Preparation method of high-performance carbon-carbon composite carbon material

A carbon-carbon composite and carbon material technology is applied in the field of preparation of high-performance carbon-carbon composite carbon materials, which can solve the problems of low strength and high production cost of graphite materials, and achieve the effects of high product performance, increased density and guaranteed product quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

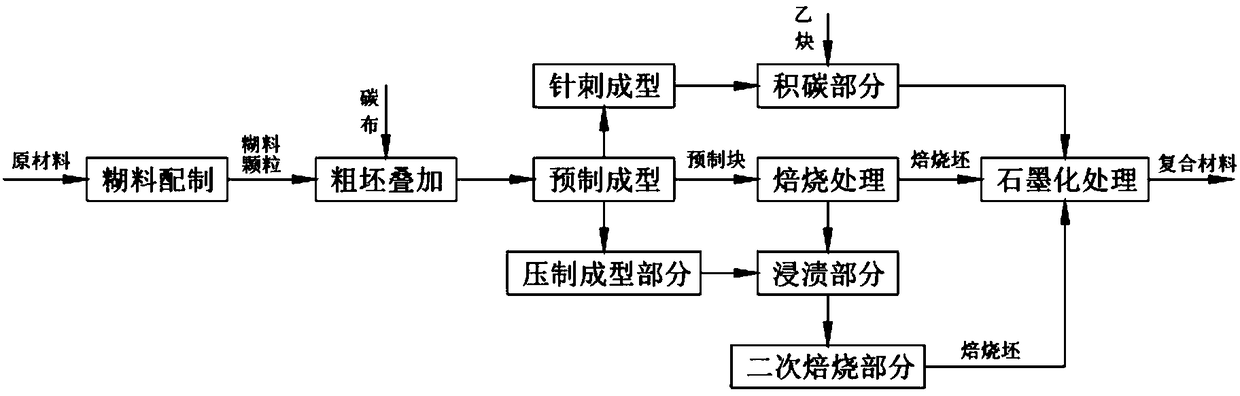

[0028] According to the drawings in the manual figure 1 A method for preparing a high-performance carbon-carbon composite carbon material in this example is described.

[0029] A method for preparing a high-performance carbon-carbon composite carbon material, comprising the following steps:

[0030] (a) Paste preparation, put the coke powder with a particle size of 3-20 μm obtained by grinding petroleum coke or asphalt glue into a carbon kneading pot and heat it to 120-140 ° C, then put it into a temperature of 200-200 ° C. After kneading in liquid asphalt at 230°C, the kneaded paste is cooled and crushed by a cold crusher to obtain a granular paste with a particle size of 2-5mm;

[0031] (b) superposition of rough bases, after the paste obtained in the step (a) is pulverized by a mechanical mill to a paste powder with a particle size of 10-100 μm, the paste is moved at a uniform speed by a distributing machine The rate of 20-80g / min is filled in the gap of the carbon cloth ...

Embodiment 2

[0039] Wherein, the same or corresponding parts as those in the first embodiment adopt the reference numerals corresponding to the first embodiment. For the sake of simplicity, only the differences from the first embodiment are described below; the difference between the second embodiment and the first embodiment is that : the step (c) also includes a press molding part, the rough blank obtained by the step (b) is packed into a mould, and the rough blank is carried out in an isostatic pressing molding mode with a pressure of 100Mpa and a molding time of 20-60min Press molding to form a prefabricated block A with a tight structure.

[0040] Further, the step (d) includes the impregnation part, placing the prefabricated block A obtained by pressing the molded part in a roasting furnace, burying it with yellow sand, and roasting it at a heating rate of 500-700 °C at a rate of 2 °C / h Afterwards, pressurize and impregnate it with an impregnation pressure of 0.2 MPa to obtain an imp...

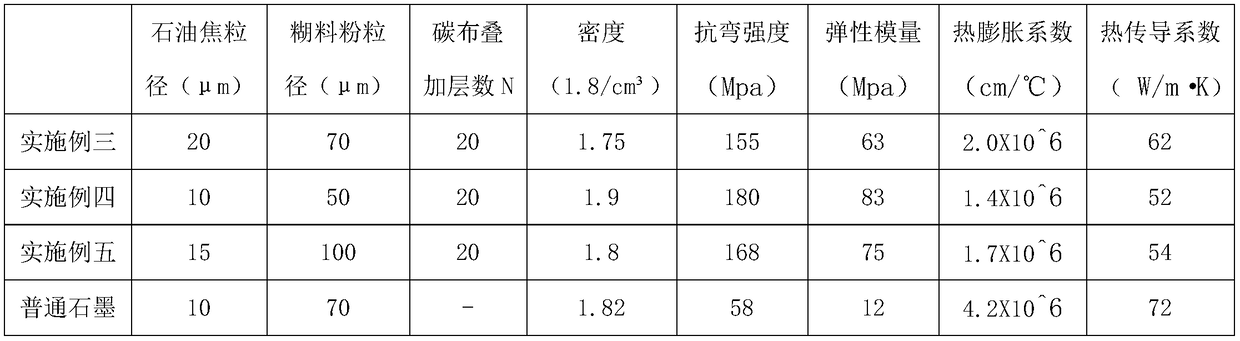

Embodiment 3

[0046] Wherein, the same or corresponding parts as those in Embodiment 2 adopt the reference numerals corresponding to Embodiment 1. For the sake of simplicity, only the differences from Embodiment 2 are described below; the difference between Embodiment 3 and Embodiment 2 is that : The petroleum coke is ground to an average particle size of 20 μm with a mechanical pulverizer, and the moisture content of the petroleum coke used is <0.5%, the moisture content is <0.5%, and the volatile content is <1%. The obtained coke powder is put into a carbon kneading pot and preheated to 120°C, and the liquid pitch at a temperature of 200°C is put into the kneading pot according to 1 / 3 of the weight of the coke powder, and kneaded under a heat preservation condition of 180°C for 30 minutes. get the paste;

[0047] Grind the paste to obtain paste powder with an average particle size of 70 μm, and load it into a distributing machine. The carbon cloth woven by carbon fiber is selected as the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com