A composite desktop production device for plastic furniture and its process

A technology for production equipment and furniture, applied in metal processing, grain processing, etc., can solve the problem of high production cost, and achieve the effect of improving work intensity, reducing production cost and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] The embodiments of the present invention will be described in detail below. Examples of the embodiments are shown in the accompanying drawings, wherein the same or similar reference numerals indicate the same or similar elements or elements with the same or similar functions. The embodiments described below with reference to the accompanying drawings are exemplary, and are intended to explain the present invention, but should not be construed as limiting the present invention.

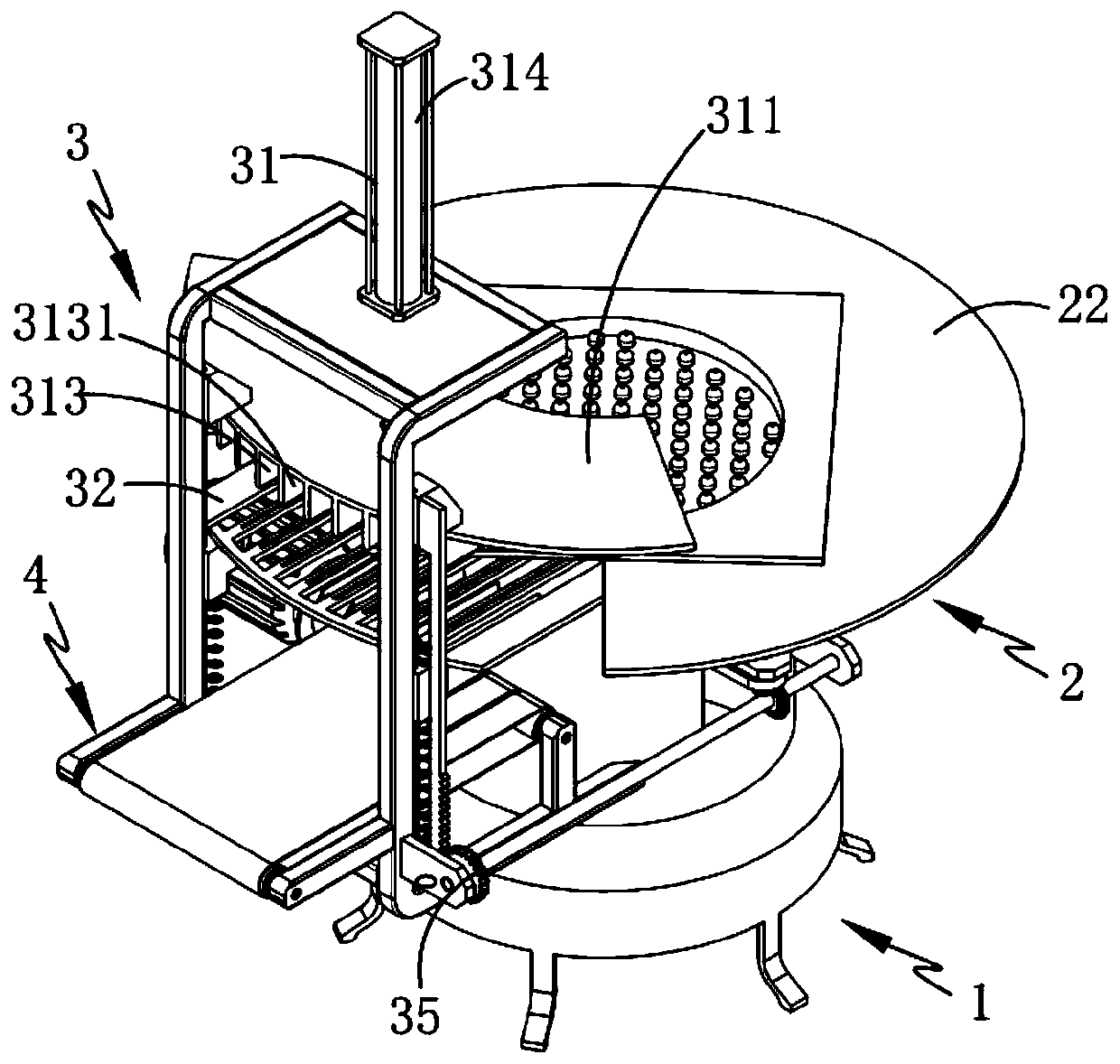

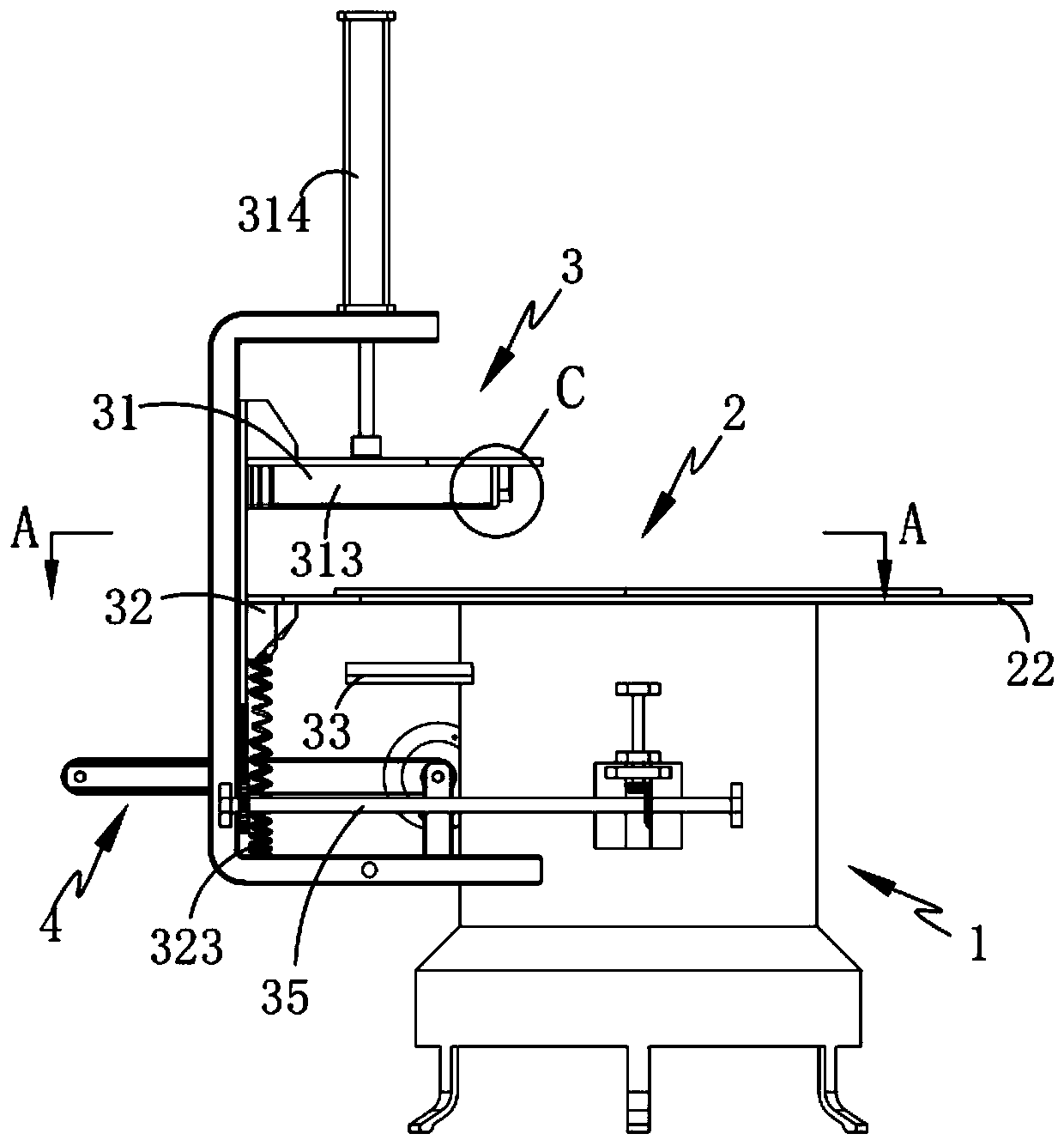

[0043] Such as figure 1 , 2 As shown in, 3 and 4, this embodiment provides a composite tabletop production device for plastic furniture, which includes a frame 1, and also includes:

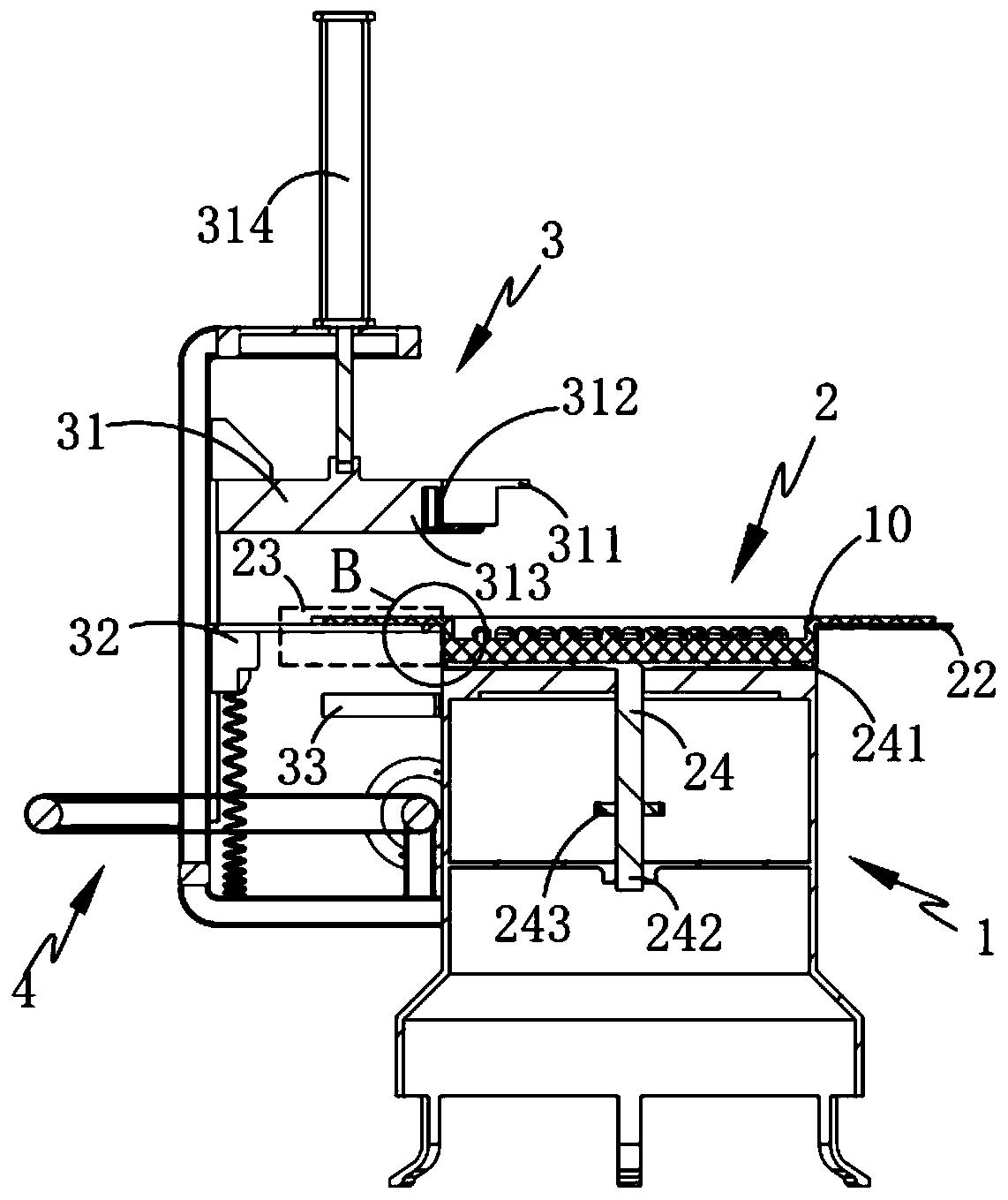

[0044] Positioning mechanism 2, the positioning mechanism 2 is located above the frame 1, which includes a limit slot 21, a bearing platform 22 arranged outside the limit slot 21 for supporting the side material on the blank mold 10, opening A cutting space 23 for cutting edge material on the carrying table 22 and a sup...

Embodiment 2

[0054] Such as figure 2 , 8 , 9 and 10, in which the same or corresponding parts in the first embodiment adopt the corresponding reference numerals in the first embodiment. For the sake of brevity, only the differences from the first embodiment will be described below; the second embodiment and the implementation The difference in example one is that the crushing assembly 33 includes a plurality of cutting knives 331 arranged side by side at intervals, and the cutting edges of the cutting knives 331 are arranged upward; the carrying assembly 32 is a flat plate structure slidably arranged in a vertical direction, It includes a plurality of blanking grooves 321 arranged on it and cooperating with the bead 3131, a cutting groove 322 opened between two adjacent blanking grooves 321 through the cutter 331, and driving the The load-bearing assembly 32 is reset to the spring 323 at the same horizontal position as the load-bearing platform 22; after the edge material is cut by the cutt...

Embodiment 3

[0057] According to the instructions attached Picture 12 The production process of a composite table top for plastic furniture in the third embodiment is described.

[0058] A production process of composite table top for plastic furniture, including the following steps:

[0059] (A) Positioning process, place the blow-molded blank mold 10 on the positioning mechanism 2, and position the outer circumferential surface of the raised portion of the table plate on the blank mold 10 through the limiting groove 21, and the bearing table 22 and the cutting mechanism The bearing assembly 32 on 3 supports horizontally the side material on the blank 10;

[0060] (B) Cutting process. After step (a), the blank is placed horizontally on the positioning mechanism 2, and the driving part 314 on the cutting mechanism 3 drives the movable knife 312 and the pressing block 313 to move down synchronously in a reciprocating motion. During the downward movement of the edge material on the bearing assem...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com