Crushing apparatus for recycling waste paper box

A shredding device and waste paper box technology, applied in the field of packaging, can solve the problems of waste paper box smashing, unfavorable waste paper box smashing, inconvenient handling, etc., and achieve the effect of ensuring normal operation, easy viewing, and convenient transportation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

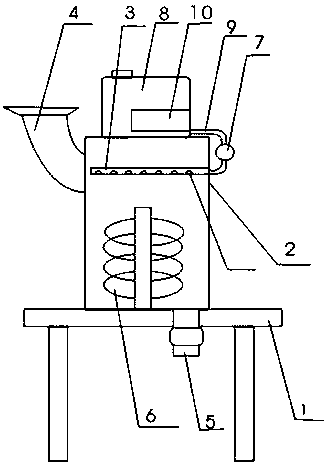

[0010] The invention provides a crushing device for recycling waste paper boxes, which includes a bracket 1, a crushing shell 2, a water spray pipe 3, a feed port 4, a discharge port 5, a crushing paddle 6, a control valve 7, a water tank 8, Water pipe 9, observation window 10, crushing shell 2 is installed on the upper side of the support 1, the side of the crushing shell 2 is provided with a feed inlet 4, the lower side of the crushing shell 2 is provided with a discharge port 5, and the crushing shell 2 is provided with a discharge port 5. Water spray pipe 3 and pulverizing stirring paddle 6 are installed inside shell 2, and described water spray pipe 3 is positioned at the upper side of crushing shell 2, and is provided with water spray port on described water spray pipe 3, and described pulverizing shell 2 is installed with A stirring paddle, a water tank 8 is installed on the upper part of the crushing shell 2, and the water tank 8 is connected with the water spray pipe 3...

Embodiment 2

[0012] During use, the carton that needs to be processed has feed inlet 4 and is put into the present invention, then opens the control valve 7 on the water delivery pipe 9, and water is sprayed by the water spray holes on the water spray pipe 3 to improve the humidity of the cardboard. Then open the pulverizing paddle 6, and pulverize the paddle 6 to pulverize it. After pulverization, the pulverized matter is discharged from the discharge port 5. When the water source inside the water tank 8 is about to run out, it can be used to add water through the water inlet on the upper side of the water tank 8. Avoid humidification of the crushing after there is no water, and ensure the normal progress of the crushing.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com