Thin film transistor and manufacturing method

A thin-film transistor and active layer technology, which is applied in transistors, semiconductor/solid-state device manufacturing, semiconductor devices, etc., can solve the problems of high production cost of metal oxides, achieve excellent stability, resist etching, and save production costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

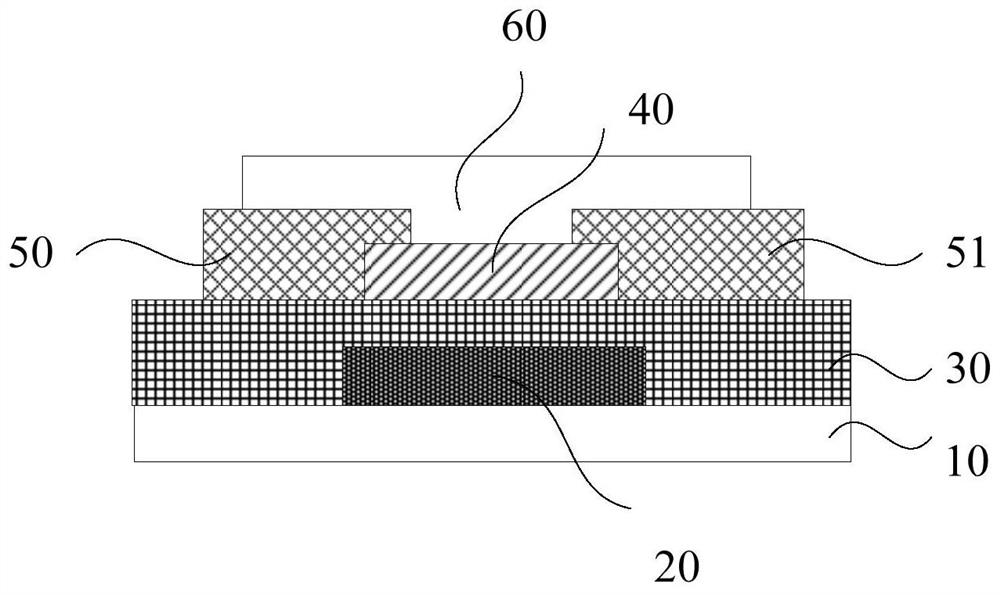

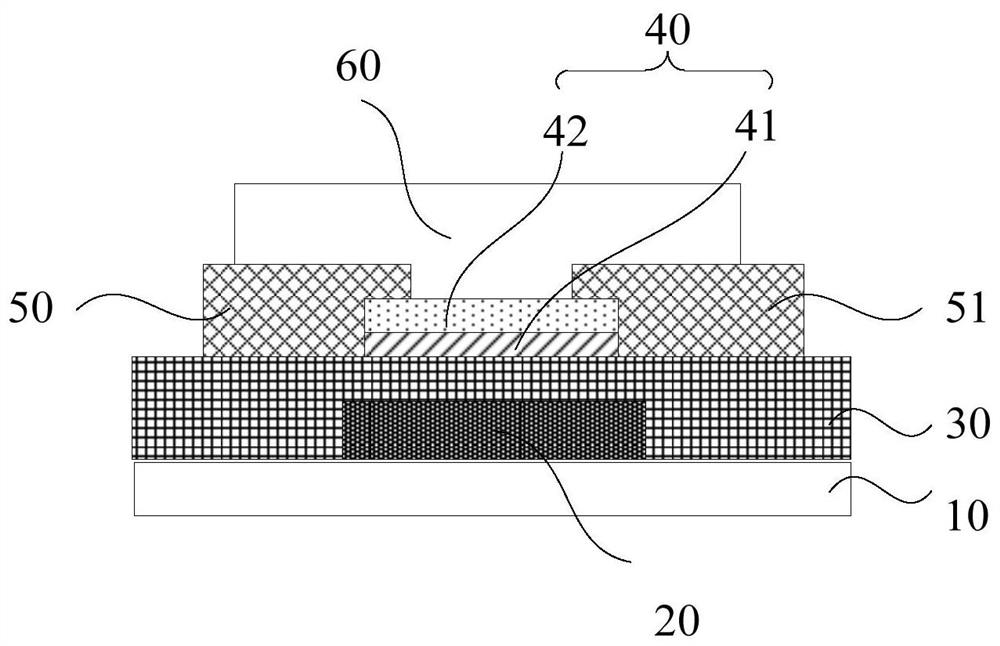

[0035] An embodiment of the present invention provides a thin film transistor. figure 1 A schematic structural diagram of a thin film transistor provided by an embodiment of the present invention. see figure 1 , the thin film transistor includes: a substrate 10; a gate layer 20 formed on the substrate 10; a first insulating layer 30 formed on the gate layer 20; an active layer 40 formed on the first insulating layer 30; The patterned source electrode 50 and the drain electrode 51 on the active layer 40 are electrically connected to the active layer 40 respectively; the organic passivation layer 60 formed on the patterned source electrode 50 and the drain electrode 51, the organic passivation layer 60 is in direct contact with the active layer 40; the active layer 40 includes a metal oxide. Metal oxides including indium oxide In 2 o 3 Composite oxides composed of oxides MO of elements of the fifth subgroup (In 2 o 3 )a(MO) b , wherein, a+b=1, 0.10≤b≤0.50; the organic pas...

Embodiment 2

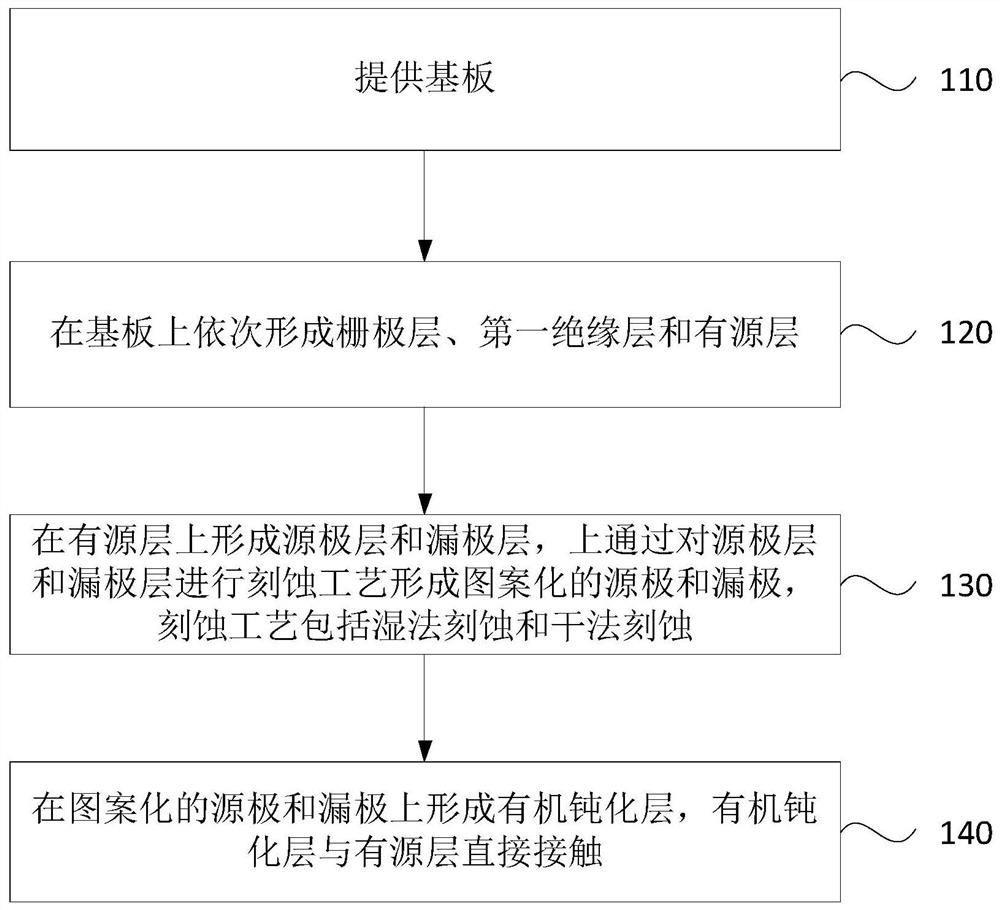

[0053] On the basis of the above-mentioned embodiments, the embodiment of the present invention provides a method for manufacturing a thin film transistor, based on figure 1 thin film transistors shown, see image 3 , the preparation method comprises the steps of:

[0054] Step 110, providing a substrate;

[0055] Step 120, sequentially forming a gate layer, a first insulating layer and an active layer on the substrate;

[0056] Step 130, forming a source layer and a drain layer on the active layer, and forming a patterned source and drain layer by etching the source layer and the drain layer. The etching process includes wet etching and dry etching;

[0057] Step 140 , forming an organic passivation layer on the patterned source and drain electrodes, the organic passivation layer is in direct contact with the active layer; the active layer includes metal oxide. The active layer includes a metal oxide including Indium oxide In 2 o 3 Composite oxides composed of oxides MO...

Embodiment 3

[0097] On the basis of the above technical solution, an embodiment of the present invention provides a display panel, including the thin film transistor mentioned in the above embodiment. Thin film transistors are used to drive display units in display panels.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com