Patents

Literature

48results about How to "Avoid incomplete crushing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

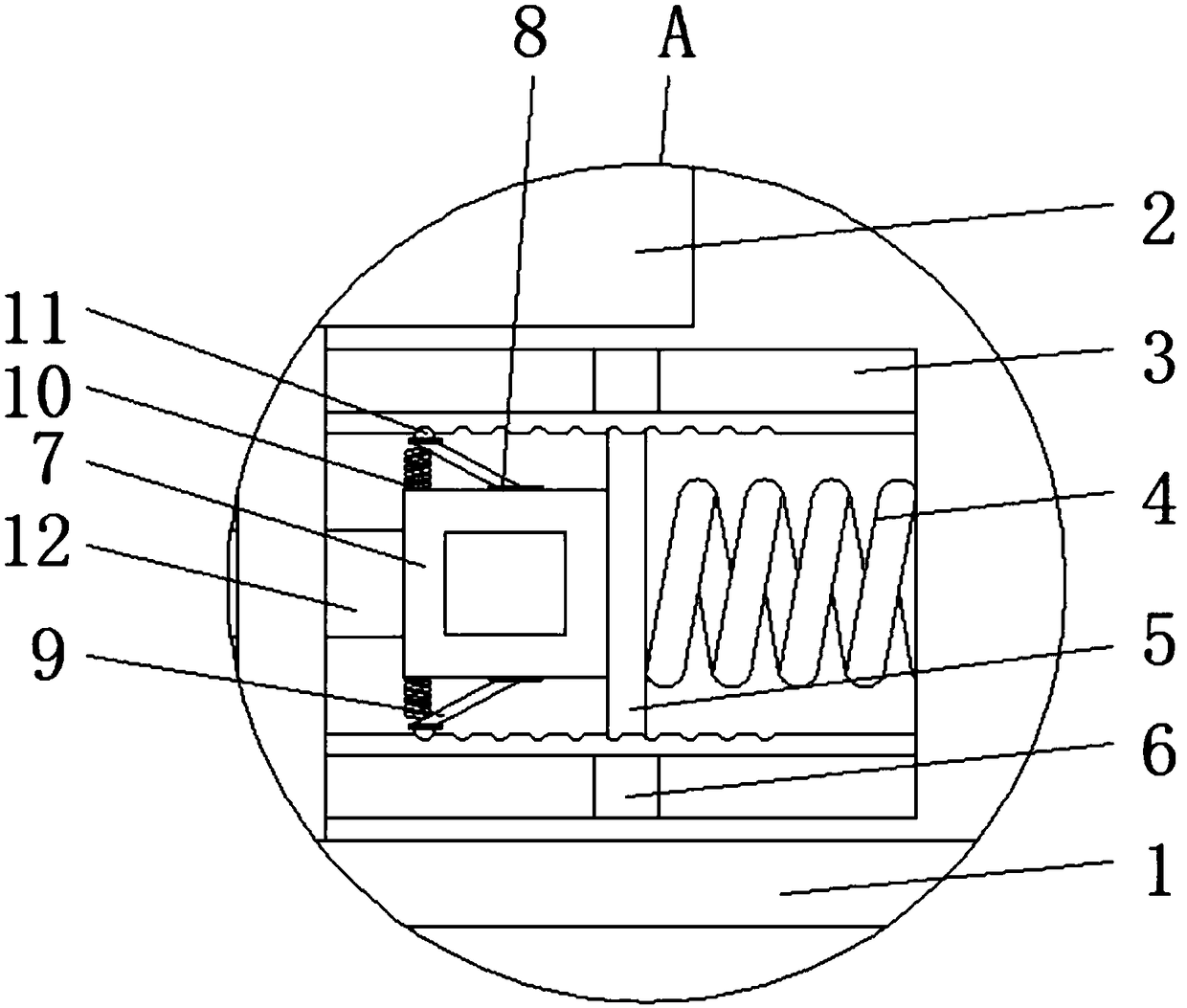

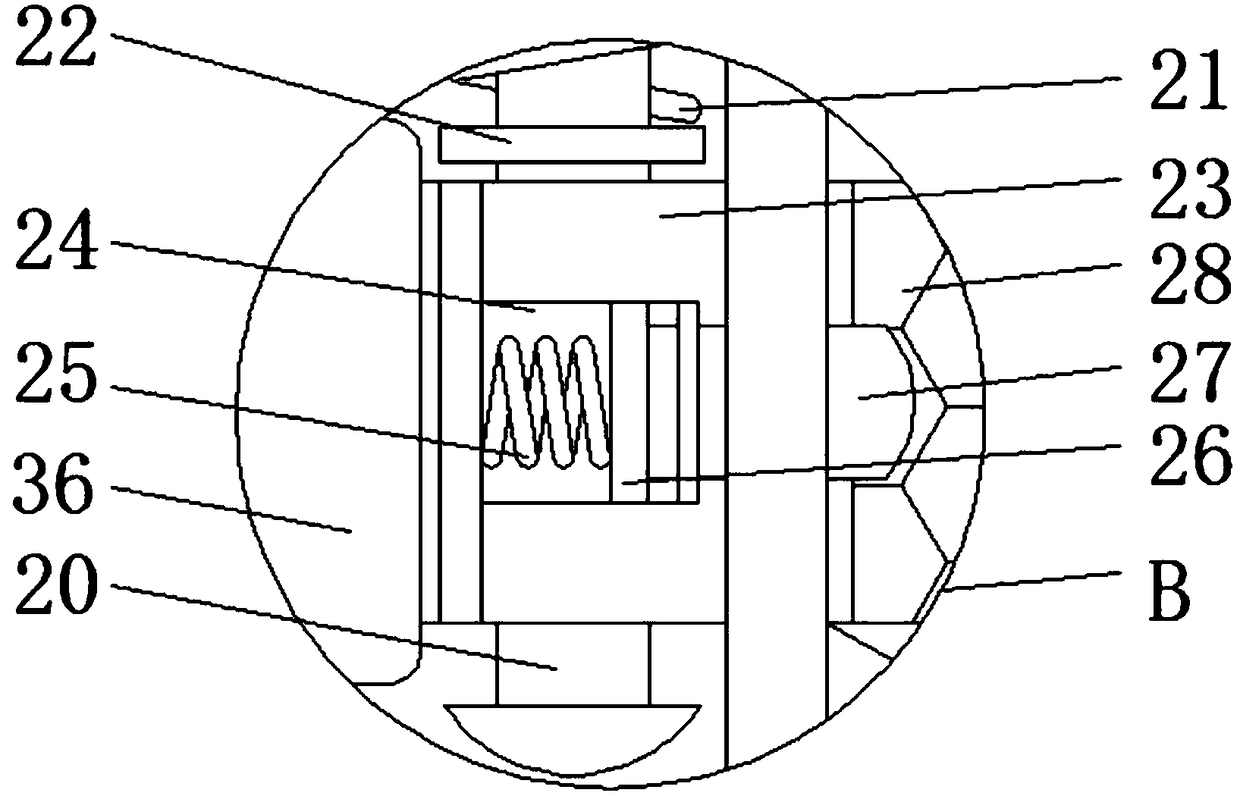

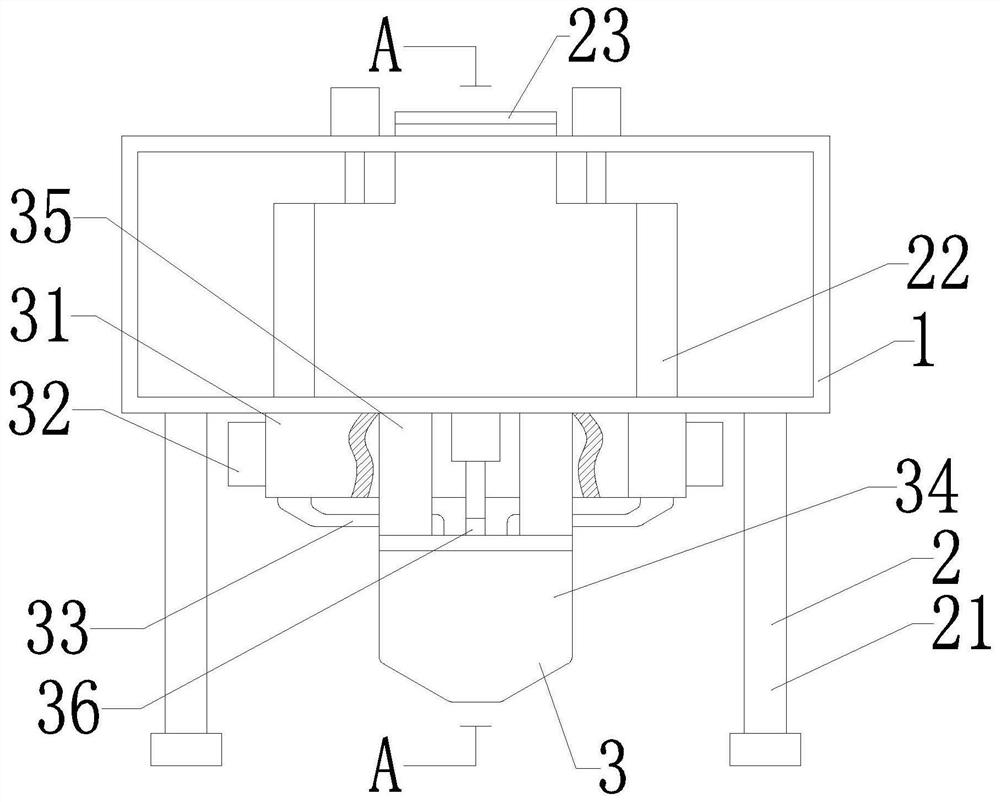

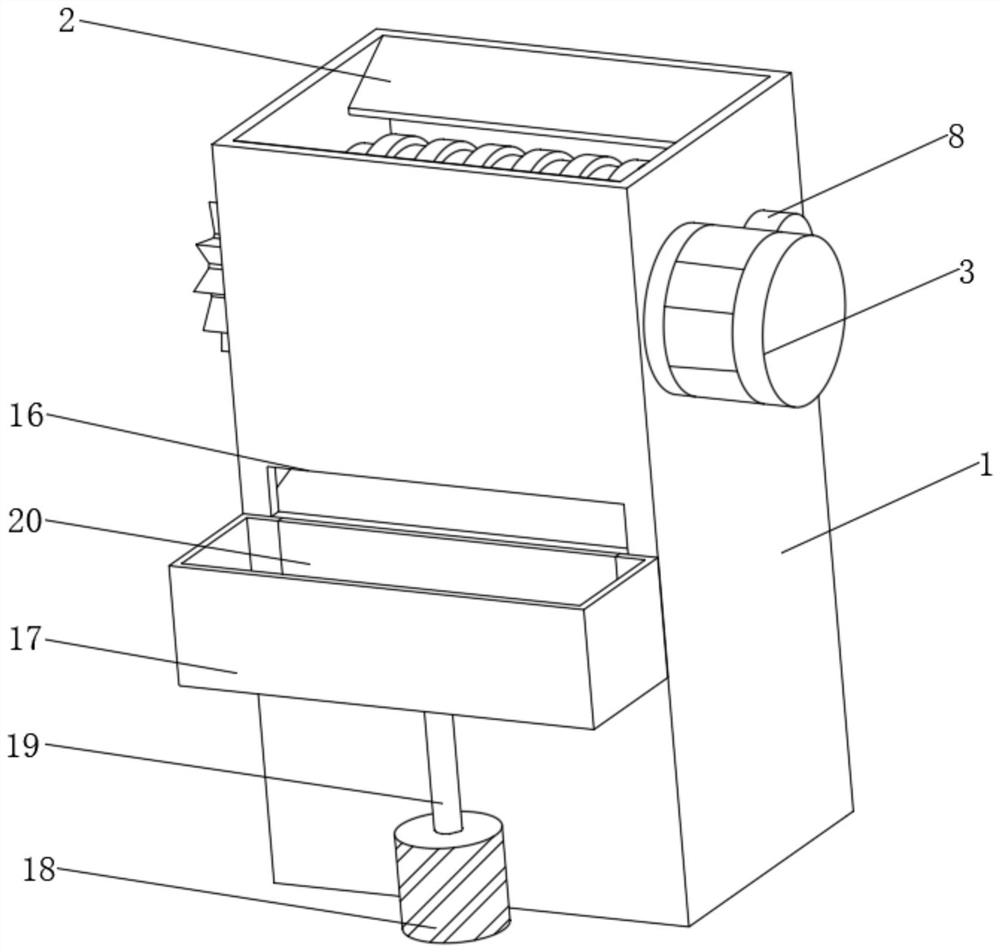

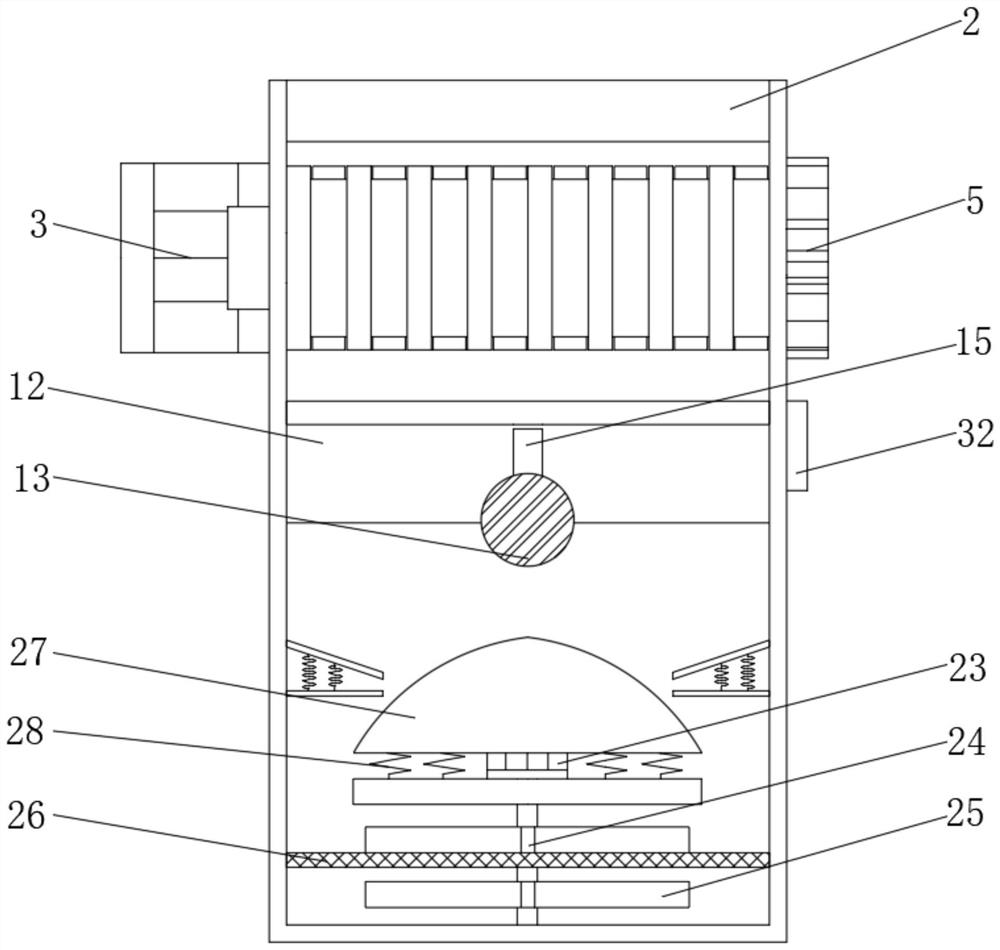

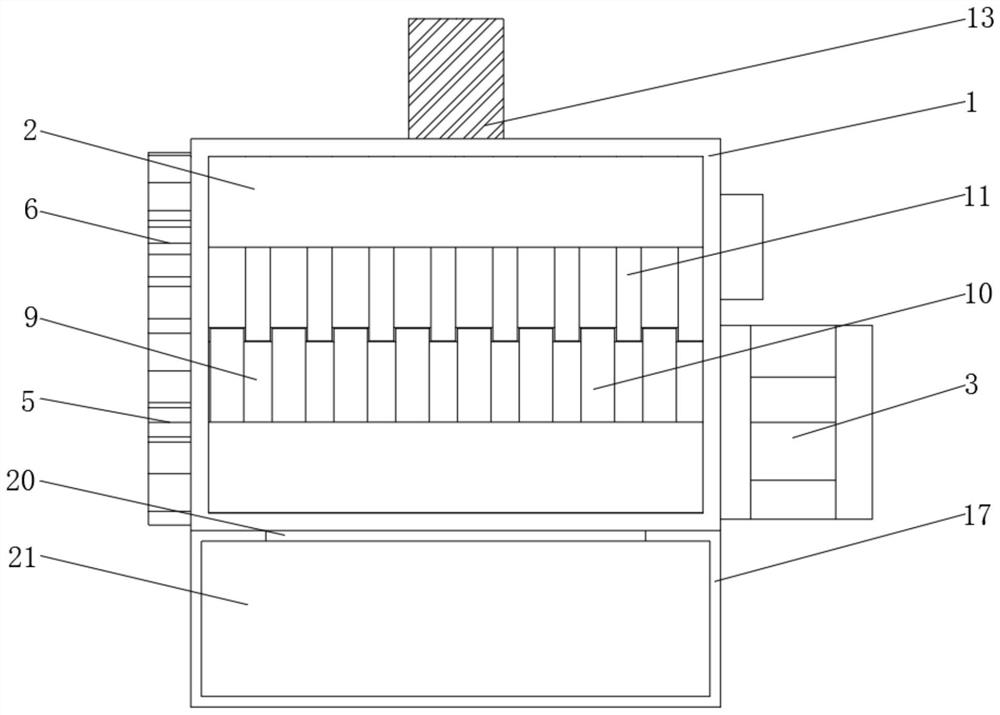

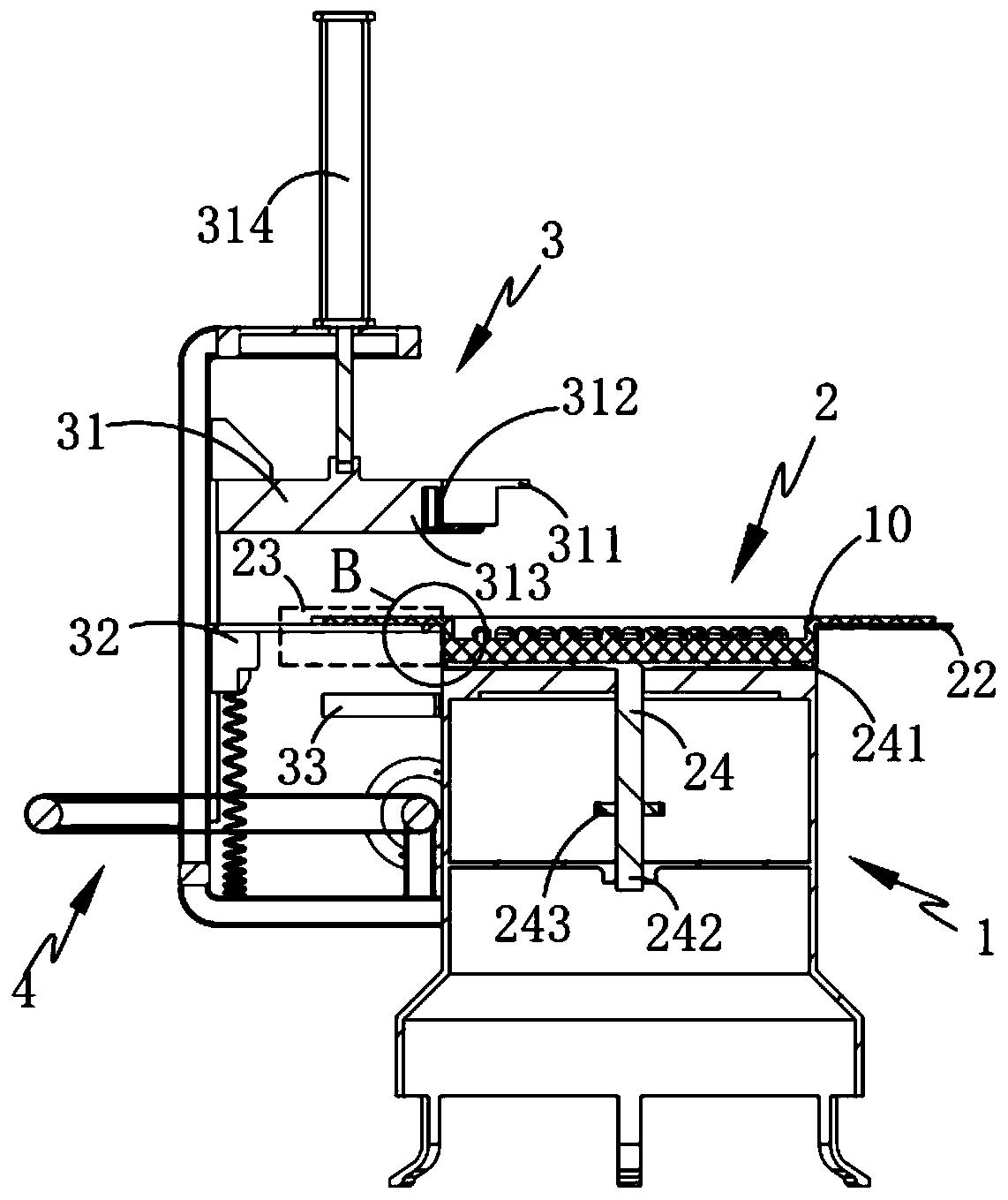

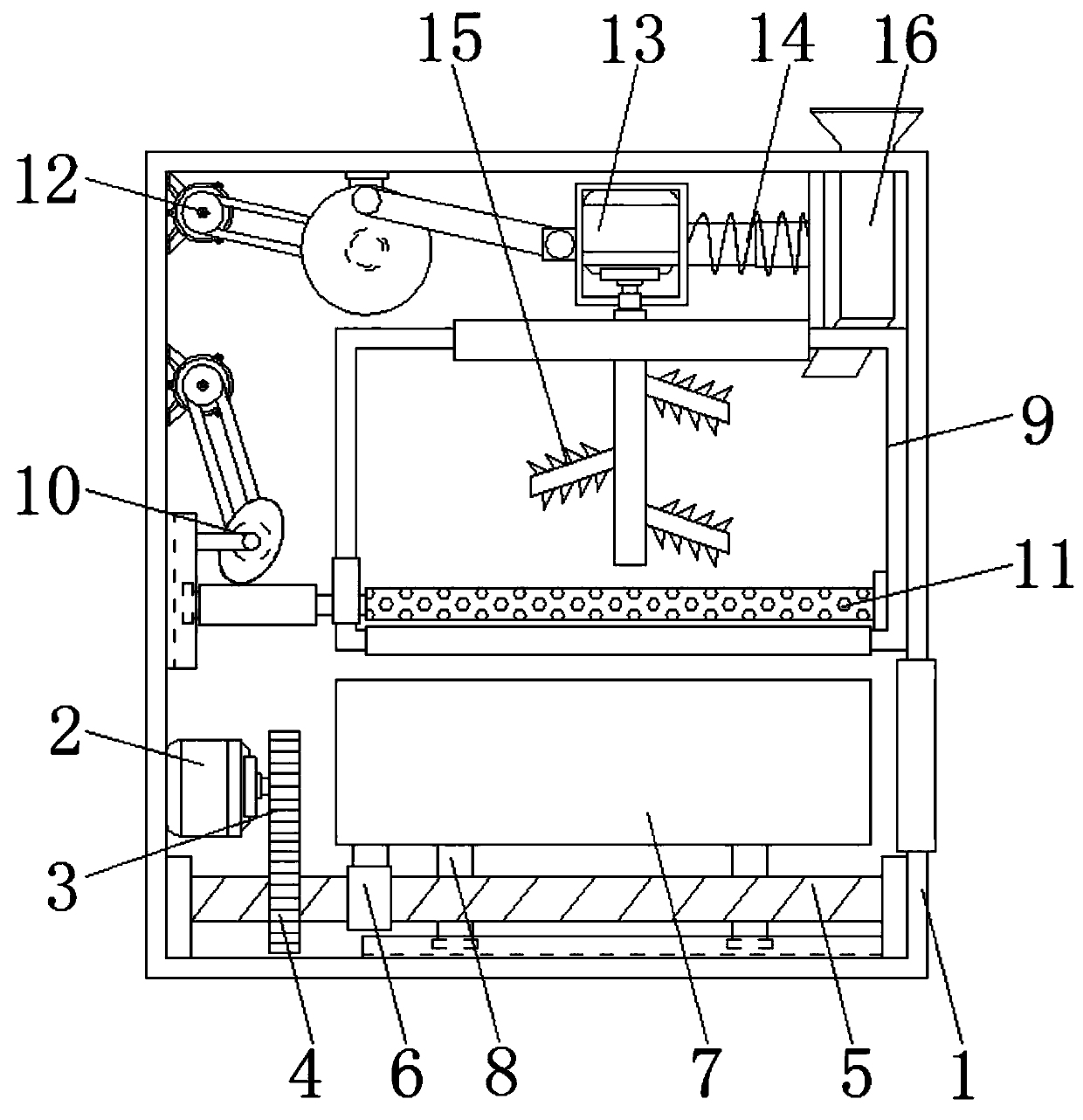

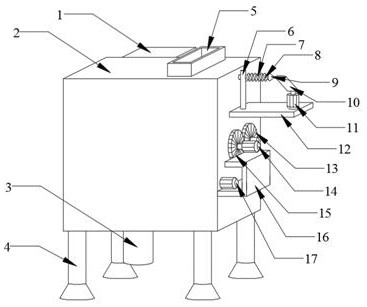

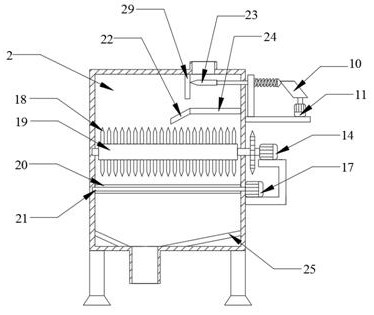

Efficient medical waste smashing and disinfecting treatment device

InactiveCN107413484AAvoid cloggingAvoid wastingMedical waste disposalGrain treatmentsDisinfectantSprayer

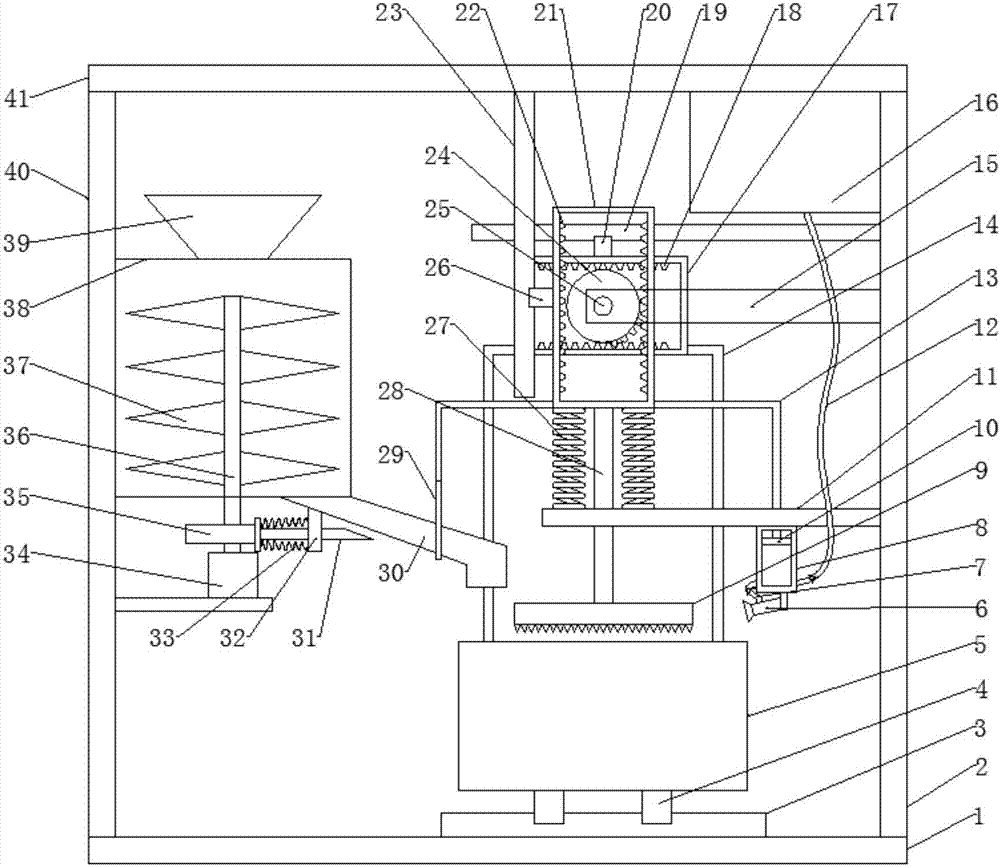

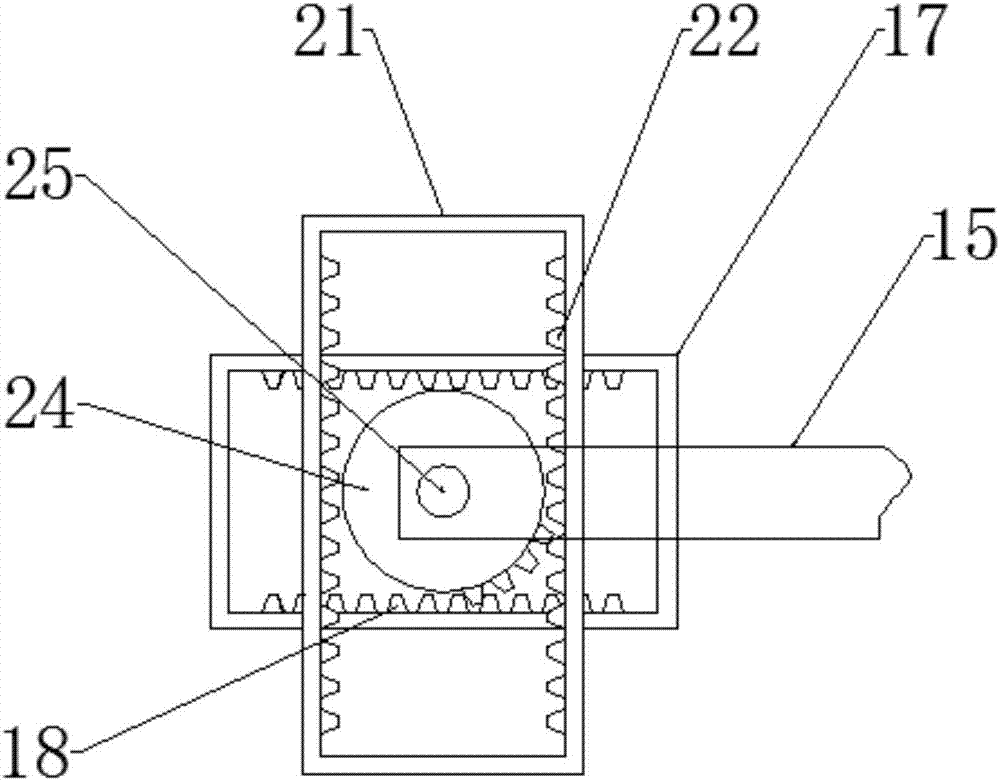

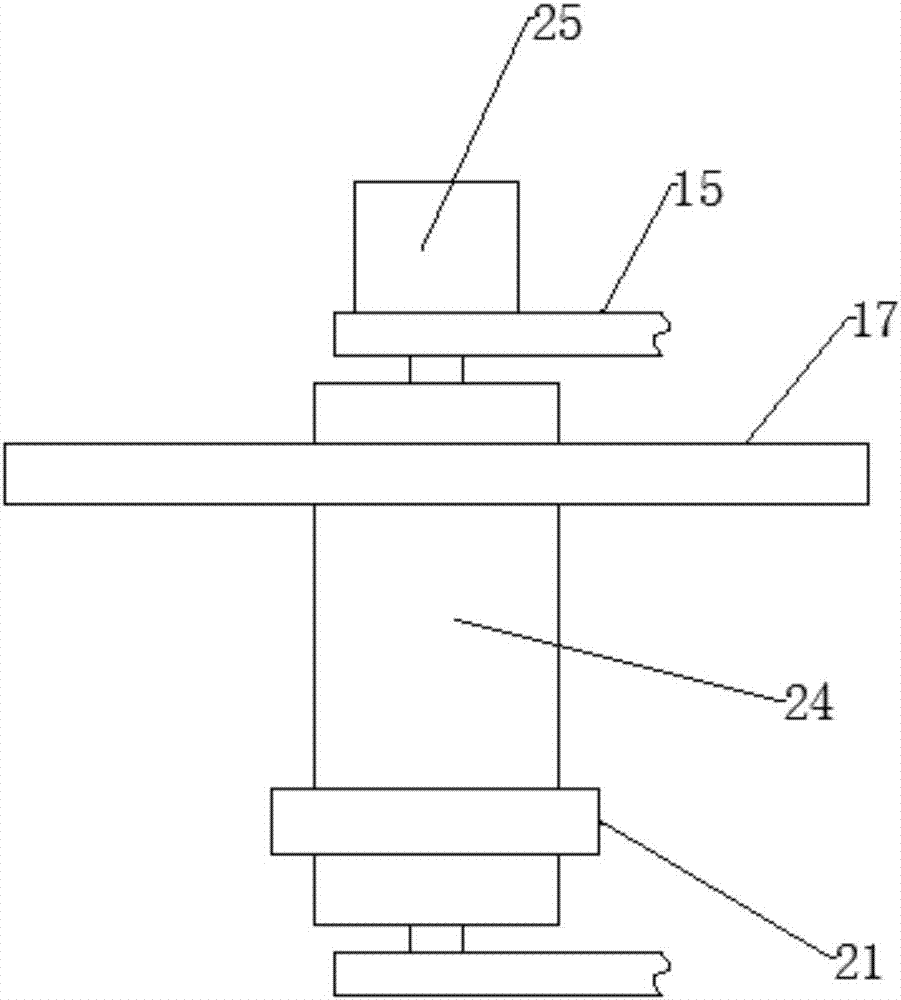

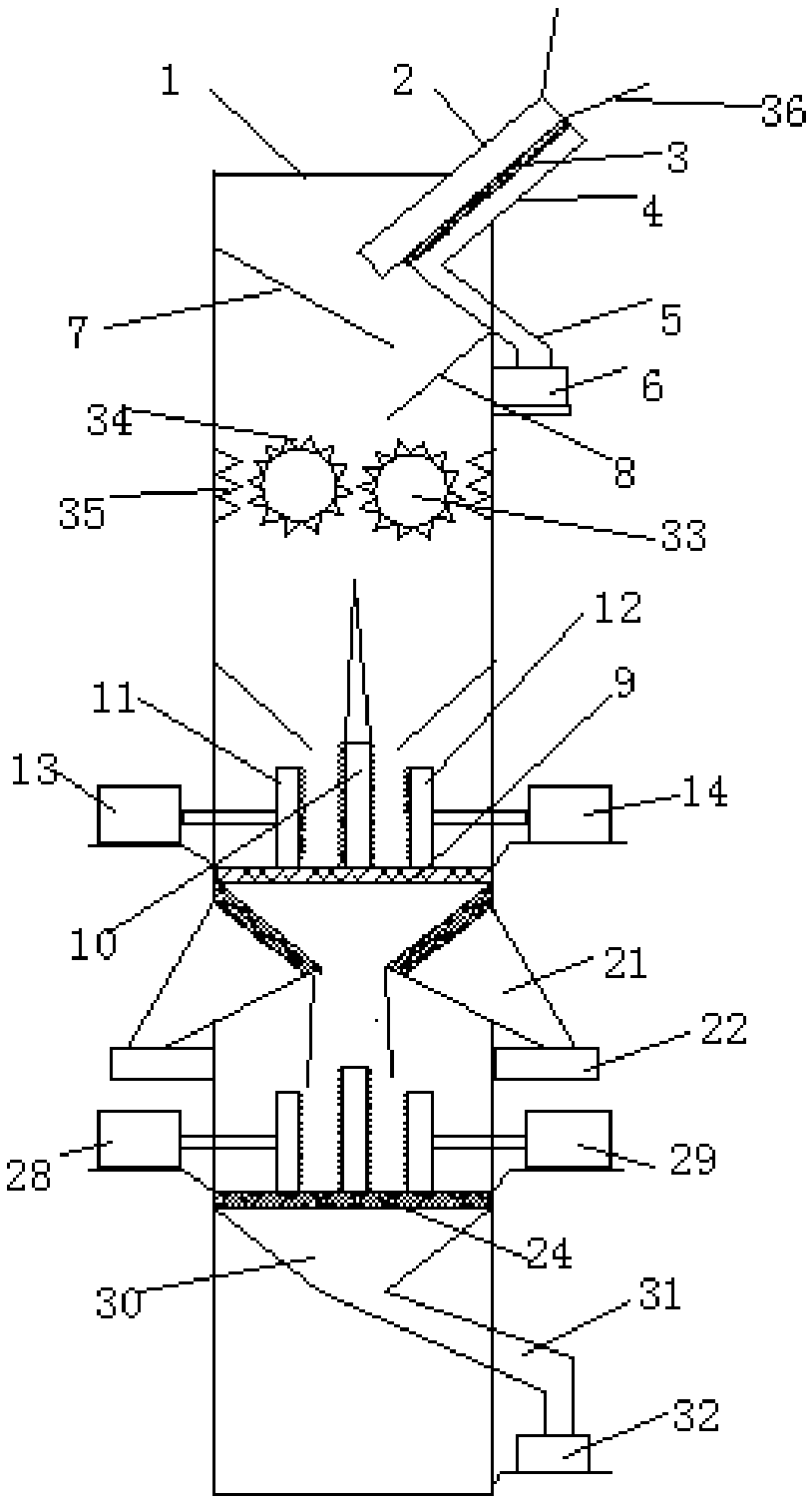

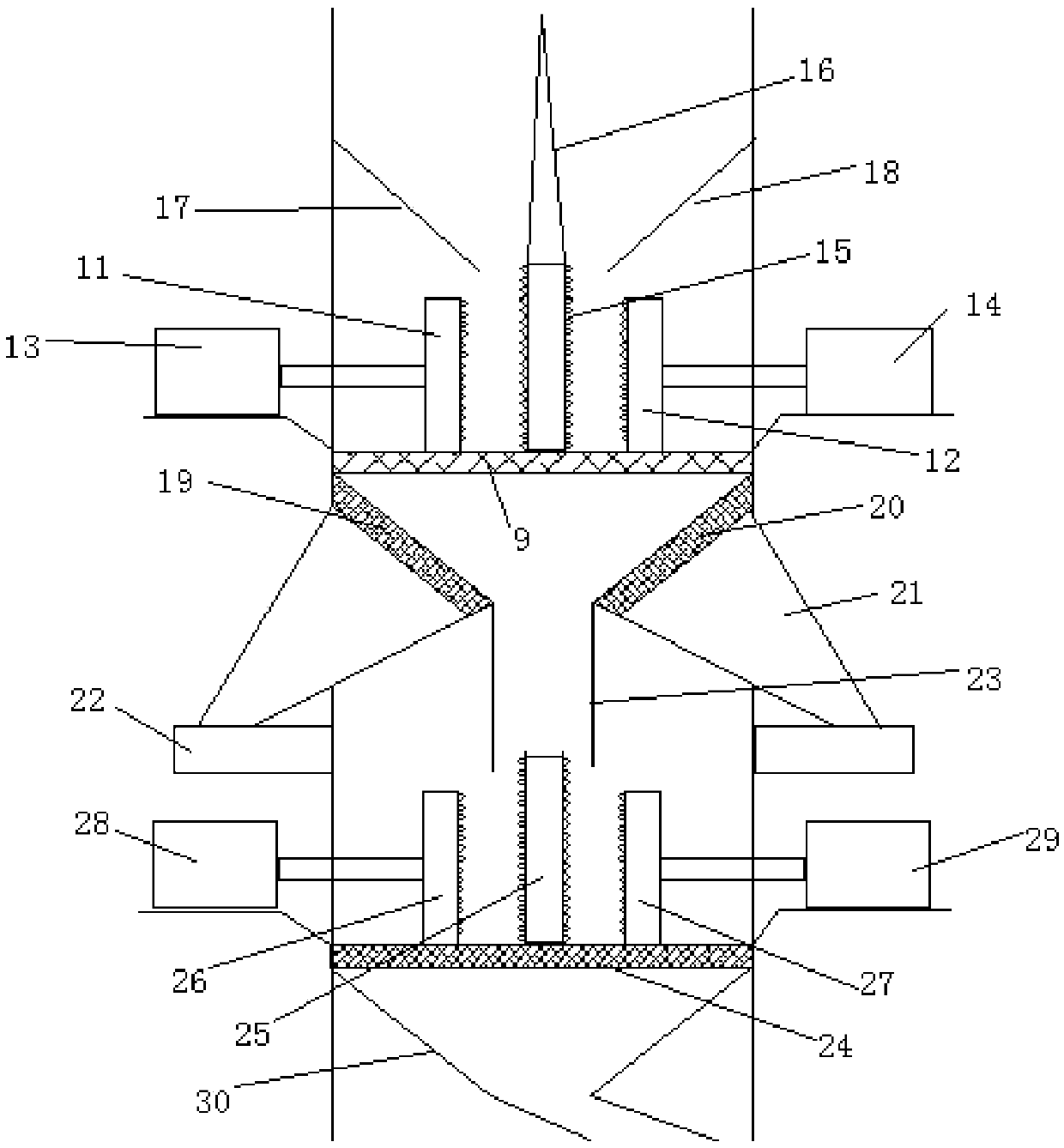

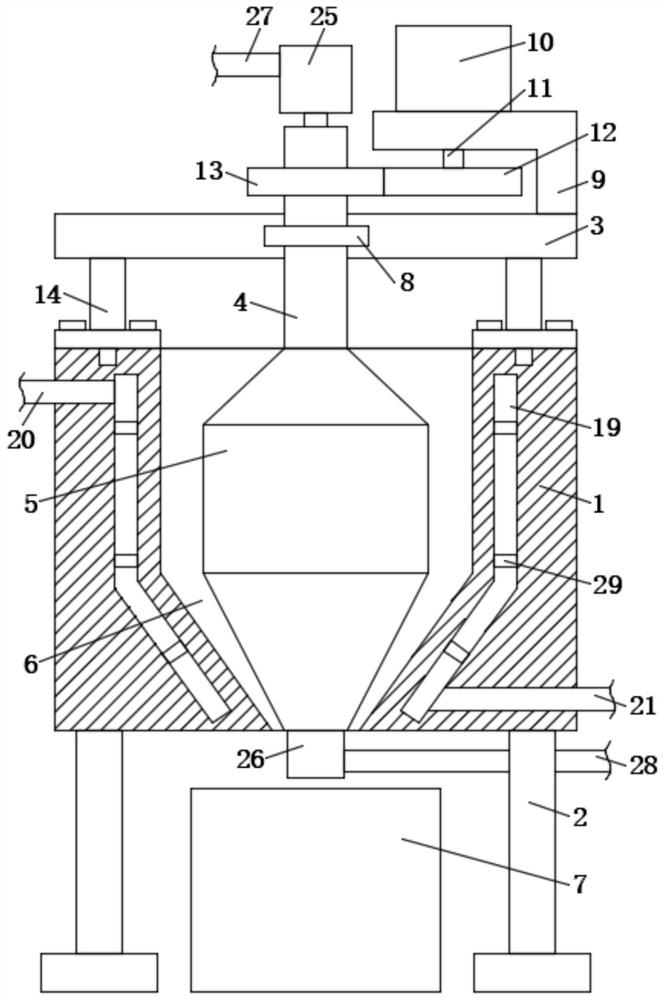

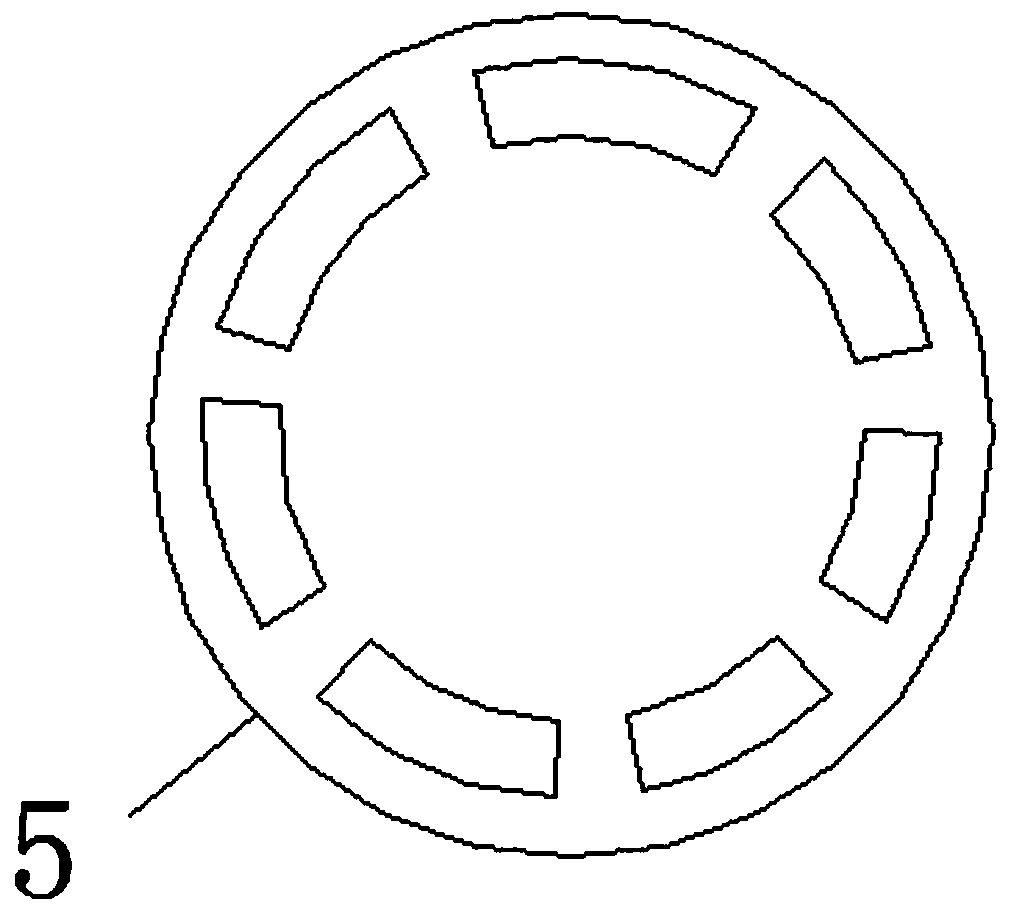

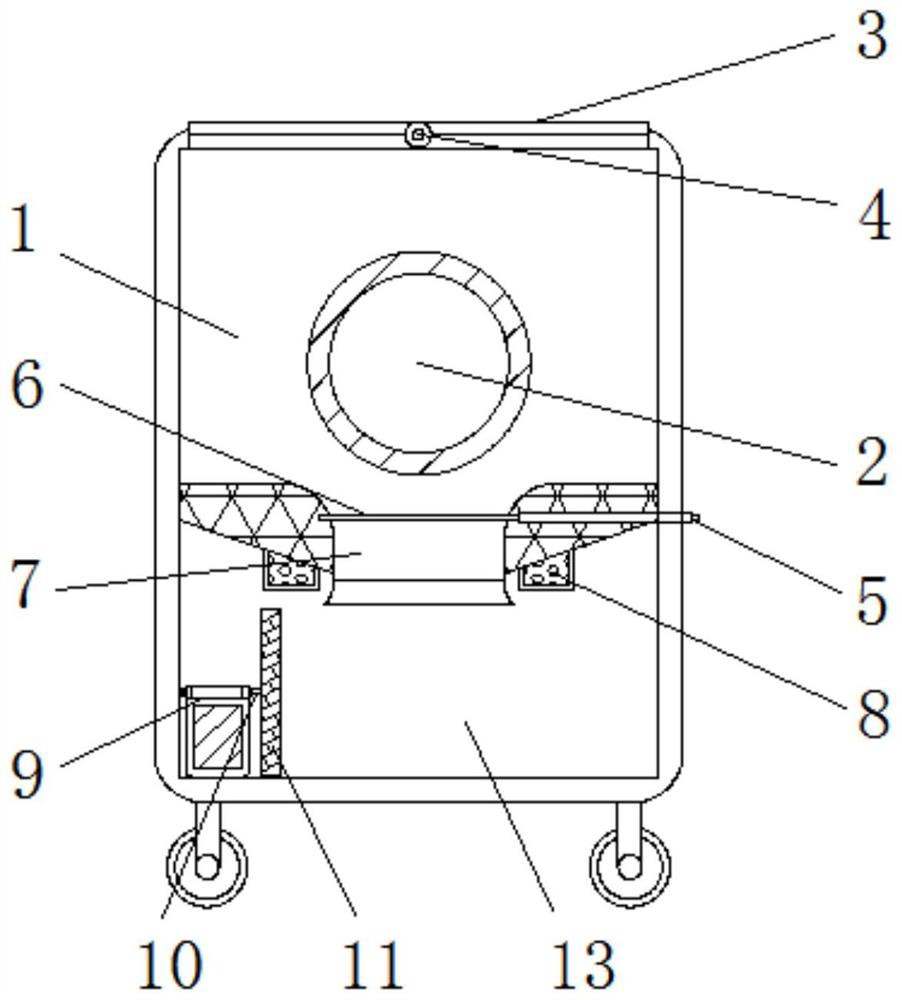

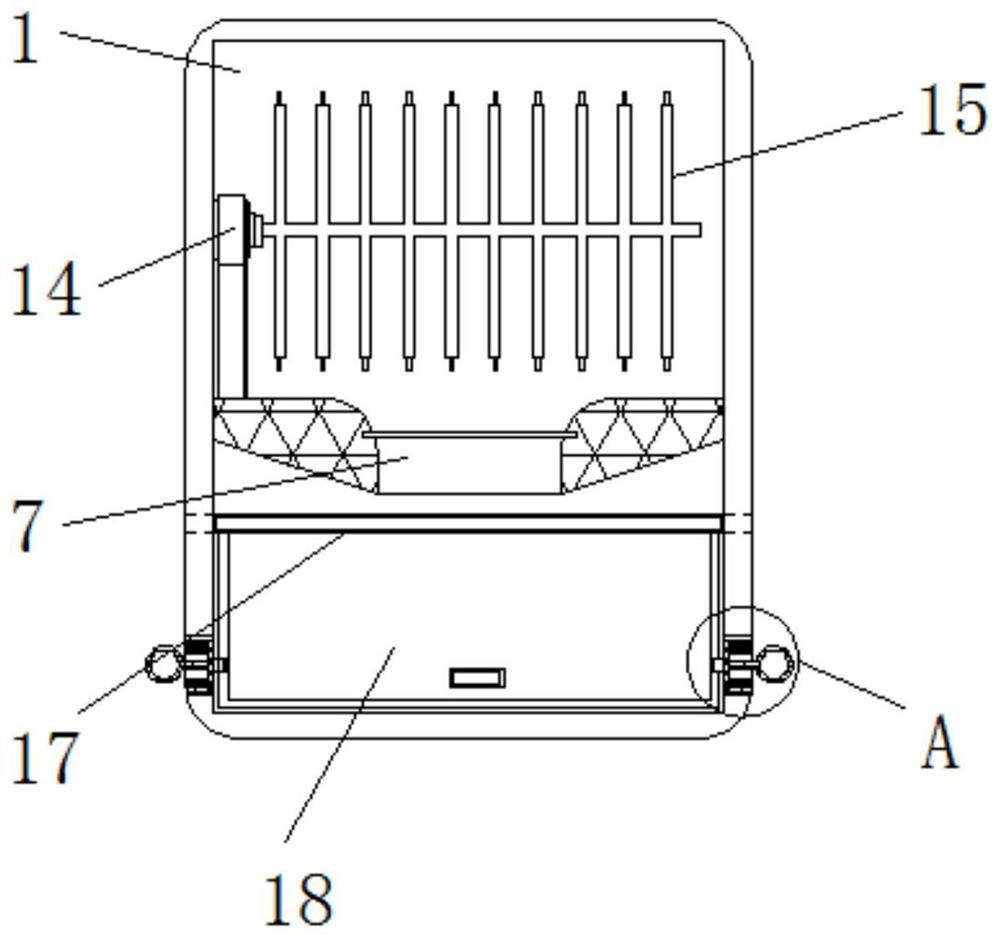

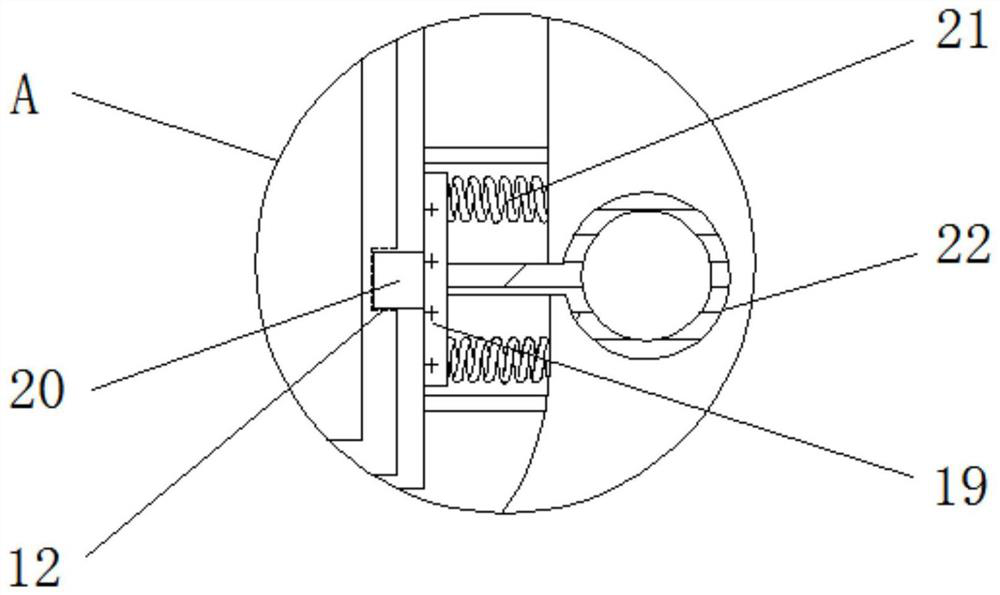

The invention discloses a high-efficiency crushing and disinfection treatment device for medical waste, which includes a bottom plate, a pre-crushing device, a secondary crushing device and a disinfection device. The pre-crushing device includes a box body, a first motor, a crushing blade, a cam and a T-shaped hammer Striker, the secondary crushing device includes a transmission mechanism, a crushing plate and a crushing frame, the transmission mechanism includes a second motor, an incomplete gear, a first rectangular frame and a second rectangular frame, and the disinfection device includes a disinfection The liquid tank, the third L-shaped rod, the piston, the cylinder body and the nozzle, the present invention is equipped with a pre-crushing device for pre-crushing medical waste, which is convenient for subsequent processes, and is equipped with a secondary crushing device for secondary crushing of medical waste , improve the crushing efficiency, and intermittently discharge materials to avoid incomplete crushing due to excessive continuous discharge. A disinfection device is provided to disinfect while crushing, so that the disinfectant can better penetrate into the interior of medical waste, improving the disinfection effect and avoiding waste. disinfectant.

Owner:宁波新材料科技城犀鸟工业设计有限公司

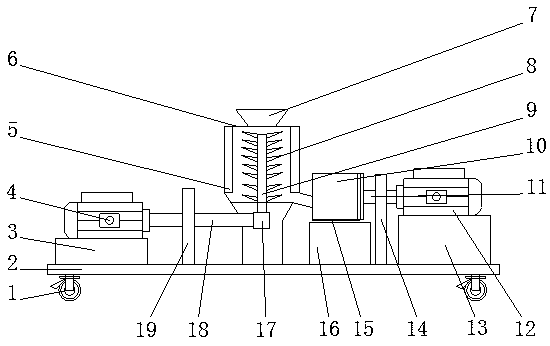

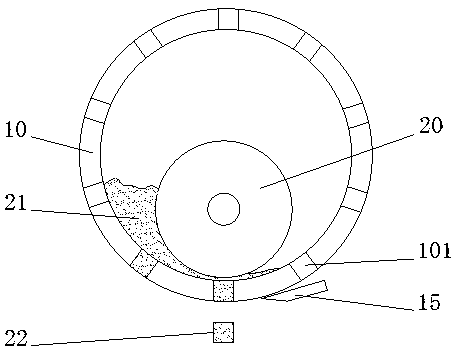

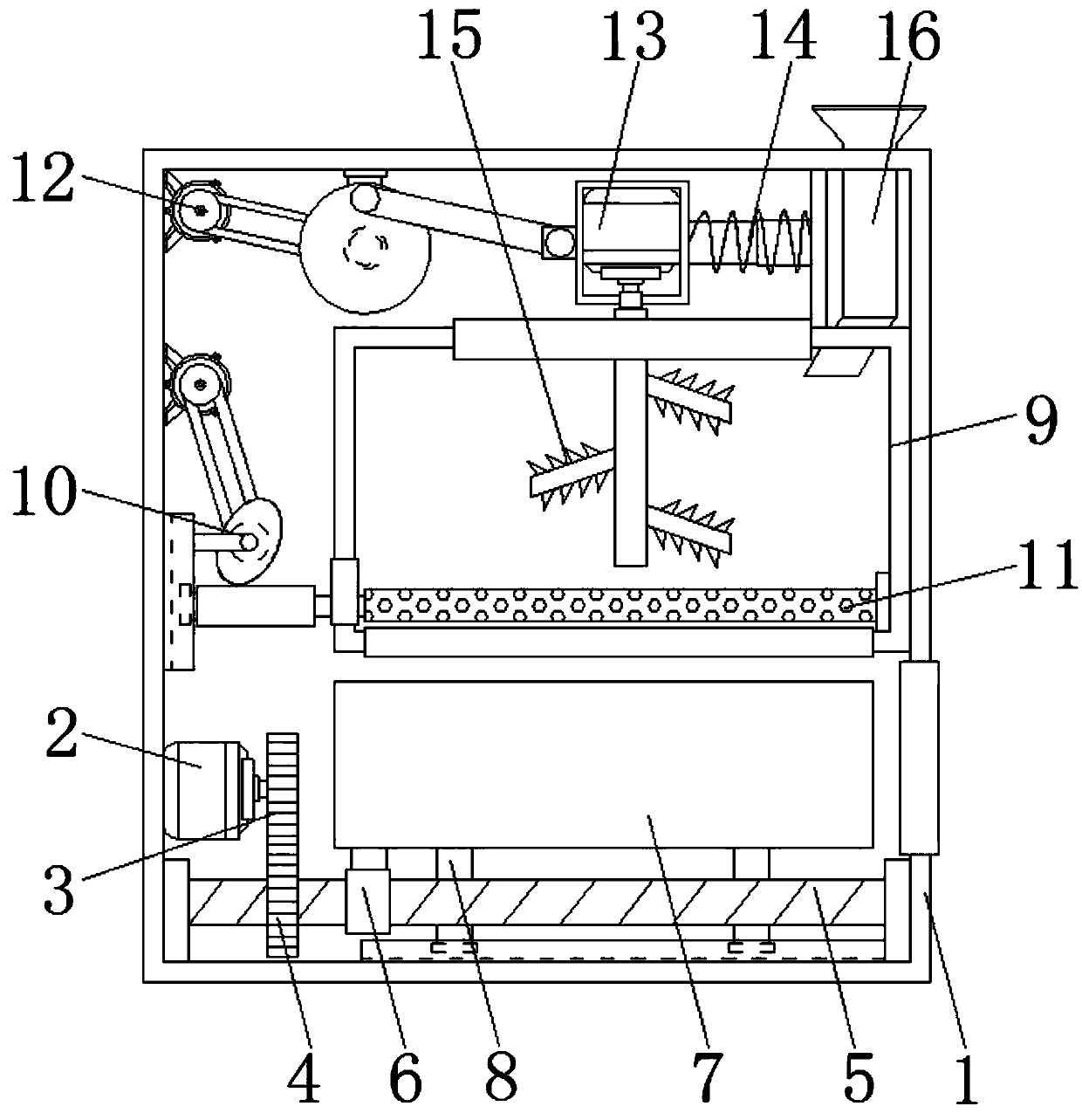

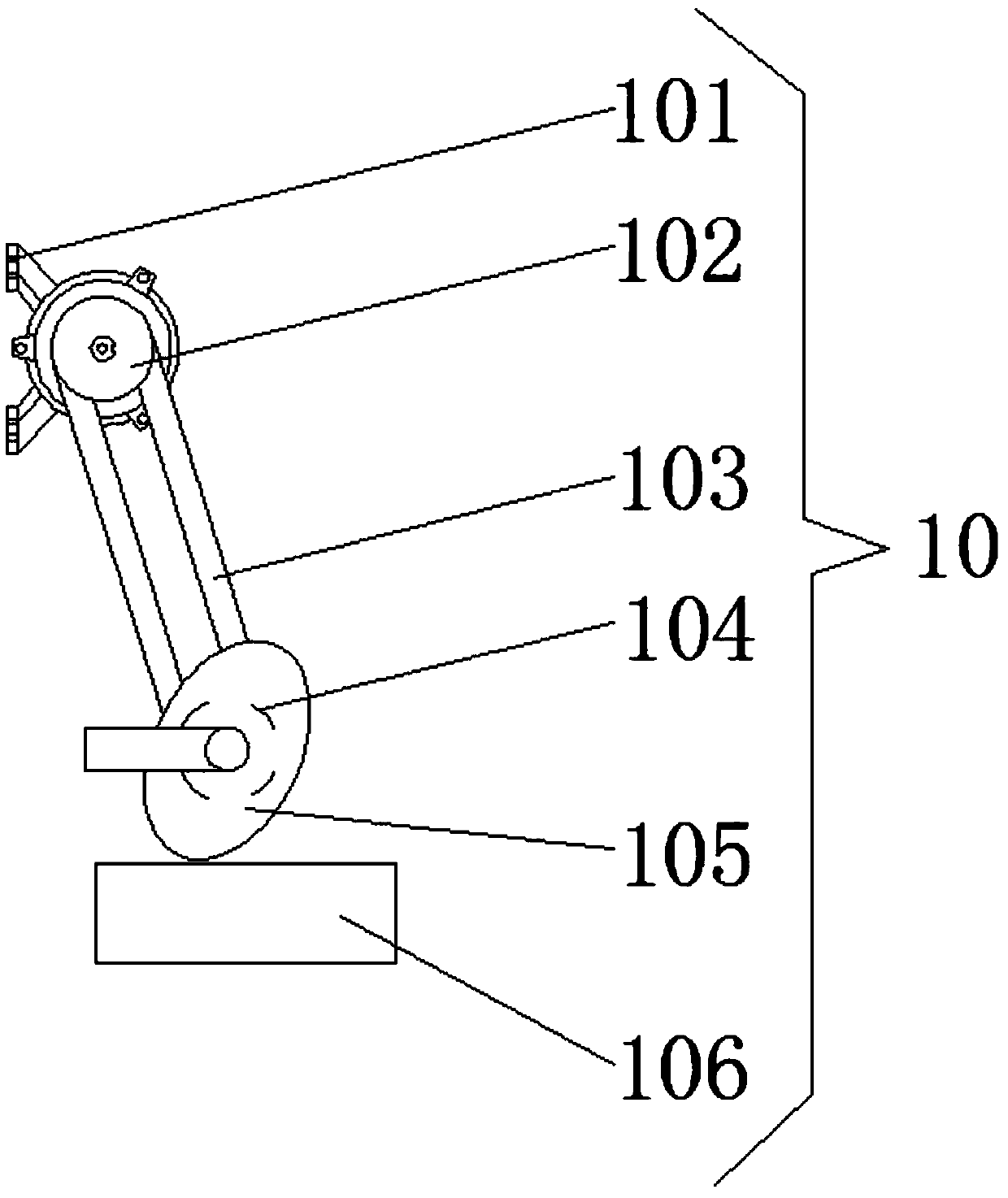

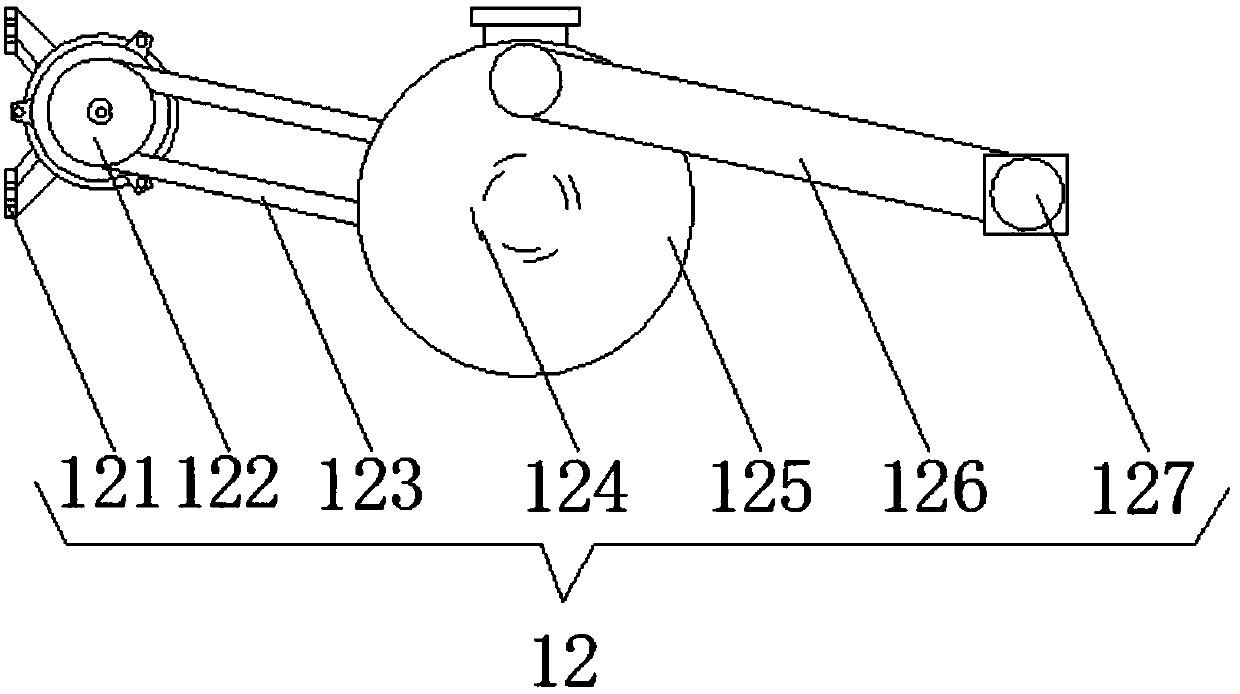

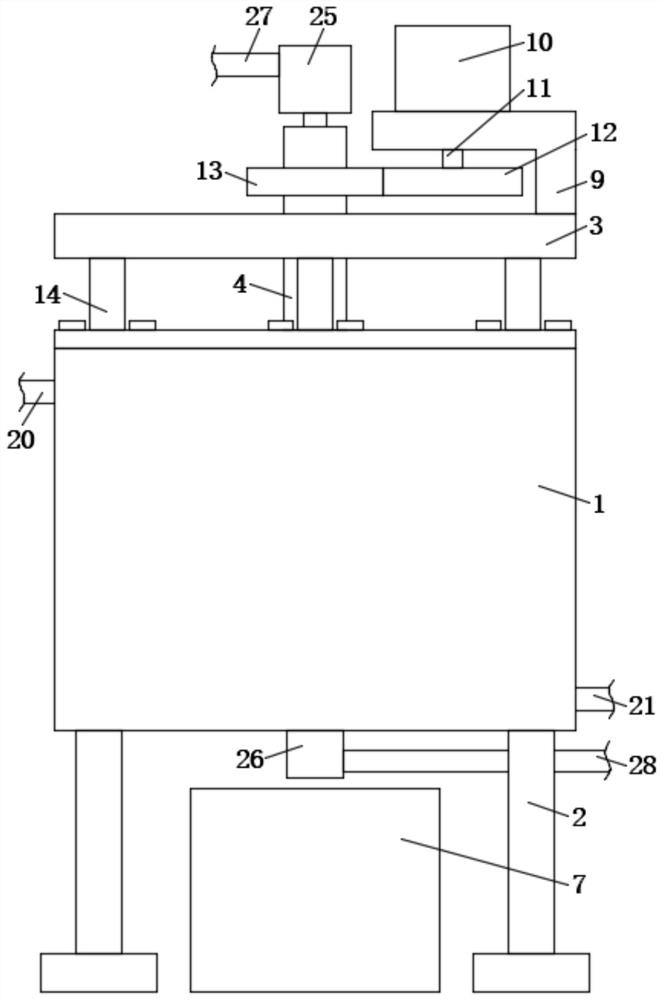

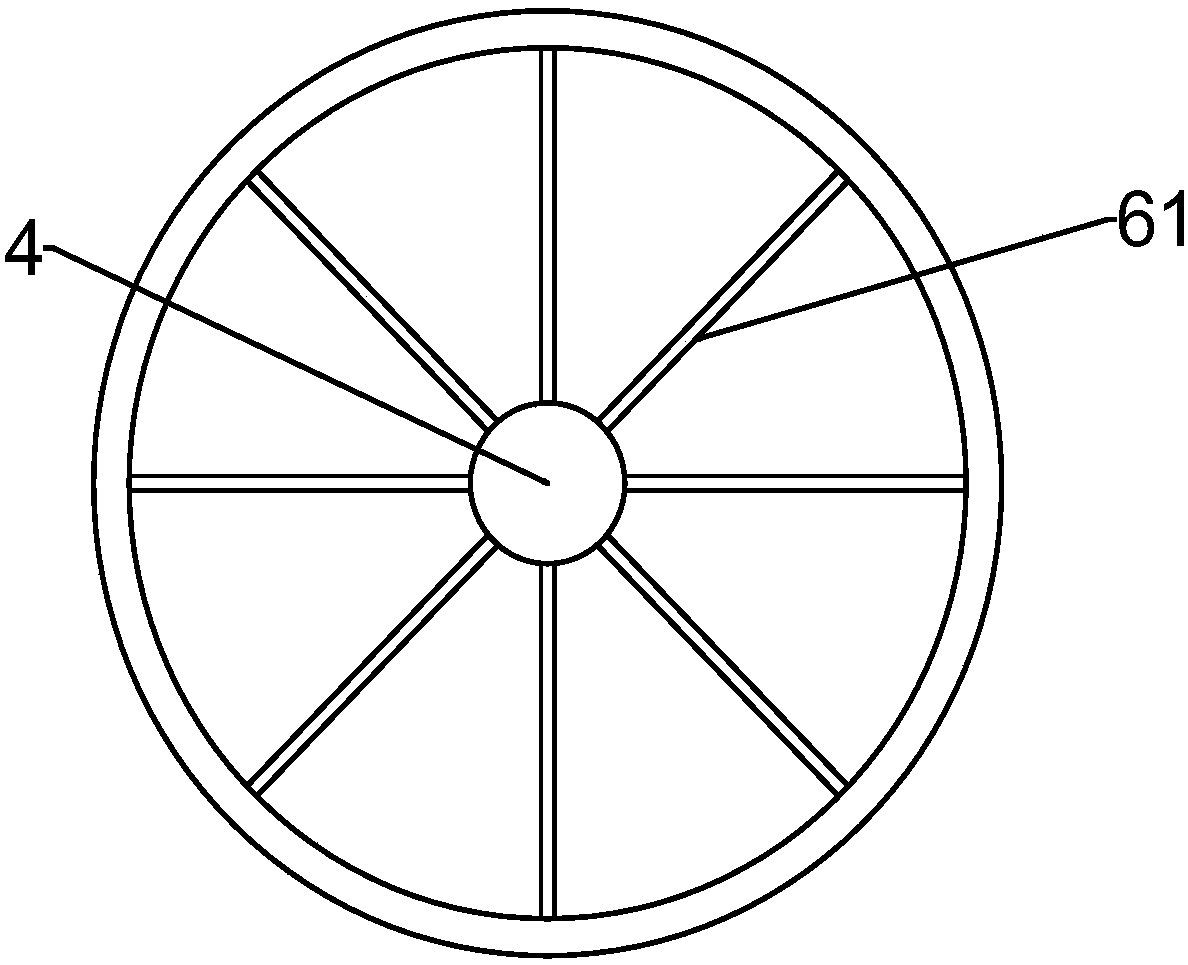

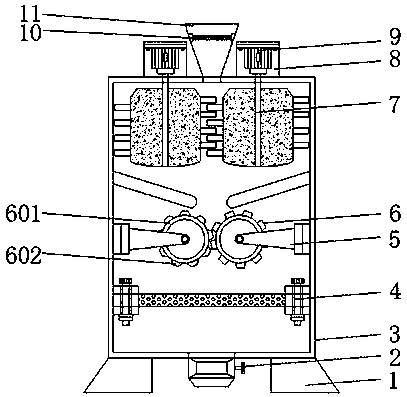

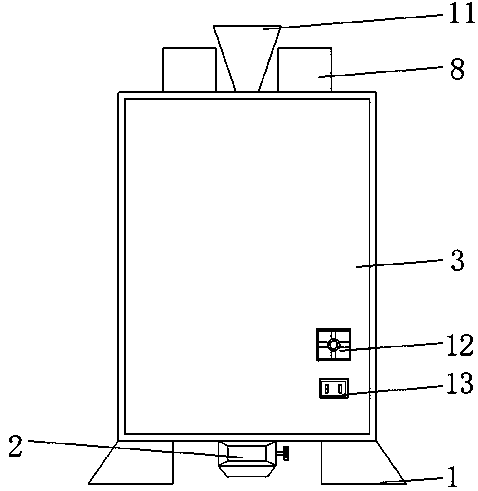

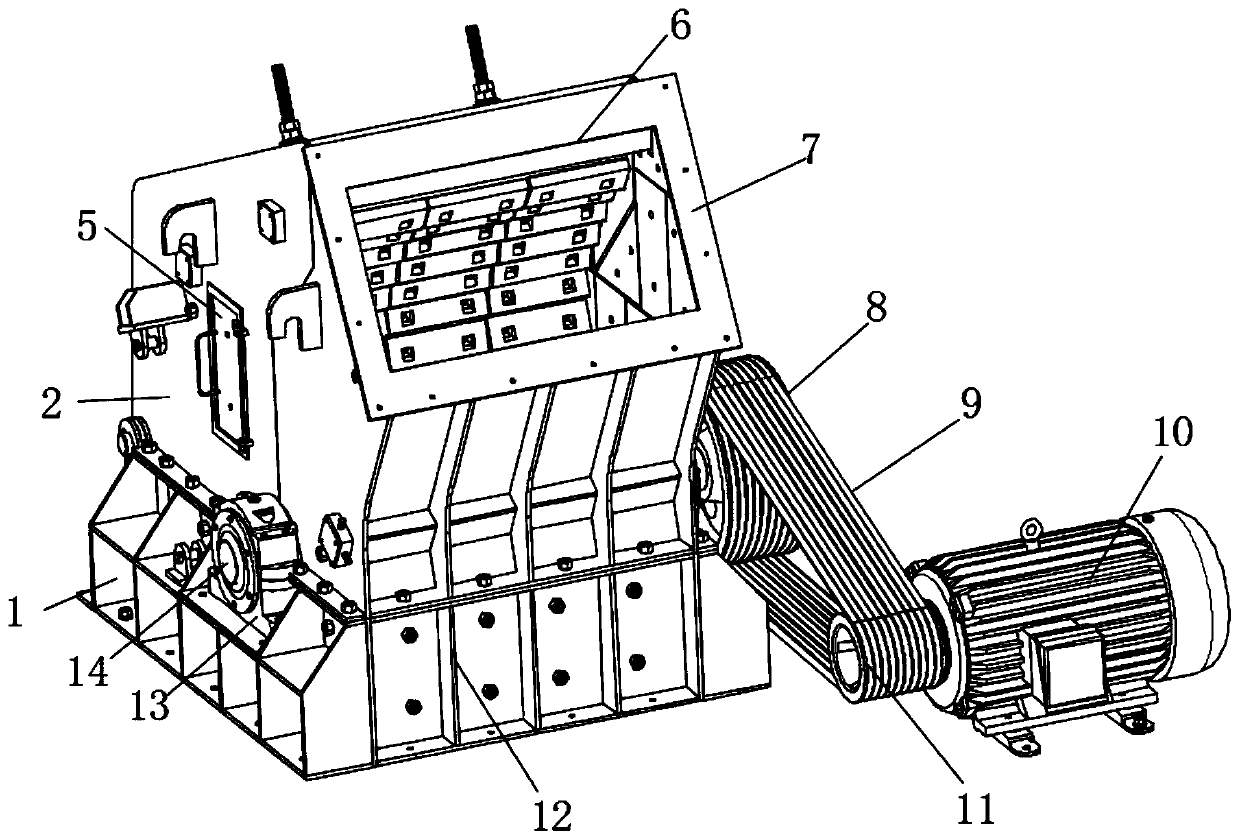

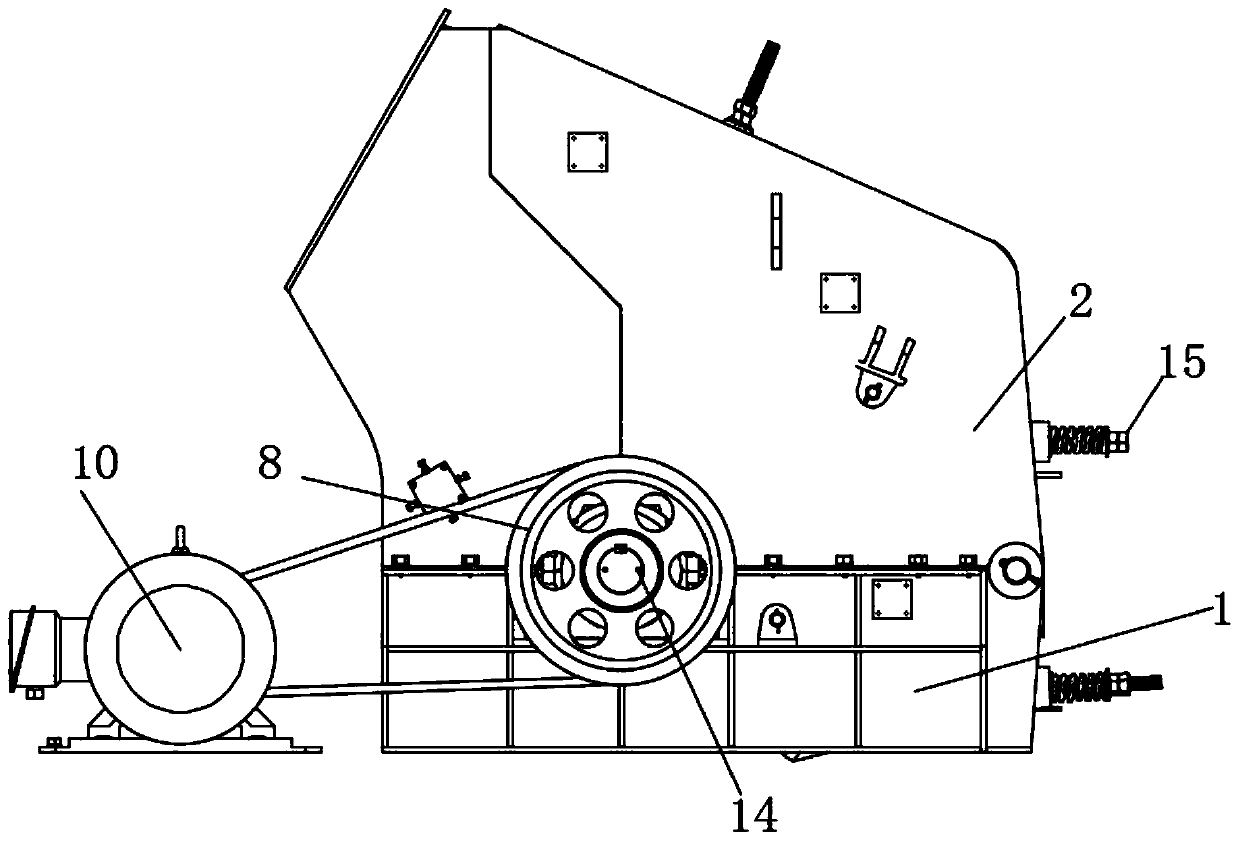

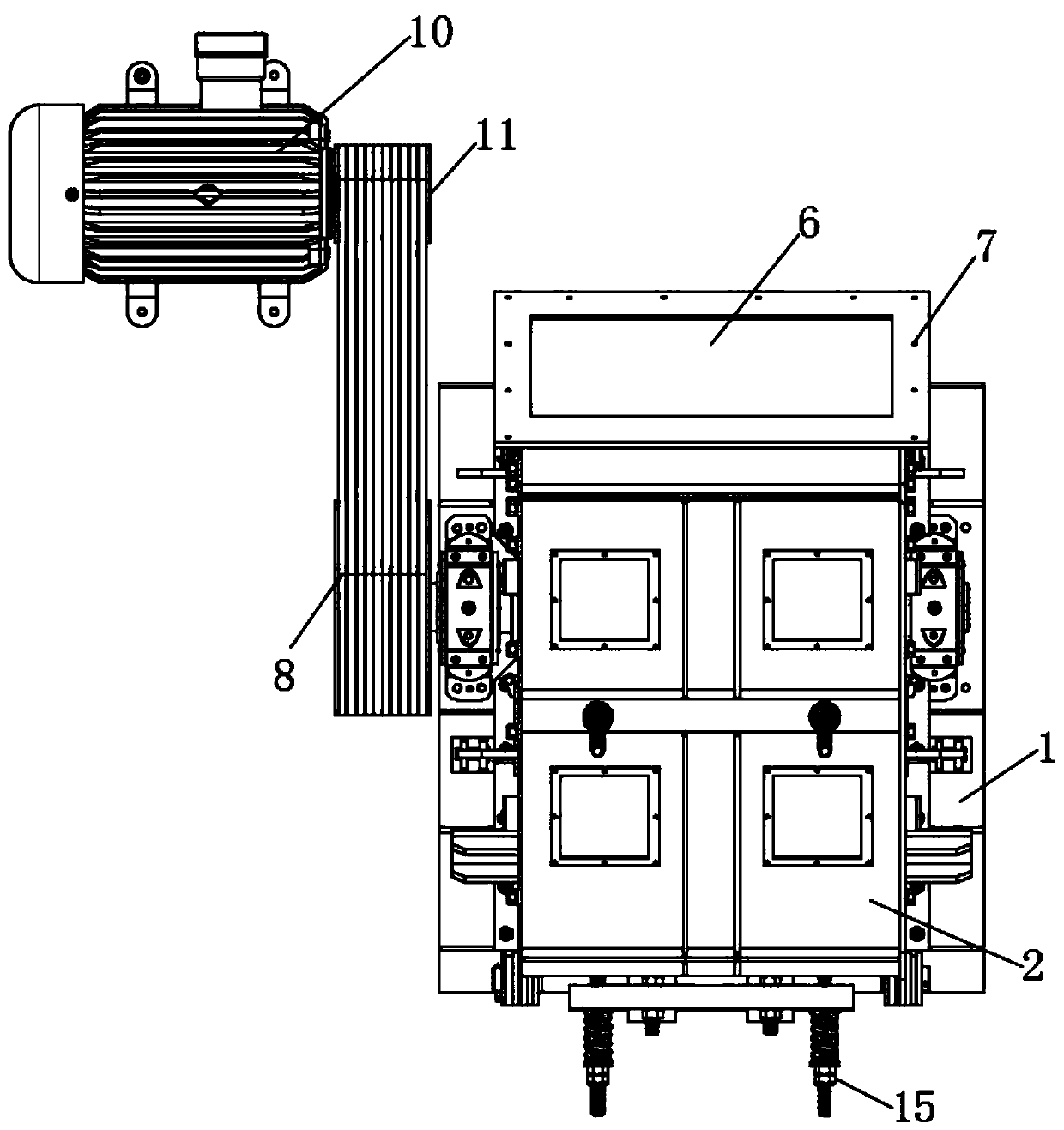

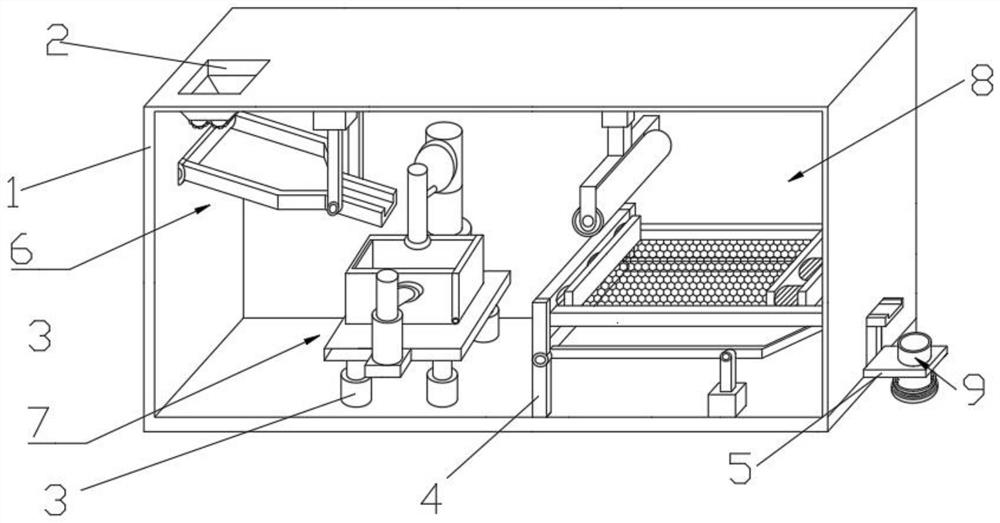

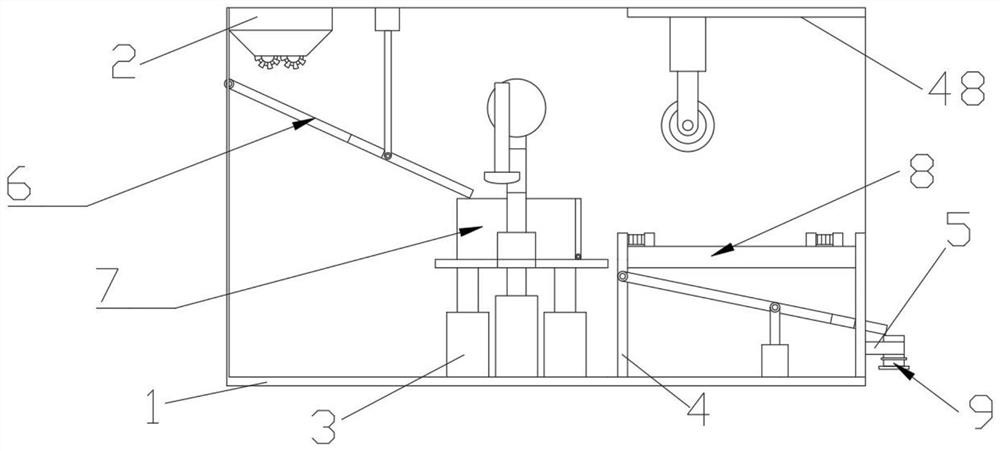

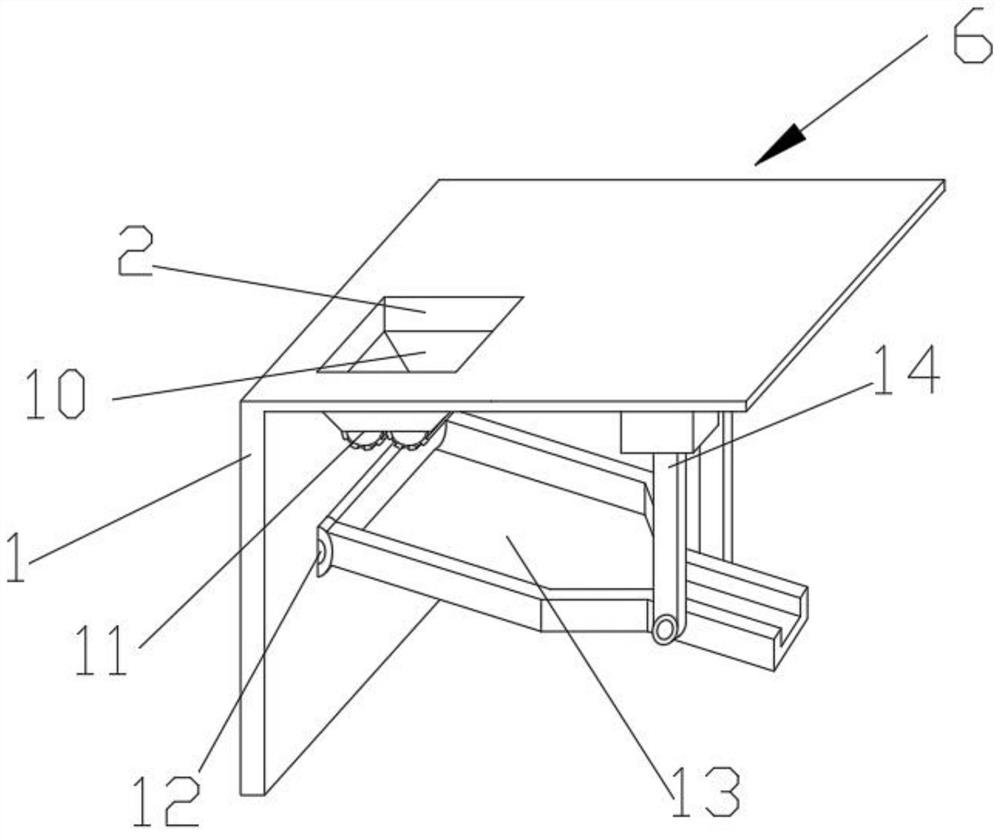

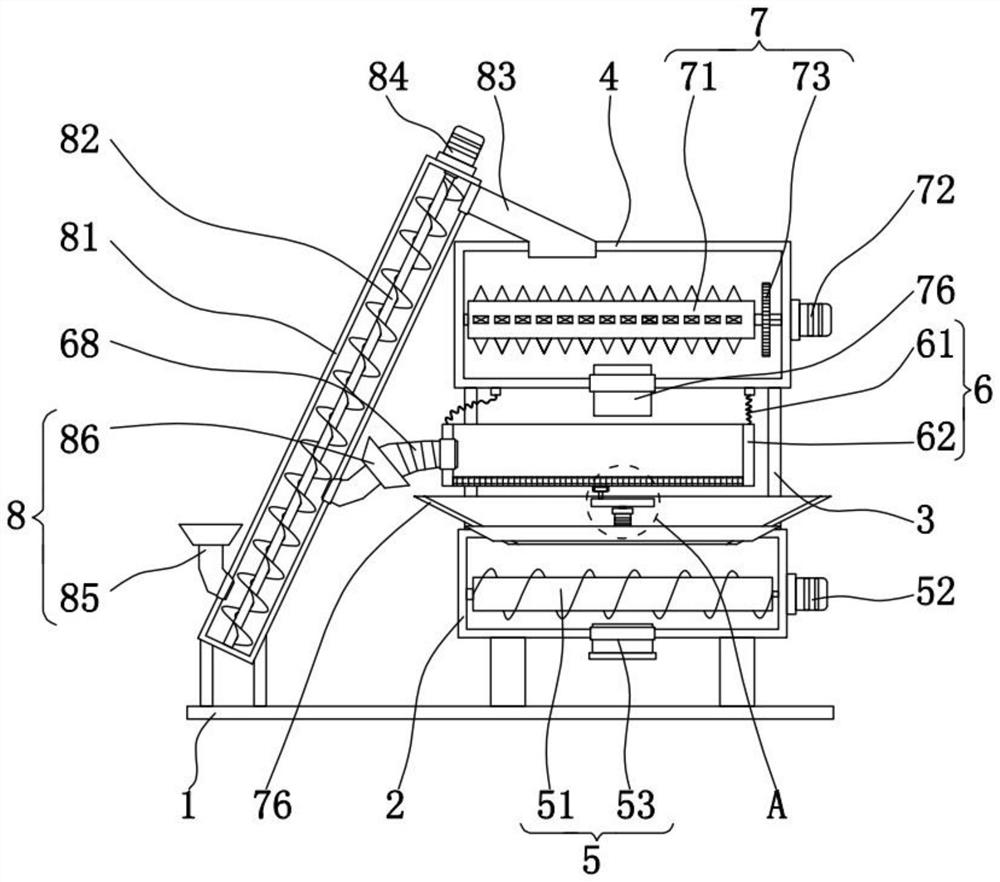

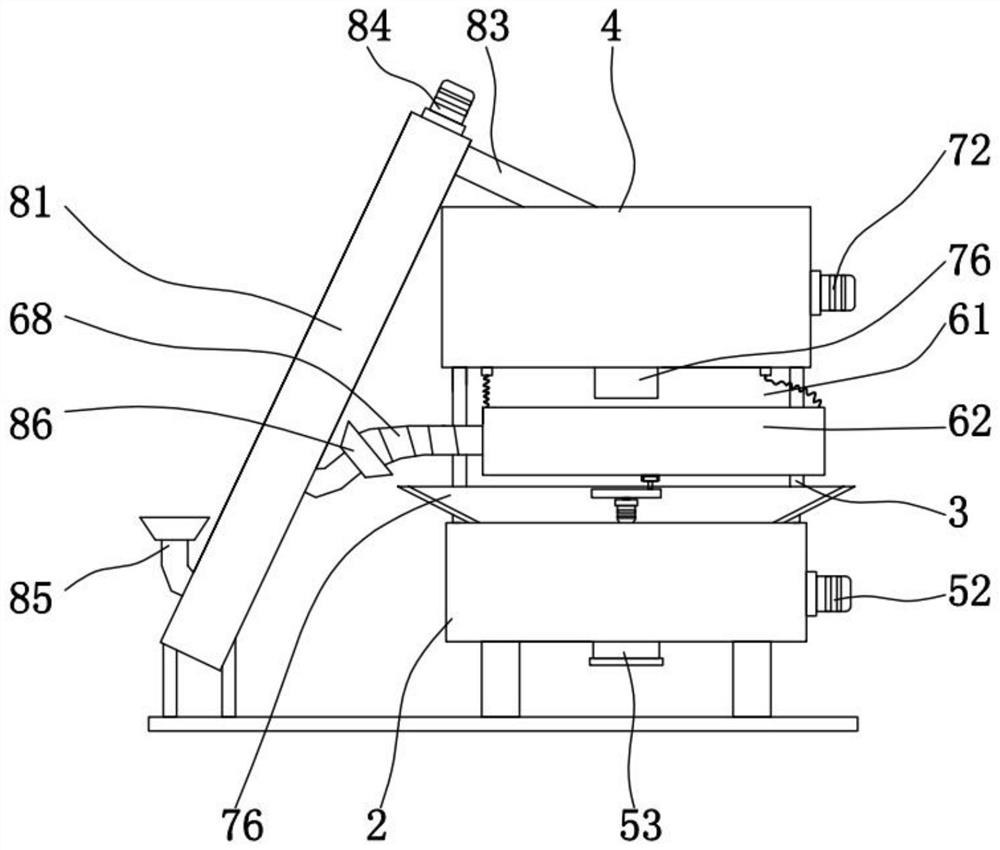

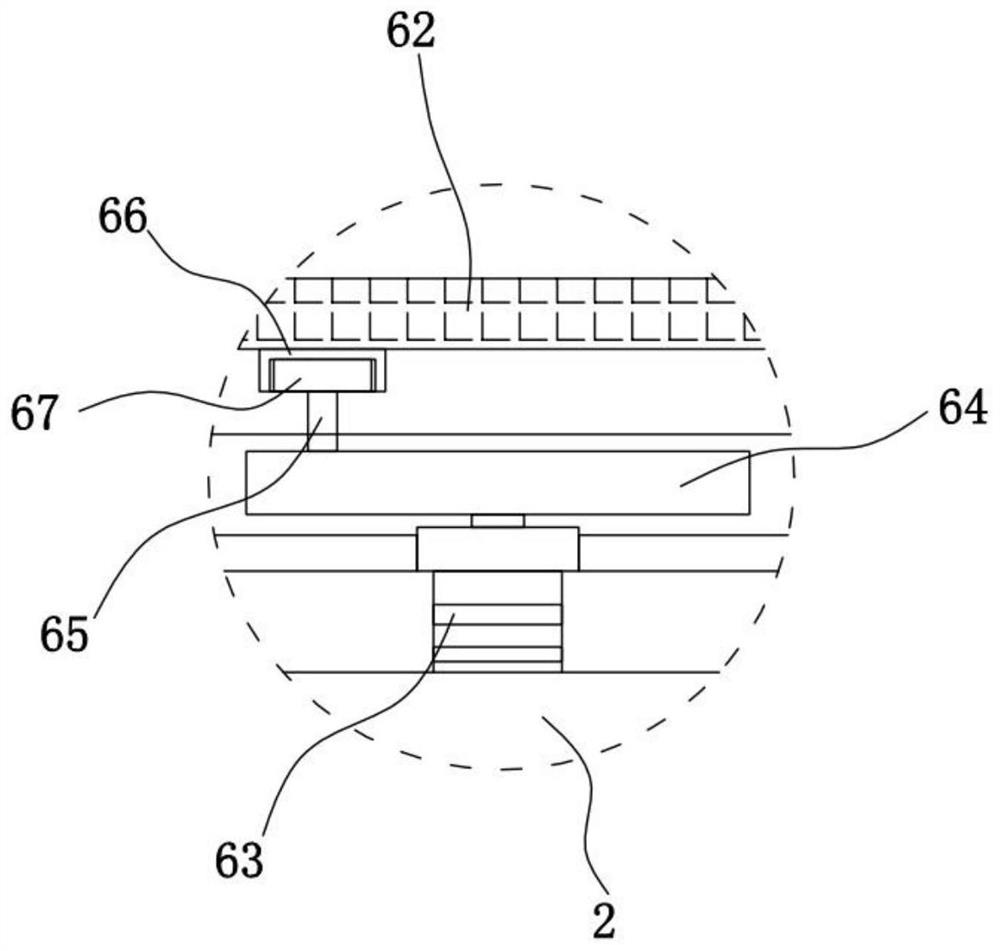

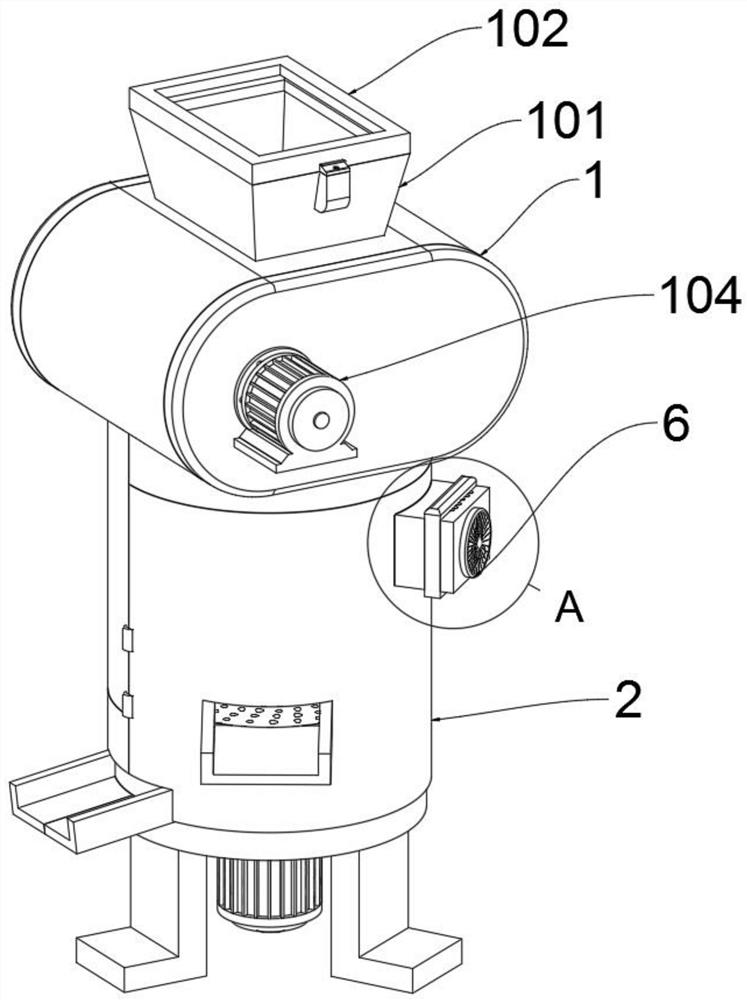

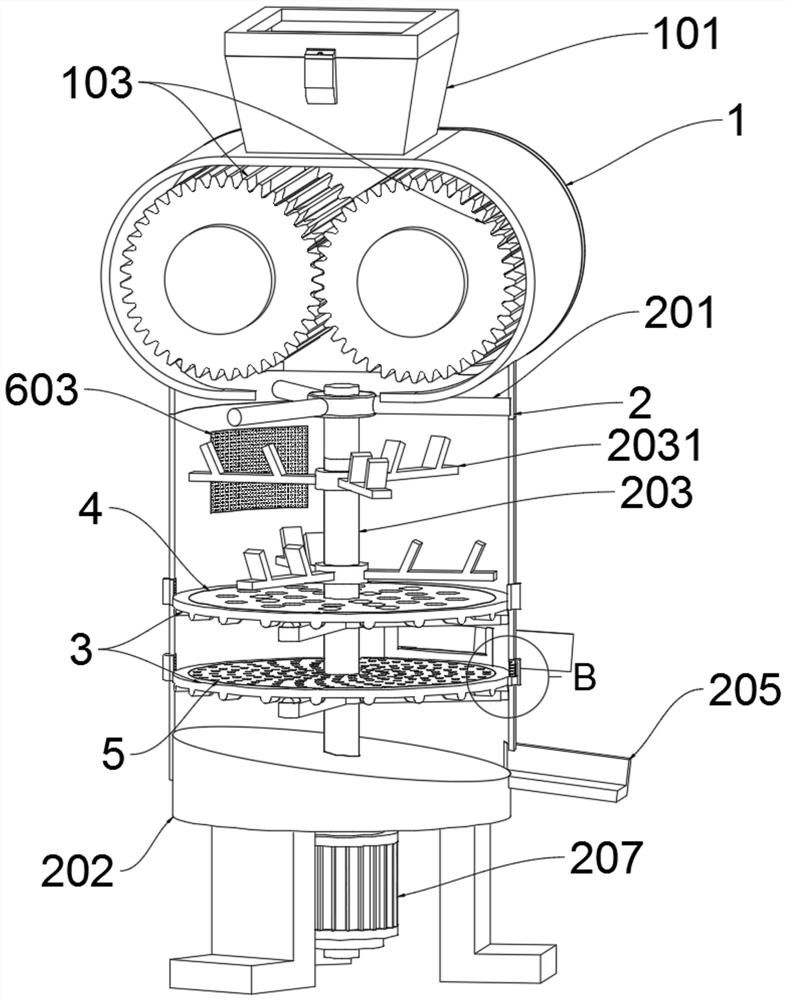

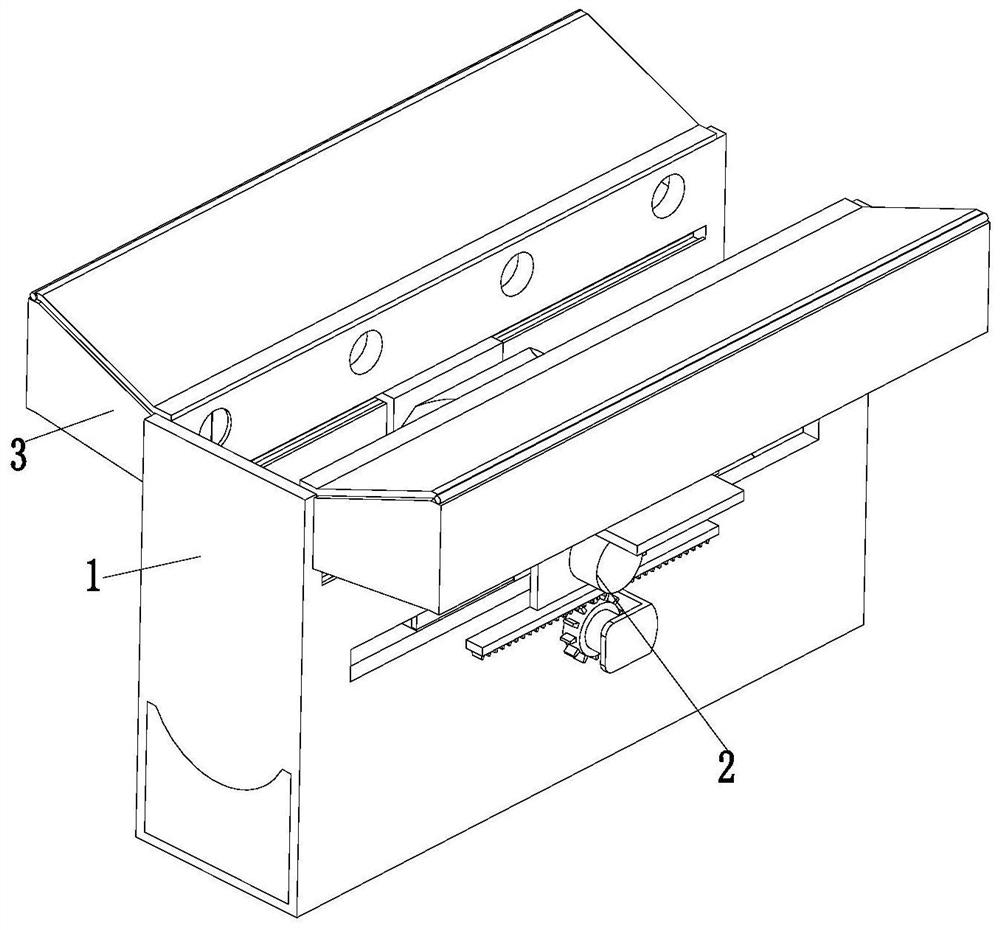

Crushing and screening equipment for automobile tire recycling

ActiveCN107009550AAvoid incomplete crushingTo achieve the screening effectSievingScreeningScreening effectTire recycling

The invention relates to crushing and screening equipment, in particular to crushing and screening equipment for automobile tire recycling. The technical problem to be solved is to provide the crushing and screening equipment which is used for automobile tire recycling and convenient to screen and controllable in feeding rate. To solve the technical problem, the crushing and screening equipment for automobile tire recycling is provided. The crushing and screening equipment comprises a bottom plate, L-shaped supports, a crushing device, a screening device and the like. The L-shaped supports are symmetrically arranged on the top of the bottom plate in a left-right manner. The crushing device is arranged between the two L-shaped supports. The screening device is arranged below the crushing device. According to the crushing and screening equipment for automobile tire recycling, a first operating crank is rocked to drive a screening frame to swing left and right, the screening effect is achieved, the feeding amount is adjusted by rocking a second operating crank, and it is avoided that crushing is not thorough due to the too large feeding amount.

Owner:TAICANG CENTURY BRIDGE IND & COMMERCIAL OFFICE

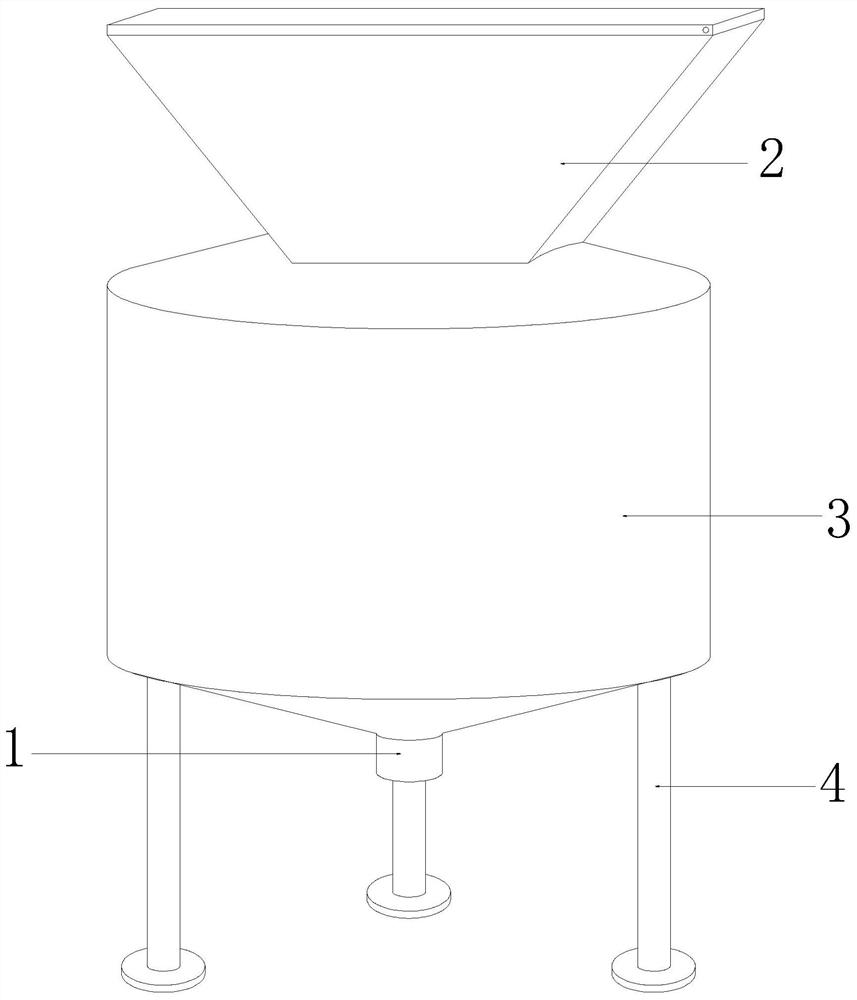

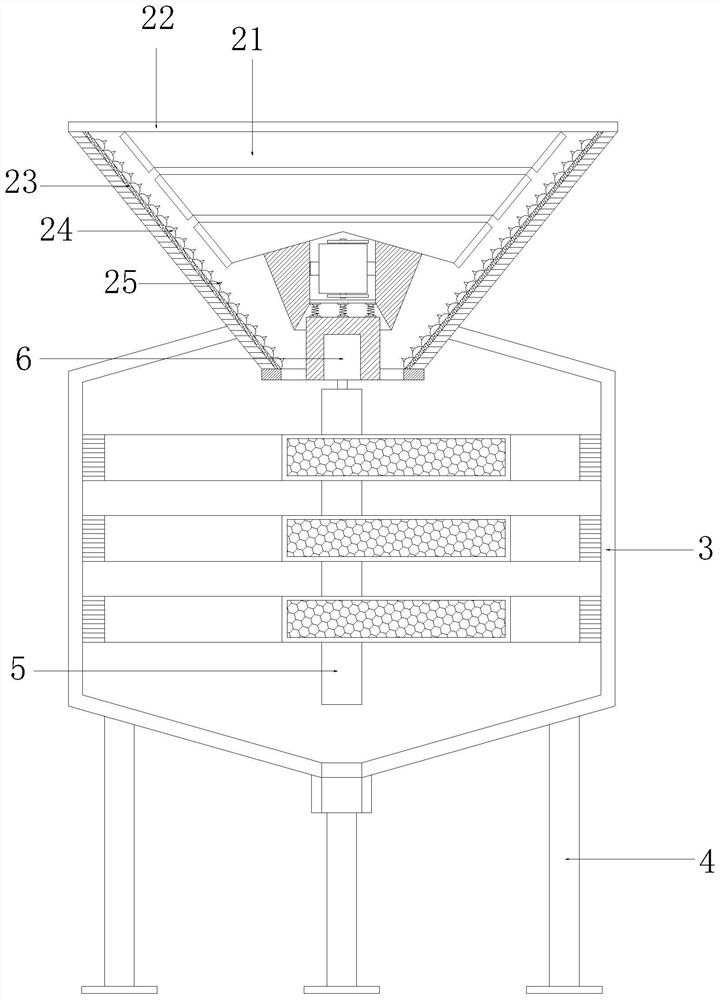

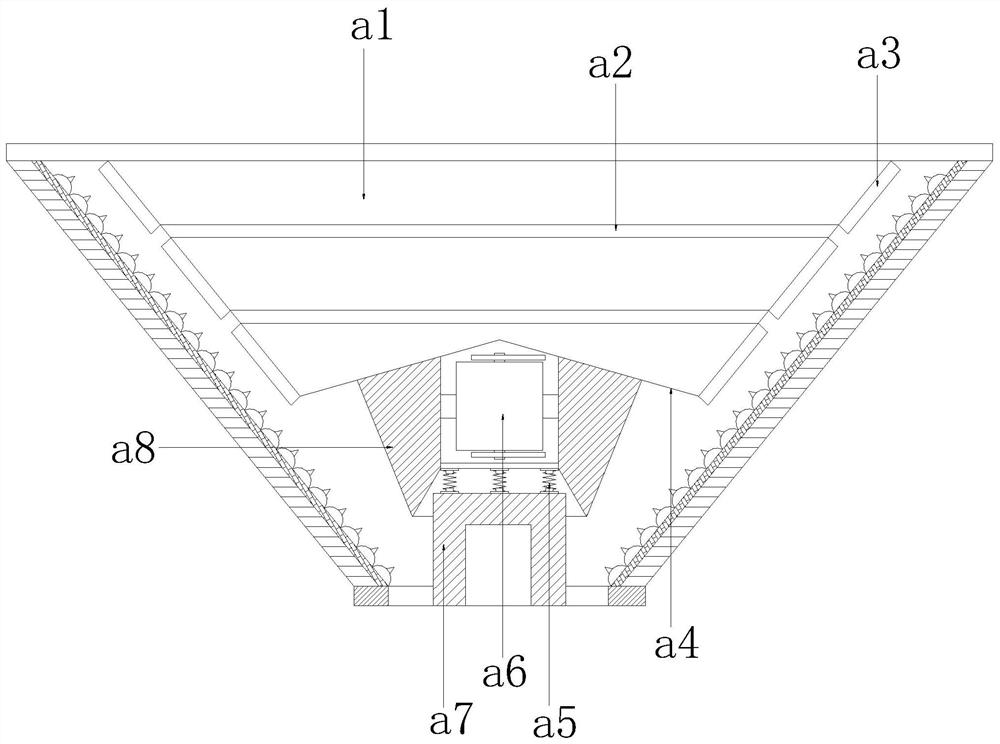

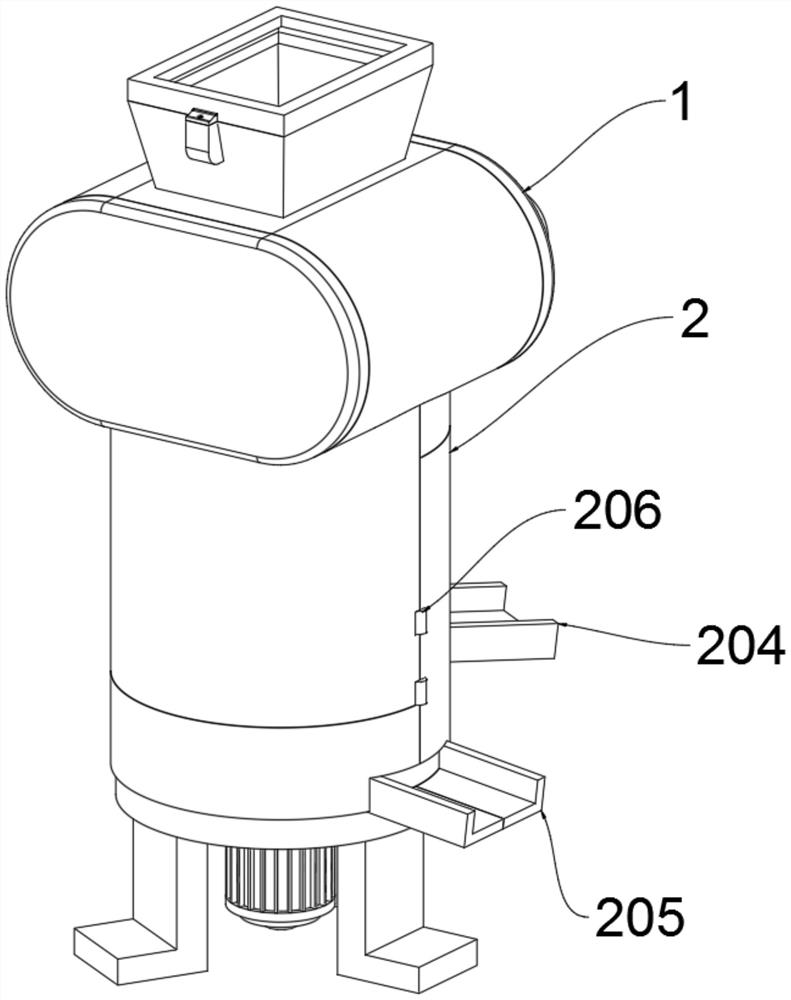

Dolomite particle smashing device with multi-stage smashing function

The invention discloses a dolomite particle smashing device with a multi-stage smashing function. The dolomite particle smashing device with the multi-stage smashing function comprises a shell, the upper end of the shell is provided with a feeding barrel which inclines towards the lower left portion, the surface of the lower side of the feeding barrel is provided with a filter screen, and the outer side of the filter screen is provided with an outer box body which is connected with the feeding barrel into a whole; and a first discharging pipe is connected to the bottom end of the outer box body. The dolomite particle smashing device is simple in structure and convenient to use, small-size ore can be collected at first without being smashed, then, large-size dolomite is subjected to multi-stage smashing, a collecting device is arranged after each stage of smashing, the smashing efficiency is high, and the smashing effect is good; by designing a second smashing device and a third smashing device, dolomite particles smashed by a first smashing device and a second smashing device are divided into two parts and smashed in the second smashing device and the third smashing device,, the dolomite particles are prevented from excessive smashing and unthorough smashing, and thus, the smashing efficiency is greatly improved.

Owner:巢湖云海镁业有限公司

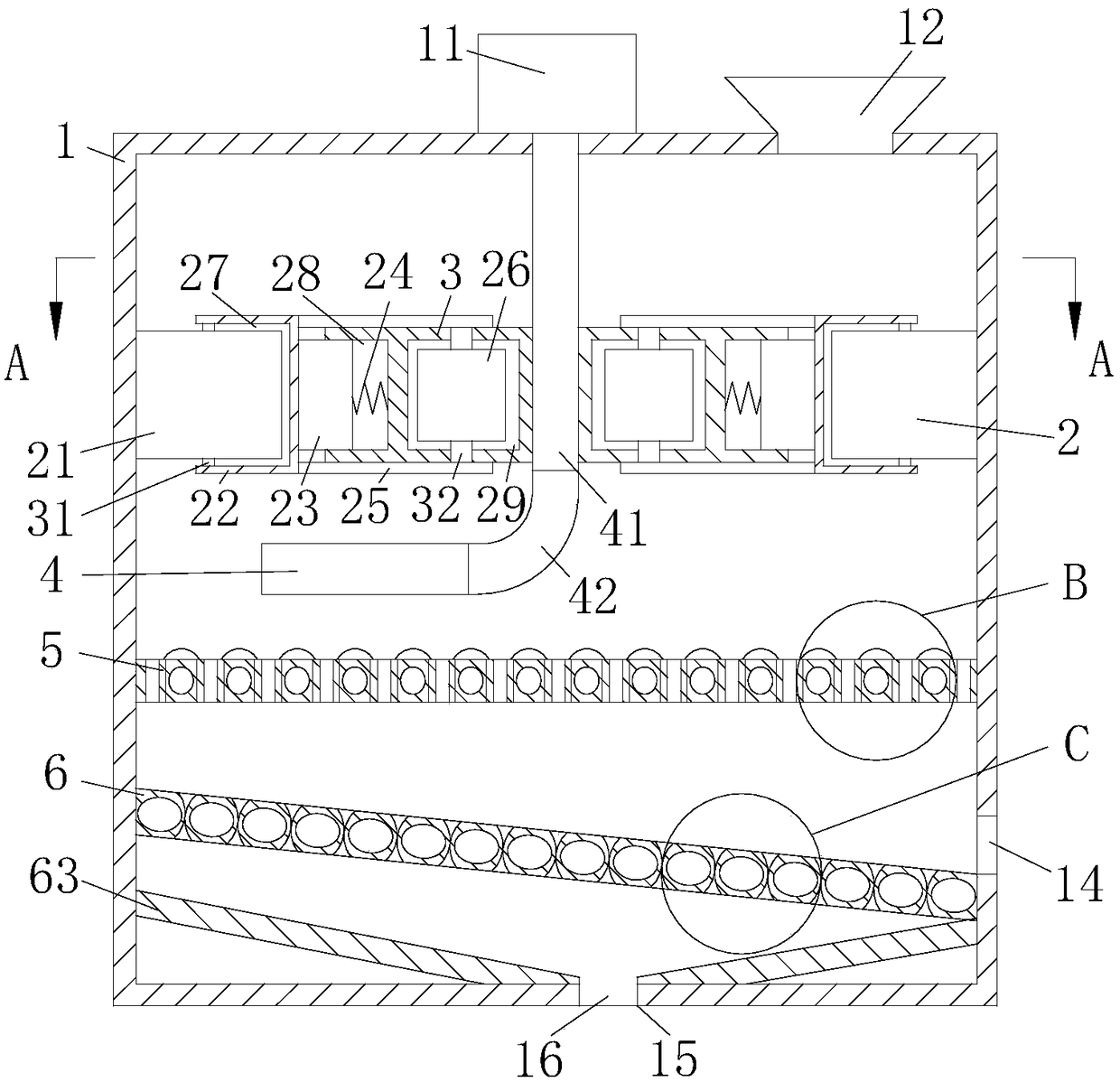

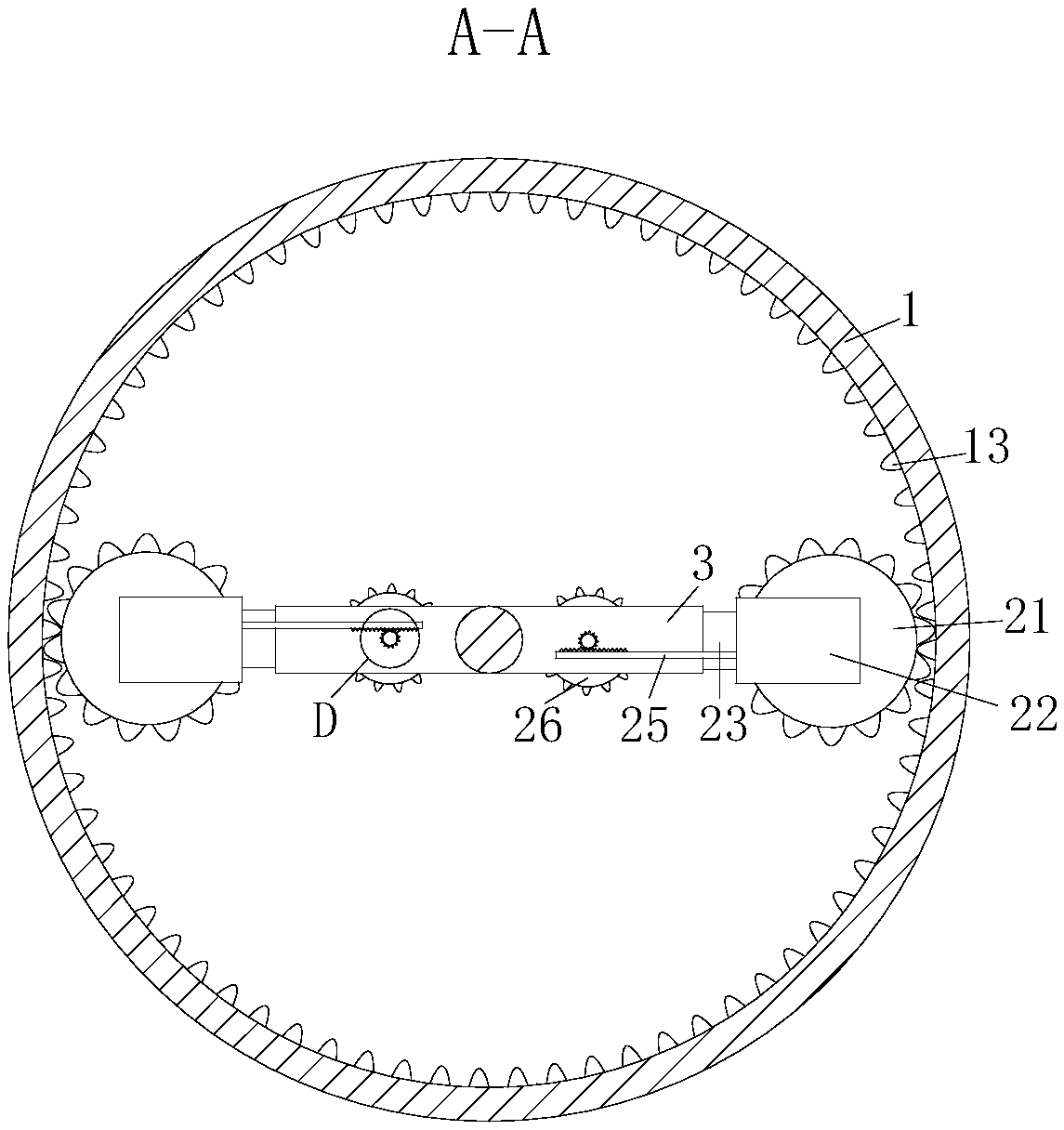

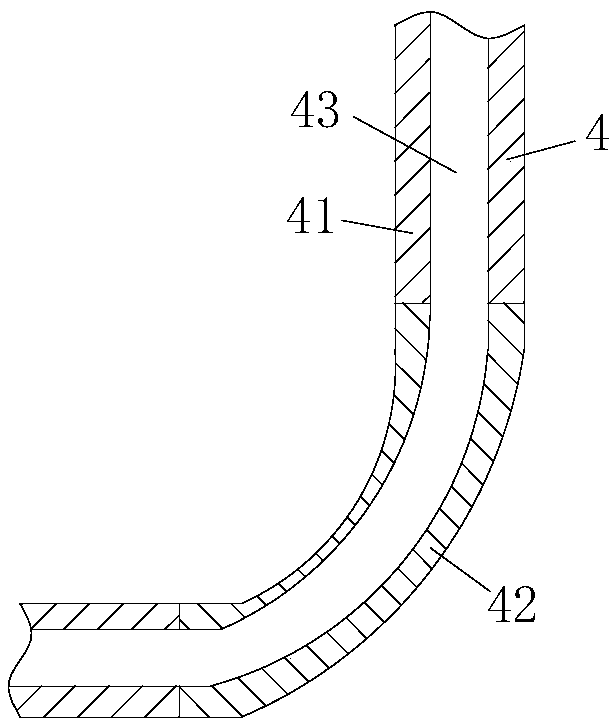

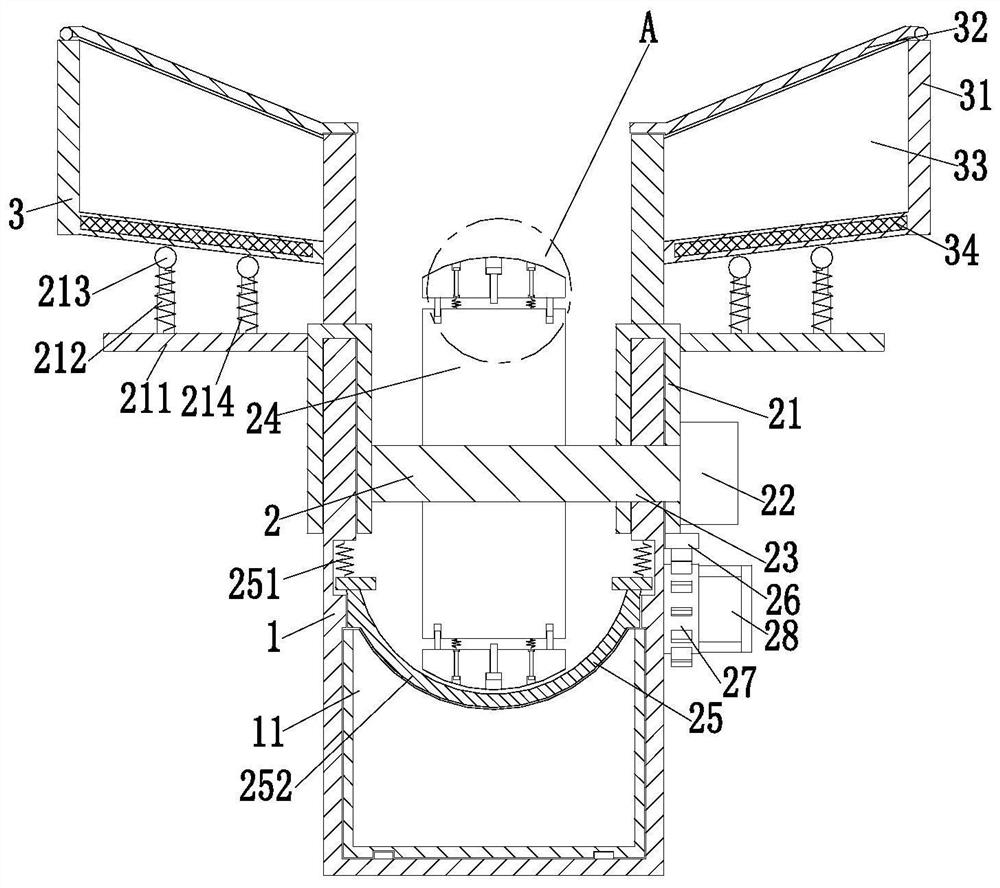

Building material processing and screening device

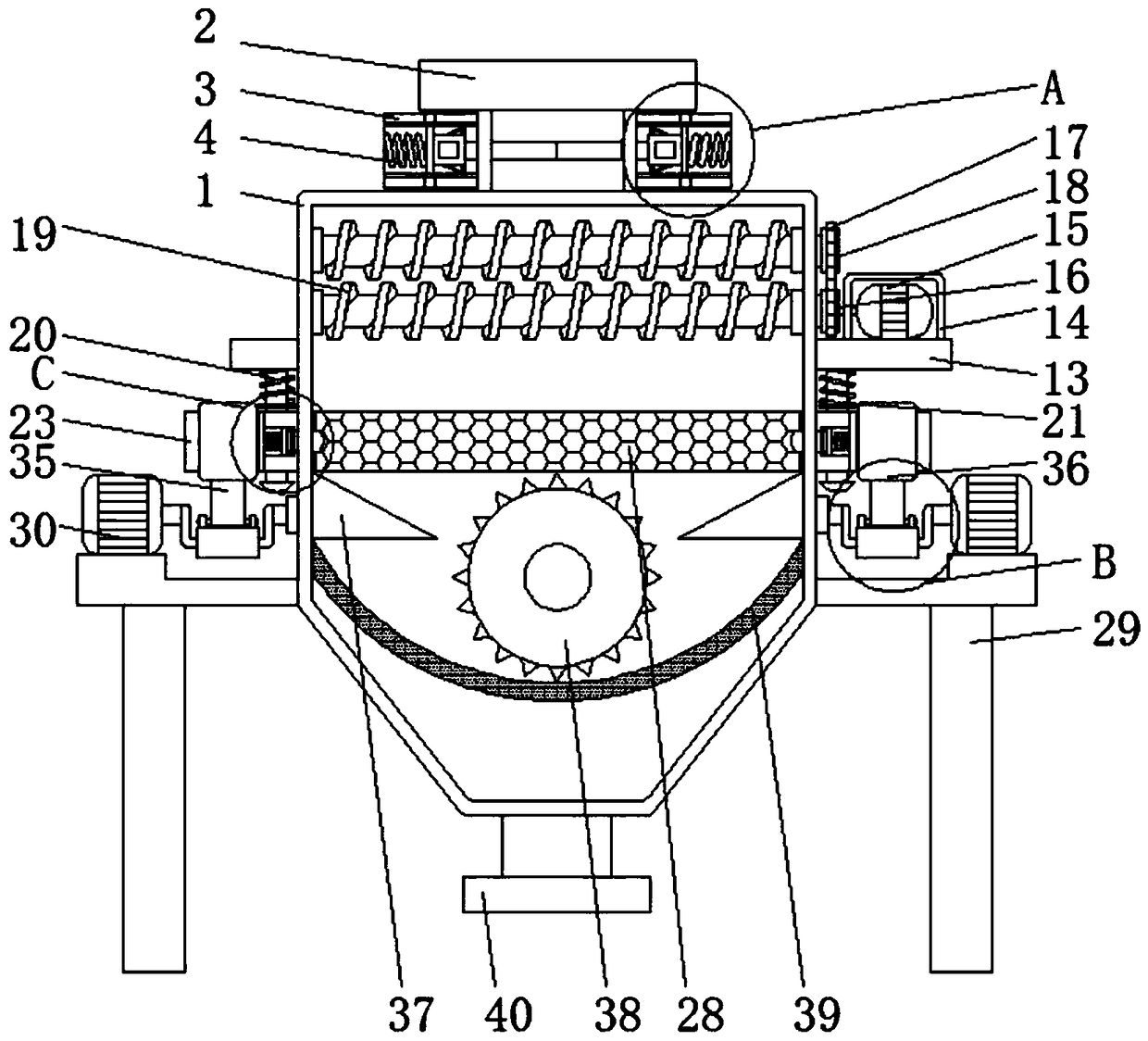

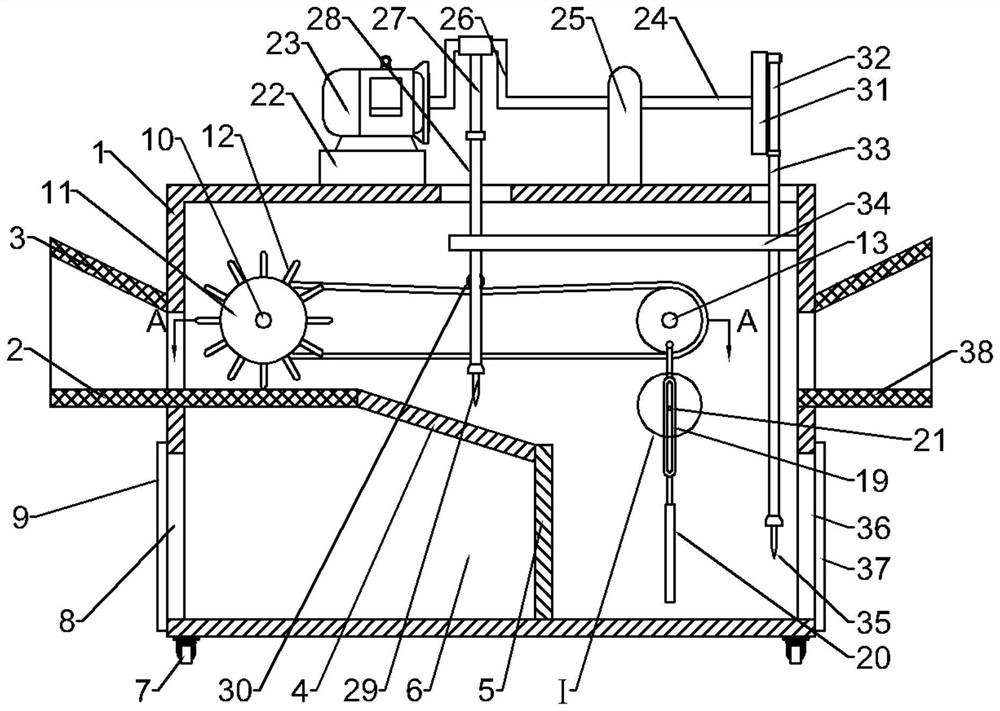

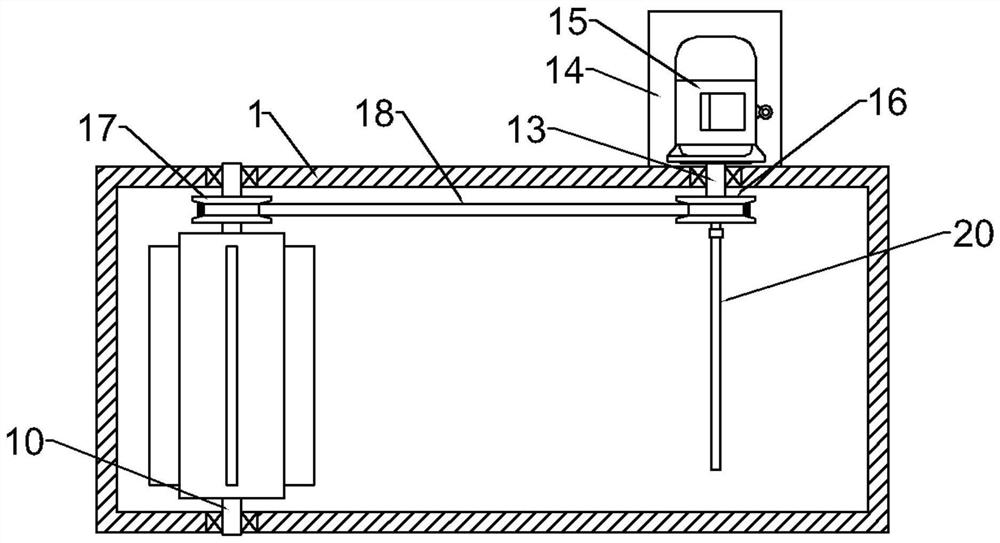

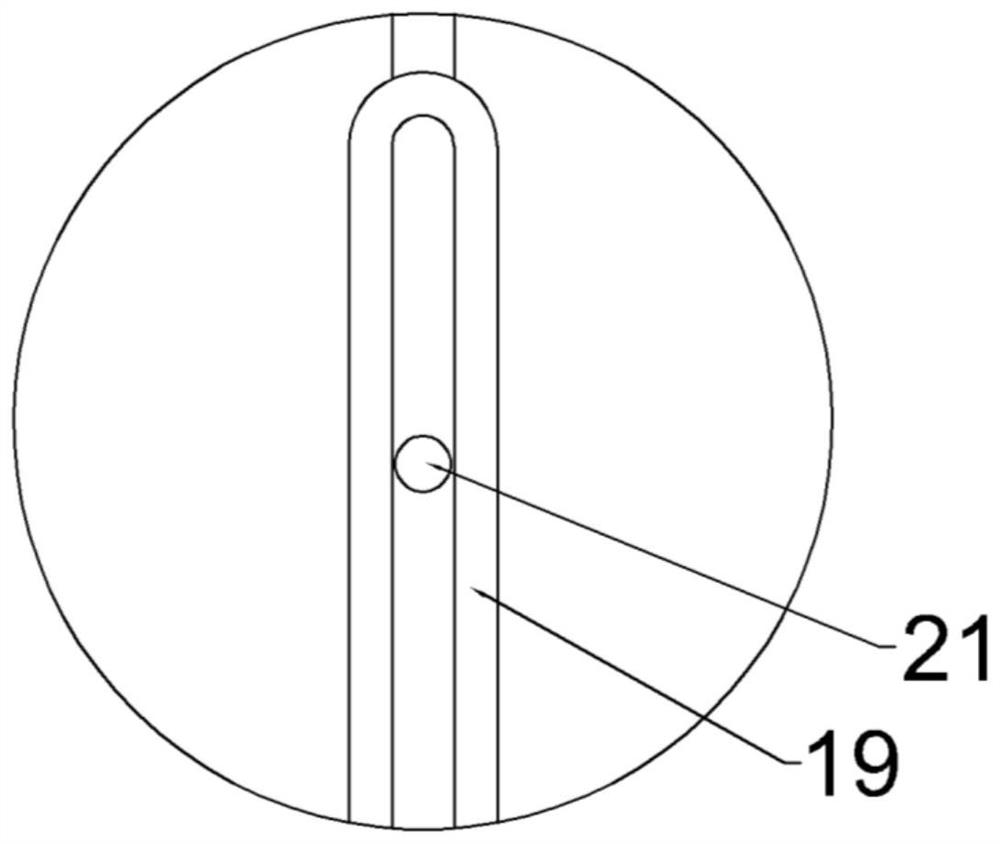

ActiveCN109317258AAvoid incomplete crushingCrushed fullySievingScreeningBuilding materialEngineering

The invention belongs to the technical field of engineering, and particularly relates to a building material processing and screening device. The building material processing and screening device comprises a frame body, wherein at least two crushing and stirring units are arranged in the frame body; each crushing and stirring unit comprises a crushing gear, a crushing shaft, a sliding rod, a spring, a rack and an auxiliary gear; the lower end of a rotating shaft of a motor is fixedly connected with a stirring rod; the stirring rod is divided into a straight rod and a bent rod; a primary filter plate is arranged below the stirring rod; and a secondary filter plate is arranged below the primary filter plate. Building materials are fully stirred through the crushing and stirring units, at the same time, the building materials are crushed, the stirring effect is enhanced through the stirring rod, the building materials are screened through vibration of the primary filter plate and the secondary filter plate, blockage of the building materials is effectively prevented, meanwhile the screening efficiency is high, and the stirring and crushing role is played in the screening process. Thebuilding material processing and screening device is high in screening efficiency and not prone to damage in the screening process.

Owner:振林建设集团股份有限公司

Drum type feed granulator

The invention discloses a drum type feed granulator which comprises a supporting base. A first motor is fixedly installed on the top of a first motor fixing base. A driving device is connected with one end of a first motor main shaft. An electric heating plate is installed on the inner wall of the supporting base. A drum is arranged at the outlet of a feed machine mixing tank. A square hole is formed in the drum wall of the drum. A press roller is arranged in the drum. A scraper is arranged outside the drum. By means of the drum type feed granulator, pulverized feed in the feed machine mixingtank enters the drum through the outlet and is pressed into the square hole by the press roller, the scraper scrapes down a finished feed product pressed into the square hole, and then processing is completed. The drum type feed granulator is simple in structure and convenient to operate; the feed is processed after being dried, the problem that pulverizing is not thorough is avoided, the pulverized feed is pressed into the square hole by the press roller, forming is rapid, disordering can not easily happen, and the quality of the produced poultry feed is high.

Owner:HAINING IDIOU ANIMAL HEALTH PROD TECH CO LTD

Small household unhusked rice pulverizing equipment

InactiveCN108525755AAvoid incomplete crushingPipe diameter is easy to controlSievingScreeningBiochemical engineering

The invention relates to the technical field of agricultural equipment, and discloses small household unhusked rice pulverizing equipment. The small household unhusked rice pulverizing equipment comprises a pulverizing equipment body, a feeding pipe is fixedly arranged at the top of the pulverizing equipment body, limiting plates are fixedly connected to the side surface of the feeding pipe, compression springs are fixedly connected to the side surfaces of inner cavities of the limiting plates, sliding blocks are fixedly connected to one ends of the compression springs, limiting blocks are fixedly connected to the side surfaces of the sliding blocks, and connecting buckles are fixedly arranged on the two sides of the limiting blocks. According to the small household unhusked rice pulverizing equipment, through the cooperation of the feeding pipe and a quantity control panel, the phenomenon that excessive unhusked rice are not thoroughly pulverized in the pulverizing process of the unhusked rice can be avoided, and meanwhile, the phenomenon that a filter screen is pressed to be bent due to the fact that the unhusked rice is excessive can be avoided; through the cooperation of the compression springs and the sliding blocks, when the quantity control panel is not used, the feeding pipe can be directly plugged, so that dust in the air can be prevented from falling into the pulverizing equipment body; and through the cooperation of limiting rods and retractable springs, the quantity control panel can move to different positions, so that the pipe diameter of the feeding pipe canbe conveniently controlled.

Owner:HUNAN UNIV OF ARTS & SCI

Inoculated log smashing and screening device convenient for discharging

The invention discloses an inoculated log smashing and screening device convenient for discharging and relates to the technical field of inoculated log smashing and screening devices. The inoculated log smashing and screening device convenient for discharging comprises an outer frame, wherein a first motor is fixedly connected with the left side of the inner wall of the outer frame, one end of anoutput shaft of the first motor is fixedly connected with a first gear, a second gear is meshed with the bottom of the first gear, a lead screw runs through the axis of the second gear, the two ends of the lead screw are respectively rotatably connected with the two sides of the inner wall of the outer frame, the surface of the lead screw is connected with a movable block by virtue of a screw thread, the top of the movable block is fixedly connected with a discharging frame, the bottom of the discharging frame is fixedly connected with a supporting rod, and the bottom end of the supporting rodis slidably connected with the bottom of the inner wall of the outer frame. The inoculated log smashing and screening device convenient for discharging achieves the aim of uniformly smashing inoculated log, working efficiency is improved, time waste is reduced, load of a worker is alleviated, incomplete smashing of inoculated log is prevented, smashing effect is improved, use of the inoculated log in later period is guaranteed, people can use conveniently, and practicability of the inoculated log smashing and screening device is improved.

Owner:安徽上造智能设备科技有限公司

Medicinal material grinding equipment for daily life

PendingCN112473965AReduce manual labor intensityEasy to operateGrain treatmentsDaily livingMedicinal herbs

The invention discloses medicinal material grinding equipment for daily life. The medicinal material grinding equipment for daily life comprises a mounting base, wherein a plurality of supporting legsare evenly mounted at the bottom end of the mounting base; a top plate is detachably mounted at the top end of the mounting base; a rotating rod is rotatably mounted on the top wall of the top plate;the bottom end of the rotating rod penetrates through the top plate and extends to the lower side of the top plate; a grinding block is fixedly mounted at the bottom end of the rotating rod; the grinding block is inserted into the mounting base; a grinding groove matched with the grinding block is formed in the mounting base; the bottom end of the grinding groove extends to the lower side of themounting base; and the outer side wall of the bottom end of the grinding block and the inner side wall of the bottom end of the grinding groove are obliquely arranged. According to the medicinal material grinding equipment for daily life provided by the invention, a driving motor drives the grinding block to rotate so as to grind and crush medicinal materials, and a gap between the grinding blockand the grinding groove is gradually reduced from top to bottom, so that only the completely ground and crushed medicinal materials can flow out of the bottom end of the grinding groove, the convenience in operation is realized, the labor intensity of workers is low, the occurrence of the phenomenon of incomplete crushing can be avoided, the design is reasonable and the practical effect is good.

Owner:刘士云

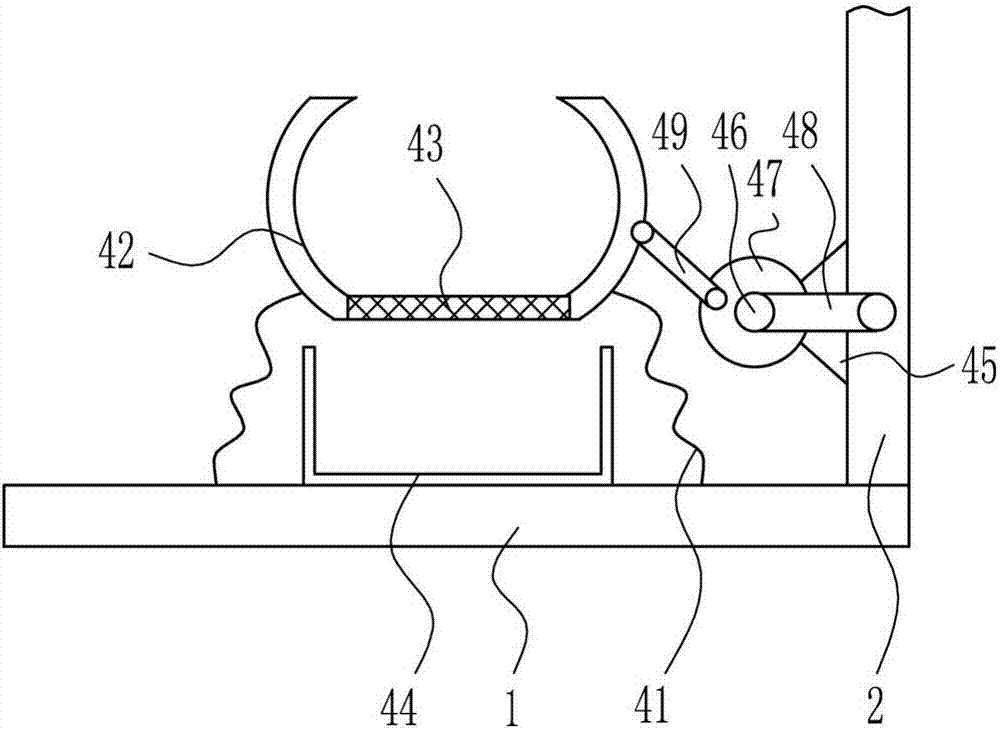

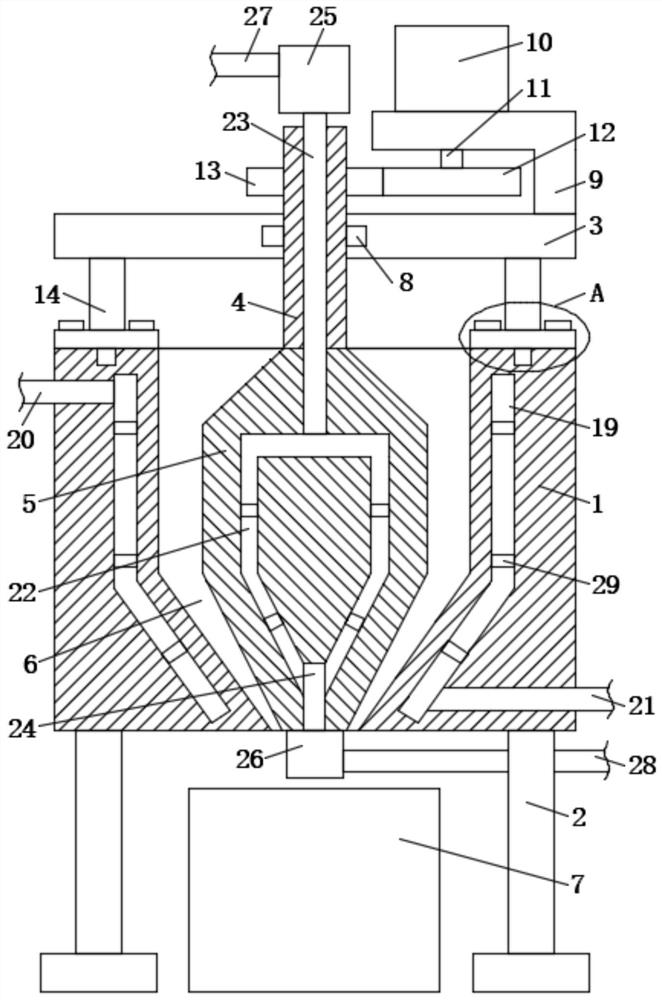

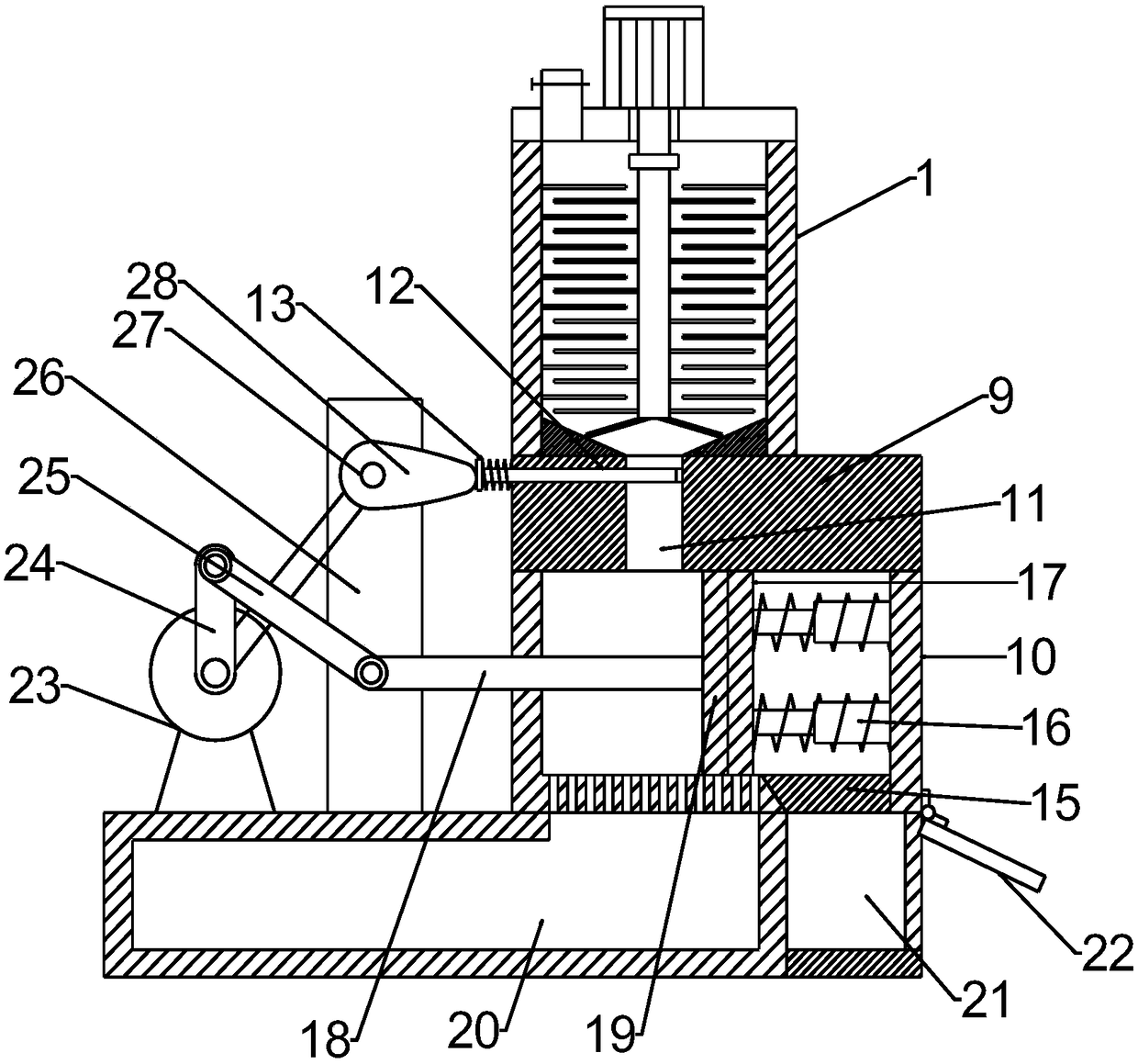

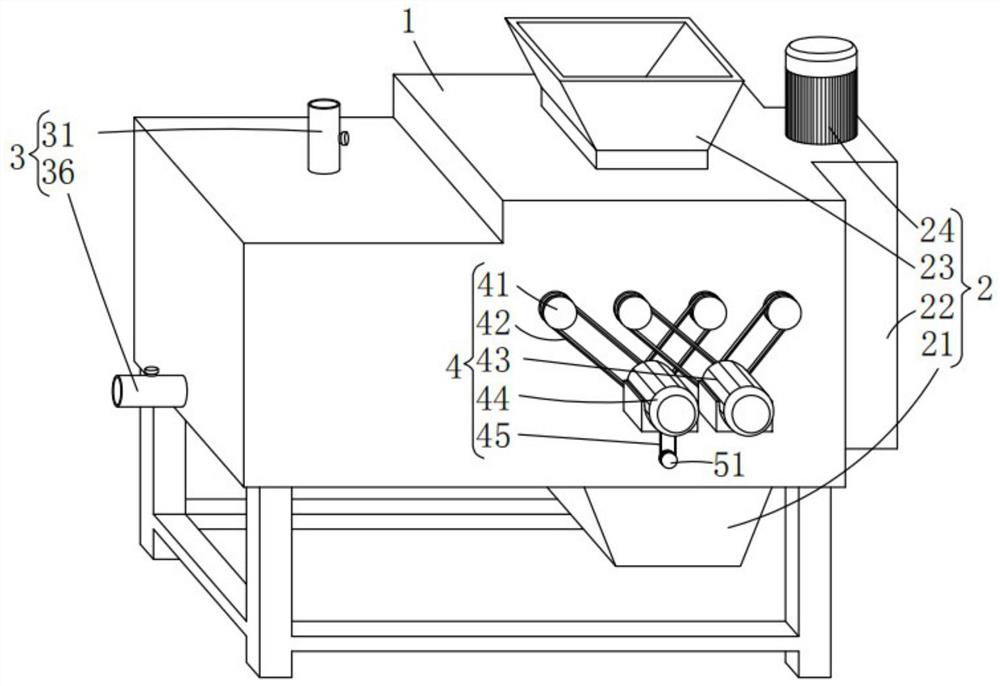

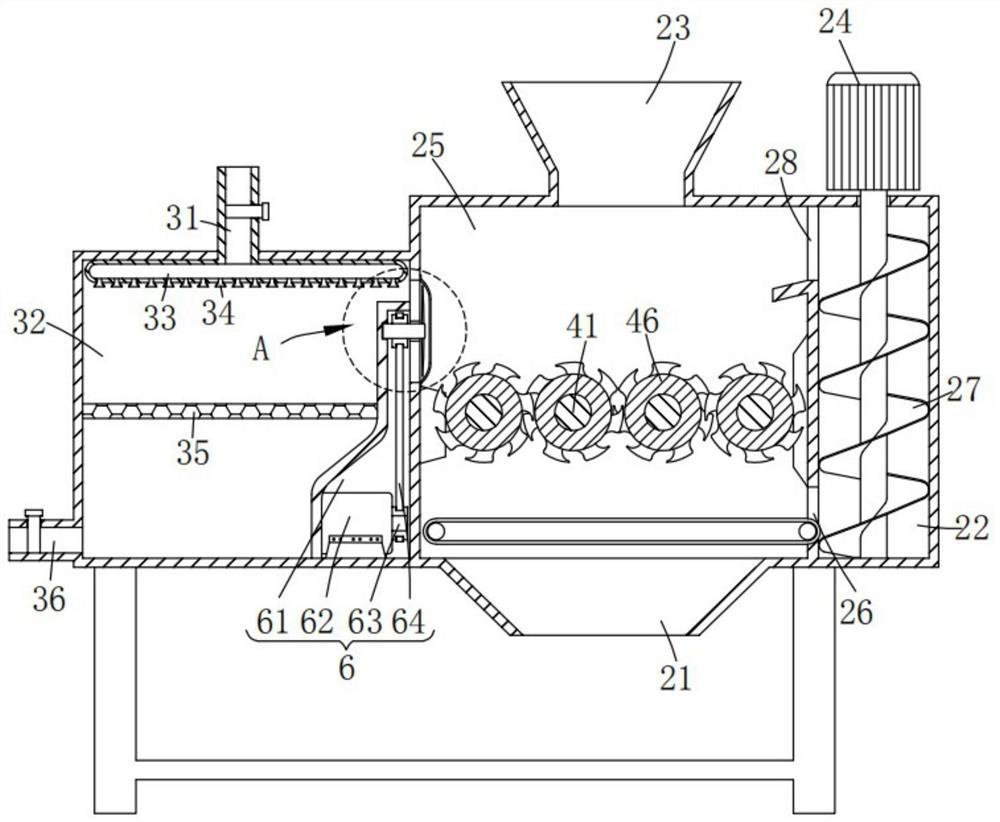

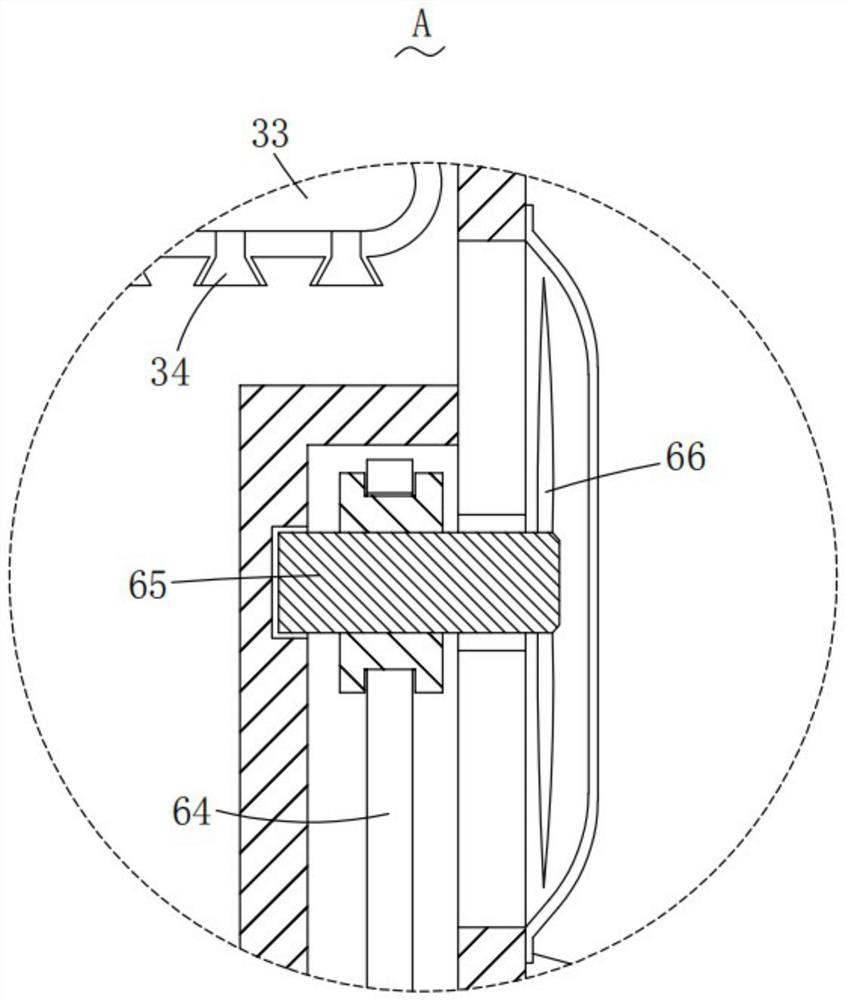

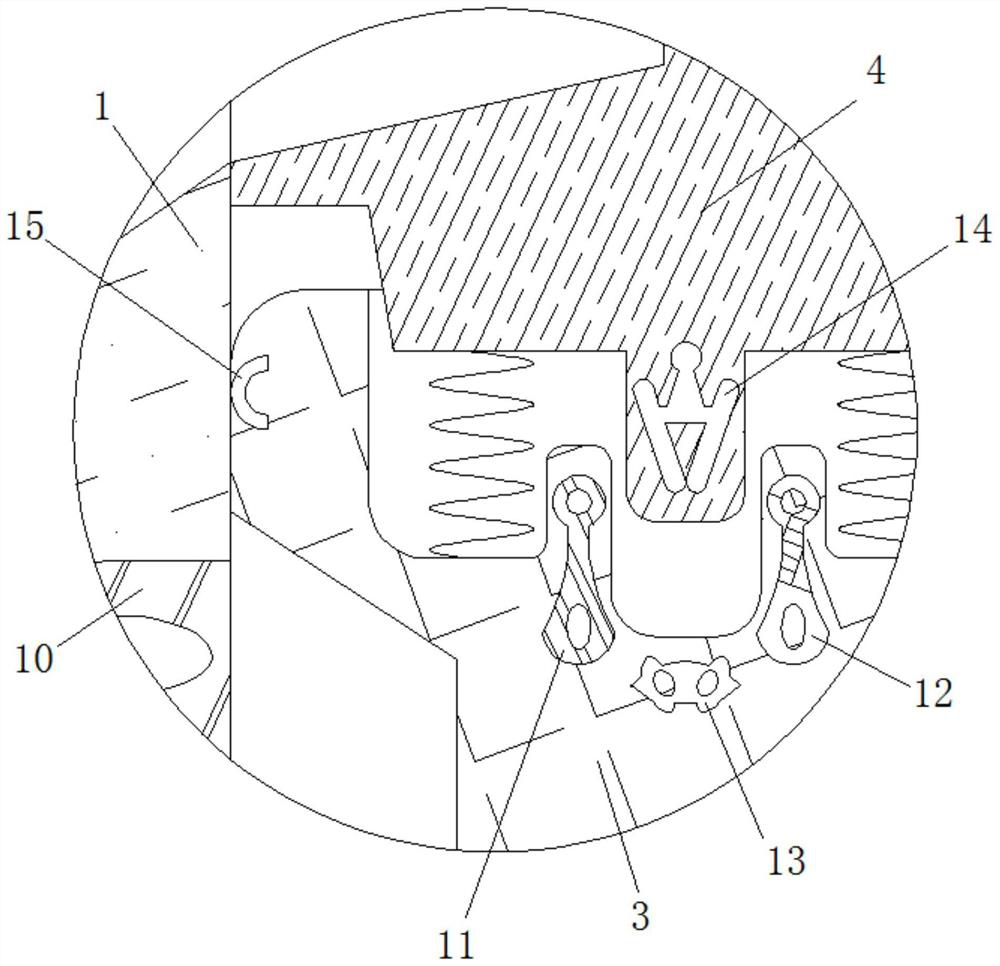

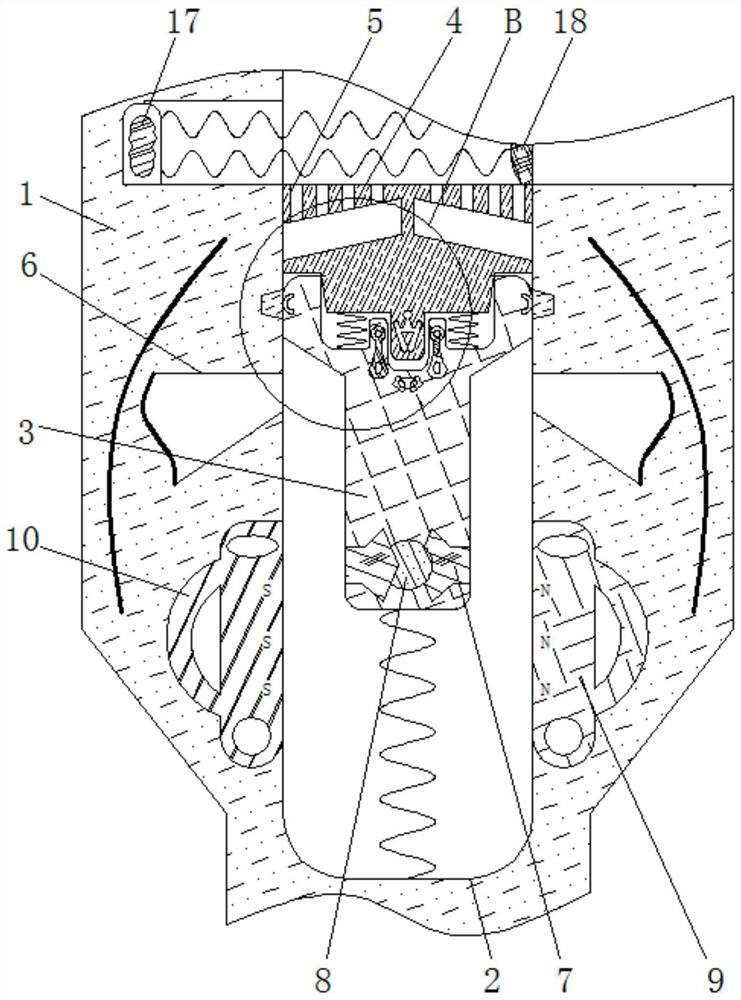

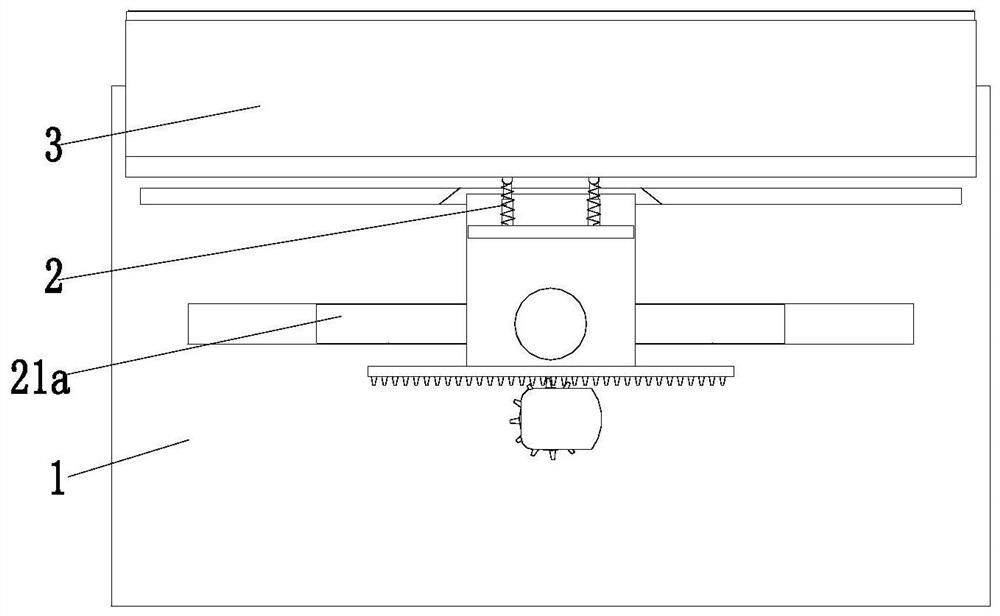

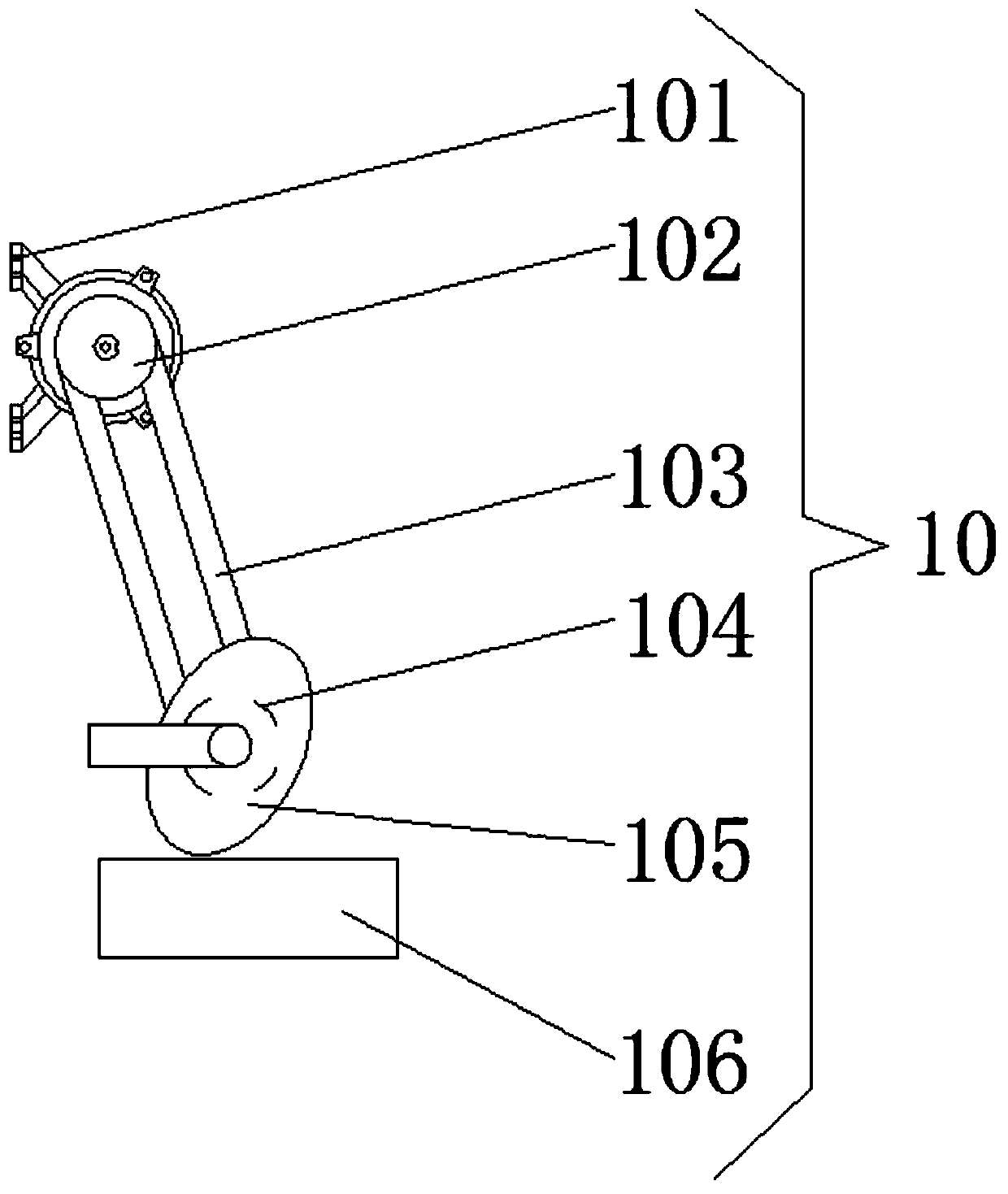

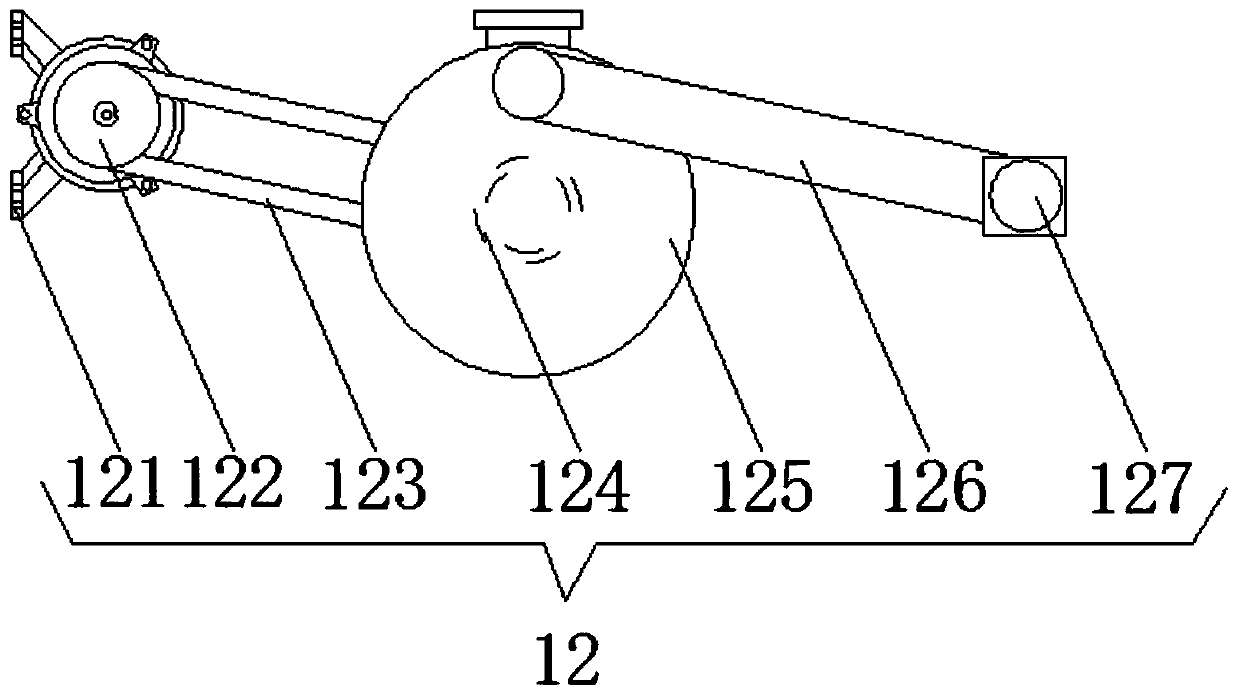

A raw material cleaning and crushing device for biomass pellet fuel

InactiveCN106914318BAvoid incomplete crushingEfficient crushingGrain treatmentsPressesCamPellet fuel

Owner:广西众新环保科技有限公司

Grinding device for grain dryer

InactiveCN109092464AEasy to crush for the first timeEasy for secondary crushingGrain treatmentsEngineeringGrinding wheel

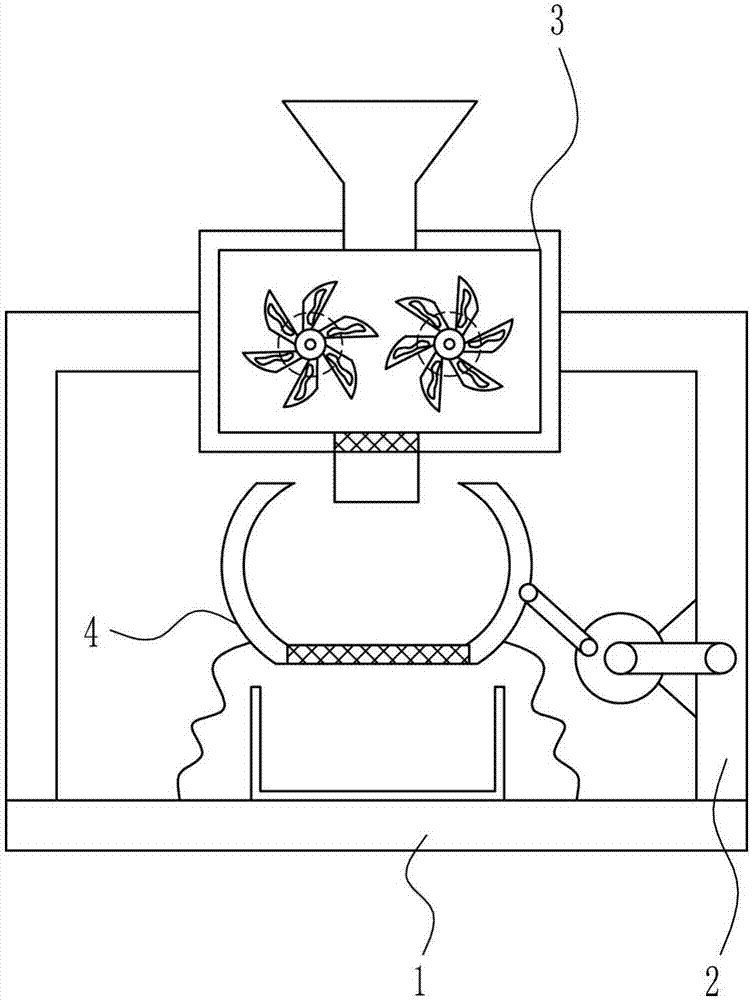

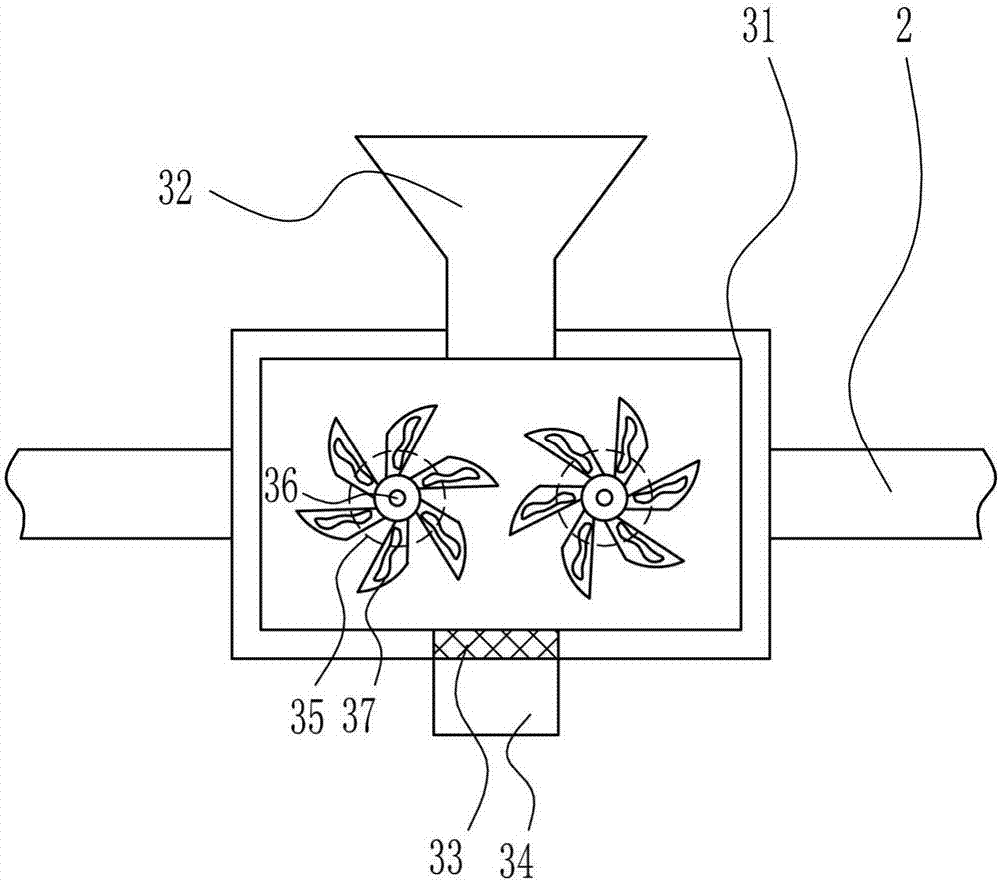

The invention discloses a grinding device for a grain dryer. The grinding device comprises bases, a box body and placing boxes. A feeding funnel is fixedly installed at the intermediate position of the top of the box body, and a screen cloth is fixedly installed in the feeding funnel. The placing boxes are fixedly mounted at the top ends, on both sides of the feeding funnel, of the box body, and first motors are fixedly mounted in the placing boxes. Primary grinding mechanisms are fixedly mounted at the output ends of the first motors, and bearing seats are correspondingly and fixedly mountedon both sides in the box body. Grinding wheels are fixedly mounted between the bearing seats, and filter mechanisms are fixedly mounted at the positions, at the bottom ends of the bearing seats, in the box body. A valve is movably mounted at the intermediate position of the bottom end of the box body, and the bases are correspondingly and fixedly mounted at the bottom ends, on both sides of the valve, of the box body. A supply hub is fixedly arranged on the surface of the box body. The grinding device has the advantages of filtering impurities and grinding thoroughly by arranging a series of structures.

Owner:ANHUI SUNMIRO AGRI TECH

Multi-dimensional crushing device for solid wastes

PendingCN110756278ARealize crushing workPrevent extrusionGrain treatmentsDrive wheelElectric machinery

The invention discloses a multi-dimensional crushing device for solid wastes. The device comprises a bottom box and a top box; the top box is arranged at the top of the bottom box; the bottom box communicates with the internal of the top box; a motor is arranged on one side of the bottom box; a driving wheel is arranged at one end of the motor; an output end of the motor is in transmission connection with the driving wheel; a first fixed nut is rotated; due to the effect of elastic force of a compression spring, a first return rod pushes a first clamp to rotate along a first rotating rod, andthe bottom end of the first clamp is adjusted to control the distance from a crushing block to a movable block; the crushing block is matched with the movable block to form an engagement effect to achieve a crushing effect on small-particle solid wastes; the distance from the first clamp to a crushing wheel is increased to achieve the crushing effect on solid wastes with different particle sizes,so that the primarily crushed wastes are crushed again; and through dual crushing, the phenomenon of halfway crushing by traditional machinery is prevented.

Owner:耿言华

Environment-friendly solid waste treatment and recovery device

InactiveCN112474729AAvoid incomplete crushingHarm reductionSievingWaste processingElectric machineDust control

The invention provides an environment-friendly solid waste treatment and recovery device. The environment-friendly solid waste treatment and recovery device comprises a working box, an ascending structure, a dust falling structure, a crushing structure, a screening and picking structure and a wind power structure, wherein the ascending structure is installed on the side wall of the working box, and the ascending structure comprises a discharging hopper, a lifting box, a feeding hopper, a first motor, a crushing chamber, a feeding port, a lifting fan and a discharging port; the dust falling structure is installed in the working box, and the dust falling structure comprises a water inlet pipe, a dust falling chamber, a distribution pipe, a spray head and a water outlet pipe; the crushing structure comprises a first wheel disc, a first belt, a second motor, a third motor, a second belt and a crushing cutter wheel; the screening and picking structure is mounted in the crushing chamber andcomprises a second wheel disc, a third wheel disc, a third belt, a screening and picking net and rolling wheels; and the wind power structure. The environment-friendly solid waste treatment and recovery device provided by the invention has the advantages of thorough crushing and dust removal.

Owner:CHANGDE JINYUAN BOILER MFG

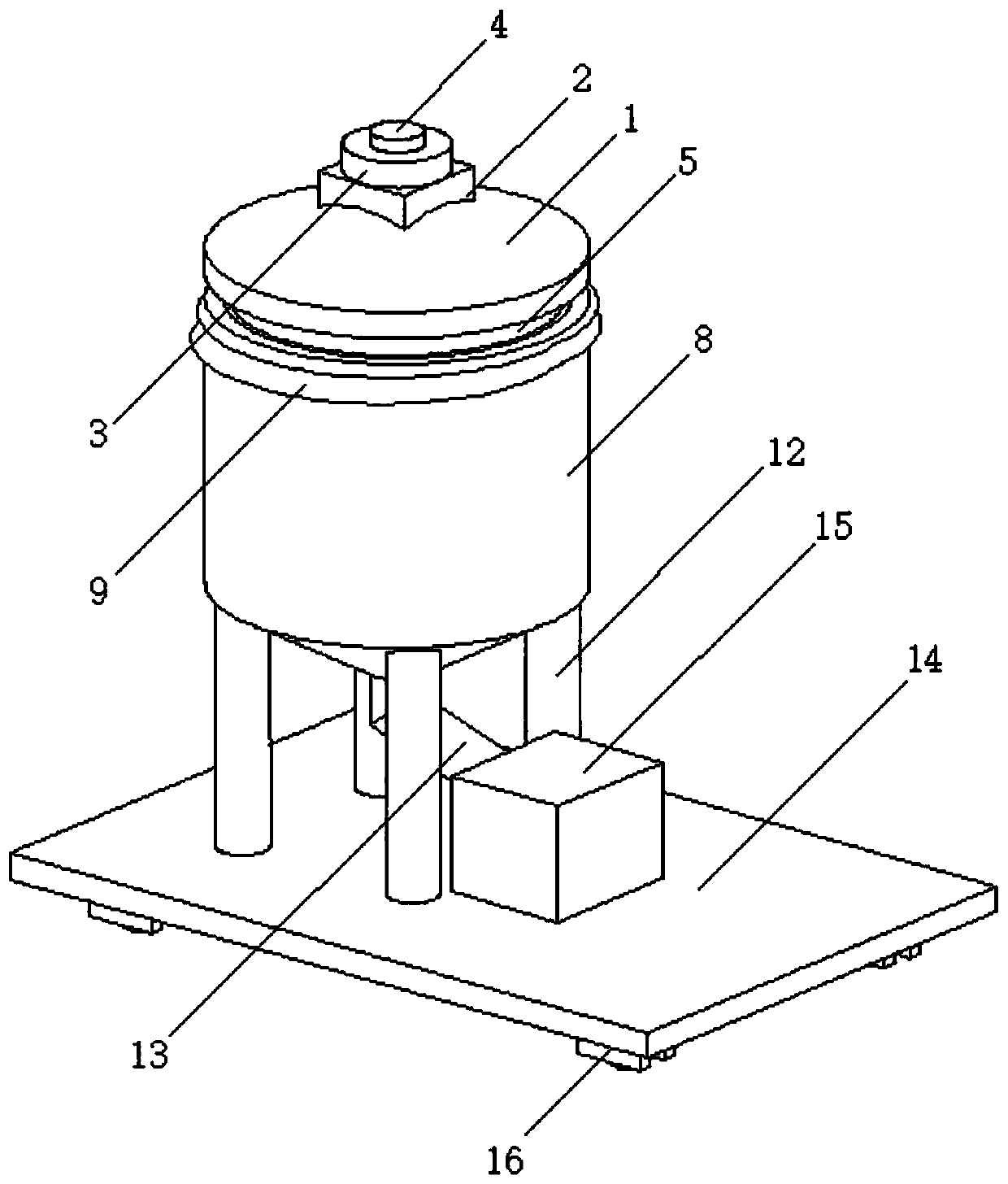

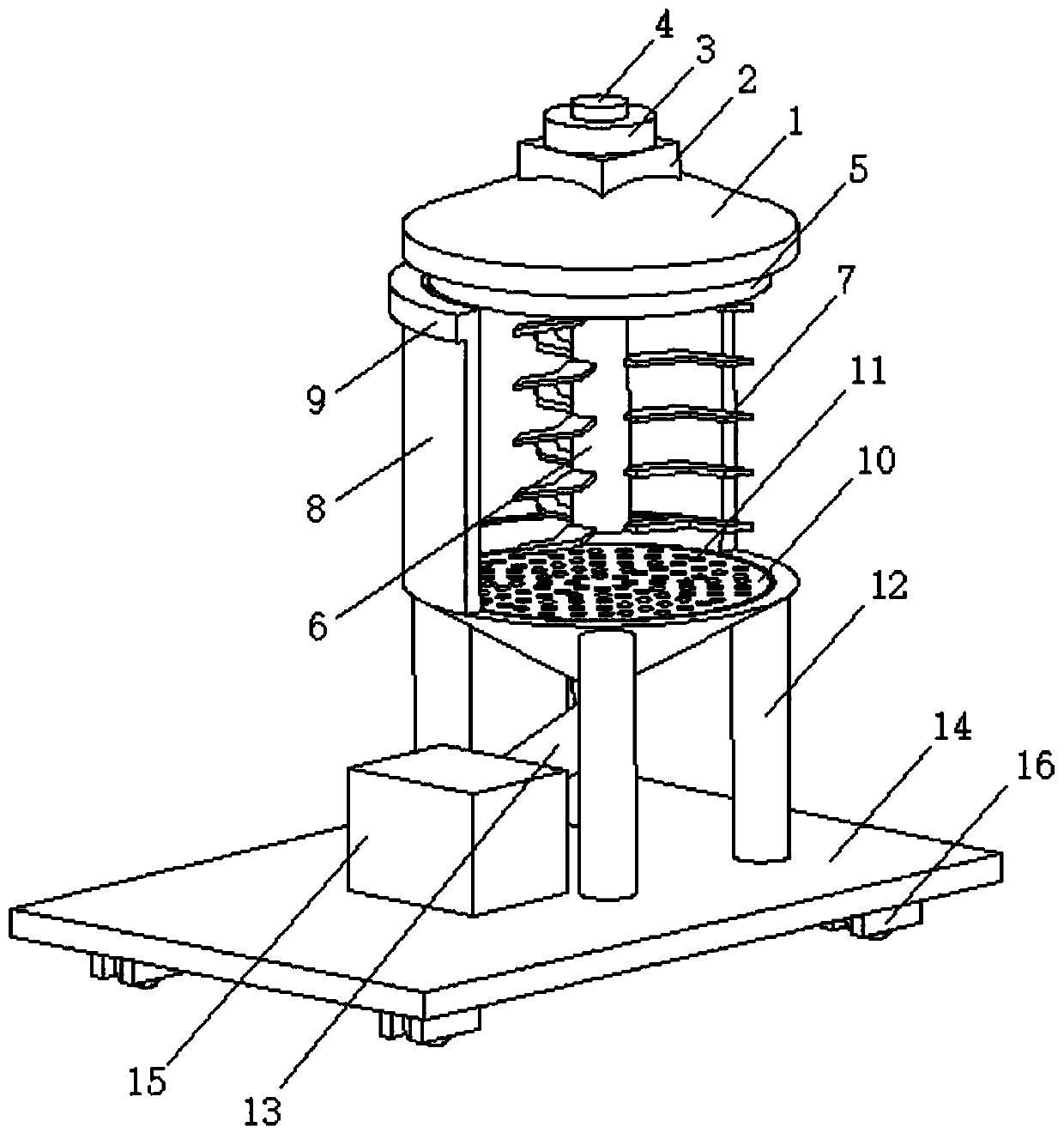

Preparation method of gingiva-protecting and whitening toothpaste

InactiveCN112354582AAvoid incomplete crushingReduce workloadCleaning using toolsFiltration separationWater filterToothpaste

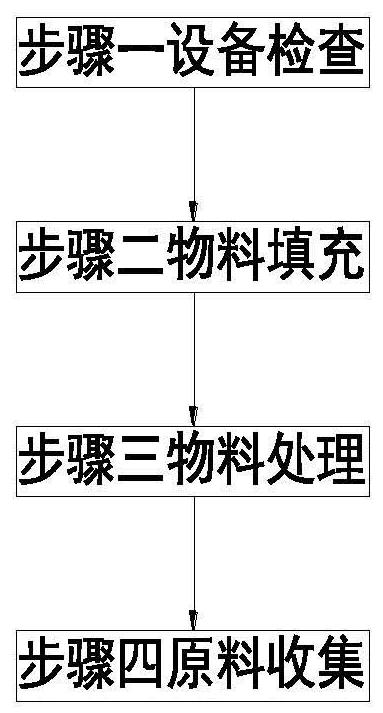

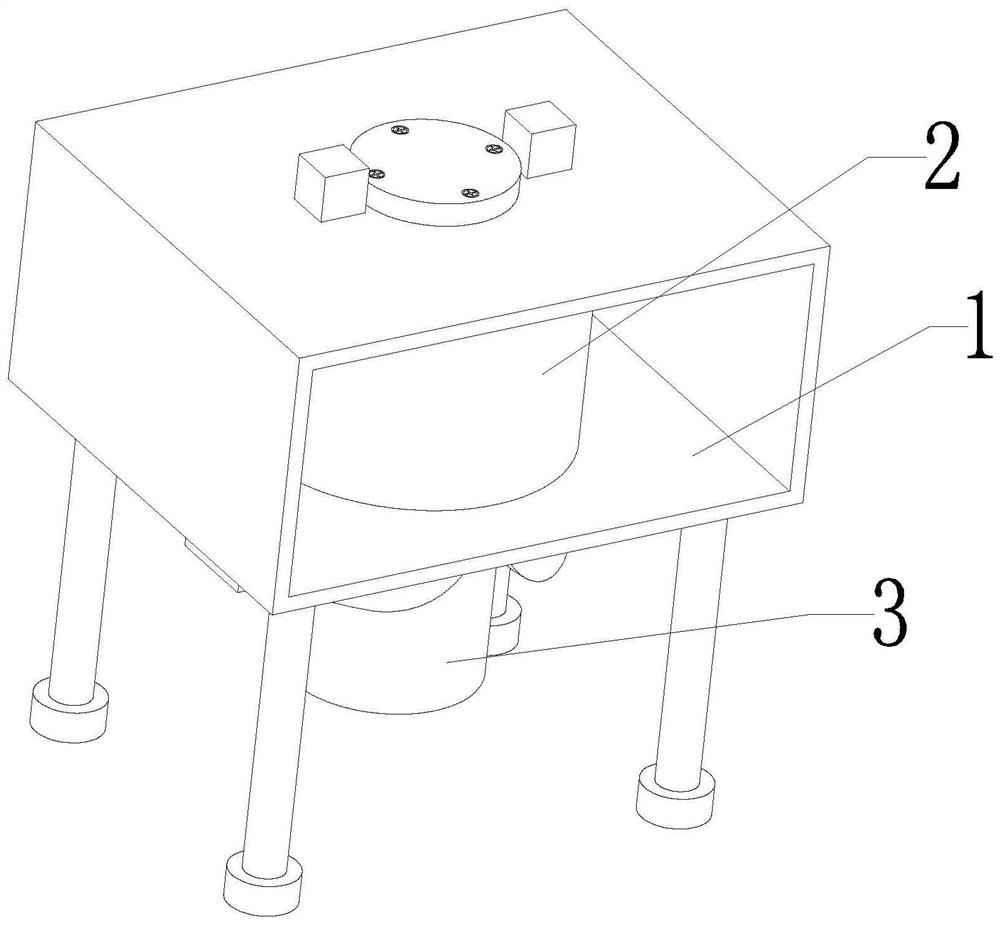

The invention relates to a preparation method of a gingiva-protecting and whitening toothpaste. The preparation method mainly comprises the following steps: equipment inspection, material filling, material treatment and raw material collection. Toothpaste raw material grinding and stirring equipment comprises a mounting frame, a grinding kit and a water filtering kit, wherein the grinding kit is mounted on the mounting frame, the water filtering kit is arranged at the lower end of the grinding kit, and the water filtering kit is mounted on the lower end face of the mounting frame. The preparation method can solve the following problems existing in the production process of an existing toothpaste friction agent: a, when an existing toothpaste friction agent is crushed, the situation that toothpaste friction agent raw materials are not completely crushed often occurs, and generated friction agent powder still contains large particles, and manual secondary inspection is needed, so that manpower is greatly wasted; and b, when the existing toothpaste friction agent is crushed, friction agent powder often adheres to the inner wall of reaction equipment, and manual cleaning is difficult,so that the situation of material waste and raw material waste are easily caused.

Owner:南京科艺通化工科技有限公司

Medical chemical pharmaceutical mixer

InactiveCN113813854AAvoid uneven mixingFast and fast processingRotary stirring mixersMixer accessoriesEngineeringSilica gel

The invention discloses a medical chemical pharmaceutical mixer which structurally comprises a discharge valve, a smashing device, a mixing cylinder, a supporting column, a mixing and stirring device and a motor, the smashing device is installed at the top of the mixing cylinder, and the discharge valve is fixed to the center of the bottom of the mixing cylinder.The vibration motor drives a vibration box to vibrate, so that materials are pushed to the thorns, the materials are pricked and crushed, non-uniform mixing of solid materials due to the difference of specific gravity density and particle volume is avoided, the materials are stirred in multiple directions through stirring blades and cutting blades, the materials are mixed and stirred more uniformly, the stirring blades are provided with silica gel brushes, the inner wall of the mixing barrel can be cleaned, the materials are prevented from being left on the barrel wall, the cutting mesh holes of the cutting blades are provided with blades which can cut the materials for the second time, so that the phenomenon that the crushing device does not crush the materials completely is avoided, and the materials are mixed and stirred to be finer and smoother.

Owner:李平

Production technology for suckling pig feed

InactiveCN104799098APromote digestion and absorptionIncrease profitAnimal feeding stuffBiotechnologyAnimal science

The invention relates to the field of livestock breeding, in particular to a production technology for a suckling pig feed. The production technology comprises the following steps: A, performing expanding treatment on 4 percent of oil, 71 percent of corns, 16 percent of soybean meal and 9 percent of broken rice to obtain an expanded mixture; B, granulating 4.5 percent of fish meal, 5 percent of white sugar, 13.2 percent of a suckling pig premix and 77.3 percent of the expanded mixture to obtain a small-granule semifinished product of 40 meshes; C, smashing part of the small-granule semifinished product into powder of 120 meshes; D, mixing vitamins and probiotics according to the weight ratio of 1: 1 to prepare an additive; E, mixing and granulating 30.7 percent of the small-granule semifinished product, 30.7 percent of the powder, 8.6 percent of milk powder, 5 percent of glucose, 2 percent of the additive, 3 percent of plasma protein powder, 4 percent of goldbeater's skin and 16 percent of flour. The suckling pig feed is favorable for digestion and absorption of suckling pigs, and the feed utilization rate is increased. The nutrition is balanced, and the formula is strict and scientific; furthermore, the feed is extremely high in expanding speed, and a novel technology is realized.

Owner:QUJING DAXING FEED

Raw material crushing mechanism for producing polyferric sulfates and working method thereof

InactiveCN112275363AAvoid wastingNo leakageSolid materialGrain treatmentsIron sulfateMechanical engineering

The invention discloses a raw material crushing mechanism for producing polyferric sulfates and a working method thereof. The crushing mechanism comprises a shell, wherein a feeding mechanism is fixedly connected to the position, close to the left side, of the upper end of the shell; the feeding mechanism comprises a feeding port; the bottom end of the feeding port is fixedly connected with four groups of first baffles; the first baffles are movably connected with crushing wheels through rotating shafts; the position, close to the upper side, of the inner wall of the left end of the shell is movably connected with a first rotating shaft; the first rotating shaft is movably connected with a first receiving disc; and the inner wall of the upper end of the shell is fixedly connected with twogroups of second telescopic rods. According to the raw material crushing mechanism, crushed raw materials are loaded into packaging bags through a steel pipe, the edges of the packaging bags are placed at a circular groove of an iron ring, and a bag pressing ring automatically lowers, so that the packaging bags are fixed, the situation that the raw materials in the packaging bags cannot leak out in the loading process is guaranteed, consequently, direct contact with people is avoided, safety of people is guaranteed, and waste of the raw materials is avoided.

Owner:马鞍山健鼎化工有限公司

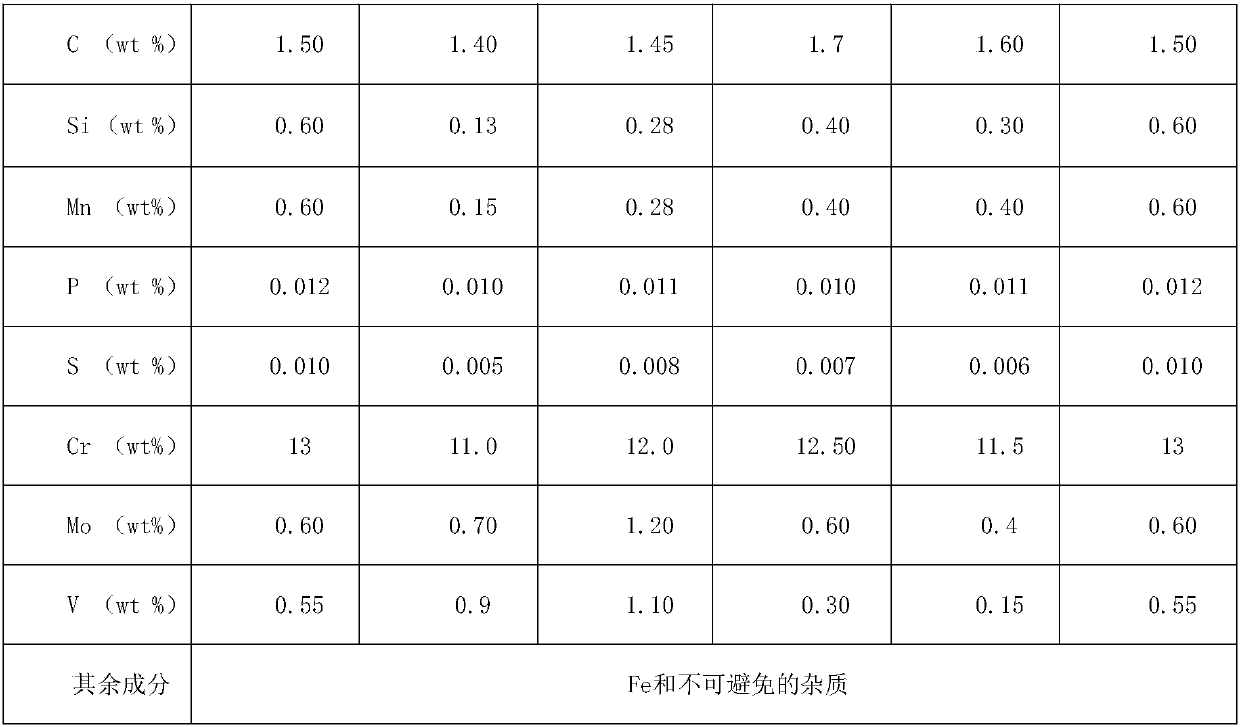

Quenching method for large-specification working roller of high-alloy cold-work die steel

ActiveCN107760849AHigh surface hardnessHigh heart toughnessFurnace typesIncreasing energy efficiencyAlloyHardness

The invention discloses a quenching method for a large-specification working roller of high-alloy cold-work die steel, and belongs to the steel processing field. The quenching method comprises the following steps: performing continuous induction thermal treatment on the working roller, quickly rising the temperature of the surface of the working roller to 1020-1100 DEG C, and performing fog cooling when the temperature is risen to a preset temperature; continuously performing fog cooling for 50-70 minutes; and guaranteeing a re-heating temperature to be not higher than 100 DEG C. The quenchingmethod disclosed by the invention is free of pollution, is low in requirement on needed equipment; surface hardness of the working roller is great, toughness of the core part of the working roller ishigh, a transitional layer is transitional in a gradient mode at uniform reducing hardness, loading requirements are met, continuous induction quenching of the roller body is realized while cracks are avoided, a thermal treatment success rate is increased, and production cost is reduced.

Owner:SINOSTEEL XINGTAI MACHINERY & MILL ROLL

Power battery recovery and processing equipment and processing method thereof

InactiveCN111957411AReduce power lossAvoid incomplete crushingWaste accumulators reclaimingProcess efficiency improvementElectric machineryElectrical battery

The invention discloses power battery recovery and processing equipment and a processing method of the power battery recovery and processing equipment. The power battery recovery and processing equipment comprises an equipment main body, wherein feeding plates are fixedly connected to positions, close to the tops, of the two inner side walls of the equipment main body. A motor I is fixedly arranged on one side, close to the top, of the equipment main body. A driving shaft is arranged at the output end of the motor I. The other end of the driving shaft penetrates through the equipment main bodyand extends to the outside. The power battery recovery and processing equipment replaces the use of two motors through the cooperation of a driving gear and a driven gear, one motor is reduced duringuse, the loss of electric energy of the recovery equipment is reduced, a certain energy saving and consumption reducing effect is achieved, subsequent recovery difficulties caused by incomplete battery crushing are avoided, the recycling and crushing function is good, the recovery rate of useful metal in a battery is improved, the internal corrosion, caused by the splashing of a dilute sulfuric acid solution caused by falling of a crushed battery, of the equipment main body can be avoided, a good buffering effect is achieved, and the service life of the equipment is prolonged.

Owner:韩邦成

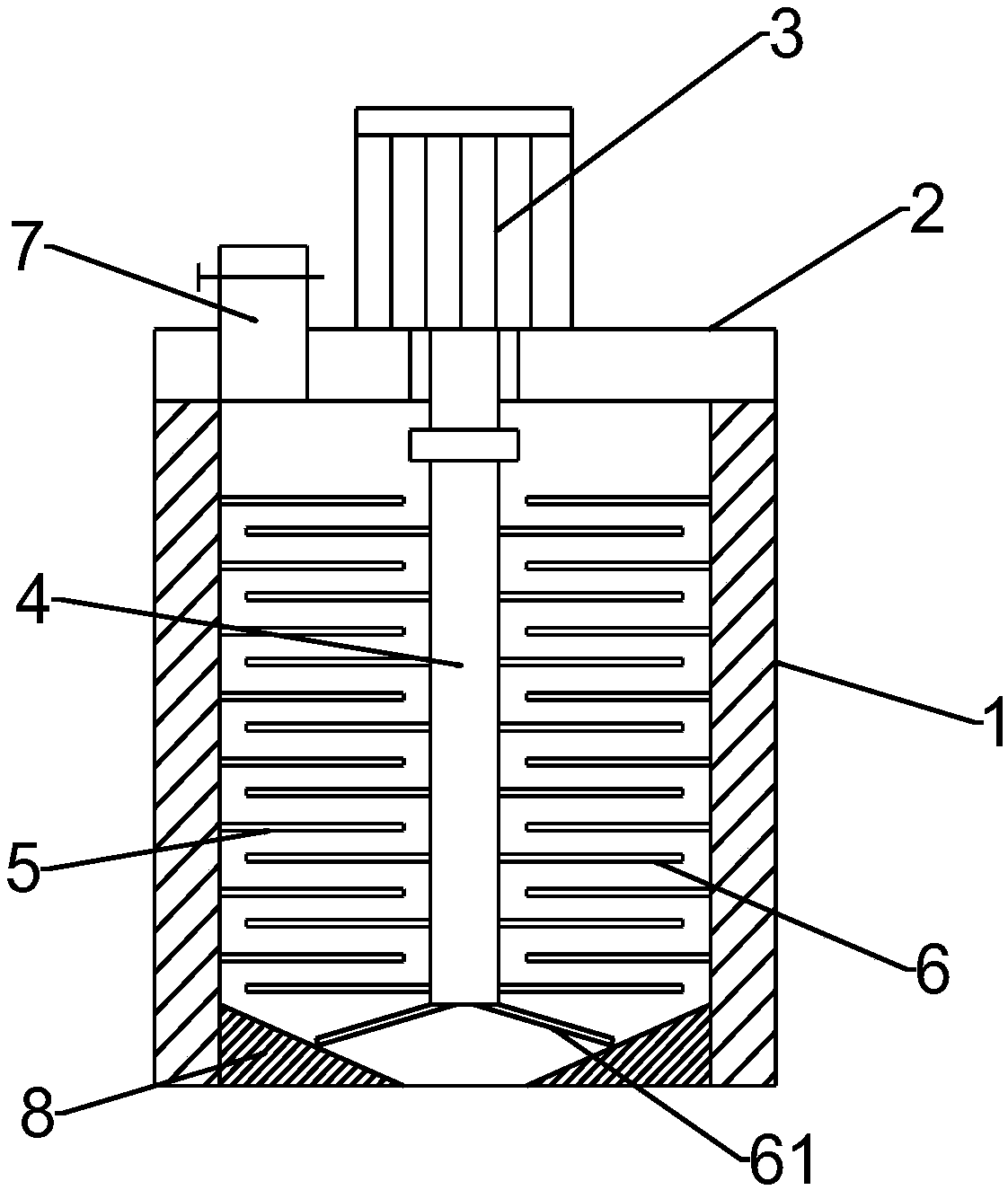

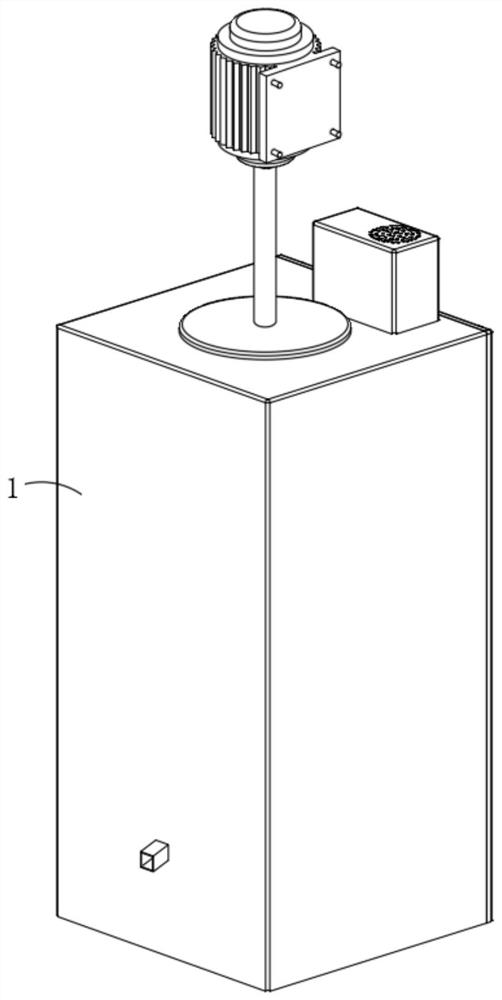

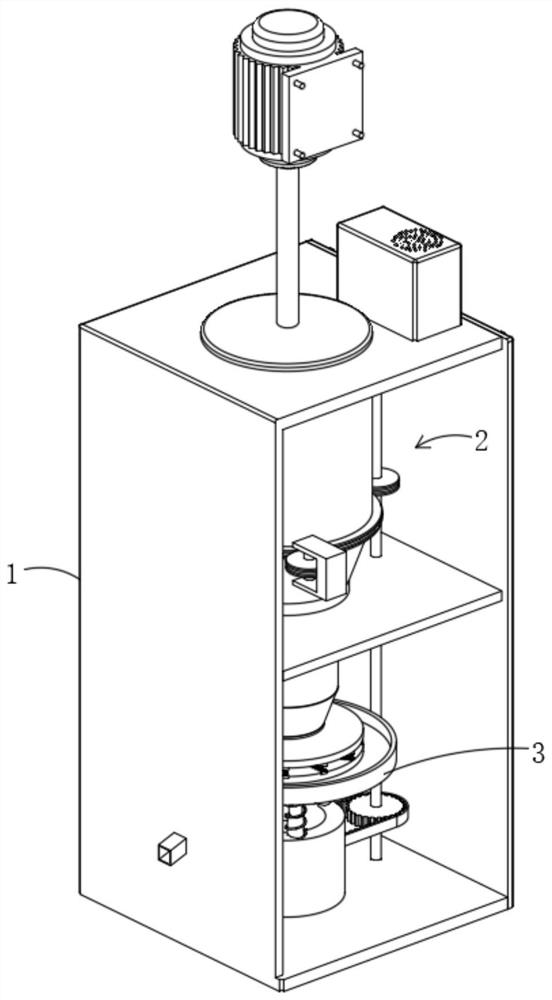

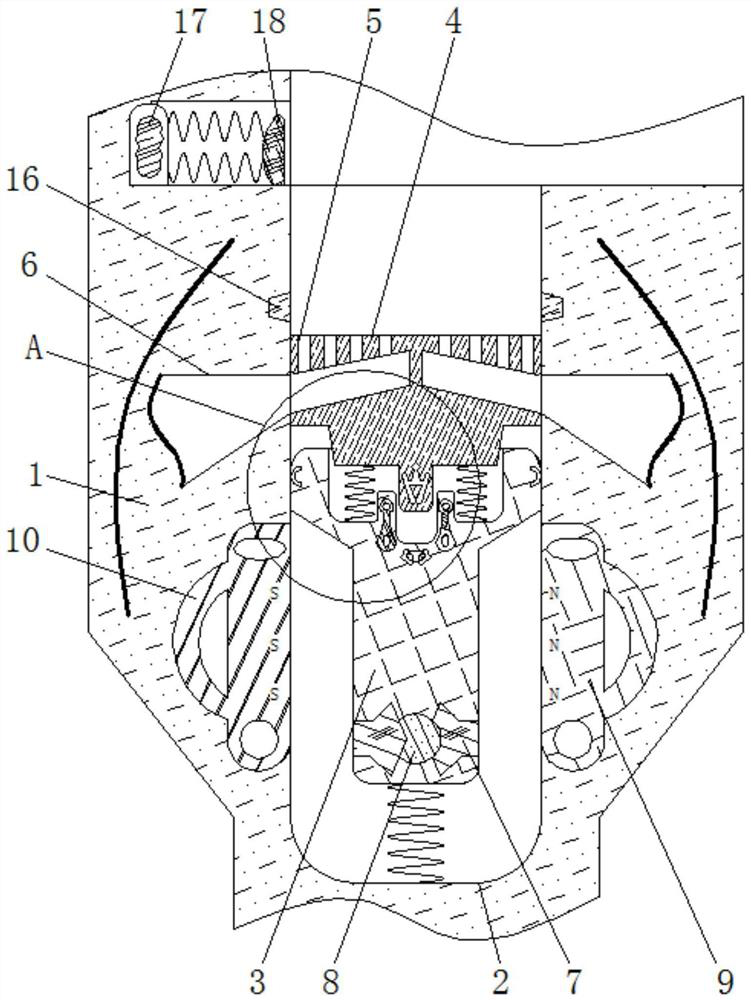

High-resilience composite filling fiber material preparation device

The invention discloses a high-resilience composite filling fiber material preparation device which comprises a pulverizer used for pulverizing recycled polyester bottle flakes. The pulverizer comprises a pulverizer body, and a pulverizing mechanism and a grinding mechanism are sequentially arranged in the pulverizer body from top to bottom. The pulverizing mechanism comprises a power part, a pulverizing cylinder, a conveying hopper, a mounting plate and a pulverizing part, the mounting plate is fixedly connected between the inner walls of the pulverizer body to support the pulverizing cylinder, the pulverizing cylinder is rotationally connected between the upper part of the pulverizer body and the conveying hopper, and the pulverizing part is arranged in the pulverizing cylinder. The power part drives the pulverizing cylinder to rotate. According to the high-resilience composite filling fiber material preparation device, raw material concentrates can be fully pulverized, incomplete pulverizing of raw materials is avoided, manual carrying and repeated crushing are not needed, and meanwhile the device has the advantages of being small in size, compact in structure and high in space utilization rate.

Owner:FUJIAN CHANGLE HANGGANG TEXTILE

Crushing device for biological medicine recycling

InactiveCN113399098AAvoid incomplete crushingIncrease productivitySievingScreeningBiotechnologyPharmacy medicine

The invention relates to the technical field of biological medicine, and discloses a crushing device for biological medicine recycling. The device comprises a shell, a sliding groove is formed in the inner wall of the shell, a push rod is elastically connected to the inner wall of the sliding groove, a screening plate is elastically connected to the inner wall of the push rod, and a round hole is formed in the inner wall of the screening plate; and a discharging port is formed in the inner wall of the shell, and a conductor rail is fixedly connected to the position, close to the outer side of the sliding groove, of the inner wall of the shell. According to the crushing device for biological medicine recycling, crushed medicine is screened through the screening plate, medicine which is not completely crushed is extruded into the crushing device again according to the effect of Ampere force, and thus the phenomenon that the medicine is not completely crushed is avoided, the situation that the sizes of crushed medicine particles are different is avoided, manual screening of the crushed medicine is avoided, time and labor are saved, waste of human resources is avoided, the medicine crushing and recycling process is reduced, the production efficiency of medicine crushing and recycling is improved, and the medicine crushing and recycling cost is reduced.

Owner:佛山市栩承生物科技有限公司

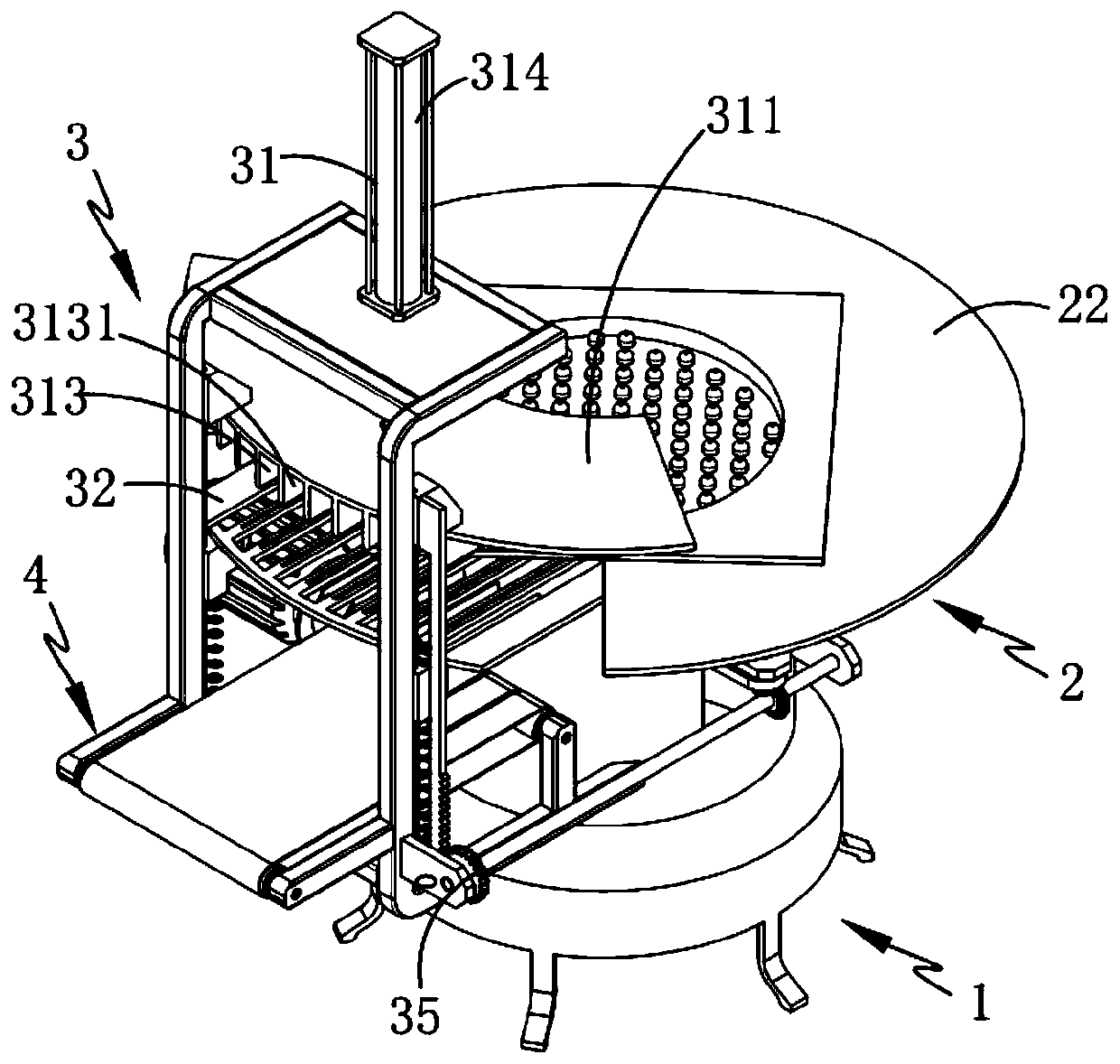

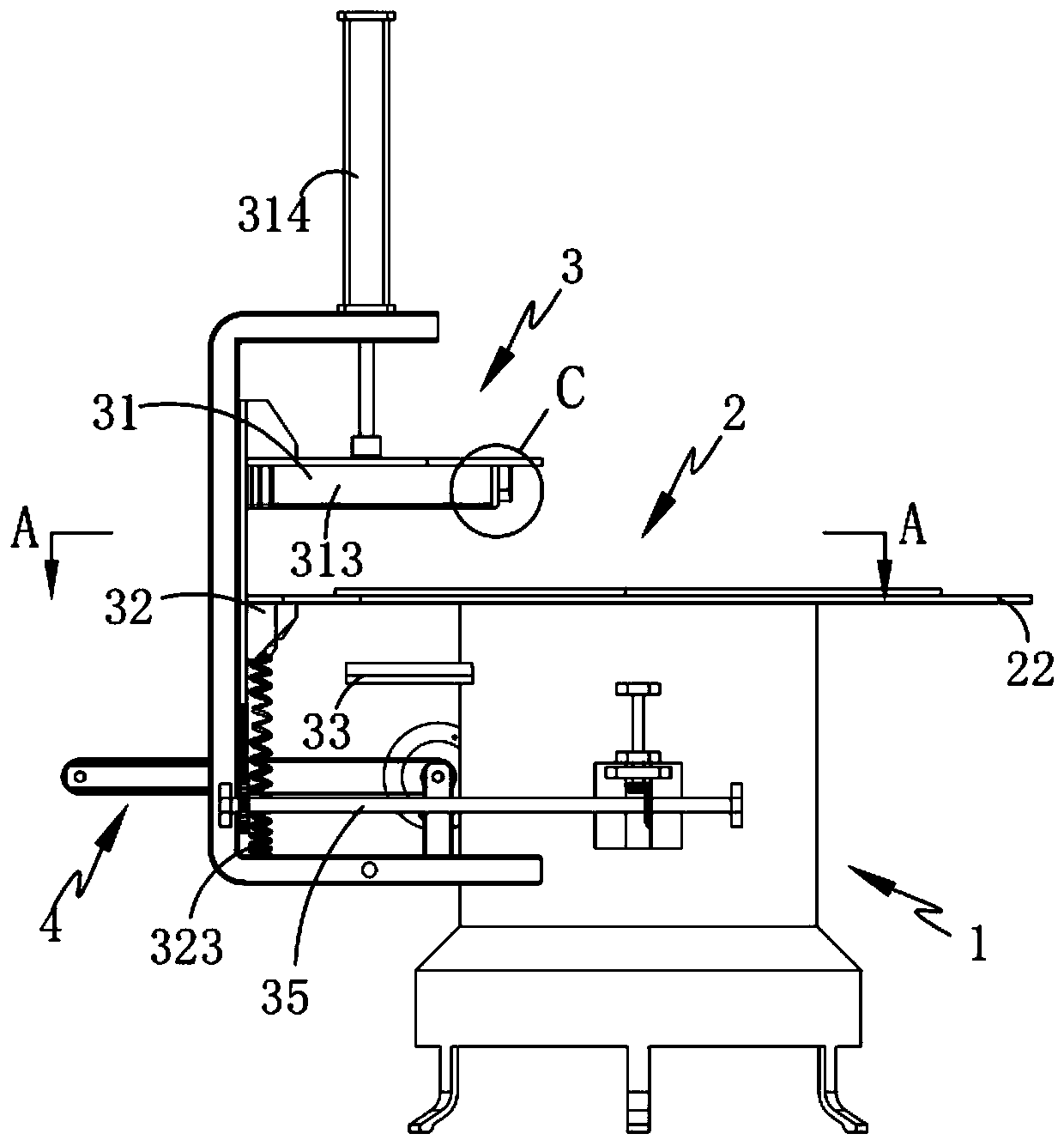

A composite desktop production device for plastic furniture and its process

ActiveCN108724276BRealize automatic transpositionRealize integrated productionGrain treatmentsMetal working apparatusMechanical engineeringIndustrial engineering

The invention relates to the technical field of blow-molding production of furniture, in particular to a production device and process for a compound table top of plastic furniture. The production device comprises a rack, a positioning mechanism, a cutting mechanism and an output mechanism, wherein the positioning mechanism comprises a limiting groove, a bearing table, a cutting space and a supporting component; the cutting mechanism comprises a cutting component, a bearing component, a crushing component arranged below the bearing component and used for crushing rim charges, and a transmission component through which the cutting component and the supporting component are connected; a mould is subjected to one-time rim charge cutting by the cutting component; the cutting component drives the transmission component to rotate so as to realize rotary position change of the mould; the rim charges are crushed by the crushing component, then fall onto the output mechanism and are directionally output by the output mechanism; and the rim charges on the mould are crushed and output while being automatically and efficiently cut by the cutting component. The technical problem of high production cost caused by the reason that the rim charges are cut and crushed independently in the prior art is solved.

Owner:ZHEJIANG LIFAN FURNITURE

Crushing and uniform-stirring device for food safety capable of uniformly chopping

InactiveCN112827598AAvoid incomplete crushing of materialsAvoid incomplete crushingTransportation and packagingRotary stirring mixersProcess engineeringStructural engineering

The invention provides a crushing and uniform-stirring device for food safety capable of uniformly chopping. The crushing and uniform-stirring device comprises a supporting bottom plate, a stirring containing box, a mixing and stirring assembly and a screening and material returning mechanism; the stirring containing box is fixedly connected to the right side of the top of the supporting bottom plate, supporting plates are fixedly connected to the two sides of the top of the stirring containing box, and a smashing containing box is fixedly connected between the tops of the two supporting plates; the mixing and stirring assembly is arranged in the stirring containing box; the screening and material returning mechanism is fixedly connected to the top of the stirring containing box, the screening and material returning mechanism comprises connecting springs, and the tops of the two connecting springs are fixedly connected with the two sides of the bottom of the smashing containing box correspondingly. According to the crushing and uniform-stirring device for the food safety capable of uniformly chopping, materials can be well crushed and stirred, the device can automatically return and reprocess the materials which are not completely crushed, and the situation that the materials are not completely crushed is effectively avoided.

Owner:长沙市运控自动化技术有限公司

Food processing device for animal husbandry

The invention discloses a food material processing device for animal husbandry, which comprises a box body, a horizontal feeding plate is fixedly connected to the middle part of the left side of the box body, an inclined feeding plate is fixedly connected to the right end of the horizontal feeding plate, and an inclined feeding plate is fixedly connected to the right side of the inclined feeding plate. The side is fixedly connected with a vertical vertical plate, the inclined blanking plate and the longitudinal vertical plate are connected with the front and rear side walls of the box body, and the inclined blanking plate and the lower left side of the longitudinal vertical plate form a storage cavity; the upper left side of the box body is fixedly connected There is a first fixed shaft, and a rotating roller is fixedly connected to the outer side of the first fixed shaft, and a feeding push plate is fixedly connected to the outer side of the rotating roller. Compared with the prior art, the beneficial effects of the present invention are: the present invention is simple in structure, easy to use, and can periodically push the raw materials inward during use, so as to prevent the raw materials from being fed too fast and pulverized completely. The raw materials are fully mixed to provide animals with better nutrition, which is conducive to the growth of animals, thereby obtaining higher economic value.

Owner:赵越 +3

Raw material crushing equipment for feed

PendingCN113769854AAvoid dustImprove filtering effectFeeding-stuffGrain treatmentsProcess engineeringRotational axis

The invention provides raw material crushing equipment for feed, and relates to the technical field of crushing equipment. The raw material crushing equipment comprises a breaking device. Two engaged crushing shaft cutters are rotationally mounted in the breaking device, and a first motor is mounted at the rear end of the breaking device. The top end of a rotating shaft in a crushing device is rotationally connected to a three-jaw supporting plate, two crushing blades are mounted on the rotating shaft, and a second motor is mounted at the bottom end of the crushing device. According to the raw material crushing equipment for the feed, the screening effect of a first filter plate and a second filter plate and the drying effect of a drying device on crushed raw materials in the device are improved through a vibration device, and the breaking device and the crushing device are arranged in a matched mode, so that the situation that crushing is not thorough when large-block raw materials are directly crushed is avoided; and through the first filter plate and the second filter plate, the broken and crushed feed can be subjected to secondary screening treatment and secondary crushing treatment, the feed is prevented from being damaged due to high moisture, the storage effect of the feed is improved, and economic benefits are facilitated.

Owner:厉泽峰

A device for pulverizing and preparing drugs in the department of pharmacy

The invention discloses a medicine smashing preparation device for the pharmacy department. The medicine smashing preparation device comprises a smashing cover and a smashing barrel. A motor is arranged on the top of the smashing cover, a PLC is arranged on the top of the motor, a touch button is arranged on the top of the PLC, a safety coil is arranged on the side face of the bottom of the smashing cover, an anode patch and a cathode patch are arranged at the bottom of the safety coil, and the anode patch and the cathode patch are staggered and used for avoiding the situation that the touch button is touched when the device is not covered with the smashing cover, so that operators are hurt by smashing blades. A rotary shaft connected with an output shaft of the motor is arranged at the bottom of the smashing cover, the smashing blades are arranged on the side face of the rotary shaft, medicine can be put and powder can be generated simultaneously, and convenience and rapidness are achieved. Dust settles through a storage box, collection is easy, particles and powder can be separated through a filter plate, it is avoided that the medicine is not completely smashed, and damage of misoperation to the operators can be avoided by means of the safety coil.

Owner:徐存军

Garbage can assembly with drying and smashing functions

InactiveCN112320146AEasy to unloadEasy to launchGlass recyclingDrying solid materials without heatElectric machineryStructural engineering

The invention discloses a garbage can assembly with drying and smashing functions. The garbage can assembly comprises a smashing chamber and a pull ring, an observation window is arranged on the outerwall of the smashing chamber, a first rotating shaft is arranged above the smashing chamber, a top cover is connected to the outer side of the first rotating shaft, a pull rod is connected to the right side of a baffle, and a drying agent is arranged below the pull rod. A drying chamber is arranged below a transition opening, an air cylinder is arranged in the drying chamber, a telescopic rod isconnected to the right side of the air cylinder, a push plate is arranged on the right side of the telescopic rod, a second rotating shaft is arranged on the outer wall of the drying chamber, a door plate is connected to the lower portion of the second rotating shaft, the pull ring is arranged on the side, away from a clamping block, of a pressing plate, and springs are arranged on both the upperside and the lower side of the pull ring. According to the garbage can assembly with the drying and smashing functions, through arranged blades, high-speed rotation can be conducted under driving of amotor, so that garbage is conveniently and rapidly smashed, the smashing efficiency is improved, and the working time is saved.

Owner:湖南武陵机械制造有限公司

A kind of Chinese medicinal material processing and grinding device

ActiveCN110876979BImprove efficiencyIncrease range of motionGrain treatmentsCircular discEngineering

The invention relates to a Chinese medicinal material processing and grinding device which comprises a medicinal material grinding base, a medicinal material grinding mechanism and medicinal materialstorage boxes. A medicinal material grinding groove is arranged in the middle of the medicinal material grinding base, the medicinal material grinding mechanism is arranged at the upper end of the medicinal material grinding groove, the medicinal material storage boxes are symmetrically arranged on the left and right sides of the medicinal material grinding mechanism, and the medicinal material grinding mechanism and the medicinal material storage boxes are installed on the side walls of the medicinal material grinding base; and the medicinal material grinding mechanism comprises a sliding rack, a rotating motor, a rotating rod, a medicinal material grinding disc, a supporting frame, a moving rack, a driving gear and a driving motor, and the medicinal material grinding disc comprises a fixed disc, a medicinal material grinding head, an adjusting screw, a connecting rod, a buffer spring, a connecting block and a connecting screw. According to the Chinese medicinal material processing and grinding device, traditional Chinese medicinal materials are fed in multiple-time small-quantity manners and are made into powder synchronously in manners of front-and-back grinding and rotation roll grinding, the medicinal material grinding efficiency is improved, and the possibility of dead corners of medicinal material grinding is reduced; and meanwhile, the medicinal material grinding intensity can be adjusted appropriately so as to match the characteristics of the processed Chinese medicinal materials, and adverse effects on the medicinal material effect are avoided.

Owner:JILIN UNIV

A convenient mushroom wood crushing and screening device for discharging

The invention discloses an inoculated log smashing and screening device convenient for discharging and relates to the technical field of inoculated log smashing and screening devices. The inoculated log smashing and screening device convenient for discharging comprises an outer frame, wherein a first motor is fixedly connected with the left side of the inner wall of the outer frame, one end of anoutput shaft of the first motor is fixedly connected with a first gear, a second gear is meshed with the bottom of the first gear, a lead screw runs through the axis of the second gear, the two ends of the lead screw are respectively rotatably connected with the two sides of the inner wall of the outer frame, the surface of the lead screw is connected with a movable block by virtue of a screw thread, the top of the movable block is fixedly connected with a discharging frame, the bottom of the discharging frame is fixedly connected with a supporting rod, and the bottom end of the supporting rodis slidably connected with the bottom of the inner wall of the outer frame. The inoculated log smashing and screening device convenient for discharging achieves the aim of uniformly smashing inoculated log, working efficiency is improved, time waste is reduced, load of a worker is alleviated, incomplete smashing of inoculated log is prevented, smashing effect is improved, use of the inoculated log in later period is guaranteed, people can use conveniently, and practicability of the inoculated log smashing and screening device is improved.

Owner:安徽上造智能设备科技有限公司

Rice straw smashing device

InactiveCN112570114AGuaranteed uptimeImprove work efficiencyGrain treatmentsMetal working apparatusElectric machineAgricultural engineering

The invention belongs to the technical field of agriculture, and particularly relates to a rice straw smashing device. In order to solve the problem that winding is likely to happen, the rice straw smashing device comprises a lifting box and a smashing box, a mounting plate is horizontally welded to the upper portion of one side of the outer portion of the smashing box, and a first rotating motorand a vertical rod are vertically mounted on the two sides of the top of the mounting plate; an inclined column is installed at the top end of an output shaft of the first rotating motor, a moving rodpenetrates through the top of the vertical rod, a conical block is welded to the top end of the moving rod, the outer side of one end of the moving rod is sleeved with a spring, a cutter is installedat the other end of the moving rod, and a driving mechanism is arranged on the outer side of the smashing box; a partition plate is arranged below two smashing rollers, a rotating mechanism is arranged on the outer side of the smashing box, and a lifting machine is vertically mounted in a lifting box. According to the rice straw smashing device, rice straw can be cut off in advance before smashing, so that the situation that the rice straw is wound around the smashing rollers is avoided, secondary smashing is conducted on the straw, and smashing is more thorough.

Owner:ZHEJIANG NORMAL UNIVERSITY

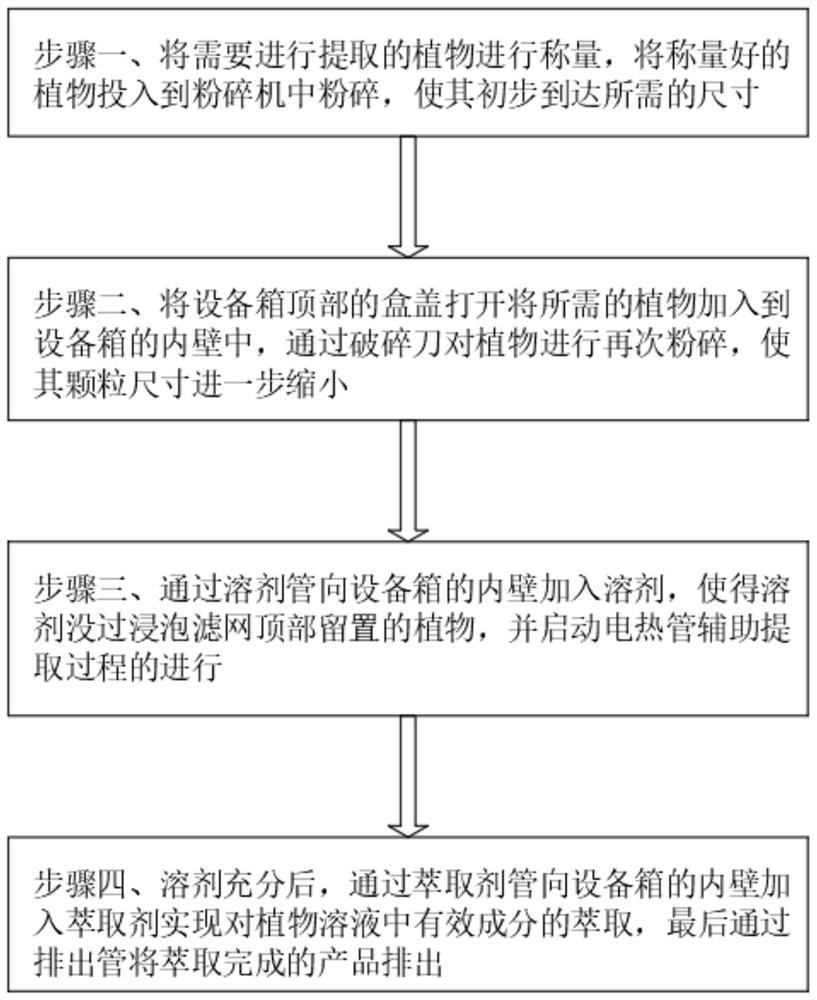

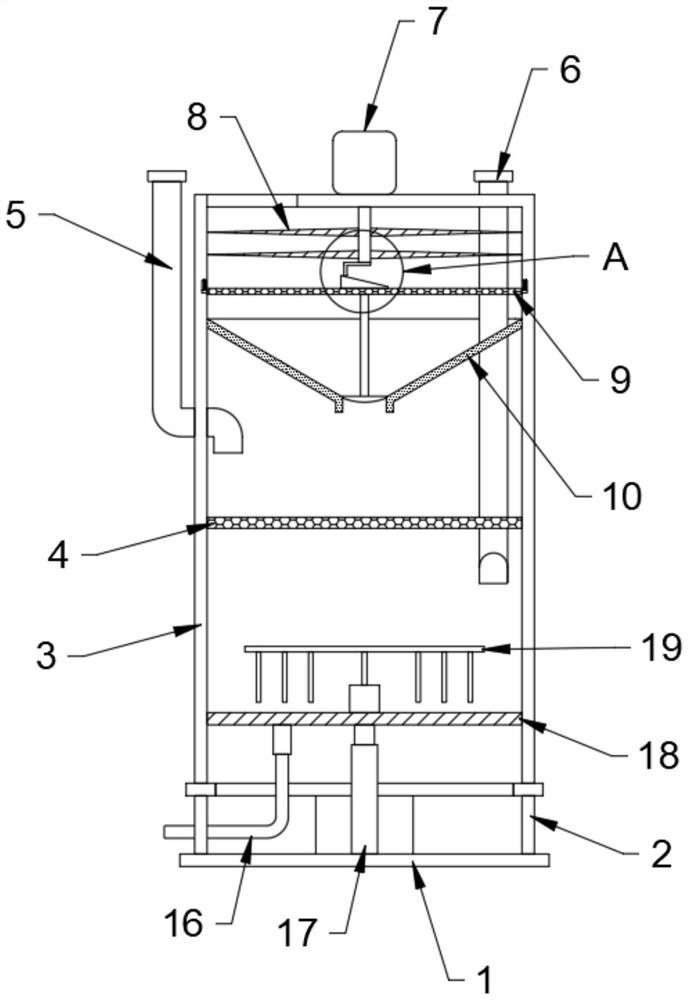

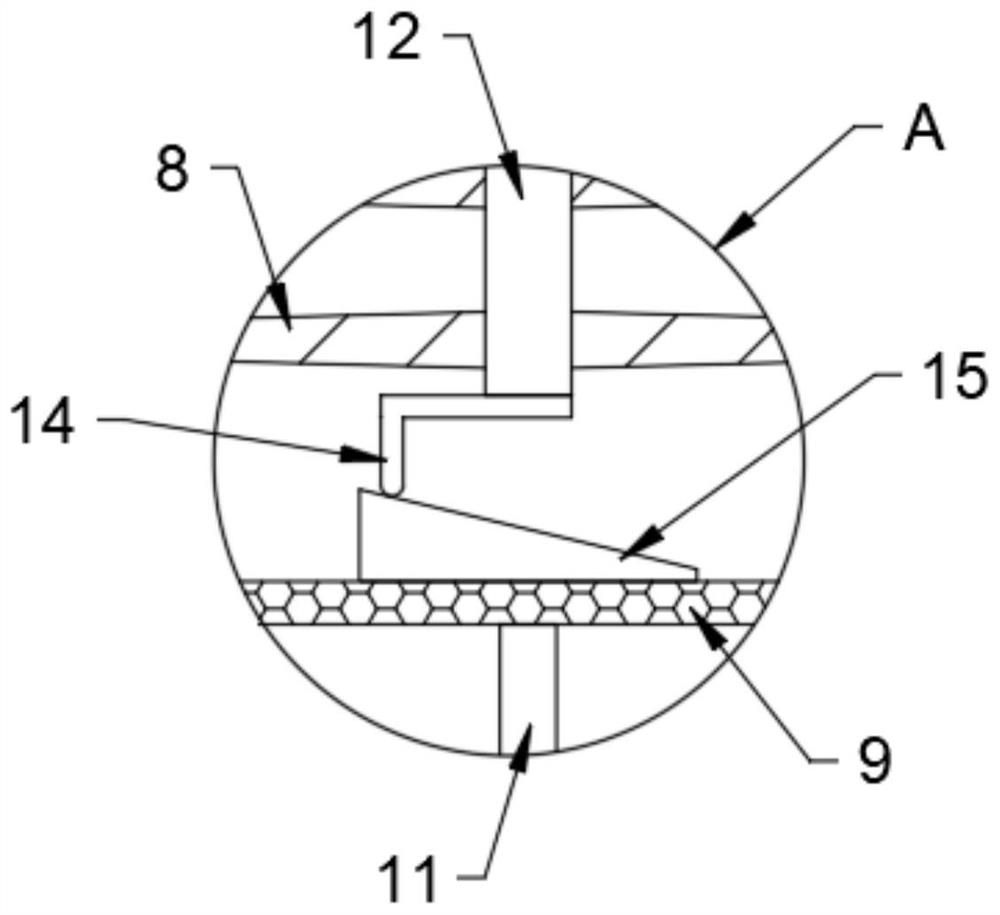

Plant extraction process capable of automatically adding extraction agent

InactiveCN114558348AFast extractionRapid solid-liquid separationSievingScreeningBiotechnologyProcess engineering

The invention relates to the technical field of plant extraction, in particular to a plant extraction process capable of automatically adding an extraction agent, the plant extraction process capable of automatically adding the extraction agent is based on an extraction device, and the plant extraction process capable of automatically adding the extraction agent comprises the following steps: step 1, weighing plants needing to be extracted; secondly, a box cover at the top of the equipment box is opened, needed plants are added into the inner wall of the equipment box, a solvent is injected into the equipment box through a solvent pipe, a hydraulic rod is started to push a piston plate upwards, the plants are immersed in the solvent on the inner wall of the equipment box, and at the moment, an electric heating pipe arranged on the inner wall of the piston plate is started to heat the solvent; and after plant extraction is completed, the piston plate is moved downwards, so that residues of the plants are retained at the top of the soaking filter screen, rapid solid-liquid separation is achieved, the quality of extracted products is improved, complex treatment of other related steps is not needed, and the working efficiency is improved.

Owner:冷永松

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com