Patents

Literature

34results about How to "Convenient post-operation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

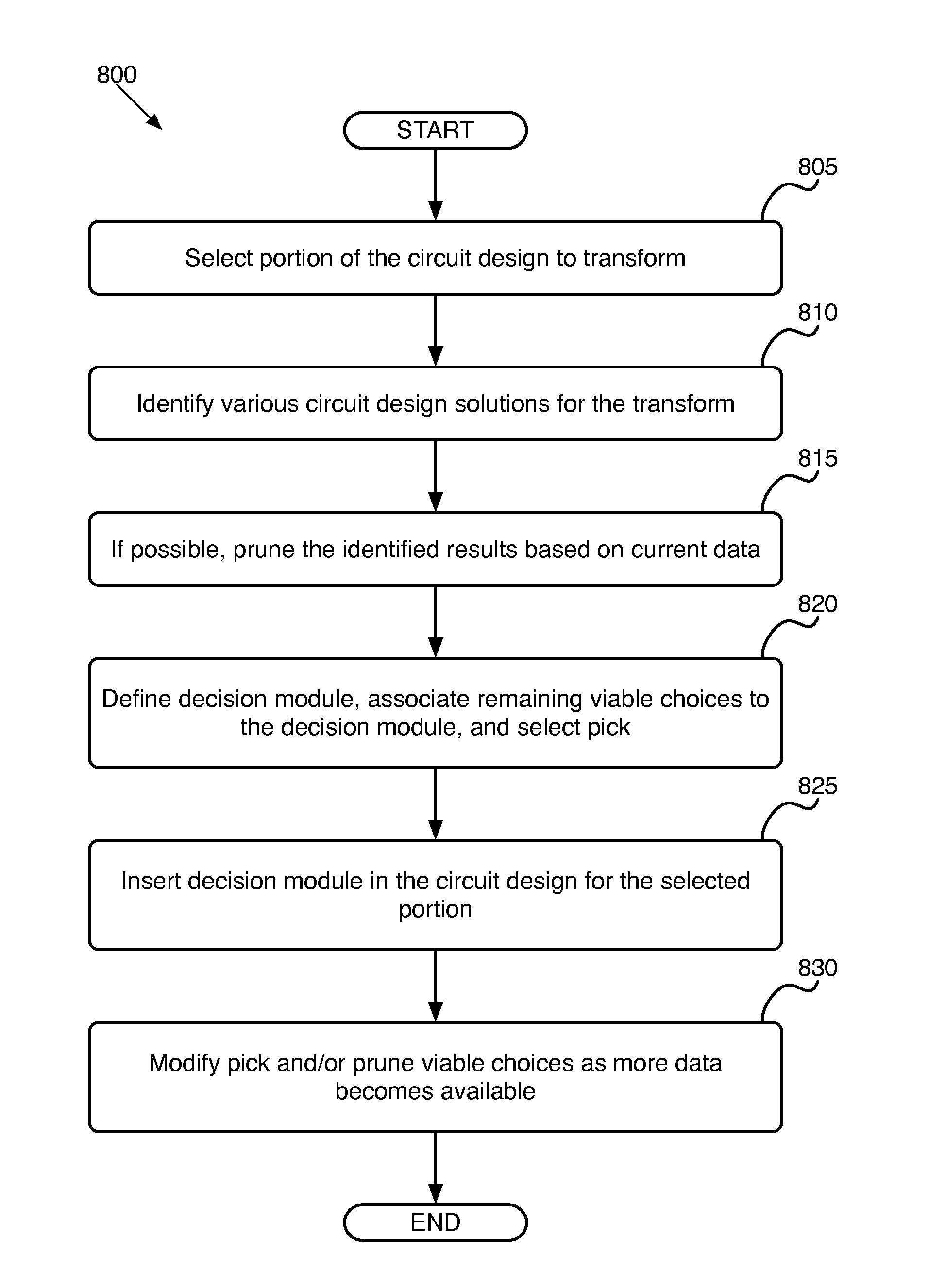

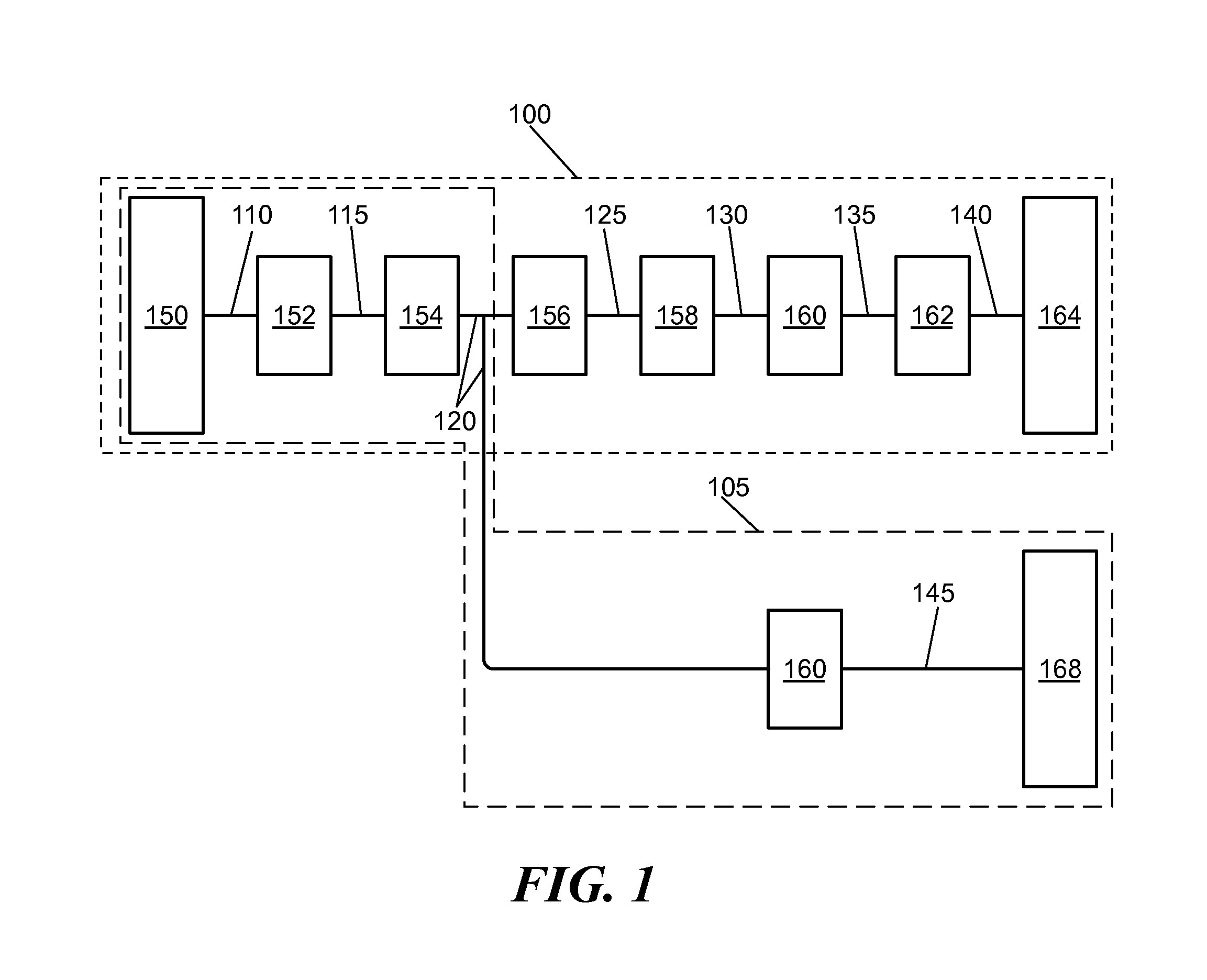

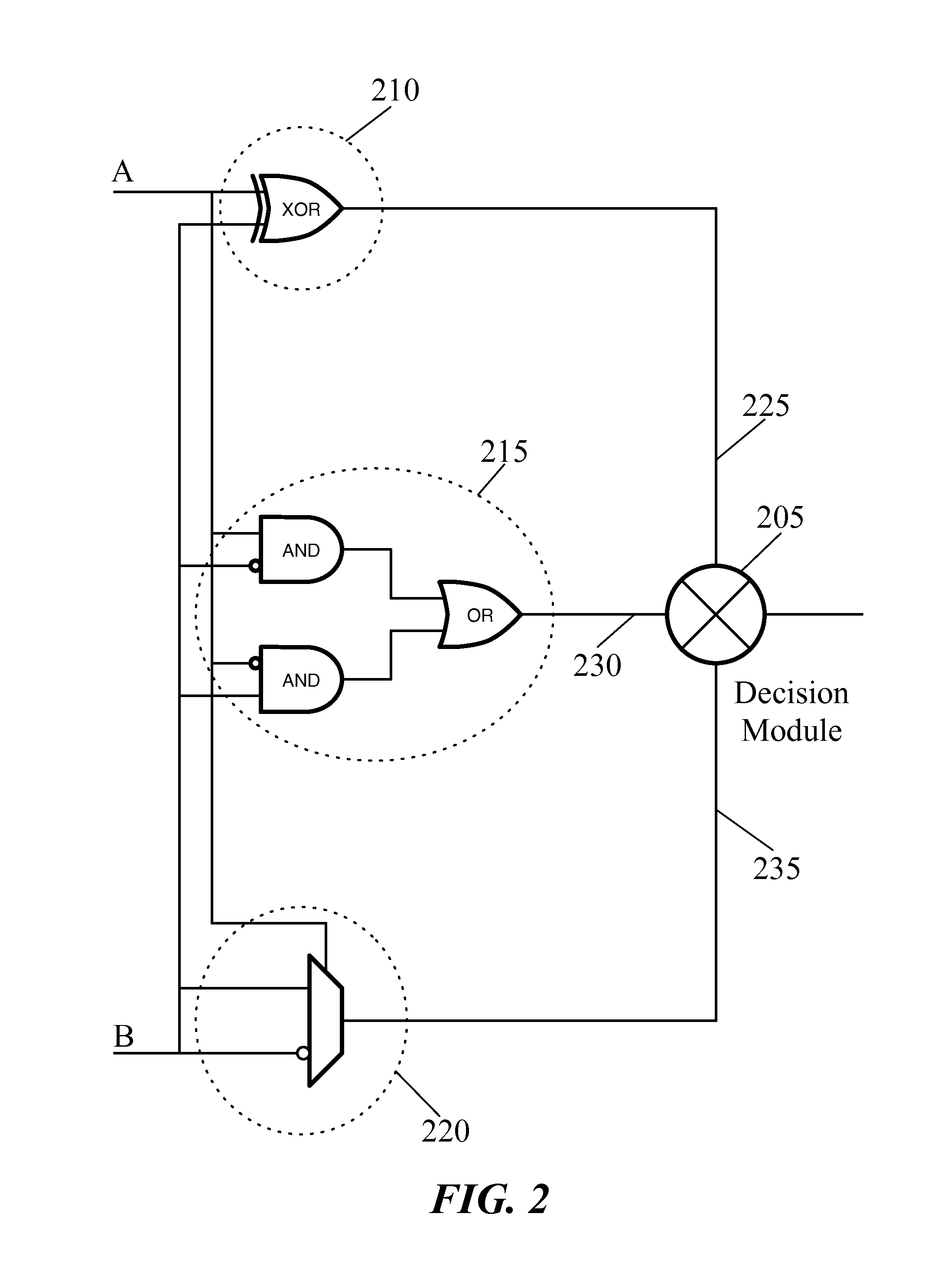

Decision modules in integrated circuit design

ActiveUS8458629B2Convenient post-operationEasy to installDetecting faulty computer hardwareCAD circuit designComputer moduleDecision taking

An abstract decision module primitive for placement within a logical representation (i.e., a netlist) of a circuit design is described. The decision module primitive receives as inputs alternative solutions for a given function or segment of a netlist. The alternative solutions include functionally equivalent, but structurally different implementations of the function or segment of the netlist. The decision module primitive alternatively selects between connecting one of the inputs to the netlist to provide a complete functional definition for the netlist based on constraint information. The selected input of the decision module may be updated as additional constraint information is determined throughout the various stages of the design process. In addition, alternative solutions for a given function or segment of the netlist may be added to and / or removed from the inputs of a decision module as additional constraint information is identified.

Owner:ALTERA CORP

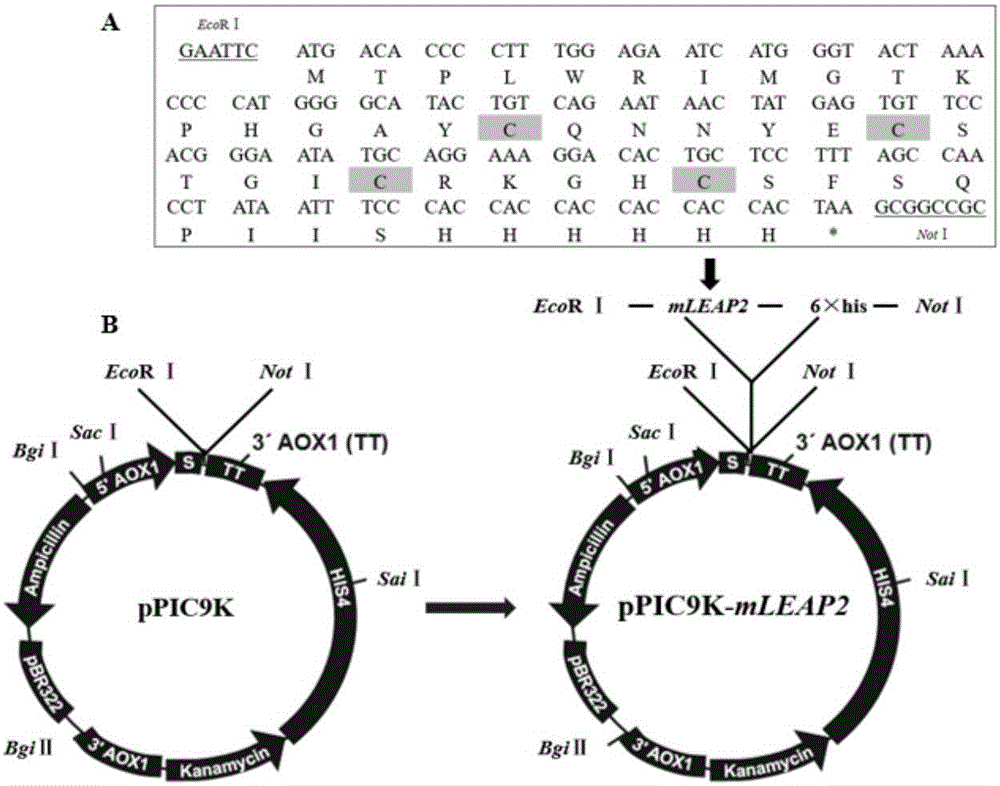

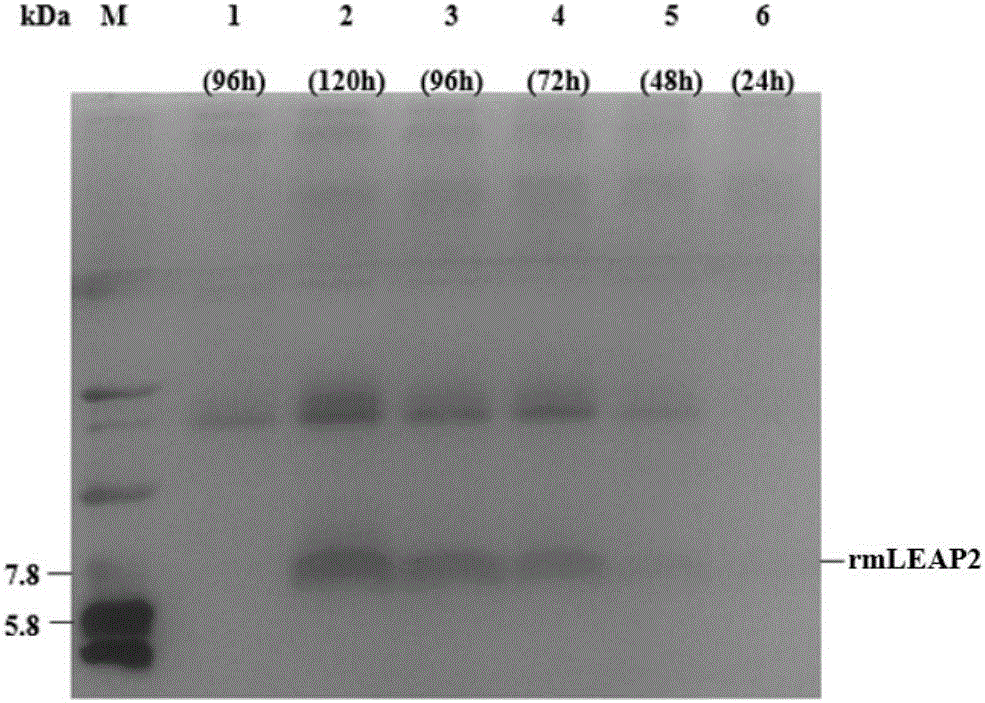

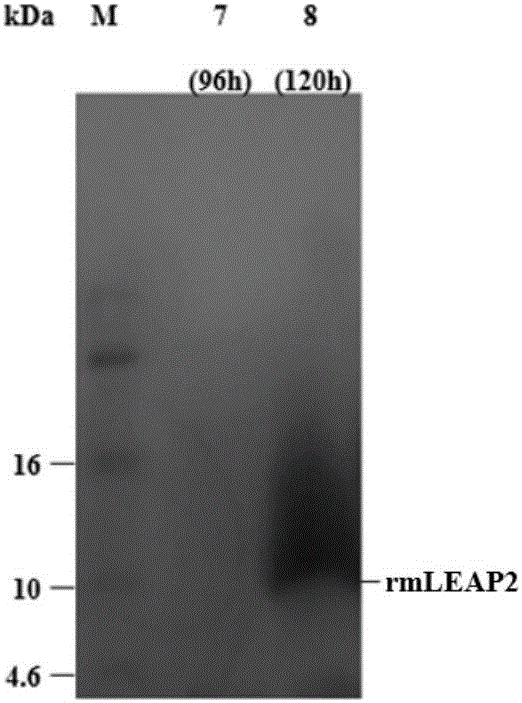

Optimized gene of ietalurus punetaus LEAP-2 mature peptide and preparation method of recombinant protein of optimized gene

InactiveCN106222175ALow costIncrease productionAntibacterial agentsPeptide/protein ingredientsPichia pastorisYeast

The invention discloses an optimized gene of ietalurus punetaus LEAP-2 mature peptide and a preparation method of recombinant protein of the optimized gene, and further provides a recombinant expression carrier and yeast host cell containing the optimized gene, application of the optimized gene to producing the ietalurus punetaus LEAP-2 mature peptide, and application of the recombinant protein to preparing antibacterial medicines. On the premise of not changing the amino acid sequence of the ietalurus punetaus LEAP-2 mature peptide, the amino acid sequence of the gene of the ietalurus punetaus LEAP-2 mature peptide is optimized according to pichia pastoris preferred codons, and the optimized sequence is SEQ ID NO:2. By expressing the optimized gene in a pichia pastoris host cell, the recombinant ietalurus punetaus LEAP-2 mature peptide is prepared. By means of the preparation method, the LEAP-2 mature peptide can be efficiently prepared, the applied culture conditions are simple, cost is low, and the obtained LEAP-2 mature peptide is good in antibacterial effect.

Owner:SHANGHAI OCEAN UNIV +1

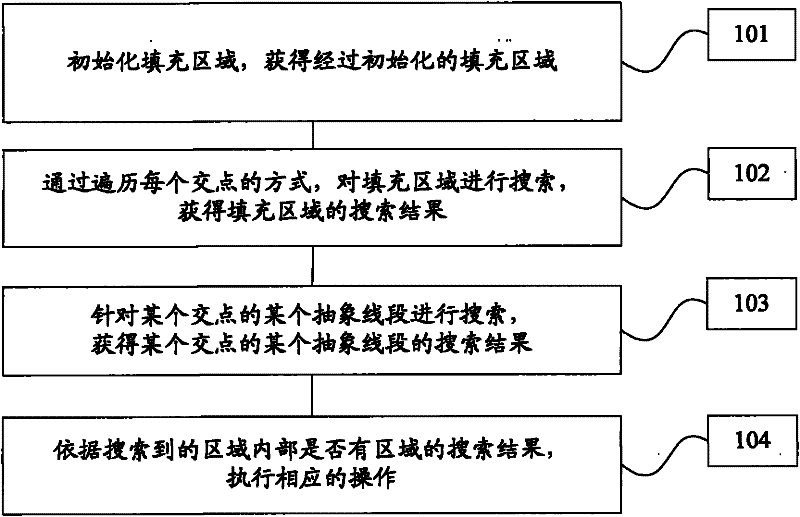

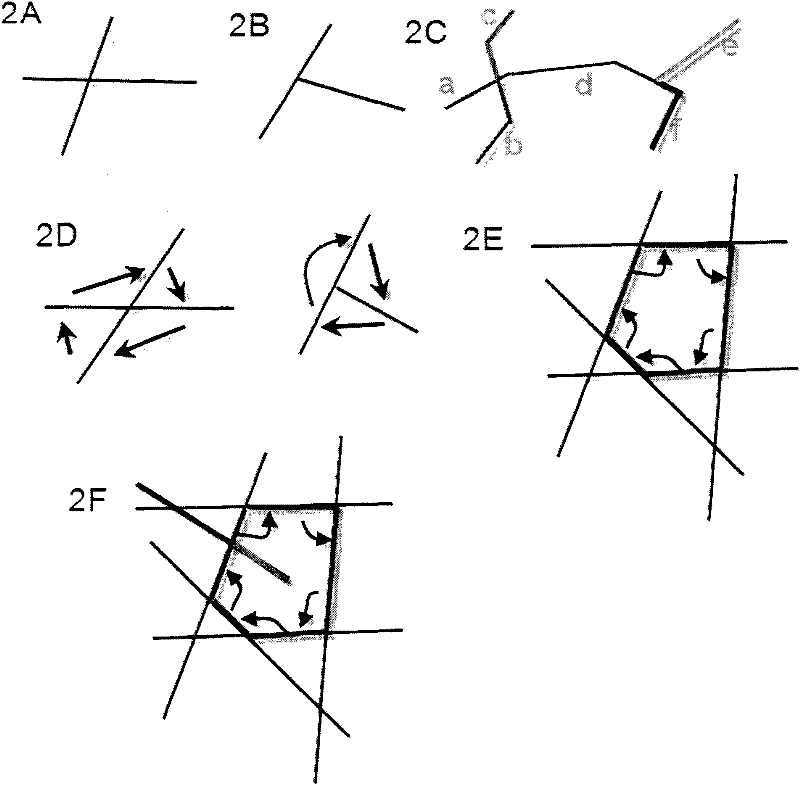

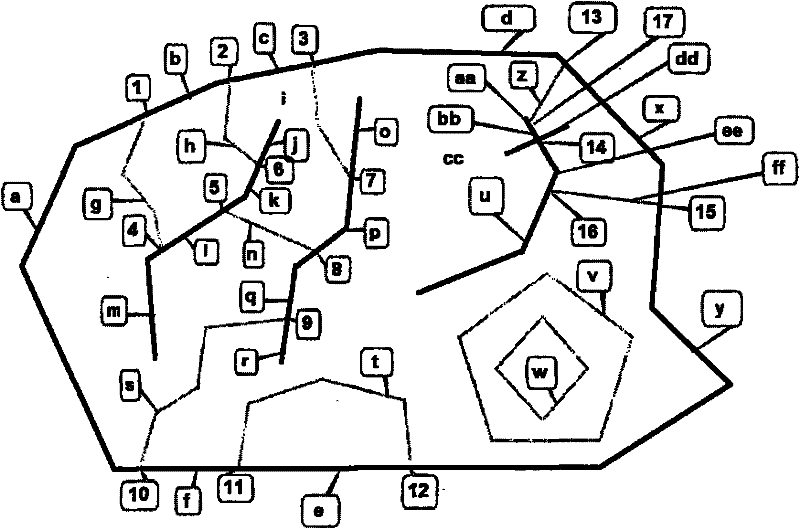

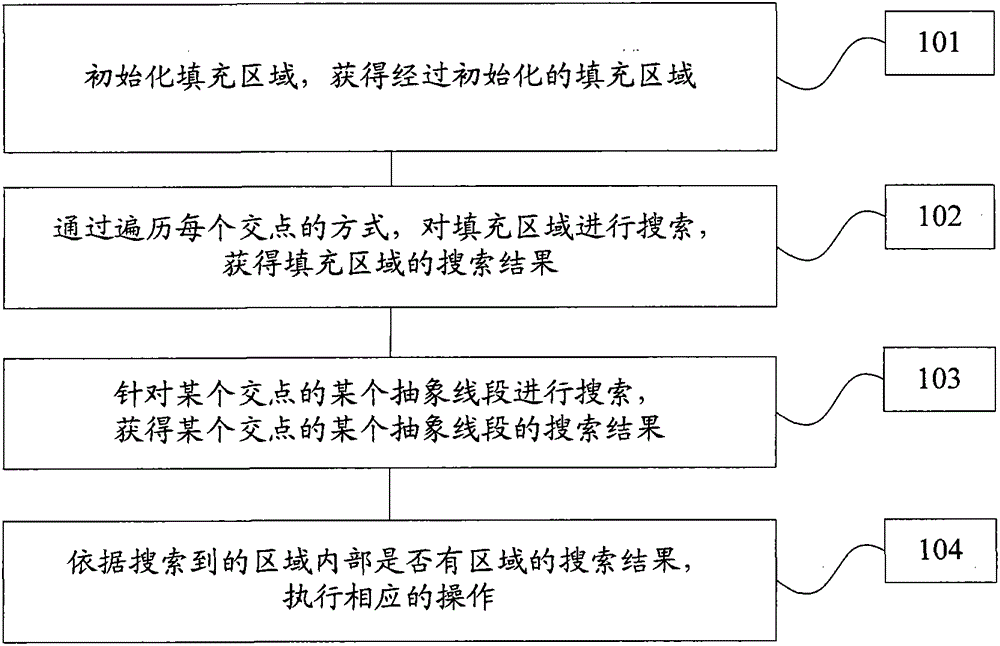

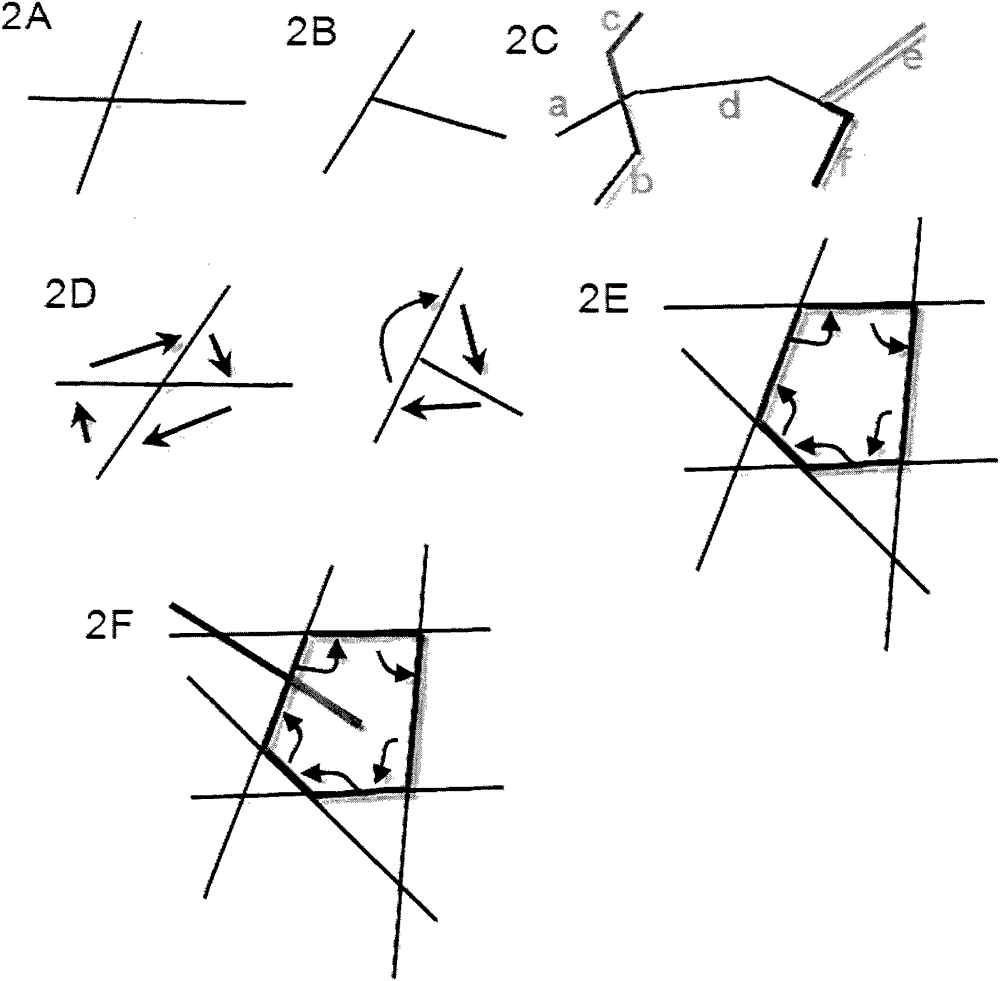

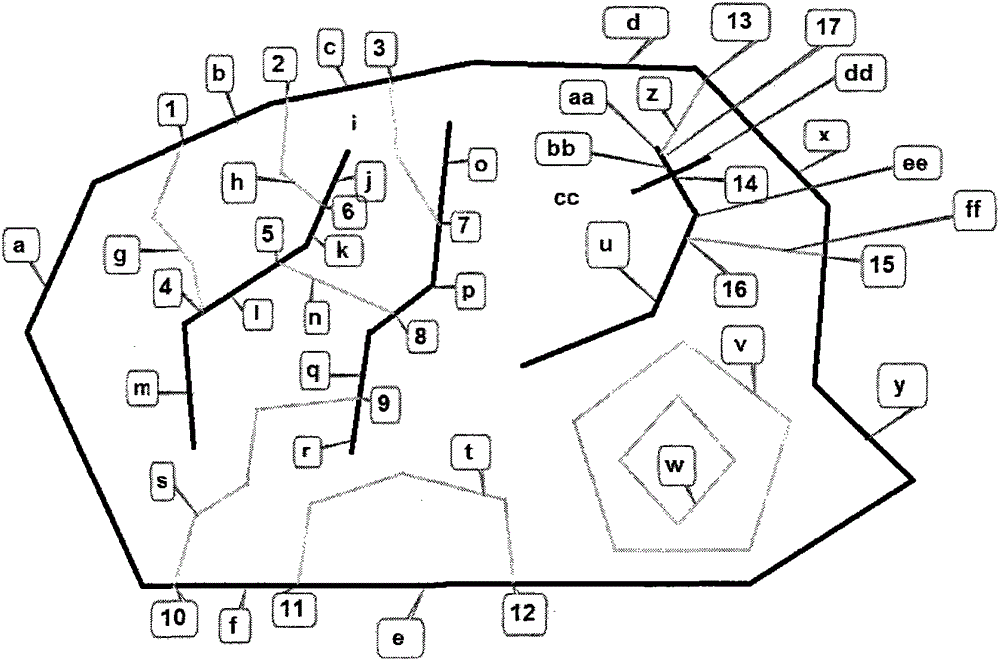

Method for searching and filling region by adopting geometric topology

ActiveCN102411789AEmbody the essenceConvenient post-operationFilling planer surface with attributesIntersection of a polyhedron with a lineComputer science

The invention provides a method for searching and filling a region by adopting geometric topology. The method comprises the following steps of: initializing a filling region to achieve the initialized filling region; searching the filling region by traversing each intersection point to obtain the search result of the filling region; searching on the basis of some abstract line segment of some intersection point to obtain the search result of some abstract line segment of some intersection point; and executing the corresponding operation on the basis that whether the search result of the region exists in the searched region or not. The method is a novel method for filling the region and has wide application range.

Owner:KARAMAY HONGYOU SOFTWARE

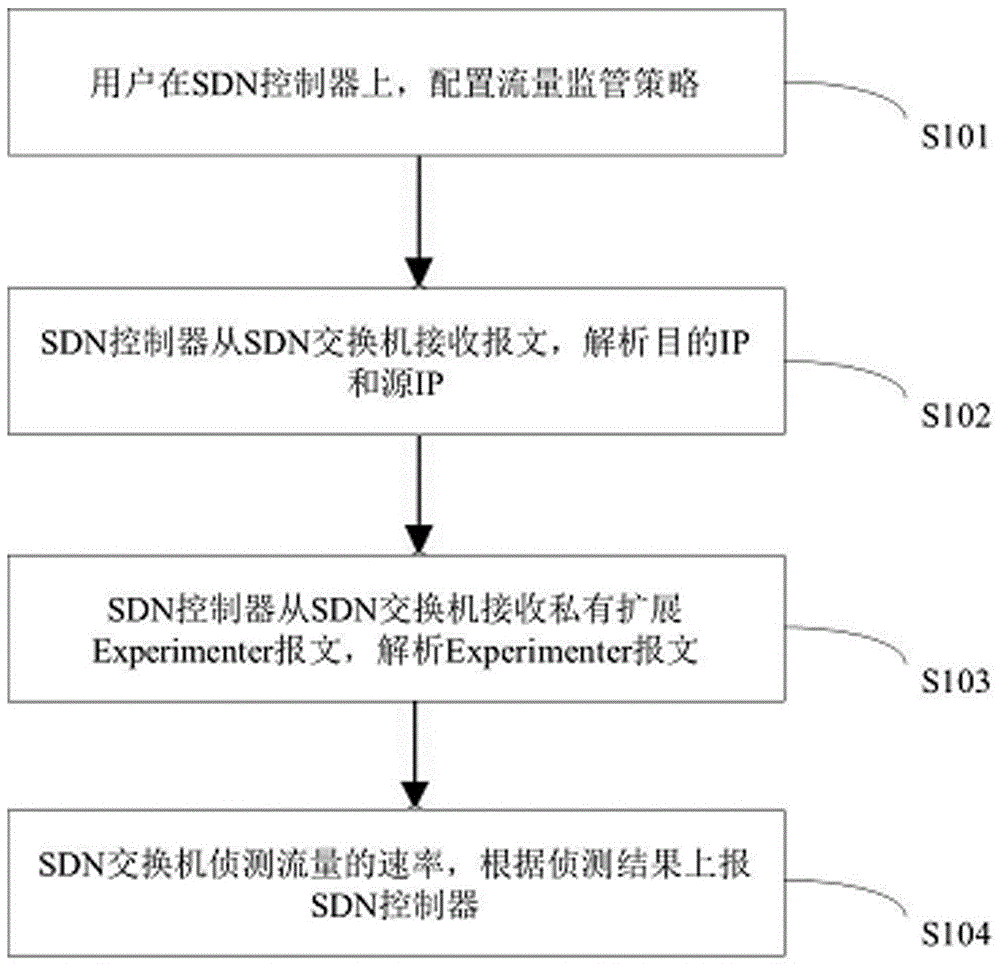

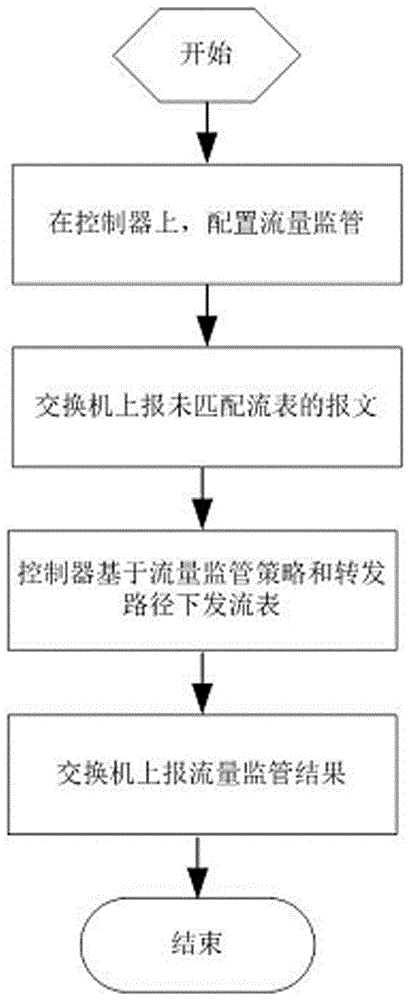

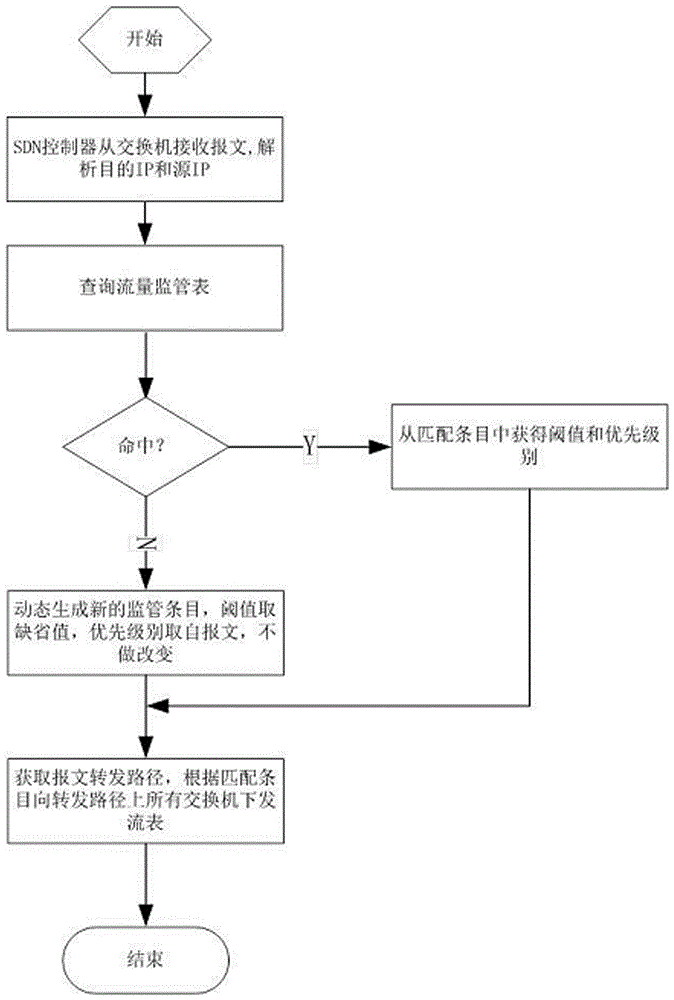

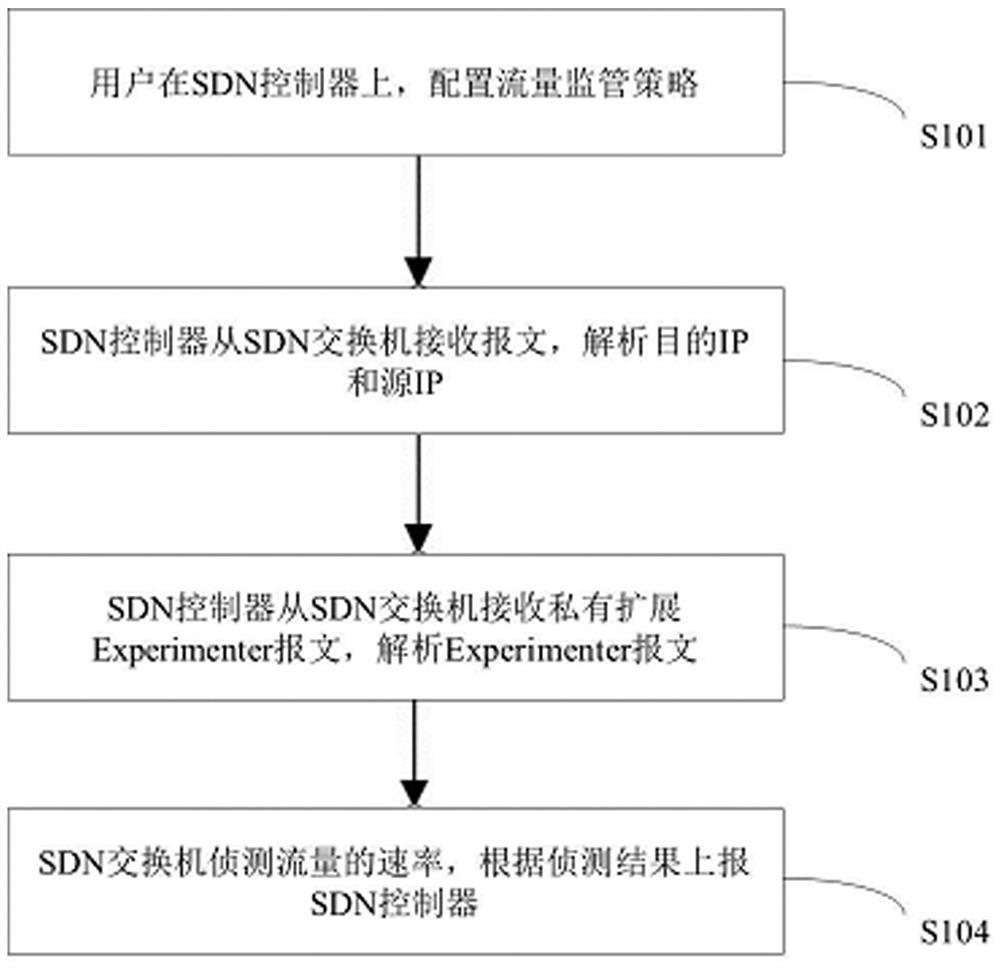

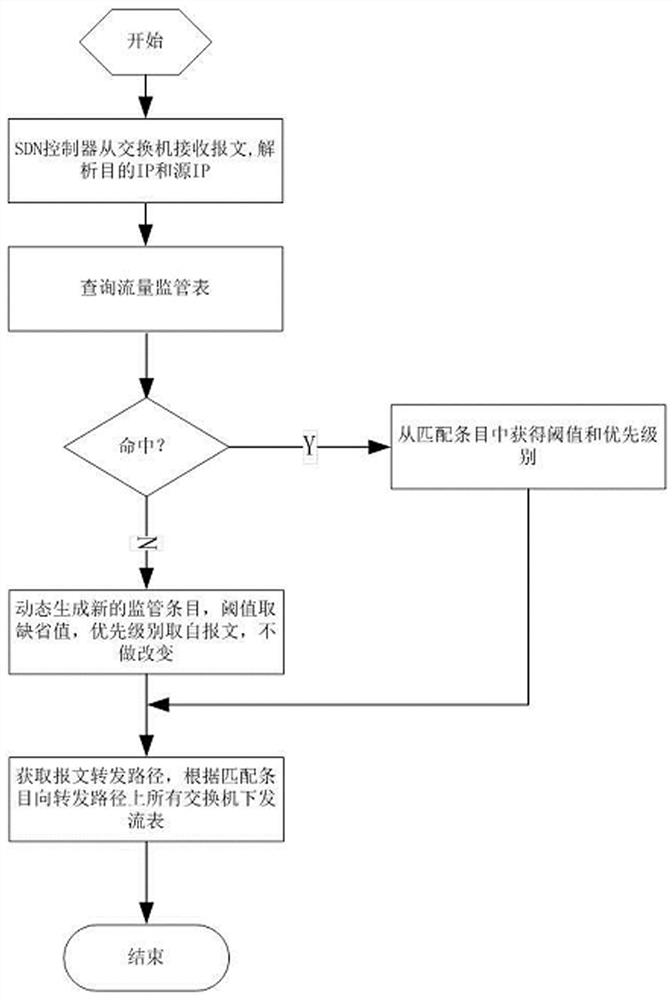

Flow control algorithm based on SDN architecture

ActiveCN106789703AProtect interestsEasy to manageData switching networksDisk controllerCentralized management

The invention relates to a flow control algorithm based on SDN architecture. The method includes the steps that S101, a user configures a flow control strategy on an SDN controller; S102, the SDN controller receives a message from an SDN switch, and a target IP and a source IP are analyzed; S103, the SDN controller receives a private extension Experimenter message from the SDN switch, and the Experimenter message is analyzed; S104, the SDN switch detects the rate of flow, and the rate is reported to the SDN controller according to the detection result. Compared with the prior art, the flow control process based on the SDN architecture is calculated by the controller in a unified mode and managed in a centralized mode, all flow control configuration is centralized in the controller, and management and later operation are convenient.

Owner:广东云栋科技有限公司

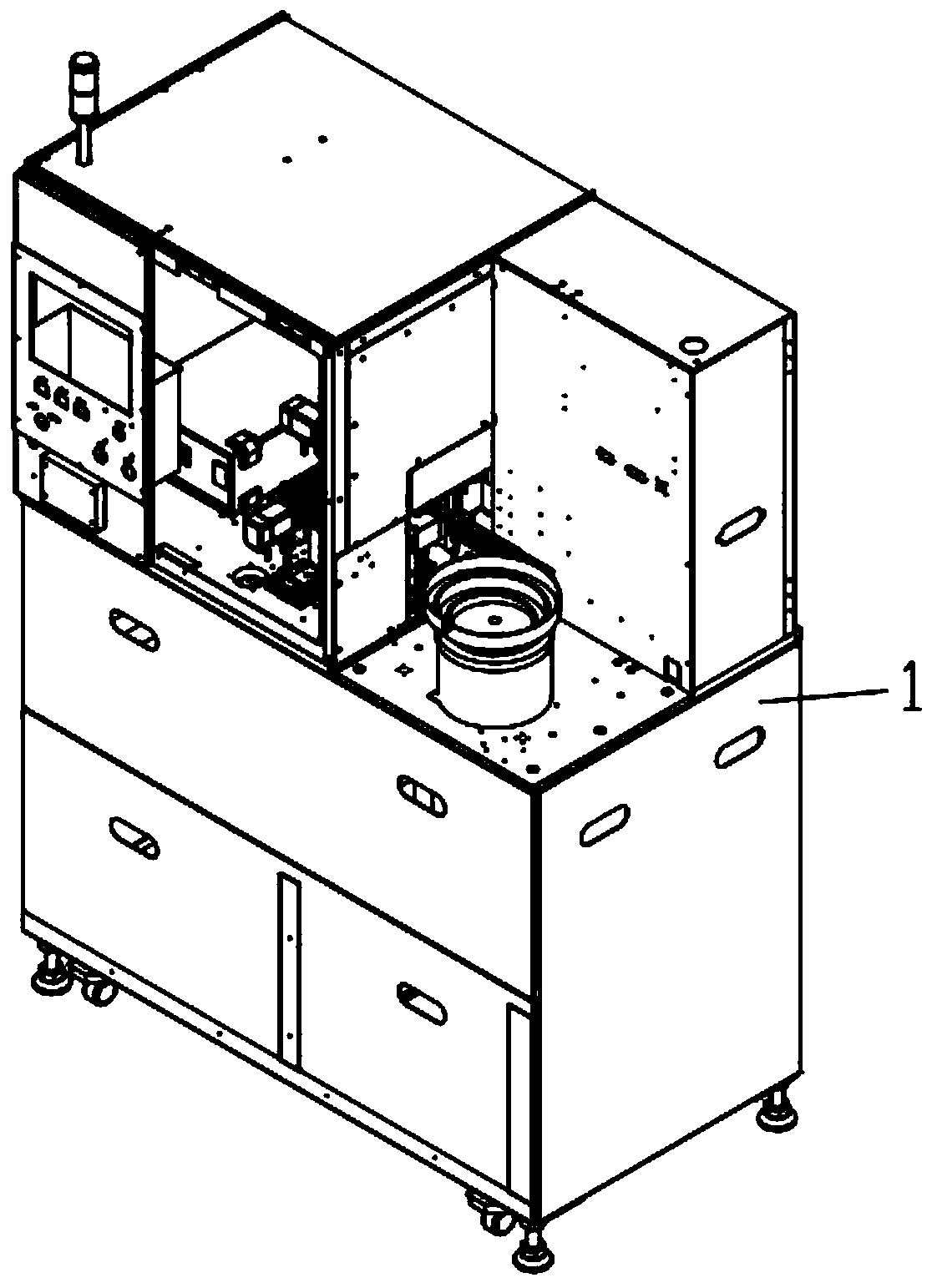

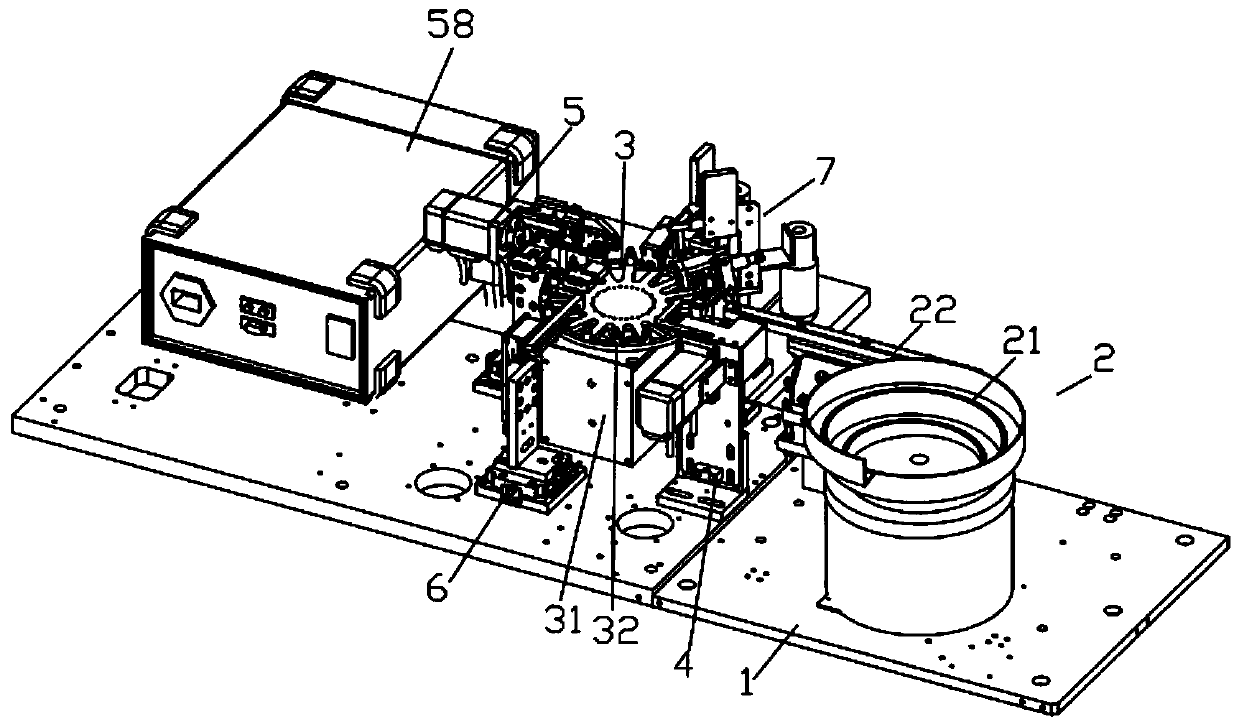

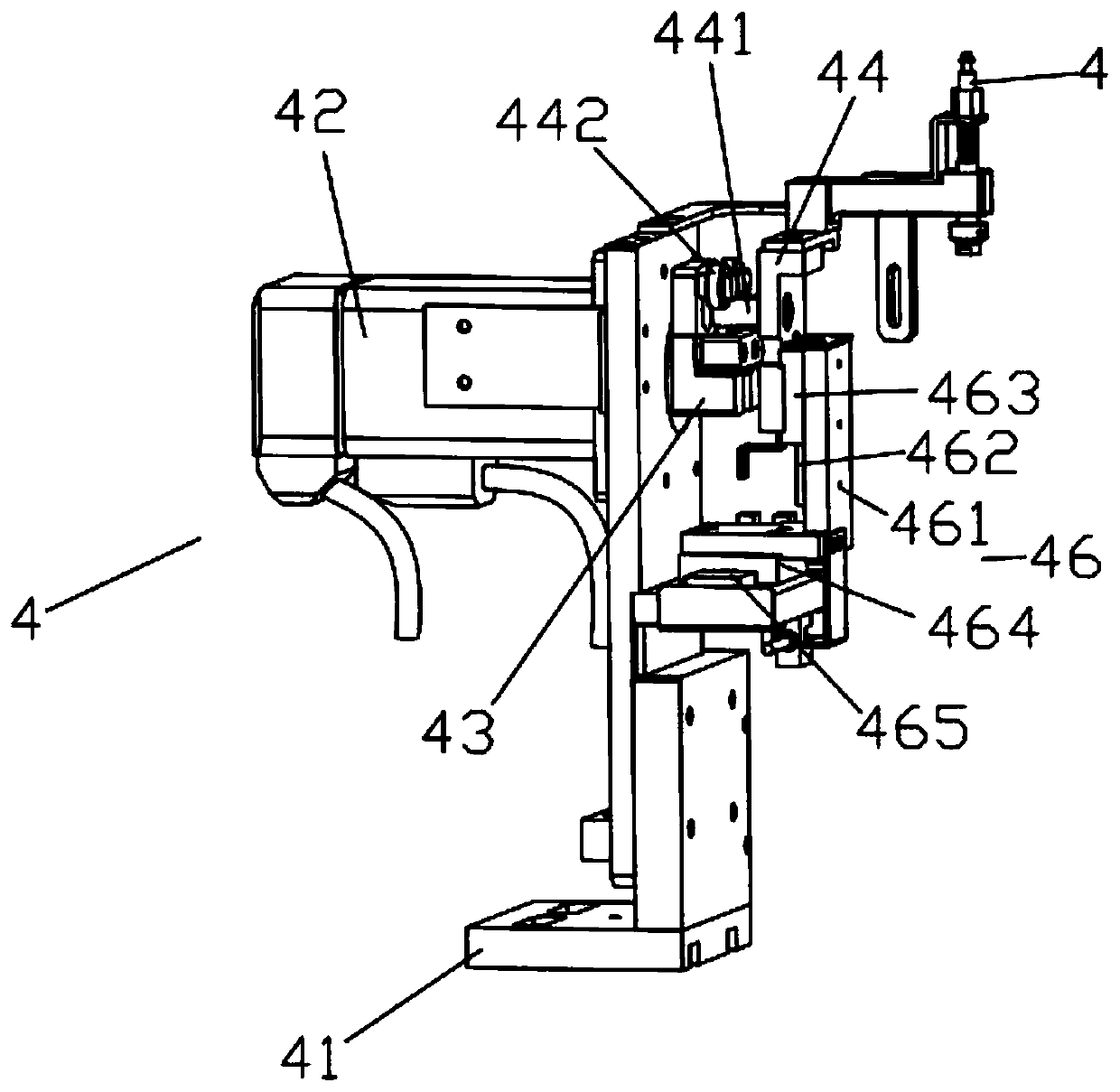

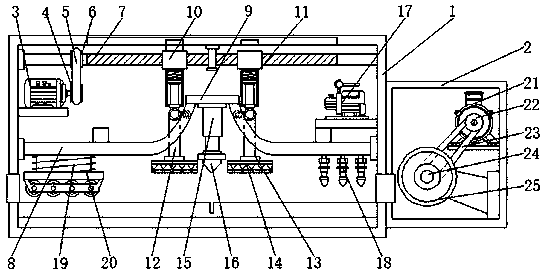

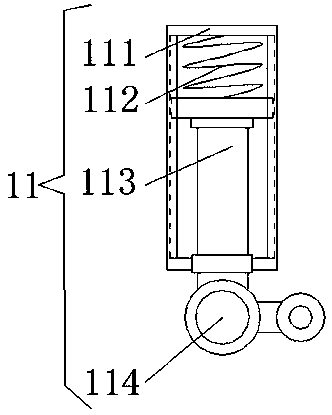

Semiconductor detection device

The invention provides a semiconductor detection device, and belongs to the technical field of semiconductor detection. The semiconductor detection device comprises a frame, and a control mechanism, afeeding mechanism, a material taking mechanism, a material placing mechanism, a detection mechanism and a discharging mechanism which are arranged on the frame. According to the semiconductor detection device, the control mechanism integrally controls the action of each mechanism, so that each mechanism is matched to realize the automation of semiconductor detection; the feeding mechanism automatically conveys a to-be-detected piece, the material taking mechanism takes down the to-be-detected piece from the feeding mechanism and places the to-be-detected piece on the material placing mechanism, the detection mechanism detects the to-be-detected piece on the material placing mechanism, and finally the discharging mechanism classifies, takes down and stores the to-be-detected piece according to a detection result; and the whole detection process is highly automatic, qualified products and unqualified products can be classified and collected according to detection results, and later operation is convenient.

Owner:苏州埃尔森自动化设备有限公司

Crushing apparatus for recycling waste paper box

InactiveCN107761423AEasy to carryEasy to viewPaper recyclingFibrous raw materialsStaging operationControl valves

The invention provides crushing apparatus for recycling a waste paper box. The crushing apparatus is characterized by comprising a support, a crushing shell, a water spraying pipe, a feeding opening,a discharging opening, crushing stirring paddles, a control valve, a water tank, a water delivery pipe and an observation window; the crushing shell is arranged on the upper side of the support; the feeding opening is formed in a side face of the crushing shell; the discharging opening is formed in the lower side of the crushing shell; and the water spraying pipe and the crushing stirring paddlesare arranged inside the crushing shell. The crushing apparatus provided by the invention is used for recycling the waste paper box. According to the apparatus, a water spraying device is additionallyarranged on the basis of an original crushing device, water spraying is carried out on the interior of the crushing shell through water spraying holes in the water spraying pipe, and the humidity of the paper box inside the crushing shell is increased, so that the crushing is convenient, the crushing is more thorough, and the later-stage operation can be conveniently carried out.

Owner:MACROSCOPIC CENTURY TIANJIN CO LTD

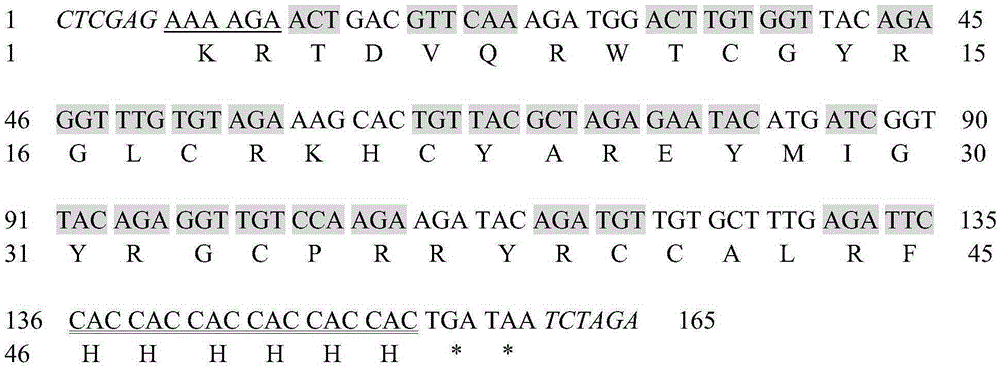

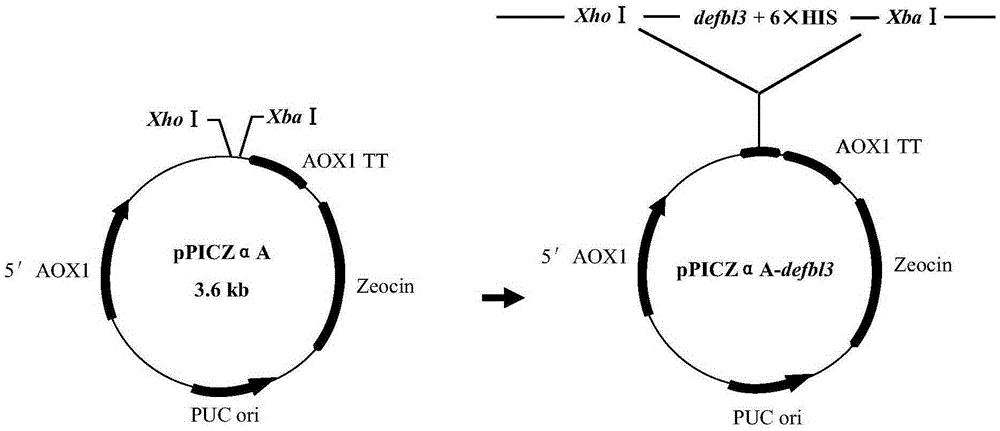

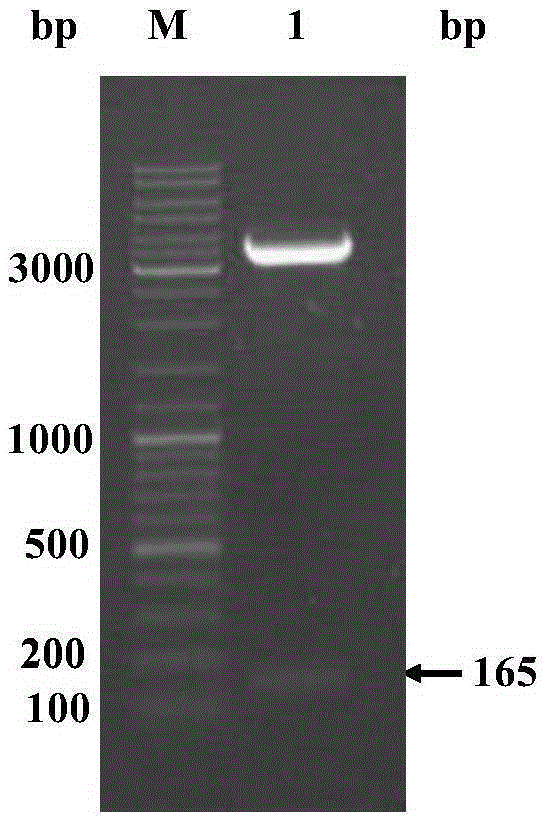

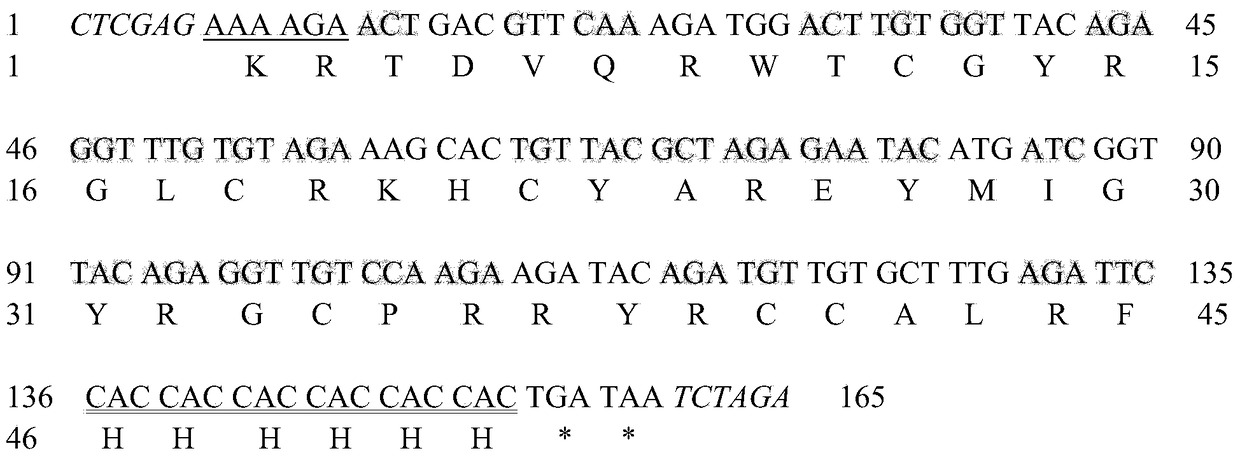

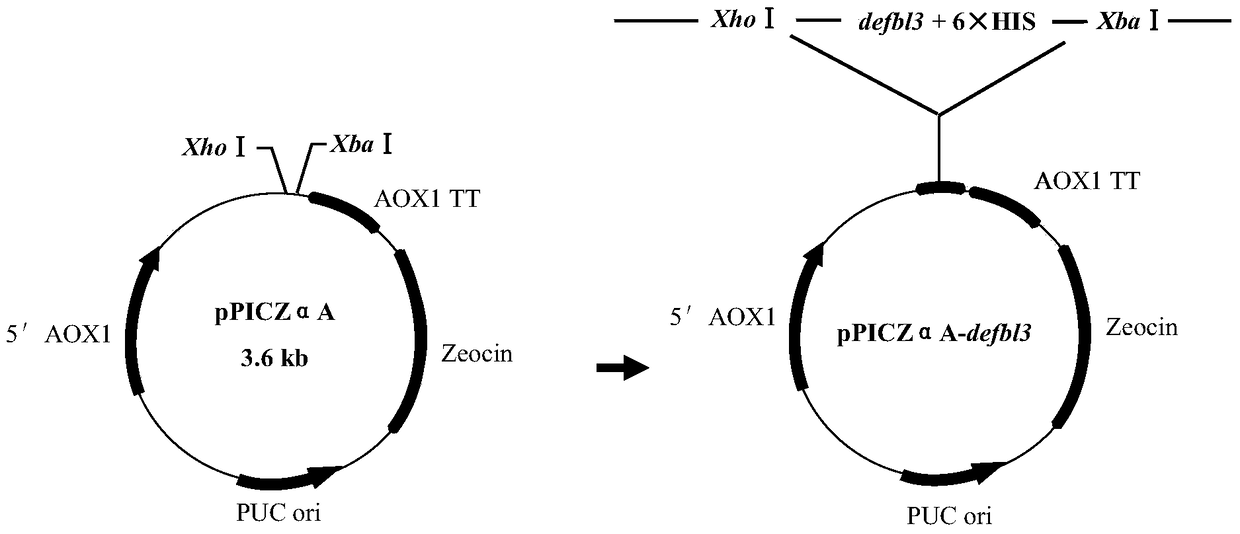

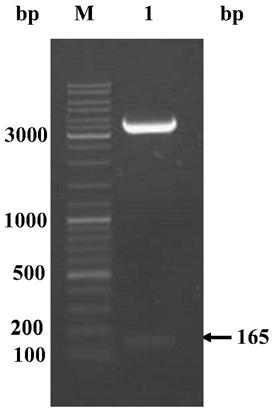

Optimized gene of zebrafish defensin defbl3 and preparation method of recombinant protein thereof

The invention discloses an optimized gene of zebrafish defensin defbl3 and a preparation method of a recombinant protein of the optimized gene and further provides a recombinant expression vector and a pichia host cell including the optimized gene, application of the optimized gene in production of the zebrafish defensin defbl3 and application of the recombinant protein in preparation of antibacterial drugs. On the premise that an amino acid sequence of the zebrafish defensin defbl3 is not changed, a nucleotide sequence of the zebrafish defensin defbl3 is optimized according to a pichia preference codon, and the optimized sequence is shown as SEQ ID NO.2. The recombinant zebrafish defensin defbl3 is prepared by expressing the optimized gene in a pichia host cell. The zebrafish defensin defbl3 can be efficiently prepared by means of the preparation method, the adopted culture conditions are simple, the cost is lower, and the obtained defensin defbl3 is good in antibacterial effect.

Owner:SHANGHAI OCEAN UNIV

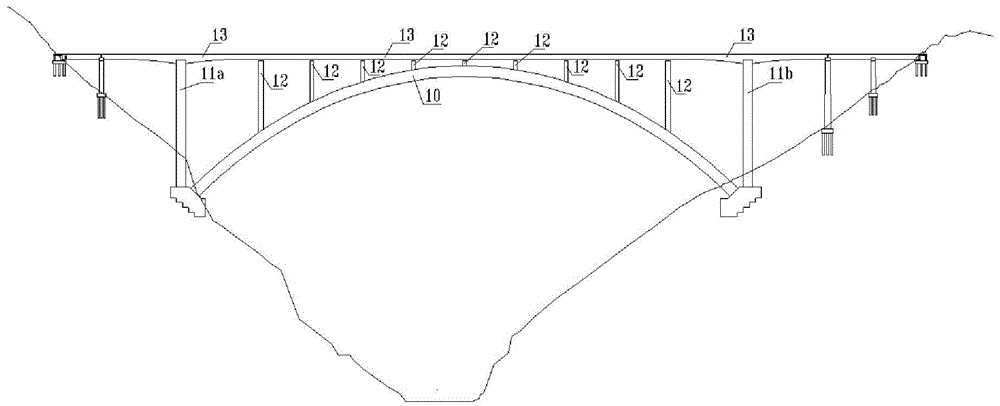

Spandrel architectural construction of ballastless track wide-span high-speed railway arch bridge

ActiveCN105463982AImprove smoothnessImprove comfortBridge structural detailsArch-type bridgeStaging operationBridge deck

The invention relates to a spandrel architectural construction of a ballastless track wide-span high-speed railway arch bridge. According to the construction, the problem that the deformation of corners of beam ends of spandrel beams is out of gauge is thoroughly solved, the smooth degree of a bridge floor is effectively improved, and the requirements of the technical conditions of a wide-span arch bridge ballastless track are met. The driving comfortability and the driving safety are improved, the construction cost of the bridge is reduced, and the later stage operation management and conservation are facilitated. The spandrel architectural construction comprises a main arch, a left junction pier, a right junction pier, spandrel pier columns and spandrel beams, wherein the left junction pier and the right junction pier are respectively arranged on two sides of the main arch, the spandrel pier columns of which the lower ends are in fixed junction with the main arch are arranged at intervals along the bridge. The spandrel architectural construction is characterized in that the spandrel beams are in continuous construction within the span range of the main arch, are in fixedly junction with the upper ends of the left junction pier and the right junction pier, and are connected with the upper ends of the pier columns of arches through a supporting seat.

Owner:CHINA RAILWAY ERYUAN ENG GRP CO LTD

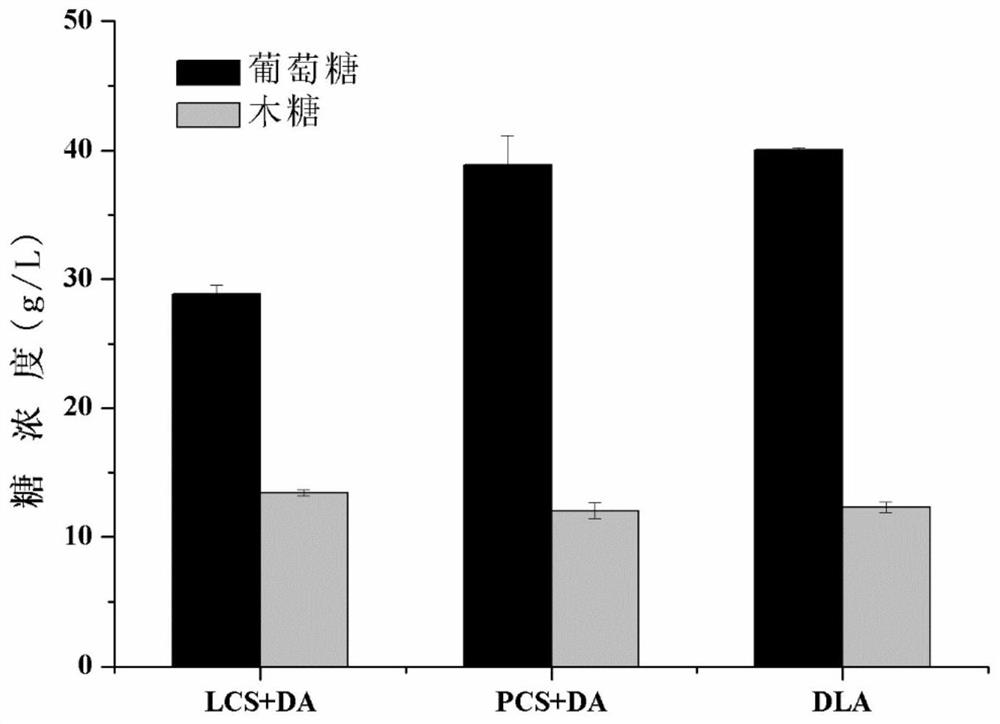

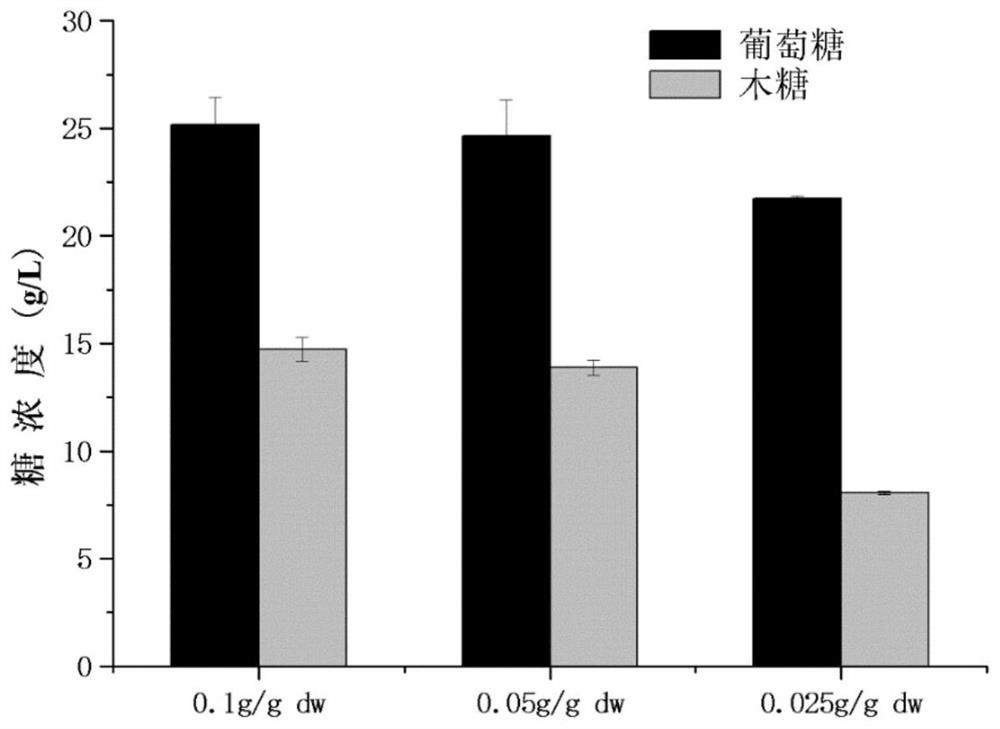

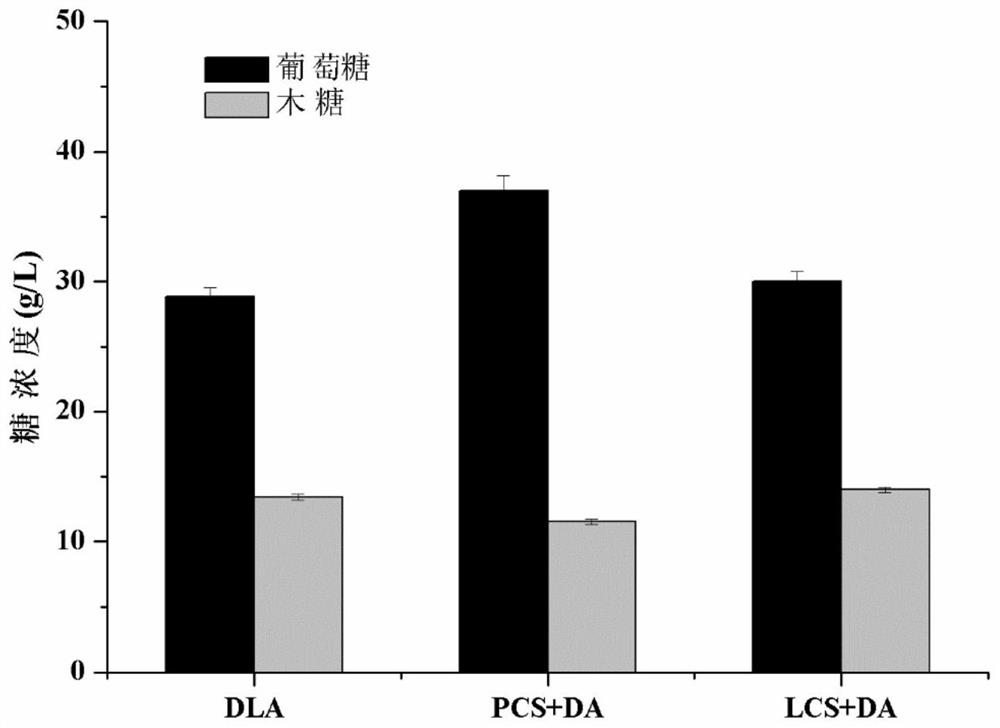

Method for performing pretreatment and biotransformation by adding acidic reagent in lignocellulose raw material densification process

ActiveCN112111540AEasy pretreatmentPretreatment, subsequent biotransformation can be directly used in the next step to facilitateBiofuelsFermentationCelluloseEngineering

The invention discloses a method for performing pretreatment and biotransformation by adding an acidic reagent in a lignocellulose raw material densification process. The method comprises the following steps: adding the acidic reagent and water into a lignocellulose raw material, performing uniform mixing, and performing densification treatment; or pretreating the lignocellulose raw material by anacid method, then performing densification treatment to obtain densified lignocellulose, then directly performing biotransformation, or performing biotransformation after subsequent selective pretreatment to produce a target chemical. The acidic reagent is added in the lignocellulose raw material densification process to destroy the original structure of lignocellulose, so that the mild pretreatment process of the lignocellulose raw material is realized in the subsequent transportation and storage processes, and the severity of further pretreatment is reduced. Compared with a loose raw material, obtained lignocellulose particles are higher in density and convenient to transport and store, the pretreatment cost is reduced, and the yield of a target product is higher in biotransformation ofthe acidified and densified lignocellulose.

Owner:NANJING UNIV OF SCI & TECH

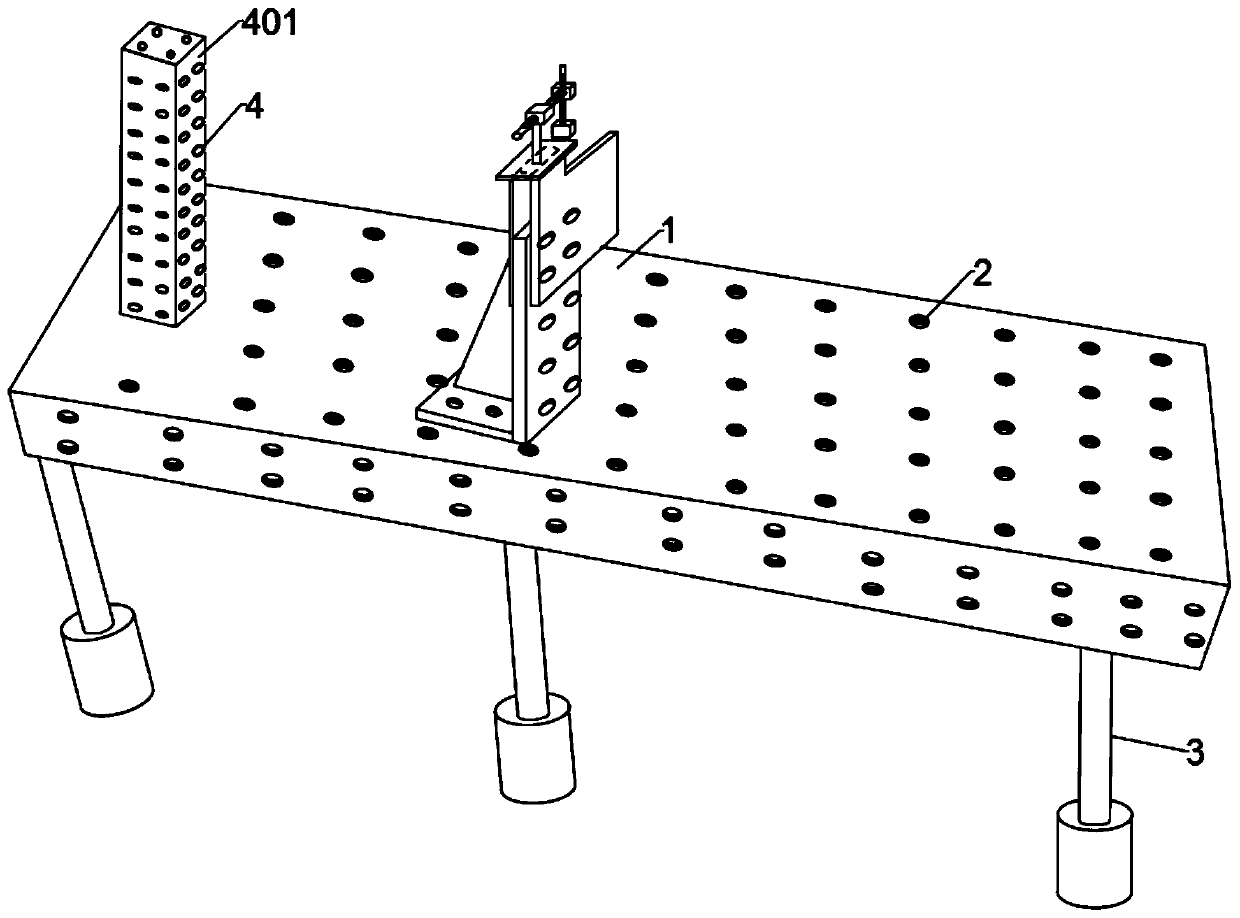

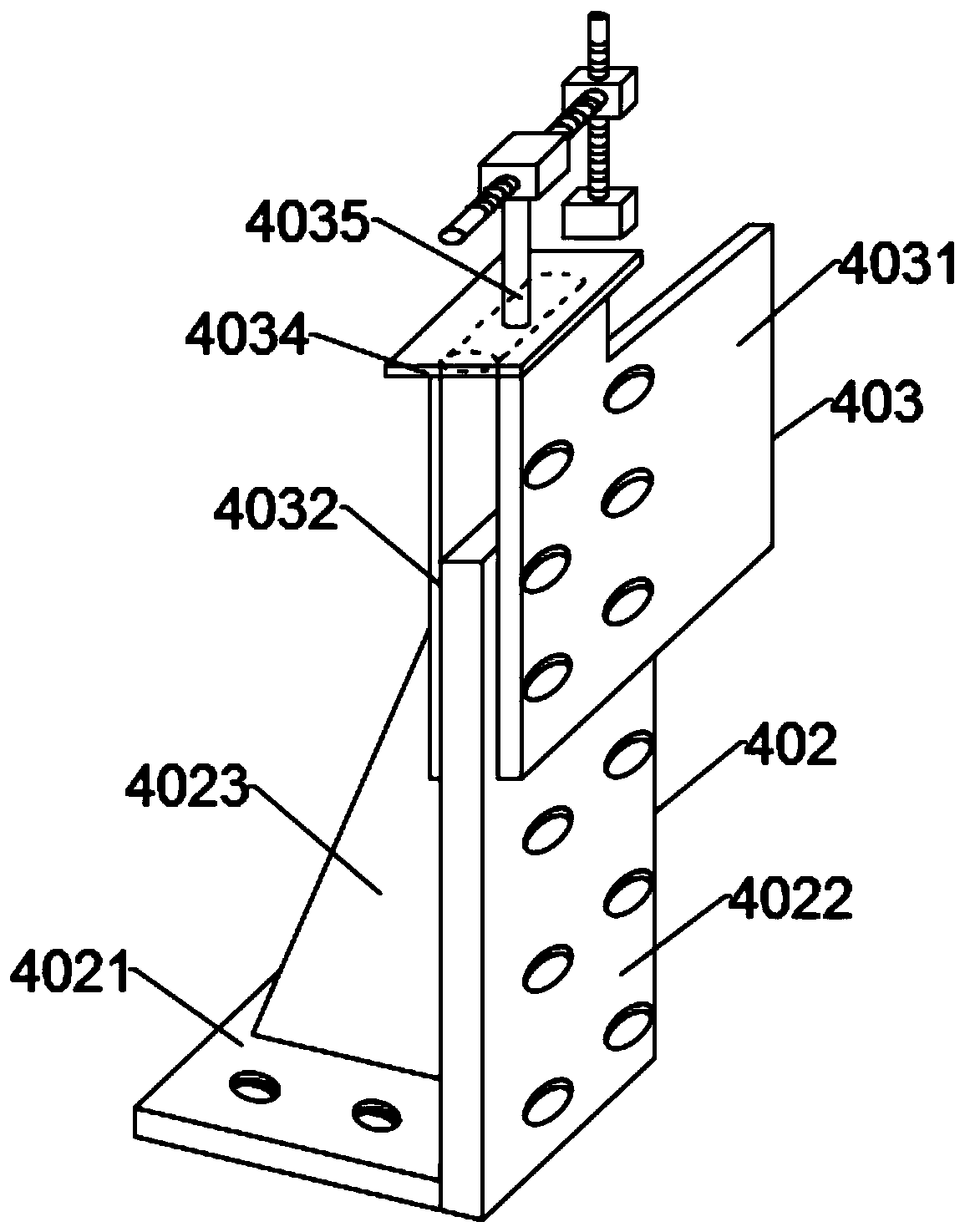

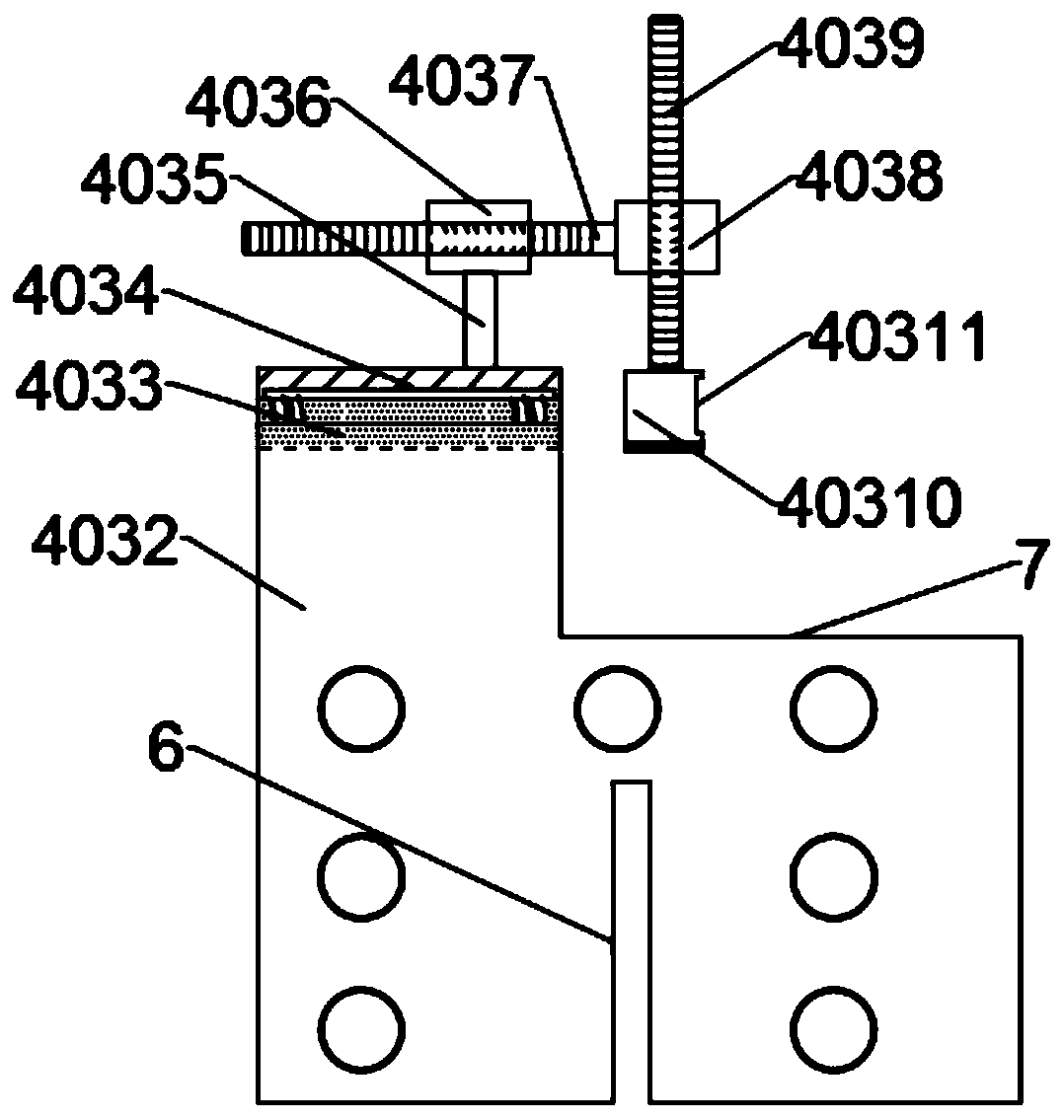

Automobile part maintenance pressing and fixing device and pressing method thereof

ActiveCN110539259AAchieve local recompressionAchieve partial relaxationWork holdersWork benchesScrew threadEngineering

Owner:湖南容光汽车部件有限公司

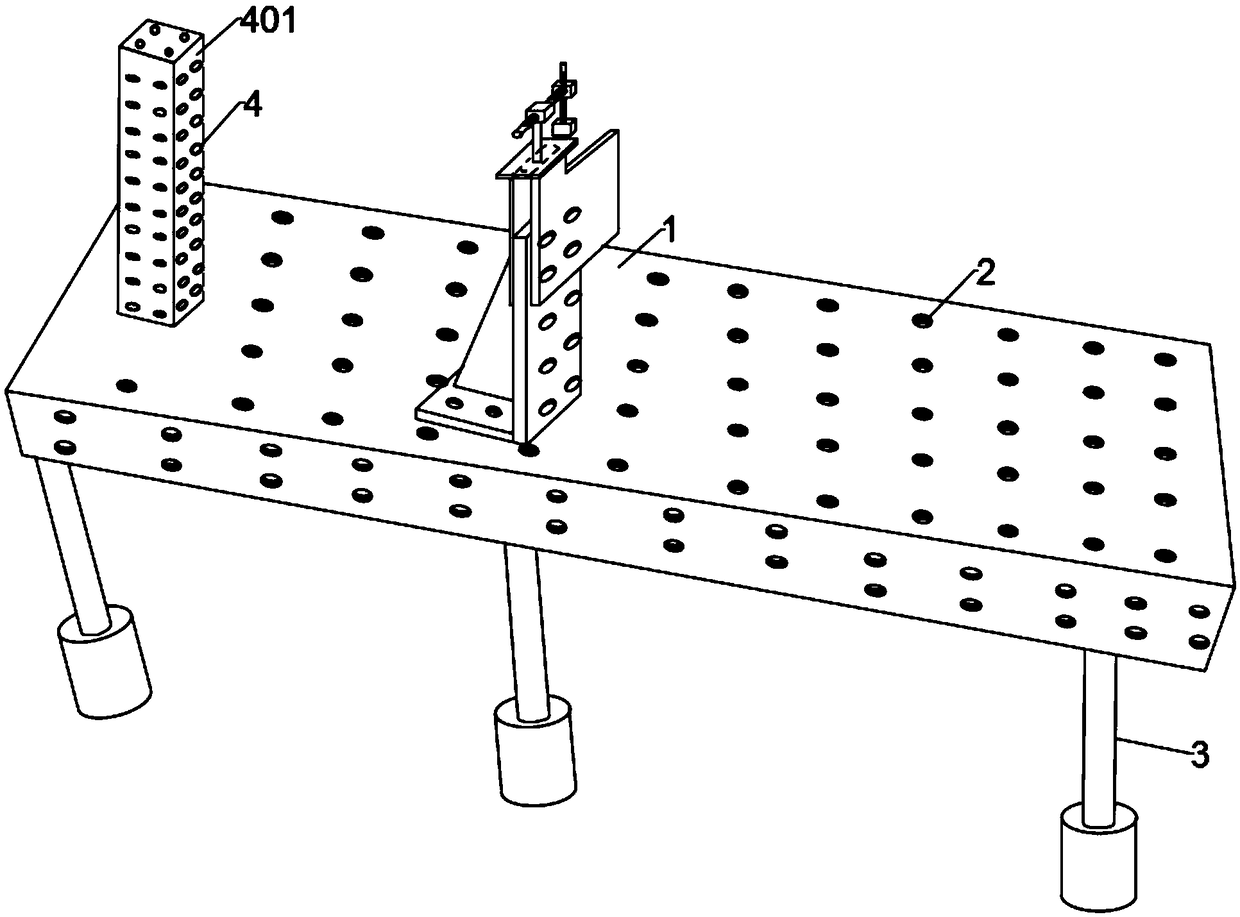

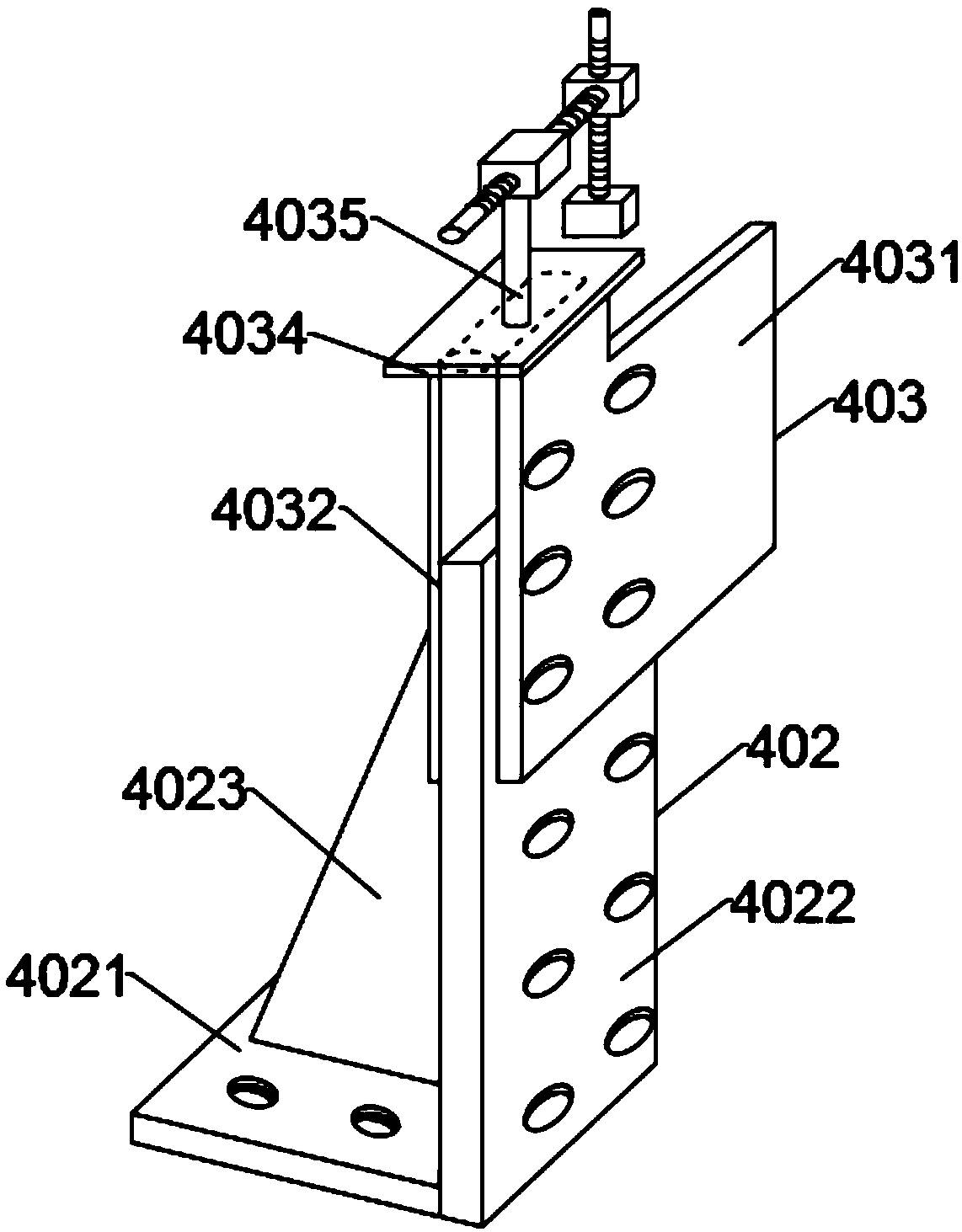

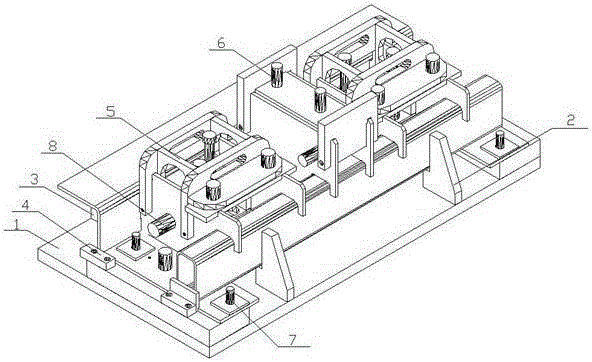

Three-dimensional positioning tool of vehicle base plate welding assembly

ActiveCN108655645ALow costAvoid damageWelding/cutting auxillary devicesAuxillary welding devicesSurface mountingEngineering

The invention discloses a three-dimensional positioning tool of a vehicle base plate welding assembly. The tool comprises an object carrying tool plate; a support inclined mechanism is mounted on thelower surface of the object carrying tool plate; a clamping mechanism is arranged on the upper surface of the object carrying tool plate; a heat dissipation cooling mechanism is arranged at the lowerend of the object carrying tool plate; the clamping mechanism comprises an assembly three-dimensional block and a positioning fixture; the positioning fixture comprises a lower fixed support plate andan upper assembly clamping plate; the upper assembly clamping plate comprises a first thread plate and a second thread plate; vertical fixed rods are arranged at the upper ends of the first thread plate and the second thread plate; horizontal thread hole through plates are arranged at the upper ends of the vertical fixed rods; horizontal displacement bolts are arranged in the horizontal thread hole through plates; vertical thread hole through plates are arranged at the tail ends of the horizontal displacement bolts; and vertical clamping bolts are arranged in the vertical thread hole throughplates. A vehicle body is hoisted for three-dimensional welding, so that the damage to an object carrying plate during welding is reduced, the welding quality is improved, the vehicle base plate manufacturing cost is reduced, the heat dissipation function is improved, and the welding safety is improved.

Owner:芜湖众梦电子科技有限公司

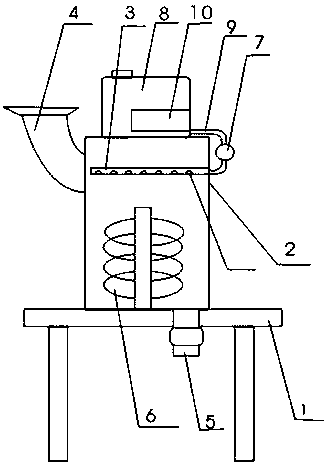

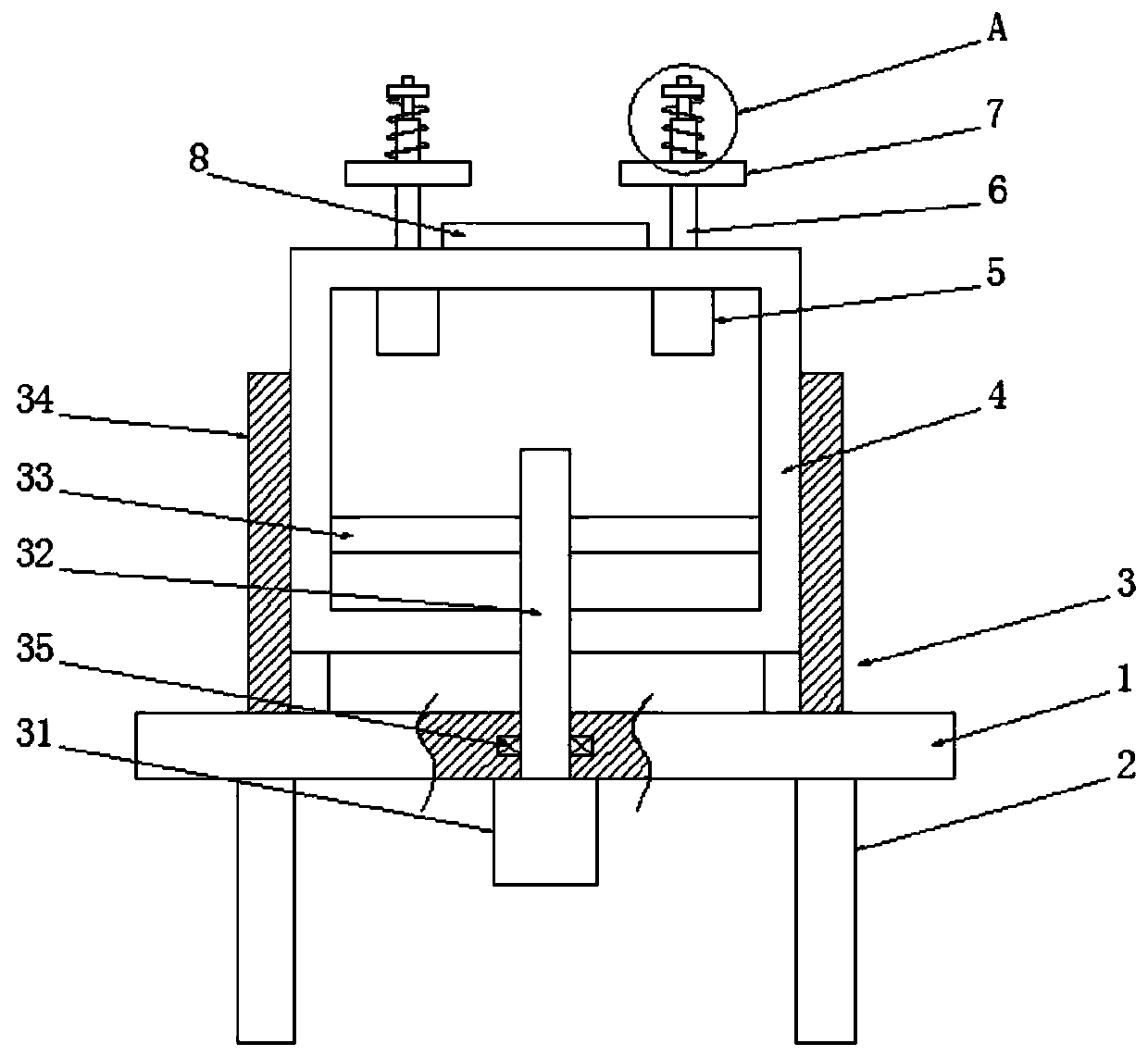

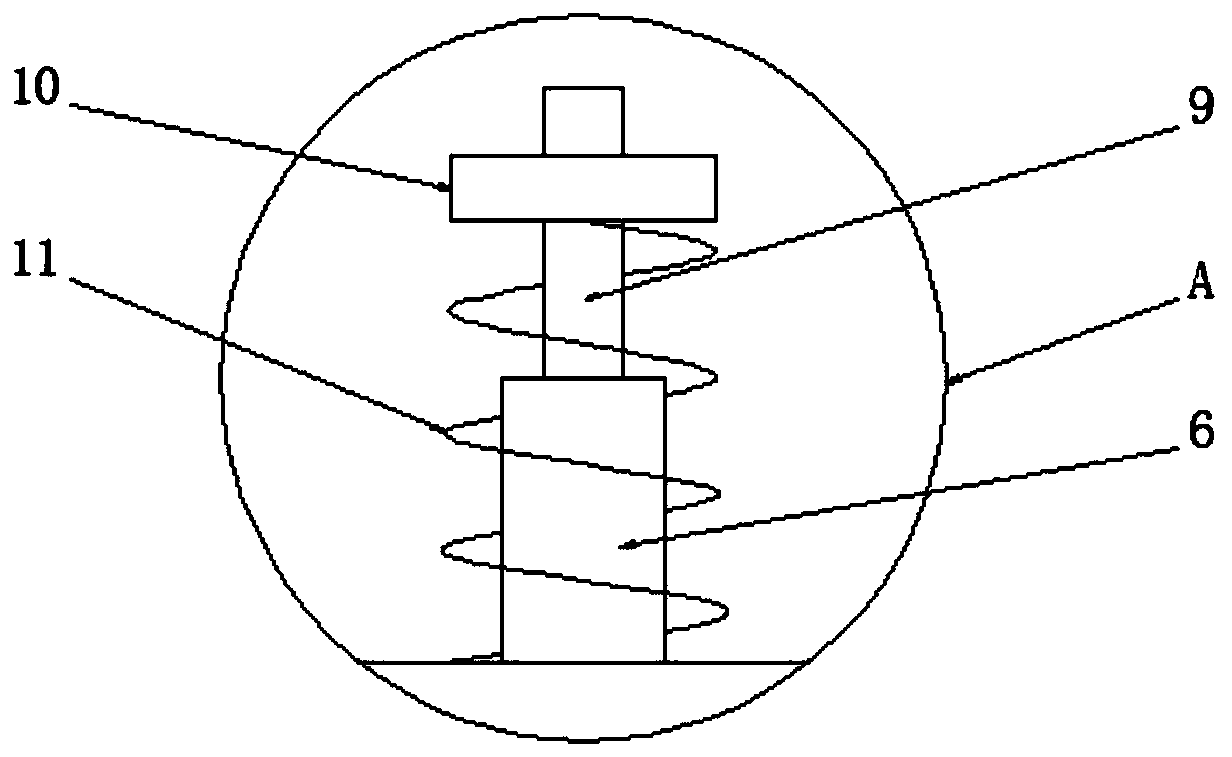

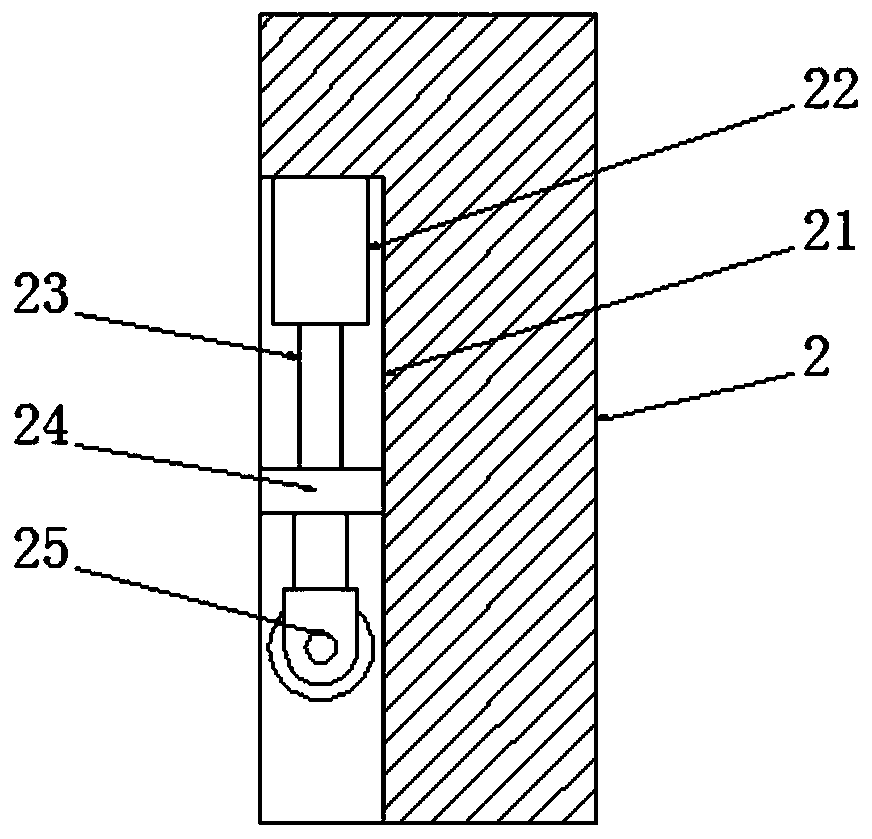

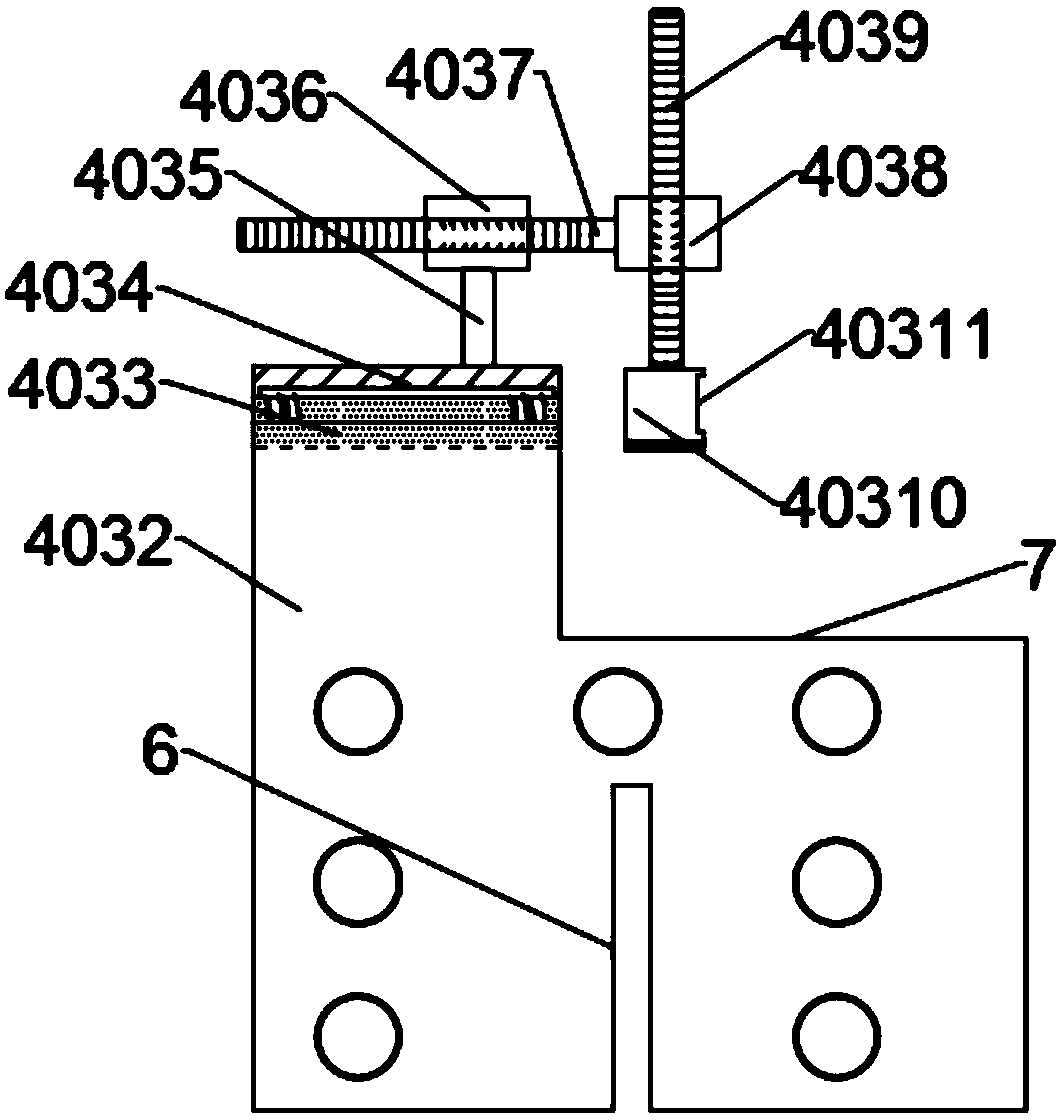

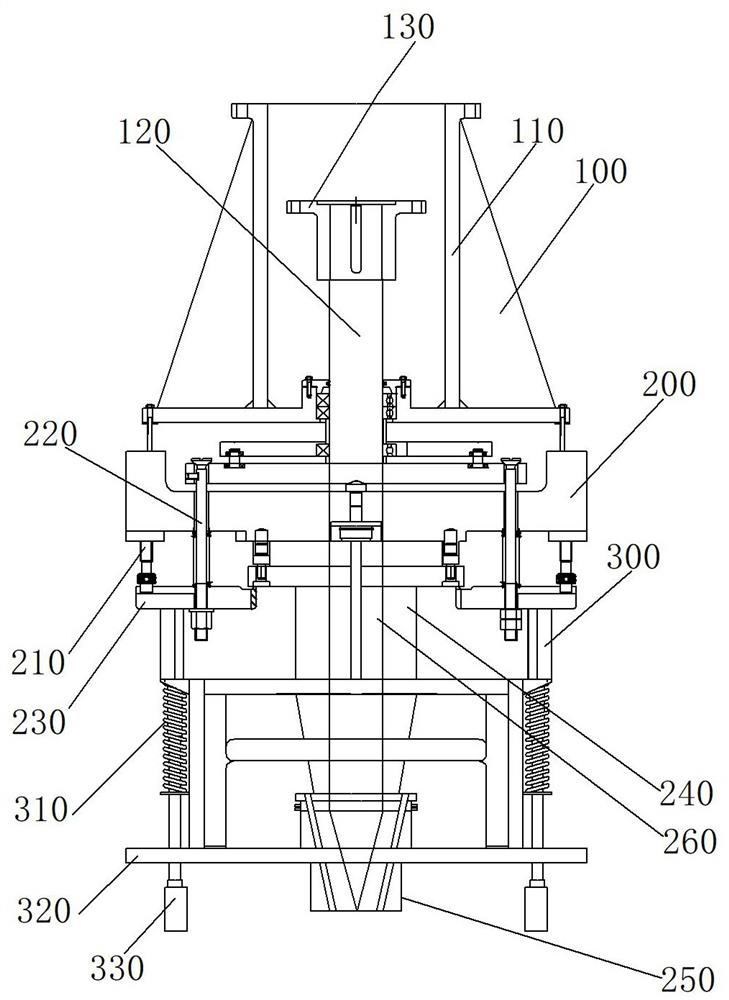

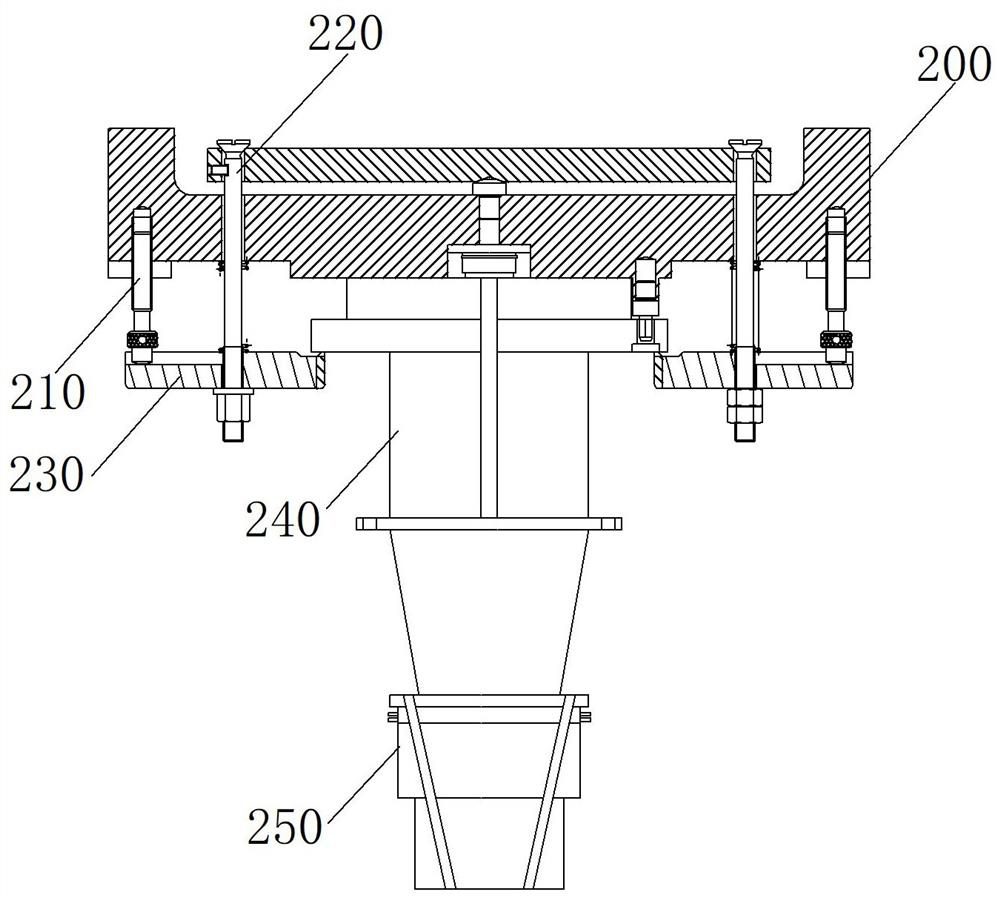

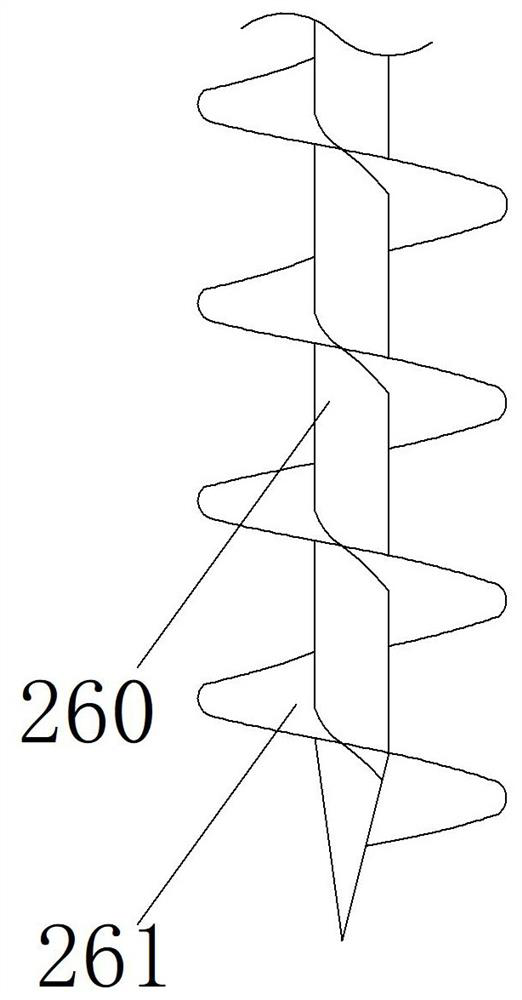

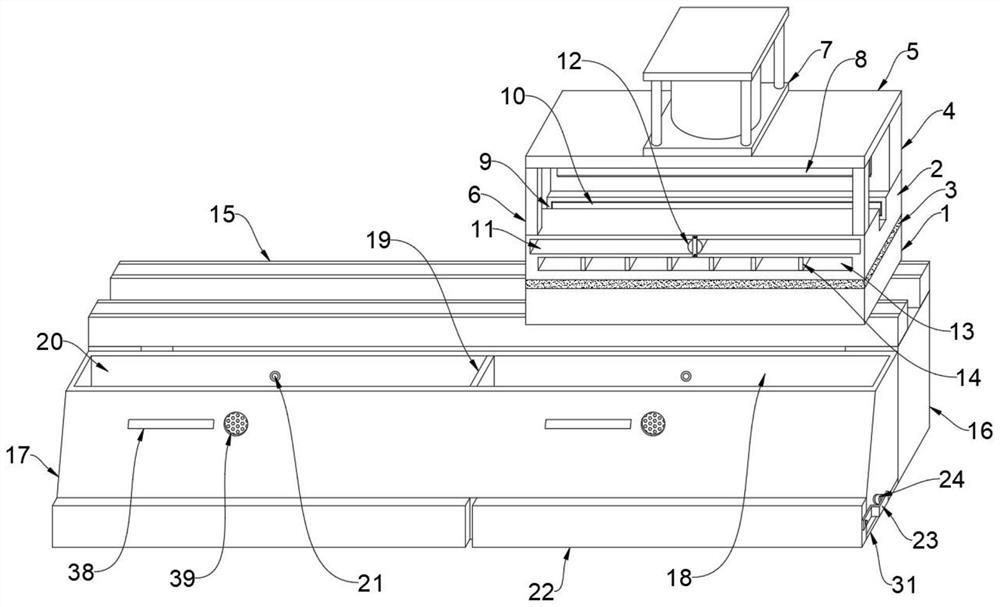

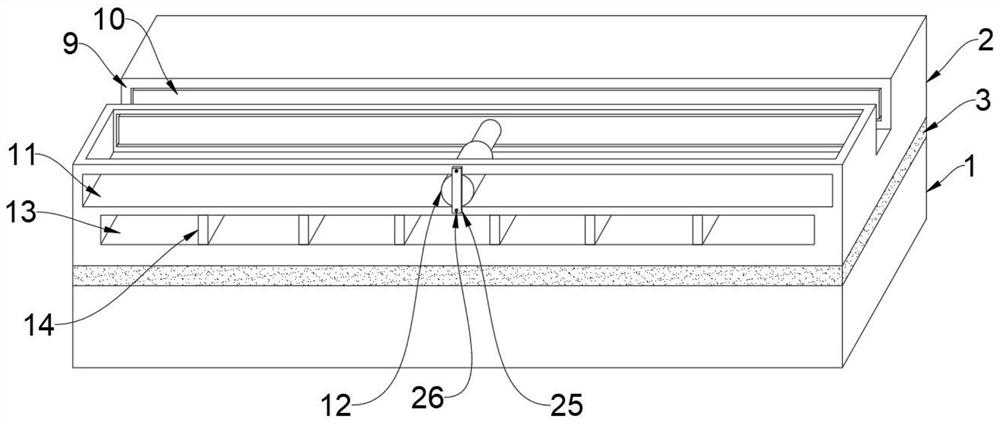

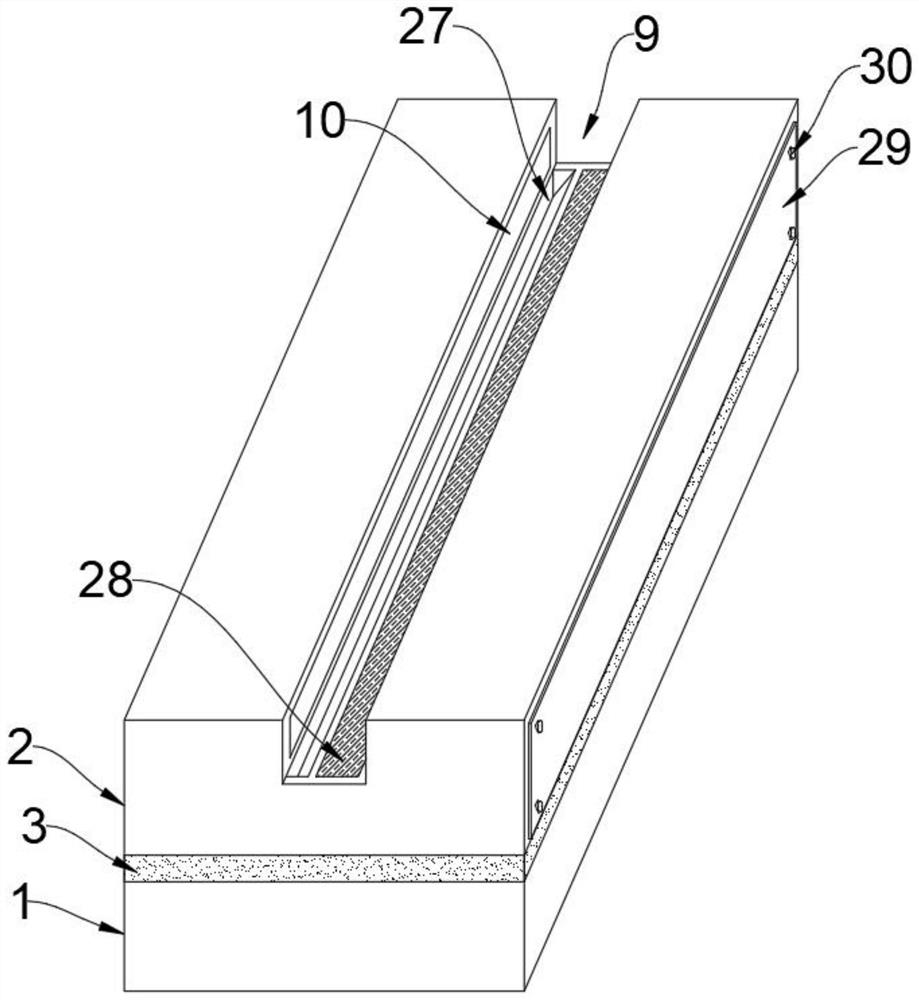

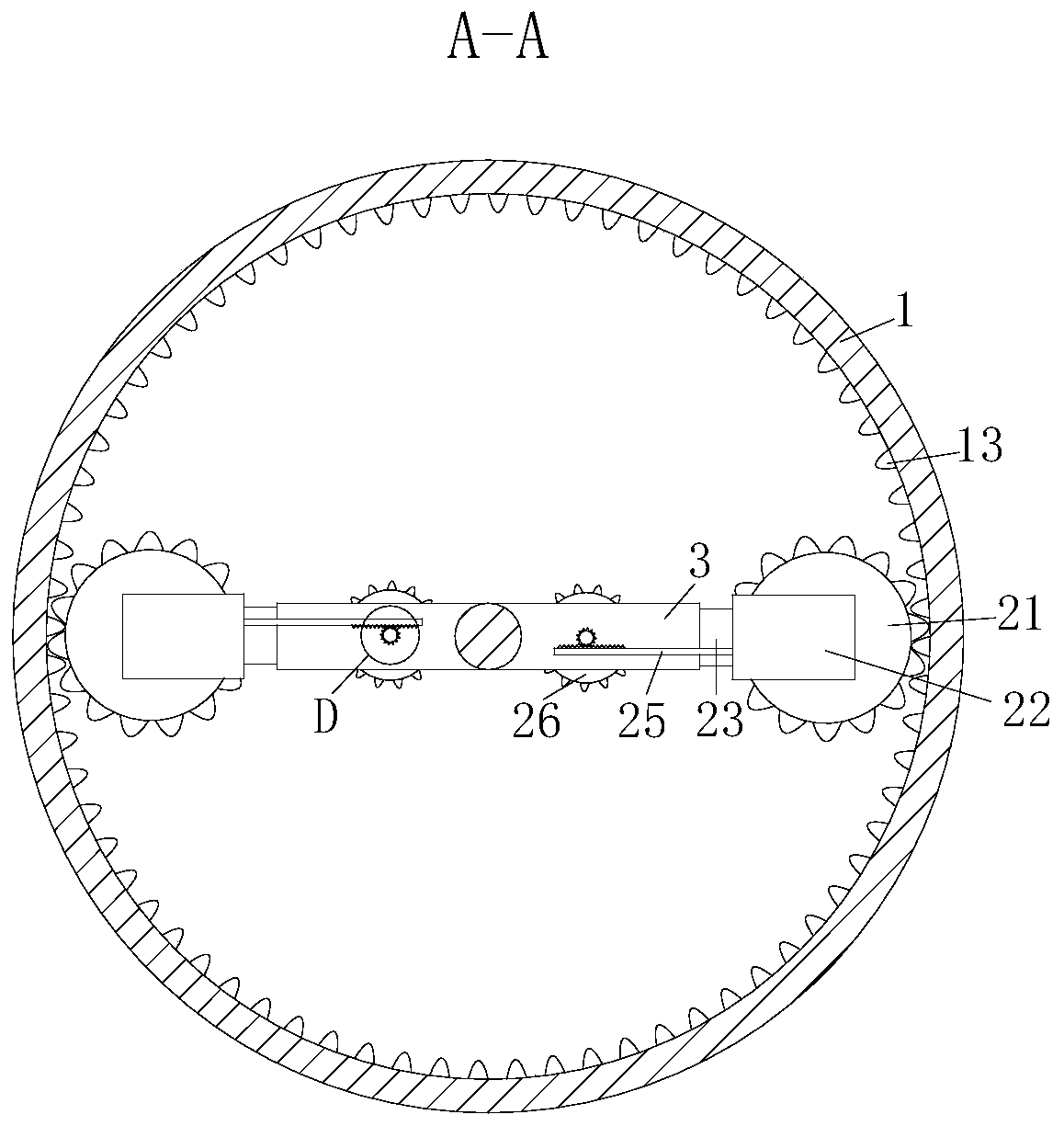

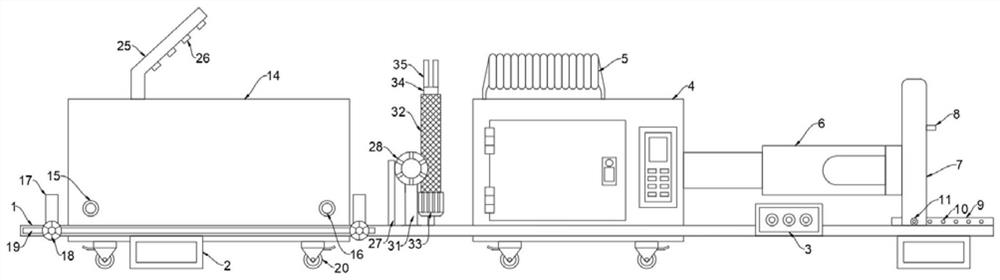

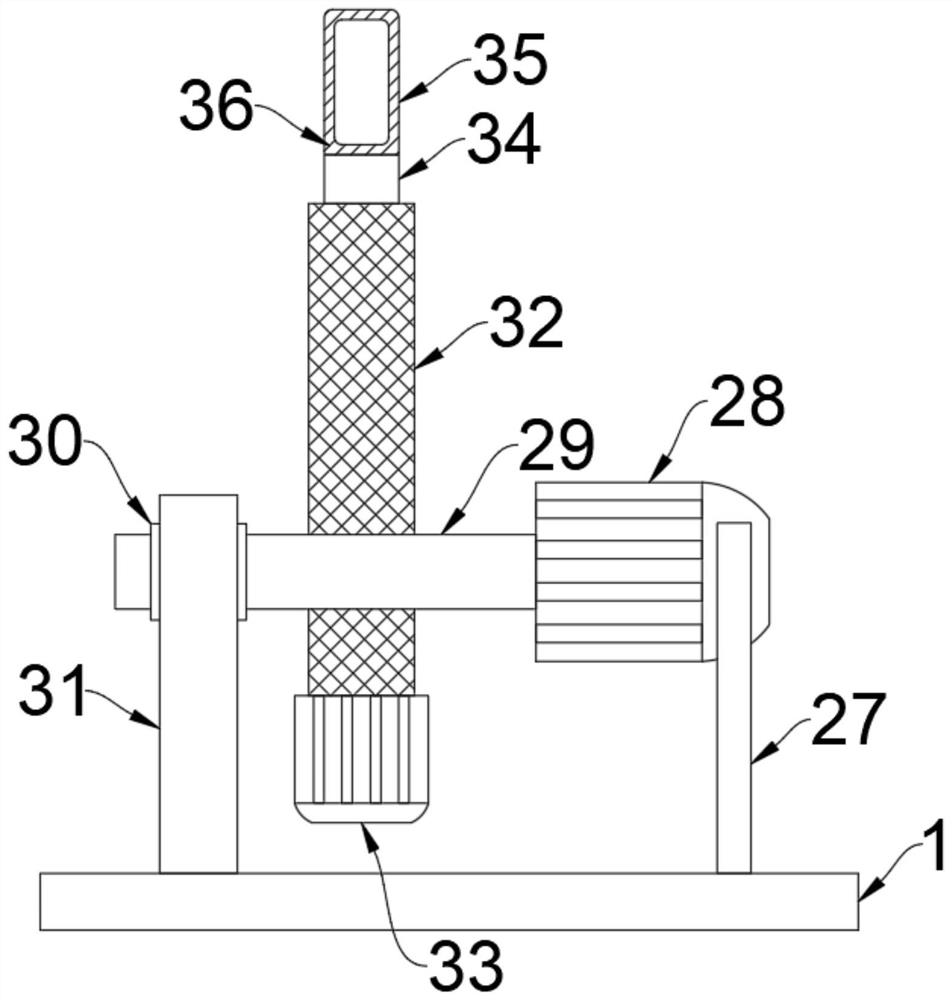

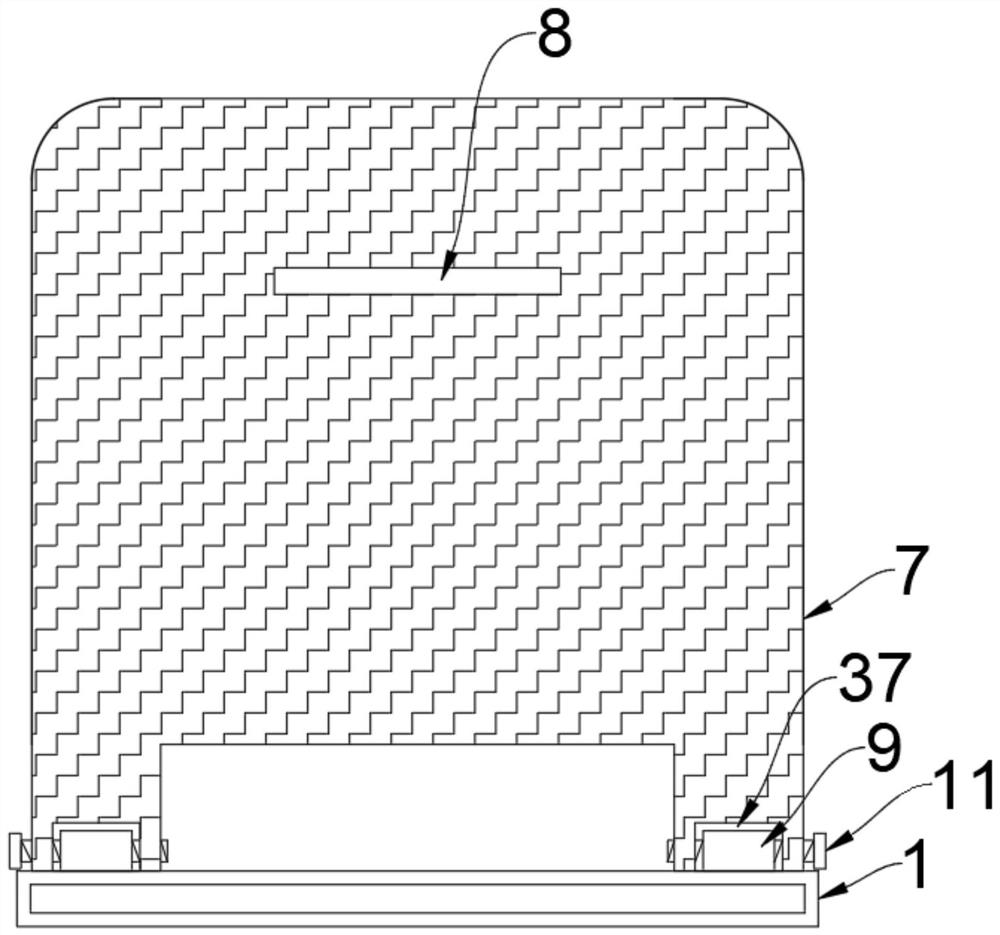

Engineering geological exploration sample sampling device

ActiveCN114577521AConvenient post-operationWithdrawing sample devicesElectric machineryStructural engineering

The invention provides an engineering geological exploration sample sampling device which comprises a driving frame, a sleeving hole is formed in the driving frame, a driving rod is rotationally connected in the sleeving hole, a driving motor is arranged on the driving frame, the driving rod is fixedly connected to the output end of the driving motor, a limiting frame is arranged on the driving frame, and two mounting plates are symmetrically arranged on the limiting frame; two limiting assemblies are symmetrically arranged on the limiting frame, each mounting plate is connected with the limiting frame through the corresponding limiting assembly, a sample barrel is connected between the two mounting plates, a first sample storage groove, a second sample storage groove, a third sample storage groove and a fourth sample storage groove are formed in the sample barrel, a sampling barrel is arranged at the bottom of the sample barrel, and the sampling barrel is communicated with the sample barrel. A drill bit is buckled on the driving rod, spiral teeth are arranged on the circumferential outer wall of the drill bit, and the drill bit is arranged in the sampling barrel and the sample cylinder. According to the invention, a plurality of equivalent to-be-detected samples can be directly formed during geological exploration sampling, manual sample separation after geological exploration sampling is not needed, and later operation is facilitated.

Owner:山东省地质矿产勘查开发局第四地质大队

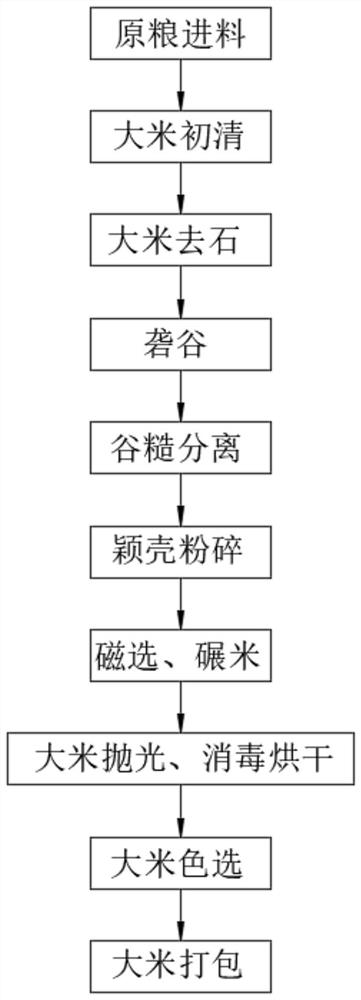

High-efficiency rice processing method

InactiveCN112604736AAvoid wear and tearEasy to useGrain treatmentsAgricultural engineeringHorticulture

The invention discloses a high-efficiency rice processing method, relates to the technical field of rice processing, and aims at solving the problems that the existing high-efficiency rice processing efficiency is relatively low and various impurities are not easy to clean. The high-efficiency rice processing method comprises the following steps of step 1, feeding unprocessed grains; step 2, preliminary cleaning of rice; step 3, removing stones from the rice; step 4, rice hulling; step 5, husked rice separation; step 6, glume crushing; step 7, magnetic separation and rice milling; step 8, polishing, disinfecting and drying the rice; step 9, rice color selection; and step 10, packaging rice.

Owner:寿县万达粮油食品股份有限公司

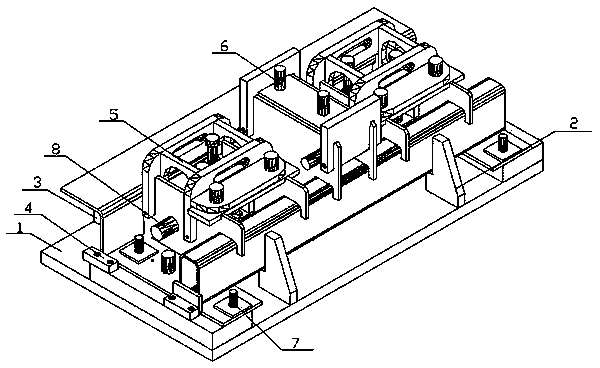

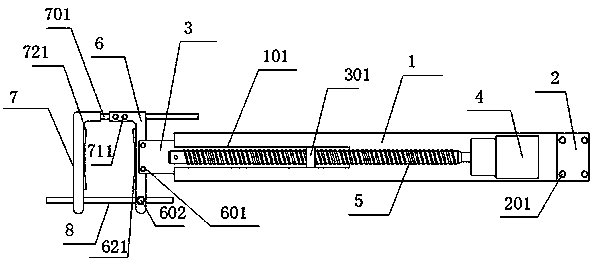

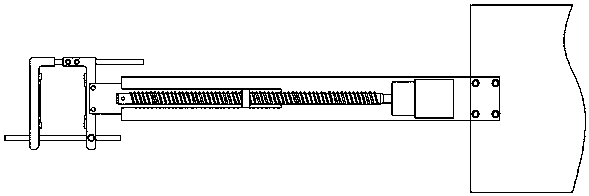

Tractor pedestal welding tool

ActiveCN104209683AMeet specificationEasy to operateWelding/cutting auxillary devicesAuxillary welding devicesTractorWelding

The invention discloses a tractor pedestal welding tool. The tractor pedestal welding tool comprises bottom plates, a front part supporting base, a rear part supporting component, a side surface fixing device and a top part fixing device, wherein the front part supporting base, the rear part supporting component, the side surface fixing device and the top part fixing device are arranged on the bottom plates; the front part supporting base can bear the front part of a tractor pedestal and can also be abutted against an upright base in front of a tractor; the rear part supporting component is a plurality of adapting devices which can be abutted against the rear surface of the tractor; the side surface fixing device is in the form of a plurality of fixing blocks which are fixed to the left side and the right side of the surface of the bottom plates to limit the bottom plates on the two sides of the tractor pedestal; the top part fixing device is in the form of a plurality of cover plates and is abutted against the top surface of the tractor. A plurality of positioning devices in the tractor pedestal welding tool are accurate in positioning, and each supporting component can fasten each surface of the tractor pedestal, so that the manufactured tractor pedestal can better satisfy specification, and the compactness among parts of the tractor pedestal is higher. The tractor pedestal welding tool is simple and convenient to use, operation of workers is benefited, and time and labor are saved.

Owner:JIANGSU CHUANGLI ELEVATOR PARTS

Cloth cutting equipment convenient to use

The invention discloses cloth cutting equipment convenient to use. The cloth cutting equipment comprises a box body, a bottom box is fixedly connected to the right side of the box body, a first motoris fixedly connected to the left side of the inner wall of the box body through a first motor base, a first belt pulley is fixedly connected to the output shaft of the first motor, and a belt is connected to the surface of the first belt pulley in a transmission mode; a second belt pulley is connected to the side, away from the first belt pulley, of the belt in a transmission mode, a threaded rodis fixedly connected to the axial center of the second belt pulley, the left end of the threaded rod is connected with the left side of the inner wall of the box body in a rotating mode, and the rightend of the threaded rod is connected with the right side of the inner wall of the box body in a rotating mode; arc plates are fixedly connected to both sides of the inner wall of the box body, and ajacking plate is fixedly connected between the sides, opposite to each other, of the two arc plates. The invention relates to the technical field of cloth cutting equipment. According to the cloth cutting equipment convenient to use, it is very convenient to take cloth, the stability of the device is improved, the structure of the device is simple, and practicability is high.

Owner:陈华

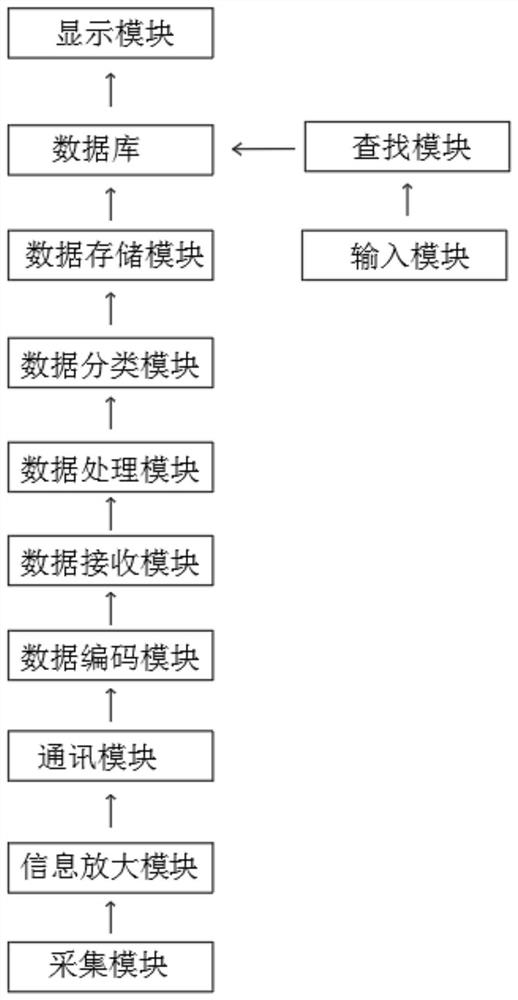

Geographic information data acquisition system

PendingCN113821578AConvenient post-operationQuick responseRelational databasesGeographical information databasesCollection systemData acquisition

The invention discloses a geographic information data collection system, and relates to the technical field of information collection, and the system comprises a collection module which is used for collecting geographic information data; a data coding module used for coding the geographic information data amplified by the information amplification module; a data receiving module used for receiving the geographic information data coded by the data coding module; a data processing module used for processing the geographic information data received by the data receiving module; and a data classification module used for classifying the geographic information data processed by the data processing module. According to the geographic information data acquisition system provided by the invention, the map data classification unit, the image data classification unit, the topographic data classification unit and the measurement data classification unit in the data classification module are matched for use, so that the geographic information data can be classified in a large scale.

Owner:袁犁

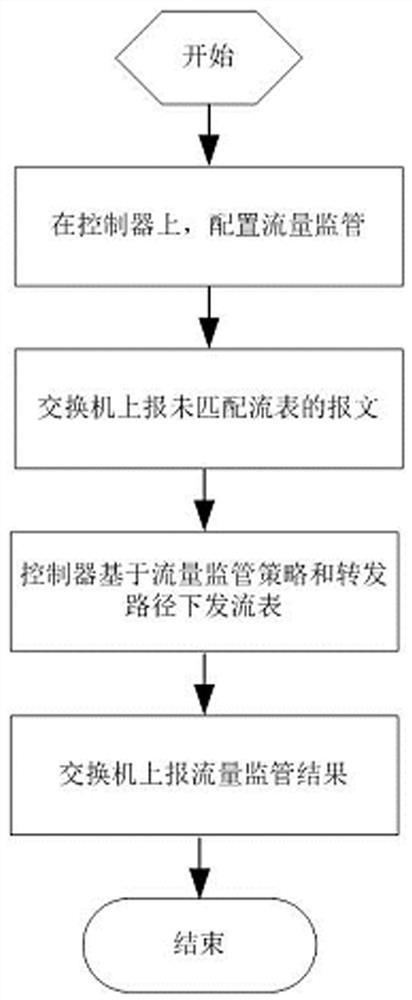

A traffic monitoring method based on SDN architecture

ActiveCN106789703BProtect interestsEasy to manageData switching networksEngineeringCentralized management

Owner:广东云栋科技有限公司

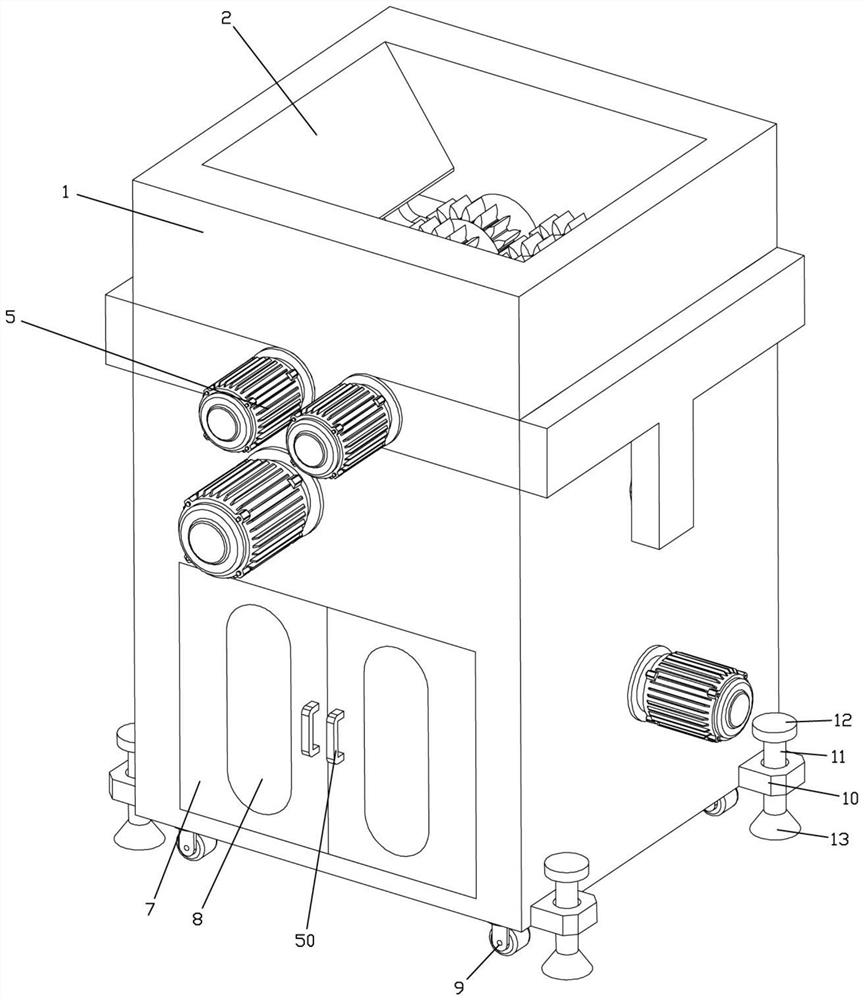

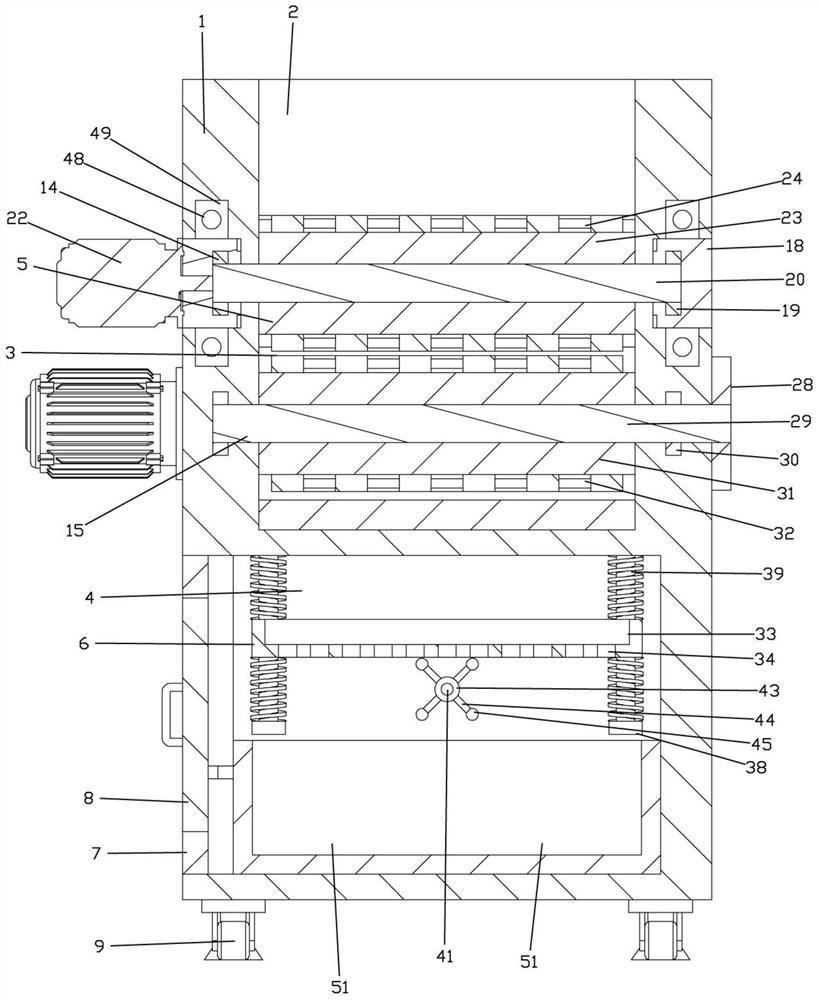

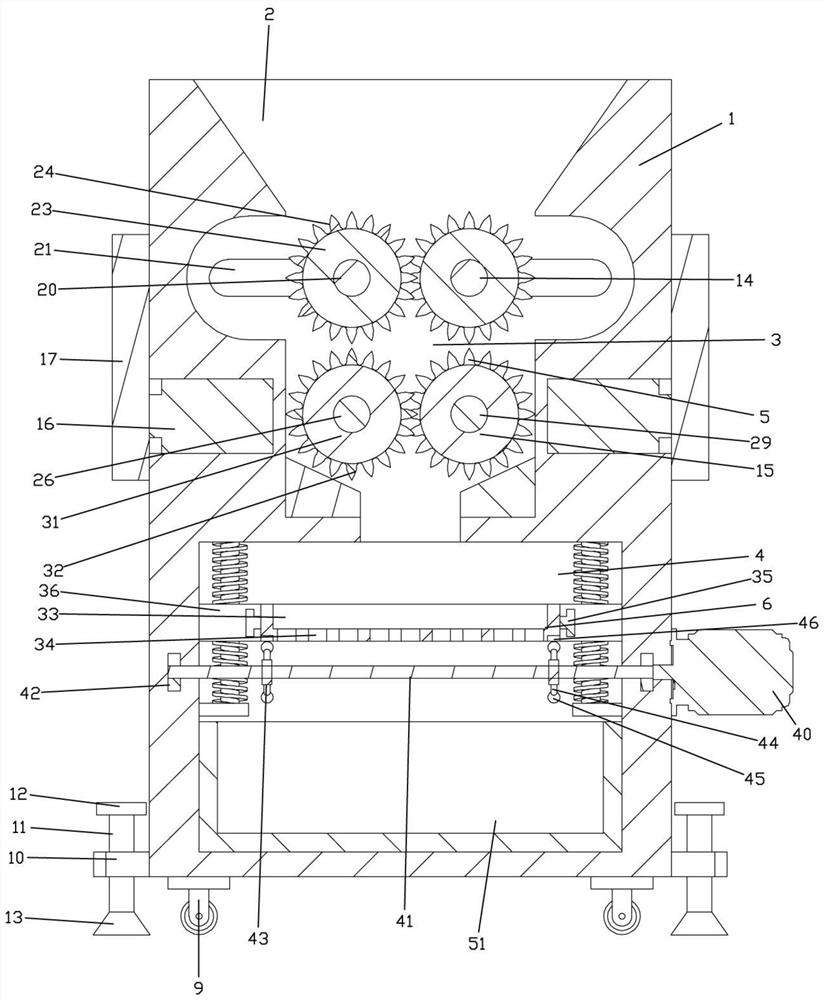

Smashing and sorting equipment for waste building structures

InactiveCN114029316AConvenient Primary CrushingPrevent problems with chunky larger piecesSolid waste disposalTransportation and packagingFoot cushionConstruction engineering

The invention discloses smashing and sorting equipment for waste building structures, which comprises a treatment box body, wherein a feeding port, a crushing cavity and a sorting cavity are sequentially formed in the treatment box body from top to bottom, a crushing device is installed in the crushing cavity, a sorting device is installed in the sorting cavity, a collecting box is installed at the bottom of the sorting cavity, a through groove is formed in the position, which is on one side of the sorting cavity, of the treatment box body, a sealing box door is installed in the through groove, an observation groove is formed in the sealing box door, a transparent plate is fixedly embedded in the observation groove, universal wheels are installed at the four corners of the bottom of the treatment box body, side lugs are fixedly connected to the two sides of the bottom of the treatment box body, threaded holes are formed in the side lugs, threaded rods are connected into the threaded holes, the top of each threaded rod is connected with a rotating disc, and the bottom of each threaded rod is connected with an anti-skid foot pad. According to the invention, the smashing and sorting process of the waste building structures is achieved, the smashing efficiency is high, waste building structures of different sizes can be smashed conveniently, and then convenience is brought to later operation of materials.

Owner:深圳市中深建装饰设计工程有限公司

The optimized gene of zebrafish defensin defbl3 and the preparation method of its recombinant protein

InactiveCN105400791BLow costConvenient post-operationAntibacterial agentsFungiBiotechnologyNucleotide

The invention discloses an optimized gene of zebrafish defensin defbl3 and a preparation method of a recombinant protein of the optimized gene and further provides a recombinant expression vector and a pichia host cell including the optimized gene, application of the optimized gene in production of the zebrafish defensin defbl3 and application of the recombinant protein in preparation of antibacterial drugs. On the premise that an amino acid sequence of the zebrafish defensin defbl3 is not changed, a nucleotide sequence of the zebrafish defensin defbl3 is optimized according to a pichia preference codon, and the optimized sequence is shown as SEQ ID NO.2. The recombinant zebrafish defensin defbl3 is prepared by expressing the optimized gene in a pichia host cell. The zebrafish defensin defbl3 can be efficiently prepared by means of the preparation method, the adopted culture conditions are simple, the cost is lower, and the obtained defensin defbl3 is good in antibacterial effect.

Owner:SHANGHAI OCEAN UNIV

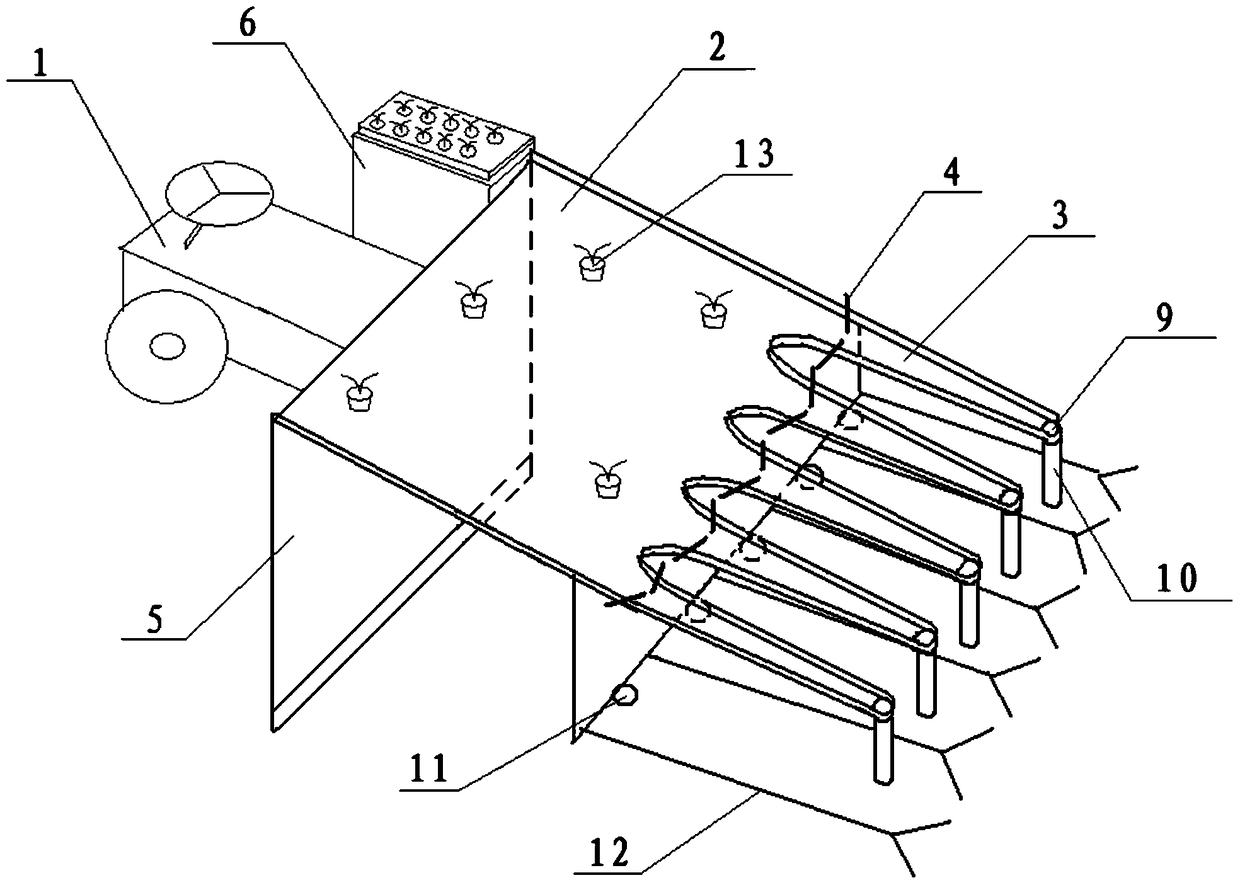

A kind of mechanized rice seedling transplanting method

ActiveCN105409667BRealize mechanized workSuitable for mass production applicationsTransplantingCultivating equipmentsRapeseedTillage

Owner:SHANDONG RICE RES INST

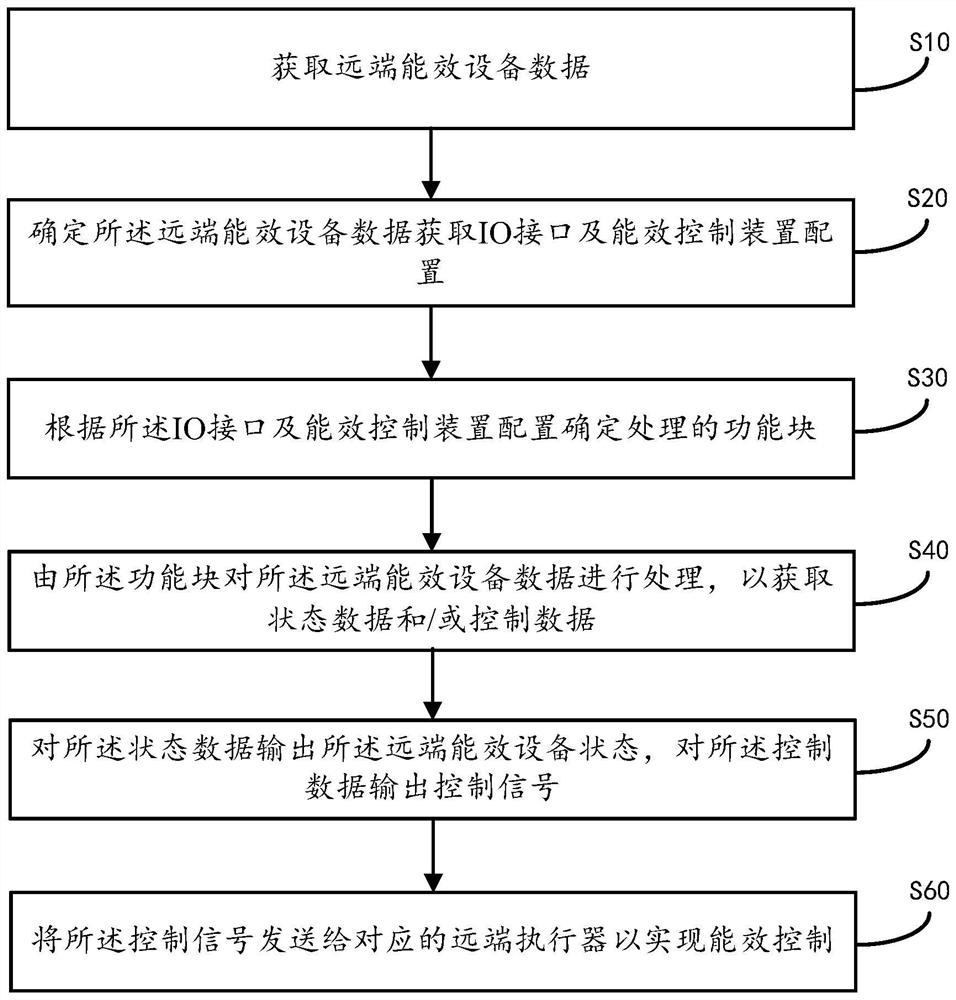

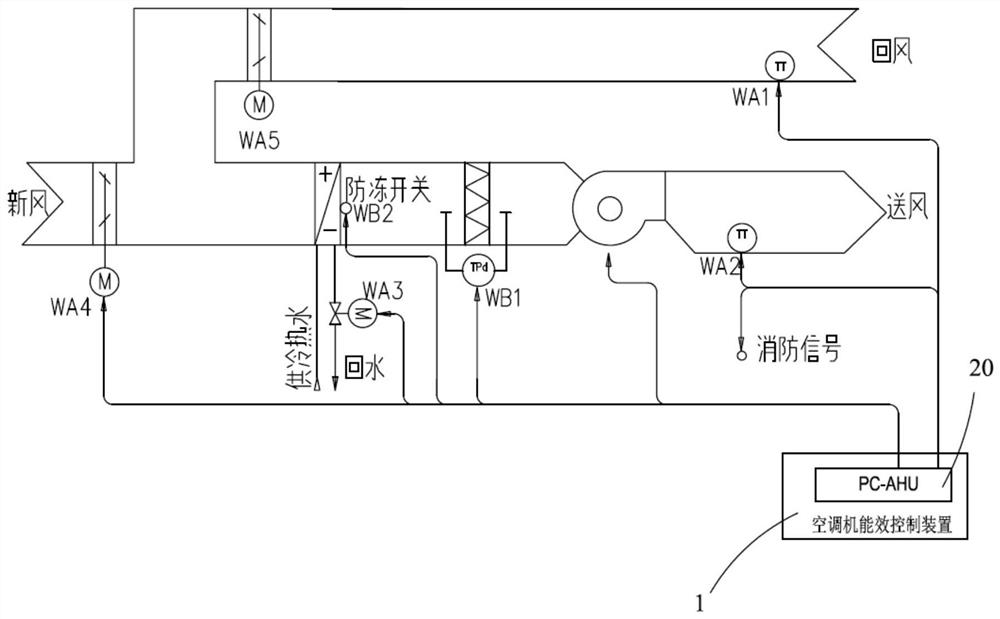

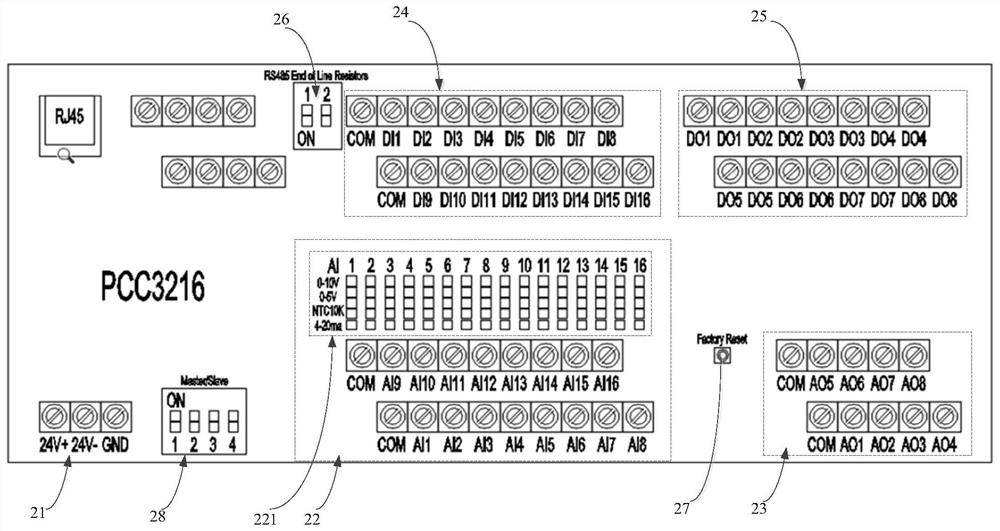

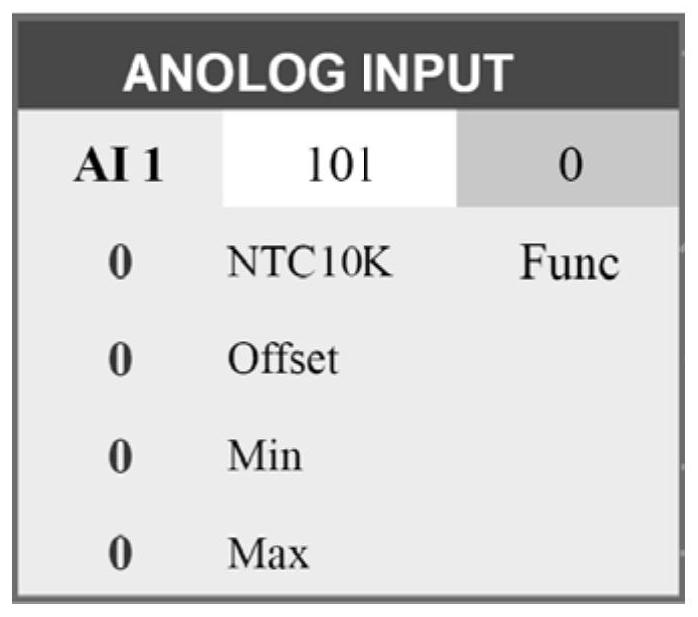

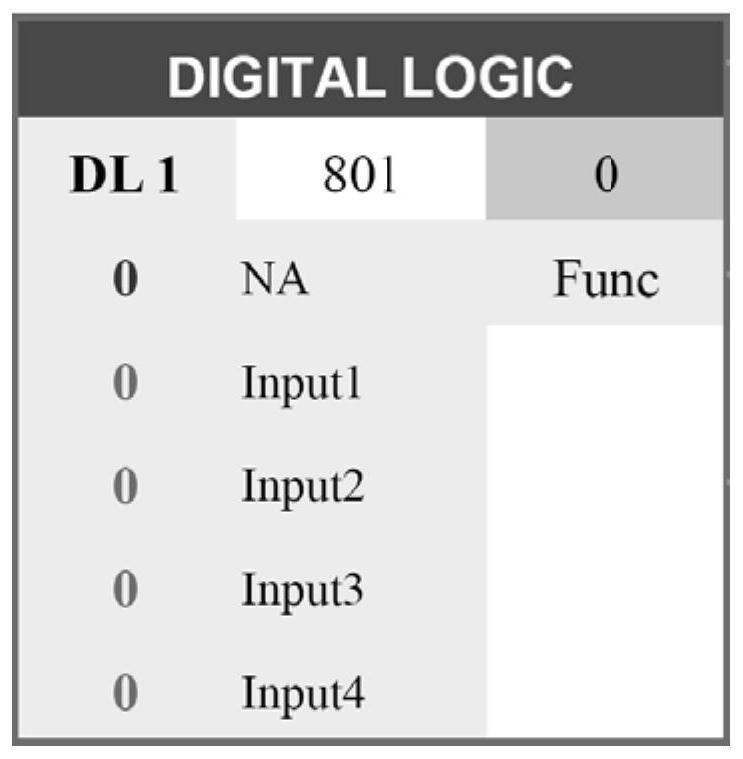

Energy efficiency control method and device and storage medium

PendingCN112764370ASimplify complexityRefined energy efficiency managementProgramme controlComputer controlControl signalControl system

The invention discloses an energy efficiency control method. The method comprises the following steps: acquiring far-end energy efficiency equipment data; determining the configuration of a data acquisition IO interface and an energy efficiency control device of the far-end energy efficiency equipment; determining a function block to be processed according to the IO interface and the energy efficiency control device configuration; enabling the function block to process the far-end energy efficiency equipment data to obtain state data and / or control data; outputting the state of the far-end energy efficiency equipment according to the state data, and outputting a control signal according to the control data; and sending the control signal to a corresponding far-end actuator to realize energy efficiency control. In addition, the invention further provides an energy efficiency control device and a storage medium. According to the energy efficiency control method provided by the invention, energy efficiency control on the far-end energy efficiency equipment is realized, the complexity of an energy efficiency control system is simplified, refined energy efficiency management and strong and weak current energy efficiency integrated management can be quickly realized, the construction cost is saved, and meanwhile, later operation and maintenance are facilitated.

Owner:罗杰韦尔控制系统(广州)股份有限公司

A three-dimensional positioning tool for welding assembly of automobile floor

ActiveCN108655645BLow costAvoid damageWelding/cutting auxillary devicesAuxillary welding devicesScrew threadWelding

The invention discloses a three-dimensional positioning tool of a vehicle base plate welding assembly. The tool comprises an object carrying tool plate; a support inclined mechanism is mounted on thelower surface of the object carrying tool plate; a clamping mechanism is arranged on the upper surface of the object carrying tool plate; a heat dissipation cooling mechanism is arranged at the lowerend of the object carrying tool plate; the clamping mechanism comprises an assembly three-dimensional block and a positioning fixture; the positioning fixture comprises a lower fixed support plate andan upper assembly clamping plate; the upper assembly clamping plate comprises a first thread plate and a second thread plate; vertical fixed rods are arranged at the upper ends of the first thread plate and the second thread plate; horizontal thread hole through plates are arranged at the upper ends of the vertical fixed rods; horizontal displacement bolts are arranged in the horizontal thread hole through plates; vertical thread hole through plates are arranged at the tail ends of the horizontal displacement bolts; and vertical clamping bolts are arranged in the vertical thread hole throughplates. A vehicle body is hoisted for three-dimensional welding, so that the damage to an object carrying plate during welding is reduced, the welding quality is improved, the vehicle base plate manufacturing cost is reduced, the heat dissipation function is improved, and the welding safety is improved.

Owner:芜湖众梦电子科技有限公司

Concave angle stamping device for steel rail bolt machining and using method thereof

InactiveCN113649450AImprove convenienceIncrease flexibilityMetal-working feeding devicesNutsStampingStructural engineering

The invention discloses a concave angle stamping device for steel rail bolt machining and a using method thereof, relates to the technical field of bolt production stamping, and aims to solve the problem of inconvenient blanking caused by manual blanking during concave angle stamping of existing steel rail bolts. A stamping seat is arranged above a movable base, an electric sliding rail mechanism is arranged at the lower end of the movable base, a storage box is arranged in front of the electric sliding rail mechanism, a top plate is arranged above the stamping seat, an air cylinder mechanism is arranged at the upper end of the top plate, a stamping cutter mechanism is arranged at one end of the air cylinder mechanism, a stamping groove is arranged on the upper surface of the stamping base, an electromagnet is arranged on the surface of the stamping groove, a discharging opening is arranged at one side of the electromagnet, pushing plates are arranged on the surfaces of the two sides of the stamping groove correspondingly, an electric push rod mechanism is arranged at one end of each pushing plate, a discharging inclined groove is arranged on the front surface of the stamping base, and an infrared sensor is arranged on the inner wall of the storage box.

Owner:马鞍山市莱能节能科技有限公司

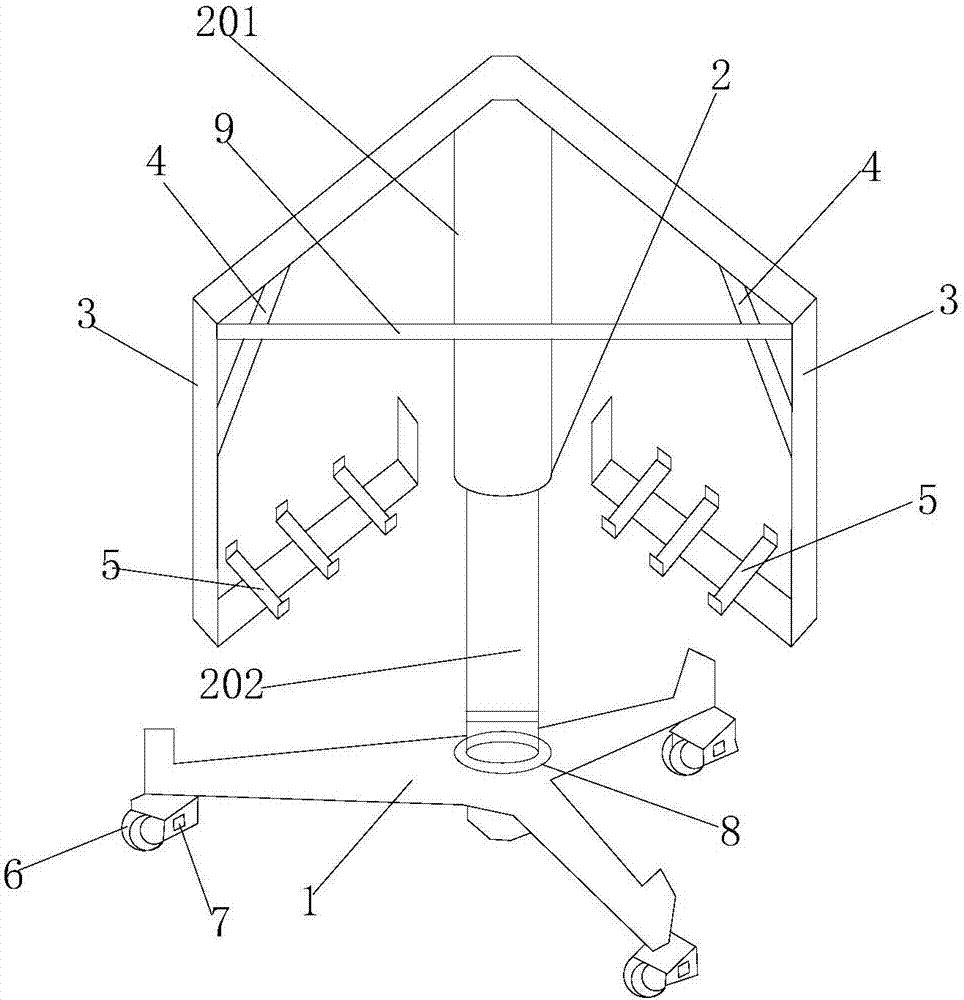

Movable metal placing frame

The invention provides a movable metal placing frame with stable structure and high bearing capacity. The movable metal placing frame comprises a placing frame support leg and a telescopic support rod, wherein the lower end of the telescopic support rod is fixedly arranged on the placing frame support leg; the upper end of the telescopic support rod is connected with metal hooks; a reinforcing ribis bilaterally symmetrical around a longitudinal center section of the hook is arranged on each metal hook; the reinforcing ribs are fixedly connected with the metal hooks; each metal hook is fixedlyconnected with a plurality of U-shaped hanging parts; universal wheels are arranged under the placing frame support leg; a brake is arranged on each universal wheel; the metal hooks and the U-shapedhanging parts are used for placing different-sized metal parts by distinguishing the metal parts, so that the operation in the later period can be facilitated; the telescopic support rod is capable ofrotating along a rotating groove of a placing frame bracket, stretching and retracting up and down, conveniently taking and placing the metal parts; the universal wheels are arranged, so that the whole placing frame can be conveniently moved; the movable metal placing frame is simple in structure, convenient to operate and high in bearing capacity; the operating efficiency can be improved.

Owner:四川辉冠金属材料有限公司

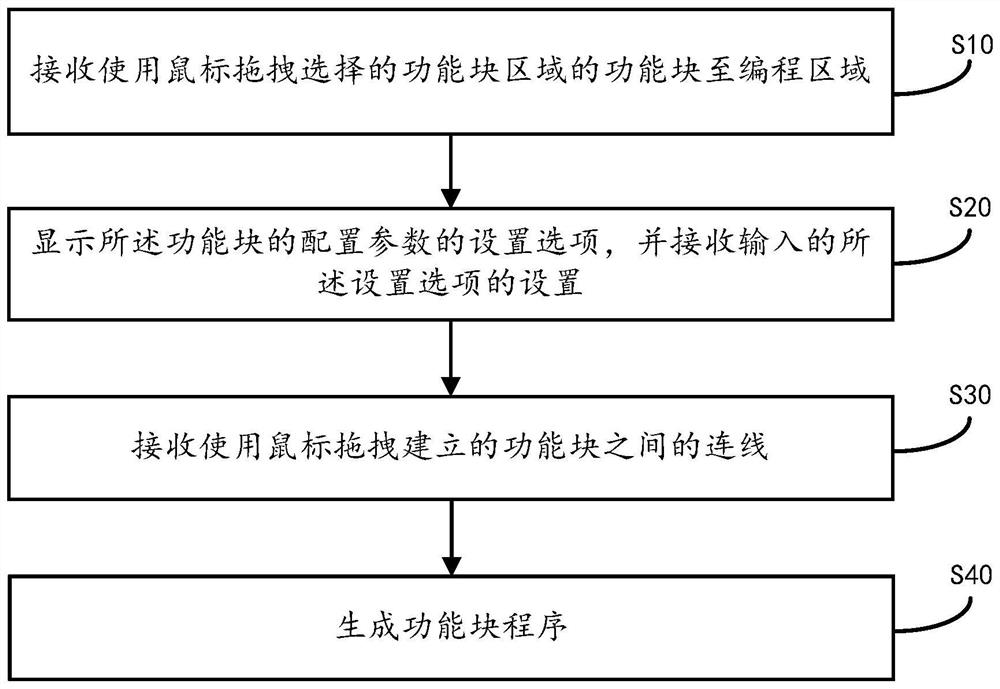

Method for automatically generating energy efficiency control program and device and storage medium

PendingCN112711198AEasy to operateHigh speedProgramme control in sequence/logic controllersControl engineeringReliability engineering

The invention discloses a method for automatically generating an energy efficiency control program. The method comprises the following steps of: receiving a functional block of a functional block area dragged and selected by using a mouse to a programming area; displaying setting options of the configuration parameters of the function block, and receiving the setting of the input setting options; receiving a connection line between the function blocks established by dragging of a mouse; and generating a function block program. In addition, the invention further provides an energy efficiency control program automatic generation device and a storage medium. According to the automatic generation method for the energy efficiency control program, the energy efficiency control program is automatically generated in a graphical mouse dragging mode, operation is easy, the speed of generating the energy efficiency control program is high, energy efficiency control over various devices is managed and controlled through the generated energy efficiency control program in a unified mode, the development cost and the construction cost of one-by-one customization are saved, and meanwhile later operation, expansion and maintenance are facilitated.

Owner:罗杰韦尔控制系统(广州)股份有限公司

Method for searching and filling region by adopting geometric topology

ActiveCN102411789BEmbody the essenceConvenient post-operationFilling planer surface with attributesIntersection of a polyhedron with a linePopulated area

The invention provides a method for searching and filling a region by adopting geometric topology. The method comprises the following steps of: initializing a filling region to achieve the initialized filling region; searching the filling region by traversing each intersection point to obtain the search result of the filling region; searching on the basis of some abstract line segment of some intersection point to obtain the search result of some abstract line segment of some intersection point; and executing the corresponding operation on the basis that whether the search result of the region exists in the searched region or not. The method is a novel method for filling the region and has wide application range.

Owner:KARAMAY HONGYOU SOFTWARE

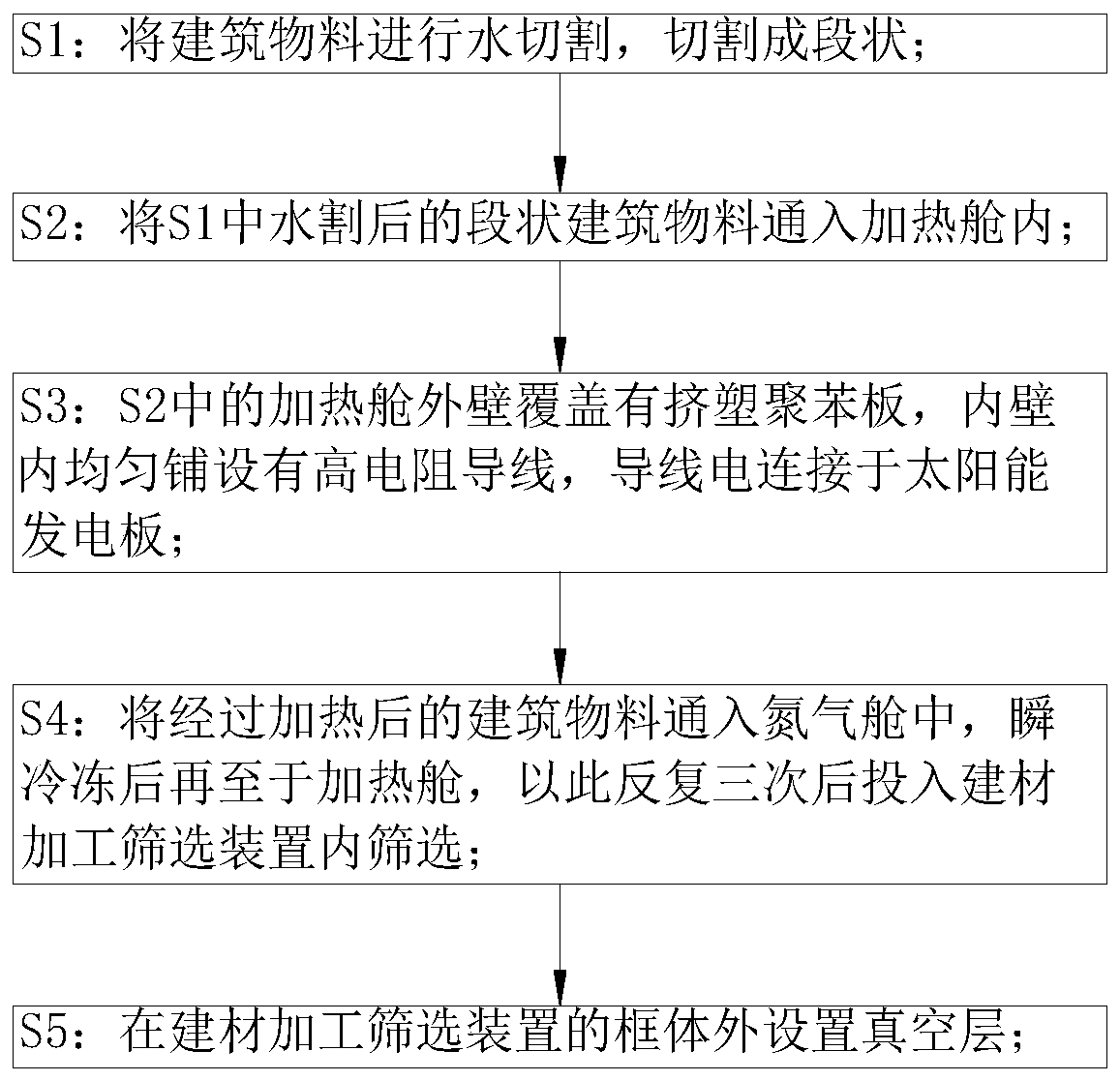

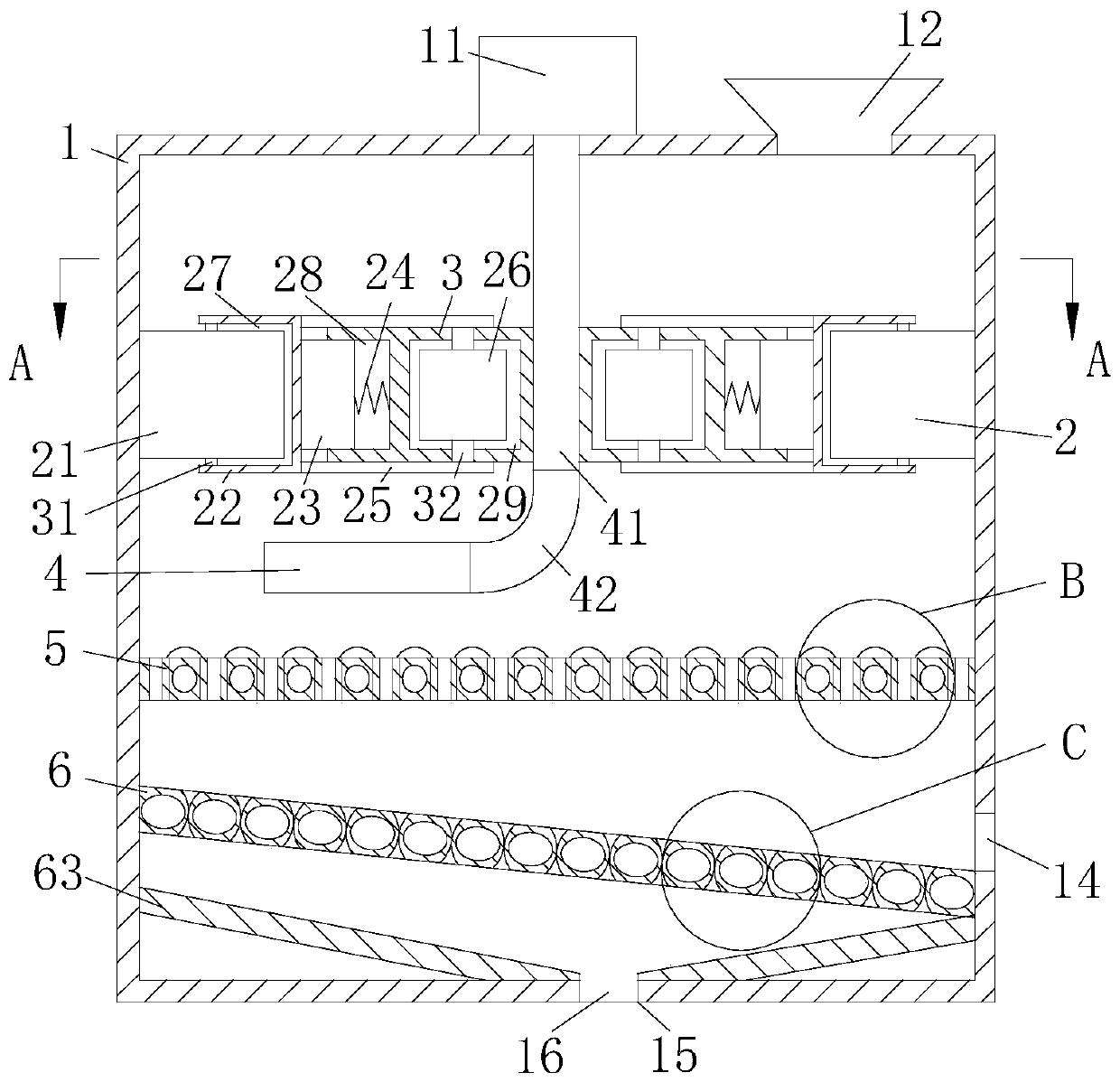

A sorting process for building materials

InactiveCN109317257BStrong heat insulation abilityEfficient cuttingSievingScreeningElectric machineryStructural engineering

The invention belongs to the field of engineering technology, and specifically relates to a sorting process for building materials. , and then put it into the heating chamber after being frozen for a while, and then put it into the building material processing and screening device after repeated three times to realize the crushing before sorting, which makes the sorting faster and more convenient. The device includes a frame body; a stirring rod is fixedly connected to the lower end of the rotating shaft of the motor; the stirring rod is divided into two parts: a straight rod and a curved rod; a first-stage filter plate is arranged under the stirring rod; There is a secondary filter plate under the plate; the present invention fully stirs the building materials through the crushing and stirring unit, and at the same time, the building materials are crushed, and the stirring effect is enhanced by the stirring rod. blocked.

Owner:HUBEI JINGBIAO CONSTR ENG CO LTD

An efficient and fast annealing equipment for die steel processing and production

ActiveCN112342346BConvenient post-operationEasy to operateFurnace typesIncreasing energy efficiencyElectric machineElectromagnetic heating

The invention discloses an efficient and quick annealing equipment for die steel processing and production, relates to the technical field of annealing, and aims to solve the problem that the existing annealing equipment for die steel processing and production has a complex structure and cannot be used efficiently and quickly. The lower end of the bottom plate is provided with a stressed leg, and the stressed leg is fixedly connected to the bottom plate. The upper surface of the bottom plate is provided with a first empty slot, and one side of the first empty slot is provided with a second empty slot. The inside of the first empty slot is provided with an electromagnetic heating mechanism, the inside of the second empty slot is provided with a cooling box, the inside of the cooling box is provided with a partition, and the partition is fixedly connected with the cooling box, and the cooling box is a The surface of the side is provided with a bevel, a support frame is provided between the first empty slot and the second empty slot, and the support frame is fixedly connected with the bottom plate, and one end of the support frame is provided with a first rotating motor mechanism, and the One side of the first rotating motor mechanism is provided with a first rotating shaft.

Owner:浙江鑫哲模具有限公司

Traction machine base welding tooling

ActiveCN104209683BMeet specificationEasy to operateWelding/cutting auxillary devicesAuxillary welding devicesEngineeringTractor

Owner:JIANGSU CHUANGLI ELEVATOR PARTS

Mechanical arm

InactiveCN108098800AConvenient rightingAvoid sloping growthGripping headsForestryControl engineeringManipulator

Owner:张林球

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com