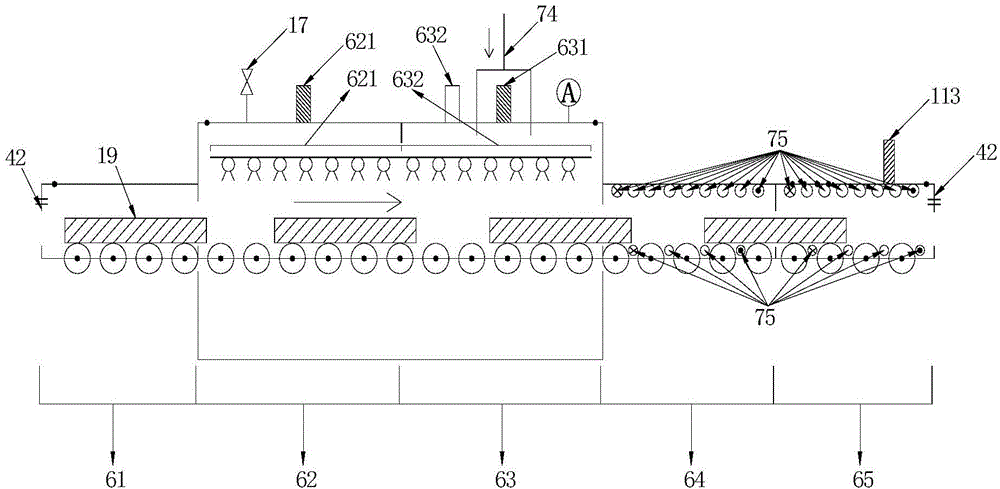

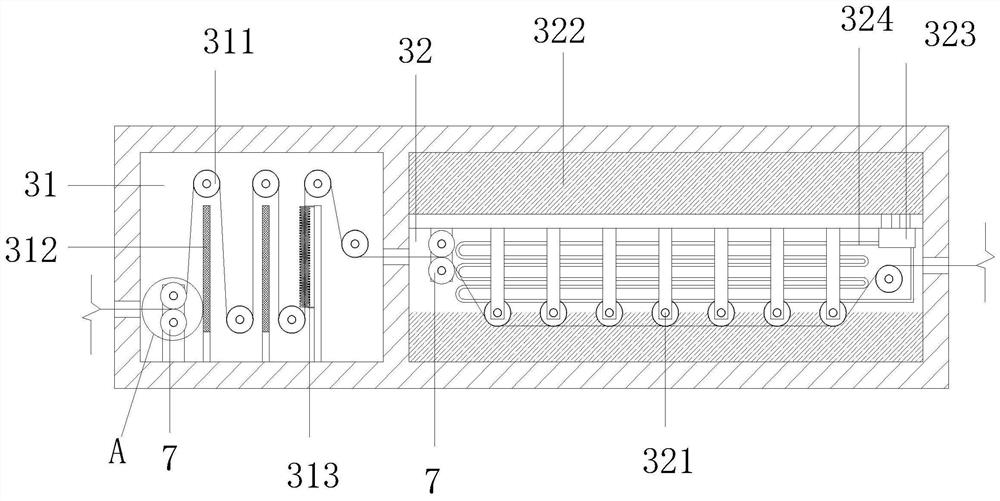

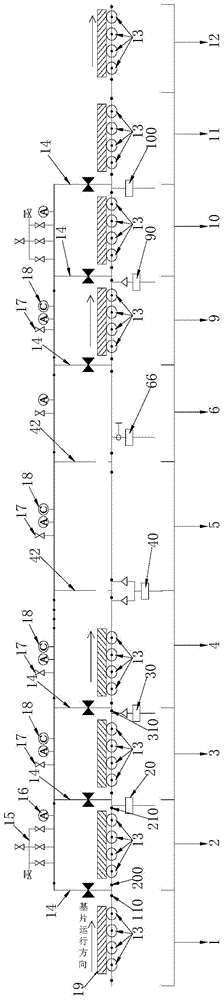

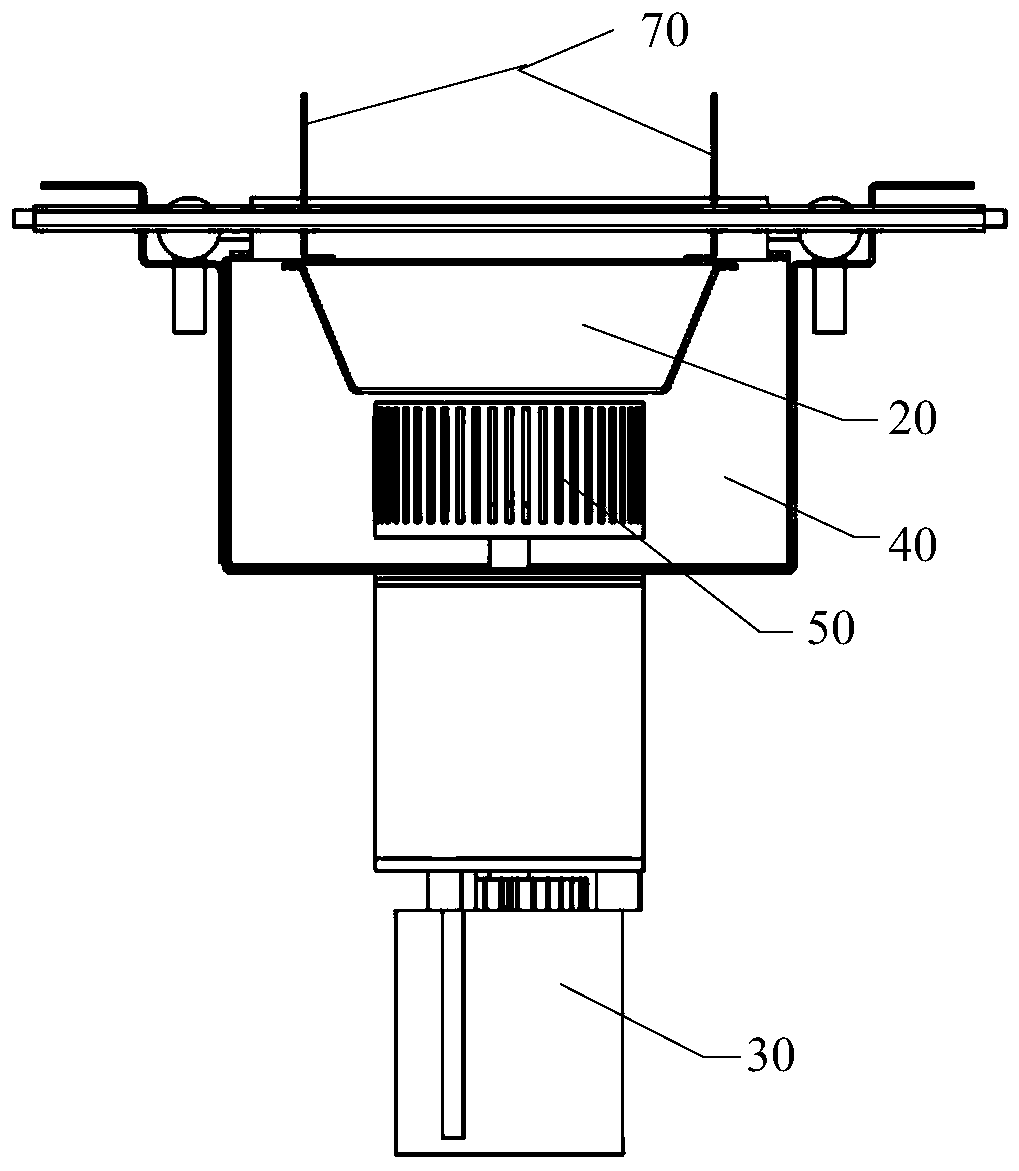

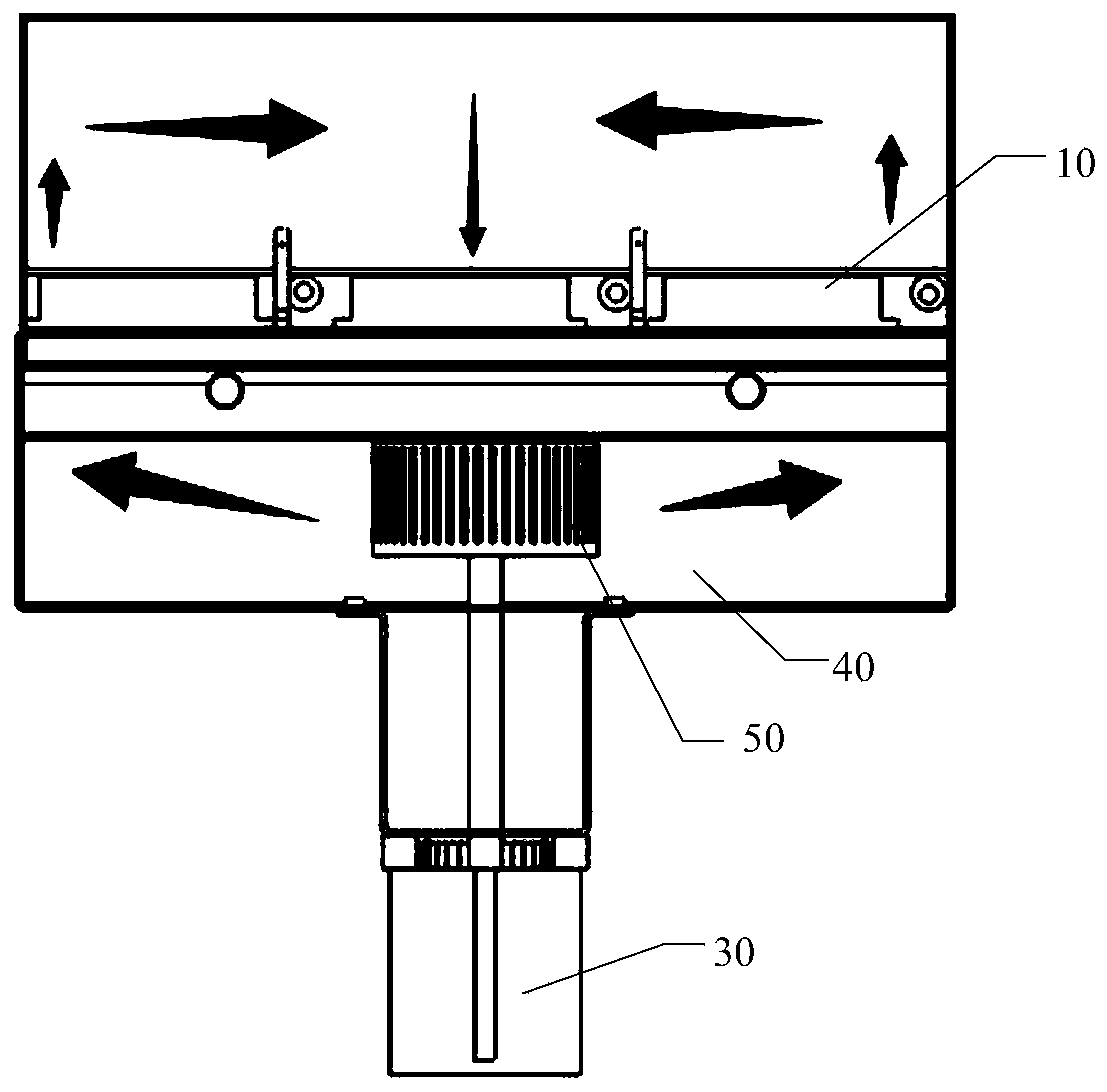

Continuous coating production system of sheet substrates

ActiveCN104060236AReduce stress lossComply with glass safety performance requirementsVacuum evaporation coatingSputtering coatingProduction lineComposite film

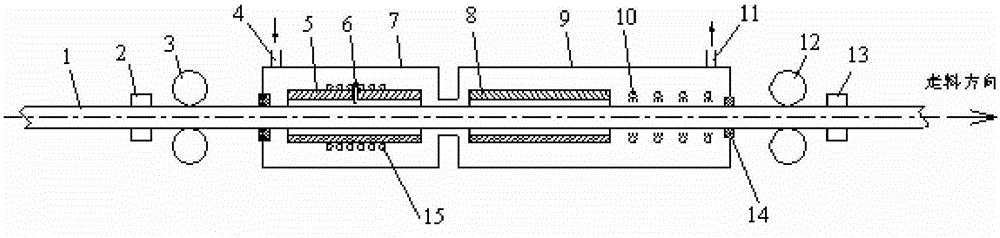

The invention discloses a continuous coating production system of sheet substrates. The continuous coating production system comprises a feeding area, a working area and a discharge area, all of which are orderly communicated with each other; the feeding area comprises a sheet feeding table; the working area comprises a plurality of pre-vacuumizing chambers, a first transition chamber, a coating deposition chamber, a quick atmosphere annealing chamber and a plurality of pre-vacuumizing chambers orderly in the coating process flow direction; the discharge area comprises a discharge table; each chamber of the working area is provided with the desired vacuum environment. The continuous coating production system further comprises a transporting device capable of realizing linear transmission; the transporting device penetrates through the whole feeding area, the working area and the discharge area. The continuous coating system has the advantages that the regional continuous film deposition and annealing of a one-layer or multi-layer composite film containing a hot color coating material in the same production line are realized, the production efficiency is obviously improved, and meanwhile, the material loss cost of the material in the off-line annealing process after coating is reduced. Due to unique structural design of the system, the problem of tempering stress loss can be obviously solved; the stress of the tempered glass based smart glass produced by the system is up to the stress standard of the national building energy-saving safety glass, namely greater than or equal to 90Mpa.

Owner:GUANGZHOU INST OF ENERGY CONVERSION - CHINESE ACAD OF SCI

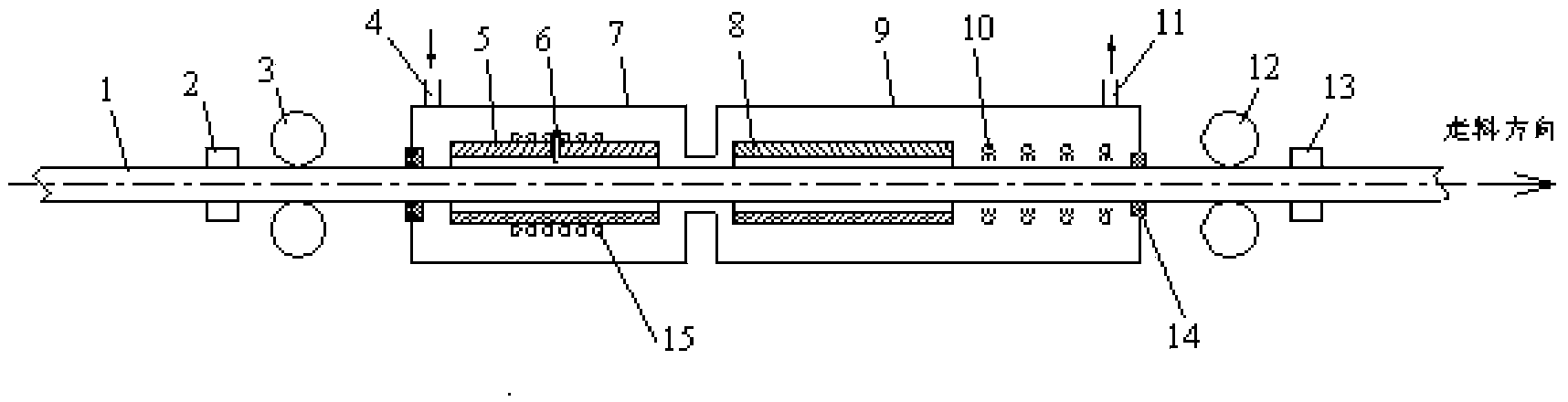

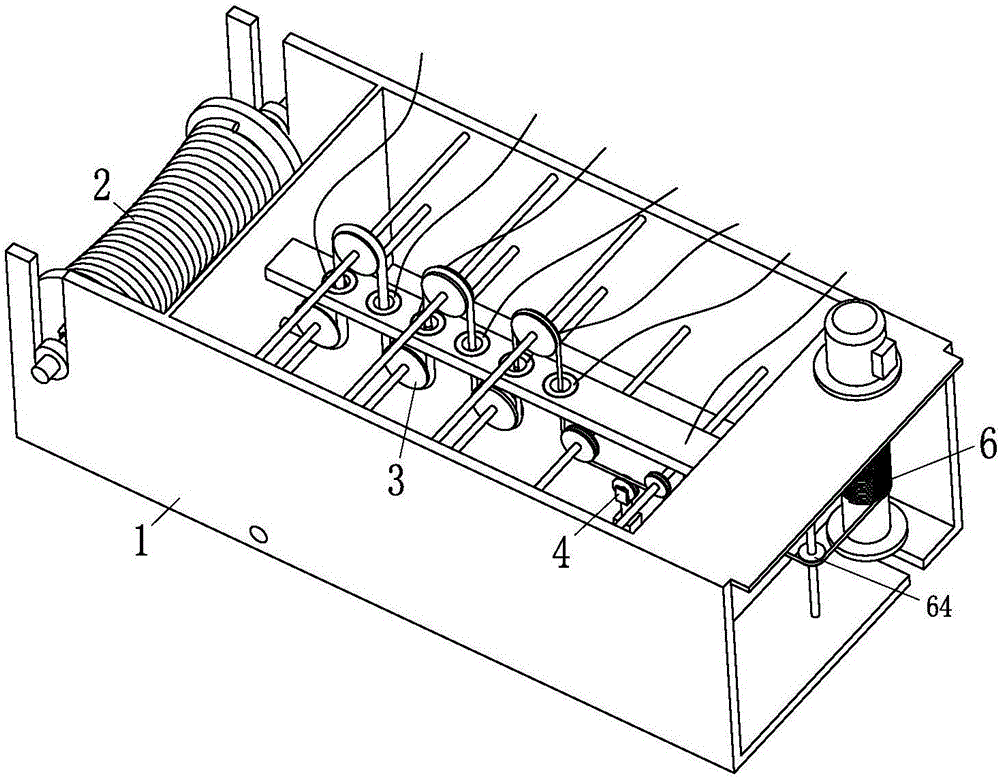

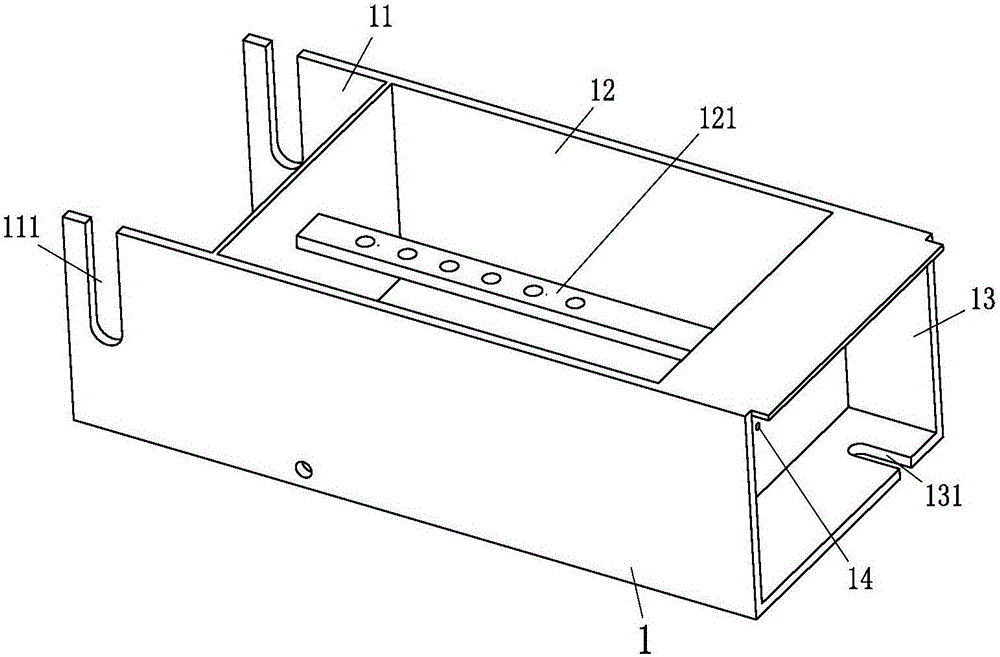

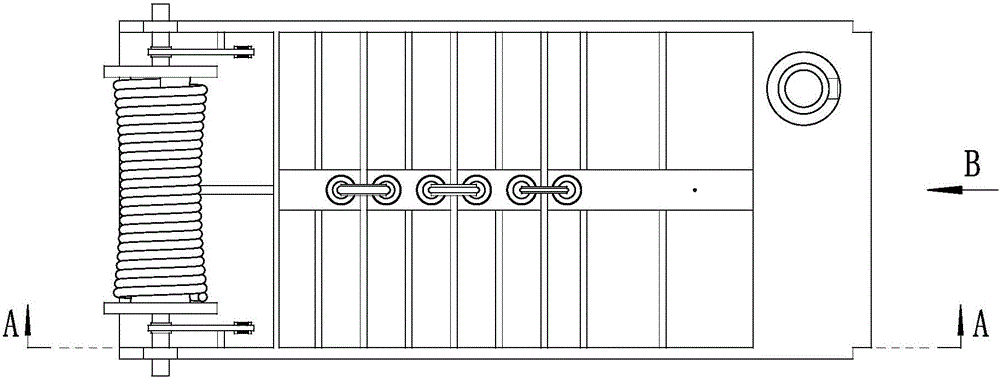

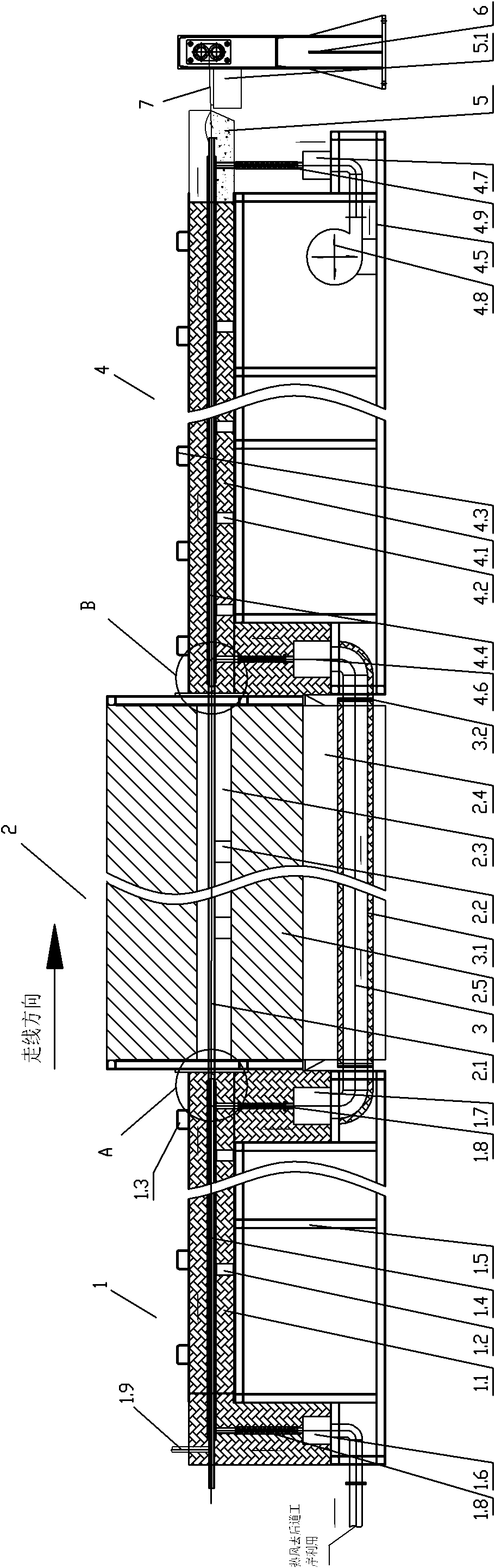

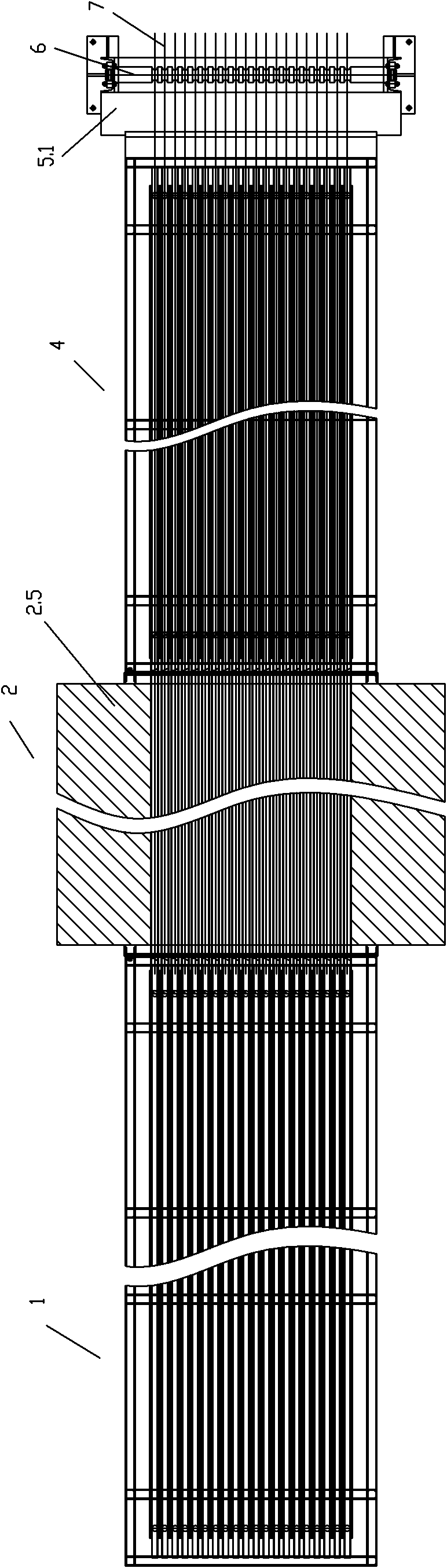

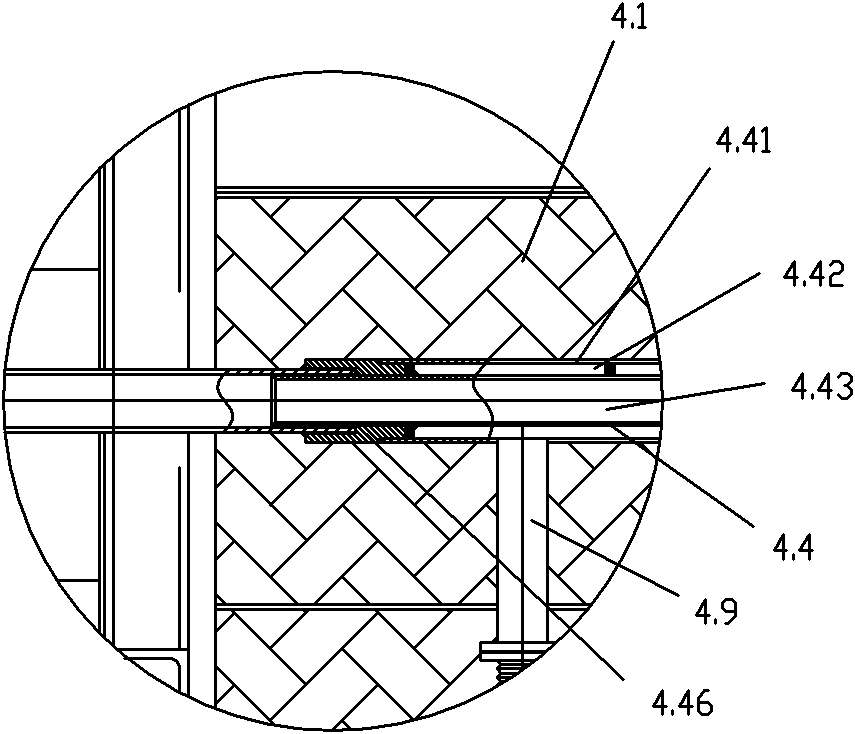

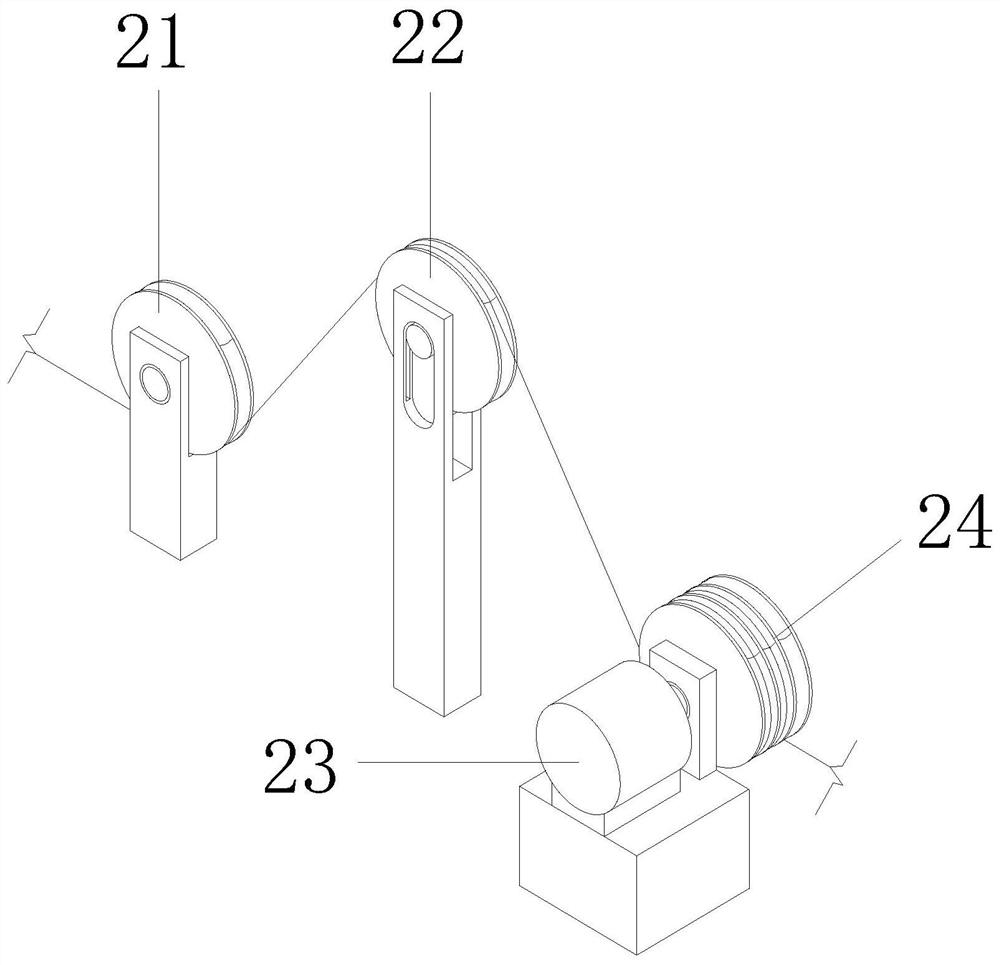

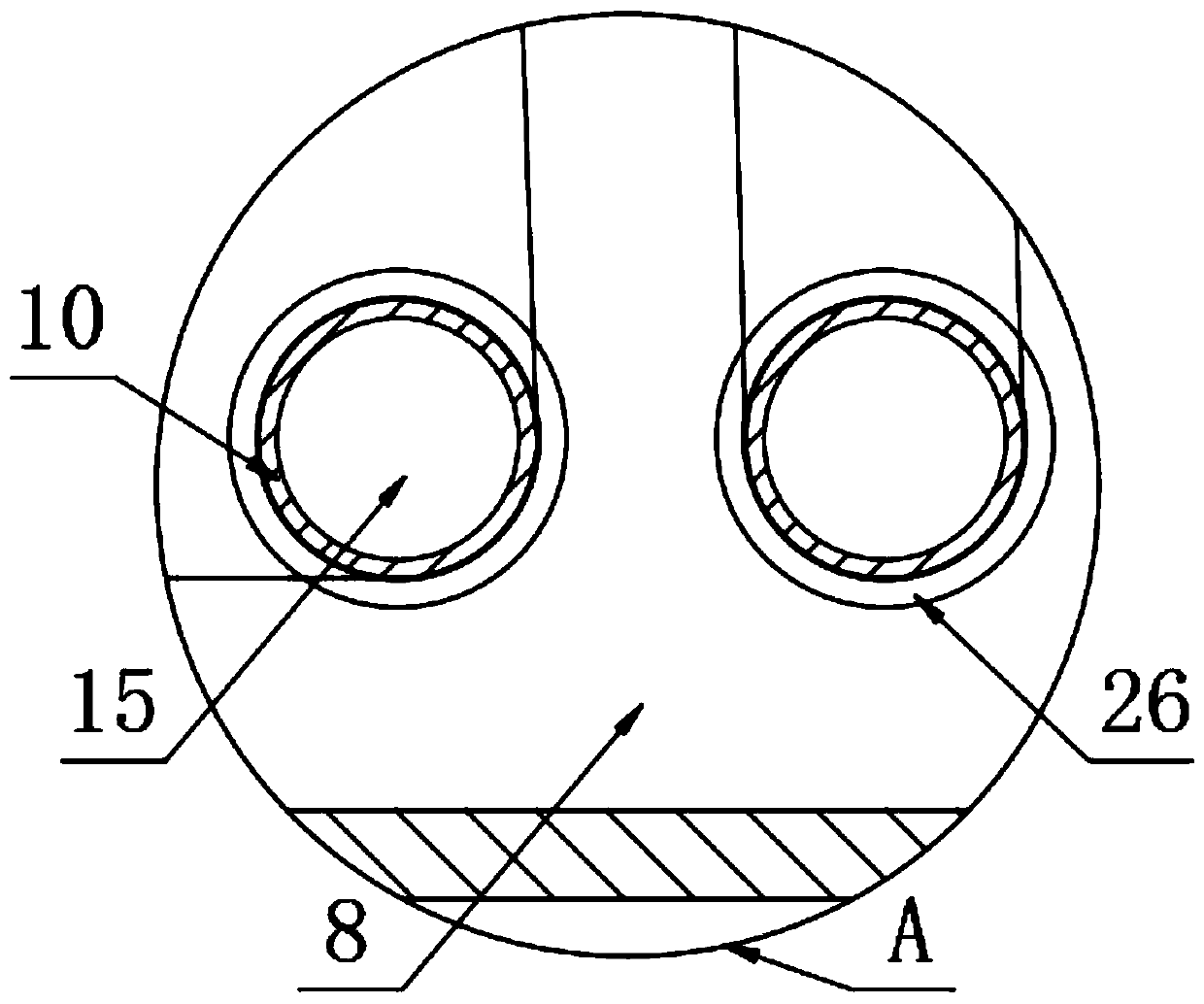

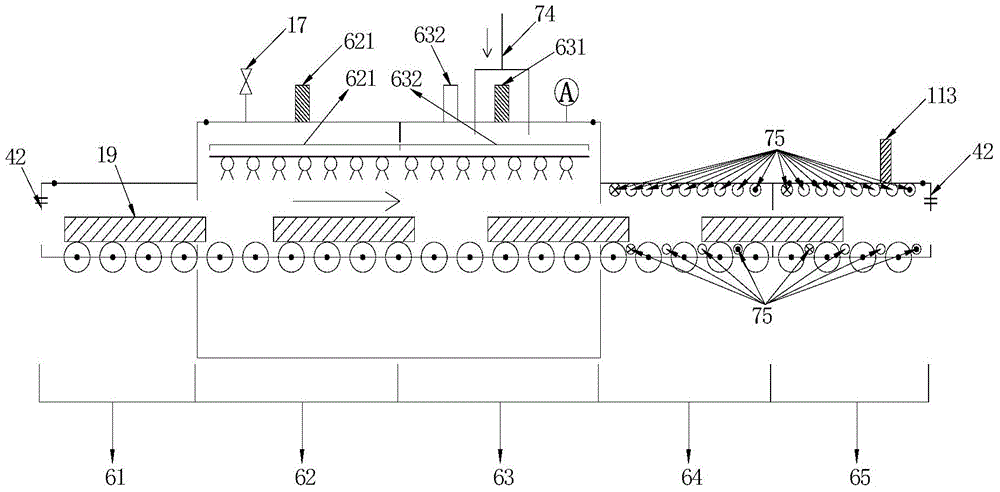

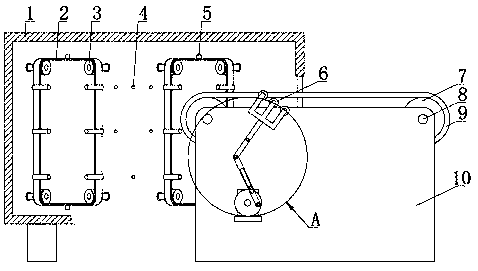

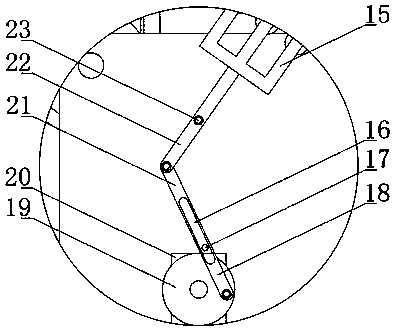

Copper-clad aluminium composite flat cable induction continuous annealing equipment and process using equipment

ActiveCN103710522AControl thicknessImprove performanceFurnace typesIncreasing energy efficiencyHeating timeContinuous annealing

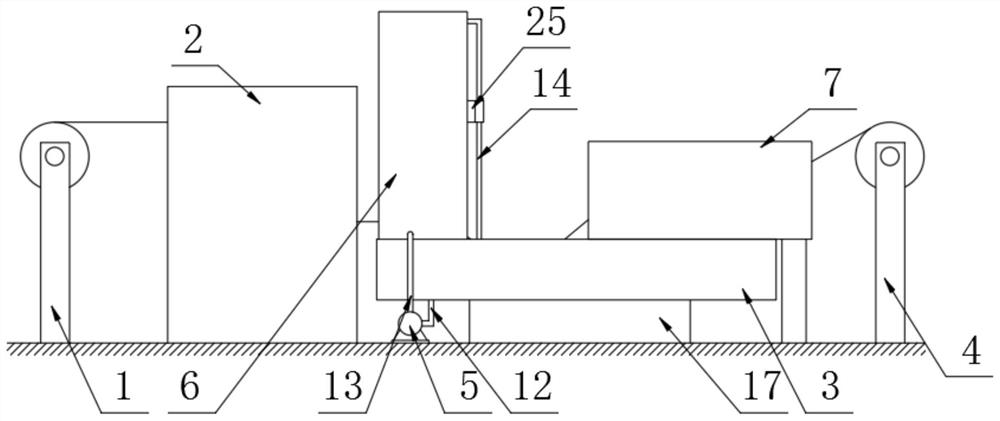

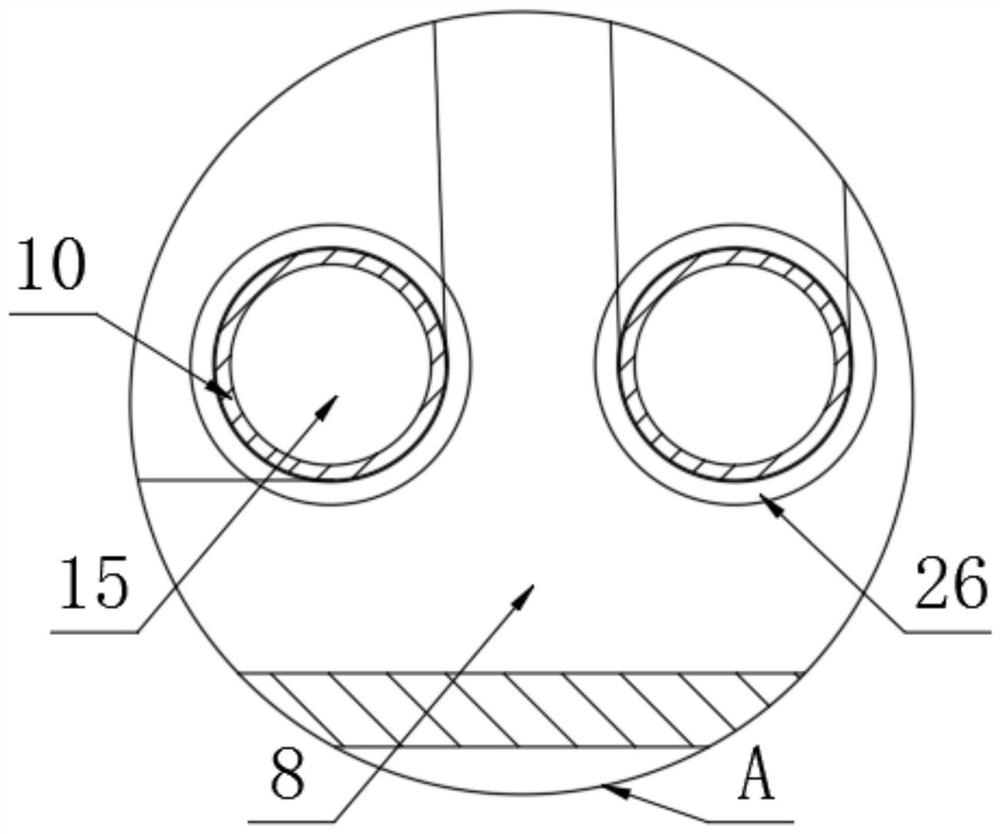

The invention relates to induction heating continuous annealing equipment meeting the characteristics of a copper-clad aluminium composite electrical flat cable and a process using the equipment. The equipment mainly comprises a guide device, a drive device, a temperature measuring device, an induction heating system, a heat preserving section, a cooling section and a gas protective system. The equipment is characterized in that an induction heating power source adopts a frequency on the high side of an intermediate frequency so as to increase the rate of the induction heating, shorten the heating time and control the interface layer thickness; the cross section of an induction heating coil is of a flat shape similar to the shape of the cross section of the copper-clad aluminium flat cable so as to benefit the uniform distribution of temperature and the shortening of the heating time and control the interface layer thickness; a ceramic tube with a certain length and the heat preserving section are arranged to ensure that the temperature is uniform during the heating and enough time is provided to finish the recrystallization of a copper layer and an aluminium core; the forced cooling section is arranged to ensure that the temperature of the annealed flat cable can be rapidly reduced to below 150 DEG C and the copper-aluminium interface layer thickness is controlled at 2-3 micrometers. The invention further provides an annealing process using the annealing equipment.

Owner:UNIV OF SCI & TECH BEIJING

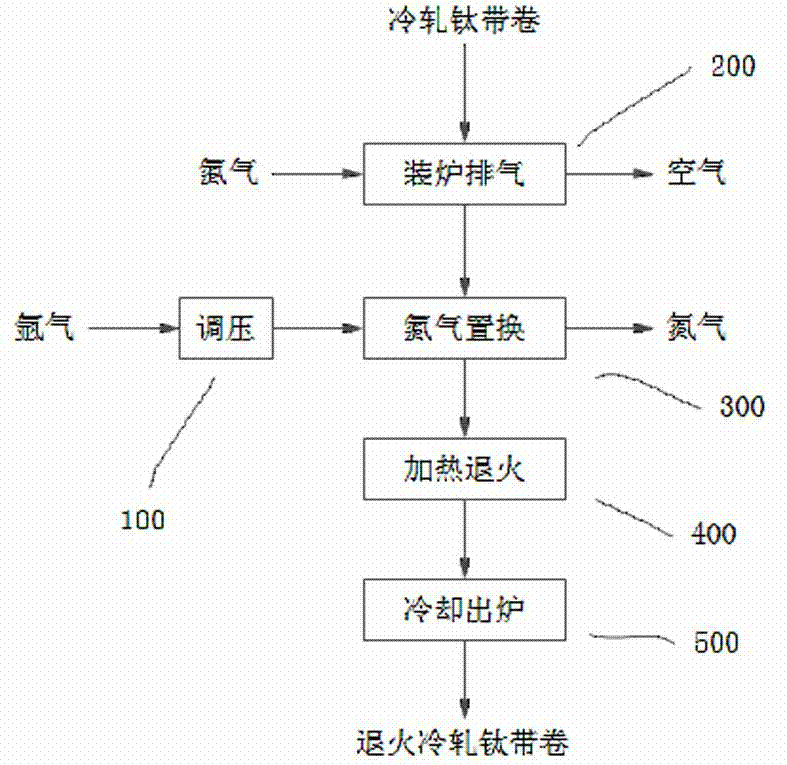

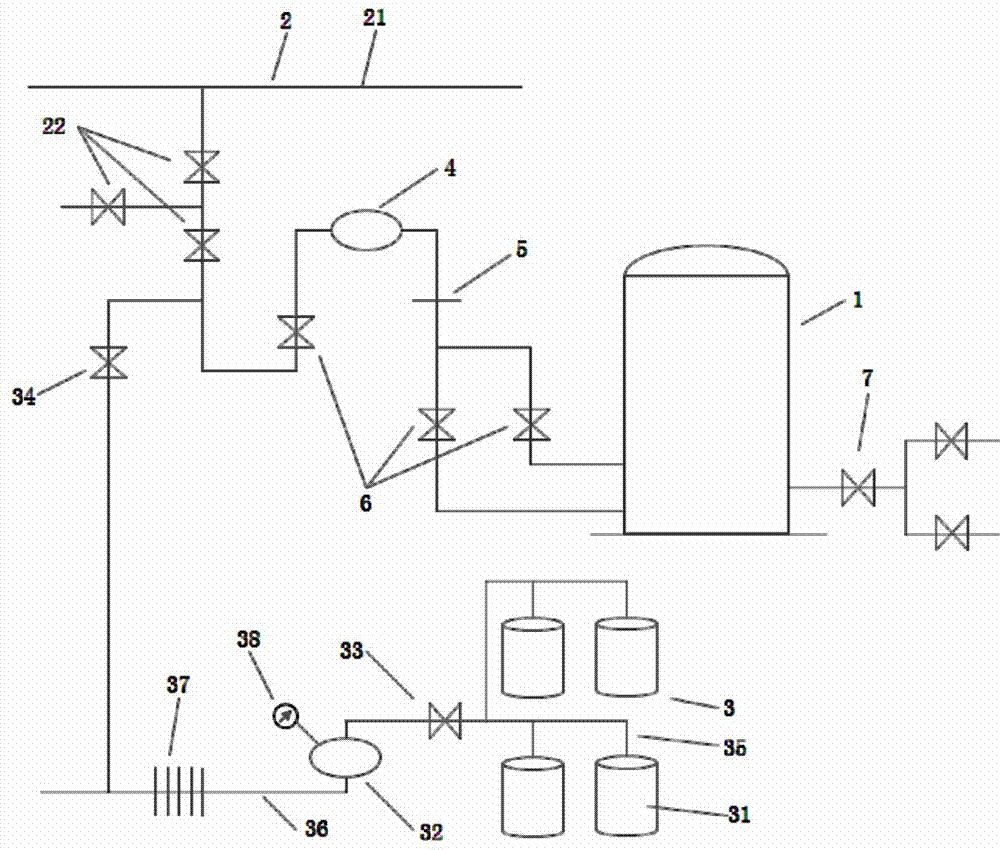

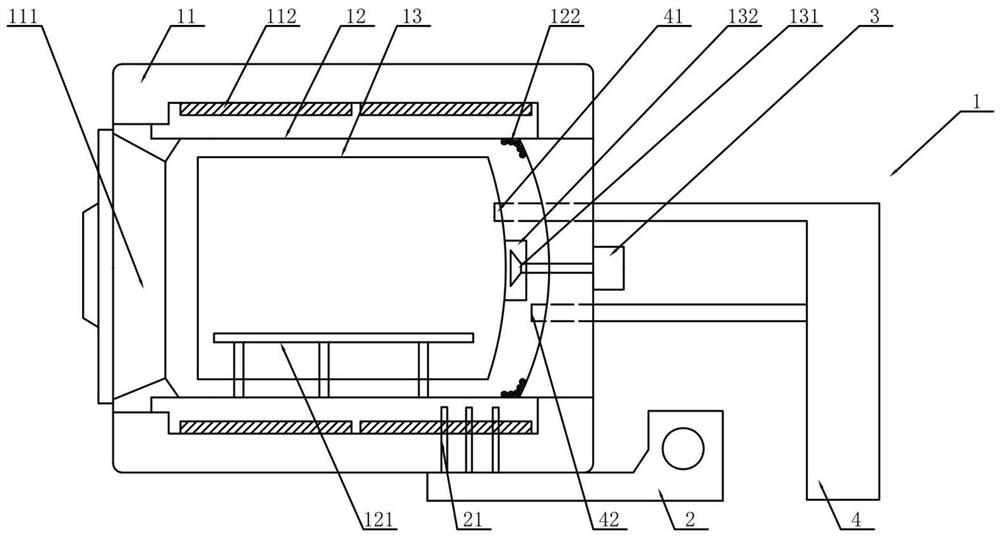

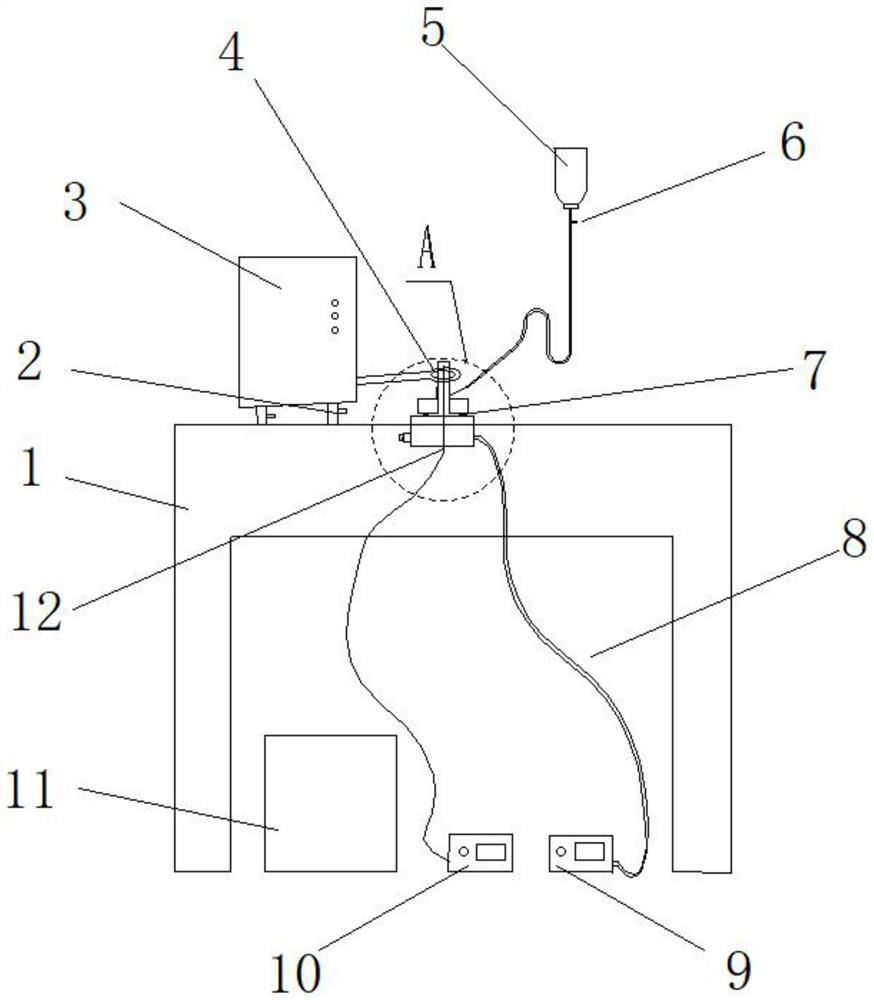

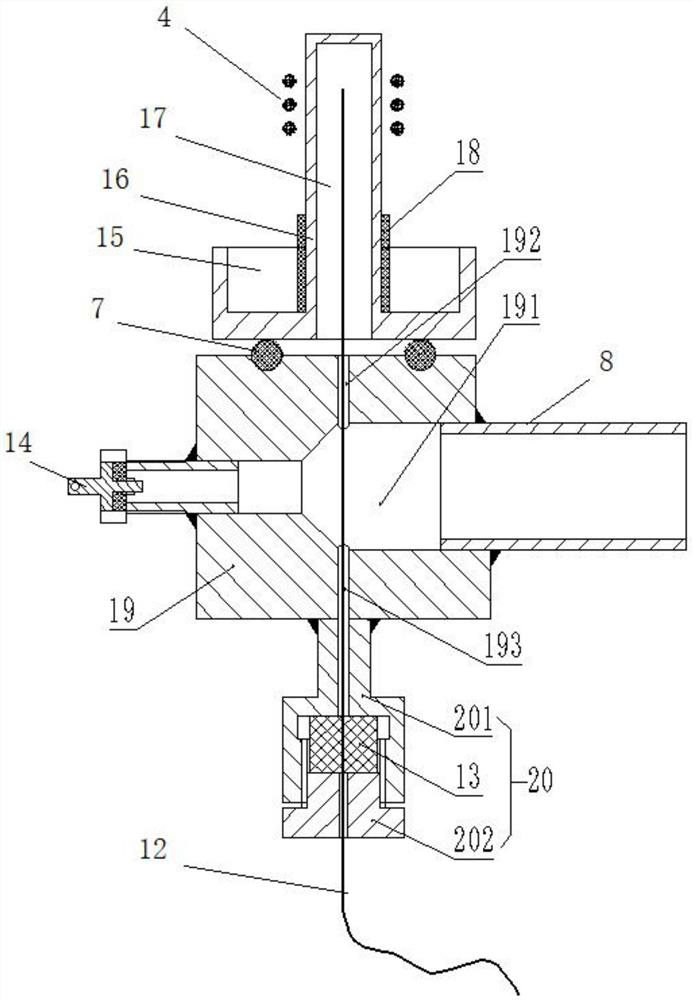

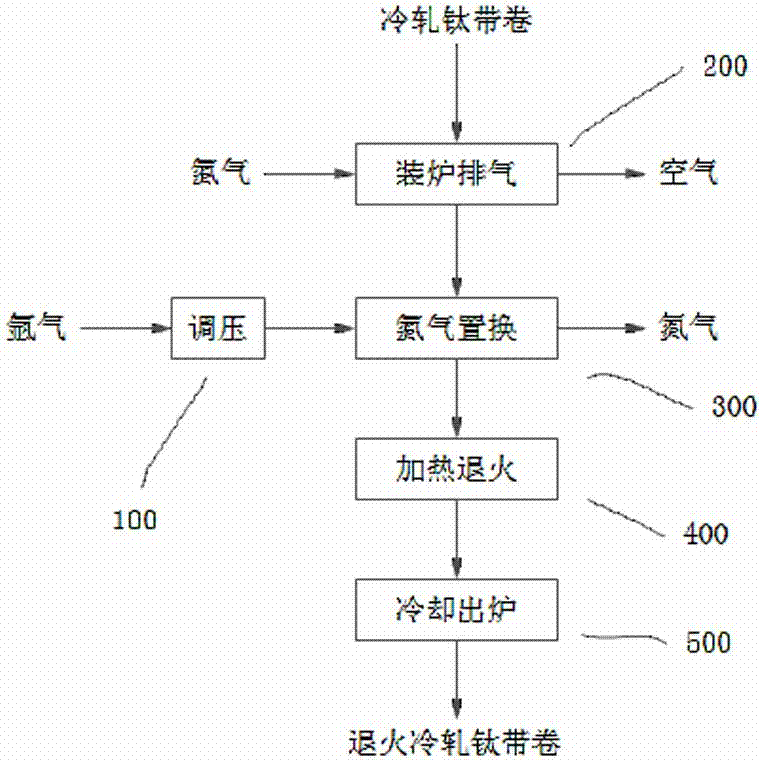

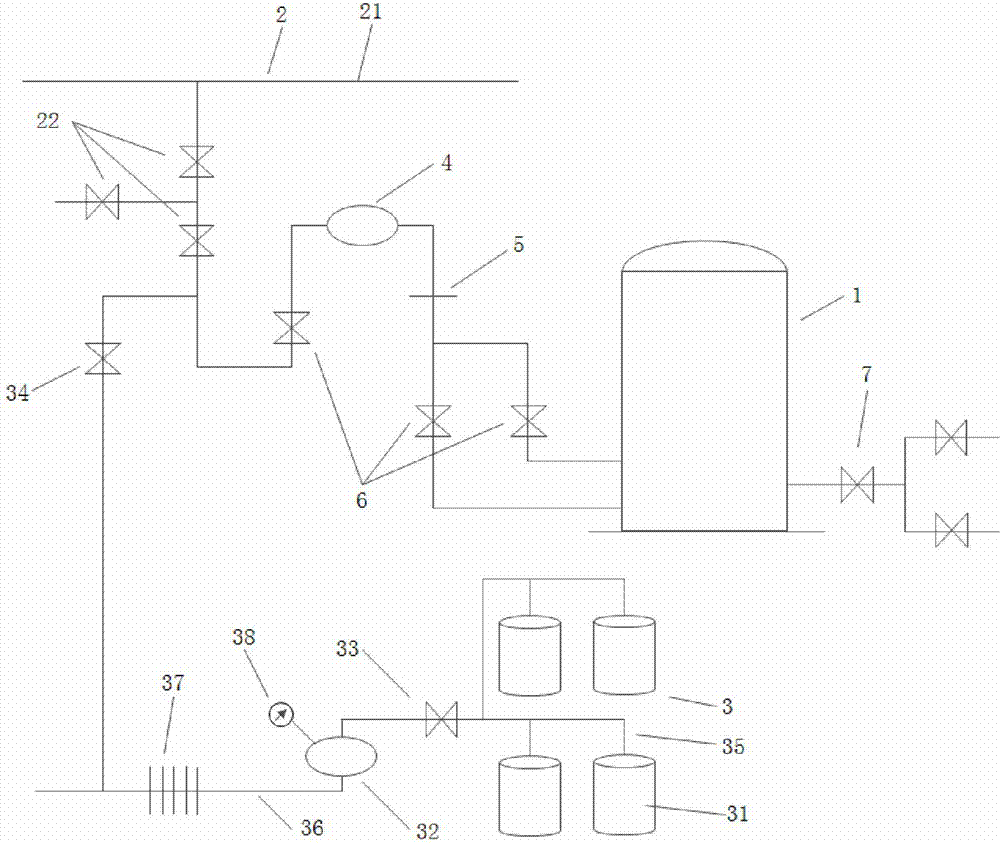

Method and device for performing inert gas protective cover type annealing on cold-rolled titanium strip coils

ActiveCN103205559AAchieve annealingImprove efficiencyFurnace typesHeat treatment furnacesTitaniumNitrogen gas

The invention discloses a method and a device for performing inert gas protective cover type annealing on cold-rolled titanium strip coils, and belongs to the technical field of nonferrous metallurgy. The annealing method comprises the following steps of: pressure adjustment, feeding and exhausting, nitrogen displacement, heating and annealing, cooling and discharging. The device comprises a cover type annealing furnace (1), a nitrogen supply device (2) and an argon supply device (3), wherein the nitrogen supply device (2) is communicated with the inner cover of the cover type annealing furnace (1); and the argon supply device (3) is communicated with the inner cover of the cover type annealing furnace (1). Based on the common full hydrogen or nitrogen-hydrogen annealing furnace, the argon supply device is additionally arranged, so that different annealing requirements of the common full hydrogen or nitrogen-hydrogen annealing furnace for cold-rolled steel strips and titanium strip coils are met; and the device has the advantages of high efficiency, process stability, convenience for transformation, multiple purposes and high reliability.

Owner:WUKUN STEEL

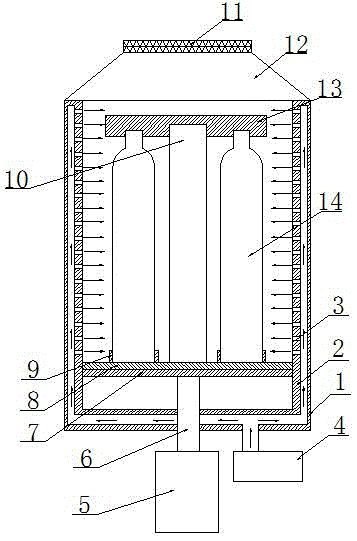

Annealing furnace

InactiveCN105063289AHeating evenlyEvenly heatedFurnace typesHeat treatment furnacesGas cylinderMetallurgy

The invention discloses an annealing furnace. The furnace comprises a furnace body. An annealing shell body is arranged in the furnace body. Gaps are arranged between the furnace body and the bottom surface of the annealing shell body as well as between the circumference surface of the annealing shell body. The upper end of the annealing shell body is fixedly connected with the furnace body. The circumference surface on the middle-upper portion of the annealing shell body is besprinkled with through holes. The inner lower portion of the annealing shell body is provided with a support plate. A thermal insulation layer is arranged on the support plate. The thermal insulation layer is provided with a fixed pillar and a plurality of fixed grooves. A fixed plate is detachably arranged at the top end of the fixed pillar. A plurality of grooves are formed in the positions, corresponding to the fixed grooves, of the fixed plate and are matched with gas cylinder openings. A furnace lid is arranged at the top end of the furnace body and provided with a gas purification cavity. An air cylinder is arranged at the lower end of the furnace body. An air cylinder output shaft extends into the furnace body and is connected with the support plate. An air heater is arranged at the lower end of the furnace body and communicated with the gap between the bottom surface of the annealing shell body and the furnace body. The annealing furnace is capable of improving the working efficiency.

Owner:SINOMA SCI & TECH CHENGDU CO LTD

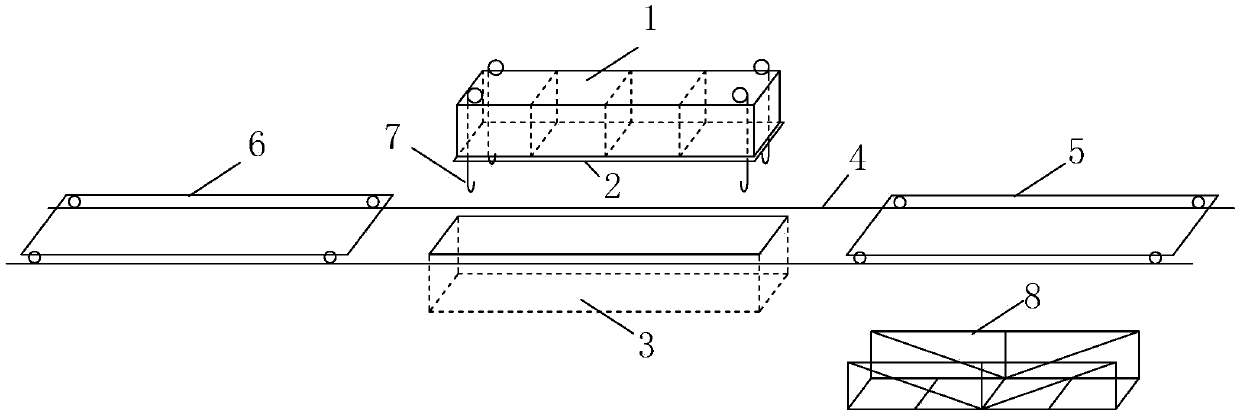

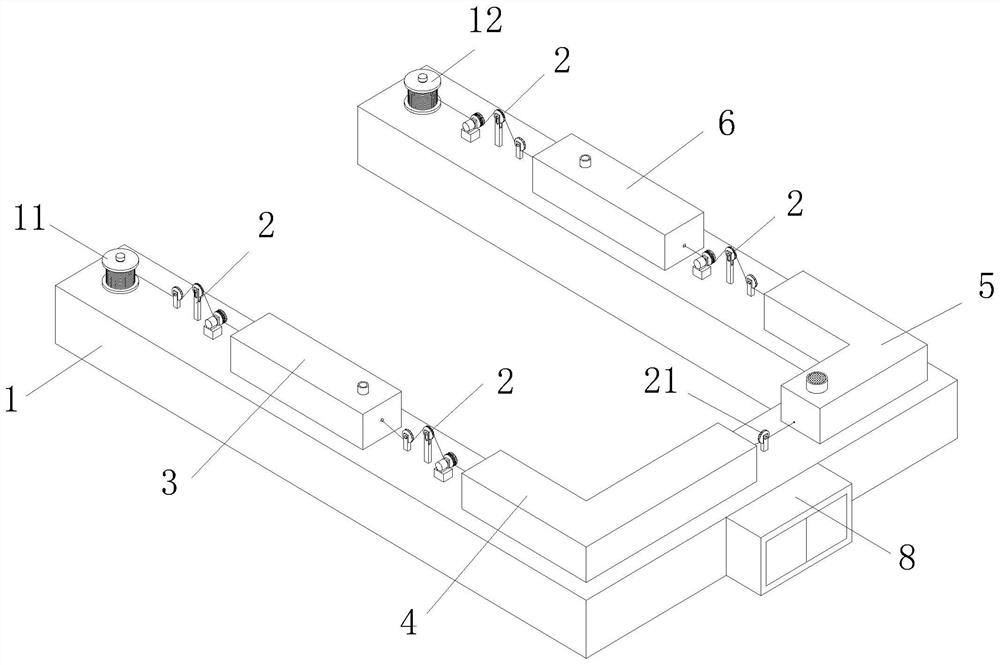

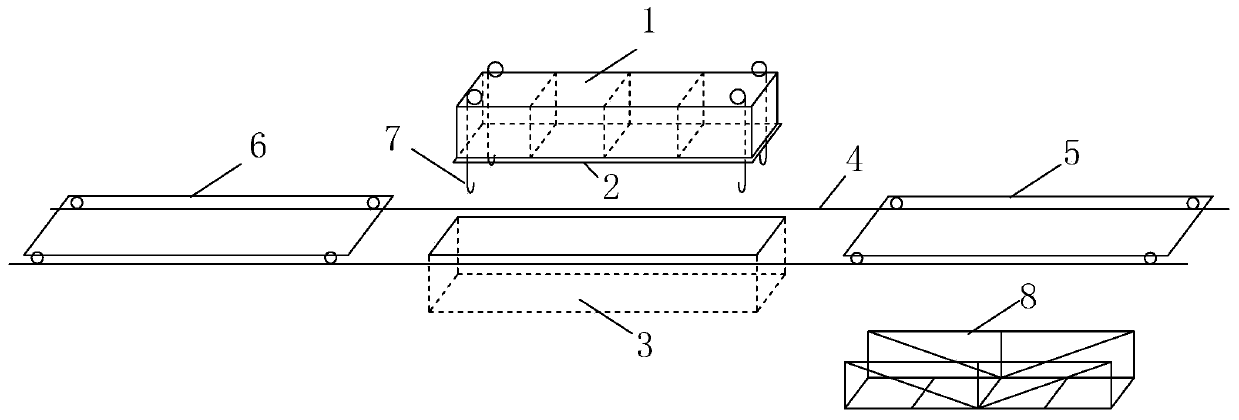

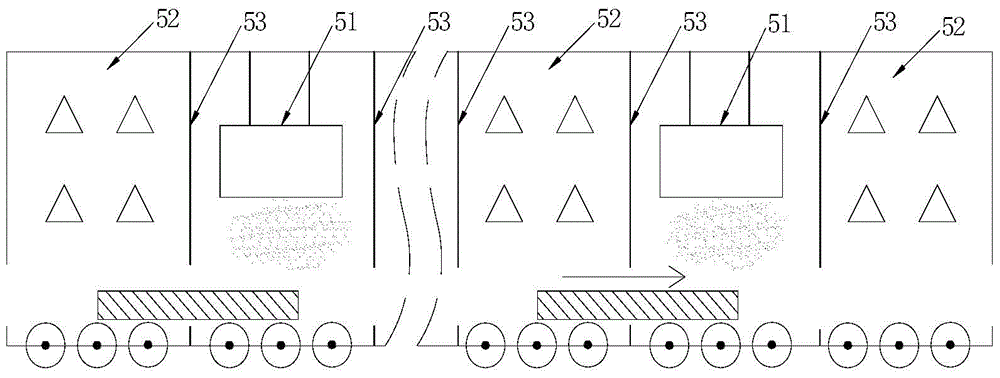

Thermal treatment device and thermal treatment technology of ultra-long aluminum extrusion

ActiveCN109536683AAchieving solution quenchingAchieve annealingFurnace typesHeat treatment furnacesMaterials processingHeating furnace

The invention discloses a thermal treatment device and a thermal treatment technology of an ultra-long aluminum extrusion, and belongs to the technical field of material processing. The thermal treatment device comprises a heating furnace, a quenching water well, a feeding and discharge rail, a feeding trolley, a discharge trolley, a lifting device and a material basket, wherein a furnace body isan ultra-long horizontal furnace composed of a plurality of regions of which the temperature is independently controlled; and a product is horizontally stacked in the material basket, and enters the furnace body or the quenching water well through the feeding trolley, the discharge trolley and the lifting device to be subjected to thermal treatment. According to the thermal treatment device and the thermal treatment technology, horizontal furnace horizontal heating and inclined descend soaking quenching technologies are adopted to replace traditional vertical quenching and roller hearth type quenching technologies, the quenching cooling speed is high and uniform, quenching deformation of the product is low, surface quality is good, and performance is uniform; solid-solution quenching, annealing and ageing functions can be achieved, production scheduling is flexible, length of a biggest product of thermal treatment is large, charge batch is large, production efficiency and heat utilization rate are high, and operation is safe and reliable; and besides, deep well, heat-resistant roller, spraying devices, and the like are not required, basic requirements on equipment are low, and investment is low.

Owner:广西百矿冶金技术研究有限公司

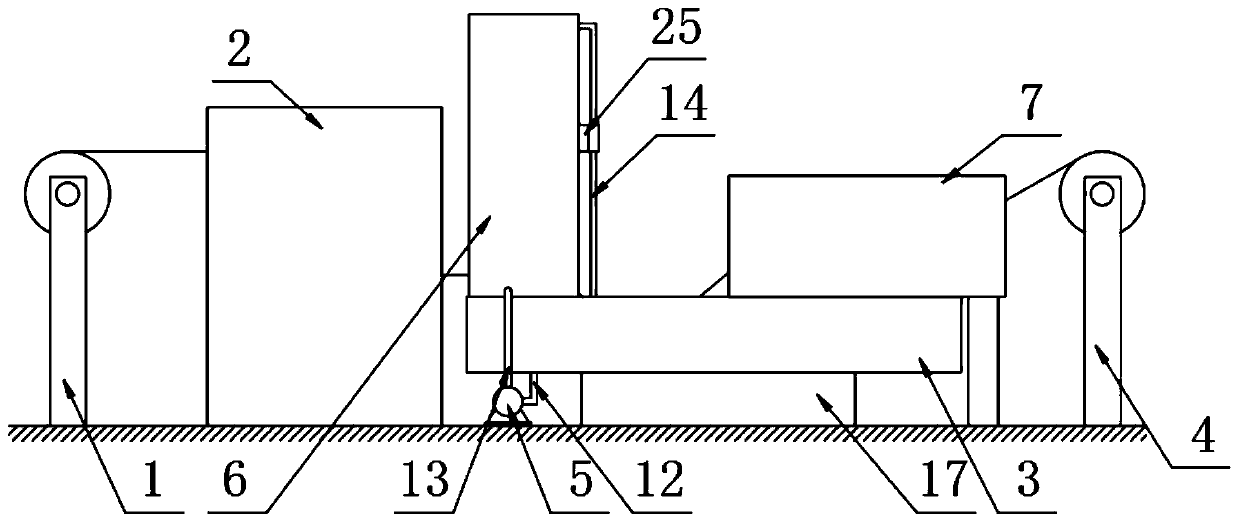

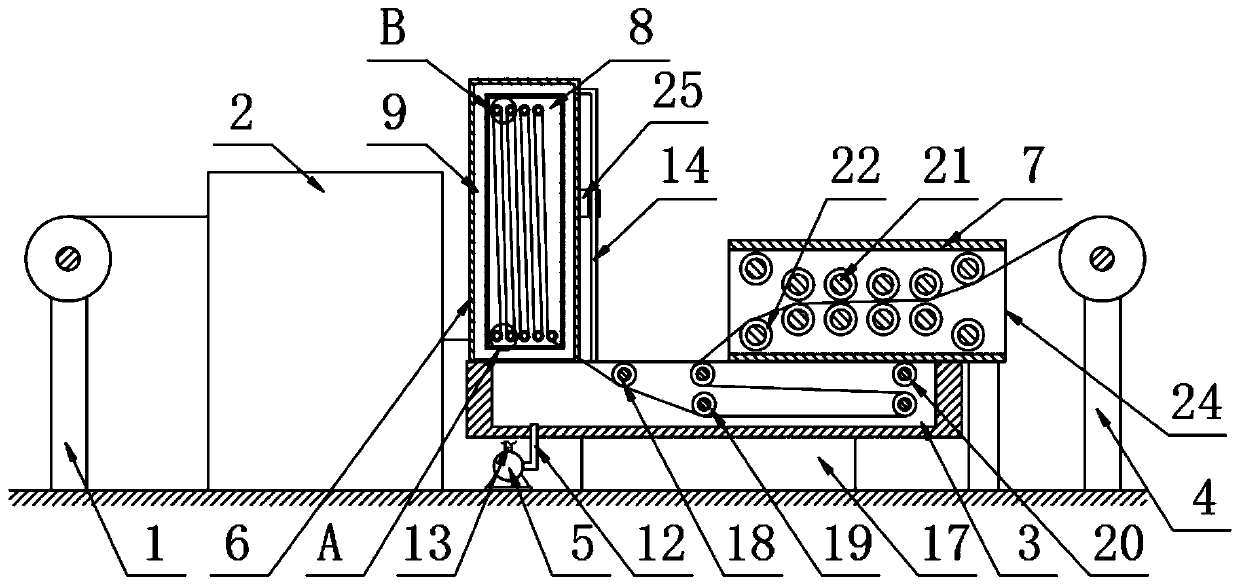

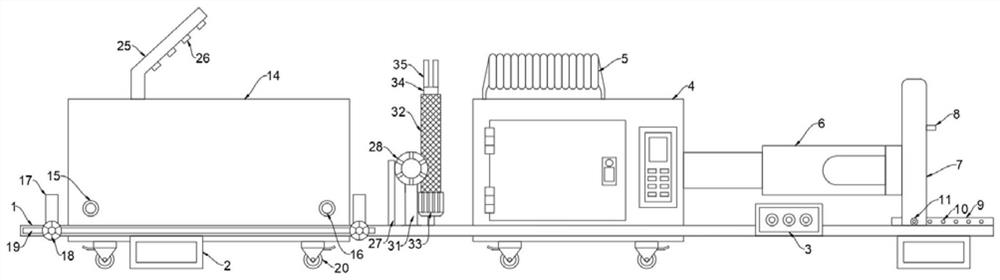

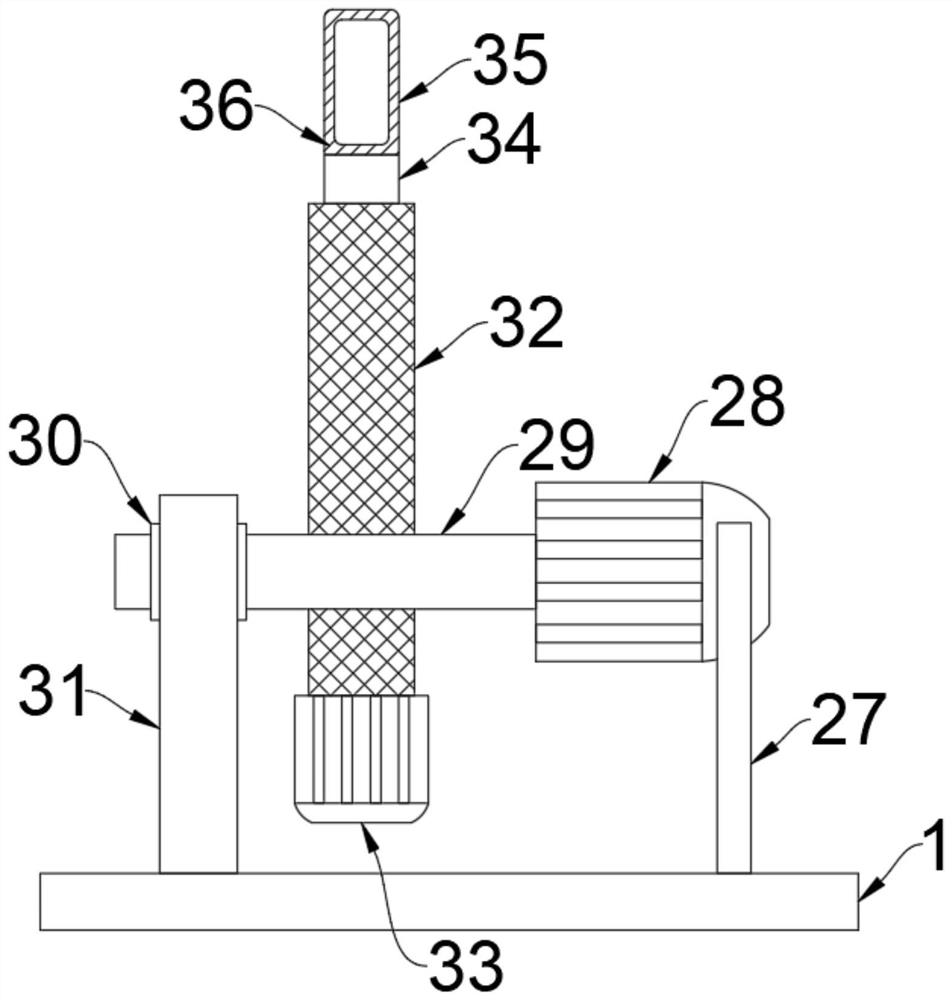

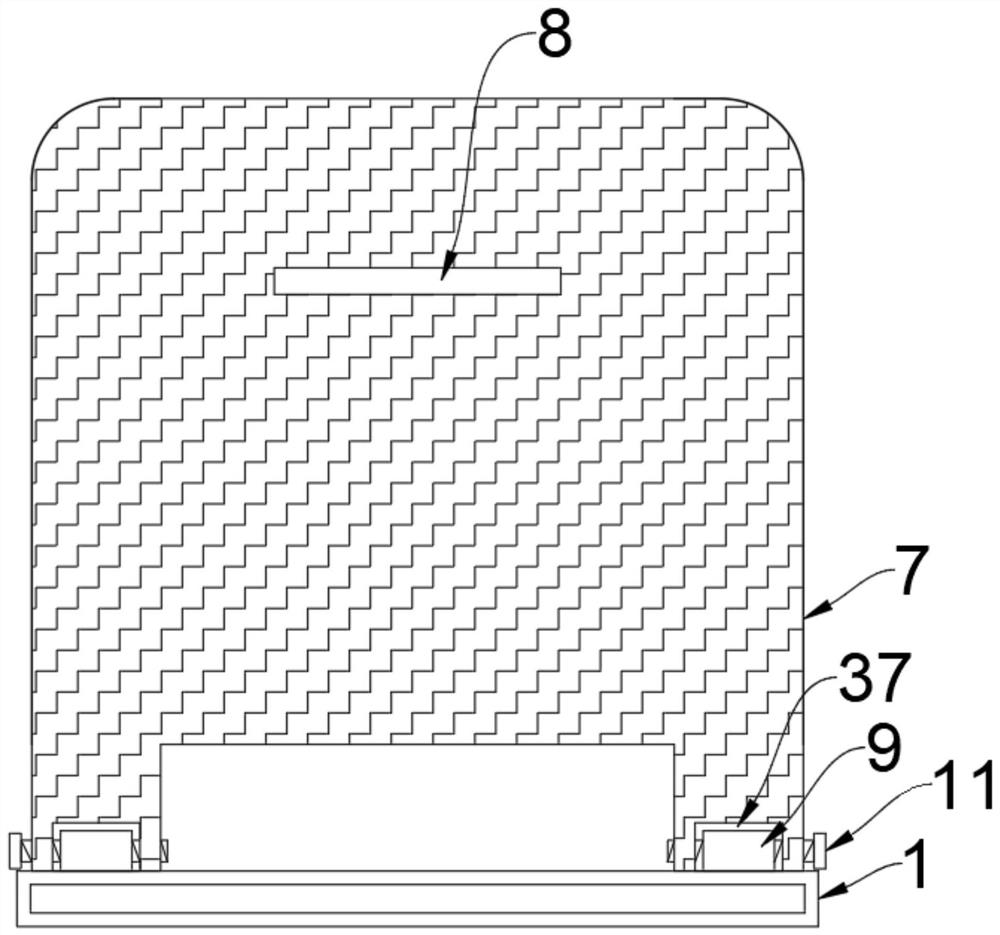

Small copper wire drawing equipment for cable

InactiveCN105945076ARealize automatic pay-offAchieve annealingFurnace typesHeat treatment furnacesCopper wireEngineering

The invention relates to the field of cable equipment and particularly relates to small copper wire drawing equipment for a cable. The equipment comprises a machine body, a wire-releasing device, a wire-drawing device, a tensioning device, an annealing device and a take-up device, wherein the wire-releasing device is positioned on the left side of the machine body, the wire-drawing device is positioned in the middle part of the machine body, the tensioning device is positioned on the right side of the wire-drawing device, the annealing device is positioned on the right side of the tensioning device, and the take-up device is positioned on the right side of the annealing device. The small copper wire drawing equipment for the cable provided by the invention can realize a full course of automatic wire release, drawing, take-up and etc. of a copper wire, and is simple in structure and high in degree of automation.

Owner:安庆潜江电缆有限公司

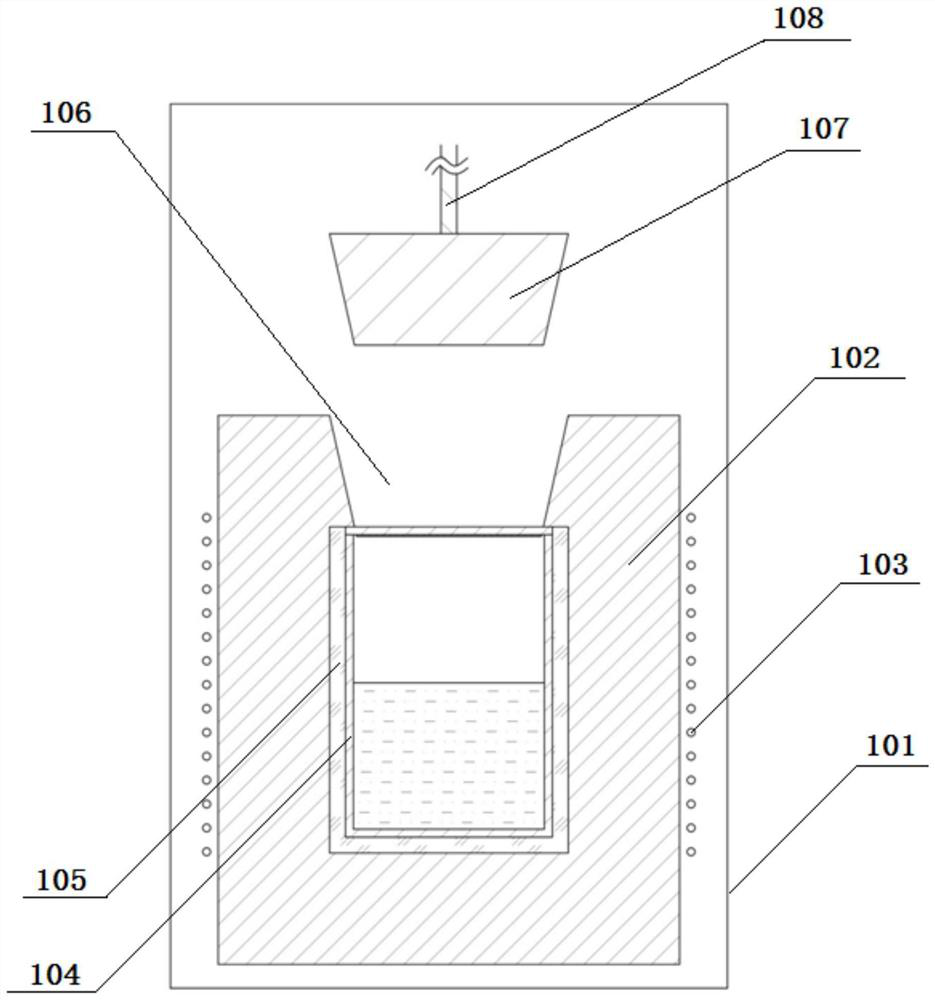

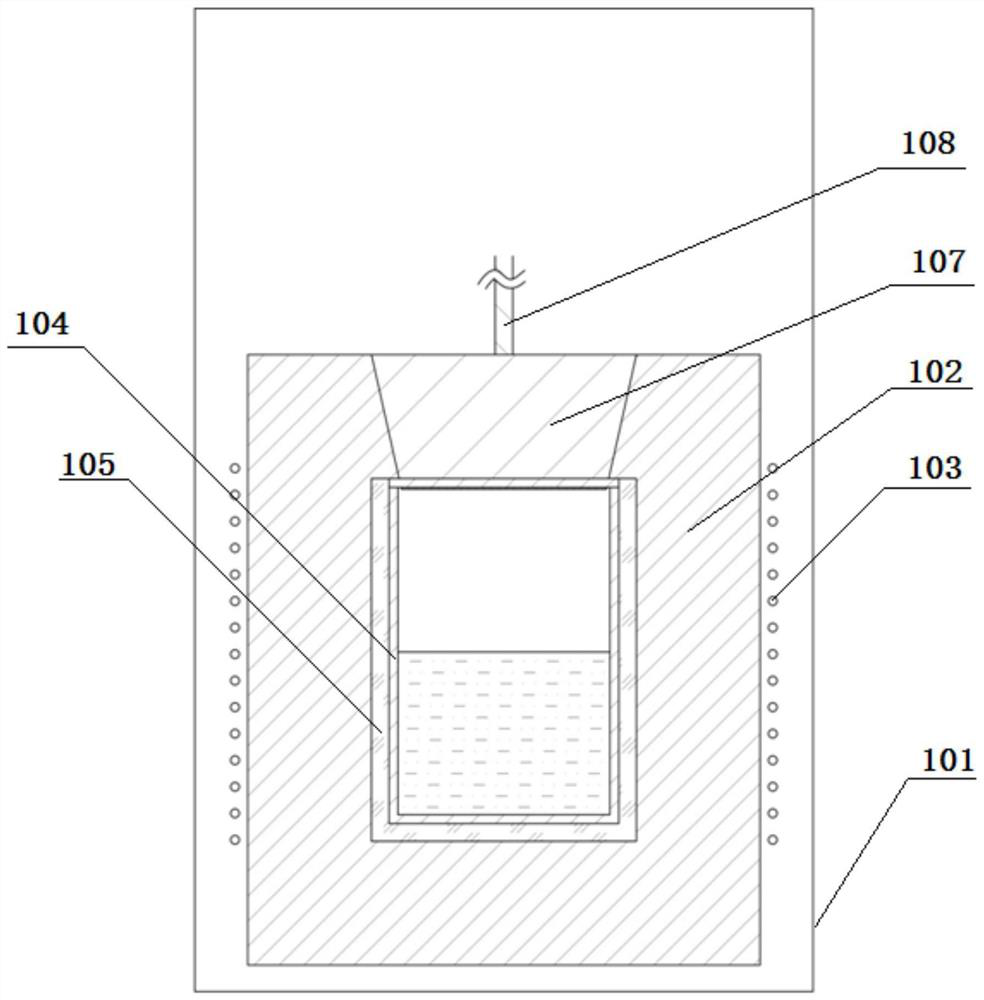

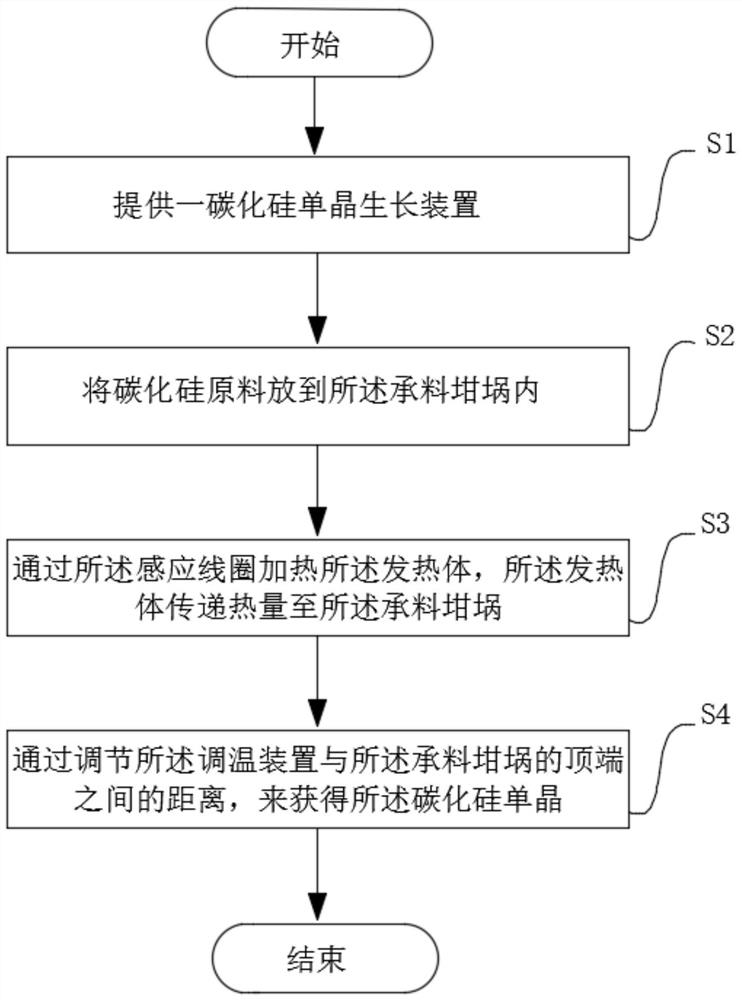

Silicon carbide single crystal growth device and method

InactiveCN111748844AReduce internal stressQuality improvementPolycrystalline material growthFrom frozen solutionsCarbide siliconInsulation layer

The present invention discloses a silicon carbide single crystal growth device and method, the silicon carbide single crystal growth device comprises a container body, a heat preservation layer is arranged in the container body, an induction coil is arranged on the periphery of the container body or the periphery of the heat preservation layer, a material bearing crucible is arranged in the thermal insulation layer and is used for placing a silicon carbide raw material, a heating body is located in the heat preservation layer and arranged around the material bearing crucible, and a temperatureadjusting device is used for adjusting the temperature gradient in the material bearing crucible. The internal stress of the crystal can be reduced, and the quality of the crystal is improved.

Owner:CEC COMPOUND SEMICON CO LTD

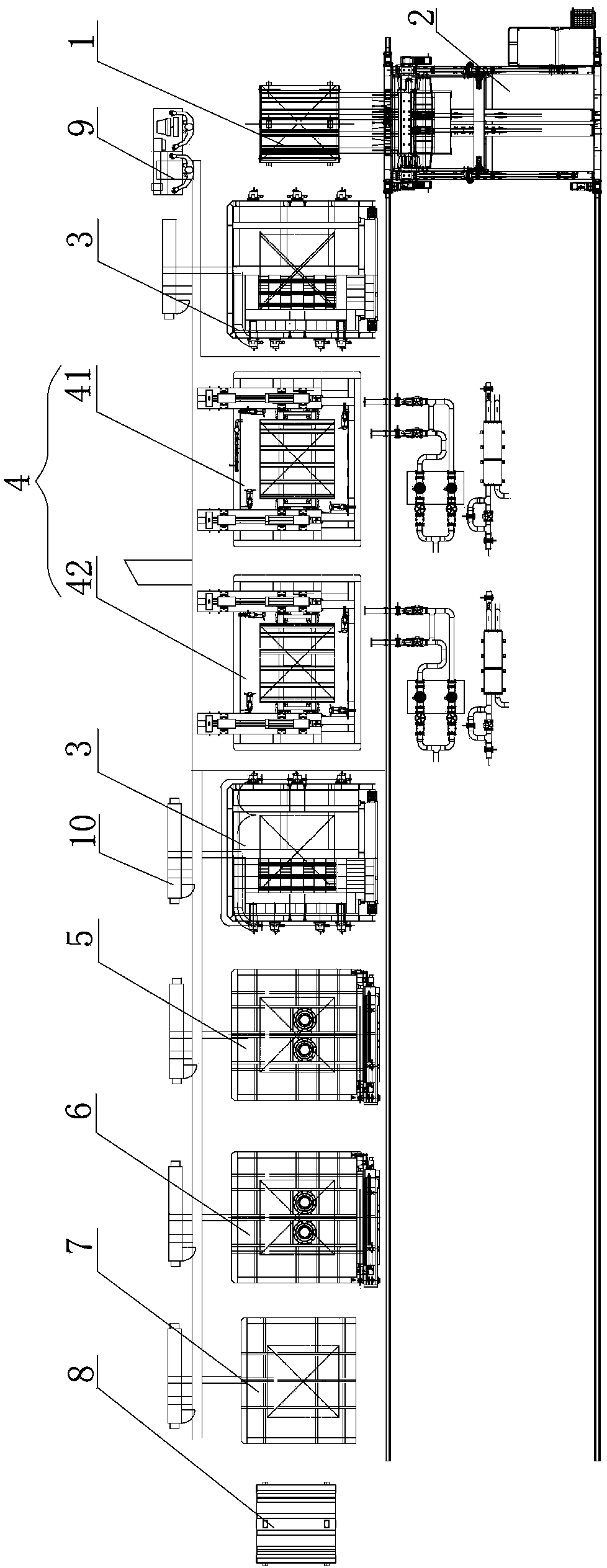

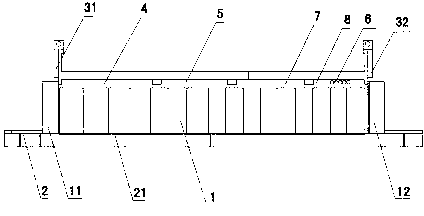

Pretreatment production line

InactiveCN103898279AHigh degree of automationIncrease productivityQuenching devicesProduction lineComputer control system

The invention relates to a heat treatment production line, and particularly relates to a multifunctional pretreatment production line. The pretreatment production line sequentially comprises a fixed loading table, transmission equipment, a first heat furnace, quenching cooling equipment, a second heat furnace, a high-temperature tempering furnace, a low-temperature tempering furnace, air-cooling equipment, an unloading table and an upper computer control system which are arranged in a straight line. According to the pretreatment production line, all the above devices are arranged in a straight line, parts can be transferred among different devices by transferring a forklift, startup of devices is controlled by the upper computer control system combined with originally developed software and the control cabinet of each device, and the production efficiency can be greatly improved due to high automatic degree.

Owner:HEPHAES HEAT TREATMENT SYST JIANGSU

Thermal treatment furnace for carrying out continuous heating and cooling circulation on steel wires

ActiveCN102061375AAchieve annealingRealize normalizingFurnace typesHeat treatment furnacesHeating furnaceThermal treatment

The invention relates to equipment for producing steel wires, in particular to a thermal treatment furnace for carrying out continuous heating and cooling circulation on steel wires. According to the technical scheme provided by the invention, a heating furnace body and a heating hearth arranged in the heating furnace body are arranged in a heating section; a heating pipe is arranged in the heating hearth; a channel allowing the steel wires to pass through is arranged in the heating pipe; a cooling section is arranged on the heating section; a cooling furnace body and a cooling pipe arranged in the cooling furnace body are arranged in the cooling section; at least two heating pipes are provided, the cooling pipes are arranged horizontally, and the corresponding cooling pipes are communicated with the heating pipes; a cooling casing pipe is arranged outside the cooling pipe; and a cooling channel is formed between the cooling pipe and the cooling casing pipe. The steel wires before entering the heating furnace are preheated by using the heat energy which is acquired by cooling the steel wires in the heating furnace during the lead-out of the high temperature through utilizing forced wind or the thermal treatment furnace is applied to other procedures so as to reduce the waste of the heat energy by fully utilizing the heat energy.

Owner:WUXI XINKE METALLURGICAL EQUIP

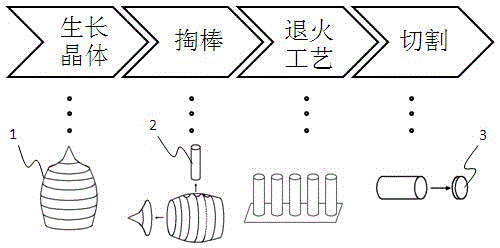

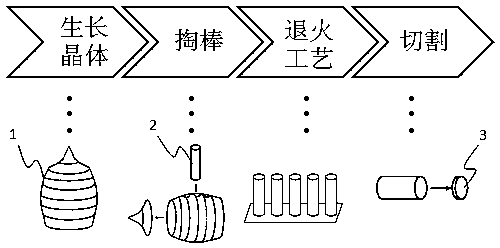

Method for producing crystal bars

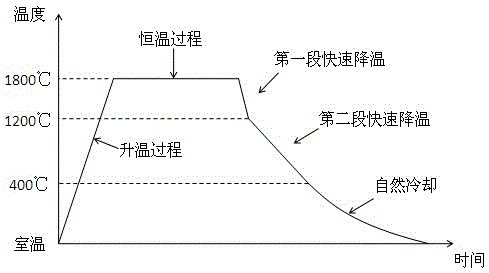

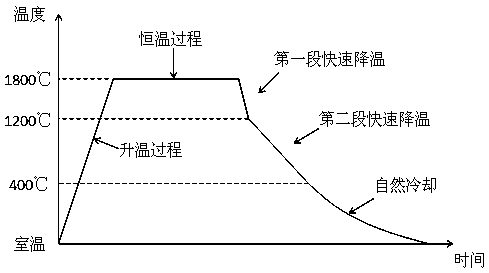

ActiveCN106544738AAchieve annealingImprove consistencyPolycrystalline material growthAfter-treatment detailsWarming processCrystal growth

The invention discloses a method for producing crystal bars. The method is characterized in that before online cutting, crystal bars which are treated by a bar picking technology are placed in a high temperature annealing furnace for carrying out annealing; the annealing process mainly comprises the following step: a heating process, a constant temperature process, and a cooling process. The annealing process method of sapphire crystal bars is provided, unified annealing processing is carried out for crystal bars produced by different crystal growths and bar picking technology, residual stress in the crystal bars is eliminated, consistency of the quality of sapphire crystal bars is improved, and posterior wafer processing, and epitaxial yield rate and uniformity are improved.

Owner:FUJIAN JING AN OPTOELECTRONICS CO LTD

Oversize heat recovery-type push disc-type wire continuously and isothermally-balling and annealing furnace

InactiveCN102808069AAchieve annealingImprove efficiencyFurnace typesHeat treatment furnacesMetallurgyContinuous annealing

The invention provides an oversize heat recovery-type push disc-type wire continuously and isothermally-balling annealing furnace, comprising a furnace body, wherein a front gate for feeding work pieces is arranged on a front end of the furnace body; a back gate for discharging work pieces is arranged on a tail end of the furnace body; a pre-heating area, a heating area and a cooling area are orderly arranged in the furnace body; an isothermal area further is arranged between the heating area and the cooling area; a roller guide rail for realizing technical movement of work pieces is arranged in the furnace body; a feeding table is arranged on an inlet end of the front gate; a discharging table is arranged on an outlet end of the back gate; and a cycle heat recovery system for increasing heat efficiency of the annealing furnace. The annealing furnace can realize annealing for work pieces in batch, especially, the annealing furnace can be applied to continuously annealing and processing wires, and therefore, the efficiency is higher.

Owner:苏州工业园区胜龙电炉制造有限公司

Automatic production line for producing enameled wires

InactiveCN114121376ASimple structureSmall footprintApparatus for feeding conductors/cablesApparatus for heat treatmentManufacturing engineeringIndustrial engineering

The invention provides an automatic production line for producing enameled wires. The automatic production line comprises a base, a conveying assembly, an annealing device, a painting device, a baking device, a cooling device, a wire drawing assembly and a control device. A pay-off roller and a take-up roller are movably arranged on the base, the conveying assembly sequentially conveys an enameled wire to the annealing device, the painting device, the baking device, the cooling device and the take-up roller from the pay-off roller, the annealing device conducts annealing processing on the enameled wire, the painting device conducts multi-layer painting processing on the enameled wire, and the baking device conducts evaporation and curing processing on paint liquid of the enameled wire. The cooling box is used for carrying out cooling processing on the enameled wire, the wire drawing assemblies are installed in the heating bin, the annealing bin, the first painting bin, the second painting bin, the baking bin, the evaporation bin, the cooling bin and the cooling bin correspondingly, and the control device controls the pay-off roller, the take-up roller, the conveying assembly, the annealing device, the painting device, the baking device and the cooling device to work normally. The automation degree and the production efficiency are high.

Owner:湖南奇洛电工器材有限公司

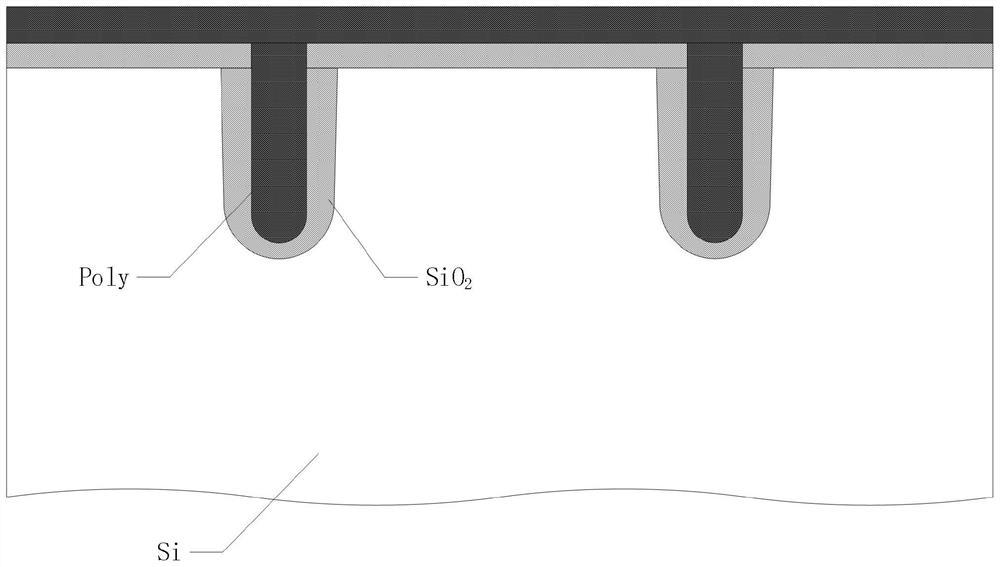

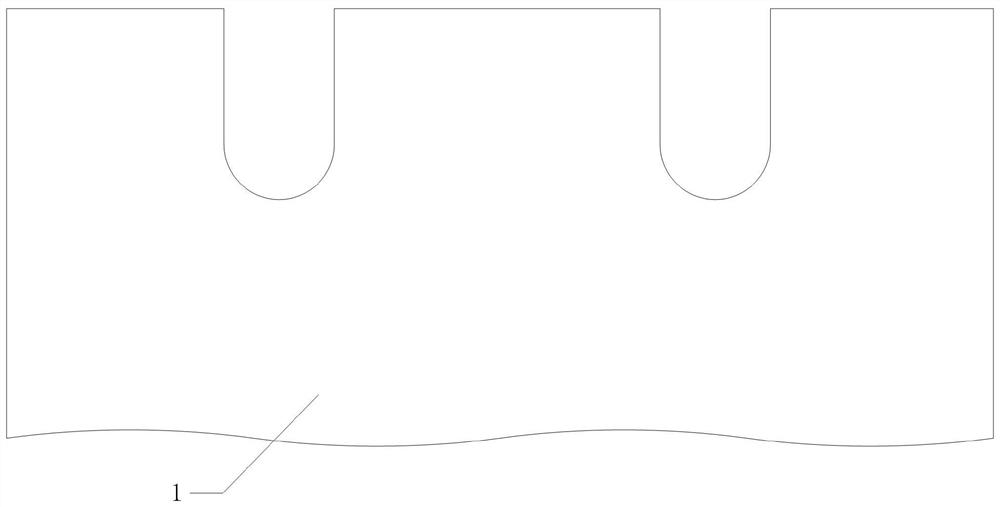

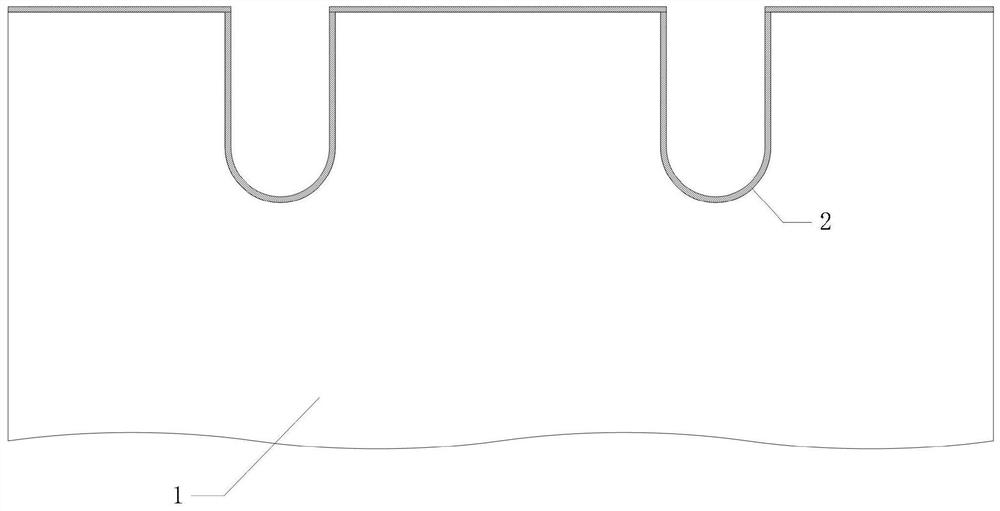

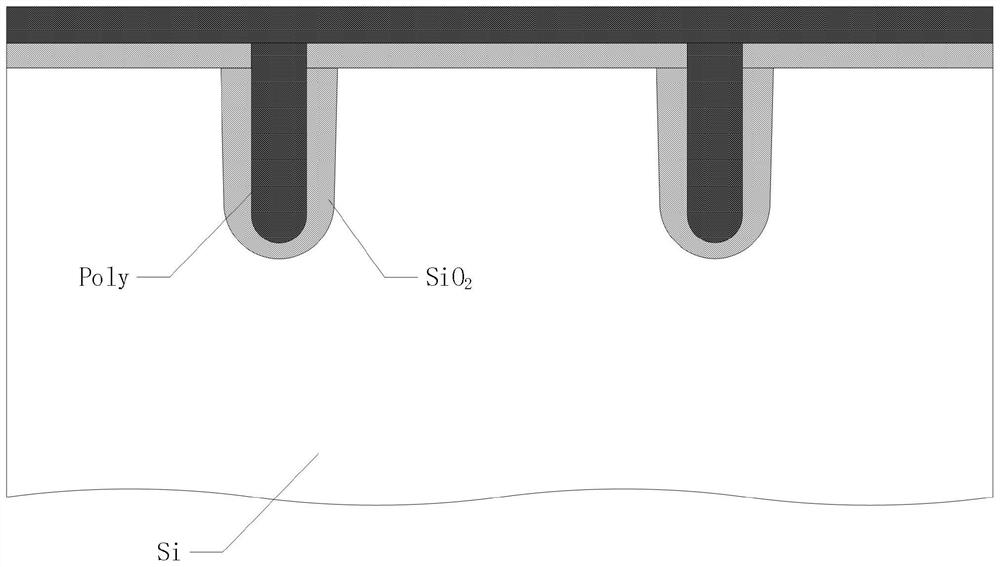

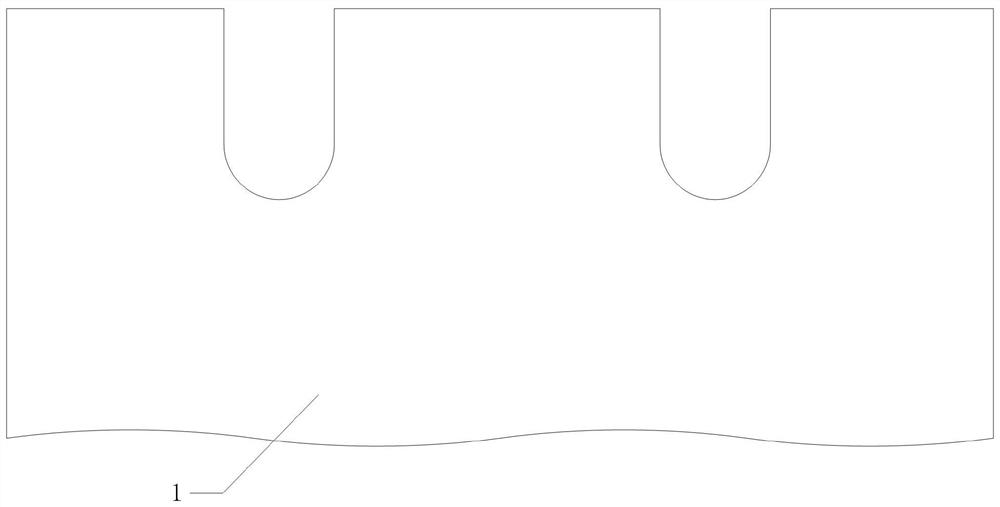

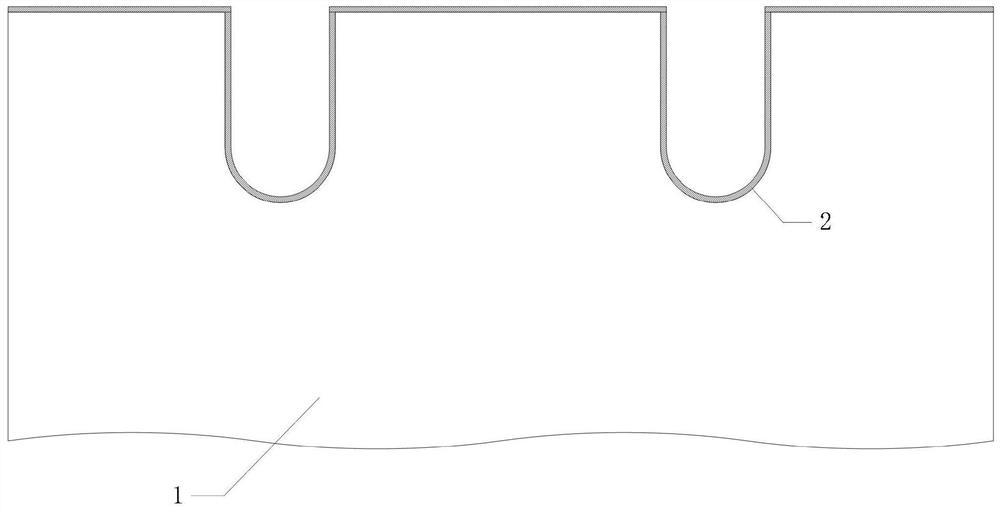

Process method for improving performance of Schottky diode with groove MOS structure

ActiveCN113517193AThin phenomenon improvementImprove thickness uniformitySemiconductor/solid-state device manufacturingSemiconductor devicesSchottky diodeDielectric layer

The invention relates to the field of semiconductors. The invention relates to a process method for improving the performance of a Schottky diode with a groove MOS structure, which comprises the following steps of 1, taking a silicon substrate with a groove etched, and removing a silicon dioxide layer and other dielectric layers on the silicon surface of the front surface of the silicon substrate by a wet process, 2, depositing and growing a thin oxygen-doped polycrystalline silicon layer by adopting an LPCVD process, 3, depositing a thin silicon nitride layer by adopting an LPCVD process, 4, depositing an undoped polycrystalline silicon layer by adopting an LPCVD process, 5, oxidizing the deposited polycrystalline silicon layer by adopting a furnace tube thermal oxidation process, and reacting to form silicon dioxide, and 6, depositing in-situ doped polycrystalline silicon by adopting a CVD process, and finally obtaining the silicon groove MOS structure required by the device. The thickness uniformity of the dielectric layer is improved, defects generated in the growth process of the dielectric layer are reduced, the charge density in the dielectric layer is reduced, and the device performance is improved.

Owner:江苏新顺微电子股份有限公司

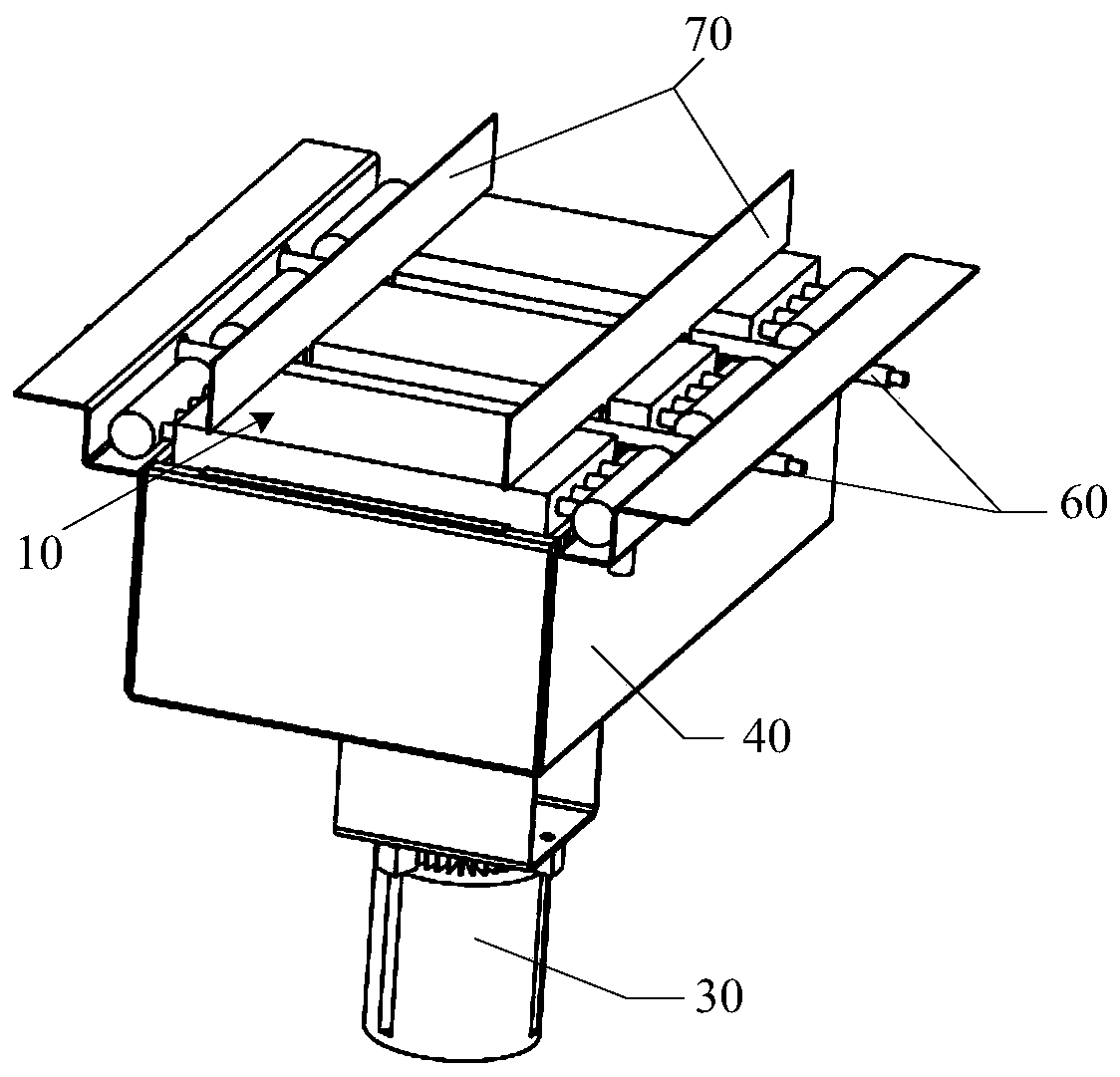

Continuous-drawing and continuous-annealing wire and cable integrated production equipment

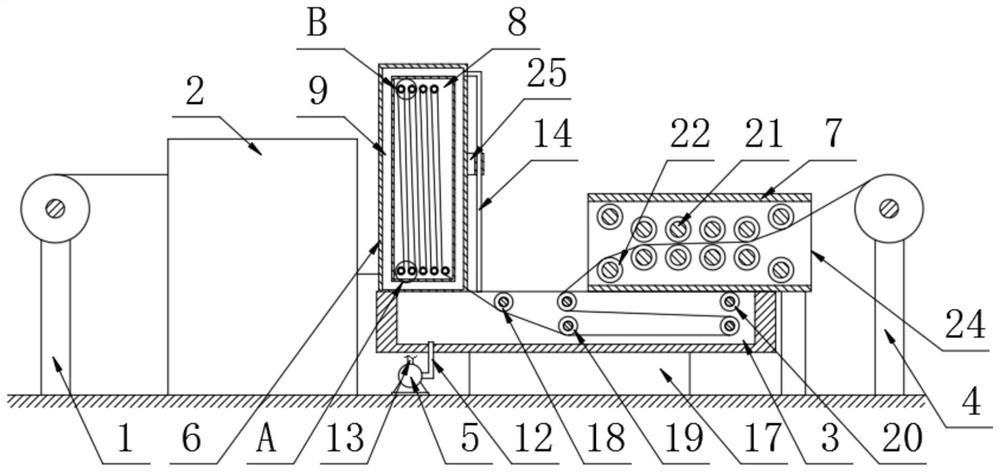

ActiveCN111223616AAchieve annealingIncrease the itineraryApparatus for feeding conductors/cablesApparatus for heat treatmentReciprocating motionStructural engineering

The invention discloses continuous-drawing and continuous-annealing wire and cable integrated production equipment, and relates to the technical field of cable production. The equipment comprises a pay-off rack, a wire drawing mechanism, a water tank, a take-up rack, a water pump, an annealing box, a traction frame, an annealing cavity, a liquid storage cavity, a first annealing roller, a second annealing roller, a first liquid conveying pipe, a second liquid conveying pipe, a return pipe, a first through groove and a second through groove. According to the invention, the annealing box and thetraction frame are both arranged at the top of the water tank, so that the occupied area of the equipment can be effectively reduced, and the production cost is reduced; cooling water in the liquid storage cavity can cool the annealing cavity, so that the annealing treatment on the cable is realized; the cable reciprocates up and down in the annealing cavity, so that the stroke of the cable in the annealing cavity is longer, and the annealing effect is better; and the cooling efficiency of the cable in contact with the first annealing roller and the second annealing roller is higher than thatof the cable in other positions in the annealing cavity, gradual annealing treatment on the cable is formed, and the annealing effect is better.

Owner:CHONGQING YUBANG WIRE & CABLE

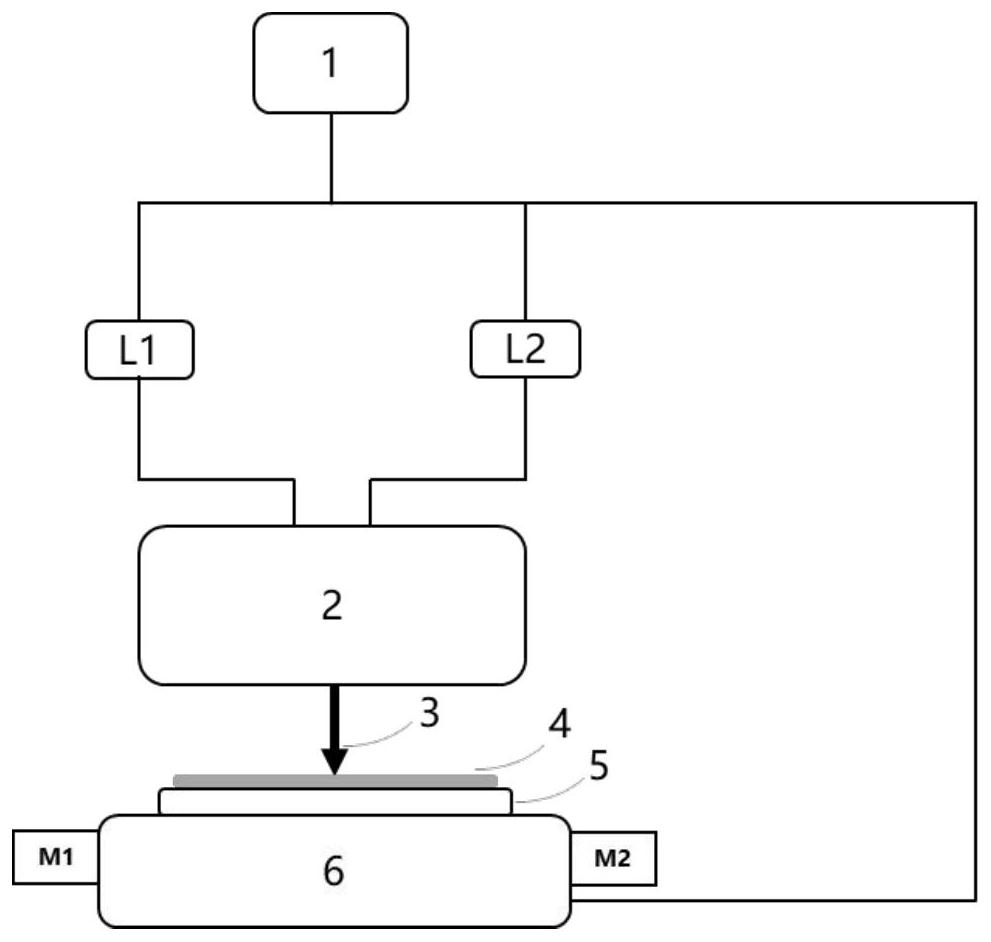

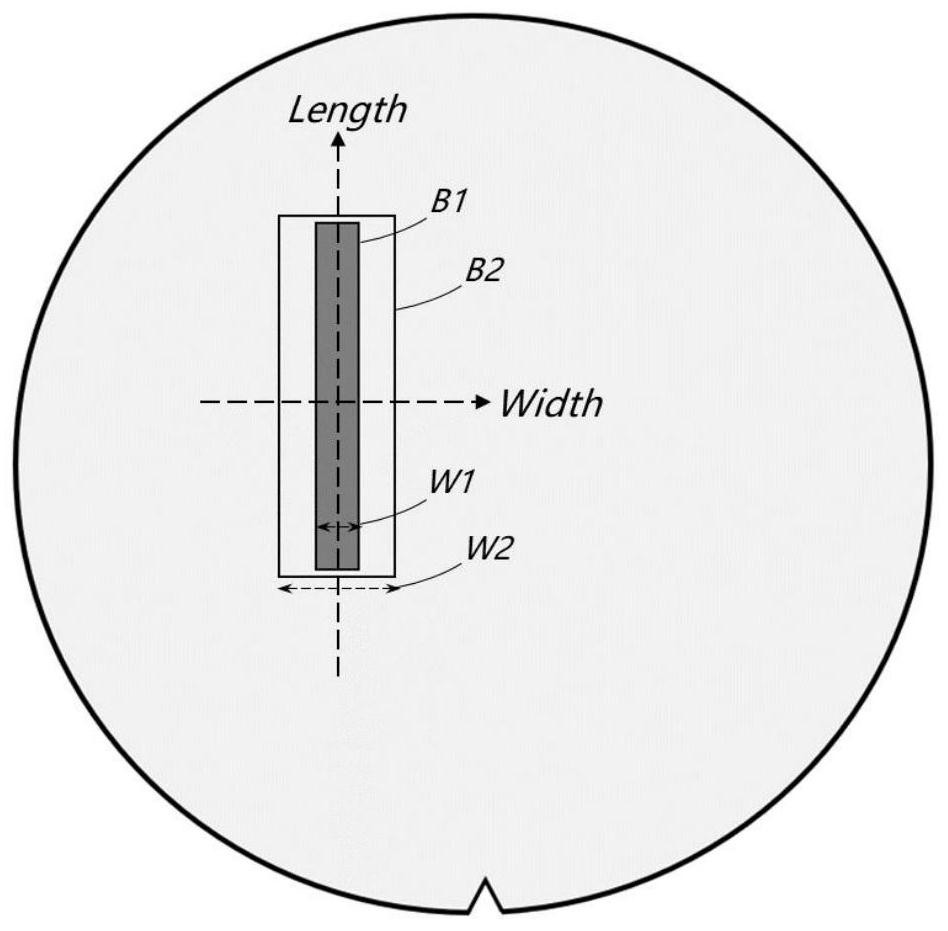

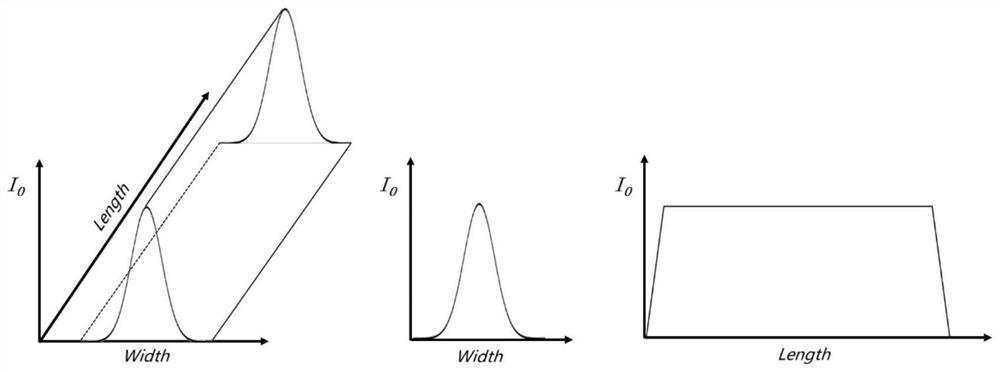

Laser annealing method and laser annealing system for power device

PendingCN112435921AAchieve implant anneal activationAchieve annealingSemiconductor/solid-state device manufacturingSemiconductor devicesWaferImpurity ions

The invention relates to a laser annealing method of a power device, in the annealing process, short-wavelength laser and long-wavelength laser are used for annealing activation, the wavelength rangeof the short-wavelength laser is 300nm to 560nm, and the wavelength range of the long-wavelength laser is 780nm to 1064nm; by selecting laser mixed configurations with different wavelengths for use, ion annealing in different melting ranges and impurity distribution depth ranges and implantation annealing of multiple layers of impurity ions are realized, and meanwhile, the laser mixed configurations with proper wavelengths are selected for use by comprehensively considering the temperature resistance and fragment resistance of different types of wafers; therefore, shallow surface activation under different thermal budget conditions is realized. The invention provides the laser annealing method and a laser annealing system for the power device, which control impurity activation efficiency and impurity distribution by using laser annealing and avoid the technical problem of fragments caused by heat accumulation due to overhigh temperature in the laser annealing process.

Owner:BEIJING U PRECISION TECH

A method of making crystal rods

ActiveCN106544738BAchieve annealingImprove consistencyPolycrystalline material growthAfter-treatment detailsWaferCrystal growth

The invention discloses a method for making crystal ingots, which is characterized in that before online cutting, the crystal ingots that have completed the rod removal process are placed in a high-temperature annealing furnace for annealing, and the annealing process mainly includes: heating process, constant temperature process, Cooling process, an annealing process method for sapphire crystal rods provided by the present invention, through uniform annealing treatment of crystal rods produced under different crystal growth and rod removal processes, the internal residual stress of the crystal rods is eliminated, and the material of the sapphire crystal rods is improved. Consistency, improve the yield and uniformity of back-end wafer processing and epitaxy.

Owner:FUJIAN JING AN OPTOELECTRONICS CO LTD

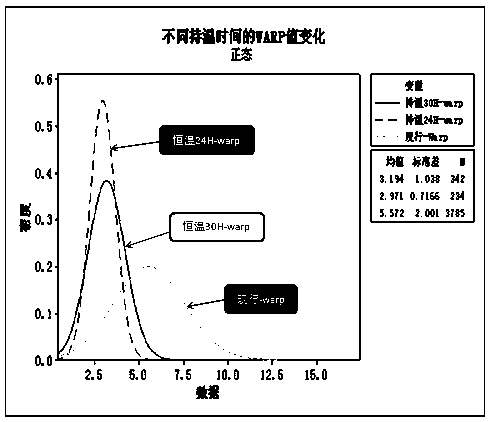

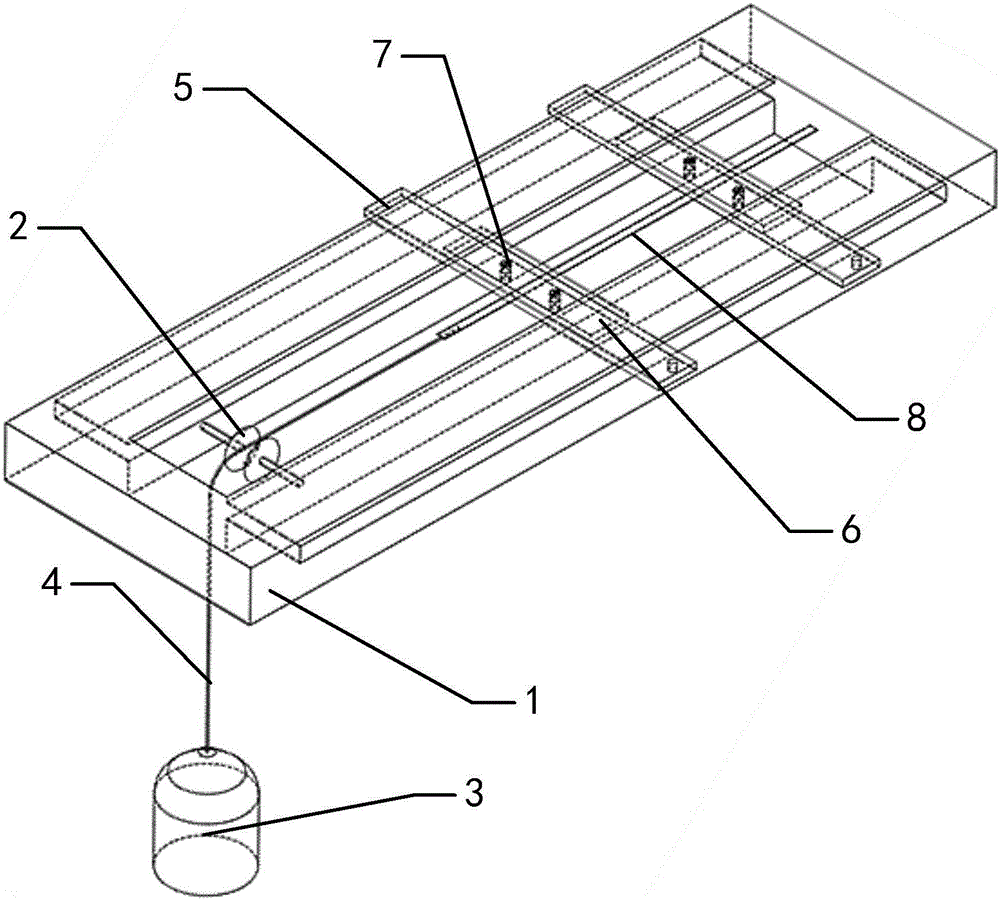

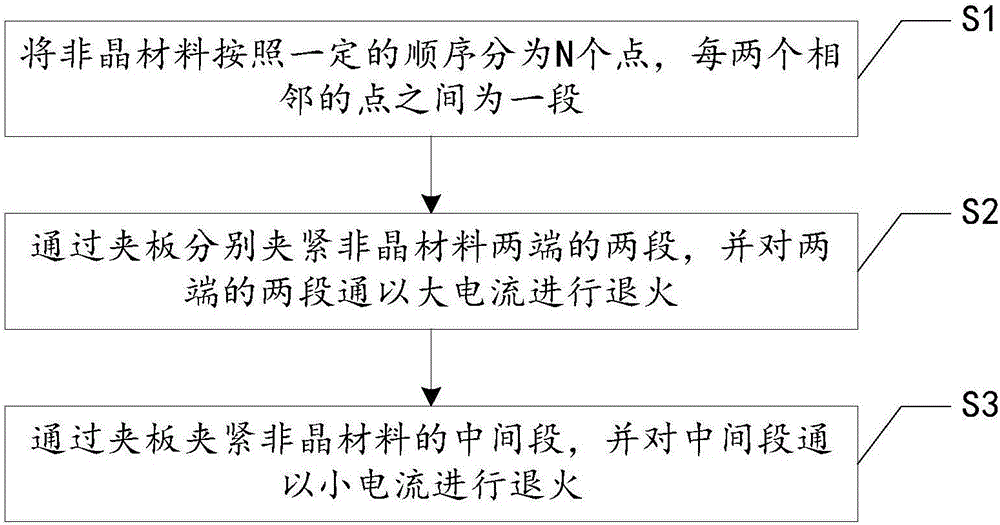

Clamp for obtaining AGMI effect and method for obtaining AGMI effect based on same

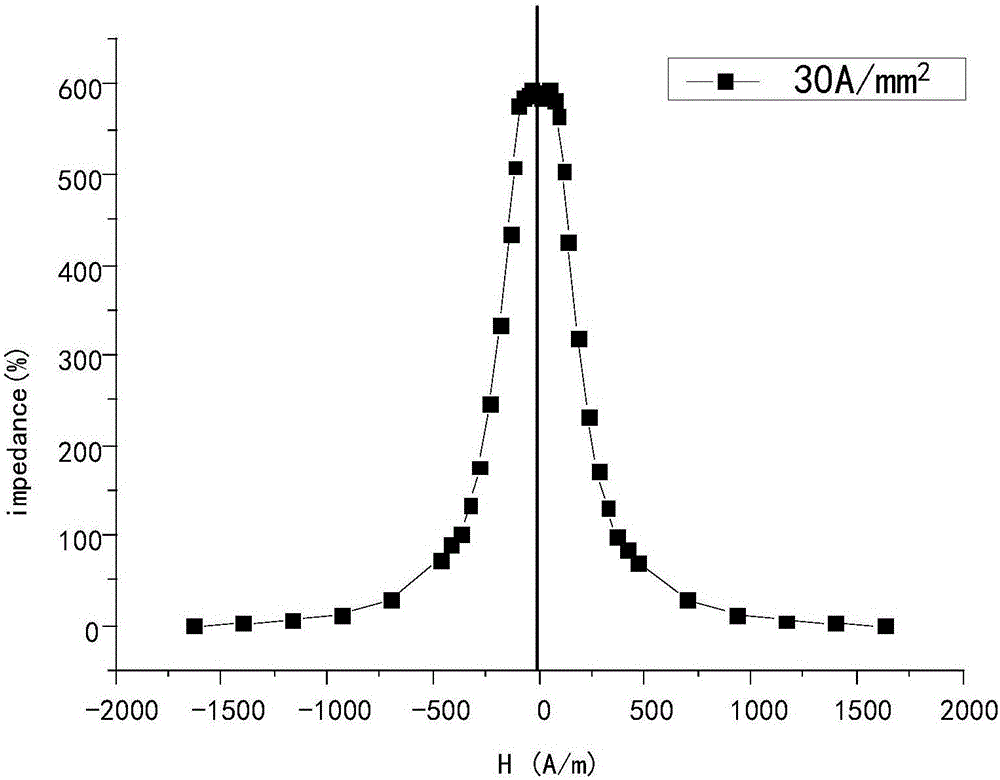

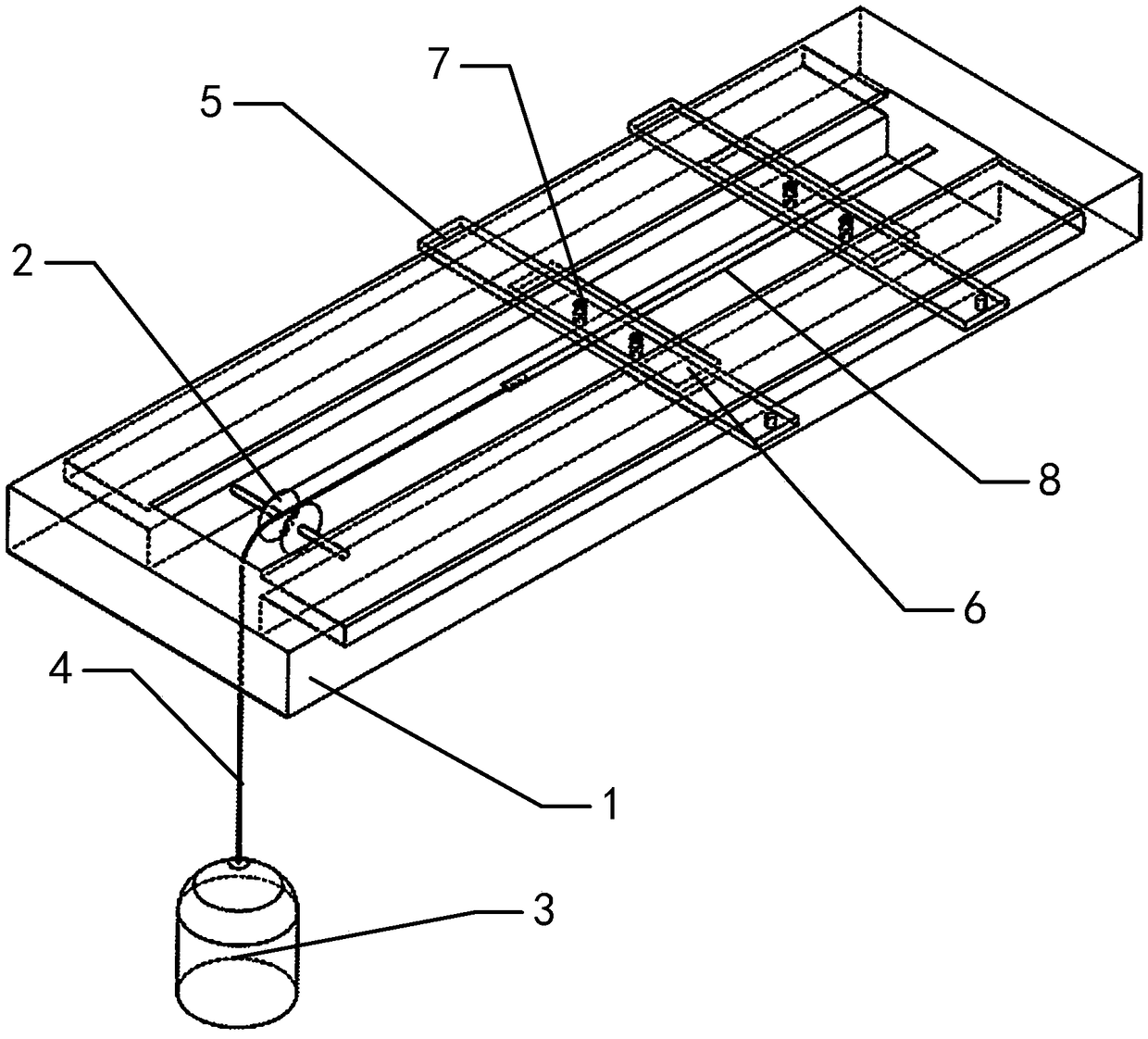

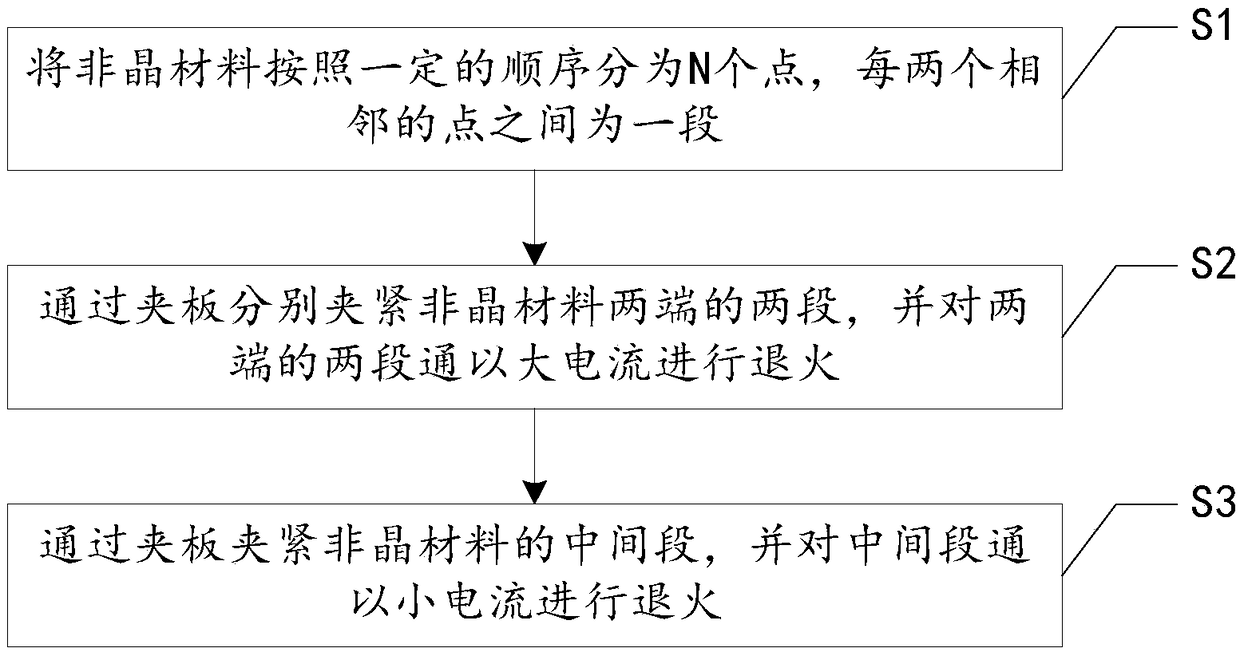

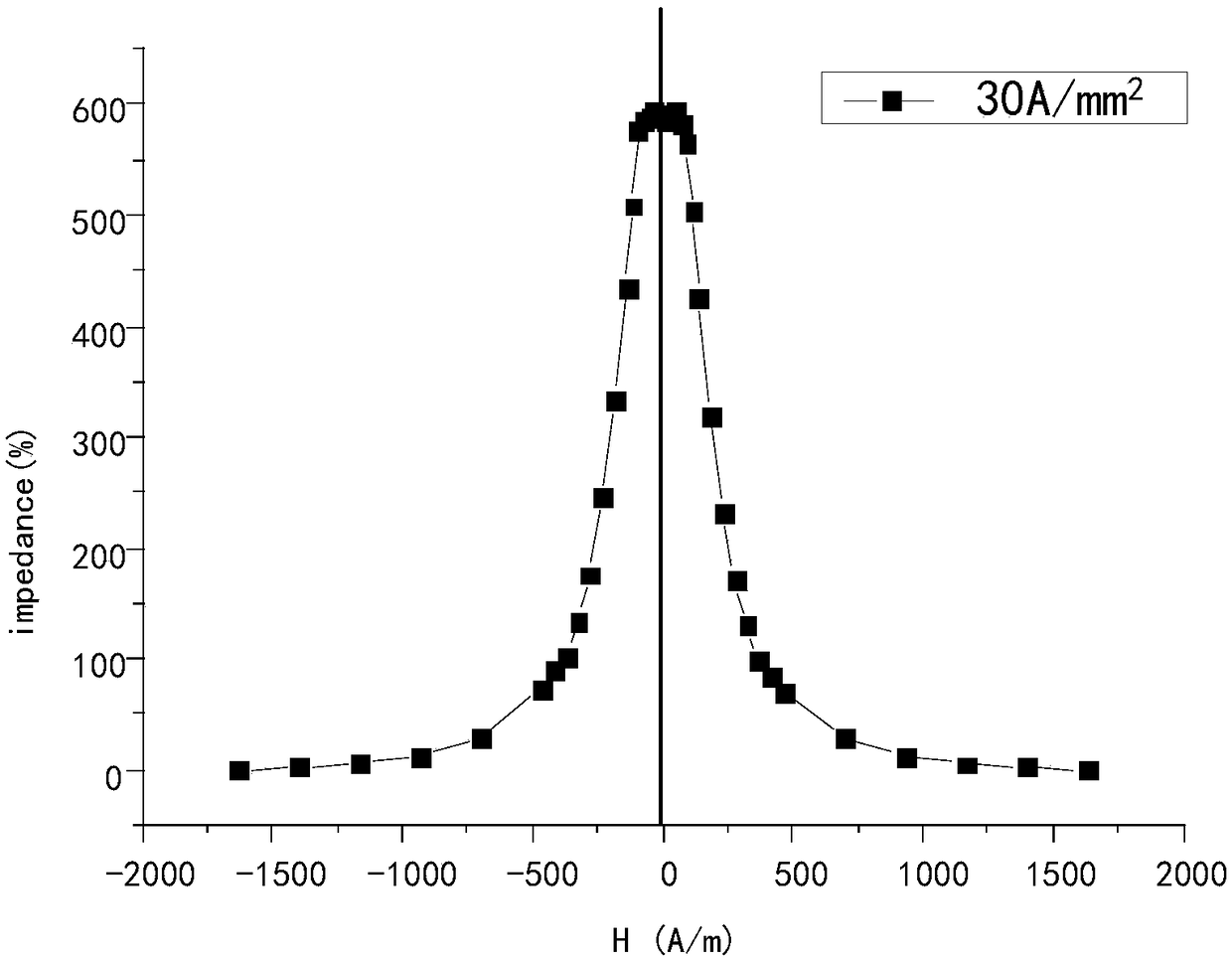

The invention relates to a clamp for obtaining an AGMI effect and a method for obtaining the AGMI effect based on the same, and relates to the field of AGMI effect generation. The problems that due to the fact that at present, an external coil or a biasing permanent magnet needs to be adopted for obtaining the AGMI effect to generate a bias field, however power consumption is obviously increased when bias is added, and an existing method for obtaining the AGMI effect is excessively complex and low in sensitivity are solved. Two clamping plates are adopted for clamping a non-crystalline material, a weight is adopted for applying stress on the non-crystalline material, different current annealing can be effectively achieved on the non-crystalline material, and in this way, the AGMI effect can be obtained.

Owner:ZHEJIANG NORMAL UNIVERSITY

A fixture for obtaining agmi effect and a method for obtaining agmi effect based on the fixture

The invention relates to a clamp for obtaining an AGMI effect and a method for obtaining the AGMI effect based on the same, and relates to the field of AGMI effect generation. The problems that due to the fact that at present, an external coil or a biasing permanent magnet needs to be adopted for obtaining the AGMI effect to generate a bias field, however power consumption is obviously increased when bias is added, and an existing method for obtaining the AGMI effect is excessively complex and low in sensitivity are solved. Two clamping plates are adopted for clamping a non-crystalline material, a weight is adopted for applying stress on the non-crystalline material, different current annealing can be effectively achieved on the non-crystalline material, and in this way, the AGMI effect can be obtained.

Owner:ZHEJIANG NORMAL UNIVERSITY

Nitrogen oxidation furnace

PendingCN112962052AOxidation after realizationAchieve annealingSolid state diffusion coatingManufacturing engineeringCooling speed

The invention relates to the field of nitrogen oxidation equipment, and discloses a nitrogen oxidation furnace. The nitrogen oxidation furnace comprises a furnace body, wherein the furnace body comprises an outer shell, an inner shell and an air guide barrel, a furnace door is arranged on the outer shell, the inner shell is arranged in the outer shell, the air guide barrel is arranged in the inner shell, a material frame support is arranged in the inner shell and extends into the air guide barrel, a heating pipe is arranged in the outer shell, and the heating pipe is arranged in the inner shell. A steam evaporation pipe is arranged in the inner shell, a draught fan is arranged on the outer side of the air guide barrel, and steam enters the air guide barrel through the draught fan. The furnace has the beneficial effects that one furnace can be used for multiple purposes; an additional heating device does not need to be configured; forced cooling of the die workpiece subjected to nitriding oxidation treatment in the furnace body is achieved, meanwhile, the cooling speed of the die workpiece is increased, and the requirement standard of the die workpiece can be met; the nitrogen oxidation furnace is space-saving and convenient to operate, and workpiece in-out furnace efficiency can be effectively improved.

Owner:SHANGHAI SHIJIN NEW MATERIAL TECH

Heat treatment device and heat treatment process for ultra-long aluminum extrusion

ActiveCN109536683BAchieving solution quenchingAchieve annealingFurnace typesHeat treatment furnacesEngineeringHeating furnace

Owner:广西百矿冶金技术研究有限公司

A process method for improving the performance of trench mos structure schottky diode

ActiveCN113517193BThin phenomenon improvementImprove thickness uniformitySemiconductor/solid-state device manufacturingSemiconductor devicesEtchingMaterials science

The present invention relates to the field of semiconductors. A process method for improving the performance of trench MOS structure Schottky diodes, step 1, take the silicon substrate that has completed trench etching, and remove the silicon dioxide layer and other dielectric layers on the silicon surface of the front side of the silicon substrate by wet process; step Two, adopt LPCVD process to deposit and grow a thin layer of oxygen-doped polysilicon layer; Step 3, adopt LPCVD process to deposit a thin layer of silicon nitride layer; Step 4, adopt LPCVD process to deposit a layer of non-doped polysilicon layer; Step 5 , use the furnace tube thermal oxidation process to oxidize the deposited polysilicon layer, and react to form silicon dioxide; step 6, use the CVD process to deposit in-situ doped polysilicon, and finally obtain the silicon trench MOS structure required by the device . The invention improves the thickness uniformity of the dielectric layer, reduces defects generated during the growth process of the dielectric layer, reduces the charge density in the dielectric layer, and improves device performance.

Owner:江苏新顺微电子股份有限公司

Vacuum local heat treatment device and method for shaft workpieces

PendingCN114657362AAchieve annealingRealize the quenching heat treatment processThermometer detailsThermometers using electric/magnetic elementsThermodynamicsDisplay device

A vacuum local heat treatment device for shaft workpieces comprises a temperature display device and an electric induction high-frequency heating machine arranged on a workbench. A containing cavity is formed in the protection cover shell and used for containing the shaft workpiece needing to be heated; the vacuum generator assembly is connected with the protective cover shell and used for vacuumizing the containing cavity of the protective cover shell; the temperature sensor is used for sensing the temperature of the accommodating cavity and is connected with the temperature display device; the quenching tank is arranged at the position close to the workbench; an annular groove is formed in the lower portion of the protective cover shell, and a cooling medium is contained in the annular groove. And an induction coil of the electric induction high-frequency heating machine is sleeved on the upper part of the protective housing. The heat treatment device provided by the invention can be used for creating a vacuum environment during local heating of shafts and displaying the temperature of a heating section, so that a non-heating section is protected during local heating of the shaft workpieces, and the heating section does not generate oxide skin by utilizing the vacuum environment.

Owner:GUIZHOU SPACE APPLIANCE CO LTD

Method and device for performing inert gas protective cover type annealing on cold-rolled titanium strip coils

ActiveCN103205559BAchieve annealingImprove efficiencyFurnace typesHeat treatment furnacesTitaniumNitrogen gas

The invention discloses a method and a device for performing inert gas protective cover type annealing on cold-rolled titanium strip coils, and belongs to the technical field of nonferrous metallurgy. The annealing method comprises the following steps of: pressure adjustment, feeding and exhausting, nitrogen displacement, heating and annealing, cooling and discharging. The device comprises a cover type annealing furnace (1), a nitrogen supply device (2) and an argon supply device (3), wherein the nitrogen supply device (2) is communicated with the inner cover of the cover type annealing furnace (1); and the argon supply device (3) is communicated with the inner cover of the cover type annealing furnace (1). Based on the common full hydrogen or nitrogen-hydrogen annealing furnace, the argon supply device is additionally arranged, so that different annealing requirements of the common full hydrogen or nitrogen-hydrogen annealing furnace for cold-rolled steel strips and titanium strip coils are met; and the device has the advantages of high efficiency, process stability, convenience for transformation, multiple purposes and high reliability.

Owner:WUKUN STEEL

A continuous coating production system for sheet substrates

ActiveCN104060236BReduce loss costIncrease productivityVacuum evaporation coatingSputtering coatingProduction lineCoating system

Owner:GUANGZHOU INST OF ENERGY CONVERSION - CHINESE ACAD OF SCI

A copper-clad aluminum composite flat row induction continuous annealing equipment and its process

ActiveCN103710522BControl thicknessImprove performanceFurnace typesIncreasing energy efficiencyHeat conservationElectric power

The invention relates to induction heating continuous annealing equipment meeting the characteristics of a copper-clad aluminium composite electrical flat cable and a process using the equipment. The equipment mainly comprises a guide device, a drive device, a temperature measuring device, an induction heating system, a heat preserving section, a cooling section and a gas protective system. The equipment is characterized in that an induction heating power source adopts a frequency on the high side of an intermediate frequency so as to increase the rate of the induction heating, shorten the heating time and control the interface layer thickness; the cross section of an induction heating coil is of a flat shape similar to the shape of the cross section of the copper-clad aluminium flat cable so as to benefit the uniform distribution of temperature and the shortening of the heating time and control the interface layer thickness; a ceramic tube with a certain length and the heat preserving section are arranged to ensure that the temperature is uniform during the heating and enough time is provided to finish the recrystallization of a copper layer and an aluminium core; the forced cooling section is arranged to ensure that the temperature of the annealed flat cable can be rapidly reduced to below 150 DEG C and the copper-aluminium interface layer thickness is controlled at 2-3 micrometers. The invention further provides an annealing process using the annealing equipment.

Owner:UNIV OF SCI & TECH BEIJING

An integrated production equipment for continuous pulling and unwinding wire and cable

ActiveCN111223616BAchieve annealingIncrease the itineraryApparatus for feeding conductors/cablesApparatus for heat treatmentReciprocating motionEngineering

The invention discloses continuous-drawing and continuous-annealing wire and cable integrated production equipment, and relates to the technical field of cable production. The equipment comprises a pay-off rack, a wire drawing mechanism, a water tank, a take-up rack, a water pump, an annealing box, a traction frame, an annealing cavity, a liquid storage cavity, a first annealing roller, a second annealing roller, a first liquid conveying pipe, a second liquid conveying pipe, a return pipe, a first through groove and a second through groove. According to the invention, the annealing box and thetraction frame are both arranged at the top of the water tank, so that the occupied area of the equipment can be effectively reduced, and the production cost is reduced; cooling water in the liquid storage cavity can cool the annealing cavity, so that the annealing treatment on the cable is realized; the cable reciprocates up and down in the annealing cavity, so that the stroke of the cable in the annealing cavity is longer, and the annealing effect is better; and the cooling efficiency of the cable in contact with the first annealing roller and the second annealing roller is higher than thatof the cable in other positions in the annealing cavity, gradual annealing treatment on the cable is formed, and the annealing effect is better.

Owner:CHONGQING YUBANG WIRE & CABLE

An efficient and fast annealing equipment for die steel processing and production

ActiveCN112342346BConvenient post-operationEasy to operateFurnace typesIncreasing energy efficiencyElectric machineElectromagnetic heating

The invention discloses an efficient and quick annealing equipment for die steel processing and production, relates to the technical field of annealing, and aims to solve the problem that the existing annealing equipment for die steel processing and production has a complex structure and cannot be used efficiently and quickly. The lower end of the bottom plate is provided with a stressed leg, and the stressed leg is fixedly connected to the bottom plate. The upper surface of the bottom plate is provided with a first empty slot, and one side of the first empty slot is provided with a second empty slot. The inside of the first empty slot is provided with an electromagnetic heating mechanism, the inside of the second empty slot is provided with a cooling box, the inside of the cooling box is provided with a partition, and the partition is fixedly connected with the cooling box, and the cooling box is a The surface of the side is provided with a bevel, a support frame is provided between the first empty slot and the second empty slot, and the support frame is fixedly connected with the bottom plate, and one end of the support frame is provided with a first rotating motor mechanism, and the One side of the first rotating motor mechanism is provided with a first rotating shaft.

Owner:浙江鑫哲模具有限公司

Cooling device and annealing furnace

PendingCN110021684AAchieve annealingAchieve constant coolingFinal product manufactureSemiconductor devicesMachine partsEngineering

The invention discloses a cooling device and an annealing furnace, and belongs to the technical field of battery piece production. The cooling device comprises at least one condenser, an inner shell and an axial flow fan used for sucking air, wherein the condenser is mounted at an upper end opening of the inner shell to be connected with the upper end opening of the inner shell; the axial flow fanis mounted below the inner shell and communicates with a lower end opening of the inner shell; the condenser is located below a furnace body and forms a furnace cavity together with the side walls and the upper wall of the furnace body; and after the axial flow fan runs, hot air in the furnace cavity is downwards sucked through the inner shell. The condenser is arranged at the lower end of the furnace body to form a water-cooling circulation structure of the furnace body, and the axial flow fan is arranged below the condenser, so that stable cooling of the closed cavity is realized, and the temperature is prevented from being increased or reduced sharply to damage a to-be-machined part.

Owner:无锡奥特维旭睿科技有限公司

Annealing furnace for production of pharmaceutical glass bottles

The invention discloses an annealing furnace for production of pharmaceutical glass bottles, comprising an outer casing, falling conveyor belts, a conveyor-belt fixing plate and a feeding motor, wherein the outer walls of the two sides of the outer casing are each fixed obliquely equipped with two falling motors, and the power output ends of the falling motors are fixedly mounted in the outer casing; the power output ends of the falling motors are fixedly equipped with falling drums, and the exteriors of the falling drums are movably sleeved by the falling conveyor belts; the outer surfaces ofthe falling conveyor belts are fixedly connected with punties; and the outer wall of one side of the outer casing is fixedly provided with a liquefied gas tank, the top of the liquefied gas tank is fixedly equipped with gas combustion nozzles via pipes, and the gas combustion nozzles are fixedly arranged at the inner walls of two sides of the outer casing. According to the invention, a method ofvertical annealing is adopted, during a falling process, the temperature of glass is gradually reduced, so that annealing is achieved, at the same time, the land occupation area of the annealing furnace is saved, and the processing process for annealing glass products in a small space is realized.

Owner:响水县泽州开发有限公司

Salt bath heat treatment molten salt device and control method thereof

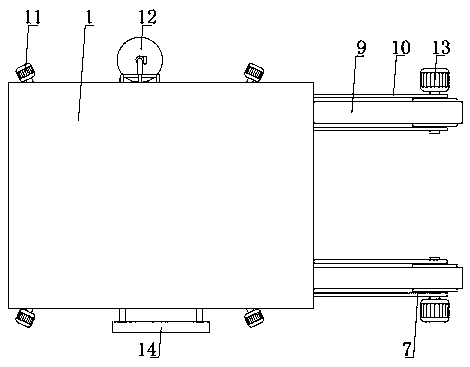

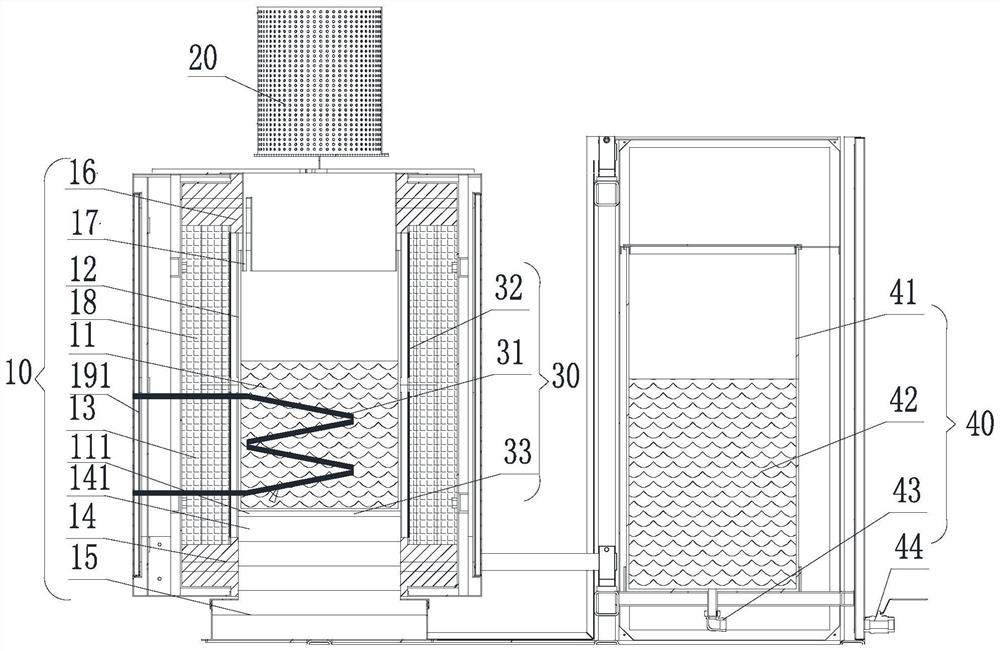

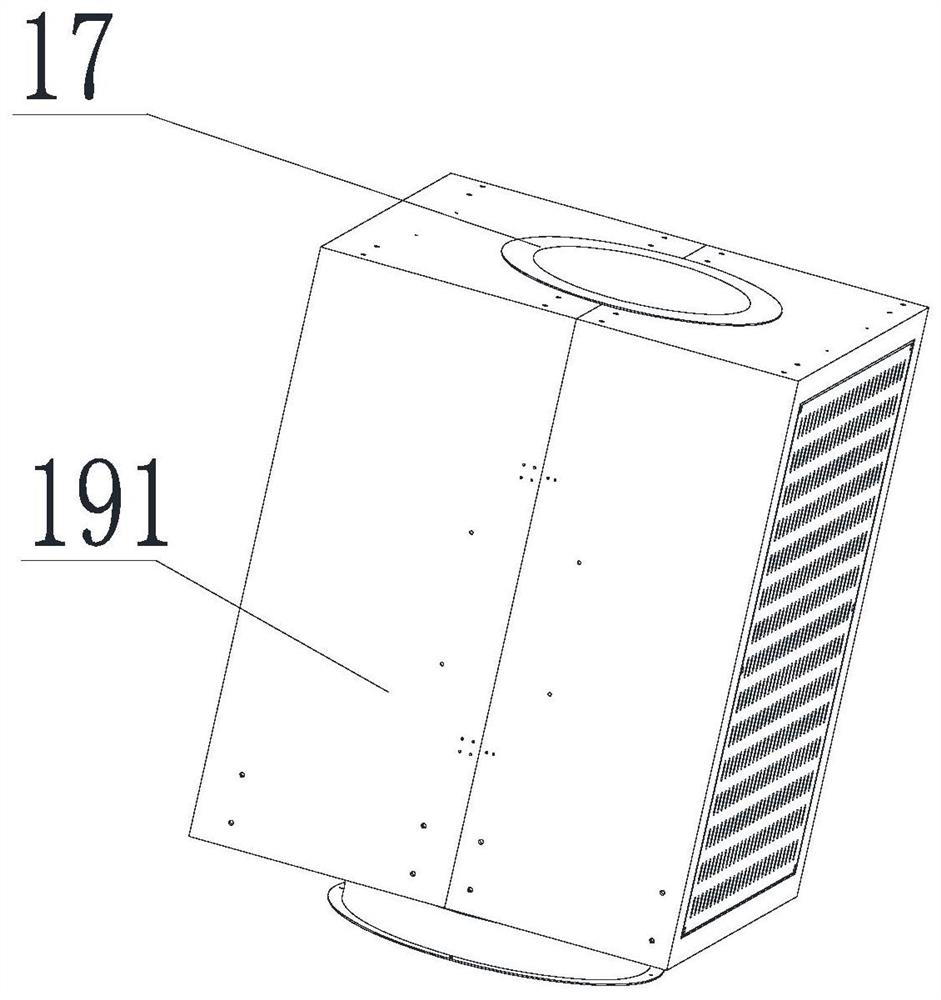

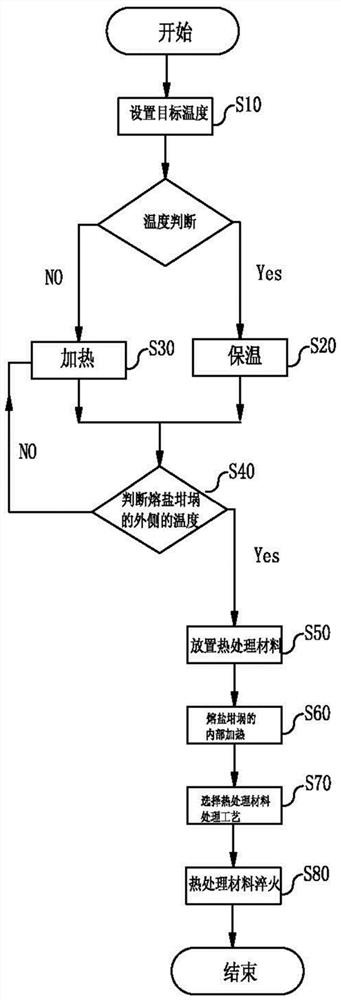

PendingCN113265515ASimple structureEasy to operateHeat treatment process controlQuenching agentsMolten saltEngineering

The invention relates to a salt bath heat treatment molten salt device and a control method thereof. The control method comprises the steps that a molten salt device body is arranged on the salt bath heat treatment molten salt device; the molten salt device body is heated when being used for quenching, and molten salt is contained in the molten salt device body; a lifting basket is arranged in the molten salt device body in the preset axis direction; during quenching, the basket is immersed in the molten salt; a heating device is arranged on the outer side of the molten salt device in the preset direction of the molten salt device; the heating device is used for heating heat treatment material in the molten salt; a cold quenching device is arranged on one side of the molten salt device; and a main control device controls the temperature and heating time of the molten salt device, after the heat treatment material is heated, the heat treatment material is moved into the cold quenching device to be quenched, or the main control device controls the temperature and heating time of the molten salt device, and the heat treatment material is annealed. According to the salt bath heat treatment molten salt device and the control method thereof, the functions of annealing and quenching are achieved at the same time, and the heat treatment process can be automatically carried out without manual intervention, so that the purposes of improving efficiency and saving cost are achieved.

Owner:上海煜志科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com