Patents

Literature

36results about How to "Solve technical problems with high production costs" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

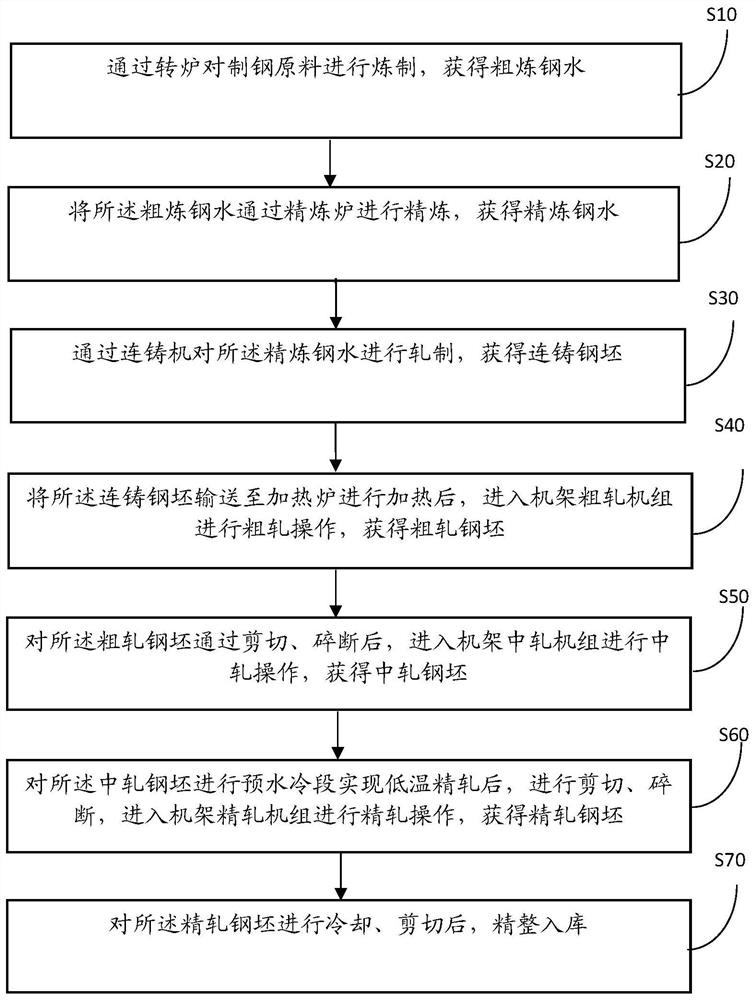

630MPa high-strength seismic resistance index rebar and production method thereof

ActiveCN110565016AImprove overall performanceLow costMetal rolling arrangementsRebarChemical composition

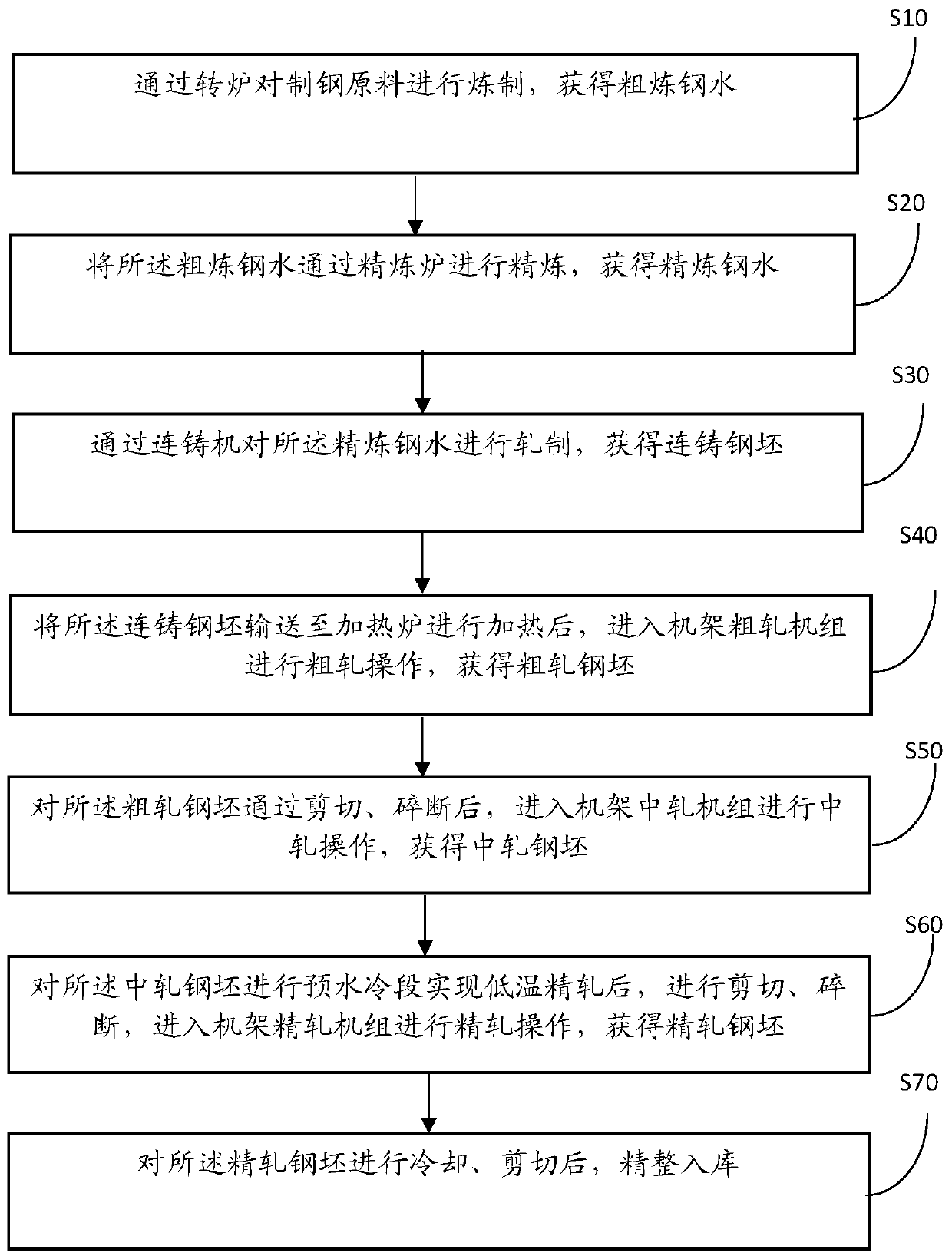

The invention provides a 630MPa high-strength seismic resistance index rebar and a production method of the 630MPa high-strength seismic resistance index rebar. The production method comprises the steps that steelmaking raw materials are processed through a converter, so that rough molten steel is obtained; the refining operation is conducted through a refining furnace, so that refined molten steel is obtained; the rolling operation is conducted through a continuous casting machine, so that a continuous casting steel billet is obtained; after the continuous casting steel billet is conveyed toa heating furnace and heated, the steel billet enters a rough rolling unit of a machine frame and is subjected to the rough rolling operation, so that a rough rolled steel billet is obtained; after the rough rolled steel billet is cut and broken, the steel billet enters an intermediate rolling unit of the machine frame and is subjected to the intermediate rolling operation; after the steel billetis processed in a pre-water-cooling section, and the low-temperature finish rolling operation is accomplished, the steel billet is cut and broken, enters a finish rolling unit of the machine frame andis subjected to the finish rolling operation; and after a finish rolled steel billet is cooled and cut, the steel billet is subjected to the finishing operation and is stored. The technical problemsthat the adopted production technology is difficult to meet the 630MPa-strength seismic resistance requirement, and the production cost is high are solved. The technical effects that chemical components and the rolling technology are adjusted on the basis of an ordinary rebar, various index requirements of a high-performance rebar are met, the industrial rolling technology is stable, the cost is reduced, and the benefit is improved are achieved.

Owner:江苏联峰实业有限公司

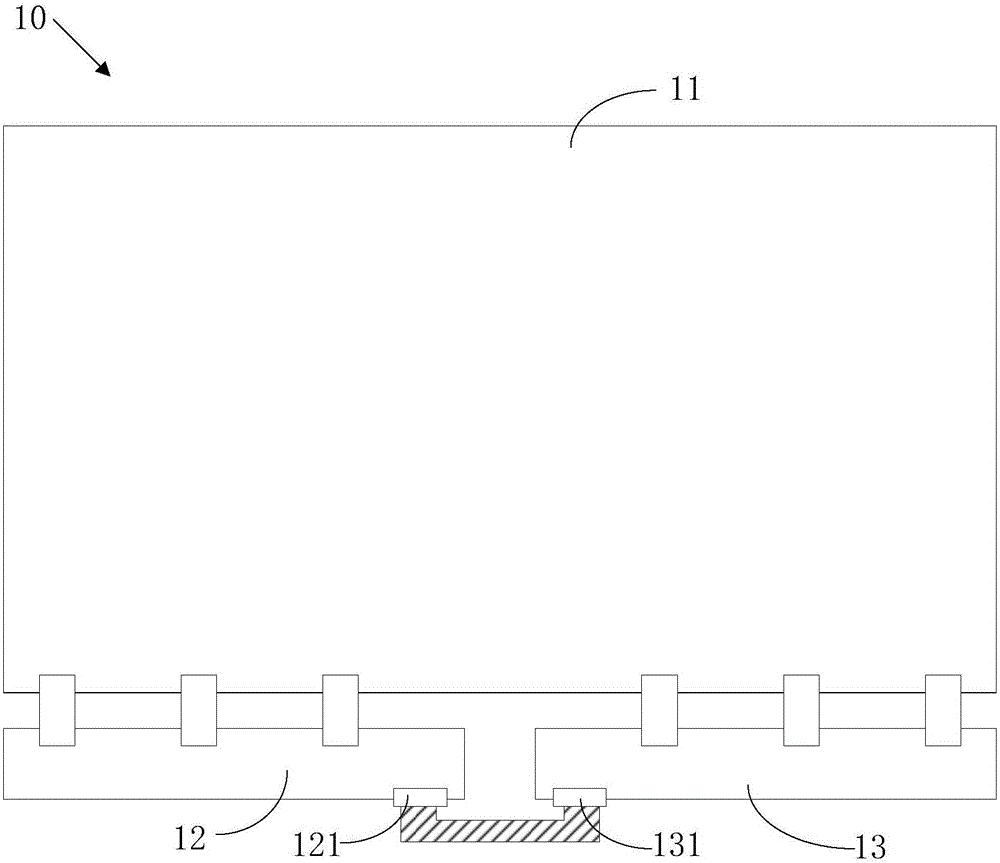

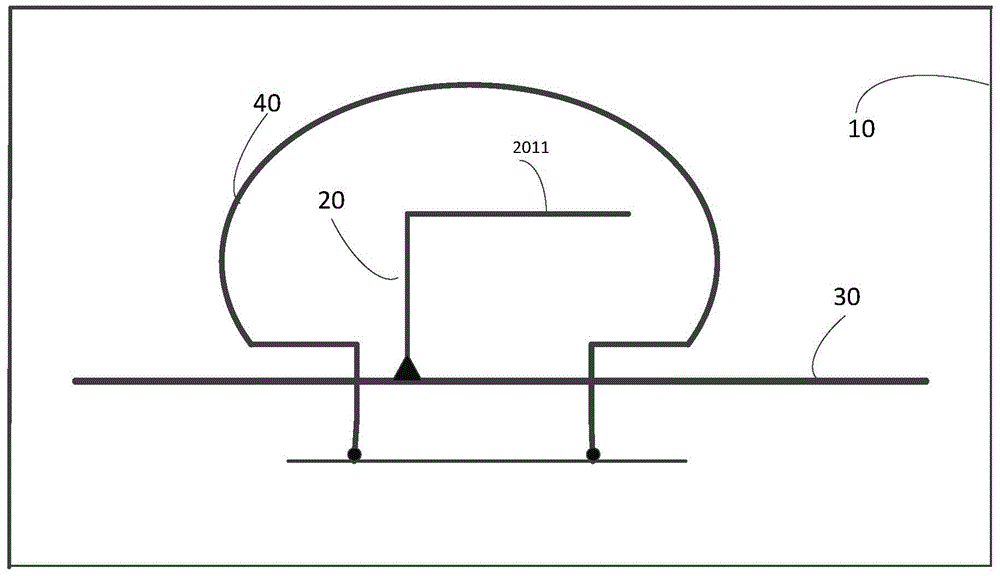

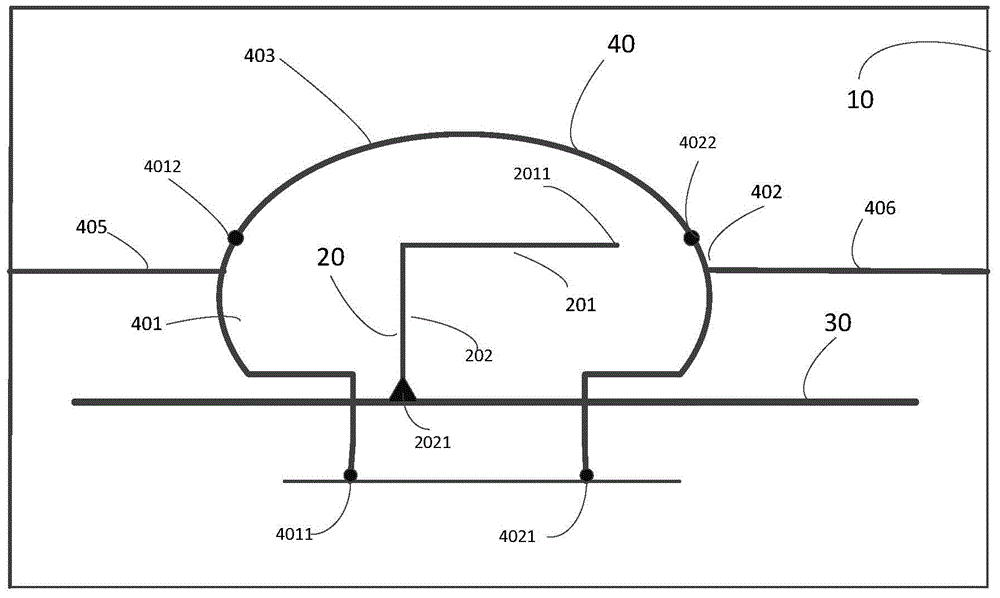

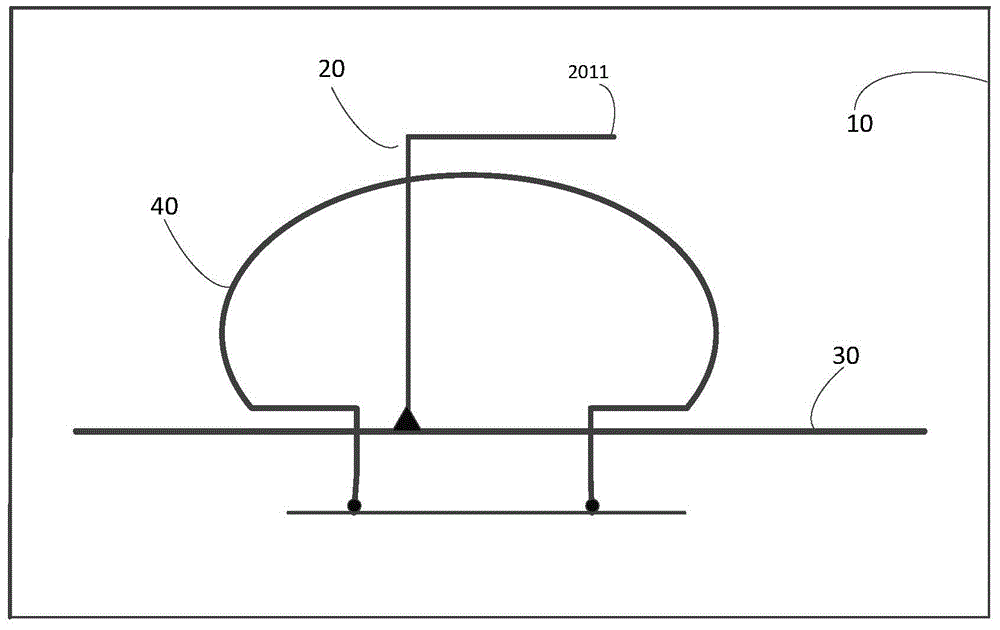

Color-resistor mask plate and application method thereof

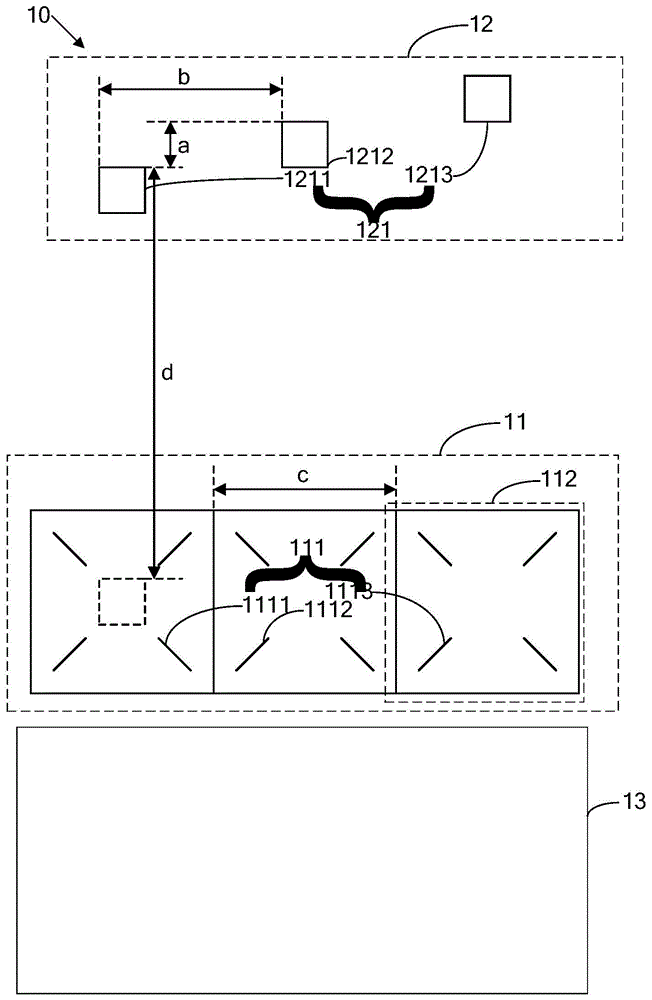

ActiveCN105182680AReduce manufacturing costSolve technical problems with high production costsLiquid surface applicatorsPhotomechanical apparatusBiochemical engineeringFilm base

Owner:TCL CHINA STAR OPTOELECTRONICS TECH CO LTD

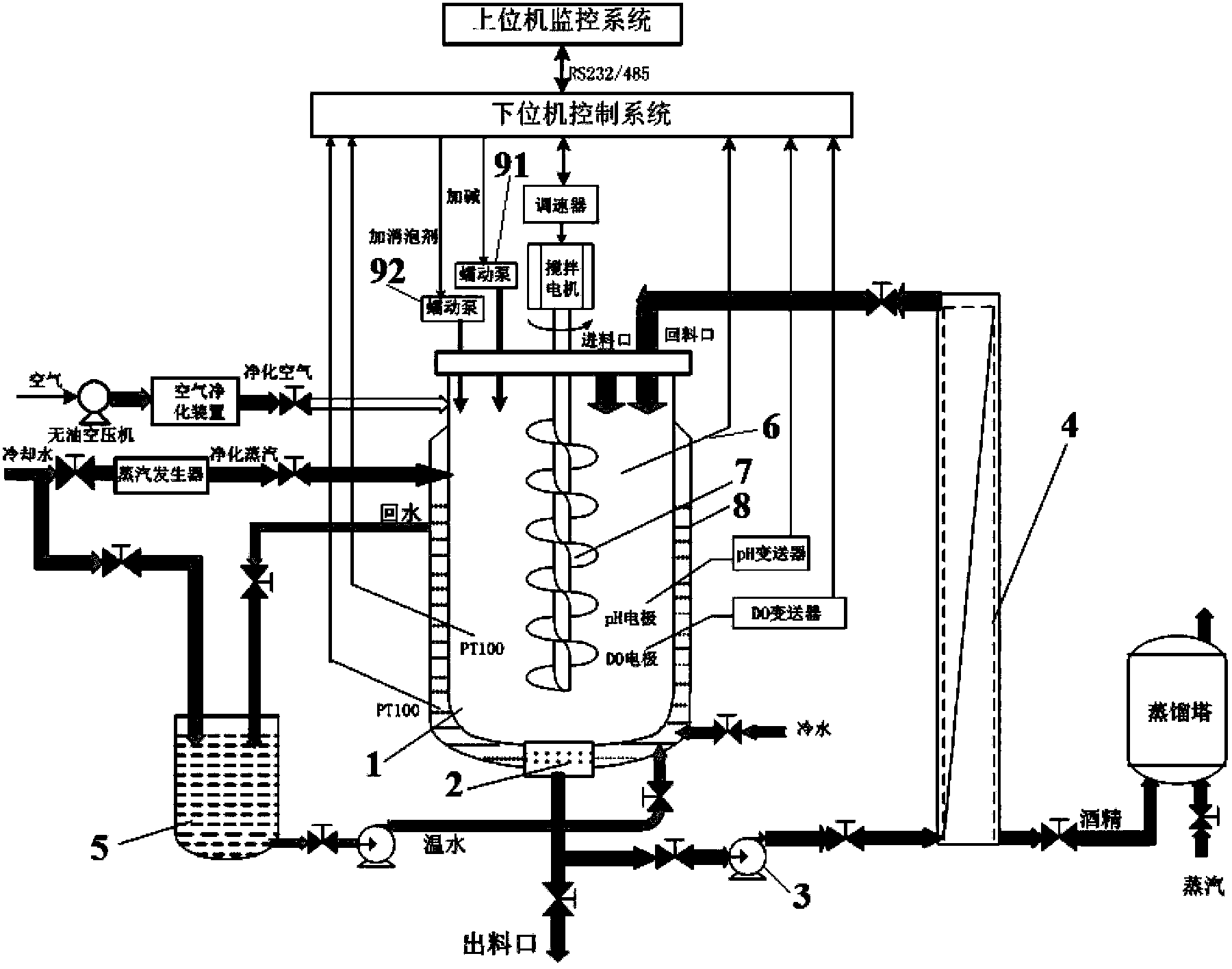

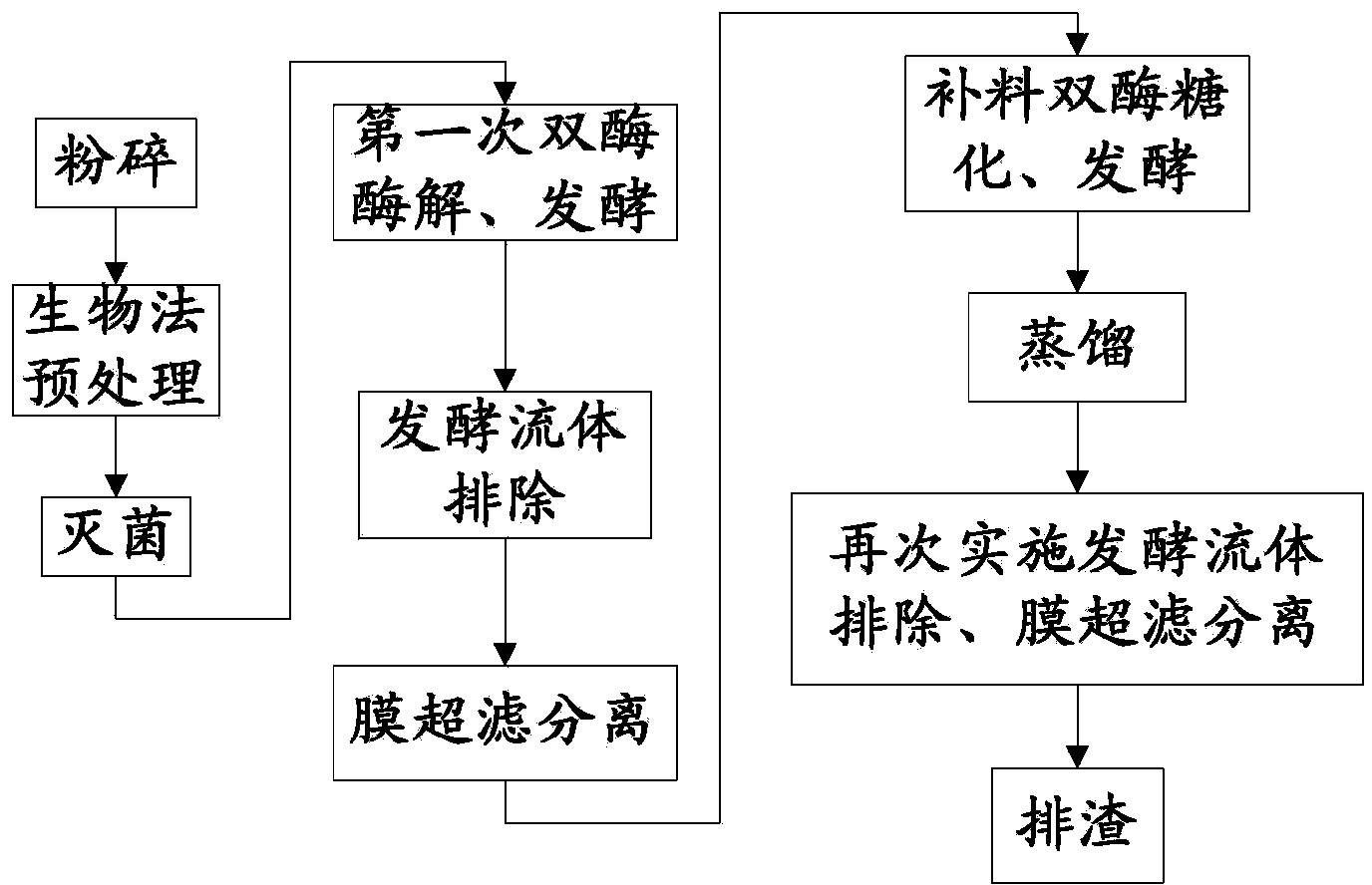

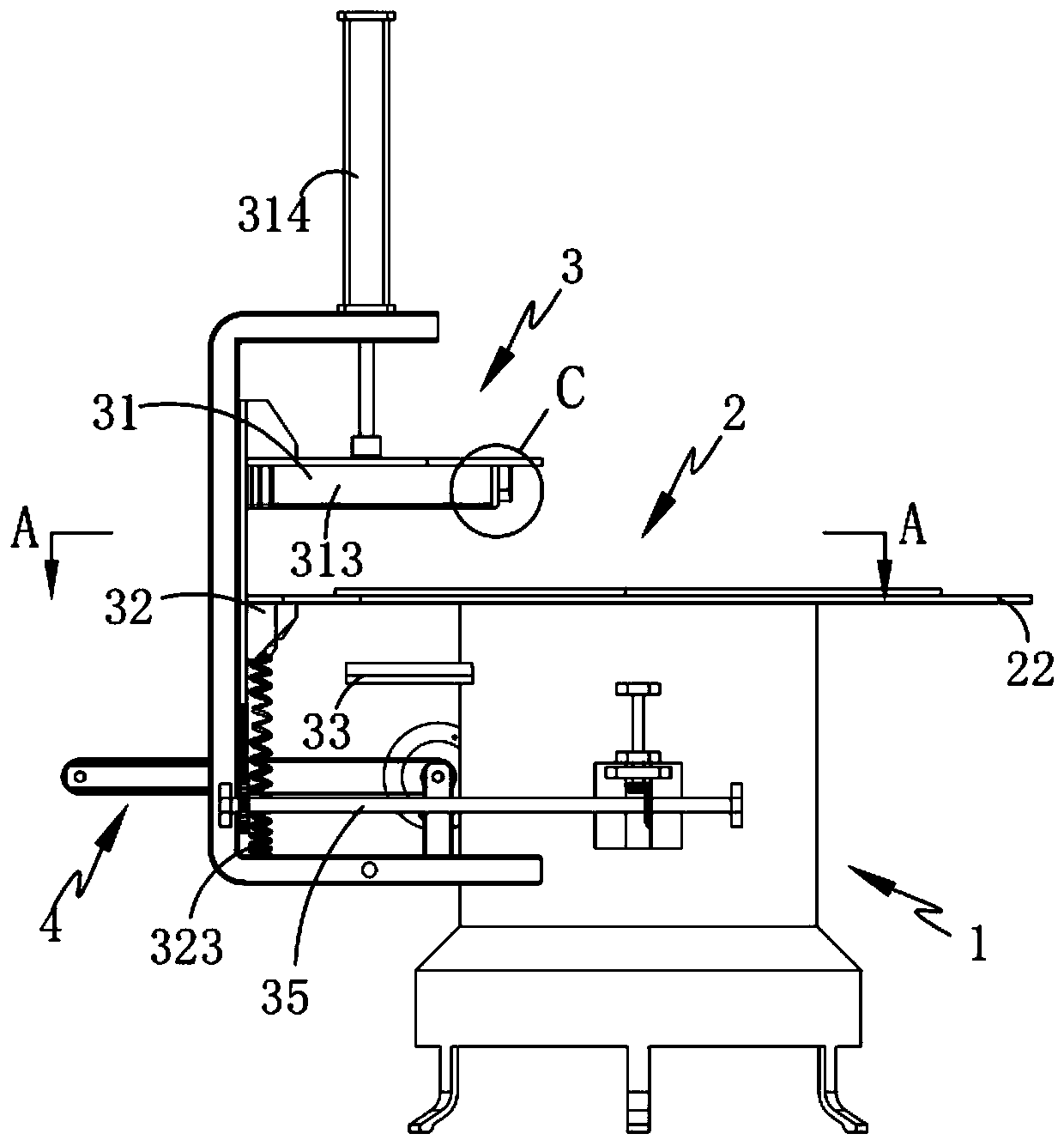

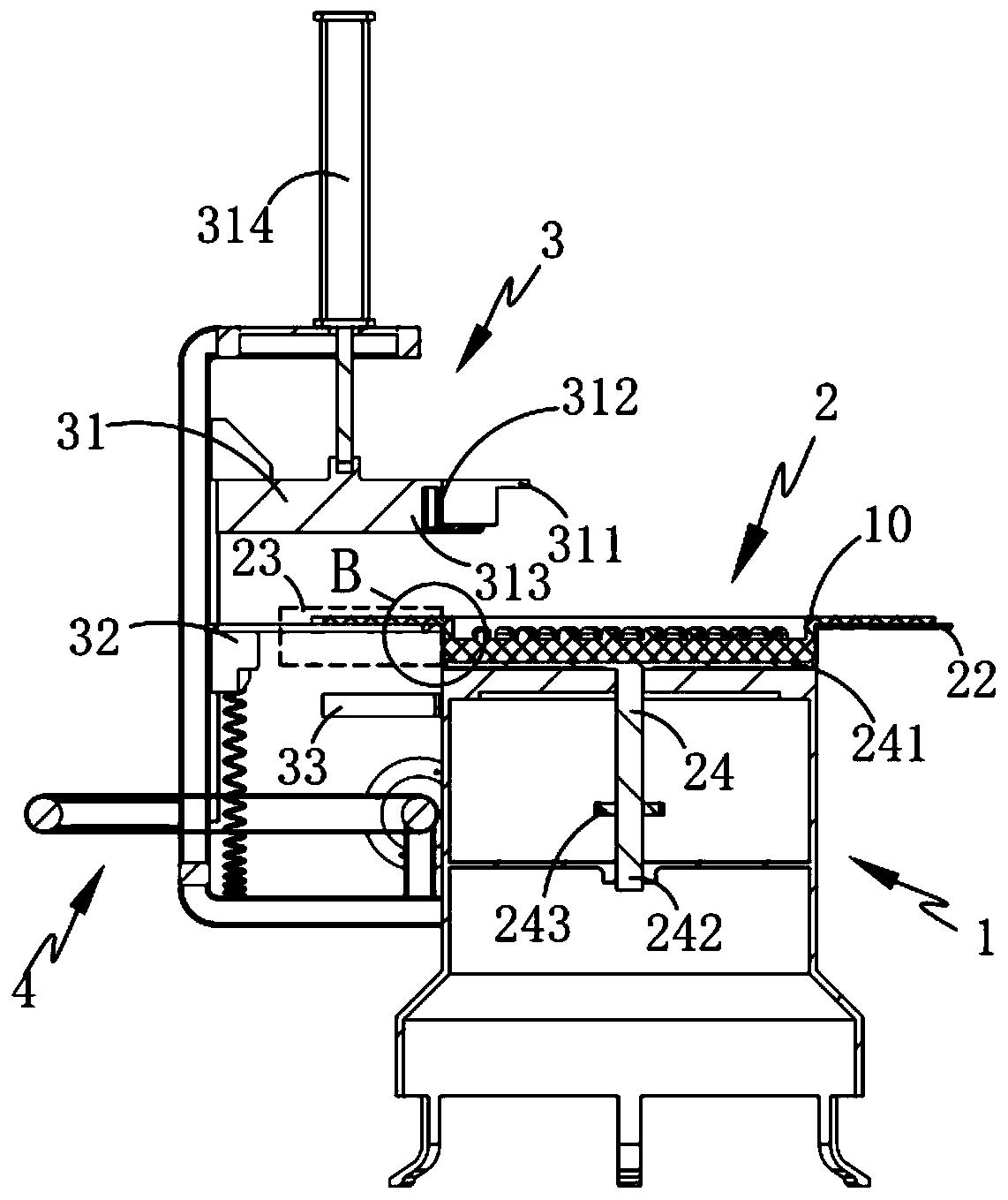

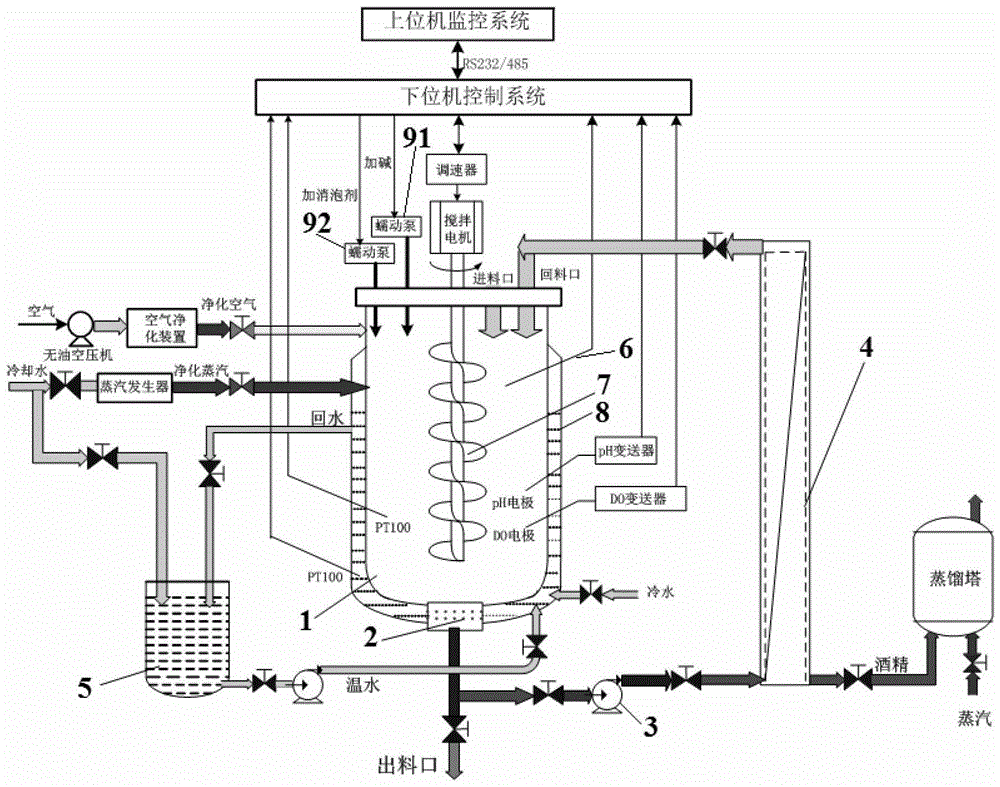

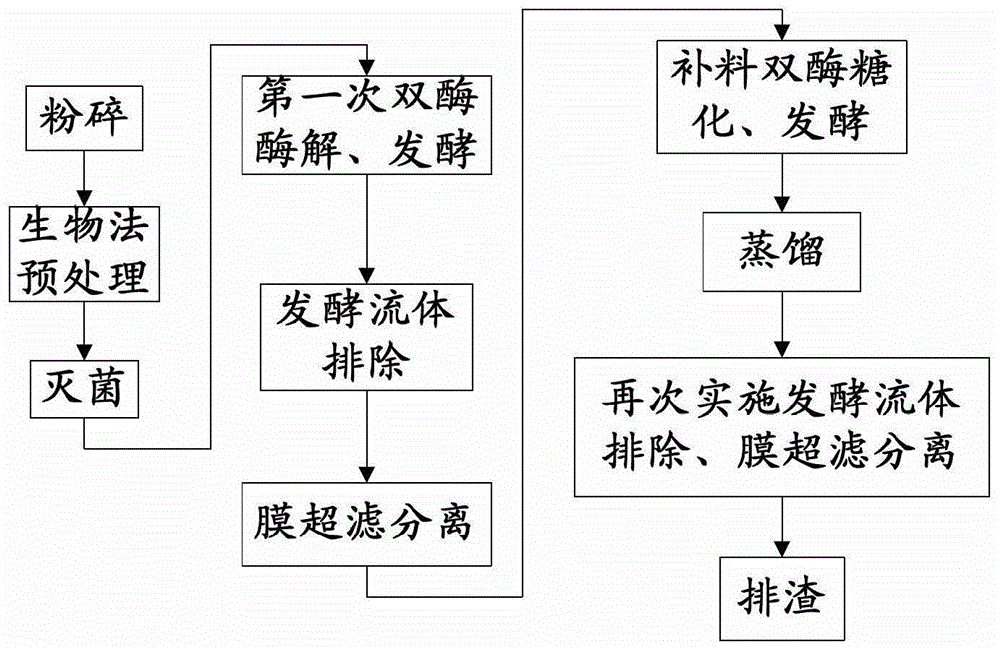

Fermentation fuel reactor and fermentation fuel production method

ActiveCN104342358AAvoid wastingLow costBioreactor/fermenter combinationsBiological substance pretreatmentsAlcoholDistillation

The invention discloses a fermentation fuel reactor and a fermentation fuel production method, relates to the technical field of microbial fermentation equipment, and solves the technical problem in the prior art that relatively high production cost of a fermentation fuel is caused because cellulase and saccharomyces cerevisiae are wasted seriously. The fermentation fuel reactor includes a fermentation tank, a filter screen, a fluid pressurization conveying device, a large and small molecule separation device and an alcohol distillation tower; the large and small molecule separation device comprises a large molecule outlet and a small molecule outlet, the large molecule outlet is communicated with a material return port of the fermentation tank, and the small molecule outlet is communicated with a raw material inlet of the alcohol distillation tower; the large and small molecule separation device enables a cellulase, xylanase and saccharomyces cerevisiae-containing filtrate in a fermentation fluid inputted by the fluid pressurization conveying device to be outputted from the large molecule outlet and allow a remaining ethanol-containing filtrate in the fermentation fluid to be outputted from the small molecule outlet. The fermentation fuel reactor and the fermentation fuel production method are used for repetitive and circular utilization of cellulase and xylanase so as to reduce the production cost of the fermentation fuel.

Owner:STATE GRID CORP OF CHINA +1

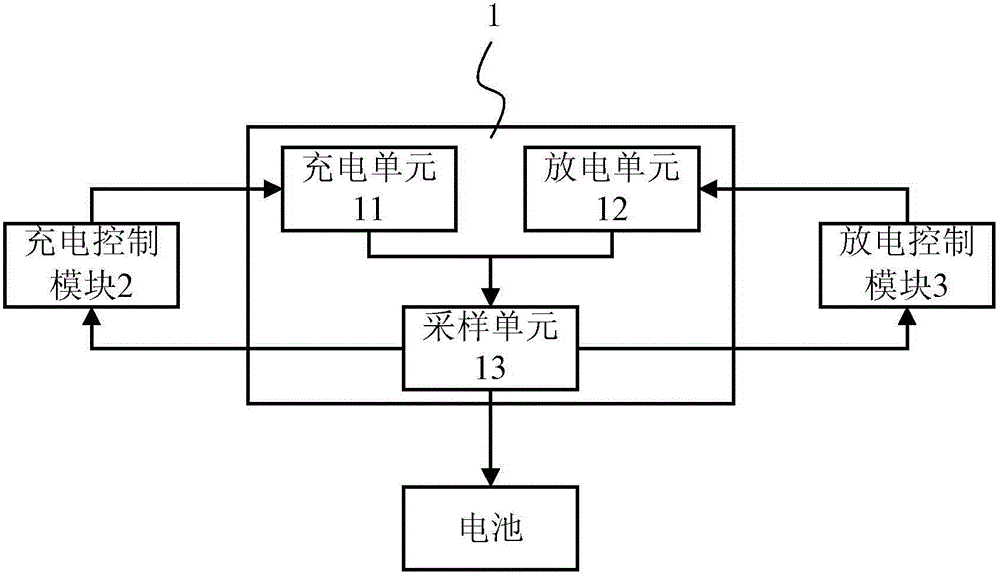

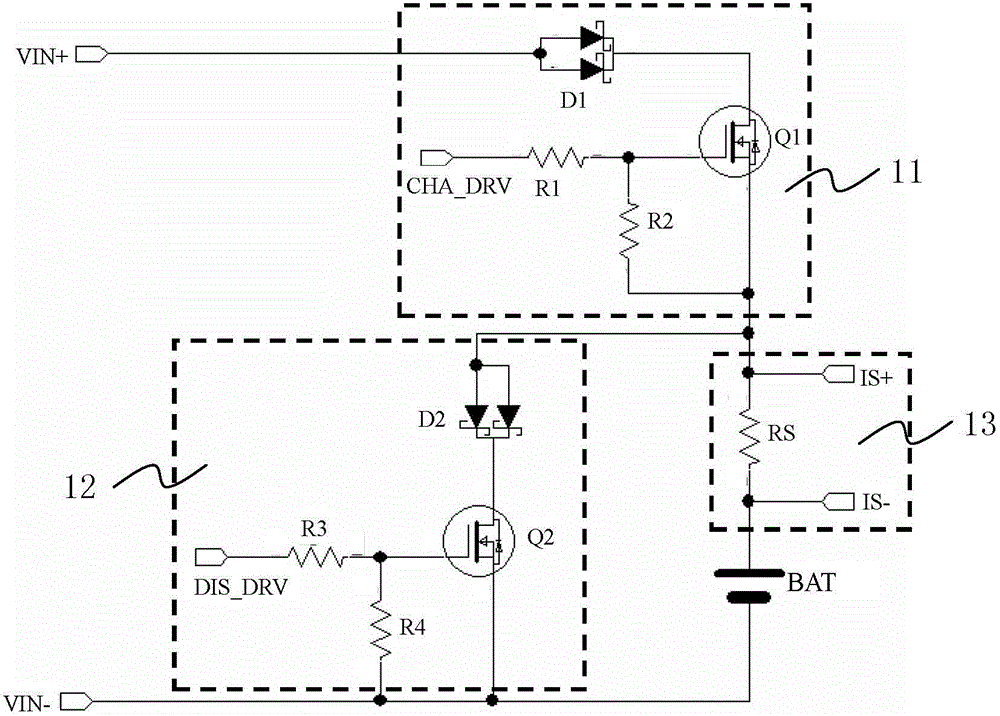

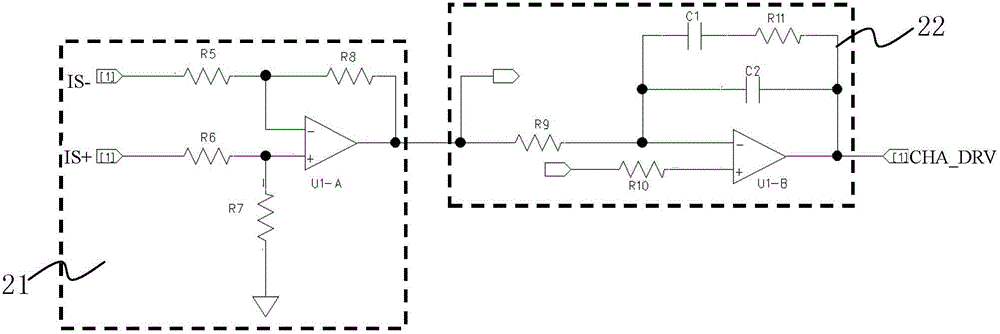

Battery charge-discharge device and battery charge-discharge system

InactiveCN102751763ASolve technical problems with high production costsIncrease profitBatteries circuit arrangementsElectric powerAutomatic controlBattery charge

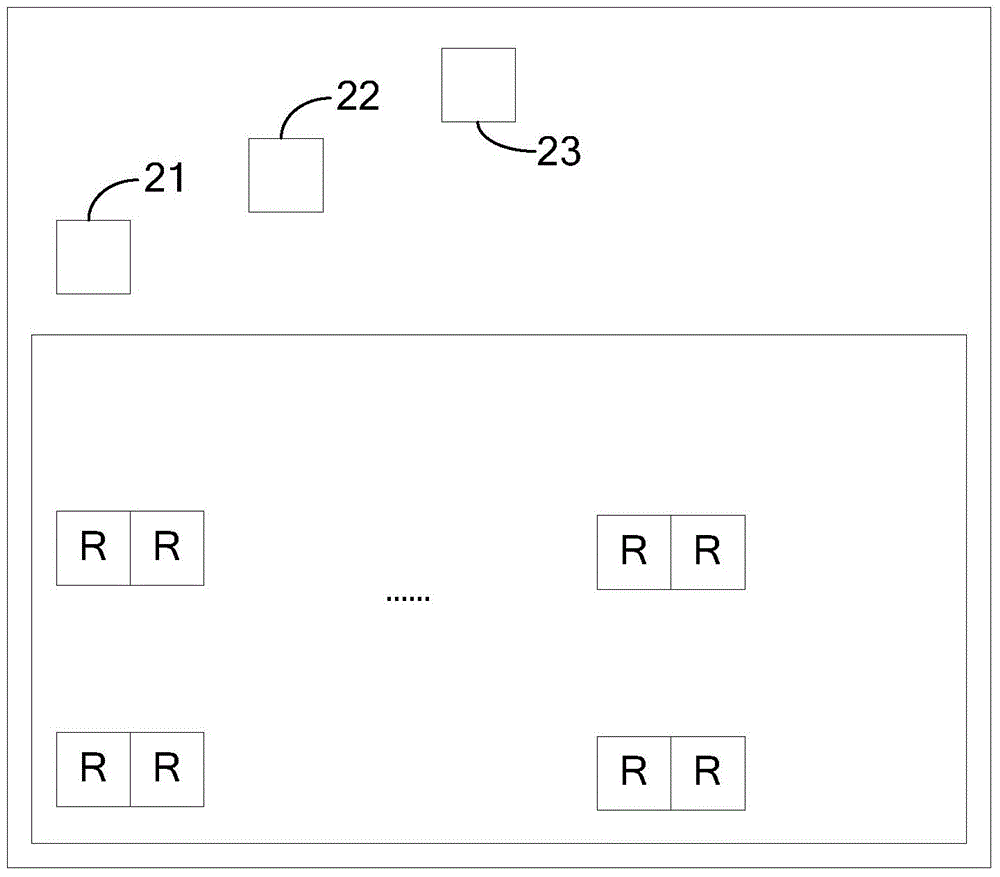

The invention relates to a battery charge-discharge device and a battery charge-discharge system. The battery charge-discharge system comprises a charging power source, at least two battery charge-discharge devices which are connected with each other in parallel, a feedback device used for feeding back the connection condition and the parameters of the battery charge-discharge devices, and a reference output device used for outputting at least two reference charging signals and at least two reference discharge signals according to the data fed back by the feedback device. The invention also relates to the battery charge-discharge device. The battery charge-discharge device and the battery charge-discharge system can be used for automatically controlling the charge-discharge current, thus improving the utilization rate of equipment.

Owner:ANHUI DYNAMIC POWER

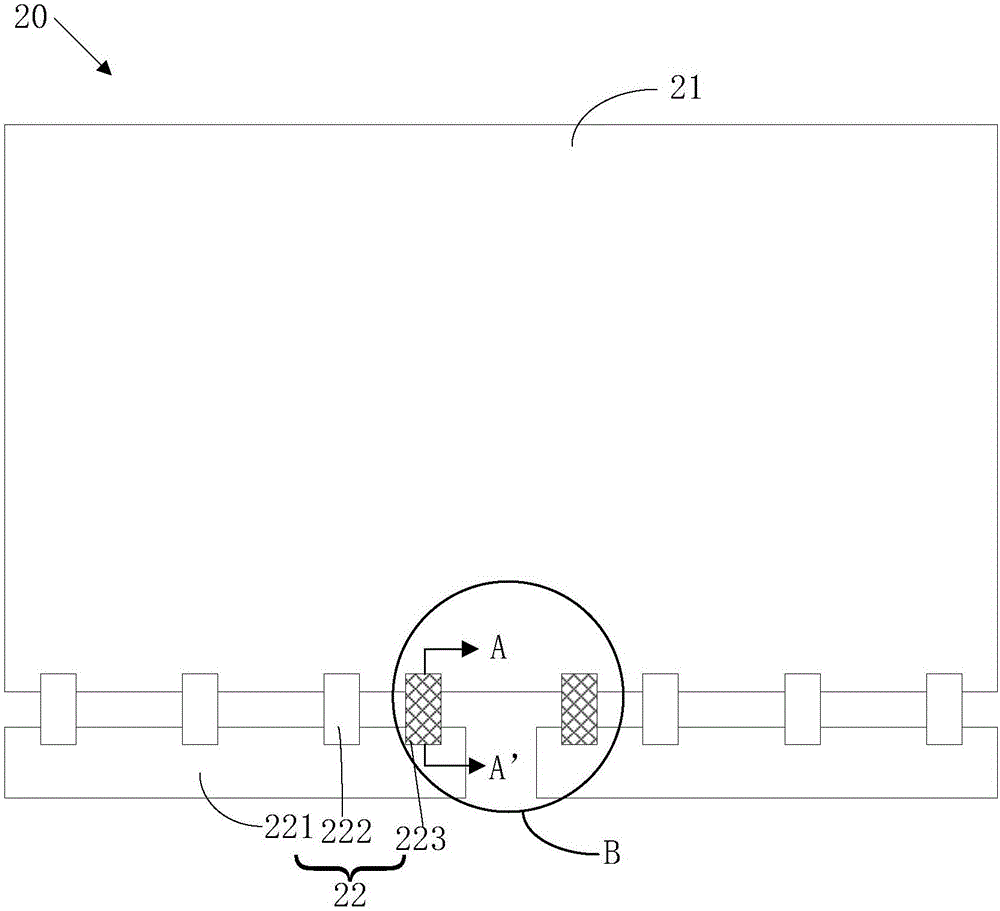

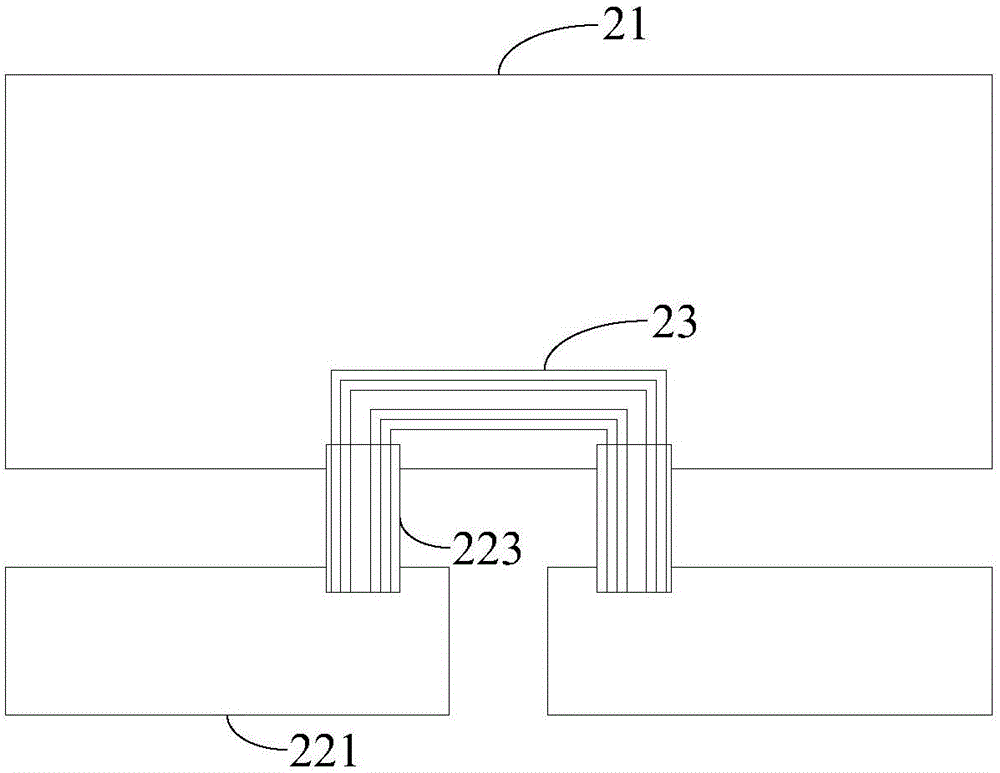

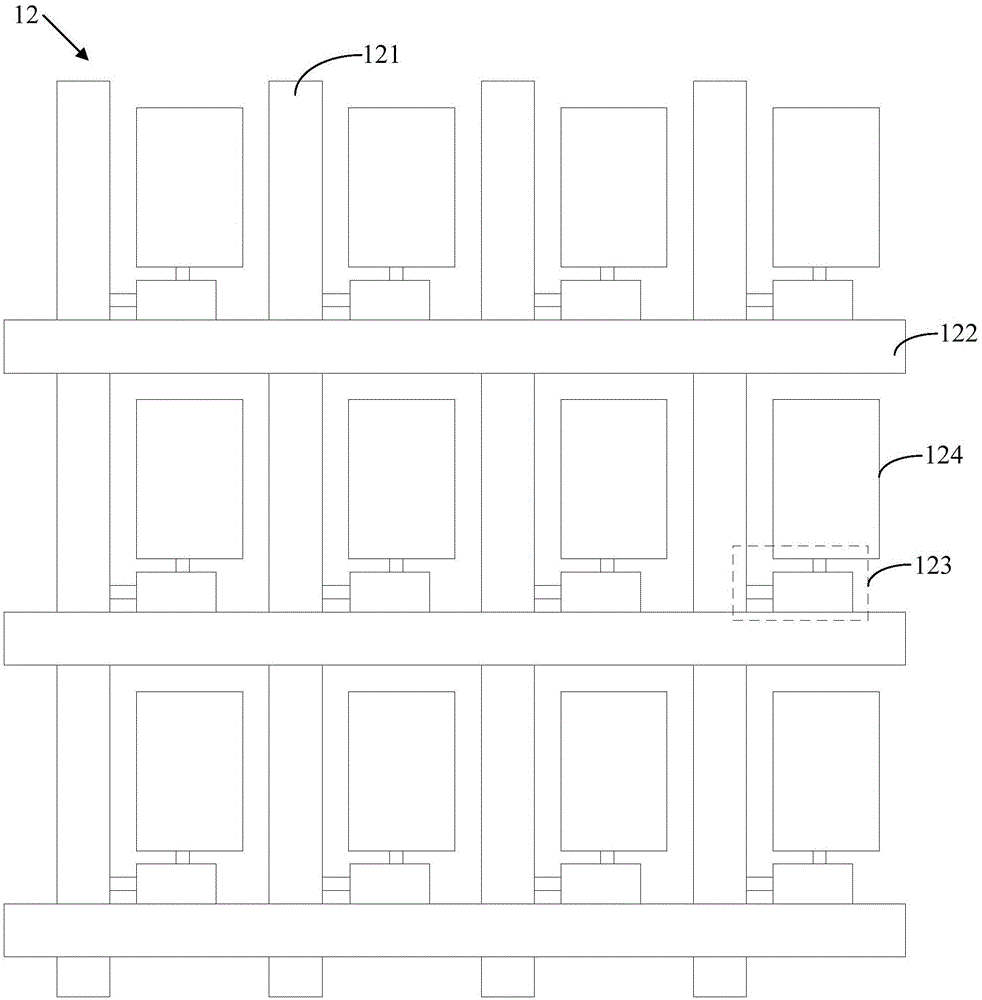

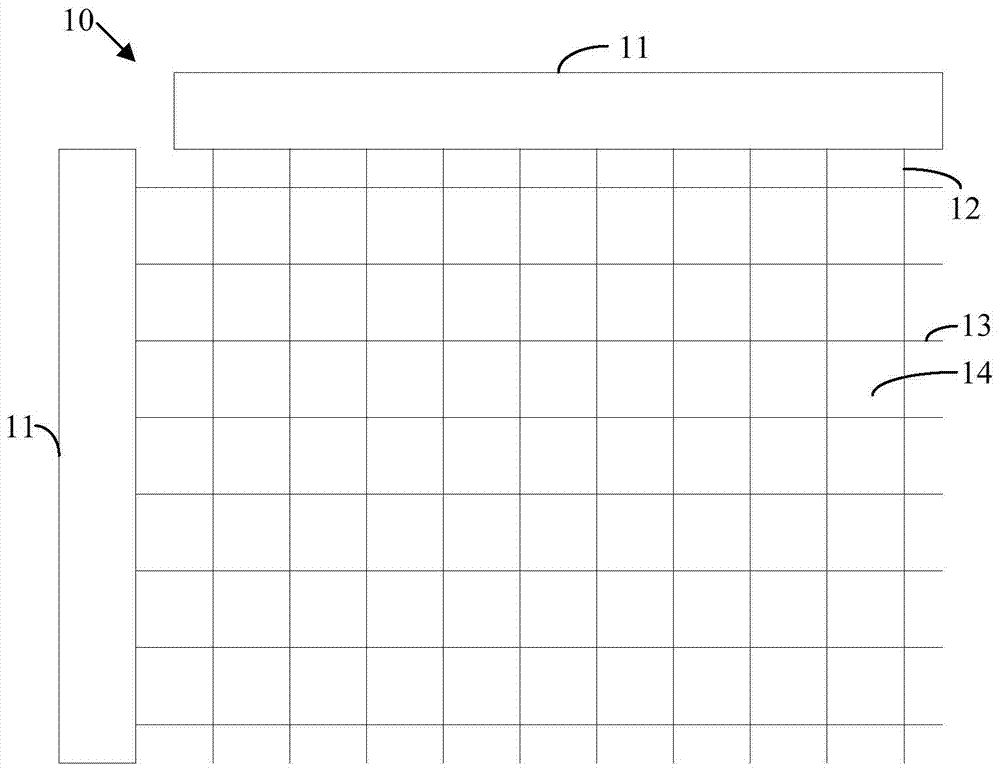

Display panel and display device

ActiveCN106601166AReduce manufacturing costSolve technical problems with high production costsStatic indicating devicesNon-linear opticsDisplay deviceData signal

The invention provides a display panel which comprises a display panel body and at least two driving circuits. The display panel body comprises data wires, scanning wires, pixel units which are formed through intersection of the data wires and the scanning wires, and a circuit board wiring which is used for different driving circuit boards. Each driving circuit board comprises a circuit board body, a first bridging wire and a second bridging wire, wherein the second bridging wire is connected with the circuit board wiring on the display panel body and the circuit board body for transmitting a cascading signal. The first bridging wire is connected with the data wires and scanning wires on the display panel body, and the circuit board body and is used for transmitting a data signal and a scanning signal in response to the cascading signal. The invention further provides a display device. According to the display panel and the display device, different driving circuit boards are connected through the second bridging wire and the circuit board wiring, thereby reducing manufacturing cost of a driving circuit board connecting device and furthermore reducing manufacturing cost of the corresponding display panel.

Owner:TCL CHINA STAR OPTOELECTRONICS TECH CO LTD

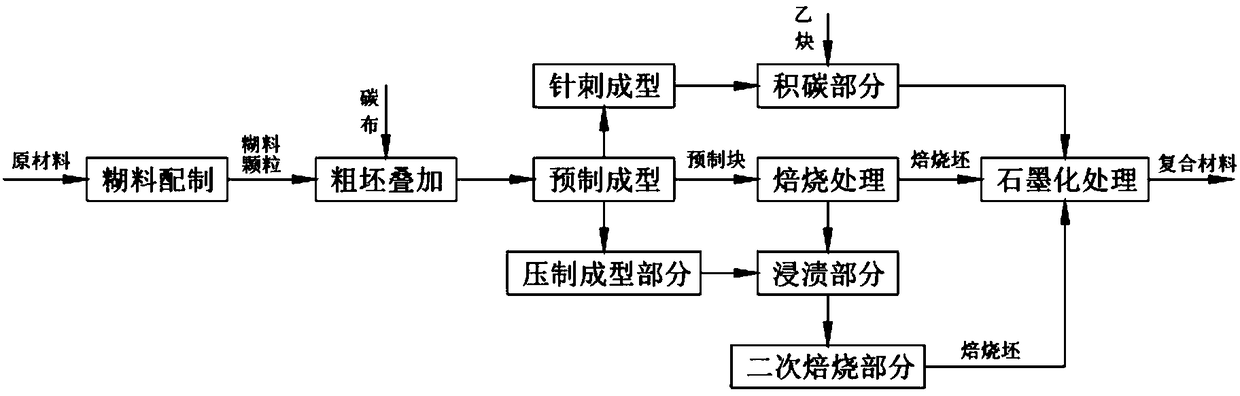

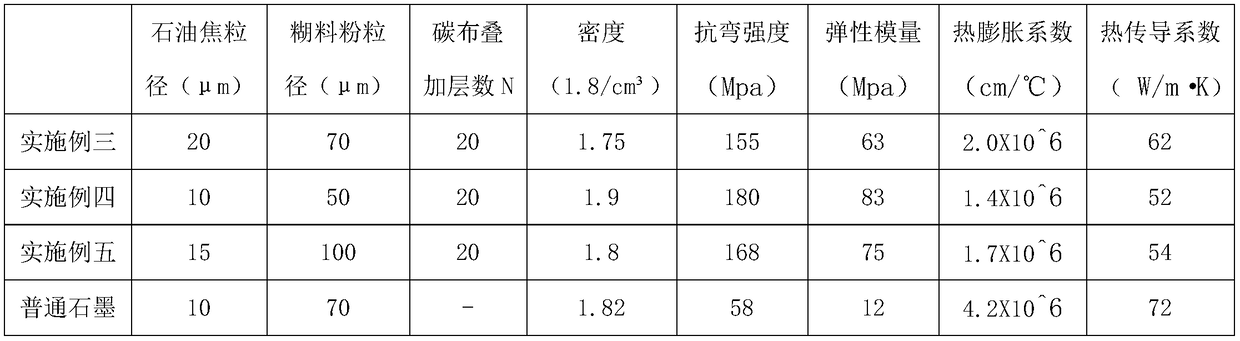

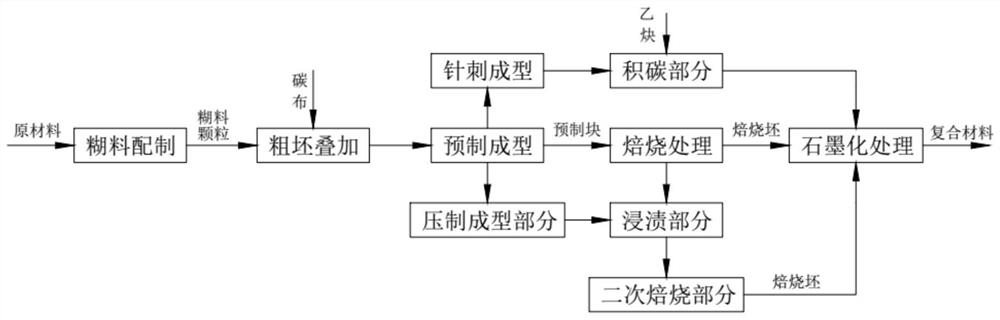

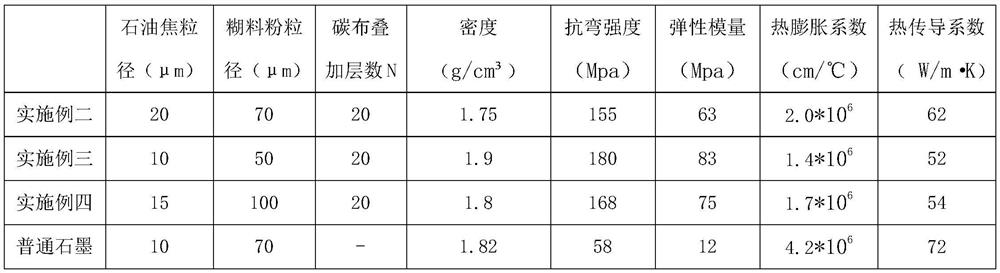

Preparation method of high-performance carbon-carbon composite carbon material

The invention relates to the technical field of artificial graphite production, in particular to a preparation method of a high-performance carbon-carbon composite carbon material. The method comprises the steps of paste material preparation, rough blank overlaying, prefabricating for shaping, calcination treatment and graphitization treatment; after coke powder is fed into a carbon kneading pot for kneading with asphalt, cooling, crushing and then grinding are conducted on the coke powder, gaps and the upper surface of carbon cloth are evenly filled with paste material powder, and then a rough blank is formed; prefabricating for shaping is conducted on the rough blank by means of ballasting or needling; after a prefabricated block is placed in a calcination furnace for calcination, treatment is conducted by means of steeping or carbon deposition to form a calcination blank; finally, graphitization treatment is conducted on the calcination blank by means of high temperature. Through the special overlaying structure of the carbon cloth and the paste material powder, not only is the overall density of the prefabricated block improved, but also even distribution of the carbon cloth and the paste material powder is achieved, great improvement of the mechanical strength of the carbon-carbon composite material is achieved, and the technical problem is solved that in the prior art, the production cost is high due to low graphite material strength.

Owner:SINOSTEEL NEW MATERIAL ZHEJIANG

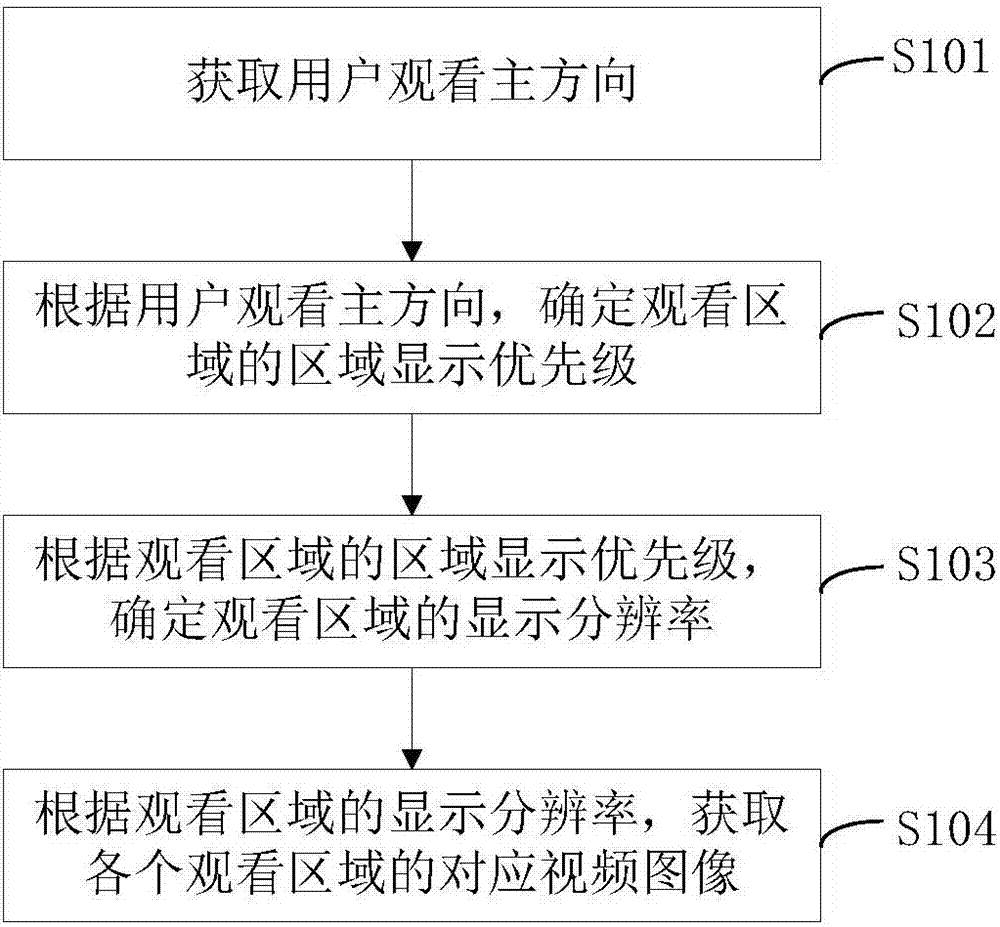

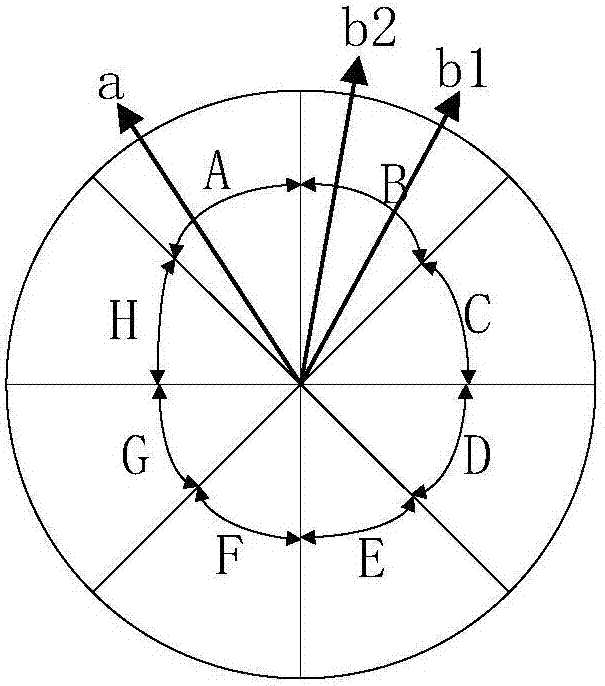

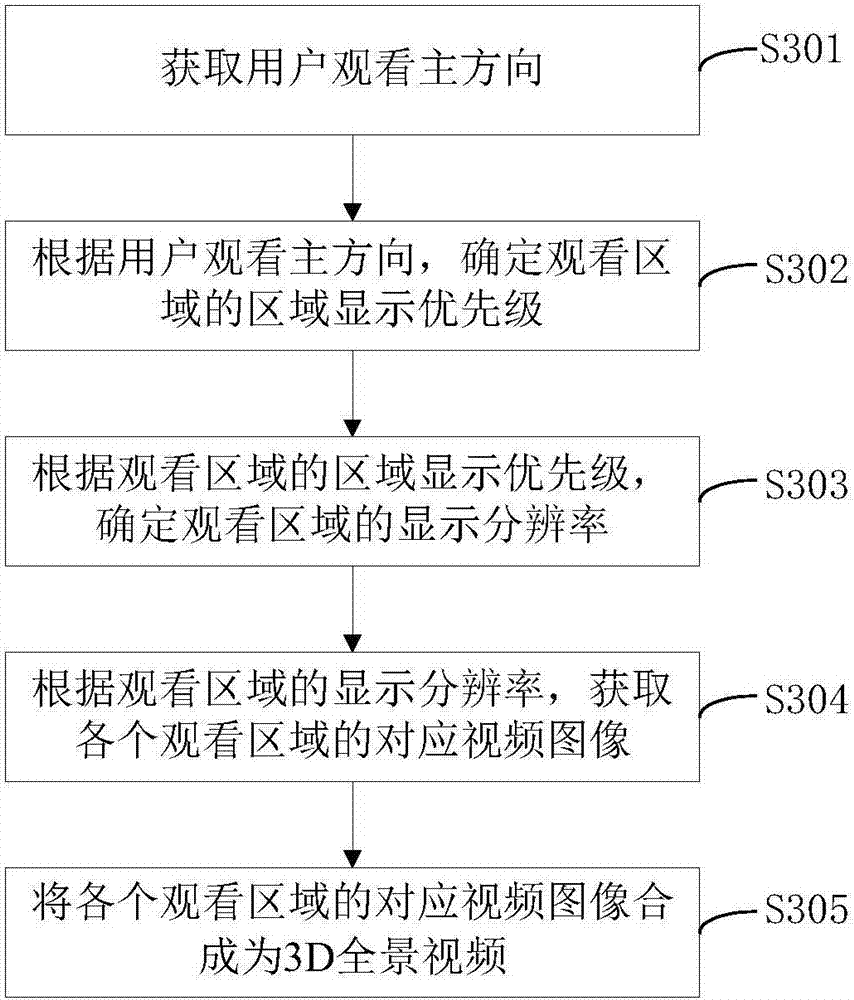

Video image obtaining method and apparatus

InactiveCN107317960AReduced Video Processing Power RequirementsReduce manufacturing costTelevision system detailsColor television detailsVideo playerImage resolution

The invention provides a video image obtaining method. The method comprises the following steps: obtaining a main viewing direction of a user; determining an area display priority of each viewing area according to the main viewing direction of the user; determining display resolution of each viewing area according to the area display priority of the viewing area; and obtaining corresponding video images of each viewing area according to the display resolution of the viewing area. The invention further provides a video image obtaining apparatus. According to the video image obtaining method and apparatus provided by the invention, the display resolution of each viewing area is set according to the main viewing direction of the user, thereby effectively reducing the video processing ability requirements of a corresponding video player and the corresponding network environment requirements, and thus the making cost of the corresponding video player is reduced.

Owner:SHENZHEN KANDAO TECH CO LTD

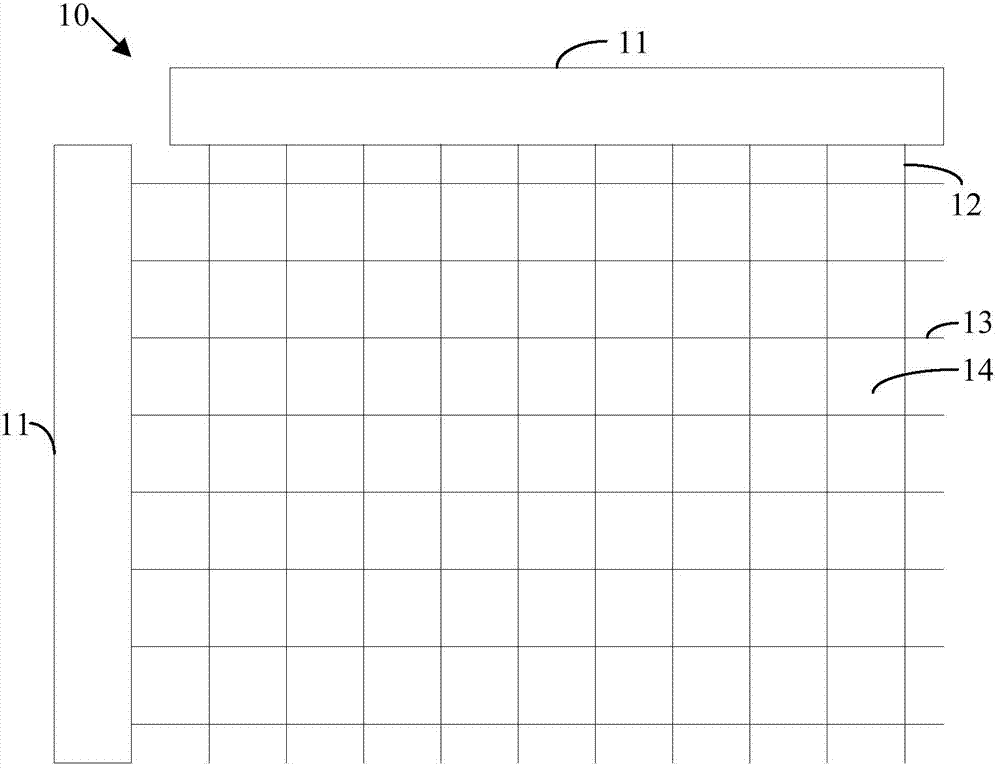

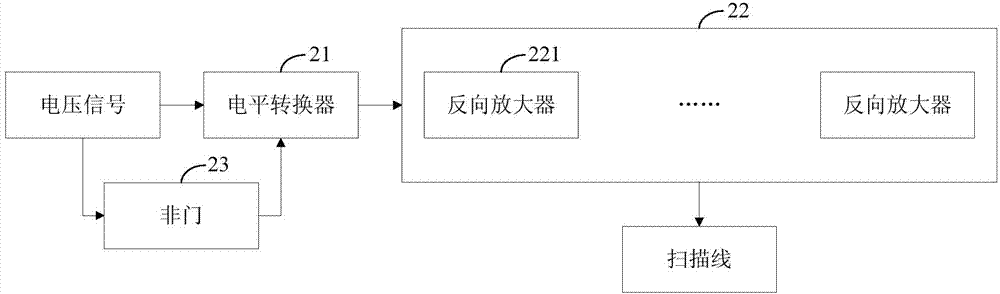

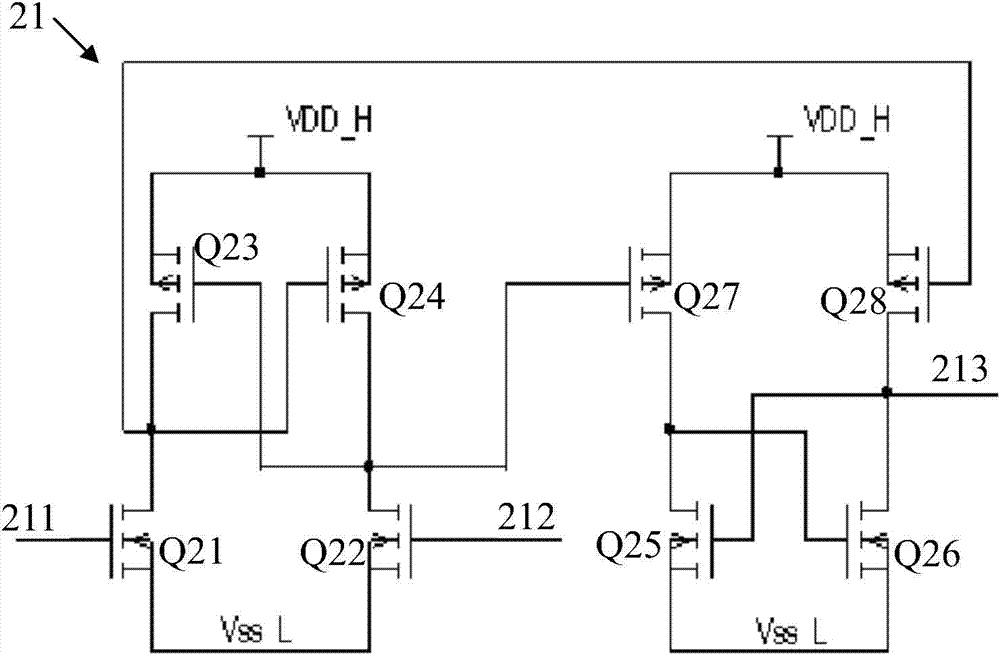

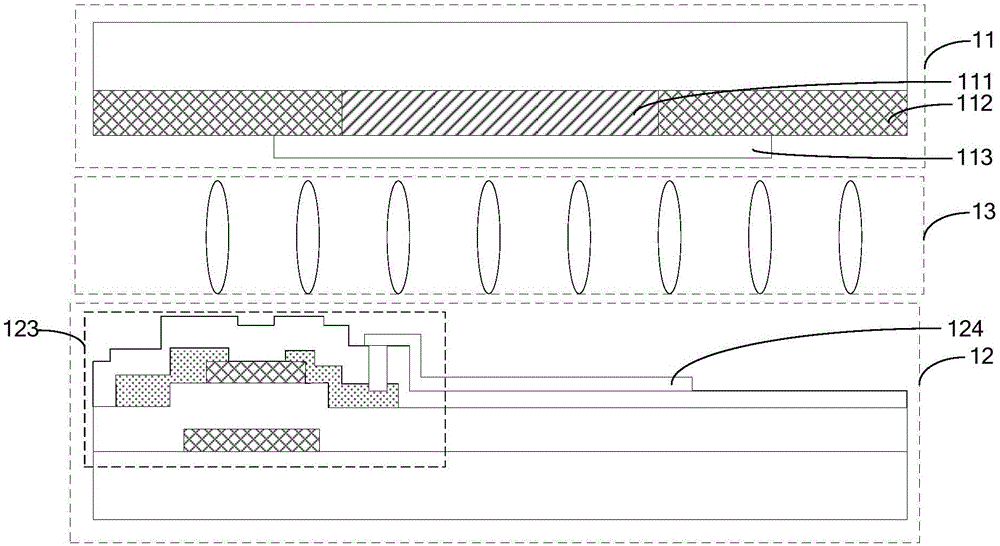

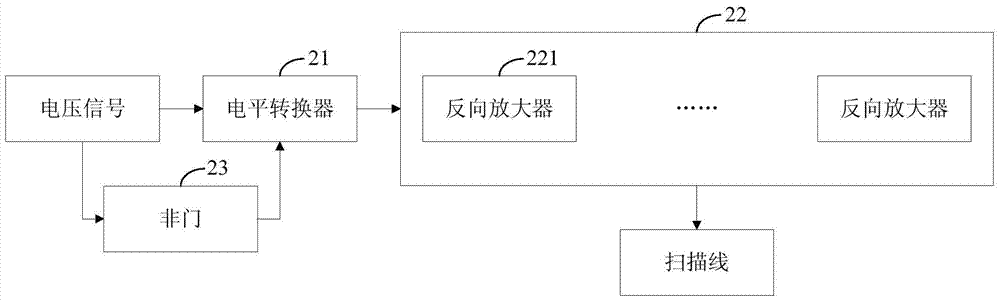

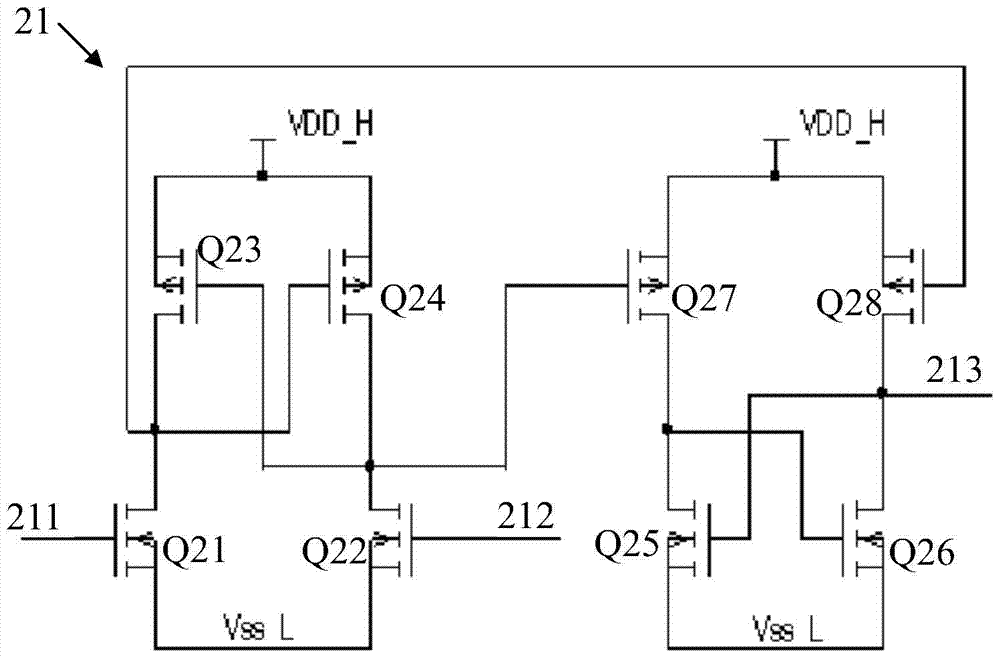

Liquid crystal display panel and liquid crystal display device

ActiveCN104714320AReduce manufacturing costSolve technical problems with high production costsStatic indicating devicesNon-linear opticsLiquid-crystal displayEngineering

The invention provides a liquid crystal display panel comprising a driving circuit, a data line, a scanning line and a pixel unit, wherein the driving circuit comprises a level translator which is used for converting an input voltage signal into a high level signal or a low level signal and an output buffer which is used for performing amplification processing on the high level signal or the low level signal; and the voltage signals input by a positive phase input end and an inverted phase input end of the level translator can be determined according to numbers of inverting amplifiers in the output buffer. The invention also provides a liquid crystal display device. By adopting the liquid crystal display panel and the liquid crystal display device provided by the invention, the manufacturing cost of the liquid crystal display panel can be effectively reduced.

Owner:TCL CHINA STAR OPTOELECTRONICS TECH CO LTD

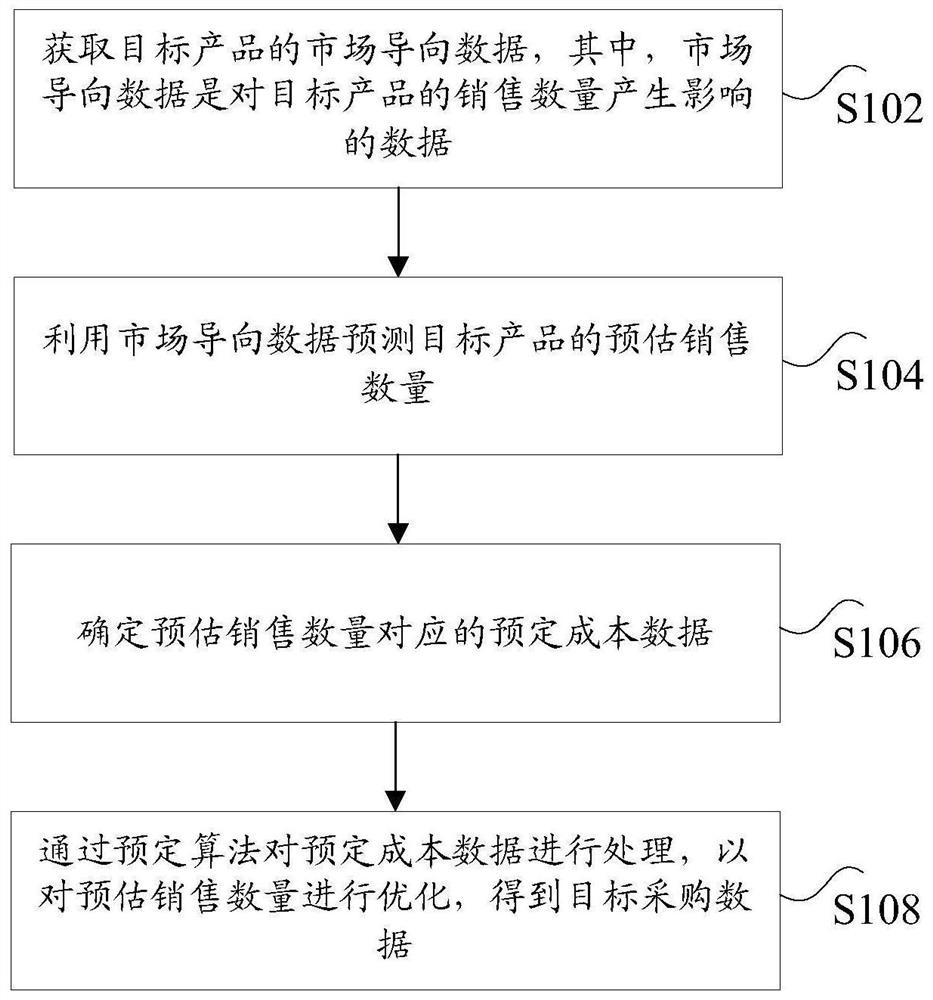

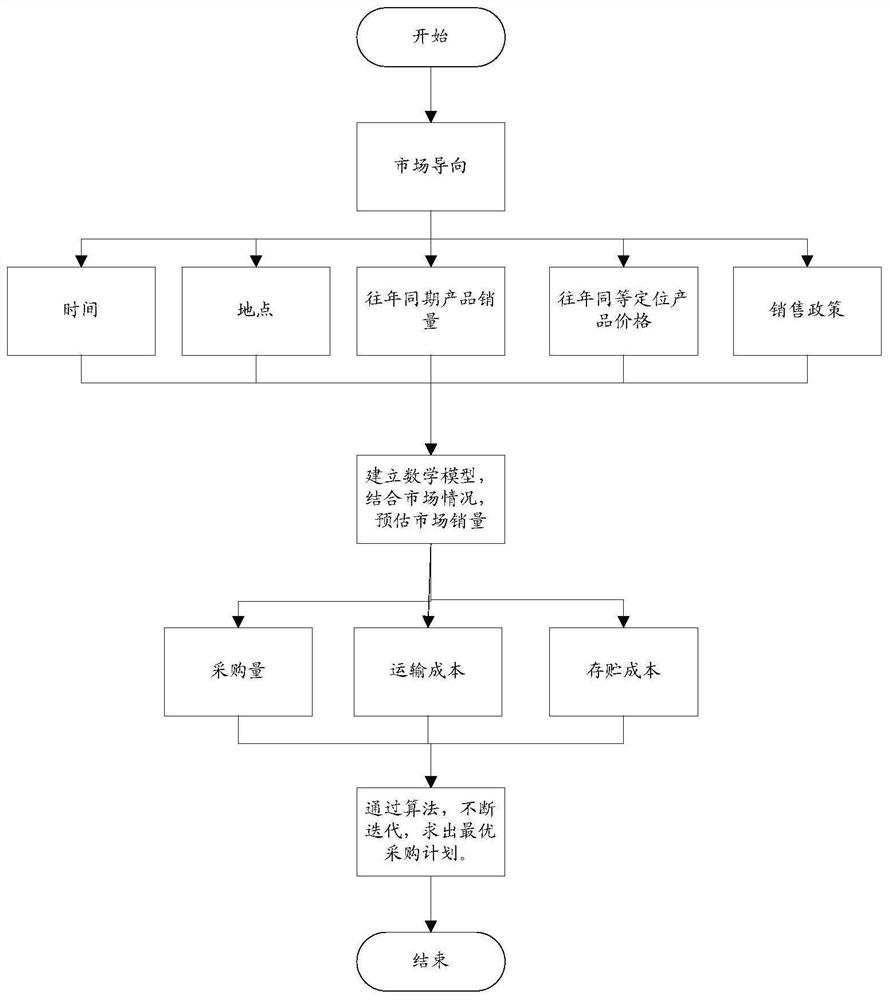

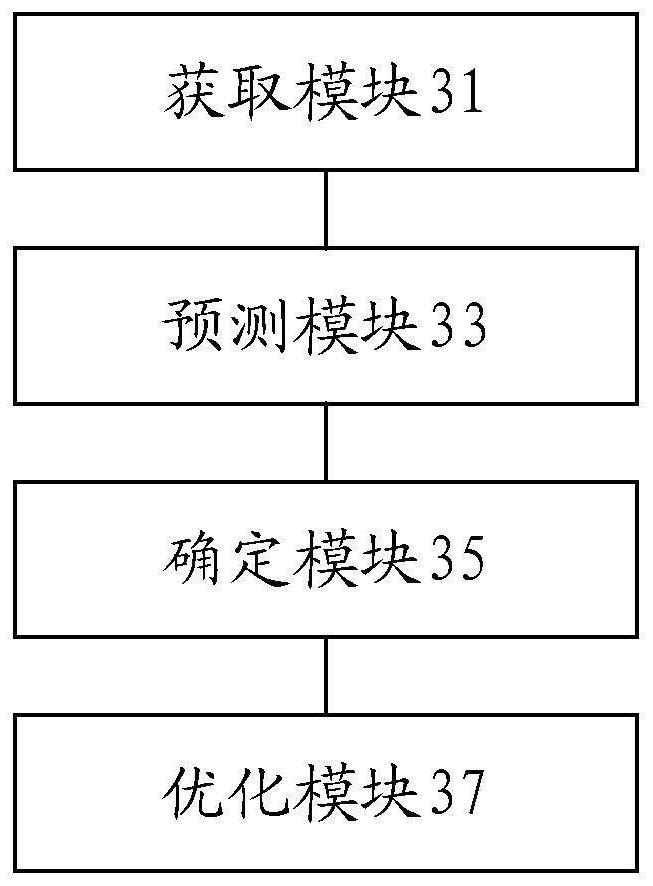

Purchase data determination method and device thereof, and computer readable storage medium

PendingCN114037383AReduce manufacturing costSolve technical problems with high production costsMarket predictionsArtificial lifeMarket orientedData mining

The invention discloses a purchase data determination method and a device and a computer readable storage medium. The method comprises the following steps: acquiring market oriented data of a target product, wherein the market oriented data is data which affects the sales quantity of the target product; predicting an estimated sales quantity of the target product by using the market oriented data; determining predetermined cost data corresponding to the estimated sales quantity; and processing the predetermined cost data through a predetermined algorithm so as to optimize the estimated sales quantity and obtain target purchase data. The technical problem of high production cost caused by the fact that the reasonable proportion of the purchase quantity of the raw materials and the productivity cannot be controlled during purchase in the prior art is solved.

Owner:GREE ELECTRIC APPLIANCES INC

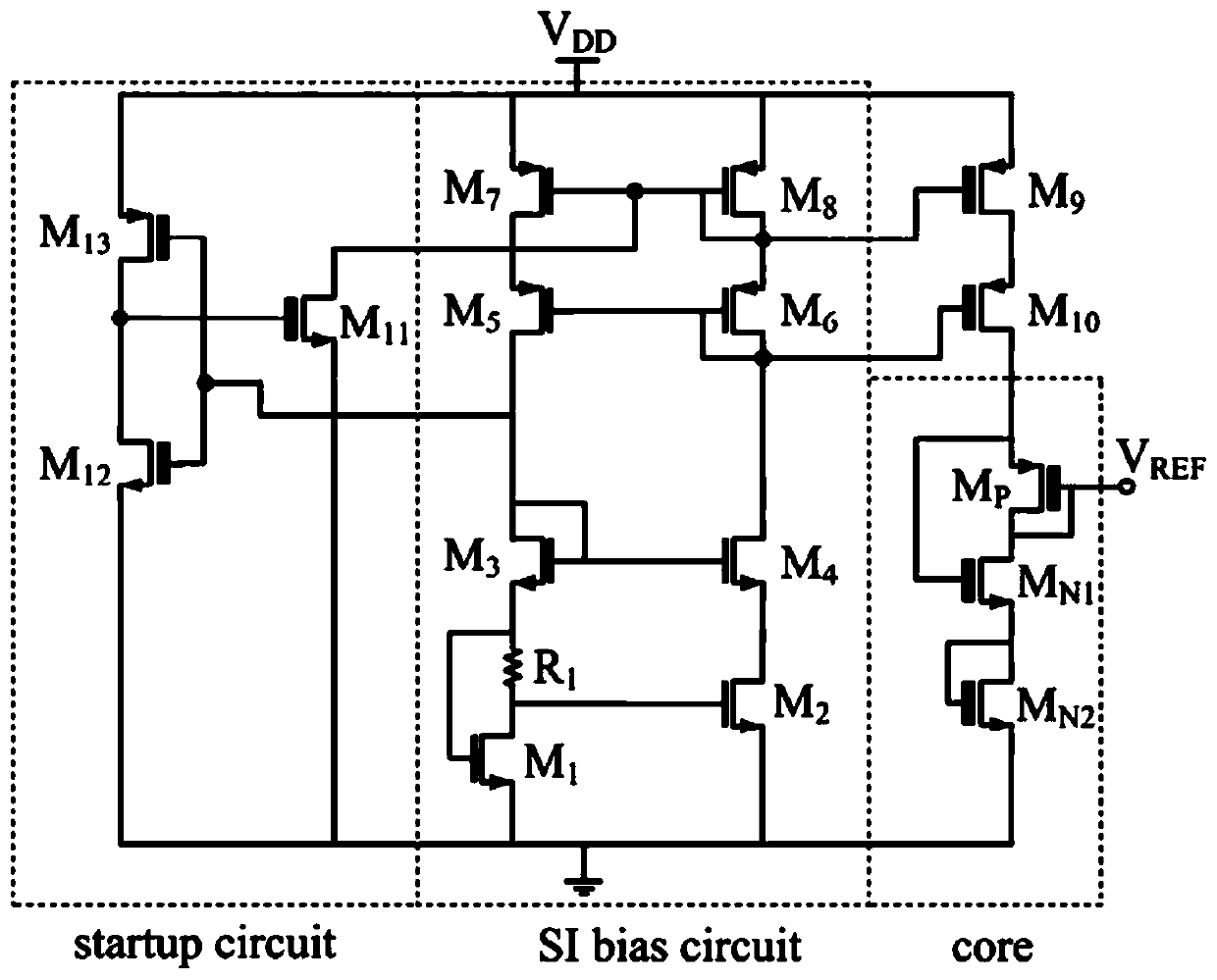

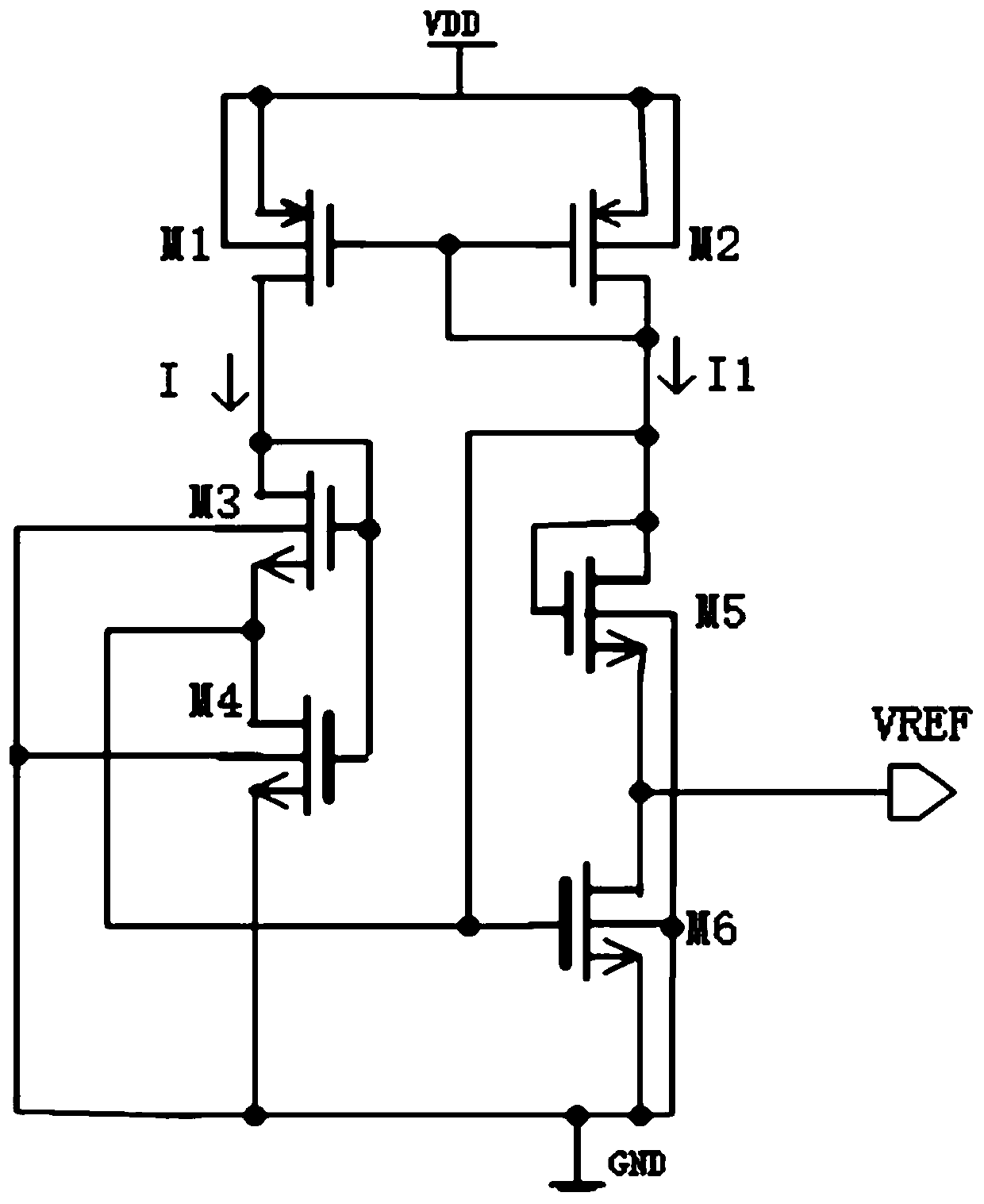

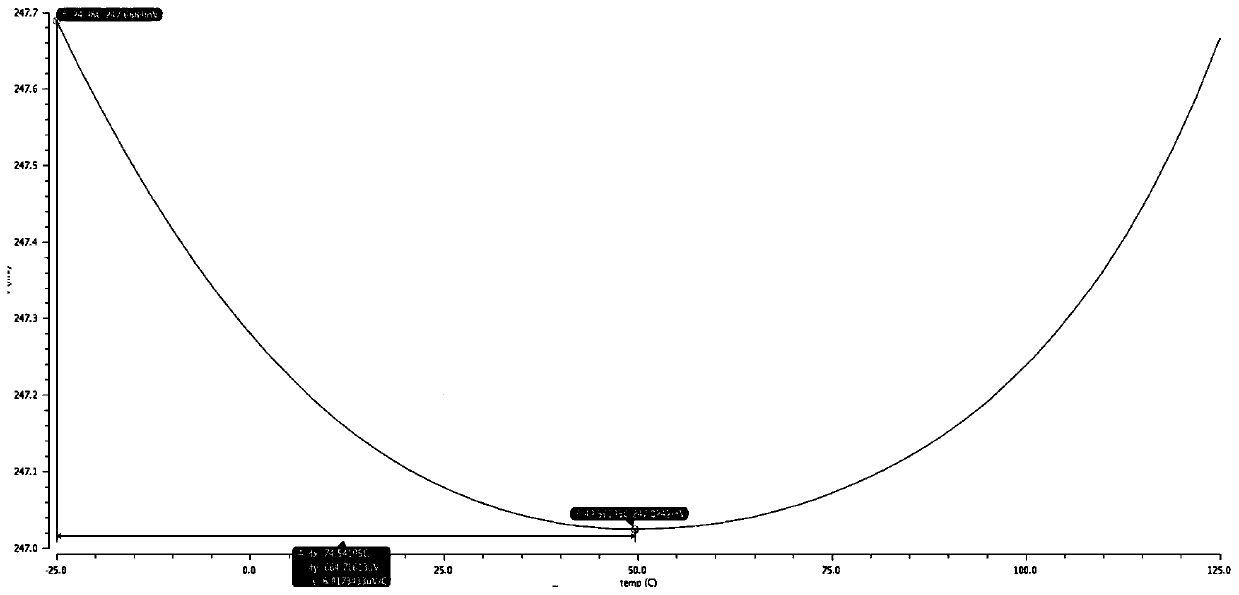

Reference voltage generating device

ActiveCN110673687AEliminates bias current branchReduce usageElectric variable regulationPhysicsCurrent mirror

The present application discloses a reference voltage generating device. A source of a first MOS tube and a source of a second MOS tube are electrically connected with a voltage source respectively; agate of the first MOS tube is electrically connected with a gate of the second MOS tube; the gate of the second MOS tube is connected with a drain of the second MOS tube to form a current mirror structure; a drain of the first MOS tube is electrically connected with a gate of a third MOS tube, and a drain and a gate of a fourth MOS tube, respectively; a source of the third MOS tube is connected with the drain of the fourth MOS tube, and is electrically connected with a gate of a sixth MOS tube, and a threshold voltage of the fourth MOS tube is greater than a threshold voltage of the third MOStube; the drain of the second MOS tube is electrically connected with a gate and a drain of a fifth MOS tube, and the gate of the sixth MOS tube; and a drain of the sixth MOS tube is connected with asource of the fifth MOS tube, and is electrically connected with an output port; and a threshold voltage of the sixth MOS tube is greater than a threshold voltage of the fifth MOS tube. According tothe circuit structure provided by the present application, the technical problem of a high manufacturing cost caused by the complicated structure of the existing reference voltage generating device issolved.

Owner:GUANGDONG UNIV OF TECH

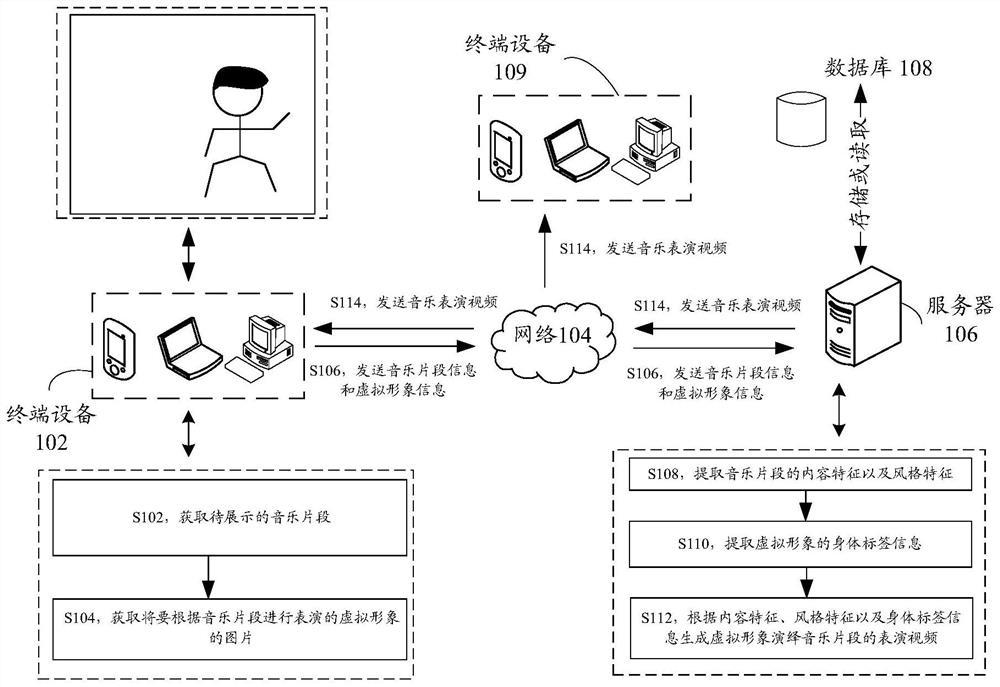

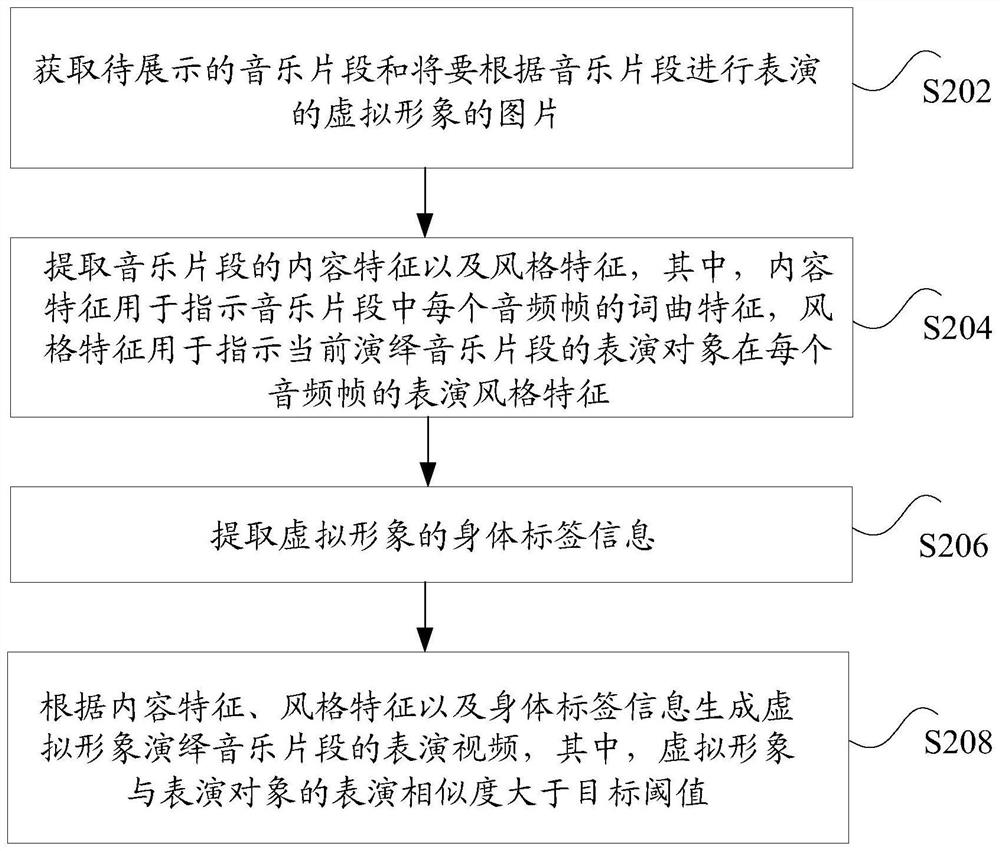

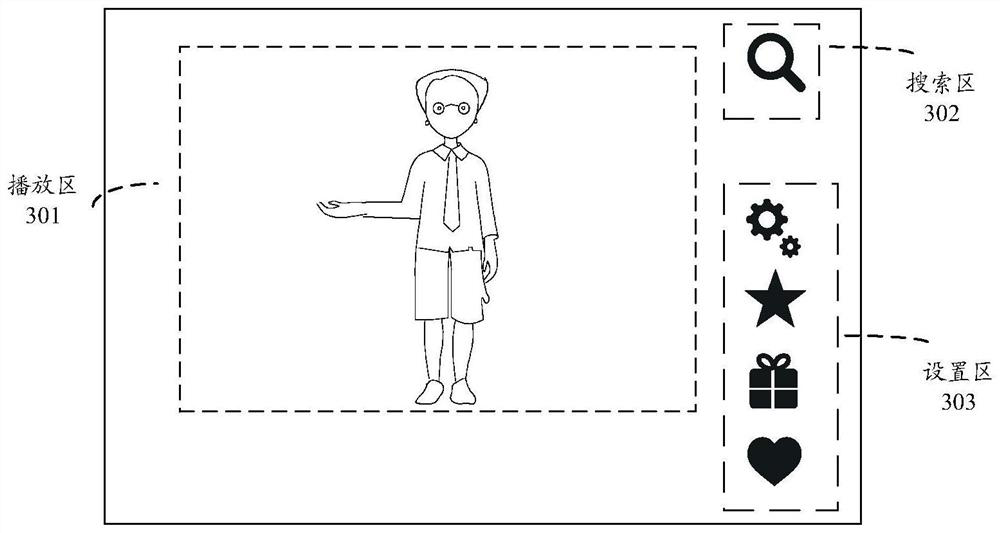

Video generation method and device, storage medium and electronic equipment

ActiveCN114554111ASolve technical problems with high production costsTelevision system detailsSpeech analysisFeature extractionEngineering

The invention discloses a video generation method and device, a storage medium and electronic equipment. The method comprises the following steps: acquiring a music clip to be displayed and a picture of a virtual image to be performed according to the music clip; content features and style features of the music clip are extracted, the content features are used for indicating word and music features of each audio frame in the music clip, and the style features are used for indicating performance style features of a performance object of the currently deduced music clip in each audio frame; extracting body label information of the virtual image; and according to the content features, the style features and the body label information, generating a performance video of a virtual image deducing music clip, the performance similarity between the virtual image and the performance object being greater than a target threshold. The technical problem that in an existing method, the production cost of a music performance video is high is solved.

Owner:广州繁星互娱信息科技有限公司

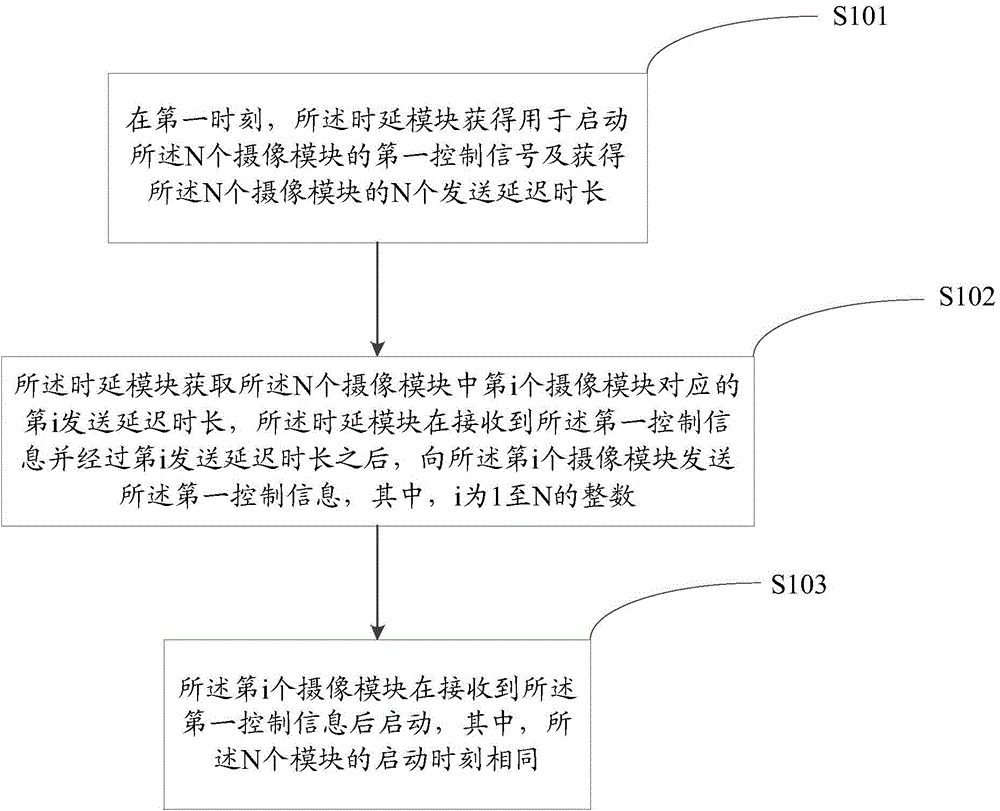

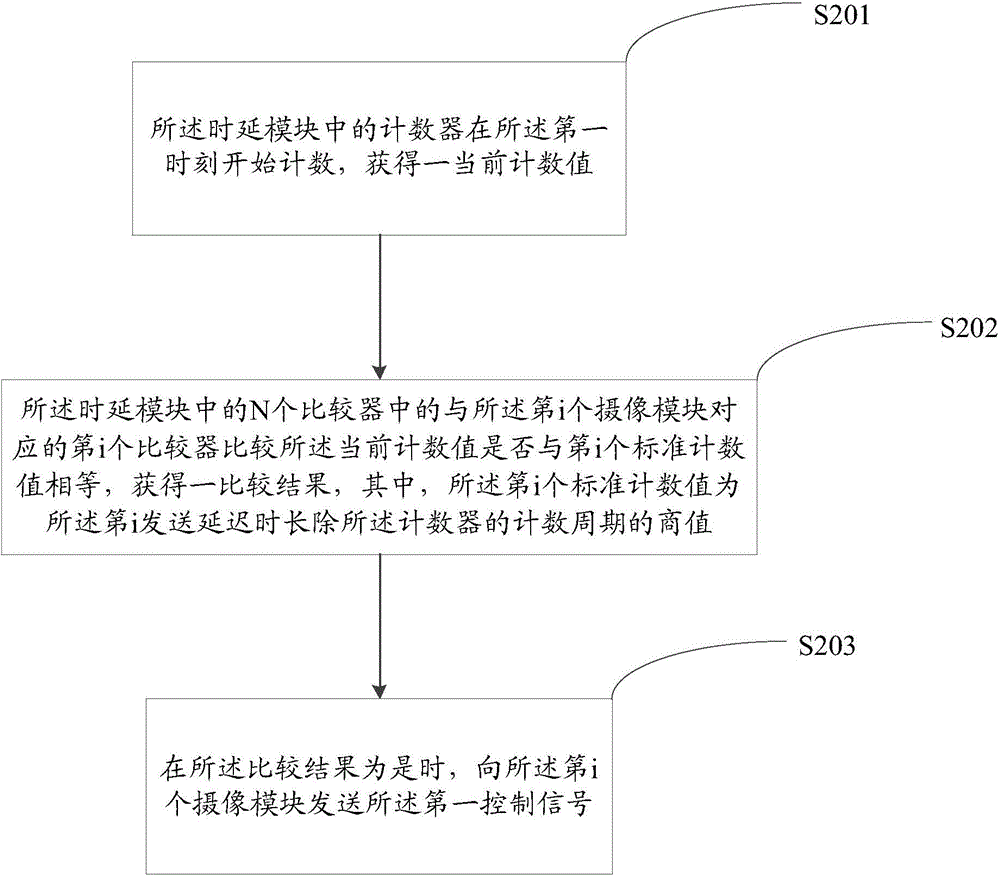

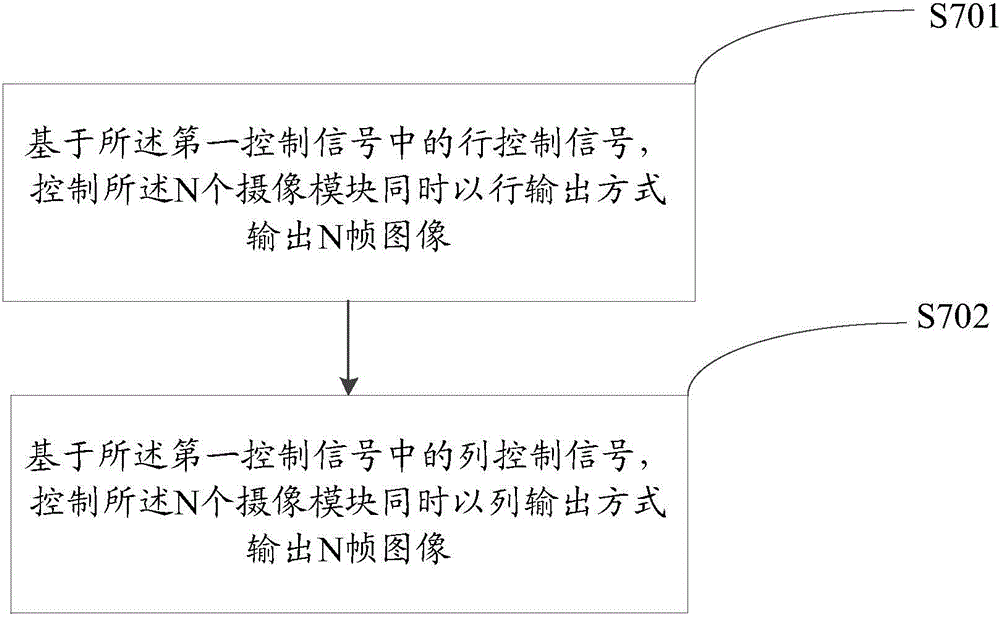

Information processing method and electronic device

InactiveCN105530420ASolve technical problems with high production costsReduce manufacturing costTelevision system detailsColor television detailsInformation processingControl signal

The invention discloses an information processing method, which is applied to an electronic device. The electronic device comprises a time delay module and N photographing modules connected with the time delay module, wherein N is an integer no small than 2. The method comprises steps: at a first time, the time delay module acquires a first control signal for starting the N photographing modules and N sending delay time durations of the N photographing modules; the time delay module acquires an ith sending delay time duration corresponding to the ith photographing module in the N photographing modules, and when the time delay module receives first control information and after the ith sending delay time duration, the first control information is sent to the ith photographing module, wherein i is an integer between 1 and N; and the ith photographing module starts after receiving the first control information, wherein the N modules have the same starting time.

Owner:LENOVO (BEIJING) LTD

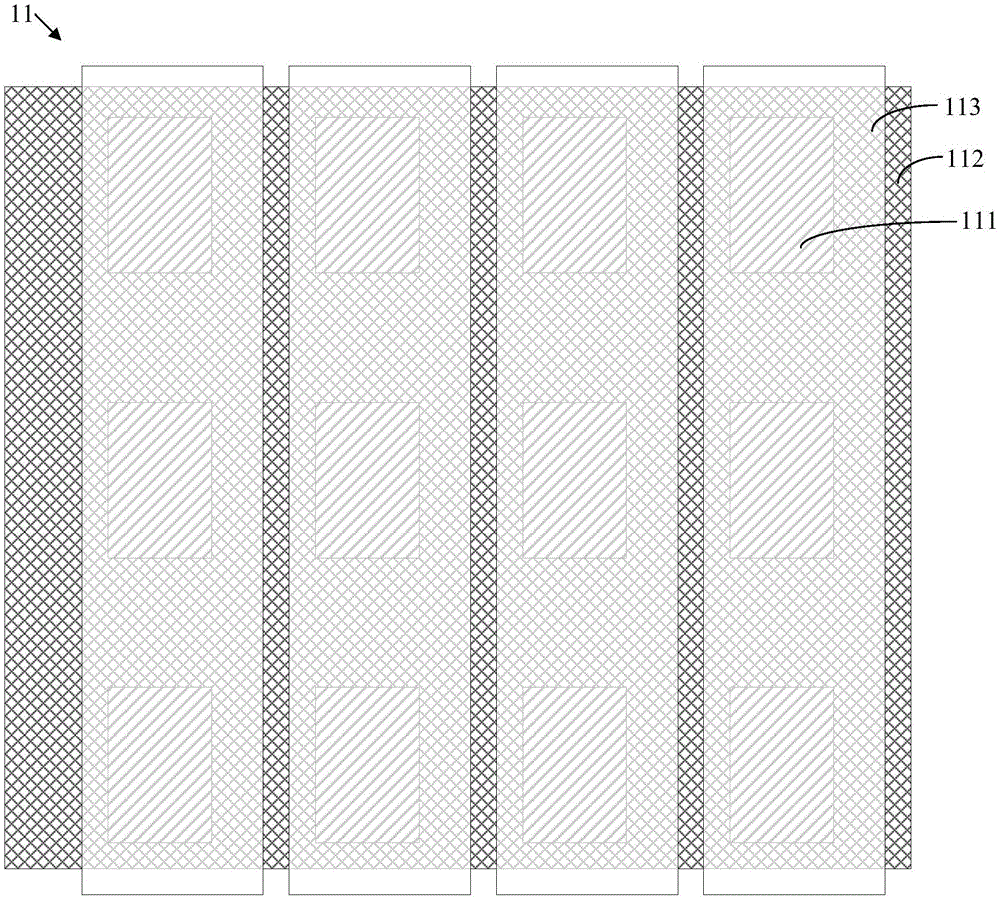

Touch display panel and touch display device

ActiveCN105159516AReduce manufacturing costSolve technical problems with high production costsInput/output processes for data processingPhysicsLiquid crystal

The invention provides a touch display panel, which comprises a color-film substrate, an array substrate and a liquid crystal layer, wherein a color-film color barrier and a common electrode are arranged on the color-film substrate; a data line, a scanning line, a thin-film transistor and a pixel electrode are arranged on the array substrate; the liquid crystal layer is arranged between the color-film substrate and the array substrate; the common electrode comprises a plurality of strip-shaped sub-common electrodes which are distributed in parallel; and when the touch display panel carries out a touch operation, the common electrode is used as a touch induction electrode and the scanning line is used as a touch drive electrode. The invention further provides a touch display device. According to the touch display panel and the touch display device provided by the invention, the common electrode is used as the touch induction electrode and the scanning line is used as the touch drive electrode, so that extra touch wire arrangement is reduced; and the manufacturing cost of the touch display panel and the touch display device is reduced.

Owner:TCL CHINA STAR OPTOELECTRONICS TECH CO LTD

Electronic device

InactiveCN105449335AGuaranteed reception performanceGuaranteed Receive Performance RequirementsAntenna arraysAntenna supports/mountingsCoaxial cableEnergy coupling

The invention discloses an electronic device comprising a device housing, a monopole antenna, a loop antenna, and a coaxial cable, wherein the monopole antenna, the loop antenna and the coaxial cable are disposed in the device housing. The coaxial cable is directly connected with the feed port of the monopole antenna, and feeds the monopole antenna in order to stimulate the monopole antenna to generate radiation such that a high-frequency resonant electromagnetic field is formed on the radiation end of the monopole antenna. The loop antenna is located within the coverage of the high-frequency resonant electromagnetic field generated by the monopole antenna. The high-frequency resonant electromagnetic field stimulates the loop antenna by means of energy coupling so as to enable the monopole antenna and the loop antenna to be both in operating states.

Owner:LENOVO (BEIJING) LTD

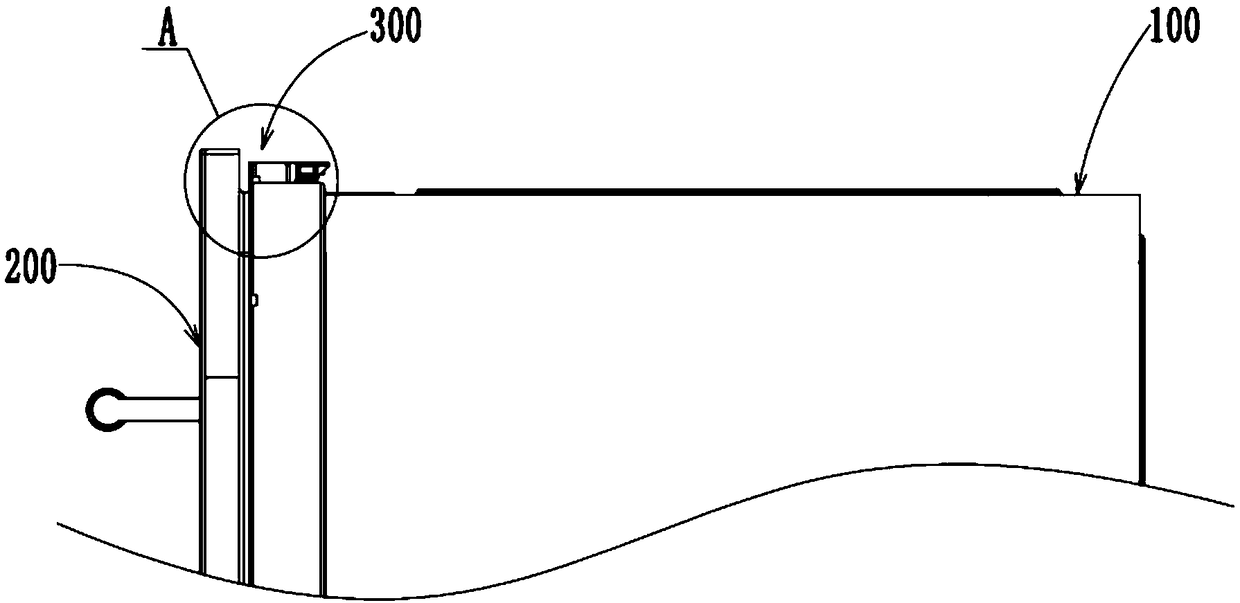

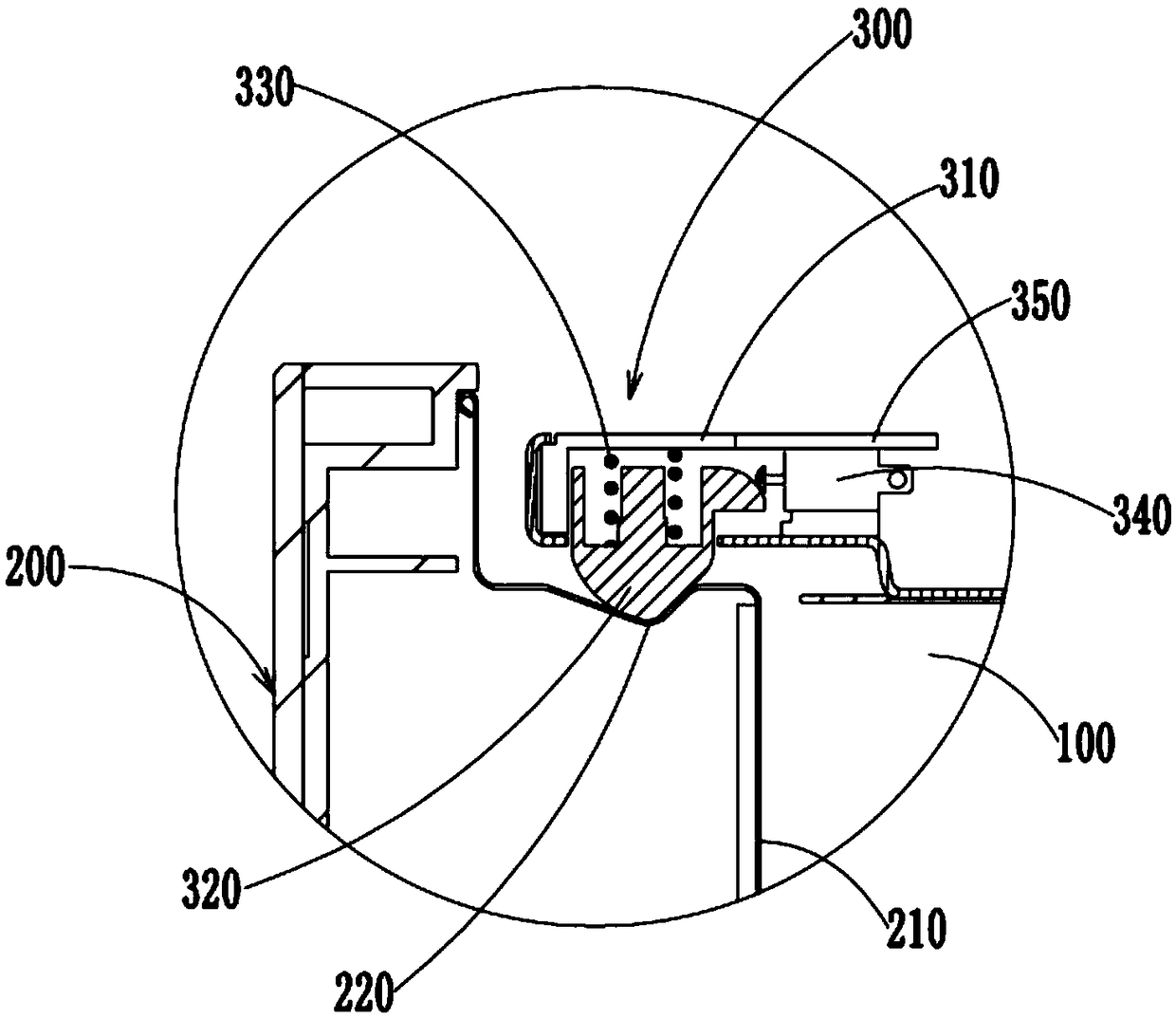

Door locking assembly and dish washing machine

PendingCN108888223ASimple structureEasy to manufactureTableware washing/rinsing machine detailsBuilding locksEngineeringMechanical engineering

The invention provides a door locking assembly and a dish washing machine and relates to the technical field of household electric appliances, which is designed for solving the problem of high production cost of the dish washing machine due to complicated door lock structure. The door locking assembly is arranged between a door body and a body of the household electric appliance with an opening and comprises a bolt, a switching element and a groove, wherein the bolt is elastically retracably arranged in the body, the switching element is mounted on the body, the groove formed in the door bodyis used for accommodating the bolt, the switching element is connected with a controller of the household electric appliance, and a touch point of the switching element can be triggered when the boltretracts; when the opening of the door body is closed, the bolt retracts to be locked in the groove, and thus, the door body is locked at a close position. The dish washing machine comprises the doorlocking assembly. The door locking assembly and the dish washing machine are used for overcoming the defects of complex manufacturing and assembling process and high cost due to the separation of a bolt structure and a locking structure in the prior art.

Owner:HANGZHOU ROBAM APPLIANCES CO LTD

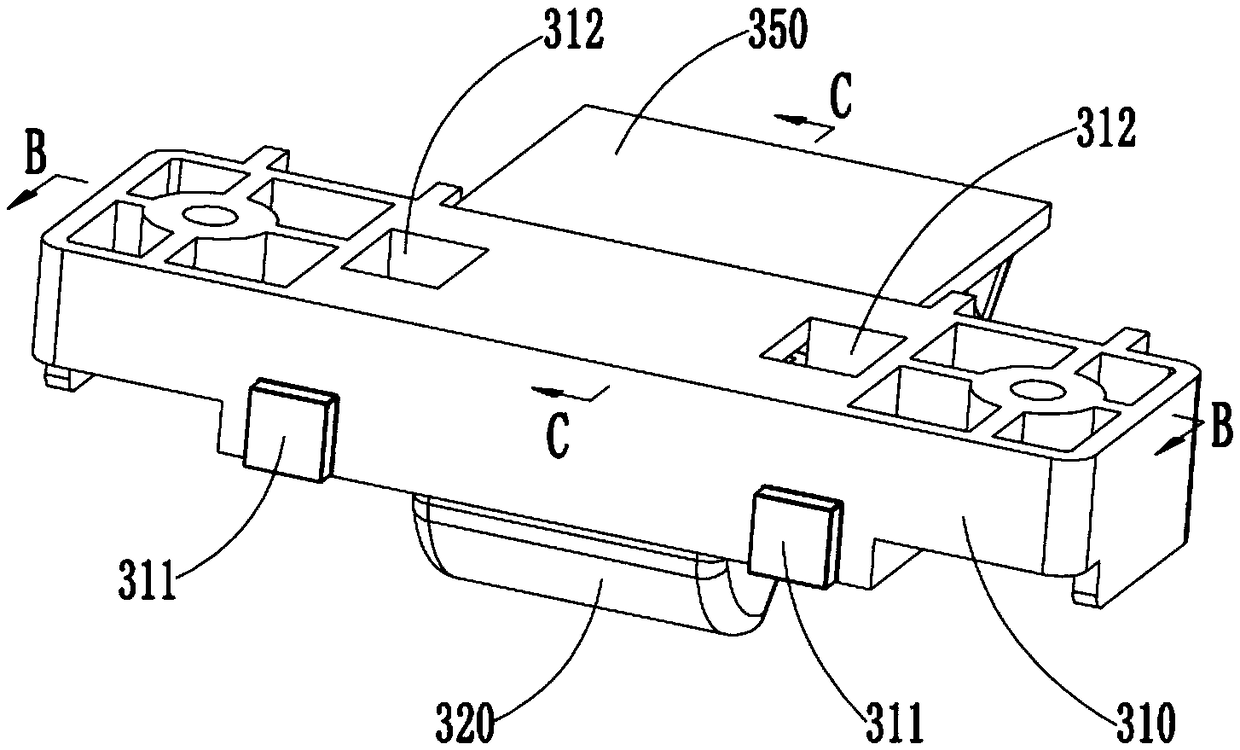

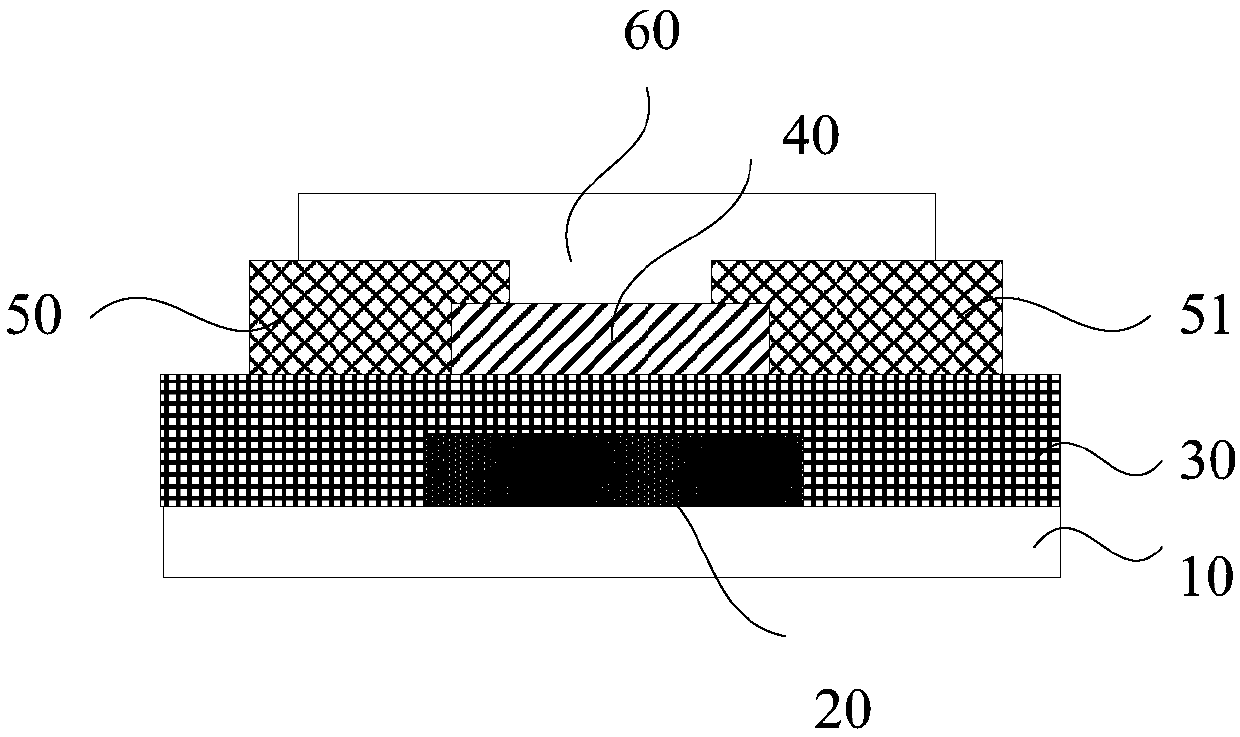

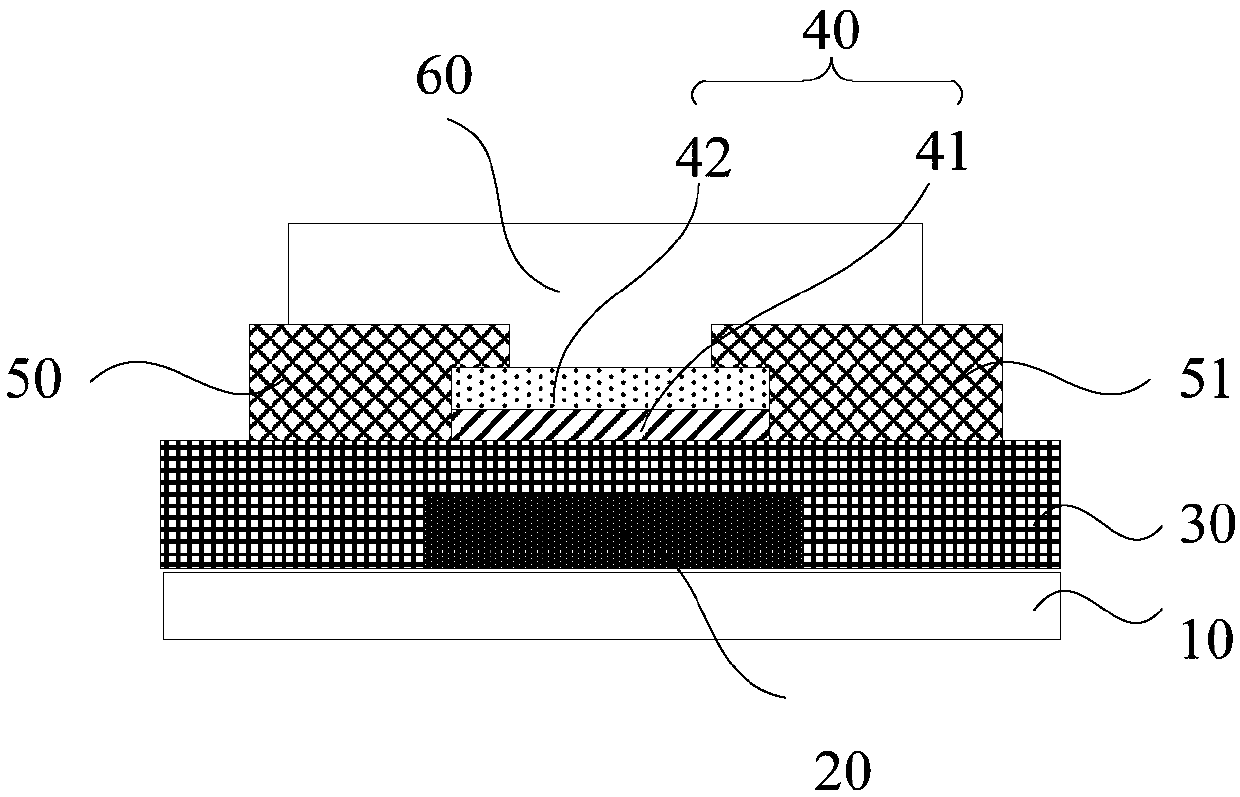

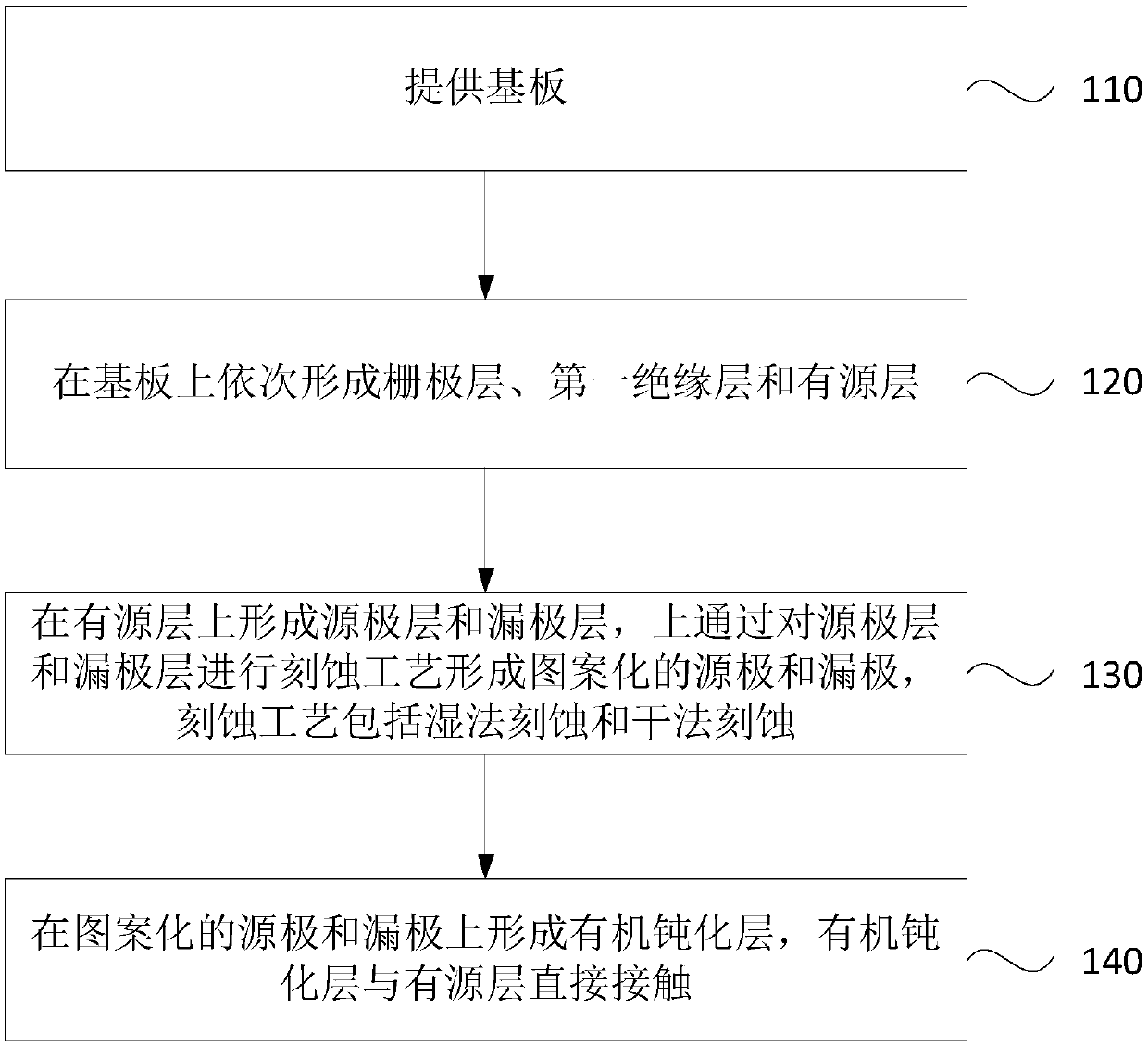

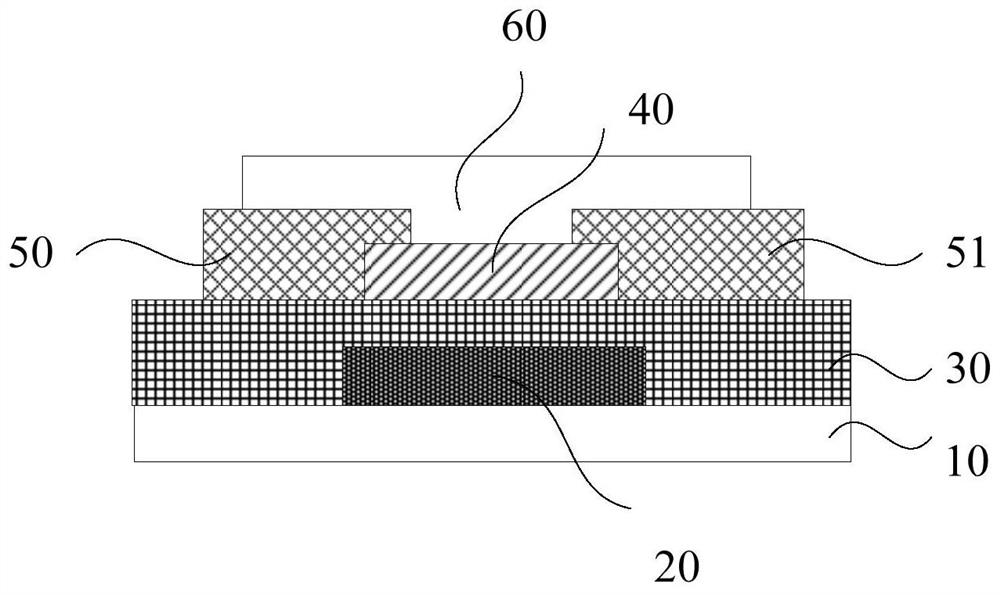

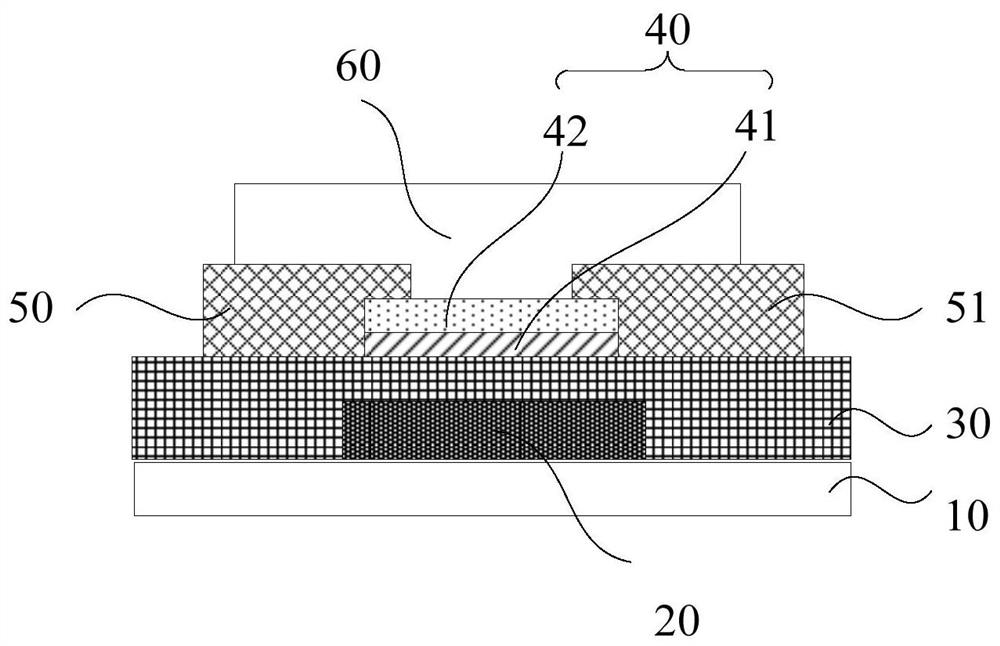

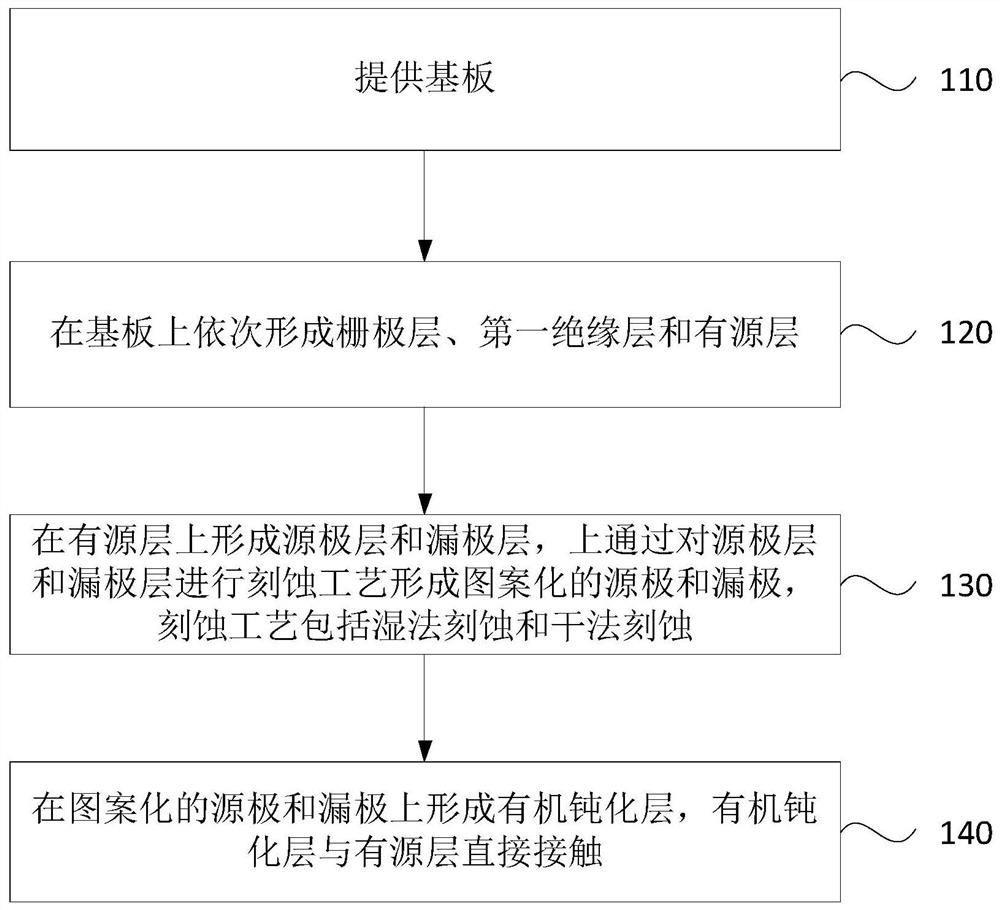

Thin film transistor and preparation method thereof

ActiveCN109638082AEtching resistanceResist bombardmentTransistorSemiconductor/solid-state device manufacturingIndiumEngineering

The invention discloses a thin film transistor and a preparation method thereof. The thin film transistor comprises a substrate, a gate layer, a first insulating layer, an active layer, a patterned source electrode, a drain electrode, and an organic passivation layer; the gate layer, the first insulating layer and the active layer are formed on the substrate, the patterned source electrode and drain electrode formed on the active layer are respectively electrically connected with the active layer; the organic passivation layer formed on the patterned source electrode and drain electrode is indirect contact with the active layer; the active layer comprises a metal oxide, the metal oxide comprises an oxide In2O3 of indium and a composite oxide formed by oxide MO of a fifth sub-group element, and the organic passivation layer is a polymer organic material. According to the technical scheme, the organic passivation layer is in direct contact with the active layer composed of the indium oxide In2O3 of indium and the composite oxide formed by the oxide MO of the fifth sub-group element; on one hand, the organic passivation layer and the active layer are in direct contact such that a donor doping effect is not caused to the active layer, and the device works normally and stably; on the other hand, the preparation process is simple, and the cost is low.

Owner:深圳庸行科技有限公司

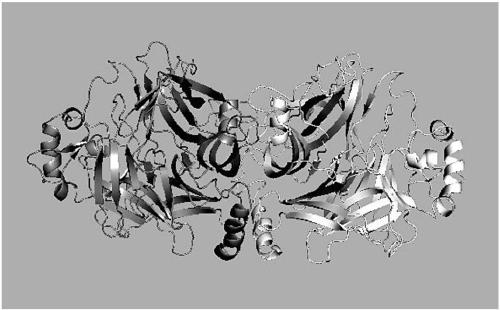

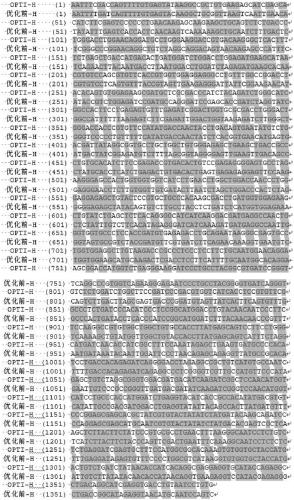

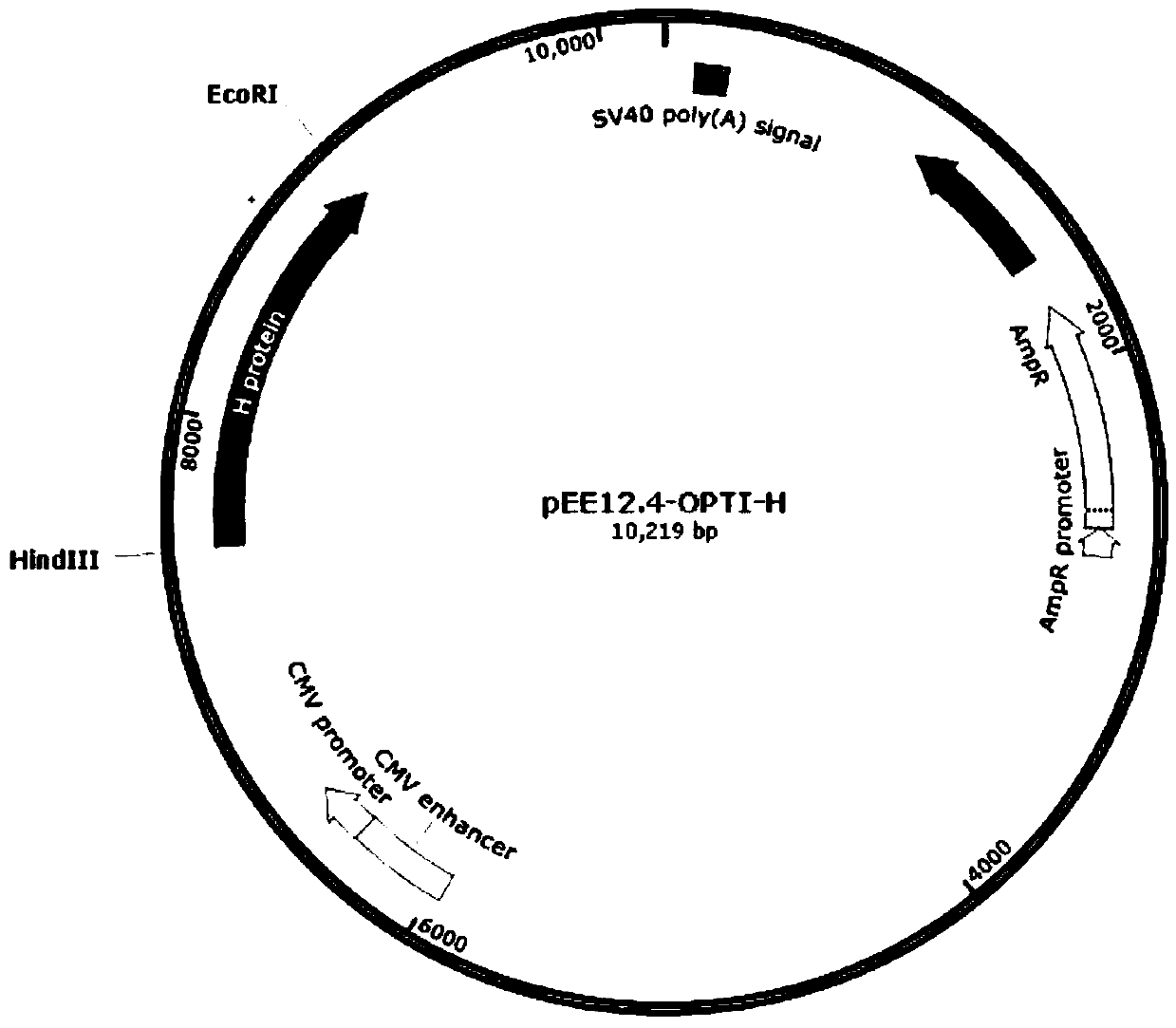

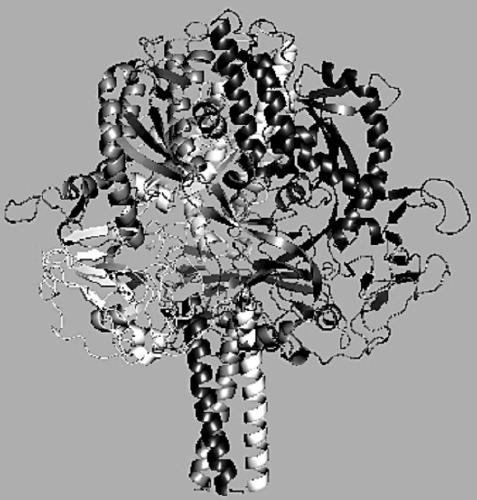

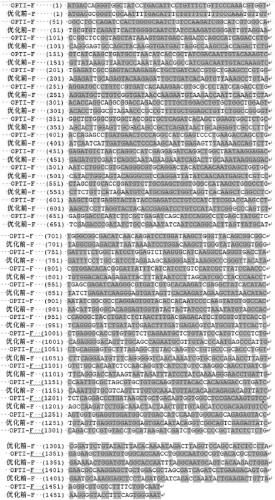

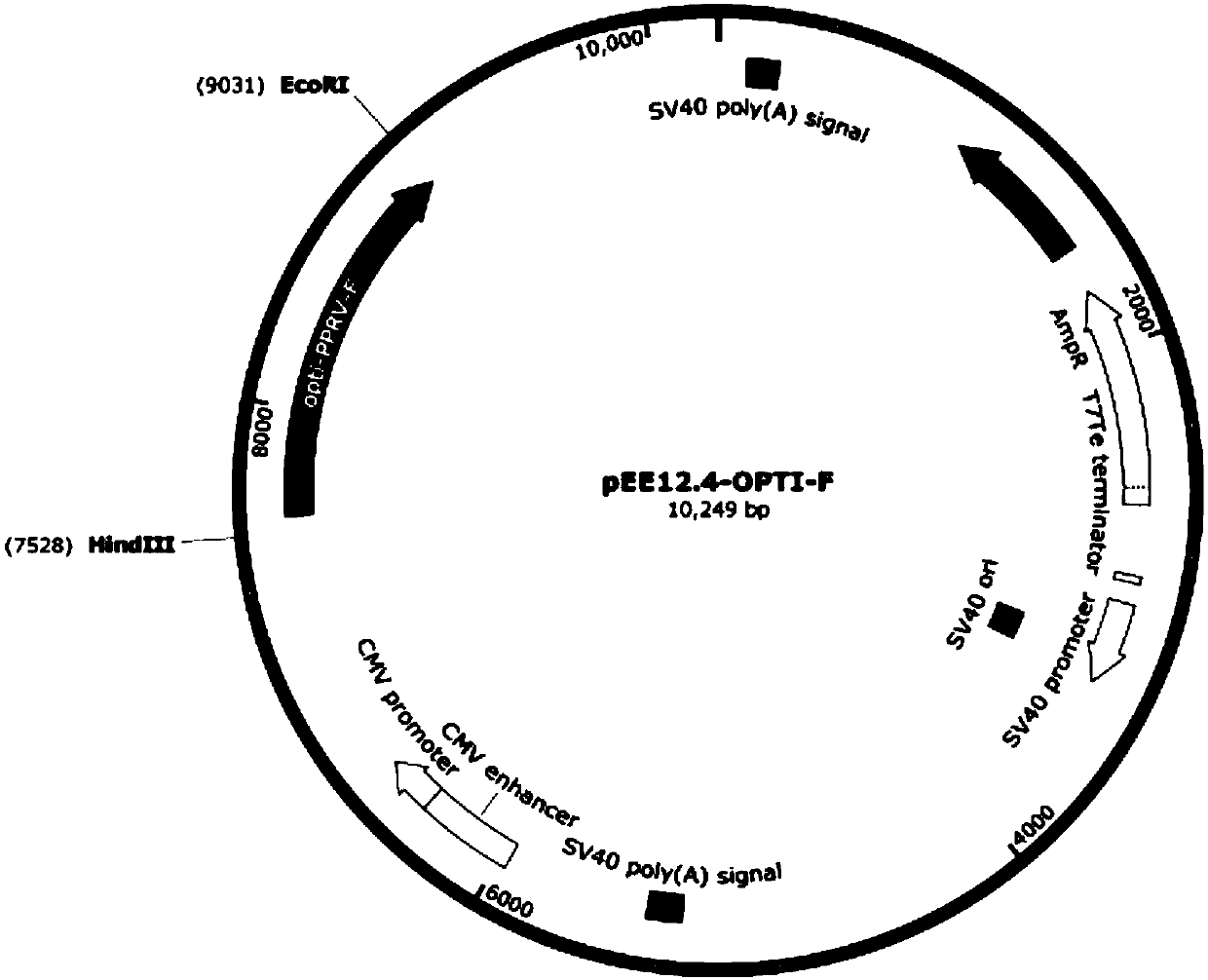

Subunit H protein of peste des petits ruminants virus and preparation method and application of subunit H protein

ActiveCN111378016ASolve technical problems with high production costsLow viral loadSsRNA viruses negative-senseViral antigen ingredientsAnimals vaccinesImmunogenicity

The present invention belongs to the technical field of animal vaccines and veterinary biological products, and particularly relates to a subunit H protein of a peste des petits ruminants virus and apreparation method and application of the subunit H protein. The subunit H protein is a truncated head functional protein of an H protein of the peste des petits ruminants virus, amino acid sequencesof the subunit H protein are an amino acid sequence (1) as shown as SEQ ID NO.1 and a derived amino acid sequence (2) having the immunogenicity and obtained by performing substitution, deletion or addition of multiple amino acids on the sequence SEQ ID NO.1, and the derived amino acid sequence and the sequence SEQ ID NO.1 have the sequence identity of 80-100%. The subunit H protein is prepared mainly by constructing recombinant plasmids, transfecting cell strains with the recombinant plasmids, screening the high-expression cell strains and purifying the subunit H protein of the peste des petits ruminants virus, can be better suitable for subunit vaccines or diagnostic reagents of peste des petits ruminants viruses, and has the characteristics of efficient secretory expression, high proteinpurity, easy purification, low production cost, high safety performance and the like.

Owner:NOVO BIOTECH CORP

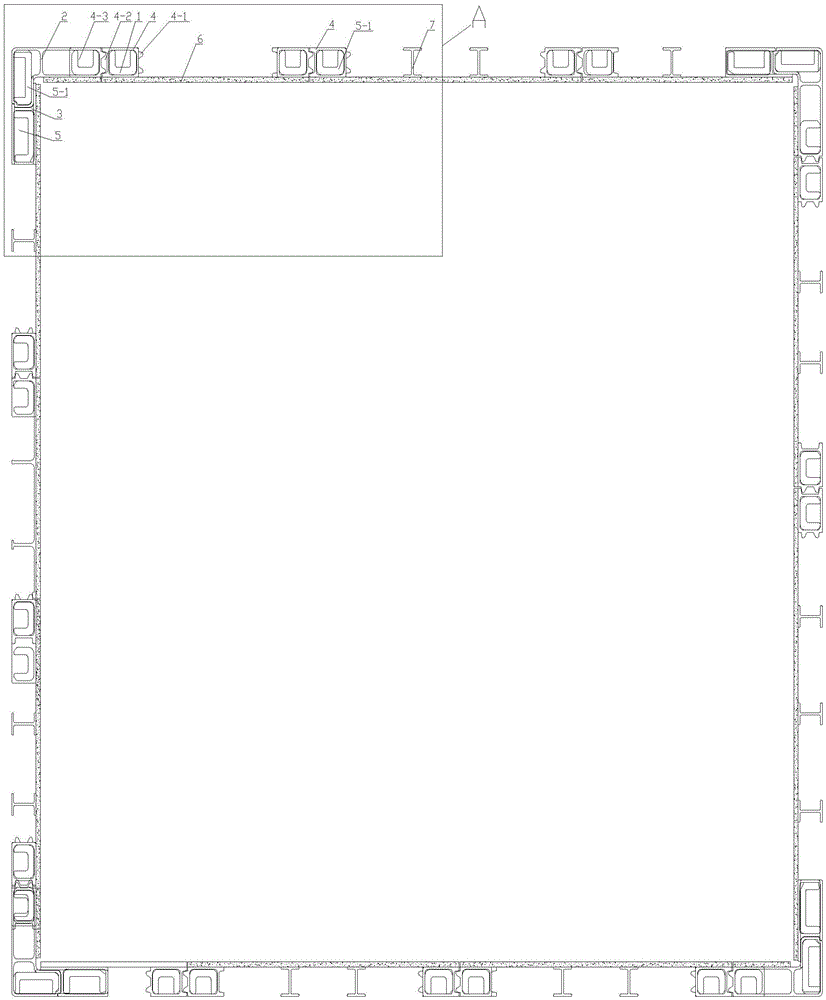

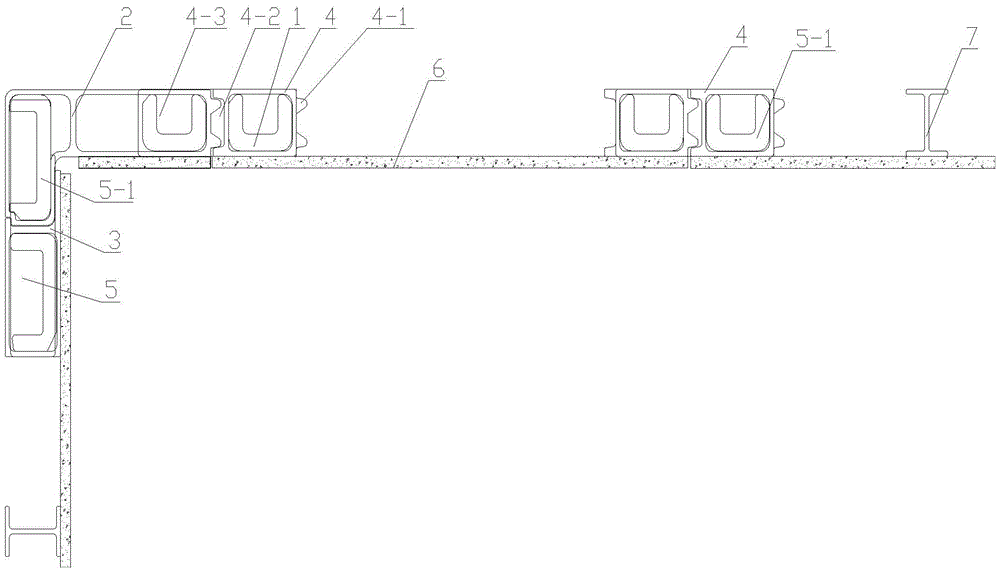

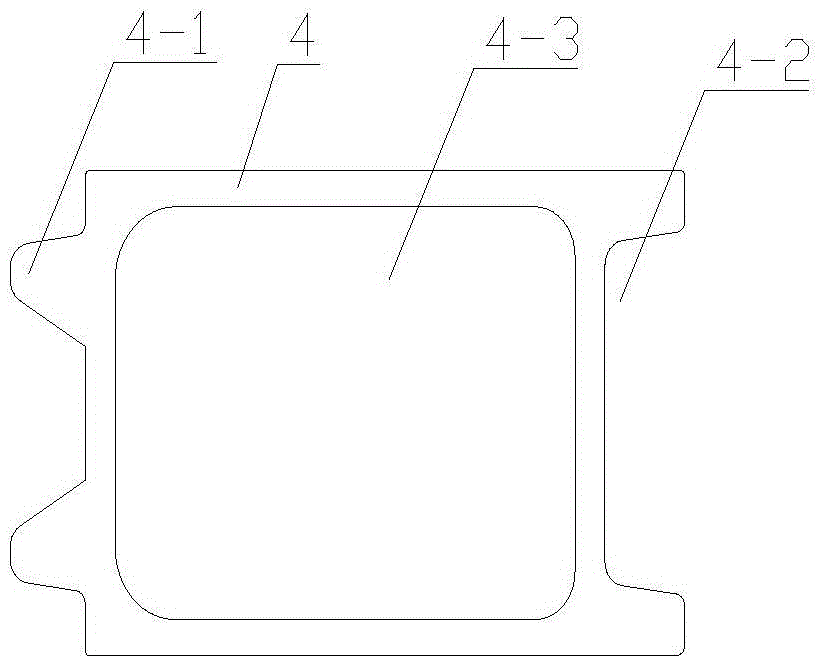

A residential industrialized assembled integral bathroom and integral kitchen wall panel

ActiveCN103899035BSolve technical problems required by professional operationsSolve the technical problem that the length size cannot be adjusted arbitrarilyConstruction materialSmall buildingsFiberProfessional skills

The invention discloses a housing industrialization assembly type unit bathroom and integrated kitchen wall plate. The technical problems that the unit bathroom wall plate is low in surface smoothness, the installation is time-consuming, the requirements on professional skills of workers are high and the length of the unit bathroom wall plate cannot be optionally selected in the prior art are solved. According to the scheme, the housing industrialization assembly type unit bathroom and integrated kitchen wall plate comprises clamping grooves, a first corner plate, a second corner plate, a splicing joint, a splicing joint pressing block, cement fiber boards and a support frame, wherein the cement fiber boards encircle to form a quadrangular wall; four corners of the quadrangular wall are connected through the first corner plate and the second corner plate; the splicing joint is arranged on the cement fiber board and is positioned at the joint of adjacent two cement fiber boards; the splicing joint pressing block is arranged on the splicing joint at the joint of the adjacent two cement fiber boards; the splicing joint pressing block is also arranged on the first corner plate and the second corner plate; the support frame is fixed on the cement fiber boards; the clamping grooves encircle to form a quadrangle and are respectively formed in the upper end and lower end of the quadrangular wall.

Owner:南京斯贝尔复合材料有限责任公司

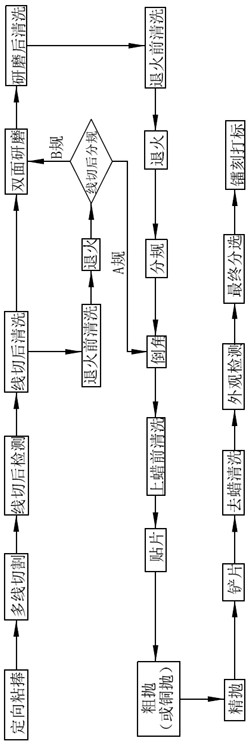

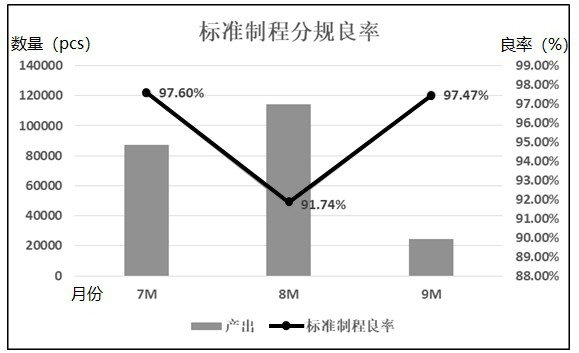

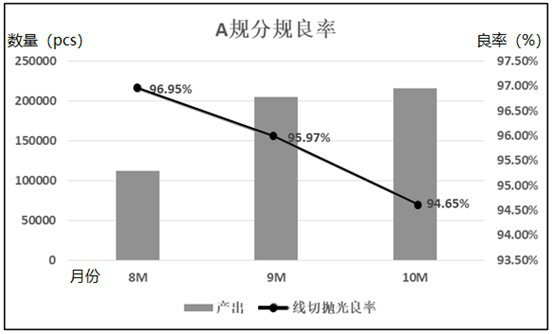

Sapphire substrate manufacturing method

InactiveCN114068773ASolve technical problems with high production costsSimple production processSemiconductor devicesWaferingMetallurgy

The invention provides a sapphire substrate manufacturing method, and the method comprises the steps: obtaining a wafer which is cleaned after wire cutting, carrying out the cleaning before annealing of the wafer which is cleaned after wire cutting, and carrying out the annealing treatment of the wafer; according to the wafer specification data, carrying out wire cutting and then dividing on the annealed wafers, screening the wafers subjected to division, and obtaining the screened wafers of the first specification; and chamfering the first specification wafer to obtain the sapphire substrate. According to the sapphire substrate manufacturing method, the wafer subjected to linear cutting is detected according to the wafer specification data to obtain the wafer of the first specification, the wafer of the first specification is chamfered, the sapphire substrate is obtained through the chamfered wafer, double-sided grinding is not needed, the manufacturing technological process is simplified, and the technical problem that in the prior art, after multi-line cutting, all products need to be subjected to double-face grinding, then subsequent production procedures can be conducted, and the single-piece production cost is high is solved.

Owner:JIANGXI ZHAO CHI SEMICON CO LTD

Subunit F protein of peste des petits ruminants virus as well as preparation method and application of subunit F protein

ActiveCN111378017ASolve technical problems with high production costsMeet needsSsRNA viruses negative-senseViral antigen ingredientsAnimals vaccinesF protein

The invention belongs to the technical fields of animal vaccines and veterinary biological products, and particularly relates to a subunit F protein of a peste des petits ruminants virus as well as apreparation method and application of the subunit F protein. An amino acid sequence of the subunit F protein is as follows: (1) an amino acid sequence represented by SEQ ID NO.1; (2) a derived immunogenic amino acid sequence obtained from the amino acid sequence represented by SEQ ID NO.1 through substitution, deletion and addition of one or more amino acids. The subunit F protein is mainly prepared by the steps of constructing recombinant plasmids, transfecting cell strains by virtue of the recombinant plasmids, screening highly-expressed cell strains, and purifying the subunit F protein of the peste des petits ruminants virus. The subunit F protein is well applied to subunit vaccines or diagnostic reagents for the peste des petits ruminants and has the characteristics that secretory expression is efficient, the protein purity is high, purification is easily realized, the production cost is lowered, the safety performance is high, and the like.

Owner:NOVO BIOTECH CORP

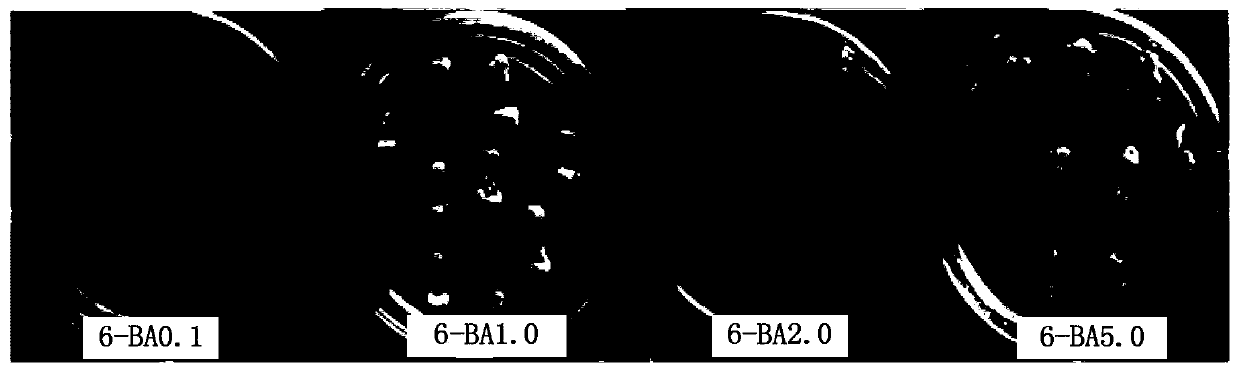

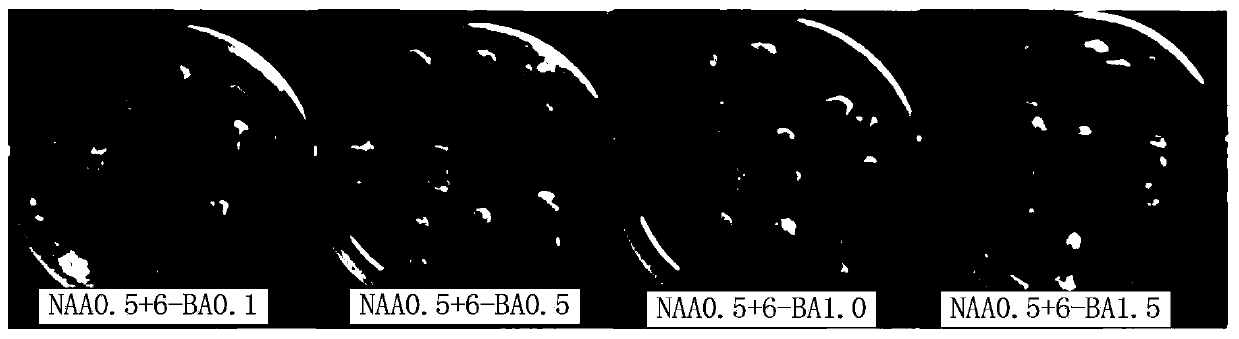

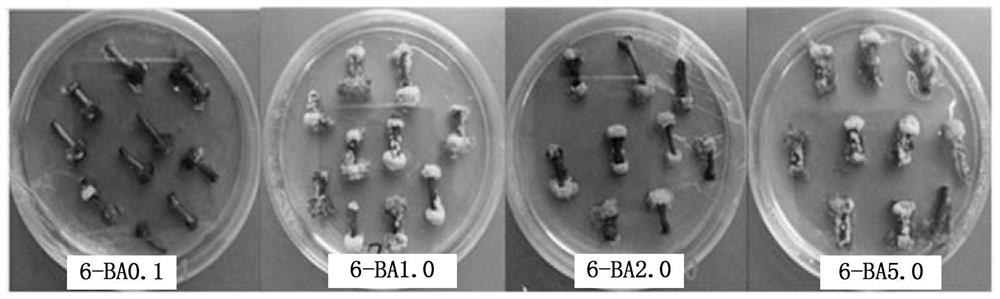

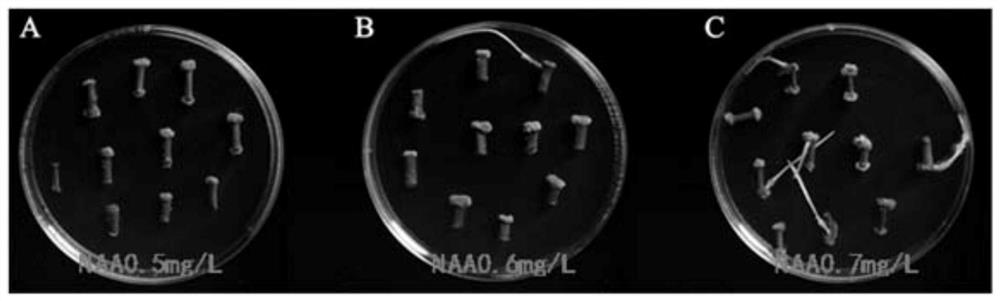

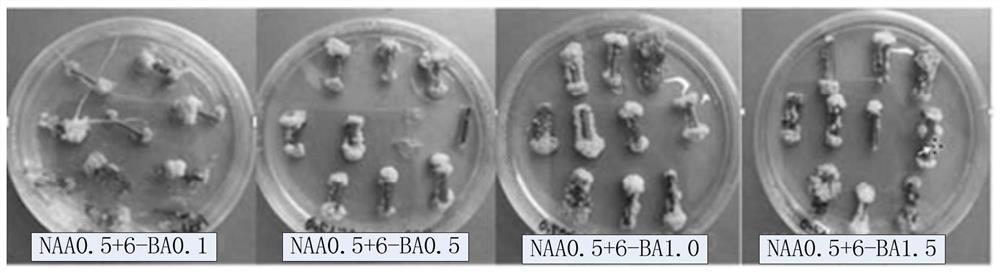

Toona sinensis clustered shoot induction and multiplication method

ActiveCN110326537AAchieve rapid propagationOvercome speedHorticulture methodsPlant tissue cultureMultiplication rateShoot

The invention discloses a toona sinensis clustered shoot induction and multiplication method. Annual branches which are not lignified are taken as explants, put on a specific induction medium, and induced under the culture conditions of the temperature of 25 DEG C, the humidity of 60%, the illumination intensity of 20-60 mu mol m<-2>s<-1> and the photoinduction time of 16 h / d, callus is formed, and then the callus is induced on a specific differentiation medium under the same culture conditions to form clustered shoots; when the clustered shoots grow to be 3 cm or longer, the clustered shootsare cut, and dense callus is selected for continued multiplication culture. With the adoption of the method, the callus inductivity of a stem can reach 100%, the induction rate of the clustered shootsis higher than 50%, and the multiplication rate of the clustered shoots is higher than 8 and is up to 26.

Owner:INST OF FORESTRY CHINESE ACAD OF FORESTRY

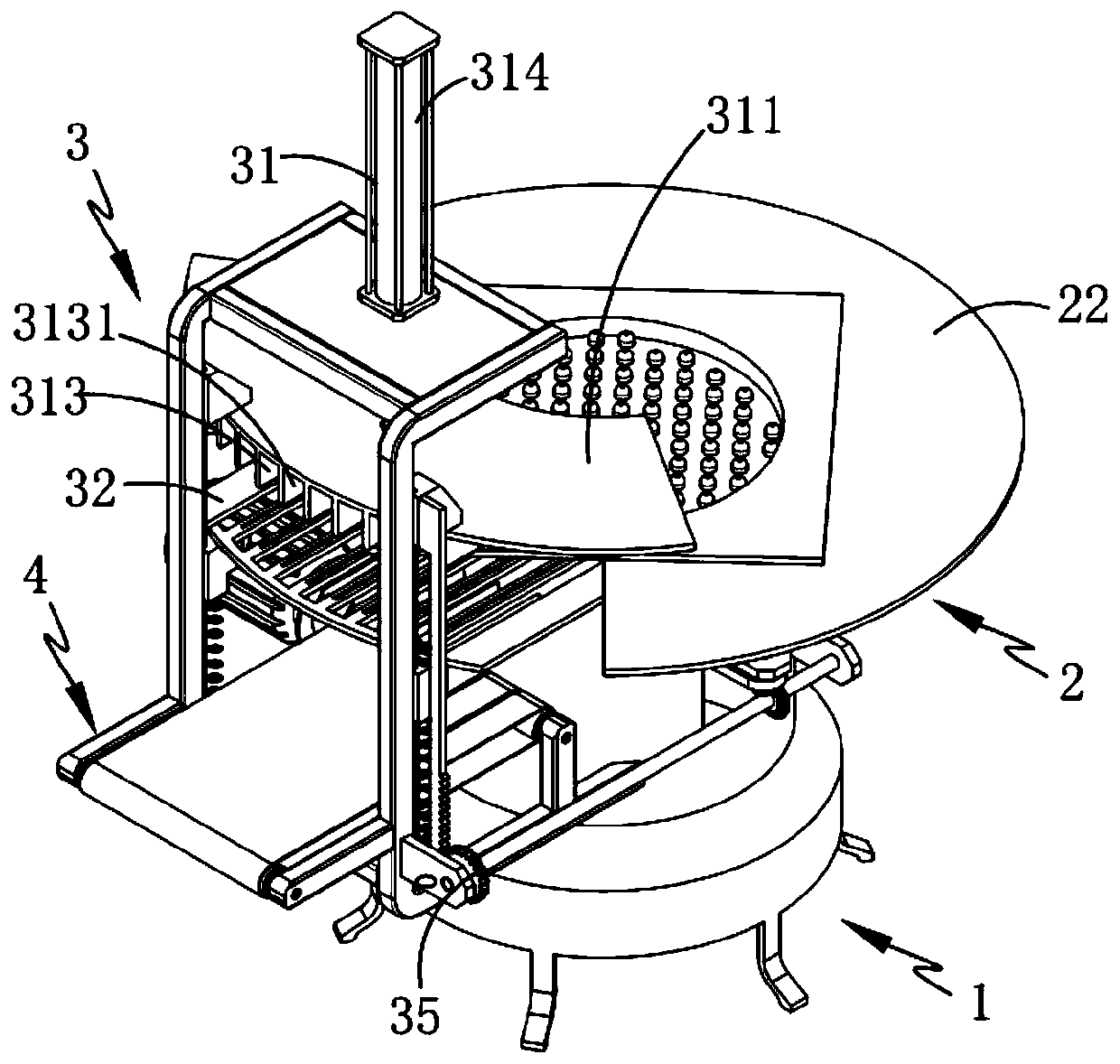

A composite desktop production device for plastic furniture and its process

ActiveCN108724276BRealize automatic transpositionRealize integrated productionGrain treatmentsMetal working apparatusMechanical engineeringIndustrial engineering

The invention relates to the technical field of blow-molding production of furniture, in particular to a production device and process for a compound table top of plastic furniture. The production device comprises a rack, a positioning mechanism, a cutting mechanism and an output mechanism, wherein the positioning mechanism comprises a limiting groove, a bearing table, a cutting space and a supporting component; the cutting mechanism comprises a cutting component, a bearing component, a crushing component arranged below the bearing component and used for crushing rim charges, and a transmission component through which the cutting component and the supporting component are connected; a mould is subjected to one-time rim charge cutting by the cutting component; the cutting component drives the transmission component to rotate so as to realize rotary position change of the mould; the rim charges are crushed by the crushing component, then fall onto the output mechanism and are directionally output by the output mechanism; and the rim charges on the mould are crushed and output while being automatically and efficiently cut by the cutting component. The technical problem of high production cost caused by the reason that the rim charges are cut and crushed independently in the prior art is solved.

Owner:ZHEJIANG LIFAN FURNITURE

Fermented fuel reactor and method for producing fermented fuel

ActiveCN104342358BAvoid wastingLow costBioreactor/fermenter combinationsBiological substance pretreatmentsAlcoholDistillation

Owner:STATE GRID CORP OF CHINA +1

Liquid crystal display panel and liquid crystal display device

ActiveCN104714320BReduce manufacturing costSolve technical problems with high production costsStatic indicating devicesNon-linear opticsLiquid-crystal displayScan line

The present invention provides a liquid crystal display panel, which includes a driving circuit, a data line, a scanning line and a pixel unit; wherein the driving circuit includes a level shifter for converting an input voltage signal into a high-level signal or a low-level signal And an output buffer for amplifying high-level signals or low-level signals; where the input of the non-inverting input and inverting input of the level shifter is determined according to the number of inverting amplifiers in the output buffer voltage signal. The invention also provides a liquid crystal display device. The liquid crystal display panel and the liquid crystal display device of the present invention can effectively reduce the production cost of the liquid crystal display panel.

Owner:TCL CHINA STAR OPTOELECTRONICS TECH CO LTD

A kind of preparation method of high-performance carbon-carbon composite carbon material

The invention relates to the technical field of artificial graphite production, in particular to a preparation method of a high-performance carbon-carbon composite carbon material. The method comprises the steps of paste material preparation, rough blank overlaying, prefabricating for shaping, calcination treatment and graphitization treatment; after coke powder is fed into a carbon kneading pot for kneading with asphalt, cooling, crushing and then grinding are conducted on the coke powder, gaps and the upper surface of carbon cloth are evenly filled with paste material powder, and then a rough blank is formed; prefabricating for shaping is conducted on the rough blank by means of ballasting or needling; after a prefabricated block is placed in a calcination furnace for calcination, treatment is conducted by means of steeping or carbon deposition to form a calcination blank; finally, graphitization treatment is conducted on the calcination blank by means of high temperature. Through the special overlaying structure of the carbon cloth and the paste material powder, not only is the overall density of the prefabricated block improved, but also even distribution of the carbon cloth and the paste material powder is achieved, great improvement of the mechanical strength of the carbon-carbon composite material is achieved, and the technical problem is solved that in the prior art, the production cost is high due to low graphite material strength.

Owner:SINOSTEEL NEW MATERIAL ZHEJIANG

Thin film transistor and manufacturing method

ActiveCN109638082BEtching resistanceResist bombardmentTransistorSemiconductor/solid-state device manufacturingIndiumElectrical connection

The invention discloses a thin film transistor and a preparation method. The thin film transistor comprises: a substrate; a gate layer, a first insulating layer and an active layer formed on the substrate; a patterned source electrode and an active layer formed on the active layer. The drain is electrically connected to the active layer respectively; an organic passivation layer formed on the patterned source and drain, the organic passivation layer is in direct contact with the active layer; the active layer includes metal oxide, metal oxide Including Indium Oxide In 2 o 3 It is a composite oxide composed of oxide MO of the fifth subgroup element, and the organic passivation layer is a polymer organic material. Technical scheme of the present invention, organic passivation layer and indium oxide In 2 o 3 It is in direct contact with the active layer composed of the composite oxide composed of the oxide MO of the fifth subgroup element. On the one hand, the direct contact between the organic passivation layer and the active layer will not cause the effect of donor doping on the active layer, and the device Normal and stable work; on the other hand, the preparation process is simple and the cost is low.

Owner:深圳庸行科技有限公司

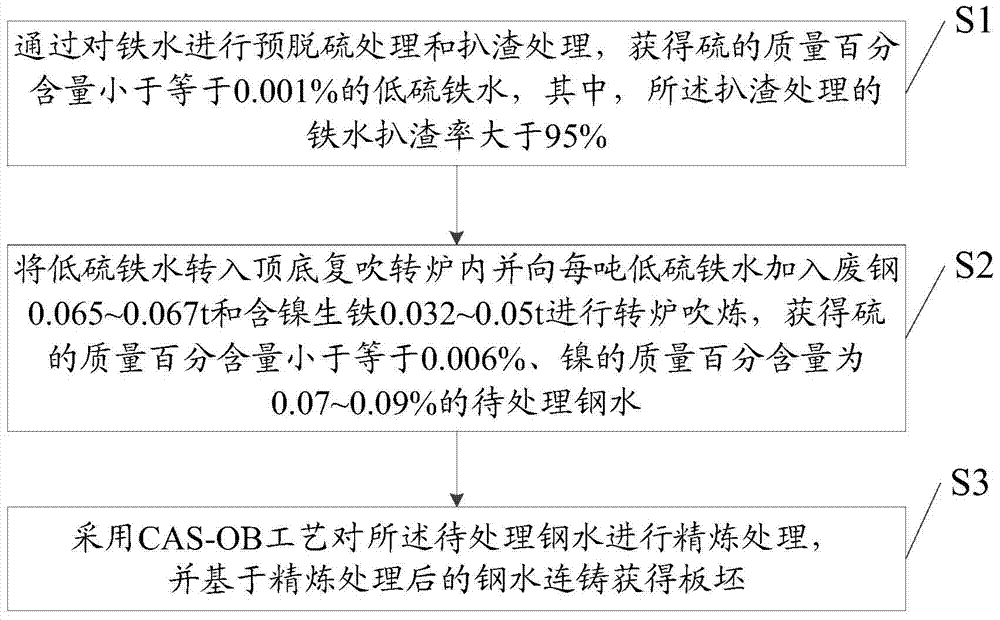

A method of smelting weathering steel

ActiveCN105256094BSolve technical problems with high production costsLow costManufacturing convertersProcess efficiency improvementSulfurMolten steel

The invention discloses a method for smelting weathering resistant steel. The method comprises the steps that pre-desulfuration processing and drossing processing are carried out on molten iron, and low-sulphur molten iron with the sulphur mass percentage composition smaller than or equal to 0.001% is obtained, wherein the drossing rate of the molten iron on which drossing processing is carried out is larger than 95%; the low-sulphur molten iron is shifted into a top-bottom combined blowing converter, 0.065-0.067 t of scrap steel and 0.032-0.05 t of nickel containing pig iron are added in each ton of low-sulphur molten iron, converter smelting is carried out, and to-be-processed molten steel with the sulphur mass percentage composition smaller than or equal to 0.06% and the nickel mass percentage composition of 0.07-0.09% is obtained; and refining processing is carried out on the to-be-processed molten steel through the CAS-OB technology, and a plate blank is obtained on the basis of continuous casting of the molten steel on which refining processing is carried out. According to the technical scheme, the content of the nickel component in the molten steel is adjusted through the nickel containing pig iron, the pre-desulfuration of the molten iron is carried out before refining, the CAS-OB technology is adopted during refining, and the cost of raw materials and production consumption are reduced; and the technical problem that in the prior art, the production cost of the weathering resistant steel is high is solved, and the production cost is reduced.

Owner:SHOUGANG JINGTANG IRON & STEEL CO LTD

A kind of 630mpa high-strength anti-seismic index steel bar and its production method

The invention provides a 630MPa high-strength anti-seismic index steel bar and a production method thereof, including: refining steel raw materials through a converter to obtain crude molten steel; refining through a refining furnace to obtain refined molten steel; The rolling mill is rolled to obtain continuous casting billets; after being transported to the heating furnace for heating, it enters the rack rough rolling unit for rough rolling operation to obtain rough rolled billets; after shearing and breaking, it enters the rack intermediate rolling group for intermediate rolling , After the pre-water cooling section realizes low temperature finishing rolling, it is sheared and broken, and then enters the finishing rolling unit of the stand for finishing rolling operation. It is difficult to solve the adopted production process to meet the 630MPa strength and anti-seismic requirements, and there is a technical problem of high production cost. To achieve the technical effect of adjusting the chemical composition and rolling process on the basis of ordinary steel bars, meeting the requirements of various indicators of high-performance steel bars, stable industrial rolling technology, reducing costs and increasing profits.

Owner:江苏联峰实业有限公司

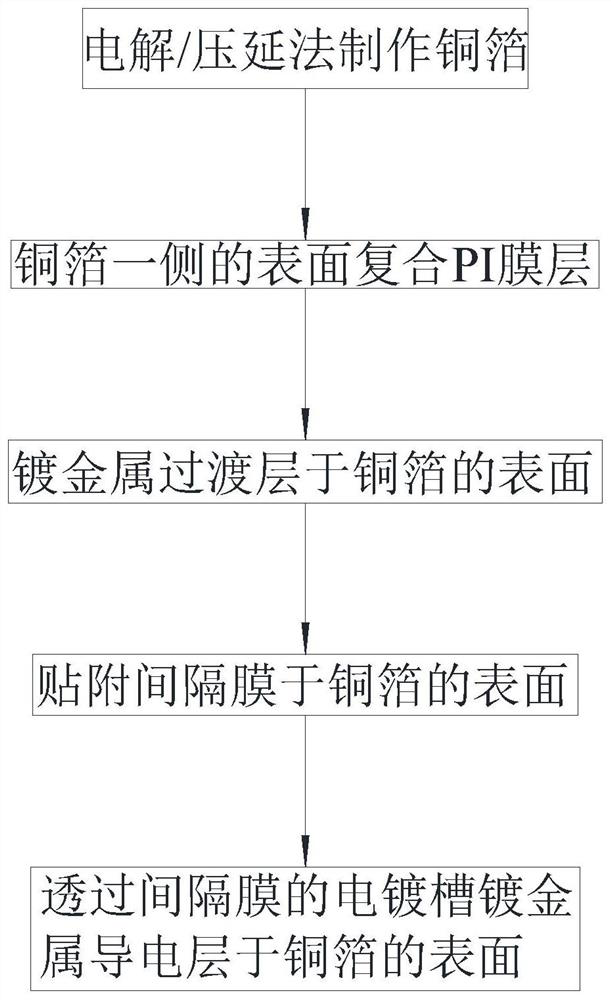

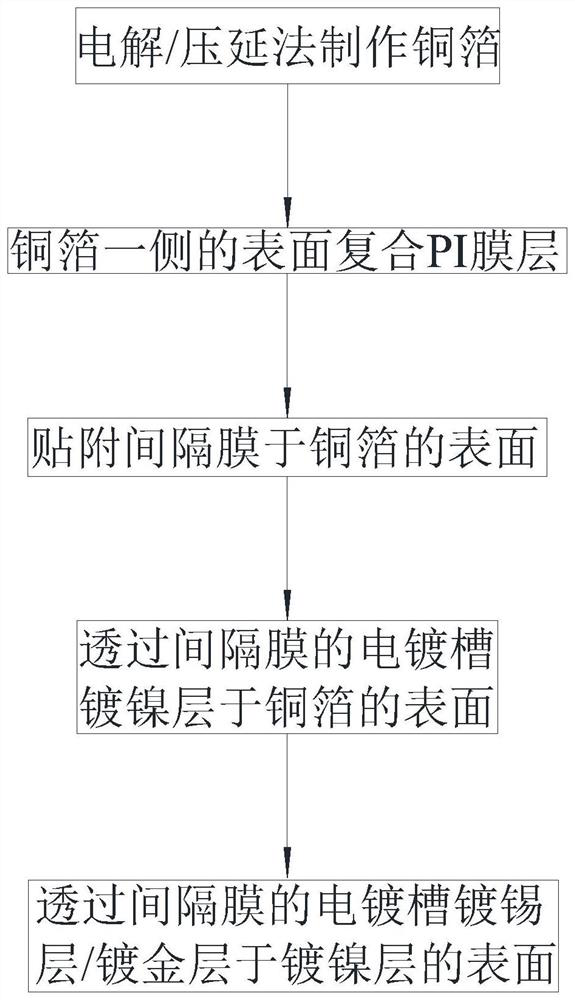

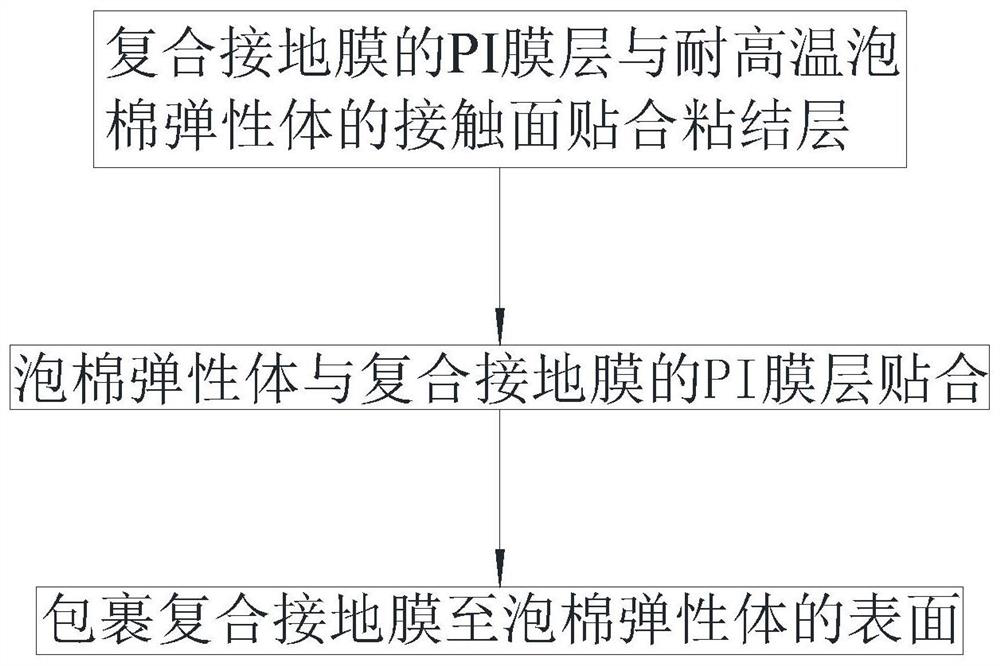

Method for manufacturing composite grounding film and method and structure of high-temperature-resistant grounding elastic piece

ActiveCN112332190ASave materialOvercoming technical problems of high production costsLine/current collector detailsCopper foilElectroplating

The invention relates to a method for manufacturing a composite grounding film and a method and a structure of a high-temperature-resistant grounding elastic piece. The invention discloses a method for manufacturing a composite ground film. The method comprises a film pasting step and an electroplating step, wherein the film pasting step comprises the following steps: attaching a separation film to the surface of the copper foil, wherein the spacing membrane is an insulator and is provided with spaced electroplating baths; the electroplating step comprises the step of plating a metal conducting layer on the surface of the copper foil through an electroplating bath of the spacing membrane. According to the utility model, the insulating spacer membrane is attached to the surface of the copper foil, and the spacer membrane is provided with the spaced electroplating baths, so that when the metal conducting layer is electroplated, the attached part of the spacer membrane cannot form the plated metal conducting layer, and the material of the plated metal conducting layer is saved. Therefore, by adopting the technical means of attaching the insulating diaphragm to the surface of the copper foil, the technical problem that the surface of the copper foil cannot be continuously electroplated into the spaced metal conducting layer in batches at low cost is solved, and the technical effectof saving precious metal conducting layer materials is achieved.

Owner:SHENZHEN JOHAN MATERIAL TECH CO LTD

A method for inducing and proliferating the clustered buds of Toona sinensis

ActiveCN110326537BAchieve rapid propagationVigorousHorticulture methodsPlant tissue cultureShootCallus

The invention discloses a toona sinensis clustered shoot induction and multiplication method. Annual branches which are not lignified are taken as explants, put on a specific induction medium, and induced under the culture conditions of the temperature of 25 DEG C, the humidity of 60%, the illumination intensity of 20-60 mu mol m<-2>s<-1> and the photoinduction time of 16 h / d, callus is formed, and then the callus is induced on a specific differentiation medium under the same culture conditions to form clustered shoots; when the clustered shoots grow to be 3 cm or longer, the clustered shootsare cut, and dense callus is selected for continued multiplication culture. With the adoption of the method, the callus inductivity of a stem can reach 100%, the induction rate of the clustered shootsis higher than 50%, and the multiplication rate of the clustered shoots is higher than 8 and is up to 26.

Owner:INST OF FORESTRY CHINESE ACAD OF FORESTRY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com