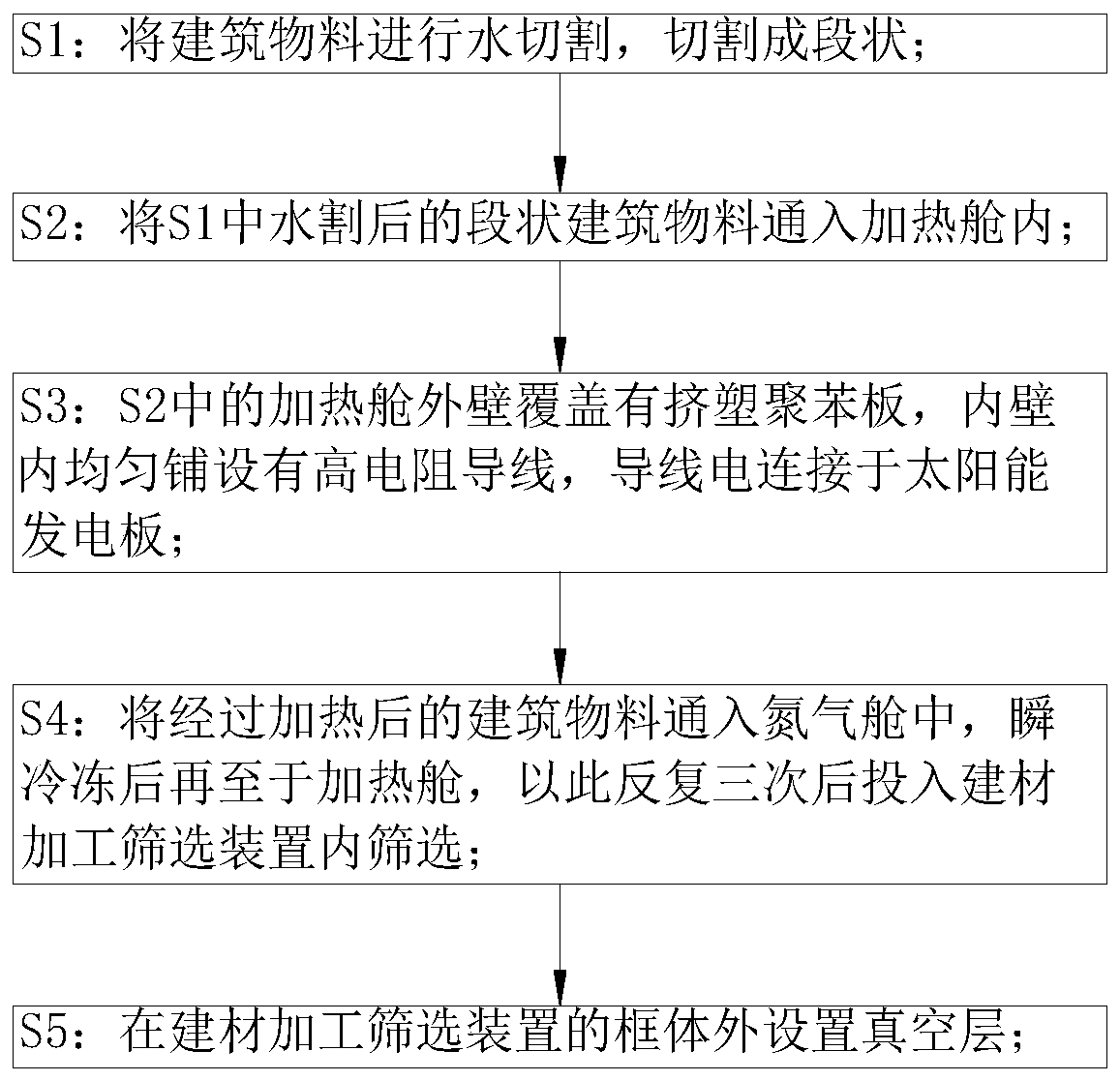

A sorting process for building materials

A technology for building materials and processes, applied in the engineering field, can solve the problems of incomplete crushing of building materials, damage to devices, incomplete filtering of building materials, etc., and achieve the effects of preventing incomplete crushing, isolating noise, and good limiting effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

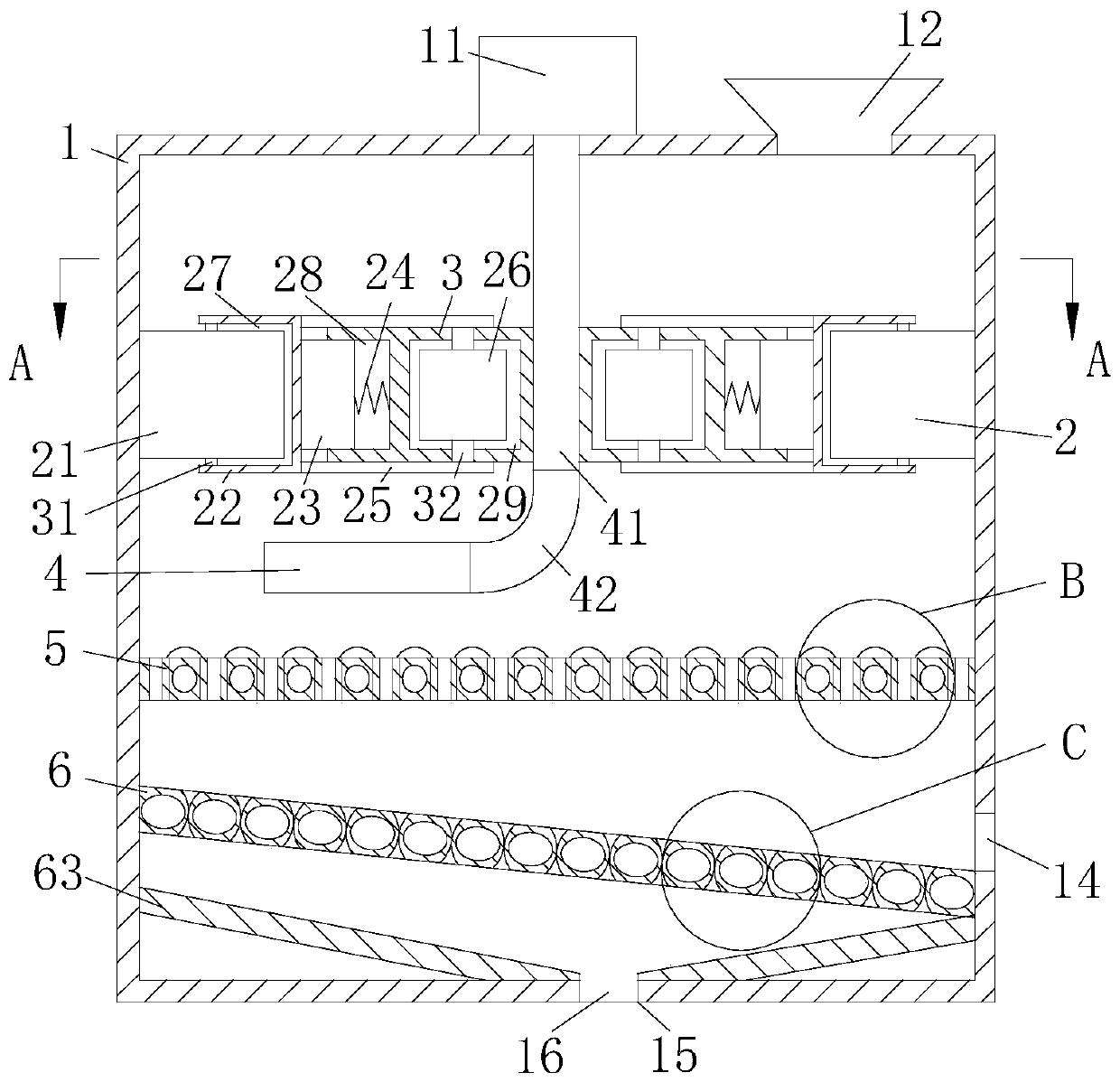

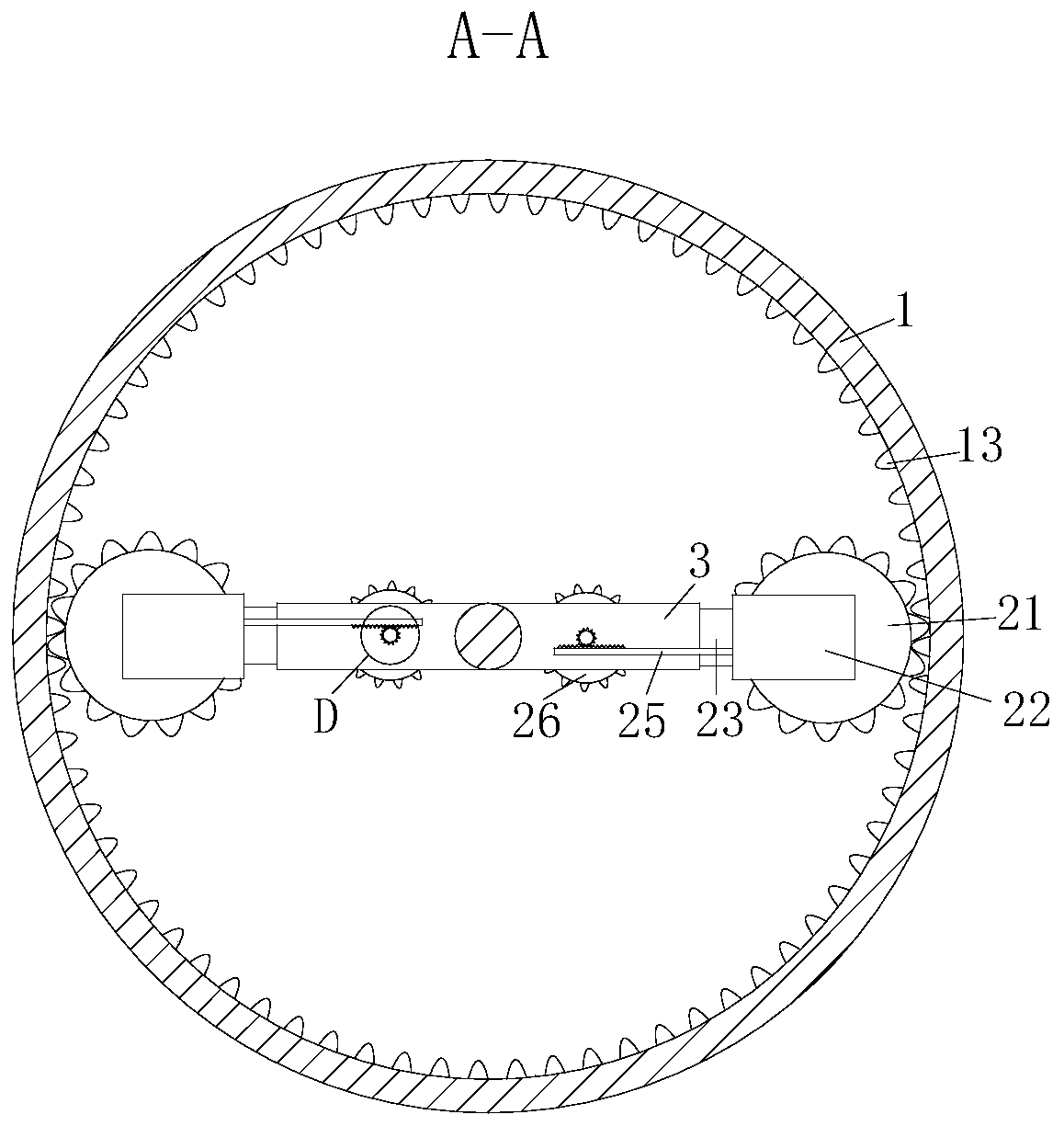

[0042] As an embodiment of the present invention, the lower end of the rotating shaft of the motor 11 is fixedly connected with the stirring rod 4; the stirring rod 4 is divided into two parts: a straight rod 41 and a curved rod 42; the straight rod 41 is positioned on the stirring rod 4 both ends, the straight rod 41 is made of metal material; the curved rod 42 is located between the straight rods 41, and the curved rod 42 is made of soft rubber; the stirring rod 4 is provided with an air passage 43, and the straight rod The width of the air passage 43 of the part 41 is less than the width of the air passage 43 of the curved rod 42 part, and the partial air passage 43 of the curved rod 42 is designed so that the wall thickness of the inner circle part of the curved rod 42 is smaller than the wall thickness of the outer circle part; the air passage 43 communicates Chute 28; when in use, the crushing shaft 22 vibrates, driving the slide bar 23 to vibrate, and the air passage 43 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com