Salt bath heat treatment molten salt device and control method thereof

A heating device and molten salt technology, applied in heat treatment process control, heat treatment bath, heat treatment equipment, etc., can solve the problem of no way to control the oxidation of titanium alloy materials, it is difficult to avoid oxidation problems, etc., to achieve simple structure, cost saving, reduce artificial effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046]In order to make the object, technical solution and advantages of the present invention clearer, various embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings. However, those of ordinary skill in the art can understand that, in each implementation manner of the present invention, many technical details are provided for readers to better understand the present application. However, even without these technical details and various changes and modifications based on the following implementation modes, the technical solution claimed in each claim of the present application can be realized.

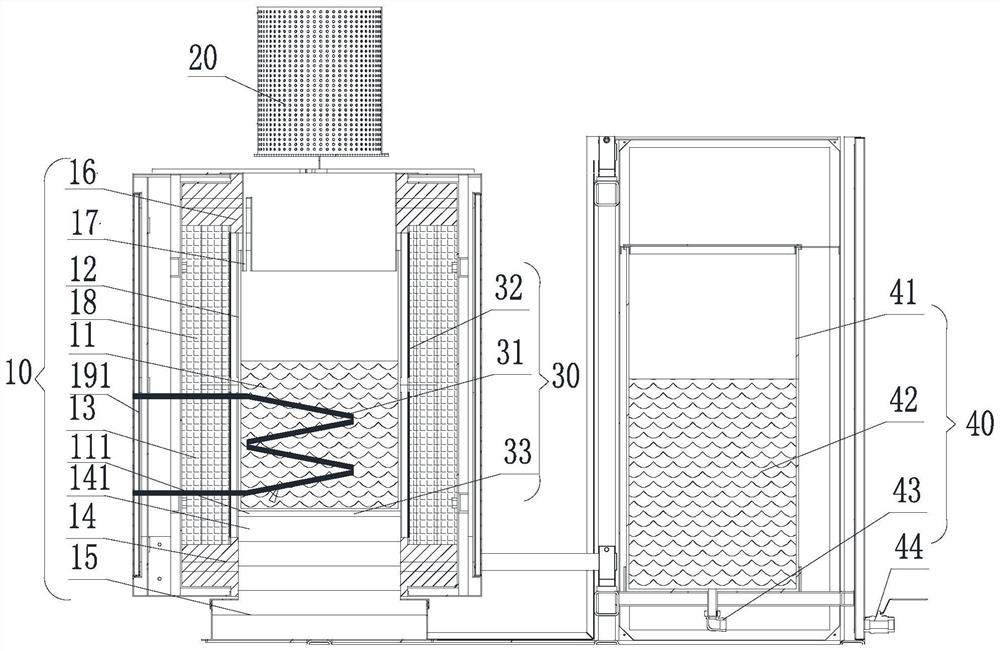

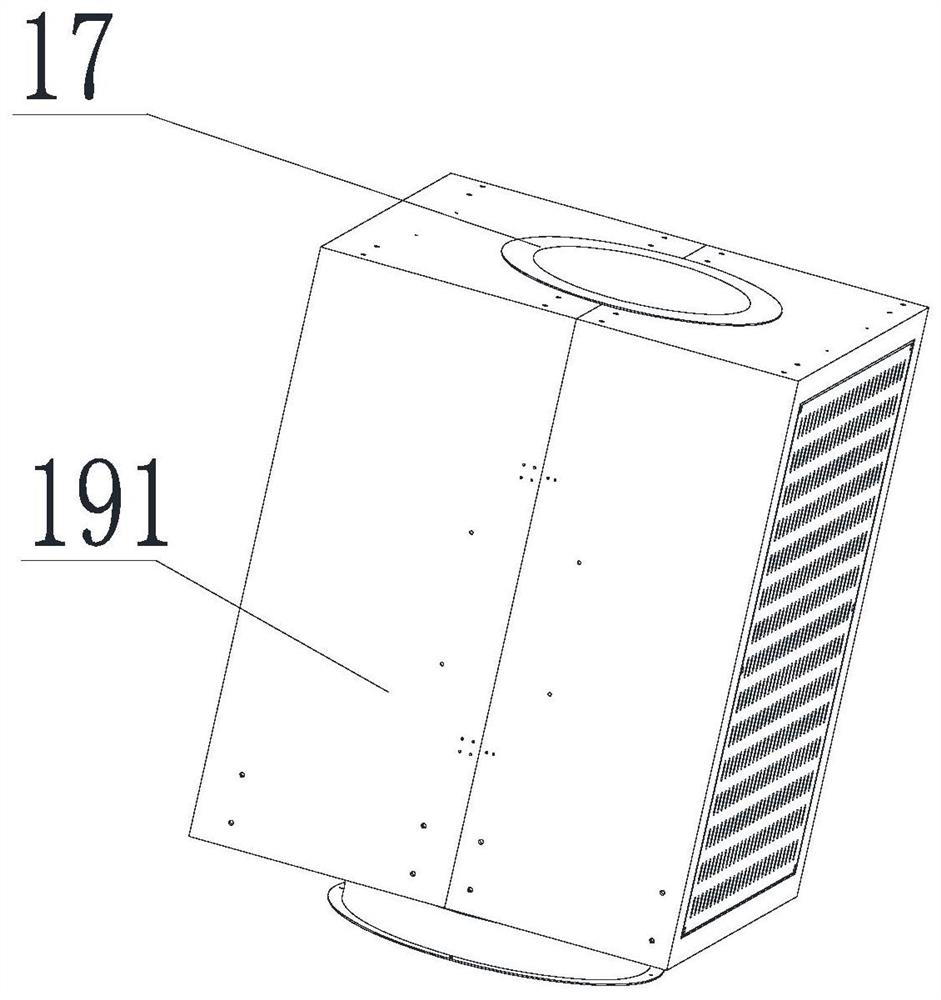

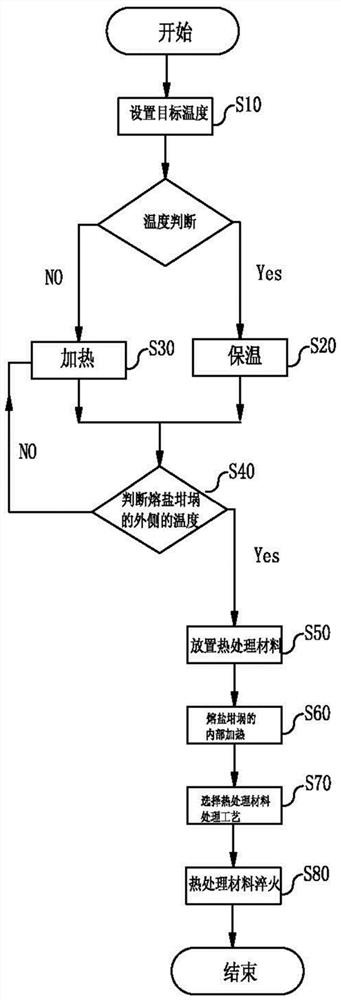

[0047] The first embodiment of the present invention relates to a salt bath heat treatment molten salt device, such as figure 1 and figure 2 , Figure 4 shown, including:

[0048] A molten salt device 10 is set on the salt bath heat treatment molten salt device; when the molten salt device 10 is used for quenching, it is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com