A fixture for obtaining agmi effect and a method for obtaining agmi effect based on the fixture

An effect and fixture technology, applied in the field of AGMI effect generation, can solve problems such as low sensitivity, increased power consumption, complex AGMI effect method, etc., and achieve the effect of strong operability, low cost, and low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

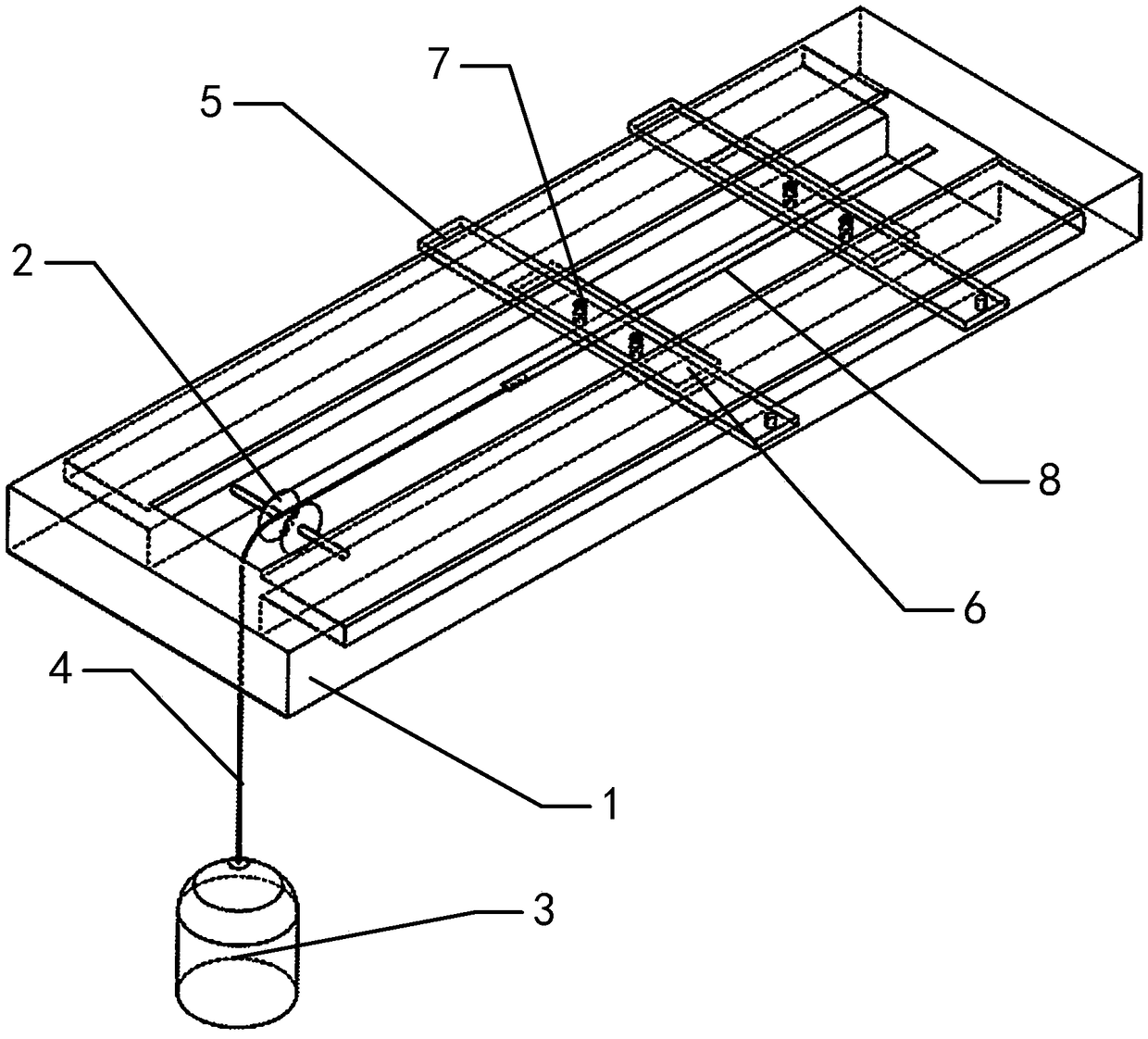

[0033] Such as figure 1 As shown, the present embodiment proposes a fixture for obtaining the AGMI effect. The fixture includes a bottom plate 1, a pulley 2, a weight 3 and two groups of splints. The bottom plate 1 is a rectangular plate structure, and the two groups of splints and The short sides of the bottom plate 1 are arranged on the bottom plate 1 parallel to each other for clamping the amorphous material 8. The center of the bottom plate 1 is provided with a strip-shaped through hole parallel to its long side, and at one end of the strip-shaped through hole A rotatable pulley 2 is arranged between the two side walls of the pulley. The plane on which the pulley 2 rotates is a vertical plane. Connect, and connect the other end with weight 3.

[0034] The amorphous material 8 is clamped by two sets of splints, and the weight 3 is used to apply stress to the amorphous material 8, which can effectively achieve different current annealing on an amorphous material 8, thereby ...

Embodiment 2

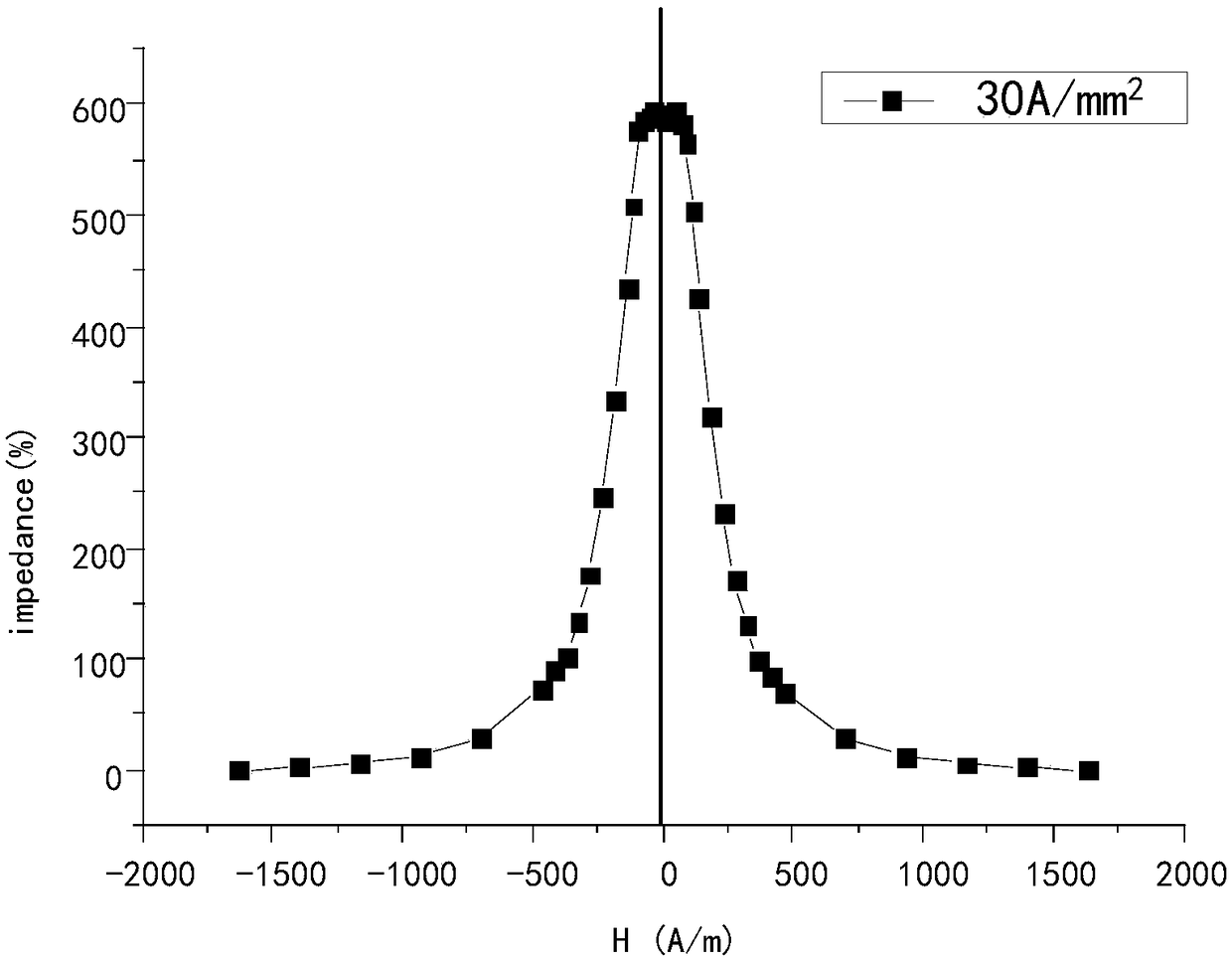

[0040] Such as image 3 The current density shown is 30A / mm 2 The GMI curve of a material annealed by current for 10 minutes has a maximum impedance ratio of 588.1%, and its impedance curve is symmetrical about zero magnetic field, which makes its sensitivity insensitive near zero magnetic field; Figure 4 The current density shown is 40A / mm 2 In the GMI curve of current annealing, due to the precipitation of the hard magnetic phase, the impedance ratio is greatly reduced, and it is no longer symmetrical about the zero magnetic field, but the linearity near the zero magnetic field reaches 99%. The method proposed in this embodiment is to select the advantages of both to achieve the AGMI effect of zero magnetic field linear response. The specific implementation process is as follows:

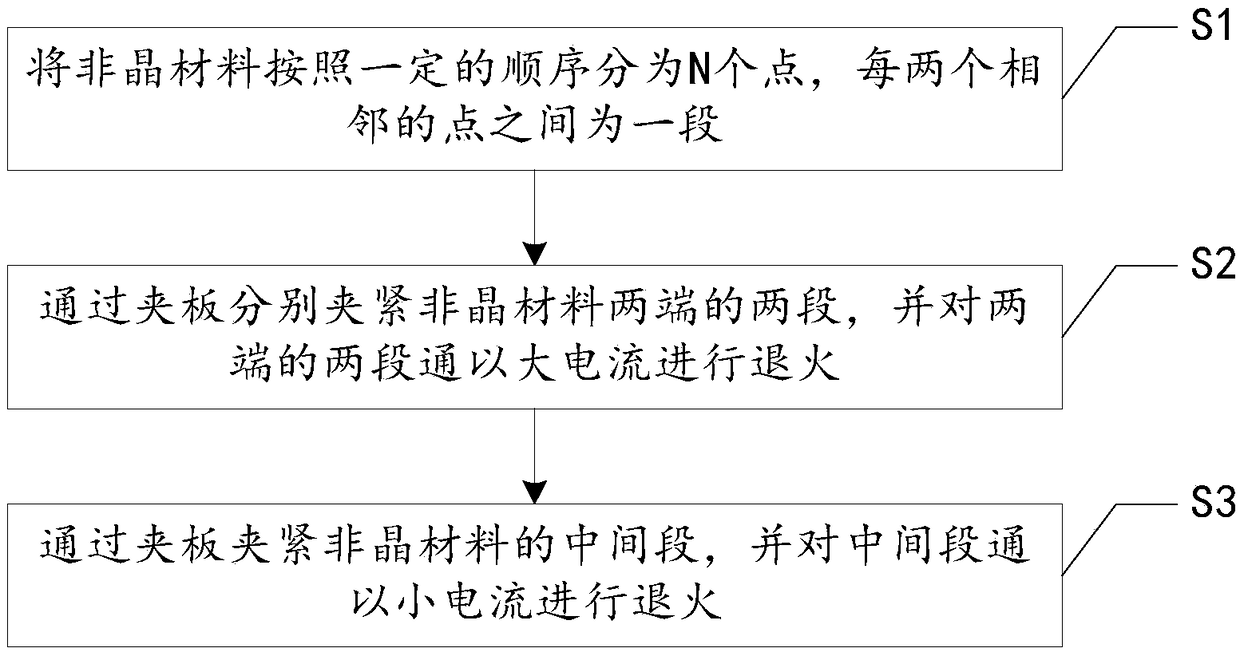

[0041] Such as figure 2 As shown, the method is realized through the following steps:

[0042] S1. Divide the amorphous material into N points in a certain order, with a section between eve...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Sensitivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com