Patents

Literature

155results about How to "Realize integrated production" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

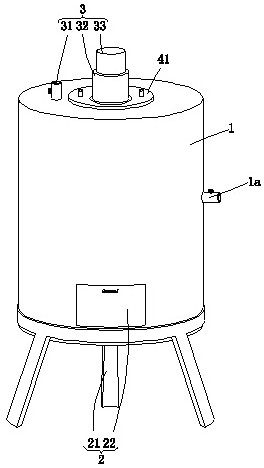

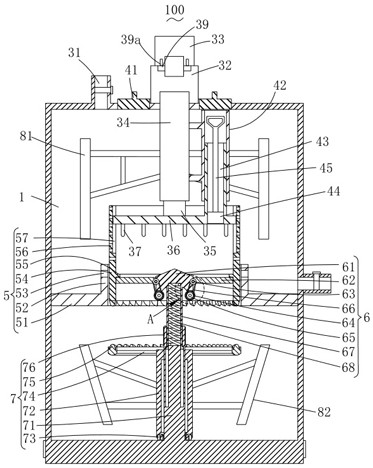

Household wine brewing machine and method for brewing wine by using household wine brewing machine

ActiveCN104498246ARealize integrated productionRich choiceWine preparationHops treatmentFruit wineIndustrial fermentation

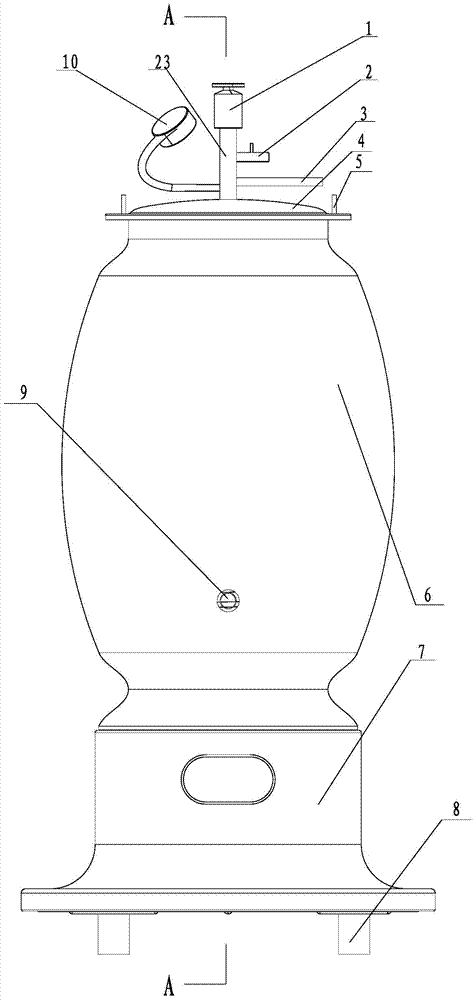

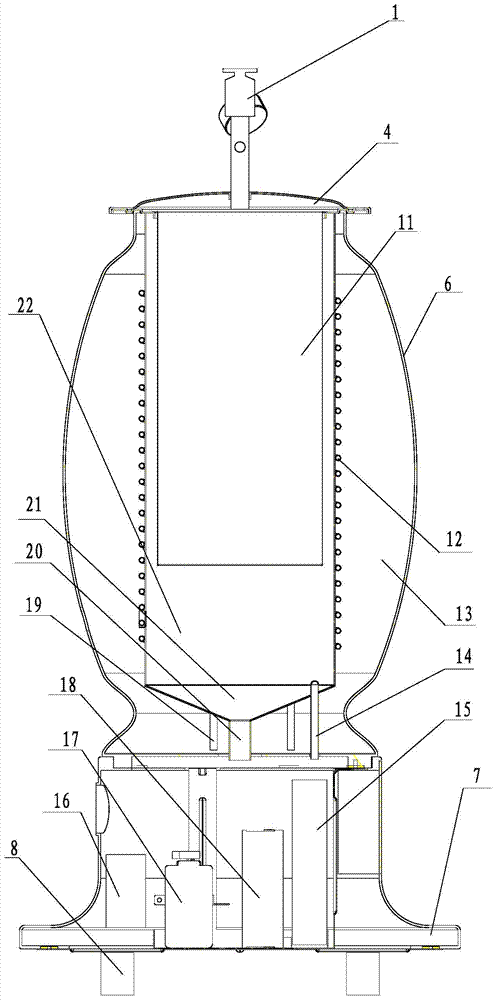

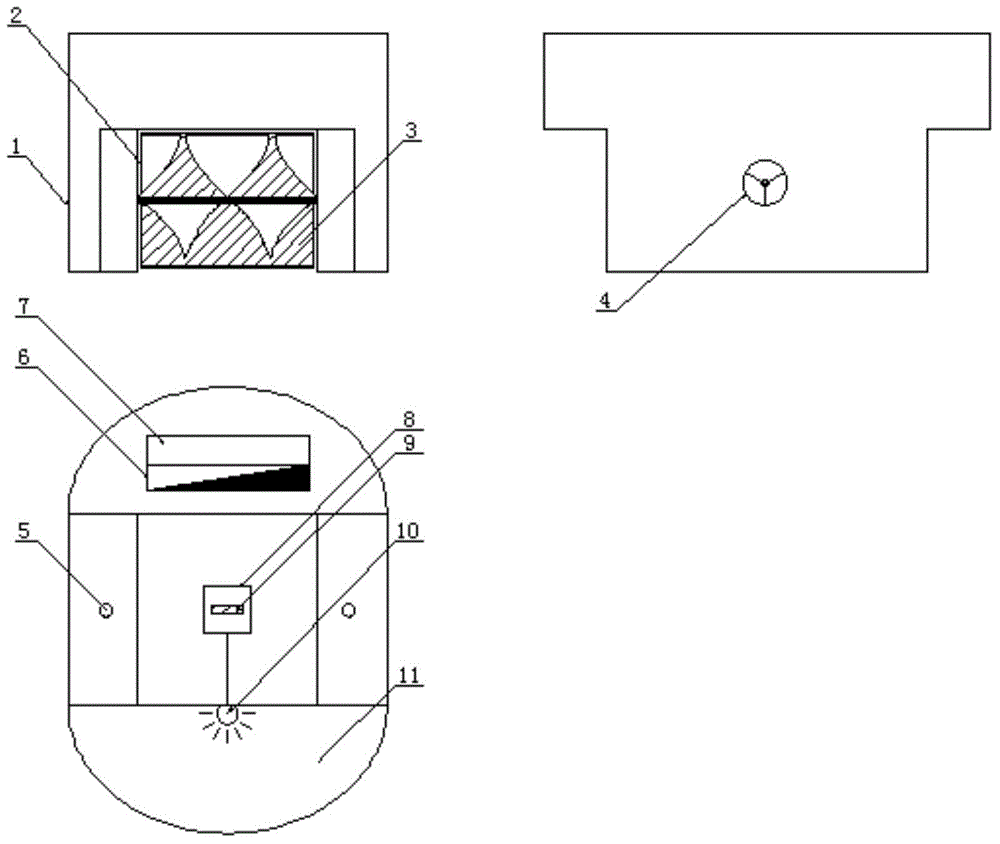

The invention relates to a household wine brewing machine and a method for brewing wine by using the household wine brewing machine. The household wine brewing machine can be used for overcoming the defects that the existing industrial fermentation equipment is oversized and cannot achieve miniaturization and domestication. The household wine brewing machine is divided into four parts, namely a sealing cover, a fermentation tank, a control part and a power part, wherein the fermentation tank adopts a brand-new design. The household wine brewing machine not only can be used for producing grape wine, but also can be used for producing various fruit wines and beers, so that the integrated production of various wines is realized to provide more choices for consumers, the equipment cost is lowered and the product quality is guaranteed.

Owner:山东九道生物科技有限公司

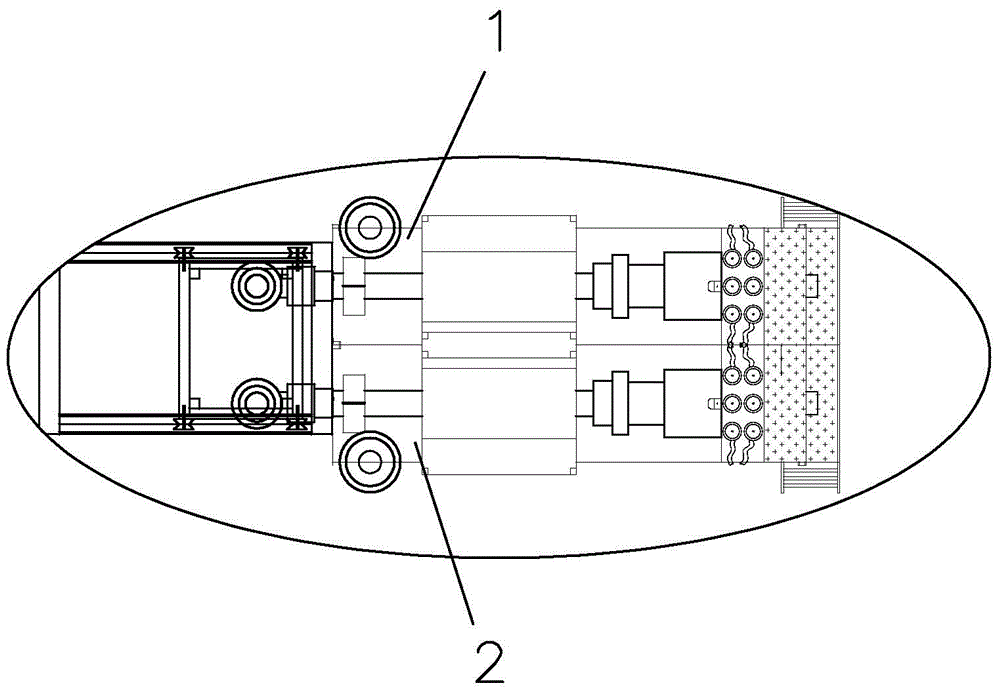

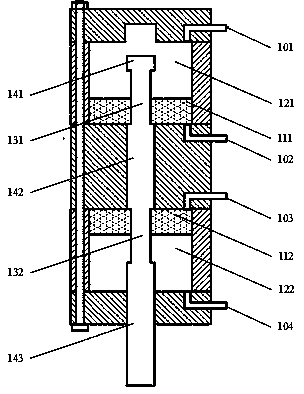

Connecting process of polar plate of lead acid batteries

ActiveCN101290981AStable and consistent electrical performanceQuality improvementLead-acid accumulatorsLead-acid accumulator electrodesProduction rateElectricity

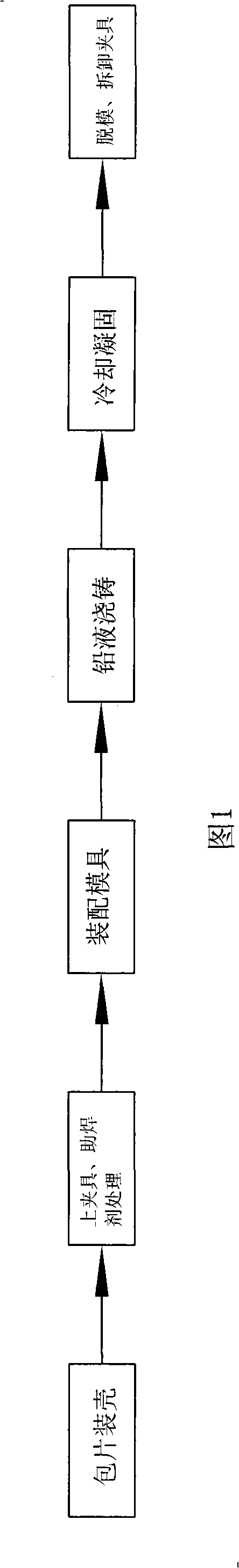

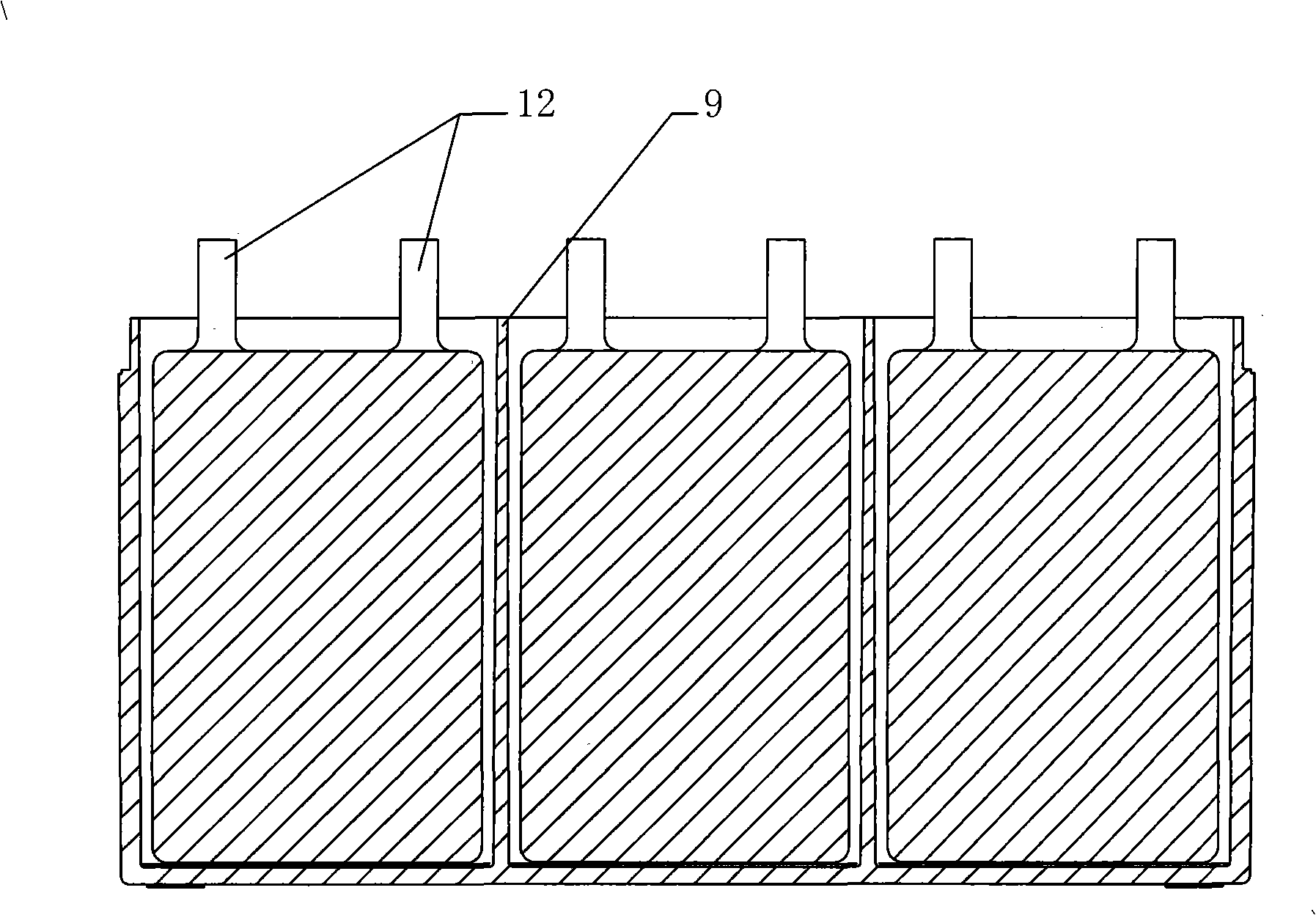

The invention discloses a connection process of pole plates of lead-acid storage batteries. The process is simple by connecting pole plates with busbars formed by pouring. Adjacent pole plates of adjacent single batteries, after being connected, integrate prior busbar structures and the bridge structures. The process can form n-type busbar connection structures which are all stable and consistent in performance, so storage batteries processed by the process have extremely high quality. The process has also improved in allowing mechanical equipment to participate the connection process, as work since a second step is completed by the cast welding machine, which contributes to improving production rate, realizing automation, reducing production costs, and improving enterprise performance.

Owner:江苏超威电源有限公司

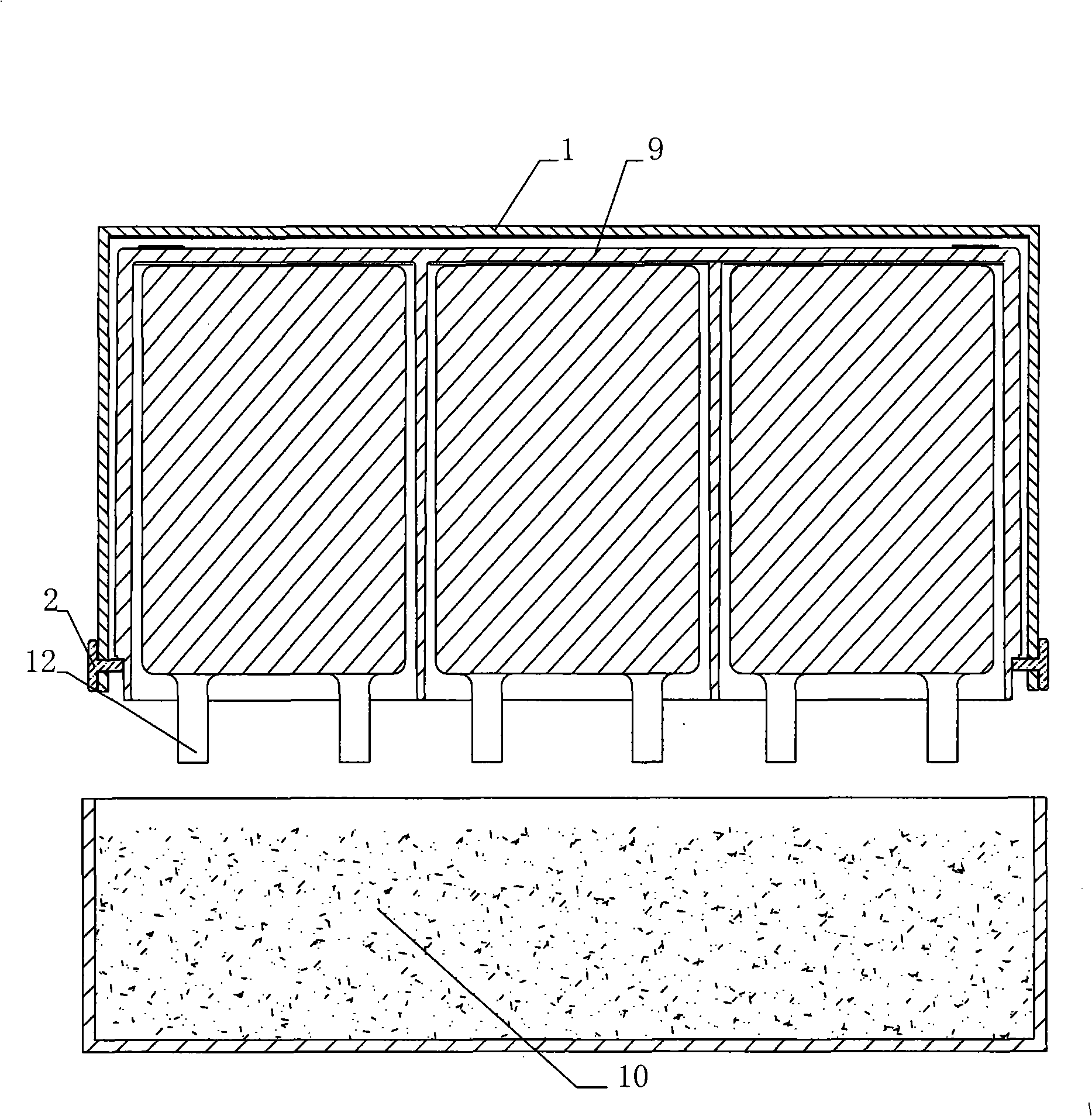

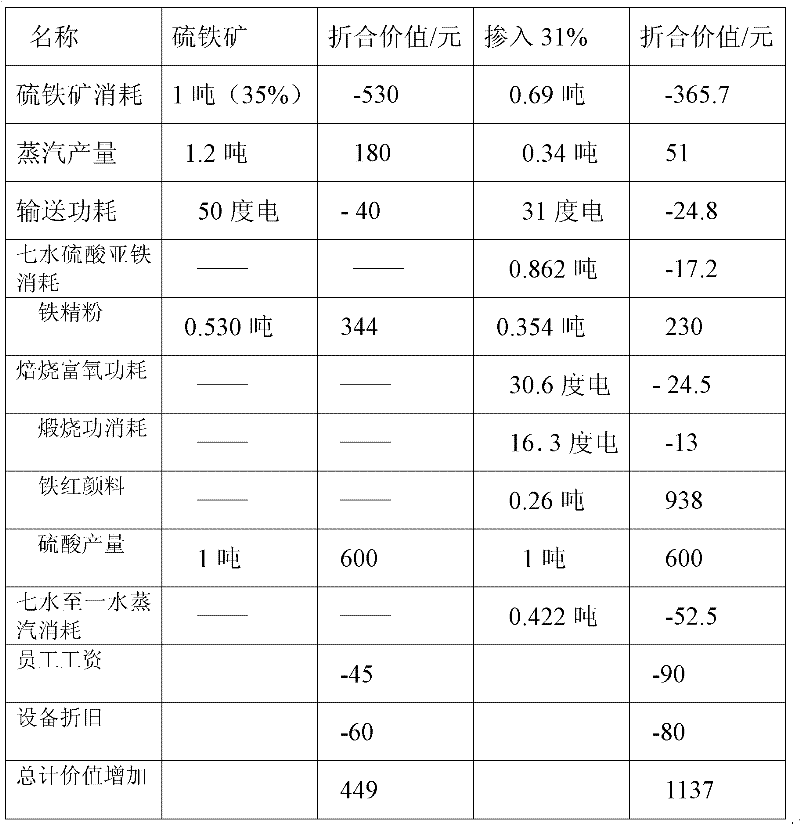

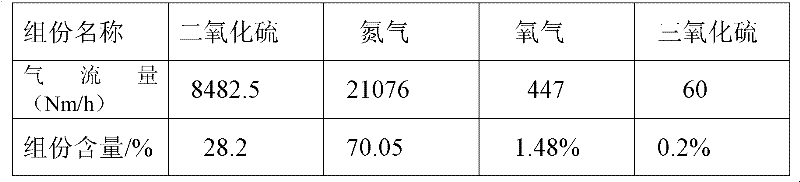

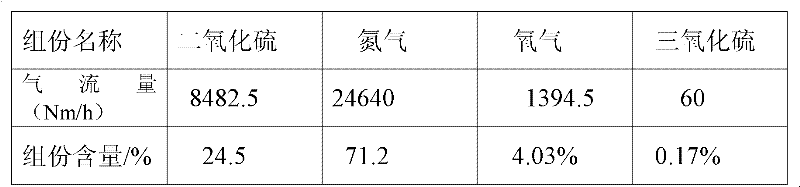

Process for co-producing sulfuric acid, fine iron powder and iron oxide red by ferrous sulfate heptahydrate and pyrite

ActiveCN102344124AIncrease incorporationImprove Pigment PerformanceSulfur compoundsEnergy inputResource utilizationFractionation

The invention provides a process for co-producing sulfuric acid, fine iron powder and iron oxide red by ferrous sulfate heptahydrate and pyrite and relates to the process technology of resource utilization of titanium dioxide byproduct solid waste ferrous sulfate. The process comprises the following steps: adopting titanium dioxide byproduct ferrous sulfate heptahydrate and pyrite as raw materials; increasing the mixing amount of the ferrous sulfate heptahydrate as much as possible through transforming the ferrous sulfate heptahydrate into ferrous sulfate monohydrate, oxygen-enriched roasting, preheating air in front of a furnace, controlling the sulfur content of the pyrite entering the furnace and the moisture and other technical means; and realizing the integrated co-production of the sulfuric acid, the fine iron powder and iron oxide red pigments through cinder fractionation, oxygen-enriched calcining and other process technologies. The process effectively improves the economic value of the heptahydrate ferrous sulfate and has an important significance on efficient and comprehensive utilization of the titanium dioxide byproduct solid waste ferrous sulfate heptahydrate.

Owner:HUNAN HENGGUANG TECH

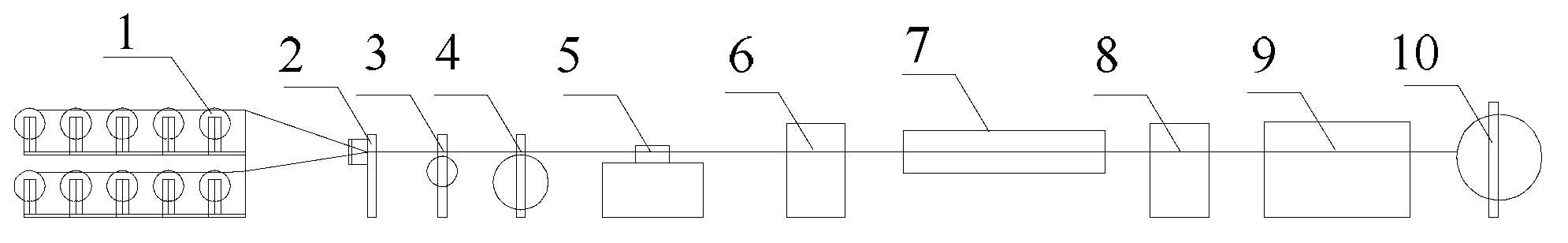

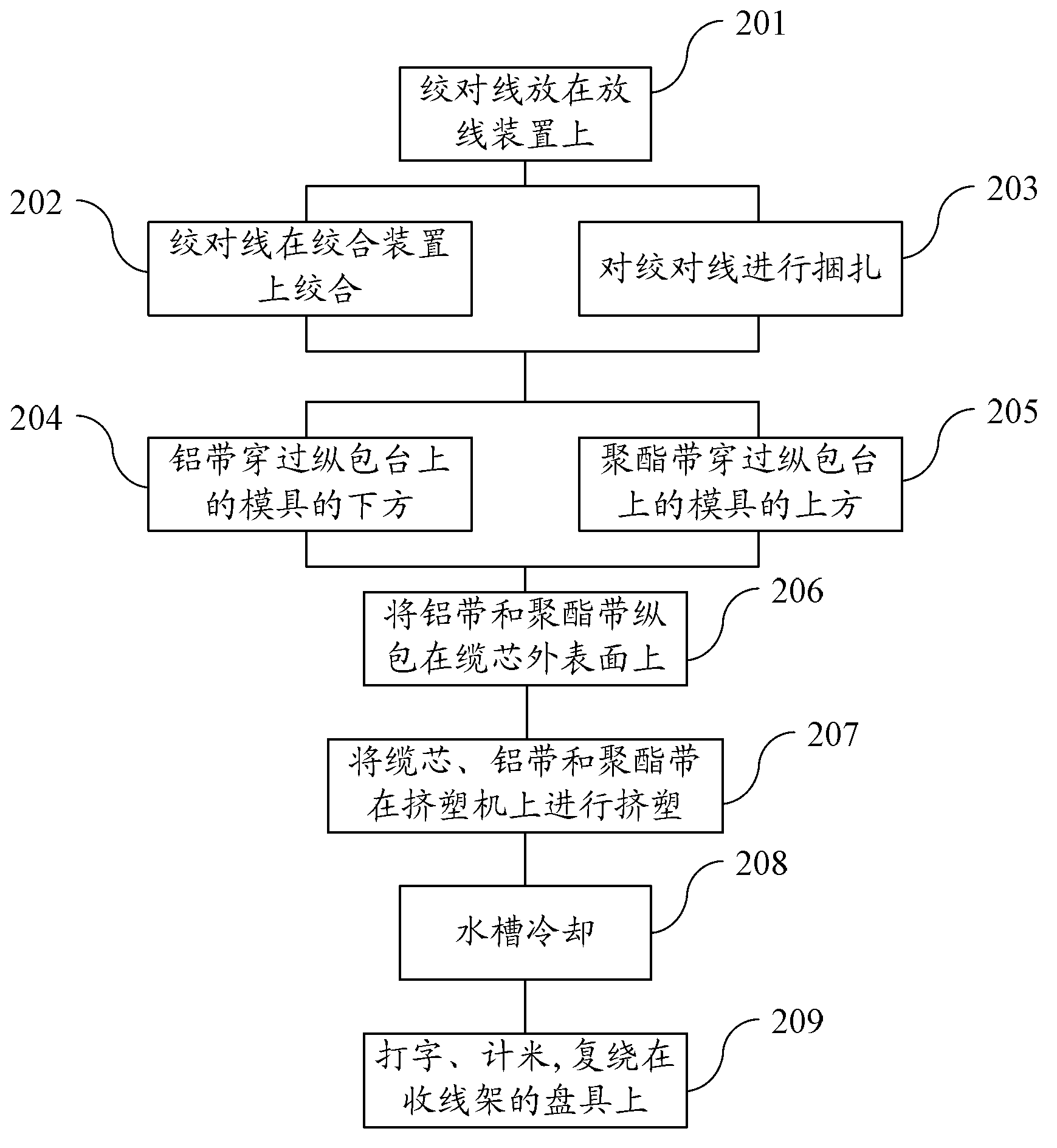

Integrated production method of cable

ActiveCN102842385ARealize integrated productionReduce production processCable/conductor manufacturePolyesterMolding machine

The invention discloses an integrated production method of a cable. The integrated production method comprises the following steps of: arranging pair twisting wires on a wire pay-off device; splitting, binding and twisting the pair twisting wires paid off by the wire pay-off device on a twisting device so as to obtain a cable core without a polyester tape; placing an aluminum tape on an aluminum tape placing rack, so that the aluminum tape penetrates through the downside of a mold on a longitudinal covering platform; placing the polyester tape on a polyester tape placing rack so that the polyester tape penetrates through above the mold on the longitudinal covering platform; longitudinally covering the aluminum tape and the polyester tape on the external surface of the cable core on the longitudinal covering platform; simultaneously carrying out extrusion molding on the cable core, the aluminum tape and the polyester tape on an extrusion molding machine, so as to obtain a prefabricated cable; and cooling the prefabricated cable so as to obtain the cable. According to the invention, only by additionally arranging a plurality of equipment, such as the wire pay-off device, the twisting device anda polyester tape placing device, on the original protective sleeve machine unit, the integrated production of cabling protective sleeves can be achieved, so that the production of a cabling procedure is reduced.

Owner:BEIJING HENGTONG SIBO COMM TECH CO LTD

Production process of EPE pearl cotton

The invention discloses a production process of EPE pearl cotton which comprises the following raw materials in parts by weight: 60-70 parts of a base material, 5-10 parts of a nucleating agent, 5-10parts of an antistatic agent, 10-20 parts of a foaming agent and 10-20 parts of an anti-shrinking agent; the base material is LDPE rubber particles, the nucleating agent is gold bubbles, the foaming agent is a butane agent, and the anti-shrinking agent is monoglyceride. According to the production process of the EPE pearl cotton, the base material, the nucleating agent, the antistatic agent, the foaming agent and the anti-shrinking agent are mixed and processed to obtain the EPE pearl cotton having the advantages of good pressure resistance and buffer performance, environmental protection, strong toughness, shock prevention, sound insulation, no deformation and good plasticity, wherein various raw materials are easy to get, the integrated production can be realized, and less pollution exists in the intermediate process; and the problems that the pressure resistance and buffer performance of conventional EPE pearl cotton produced by a general production process are bad, the produced EPEpearl cotton is easy to deform and bad in plasticity and energy saving and environmental protection effects of the production process are not obvious are solved.

Owner:南通通联海绵塑料有限公司

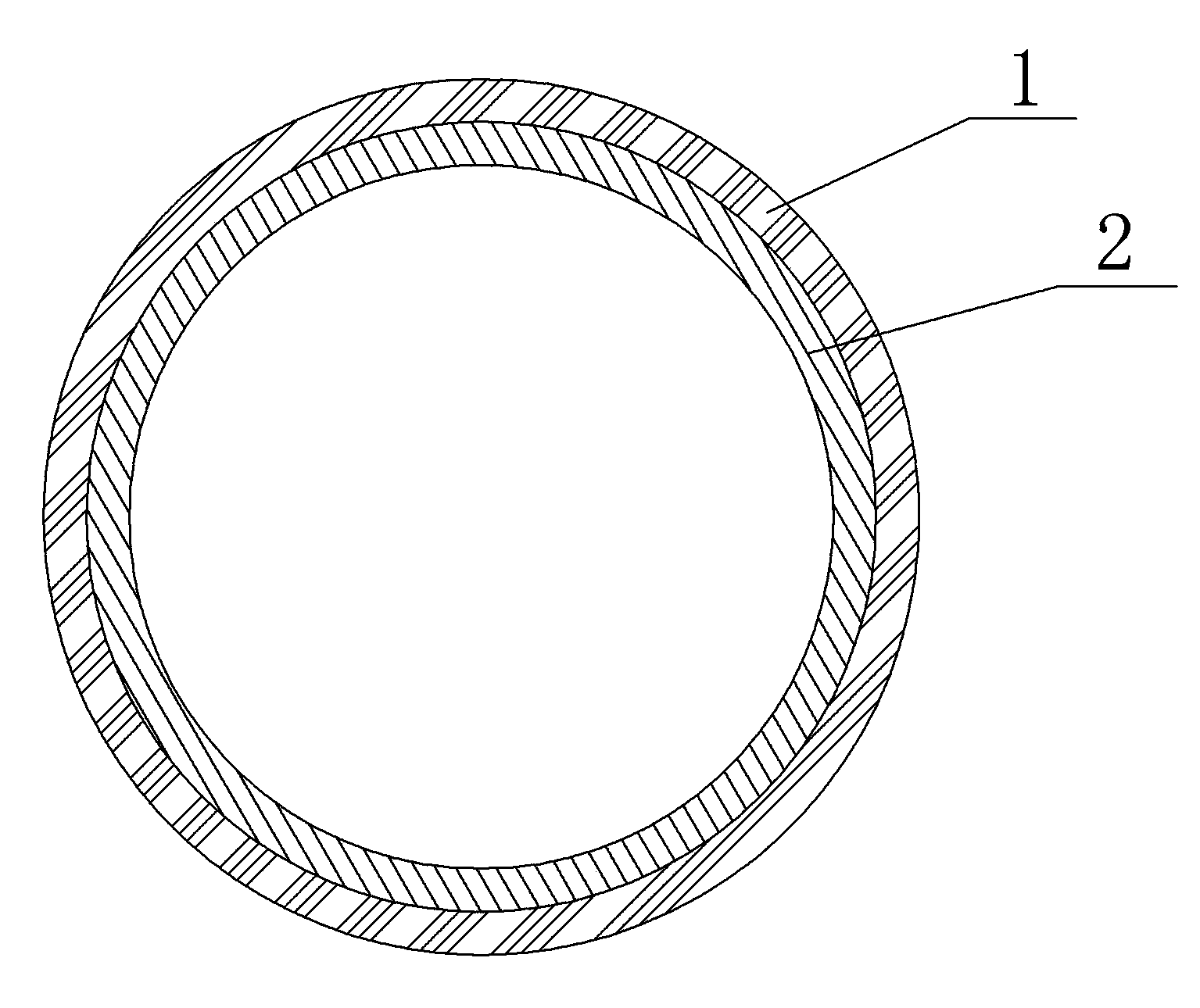

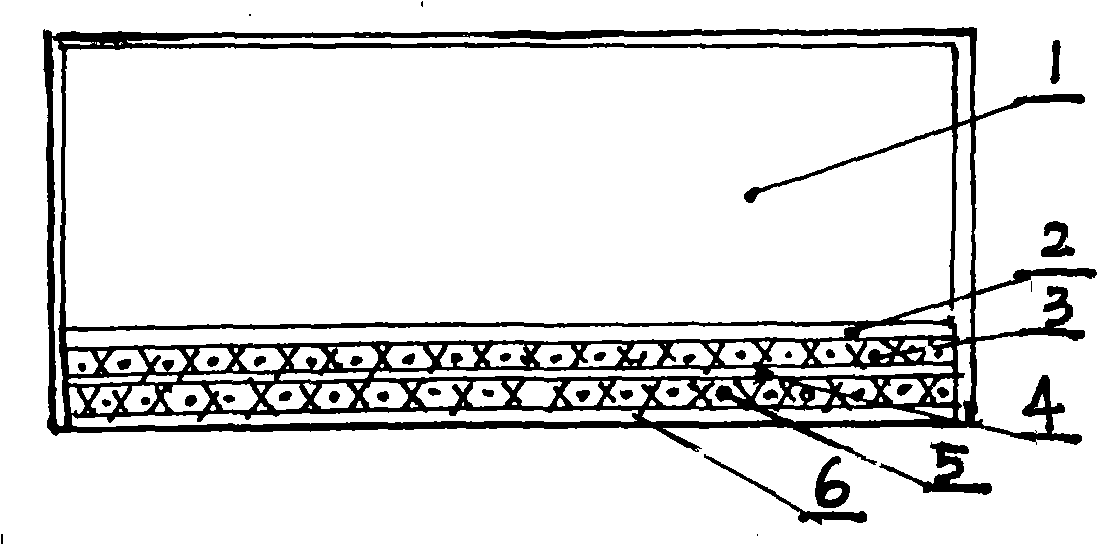

Double-layer composite tube and manufacturing method thereof

ActiveCN104019298AImprove stress resistanceFlow fastFlexible pipesLow-density polyethyleneWater quality

The invention discloses a double-layer composite tube and a manufacturing method thereof. The double-layer composite tube and the manufacturing method aim to solve the technical problems that black pigment is added into traditional HDPE tubes, accordingly inner walls are not smooth, water scale is prone to being generated, bacteria grow, and secondary pollution of water is caused. The double-layer composite tube comprises an inner layer and an outer layer, the inner layer is made of ultrahigh molecular weight polyethylene and ethylene-vinyl alcohol copolymers or low-density polyethylene, and the outer layer is made of high-density polyethylene, ethylene-vinyl alcohol copolymers and special melanin particles C of PE. The method includes the following steps of material proportioning and dehumidifying, material plastifying, material forming, vacuum sizing and spraying and cooling. The double-layer composite tube has the advantages of being good in toughness and flexibility, high in chemical stability, good in corrosion resistance, good in sealing performance, large in distribution power, long in service life, high in low temperature resistance, hygienic, free of toxin and the like. The manufacturing method is simple, easy to operate and capable of achieving integral production of the double-layer composite tube.

Owner:菏泽三垒塑业股份有限公司

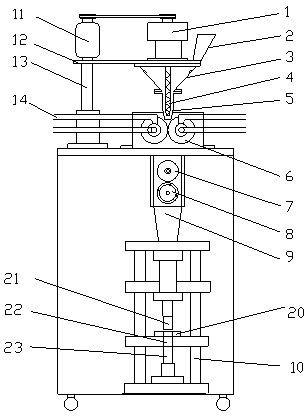

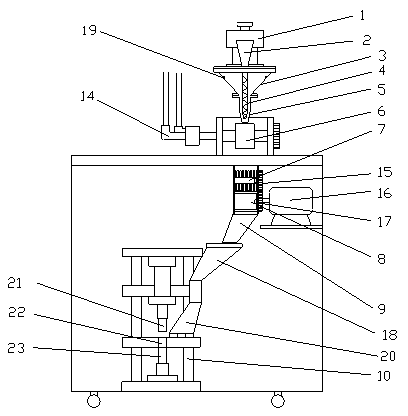

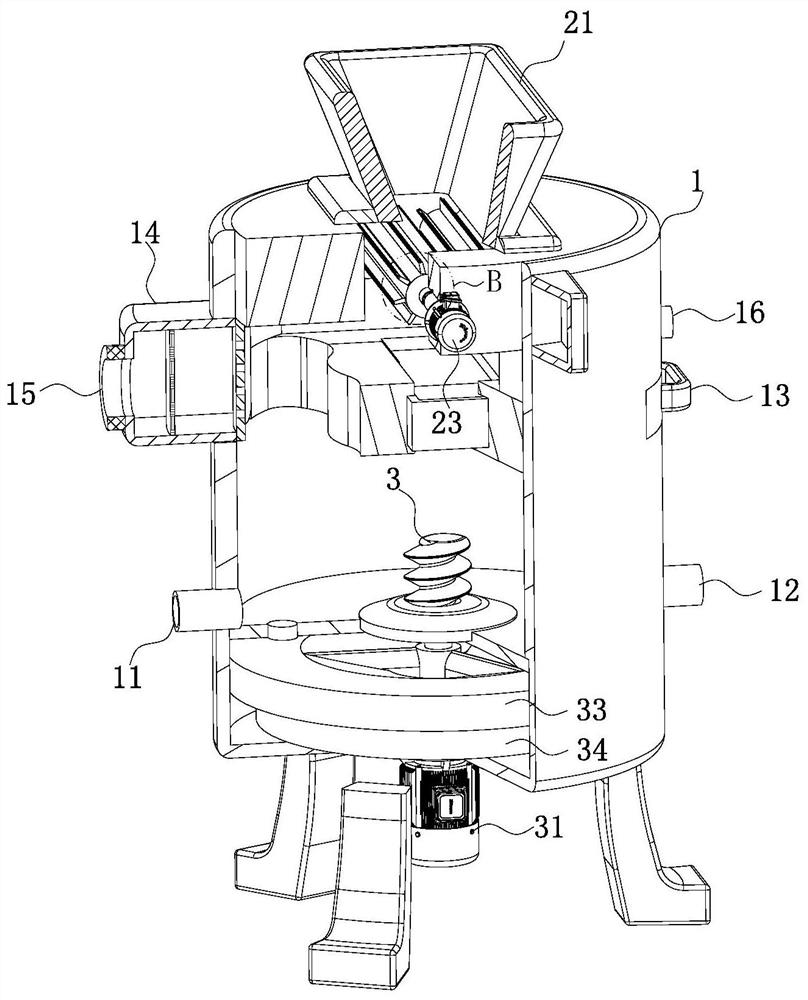

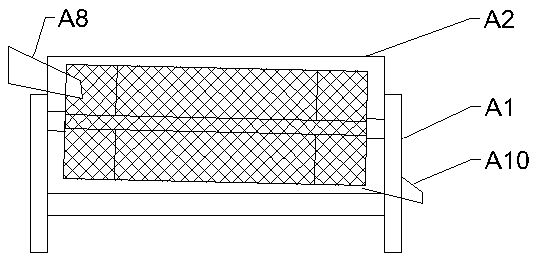

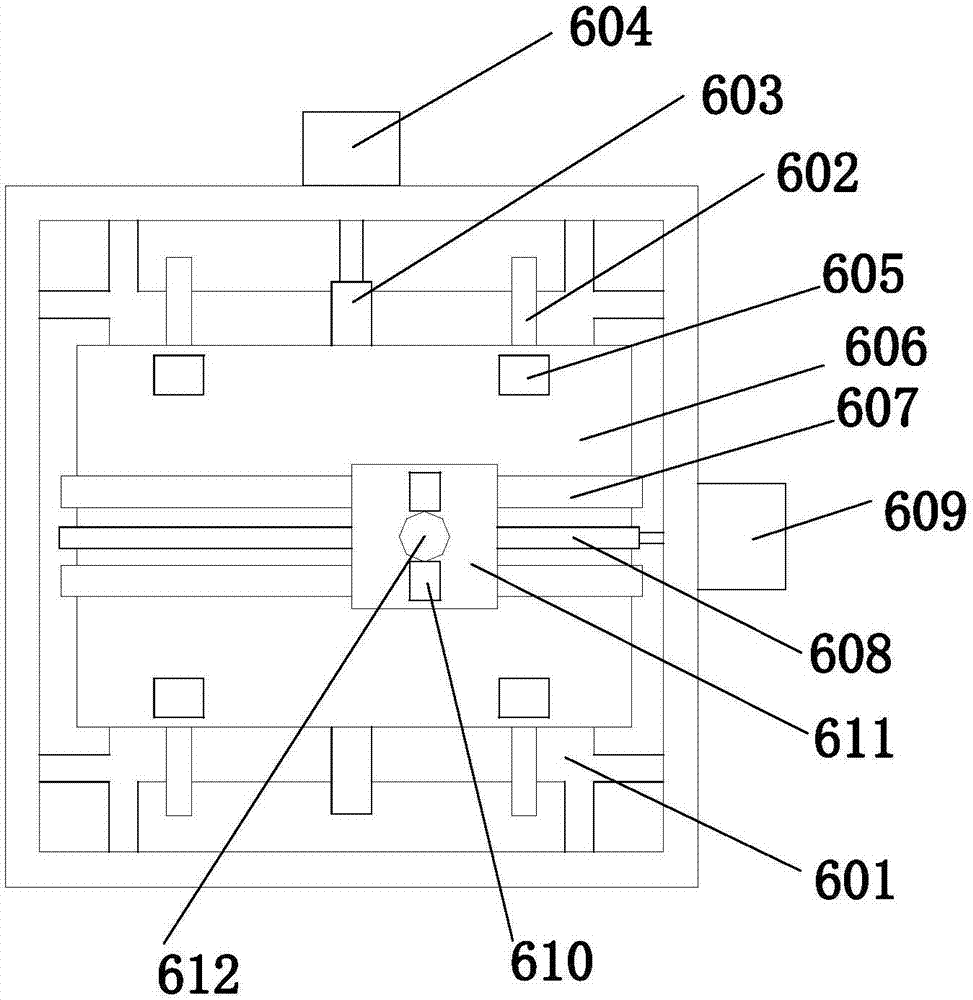

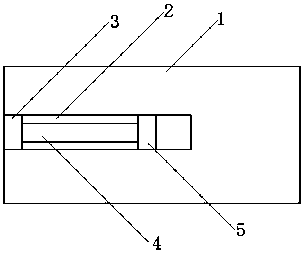

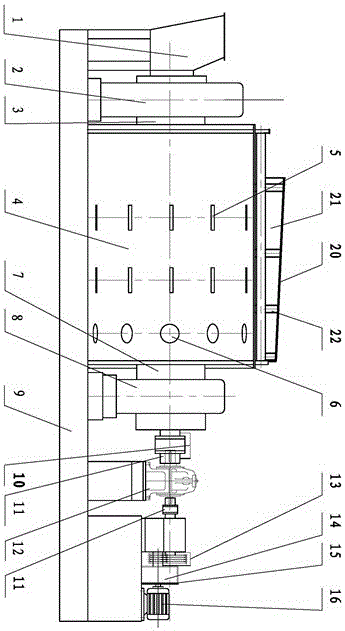

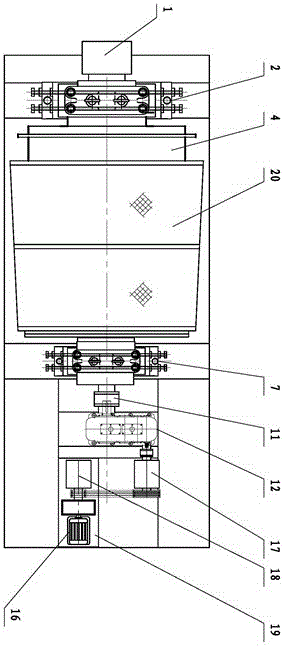

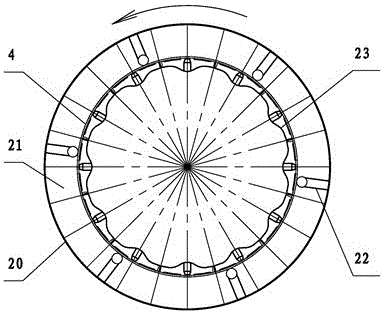

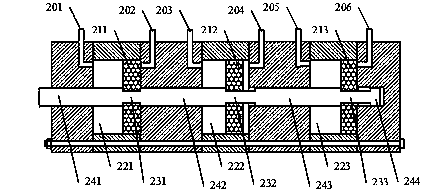

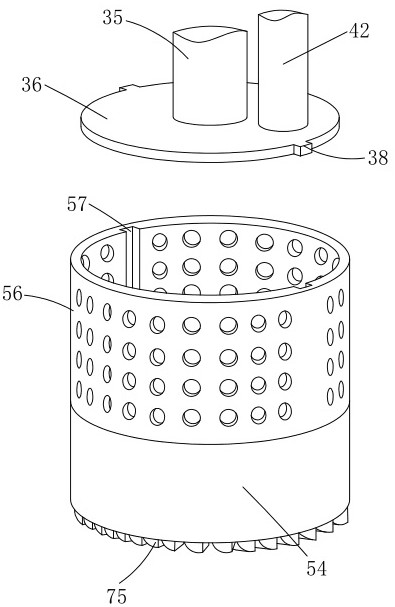

Pure powder granulation negotiable machine

ActiveCN104275822ARealize integrated productionIncrease productivityGrain treatmentsShaping pressEngineeringTableting

The invention provides a pure powder granulation negotiable machine and belongs to the field of medical instruments. The pure powder granulation negotiable machine comprises a feeding device, a roller pressing device, a granulating device and a negotiable device; the feeding device is located on the upper portion of the roller pressing device, and the granulating device is arranged between the roller pressing device and the negotiable device; the feeding device is provided with a feeding screw inside; the granulating device comprises a smashing mechanism and a granulating mechanism, and a discharging hopper is arranged below the granulating mechanism and is connected to the feeding port of the negotiable device. A radial blade and drum of the smashing mechanism are integrated as designed, a fixing bolt is arranged inside the drum, the end of the smashing mechanism is provided with the blade, the smashing dead corner is avoided, the integral production of granulating and negotiable is implemented, pure powder negotiable can be implemented, additives and water are omitted, and the producing efficiency can be improved effectively.

Owner:升生健康科技(苏州)有限公司

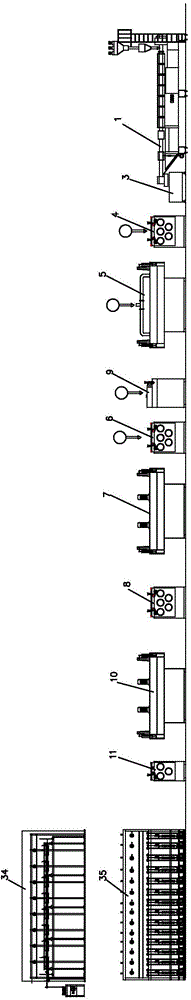

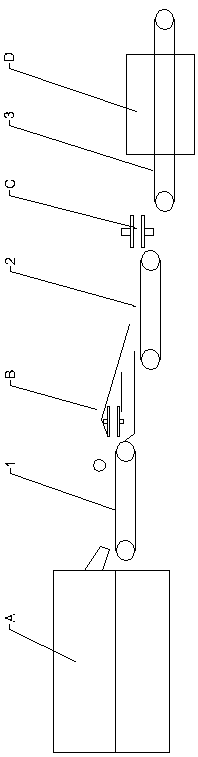

Lawn rayon production line and production method

ActiveCN104862792ASingle screw speed adjustment rangeRealize stepless speed regulationArtificial thread manufacturing machinesMelt spinning methodsProduction lineProcess time

The invention discloses a lawn rayon production line and production method. The lawn rayon production line comprises monofilament production equipment, after finishing equipment and a plying and twisting unit which are installed in sequence; two extruders of the monofilament production equipment of the lawn rayon production line are arranged in parallel and can produce monofilament with different colors and different types; the plying and twisting equipment conducts plying and twisting on the monofilament produced through the production line and monofilament which needs to be twisted, rewinding does not need to be conducted repeatedly, the process time and the workshop space are saved, requirements for plying and twisting production of two or more monofilament are met, and the production efficiency is greatly improved.

Owner:QINGDAO QINGHE ARTIFICIAL TURF

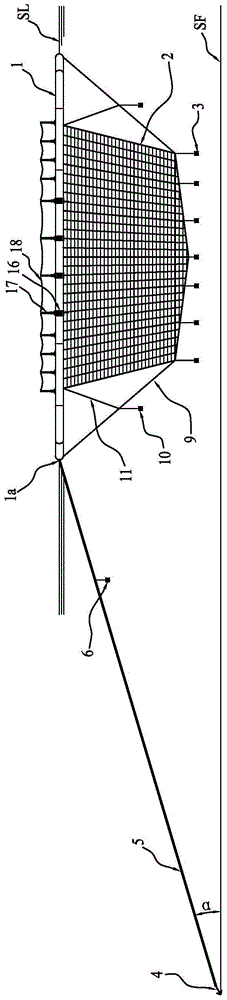

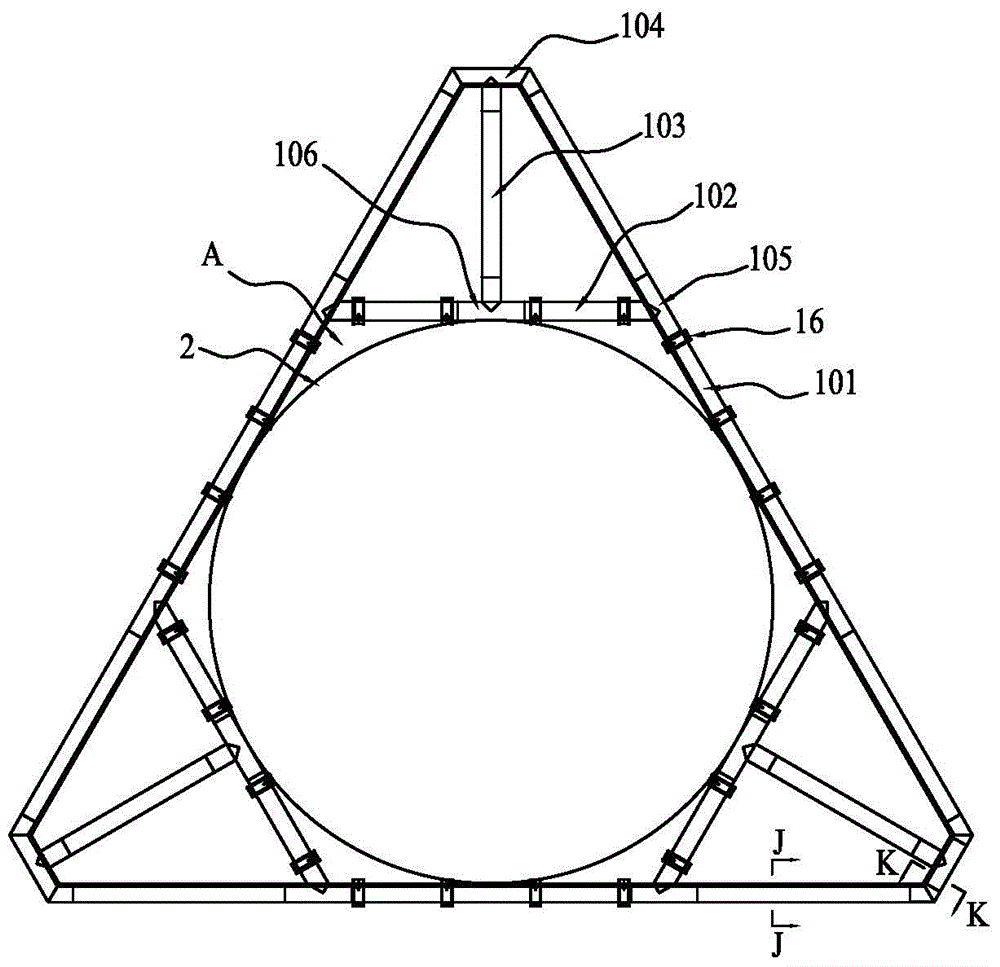

Deep water cage with single point mooring system

ActiveCN104186381BImprove typhoon resistanceHigh riskClimate change adaptationPisciculture and aquariaRisk preventionMariculture

The invention discloses a deep-water net cage with a single-point mooring system, comprising a floating pipe frame (1), a netting (2) and an anchoring system, the floating pipe frame (1) floating on the sea level (SL), The top of the net (2) is connected to the floating pipe frame (1), and the net weight (3) is hung on the bottom to form a space for mariculture. The mooring system includes an anchor (4), an anchor rope (5) and anchor rope weight (6); the floating pipe frame (1) is provided with a mooring point (1a), the anchor (4) sinks into the seabed (SF), and the anchor rope ( The lower end of 5) is connected to the anchor (4), the upper end is connected to the mooring point (1a), the anchor rope weight (6) is tied to the anchor rope (5), and the anchor rope (5) The rope length between the anchorage point of the anchor rope weight (6) and the upper end of the anchor rope (5) is close to the lowest tide water depth where the anchor (4) is located. The invention has high typhoon resistance capability and risk prevention capability.

Owner:SOUTH CHINA SEA FISHERIES RES INST CHINESE ACAD OF FISHERY SCI

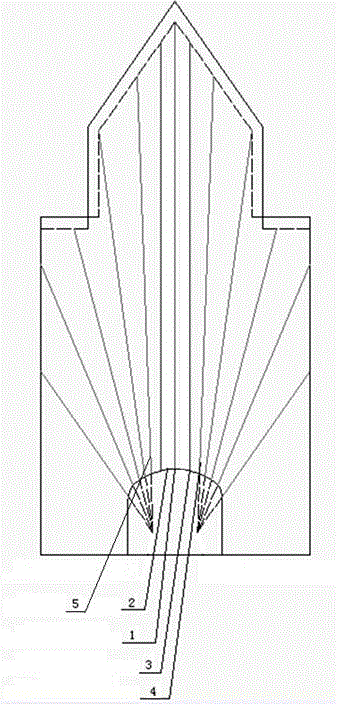

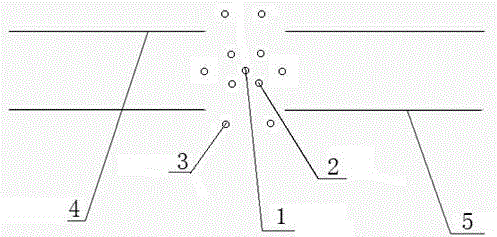

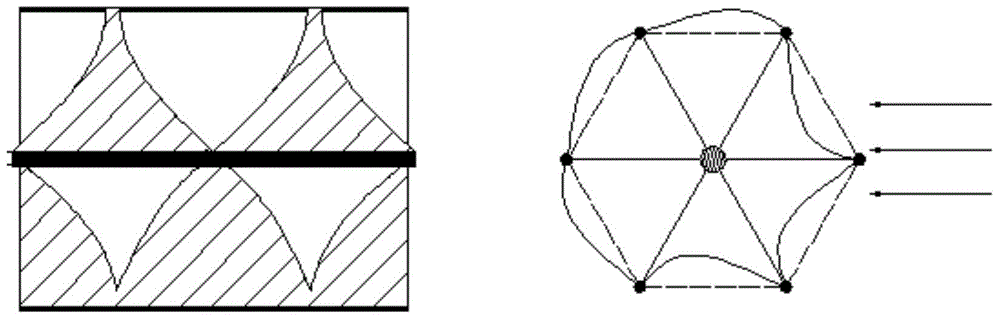

Method for forming cutting surface in deep hole blasting

ActiveCN104807381ARealize integrated productionImprove recovery rateBlastingEngineeringPsychological health

The invention discloses a method for forming a cutting surface in deep hole blasting, and relates to the technical field of underground mining blasting. The structure comprises a central charge hole (1), an empty hole (2), an auxiliary charge hole (3), cutting scallop holes (4) and emission centers (5). The structure achieves the purpose of deep hole blasting cutting, a recovery cutting process is simplified, cutting efficiency is improved, cutting cost is reduced, benefits are remarkable, ore recovery rate is increased, recovery cost is reduced, the cutting scallop holes are distributed in the double emission centers, cutting effects are improved, a cutting operation environment is effectively improved, the physical and psychological health of staff is guaranteed, cutting and recovery are integrated in production, three-grade reserve remaining period can be reduced, and the fund utilization efficiency of a mining engineering is improved.

Owner:JIUQUAN IRON & STEEL GRP

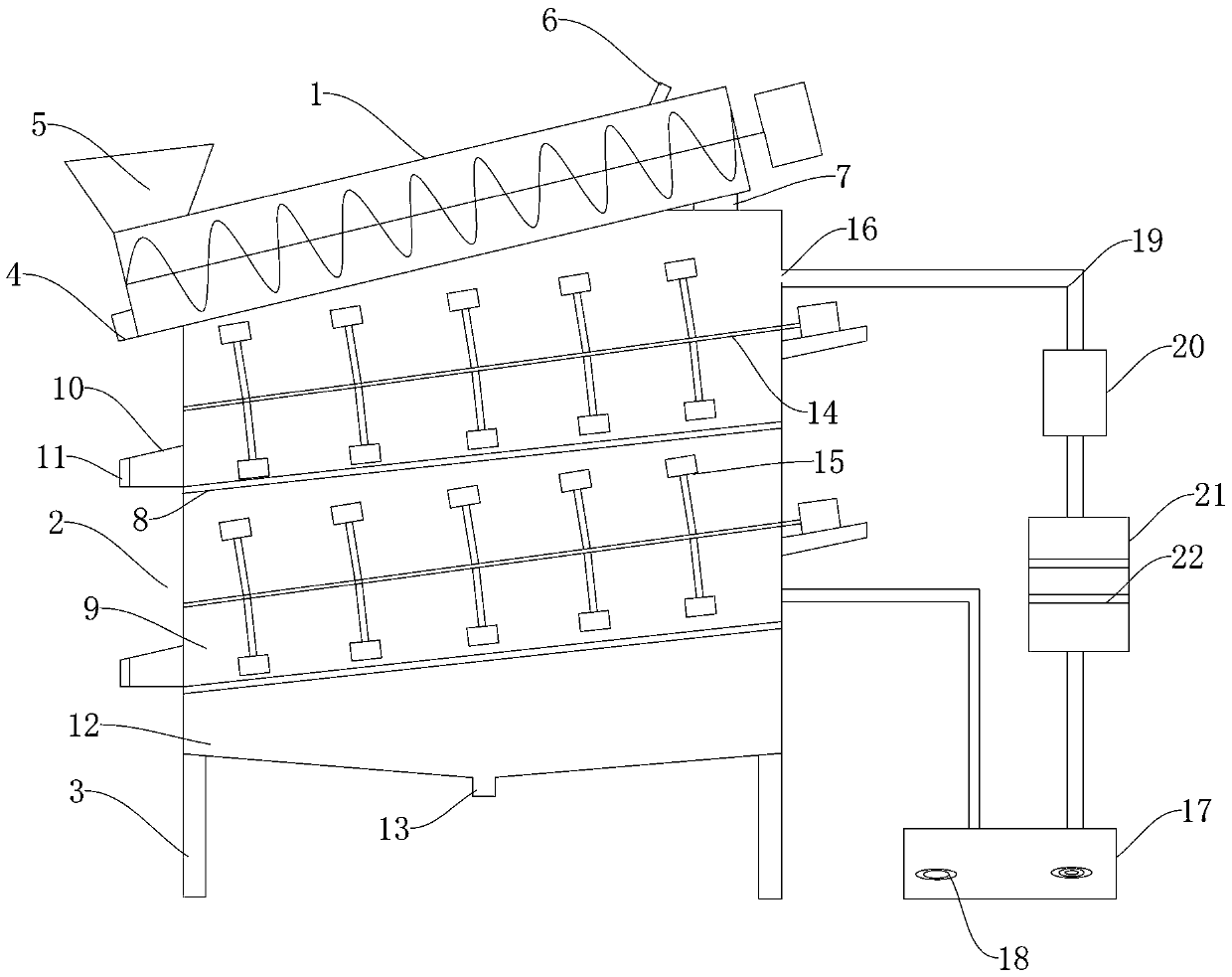

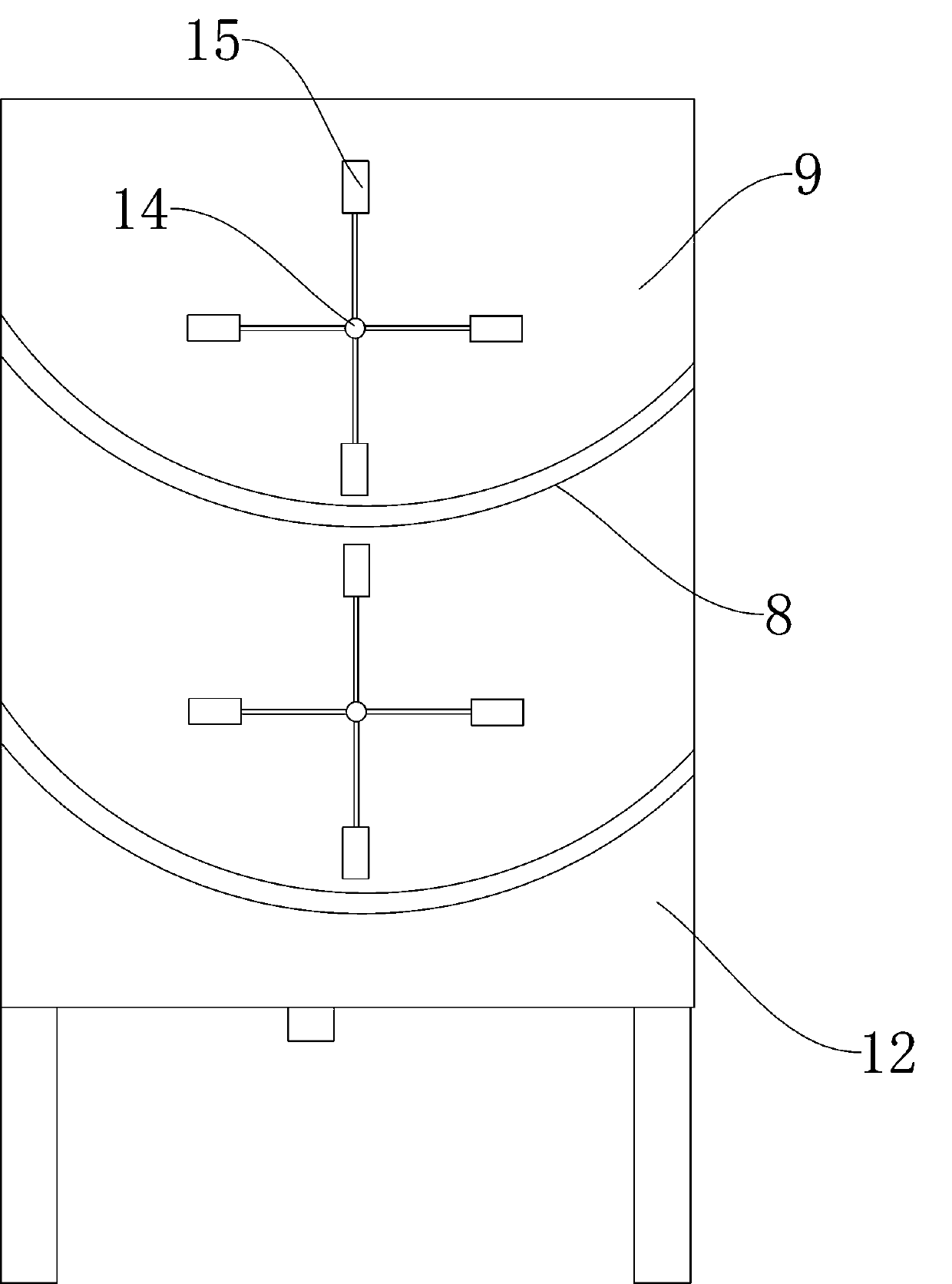

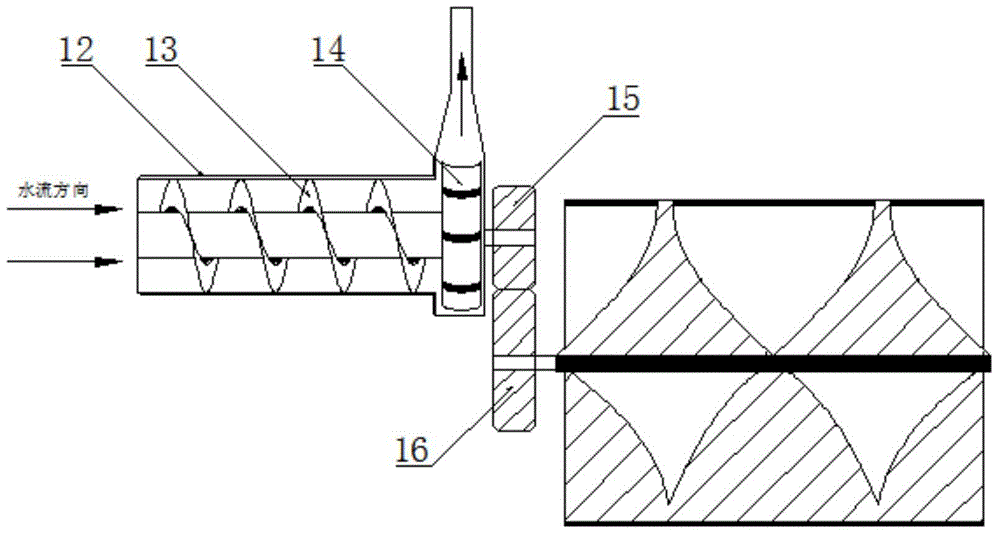

Recycled concrete aggregate machining device

InactiveCN110339995ARealize cleaning and removing impuritiesEffective classificationSievingGas current separationWater dischargeEngineering

The invention provides a recycled concrete aggregate machining device. The recycled concrete aggregate machining device comprises a spiral conveyor and a screening box, wherein the spiral conveyor isobliquely arranged, the screening box is arranged below the spiral conveyor, a supporting frame is arranged at the lower end of the screening box, a material leaking port is formed in the lower end ofthe spiral conveyor, a material inlet is arranged at the position over the lower end, a water inlet is formed in the higher end of the spiral conveyor, a discharging end is arranged under the higherend of the spiral conveyor, the discharging end is in communication with the screening box, the screening box is provided with a plurality of layers of screens from top to bottom, the hole diameters of the screens are gradually reduced from top to bottom, the screening box is divided into a plurality of stirring cavities by the screens, each stirring cavity is provided with a material discharge port, the material discharge ports are provided with sealing plates, a water collecting cavity is arranged below the lowermost layer of screens, a water discharge port is formed in the water collectingcavity, stirring shafts are arranged in the stirring cavities, blades are arranged on the stirring shafts, and the stirring shafts are driven by a motor. According to the recycled concrete aggregate machining device, cleaning and impurity removal and screening of recycled concrete aggregate can be carried out at the same time, the operation is simple, the production efficiency is improved, and theenvironmental pollution is small.

Owner:湖北乾奥建设工程有限公司

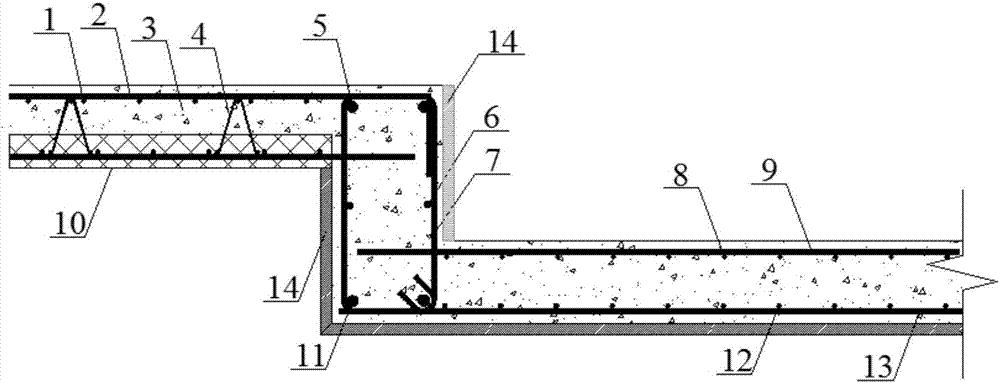

Prefabricated laminated floor slab with upturning side edge for slab descending area and construction method thereof

PendingCN107143076ASolve the workloadSolve the difficulty of formwork supportFloorsBuilding material handlingFloor slabArchitectural engineering

The invention relates to a prefabricated laminated floor slab with an upturning side edge for a slab descending area. The floor slab comprises an upper prefabricated laminated floor slab body, a lower prefabricated laminated floor slab body with the upturning side edge, a framework of steel reinforcement, an embedded nut, a split bolt, soft adhesive tape and a cast-in-situ concrete side formwork. The lower prefabricated laminated floor slab body with the upturning side edge is in sealed connection with the lower portion of the upper prefabricated laminated floor slab body through the soft adhesive tape; the embedded nut is embedded and fixed on the upturning side edge, one end of the split bolt is fixed to the embedded nut, and the other end of the split bolt is fixed to the cast-in-situ concrete side formwork. By the adoption of the prefabricated laminated floor slab with the upturning side edge for the slab descending area, the problems are solved that in a construction field, the workload of reinforcement assembling during formwork erecting is large and formwork erecting is difficult, and the work efficiency of field construction in the slab descending area is improved; the construction difficulty is greatly reduced; the integrated production of a component factory is achieved, and components are accurate in size, high in industrialization degree and guaranteed in quality; the lower prefabricated laminated floor slab body with the upturning side edge and the upper prefabricated laminated floor slab body are prefabricated separately, poured and connected on site, and the components are transported without special treatment.

Owner:上海宝悦房地产开发有限公司

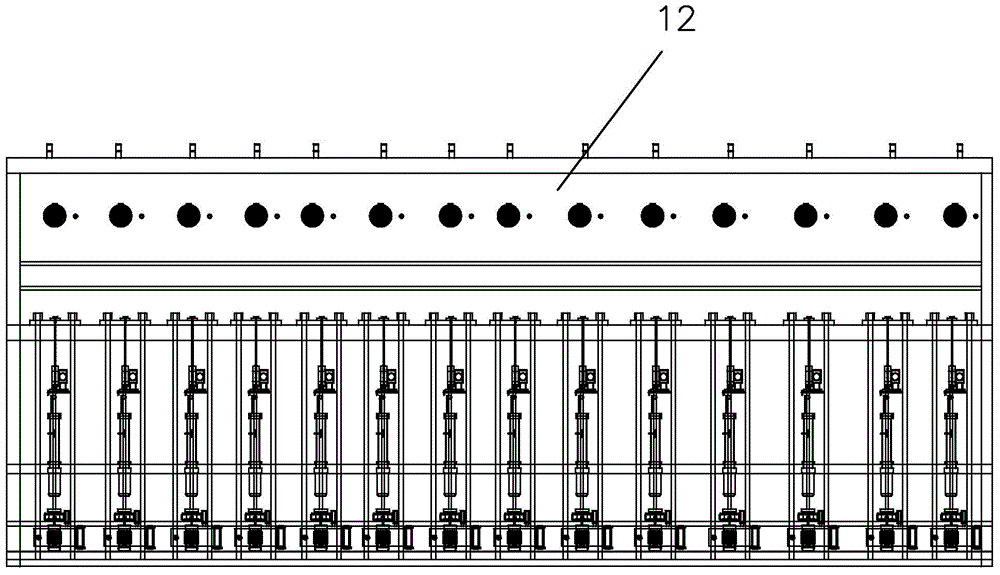

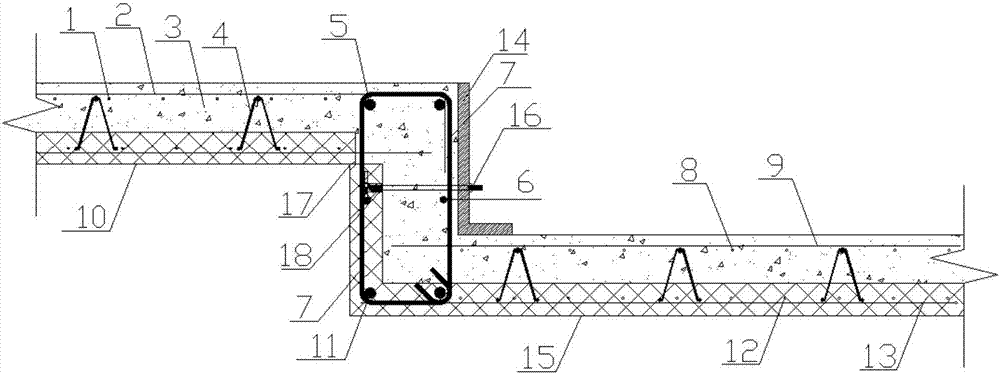

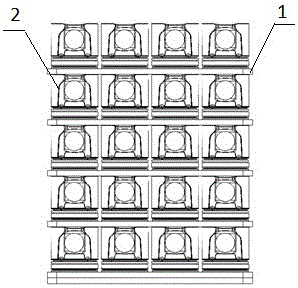

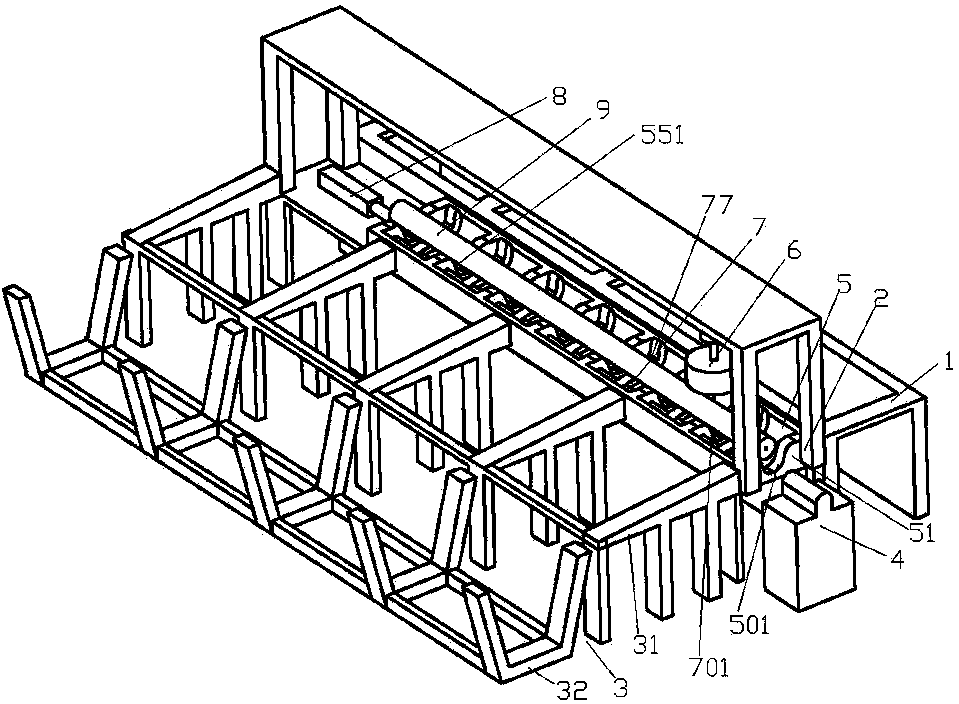

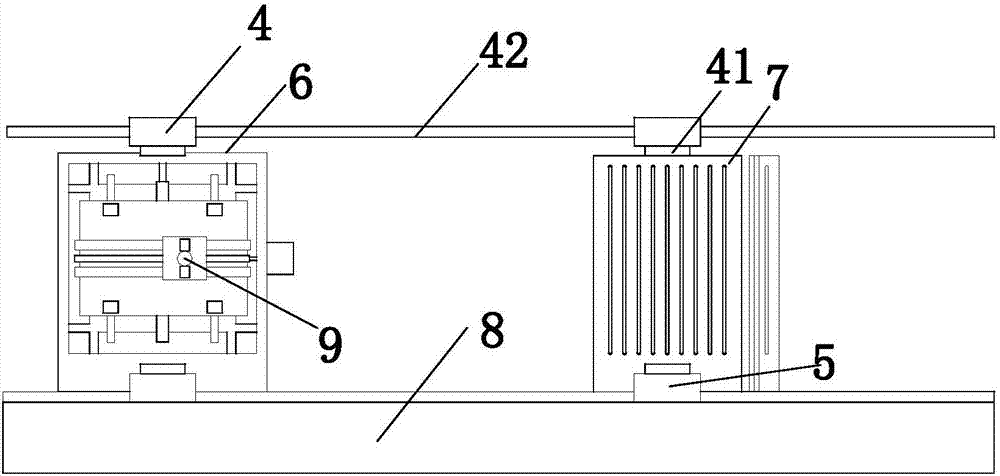

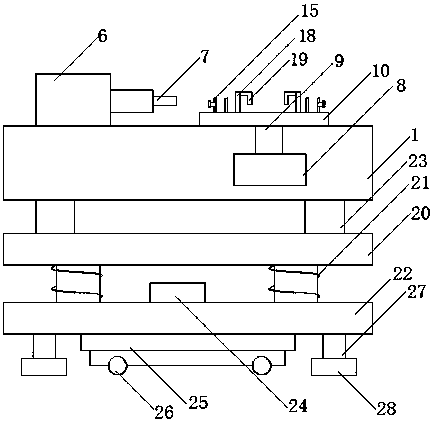

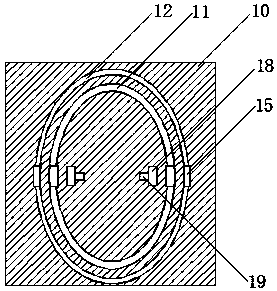

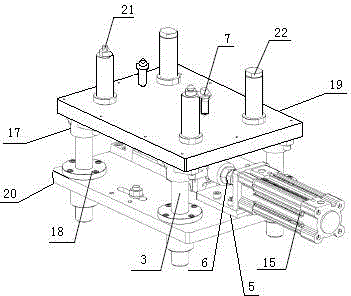

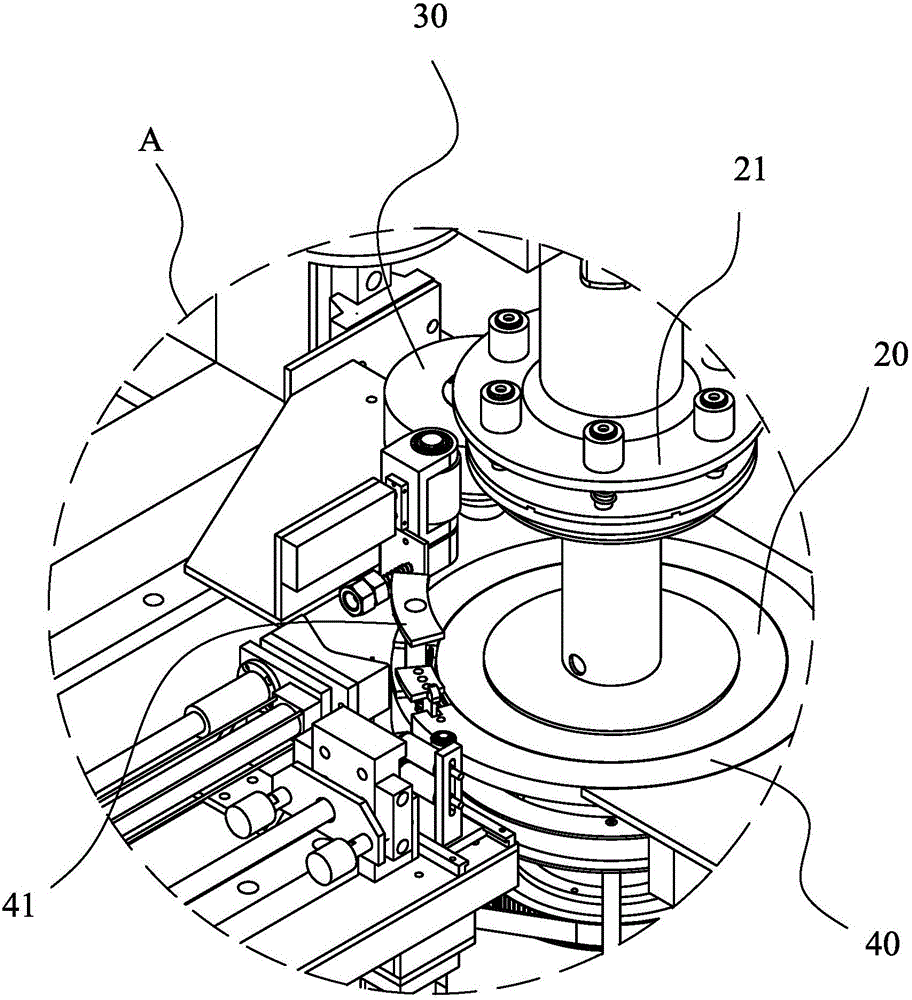

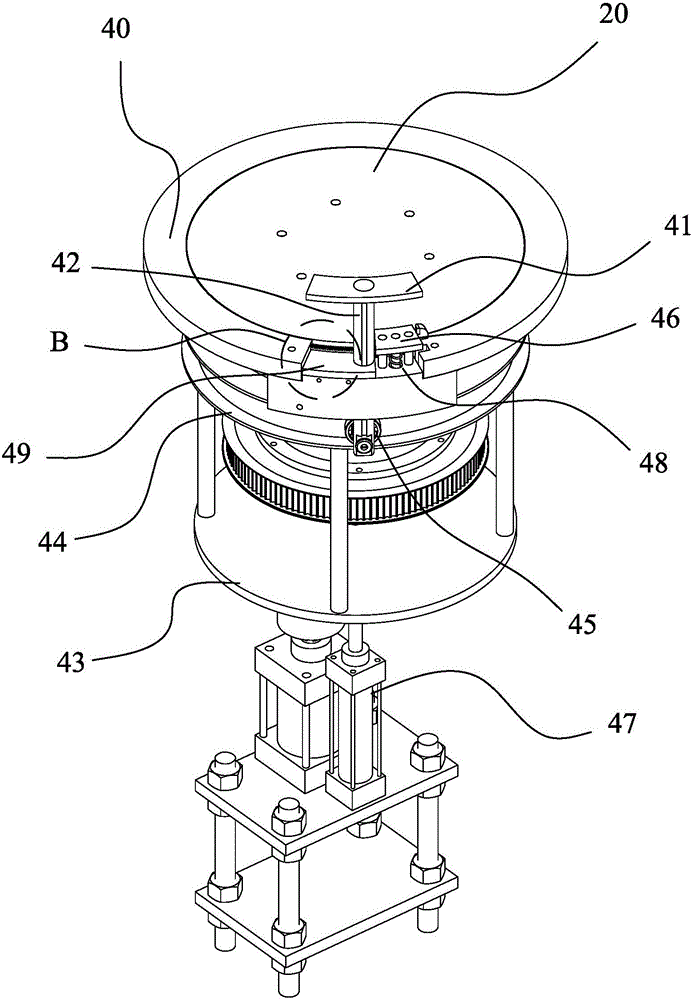

Two-station partition plate tray transferring device and transferring method

ActiveCN105966929ARealize integrated productionHigh degree of automationStacking articlesDe-stacking articlesEngineeringIntegrated production

The invention relates to a two-station partition plate tray transferring device and a transferring method. The device comprises a rodless air cylinder, biased flat steel, a linear guide block, a linear guide rail, a frame, main frames, air cylinder brackets, a slide block connecting plate, a vacuum sucking disc, a rodless air cylinder connecting plate and an L-shaped bracket, wherein the air cylinder brackets are perpendicularly arranged on the two main frames; the rodless air cylinder and the biased flat steel are fixedly arranged between the air cylinder brackets, successively; the linear guide rail is arranged on the biased flat steel; the slide block is slidably arranged on the linear guide rail; the slide block connecting plate is fixedly arranged on the slide block; the slide block connecting plate is in floating connection to the rodless air cylinder connecting plate through a bolt; the slide block connecting plate is connected to the frame through the connecting bracket; the L-shaped bracket is arranged on the frame; and the vacuum sucking disc is fixedly arranged on the L-shaped bracket. The transferring method comprises a loading and stacking process and a partition plate tray transferring process. The device provided by the invention has the beneficial effects that the device is high in degree of automation, high in efficiency and low in manufacturing cost, and realizes integrated production of stacked workpieces and other processing steps.

Owner:NINGXIA KOCEL MACHINE TOOL ACCESSORIES

Method for preparing light high-strength composite trench cover

InactiveCN101575836ARealize integrated productionQuality improvementTemporary pavingsPolyesterSurface layer

The invention relates to a method for preparing a light high-strength composite trench cover. The conventional concrete trench cover has heavy volume, is easily broken, and brings inconvenience for transportation, mounting and maintenance for constructors. The invention aims to develop the light high-strength composite trench cover with high strength, light weight, normalization and standardization, which uses high-strength low-alkali cement as a raw material, and is matched with porcelain granules, a reinforcing agent, slag and flyash packing materials, polyester granules and other materials, wherein the surface layer and the bottom layer of the light high-strength composite trench cover are cement mortar layers; two steel wire mesh inner layers are arranged in the cement mortar surface layer and the cement mortar bottom layer; the cement mortar granules, the reinforcing agent, the polyester granules, the slag and flyash packing materials and other light composite materials are filled in the steel wire mesh inner layers; and a cold-rolled ribbed reinforcing steel bar layer is clamped between the two steel wire mesh inner layers. The light high-strength composite trench cover is light, has high strength, nice appearance and smoothness, and is convenient to construct, mount and maintain.

Owner:曾锡泉

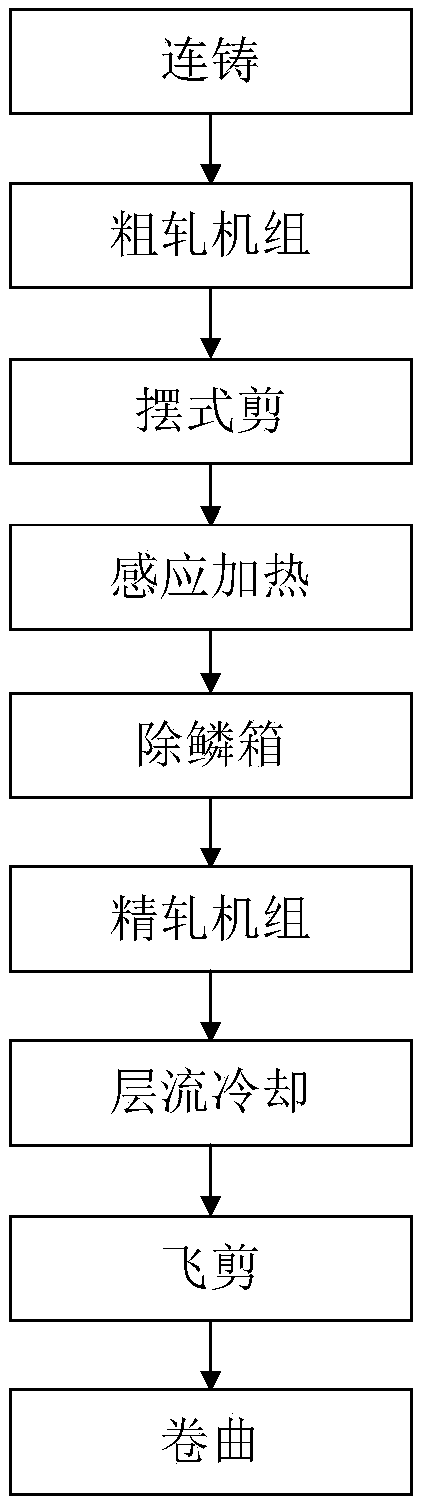

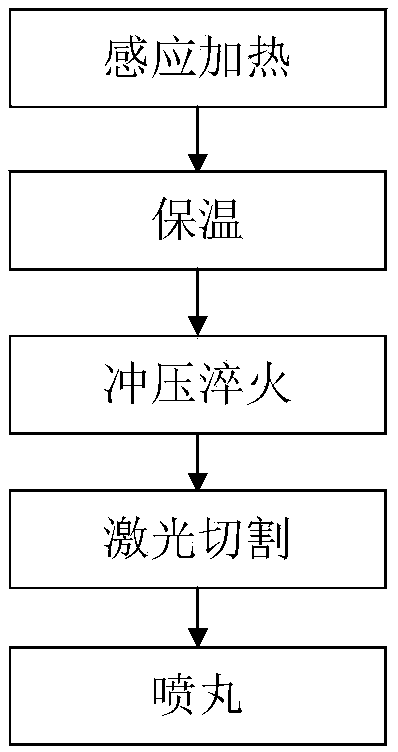

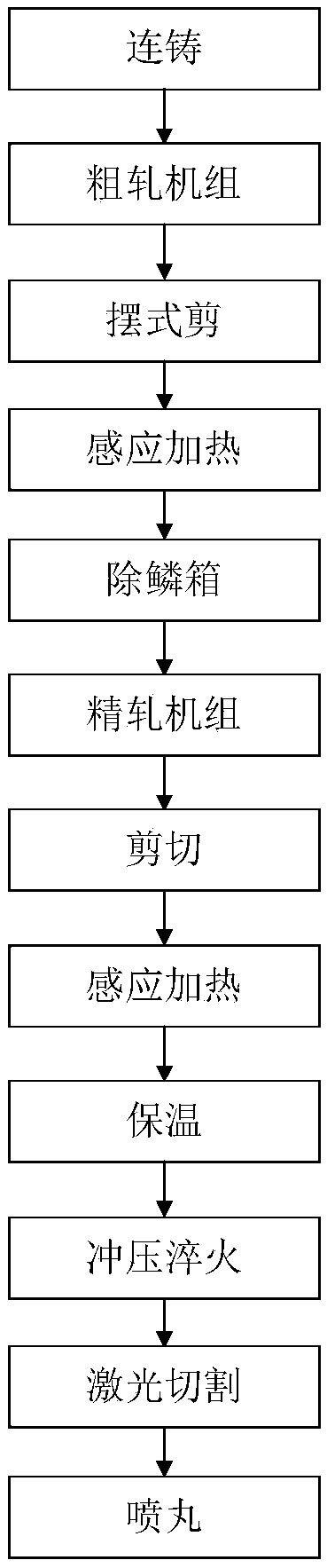

Method for manufacturing high strength steel sheet in short process, high strength steel sheet and application of high strength steel sheet

ActiveCN109433825AMeet size requirementsReduce consumptionMetal rolling arrangementsHot stampingSheet steel

The invention discloses a method for manufacturing a high strength steel sheet in a short process, the high strength steel sheet and application of the high strength steel sheet, and belongs to the field of metallurgy rolling and deep processing. The method comprises the steps that in the treating process of thin slab continuous casting and rolling, a thin slab which is subjected to finish rollingby a finishing mill group is obtained, and then the thin slab is directly cut into a preset size and is subjected to hot stamping processing after meeting the target temperature of hot stamping by induction heating to manufacture the high strength steel sheet. The method for manufacturing the high strength steel sheet in a short process realizes the integrated production from raw materials to products, saves the transportation cost of intermediate links, can achieve the purposes of energy saving, consumption reduction and green production, significantly shortens the overall manufacturing process of plate deep processing, and has the advantages of ultra-short process, deep processing and multi-variety small batch mass customization production.

Owner:YANSHAN UNIV

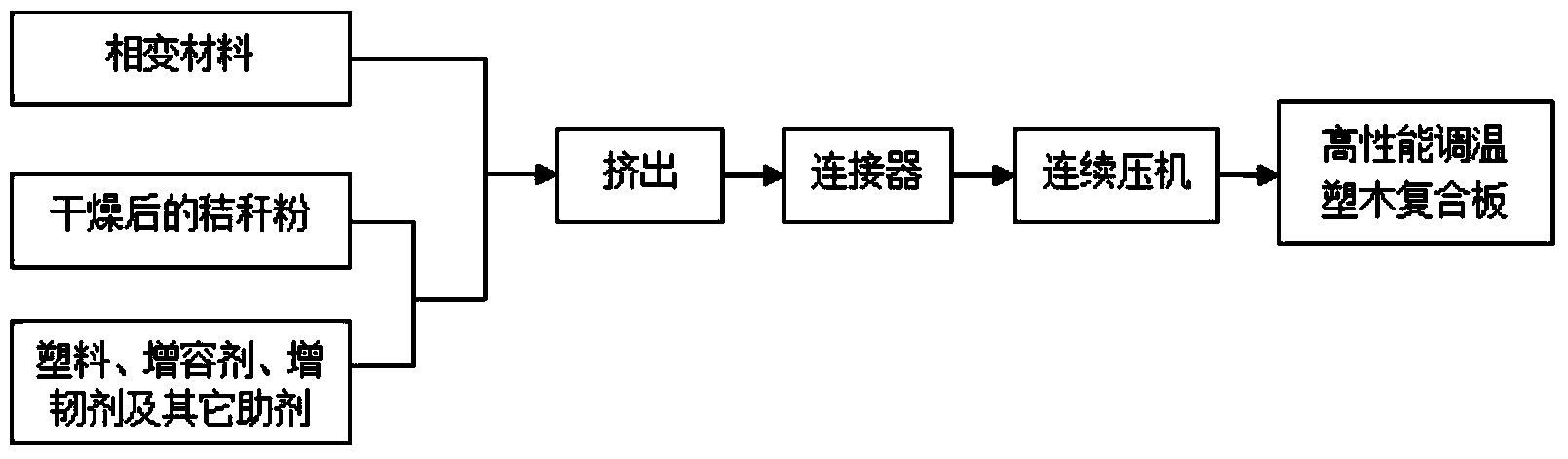

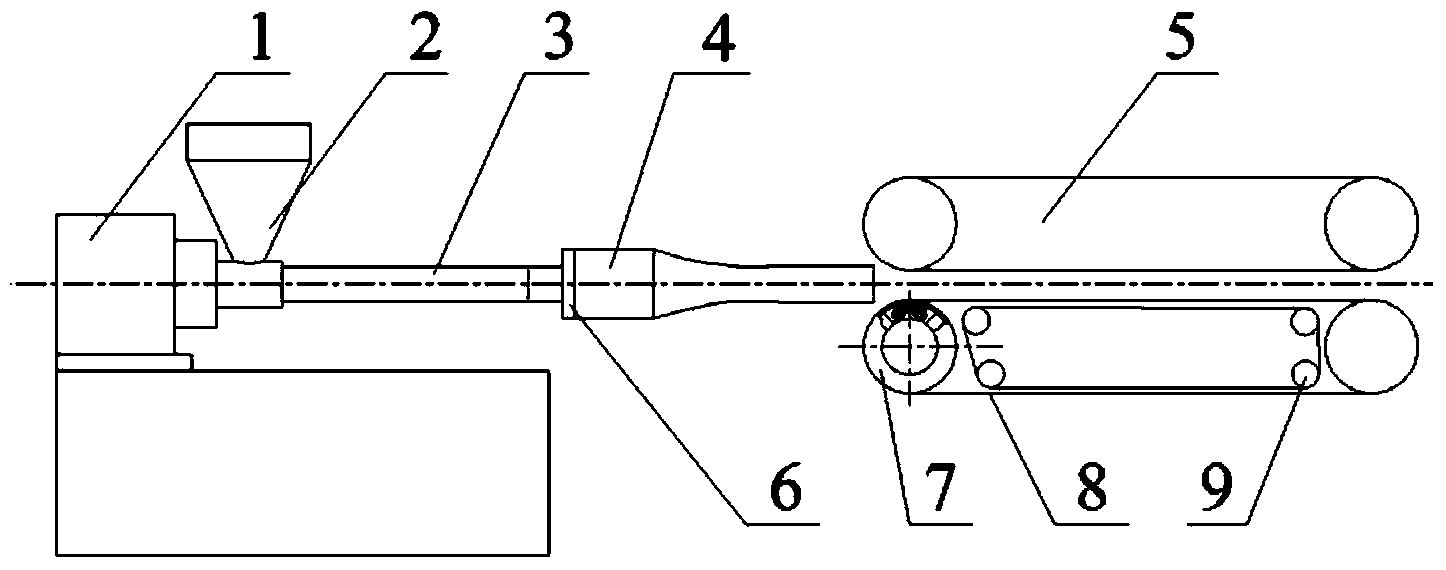

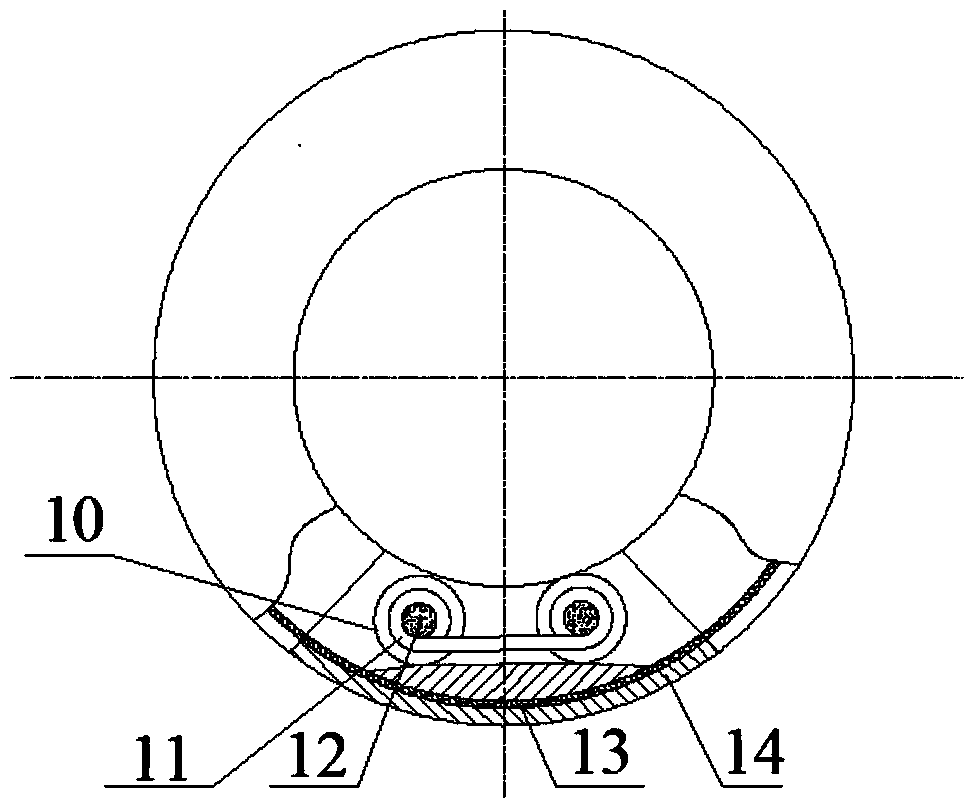

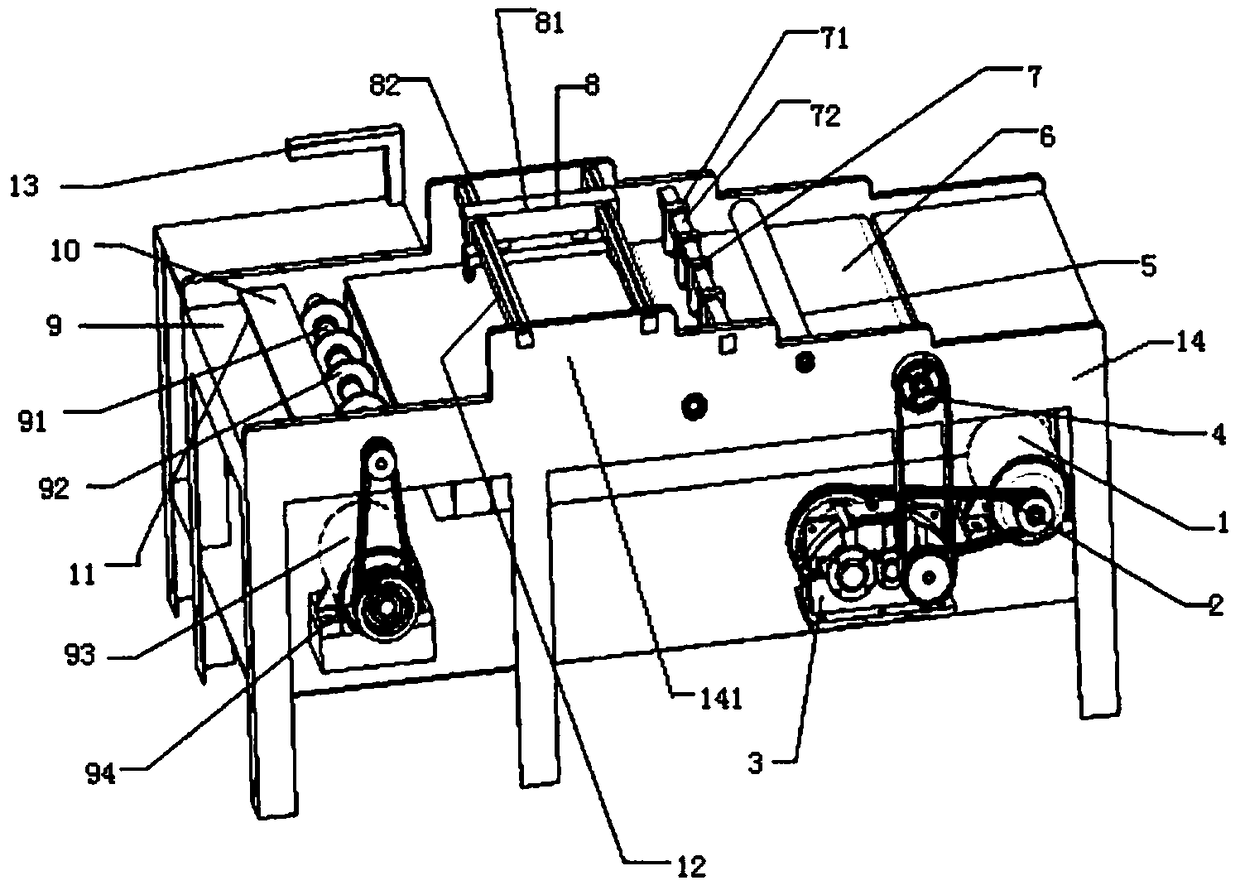

Plastic-wood composite board and preparation method thereof

The invention discloses a plastic-wood composite board and a preparation method thereof. The plastic-wood composite board comprises substances in percentage by mass as follows: 5%-35% of wood fibers, 25%-55% of a plastic base body, 15%-45% of a phase-change material, 2%-10% of a flexibilizer, 0.2%-1% of a dispersing agent and 0.2%-1% of a lubricating agent. The preparation method of the plastic-wood composite board comprises steps as follows: weighing and mixing the substances to obtain a premix, injecting melt into a continuous press provided with two steel belts via a connector through an extrusion feeder provided with a planetary screw, and finishing the integrated cooling, molding and conveying process. According to the method, the phase-change material is added into the plastic-wood composite board to realize a temperature adjusting function, the phase-change material is evenly dispersed in the composite board, and the change of the indoor temperature is absorbed by a floor, so that the indoor temperature is adjusted; a method that the planetary screw extrusion feeder and the continuous press are combined is adopted, so that straw powder granules in the board are mixed and distributed more uniformly, meanwhile, cooling, molding and conveying integrated production of the plastic-wood composite board is realized, and the annual output of the plastic-wood composite boards can be increased substantially.

Owner:BEIJING UNIV OF CHEM TECH

Environment-friendly automatic carton manufacturing machine

PendingCN109016660AStrong production adaptabilityReduce capital investmentPaper-makingBox making operationsEngineeringCarton

The invention discloses an environment-friendly automatic carton manufacturing machine which comprises an impressing device and a cutting device. The impressing device comprises a transverse impressing device and a longitudinal impressing device; a conveying structure, the longitudinal impressing device, the transverse impressing device and the cutting device are sequentially mounted on a mountingbase from left to right; the longitudinal impressing device comprises a longitudinal pressing wheel bracket, a pressing wheel shaft and a longitudinal pressing wheel; the transverse impressing devicecomprises a transverse pressing wheel bracket, a supporting shaft and a transverse pressing wheel; the cutting device comprises a cutting shaft, cutting wheels, a motor II and a belt wheel II; the two ends of the cutting shaft are mounted on a side baffle; the multiple cutting wheels are mounted on the cutting shaft; and one end of the cutting shaft penetrates through the side baffle and is connected with the motor II through the belt wheel II at the tail end. According to the carton manufacturing machine, all processes are integrated on one equipment, production working hours are greatly shortened, the production efficiency is effectively improved, and the labor intensity of workers is lowered.

Owner:TIANJIN CHENGJIAN UNIV

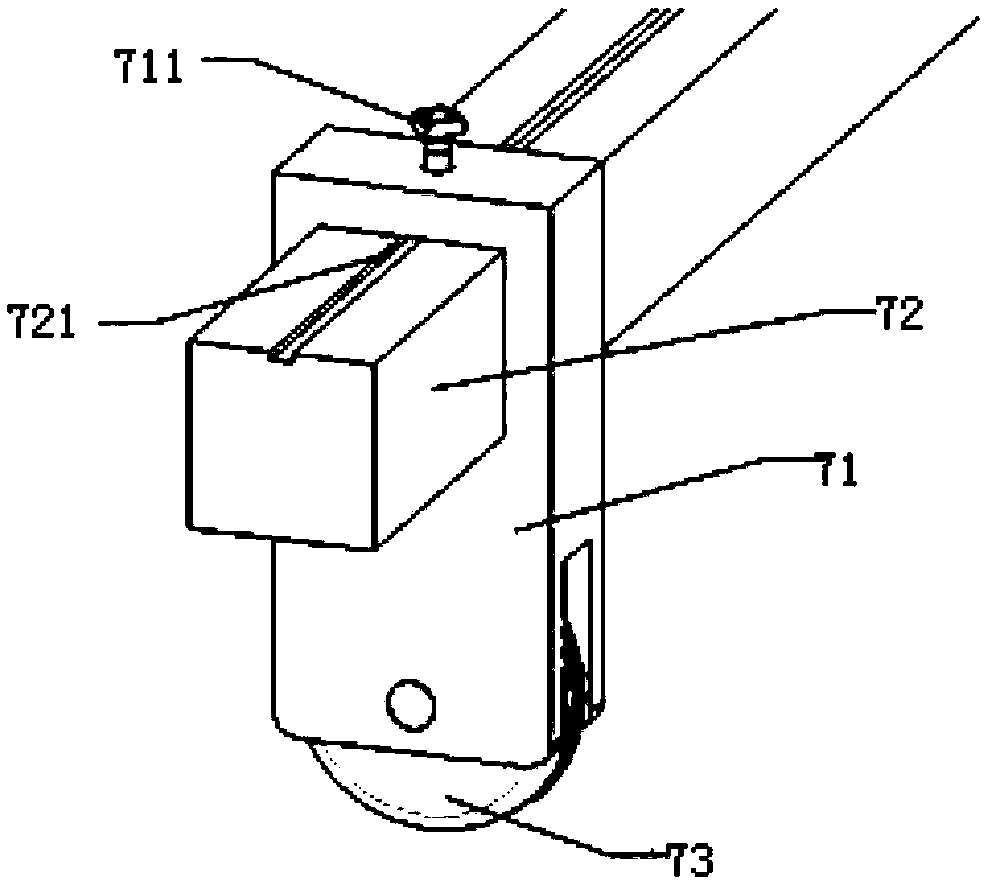

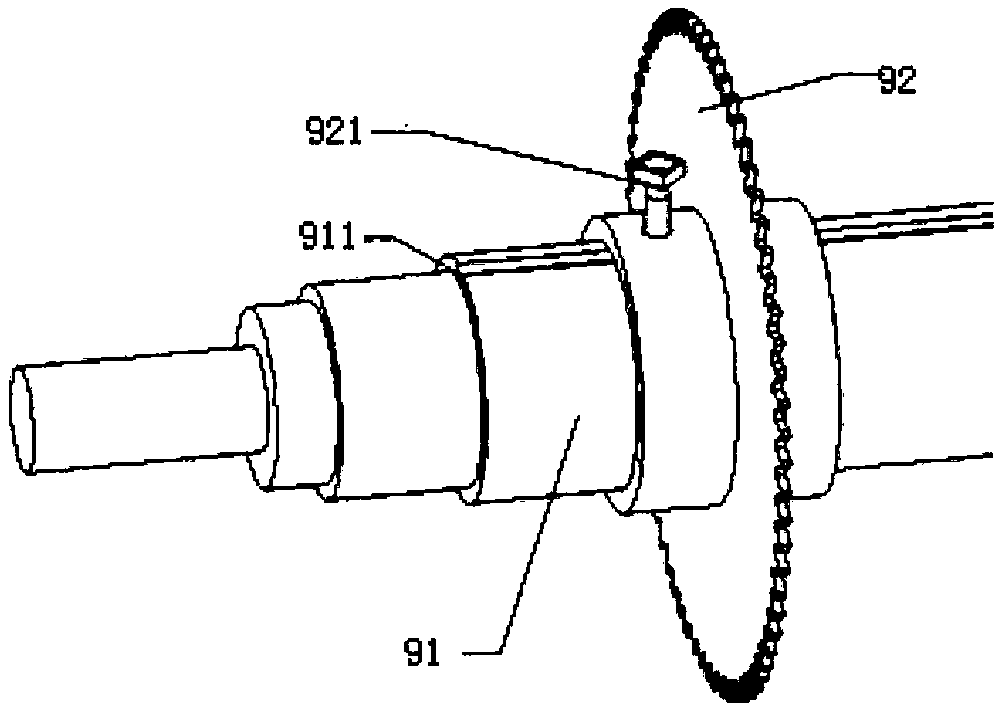

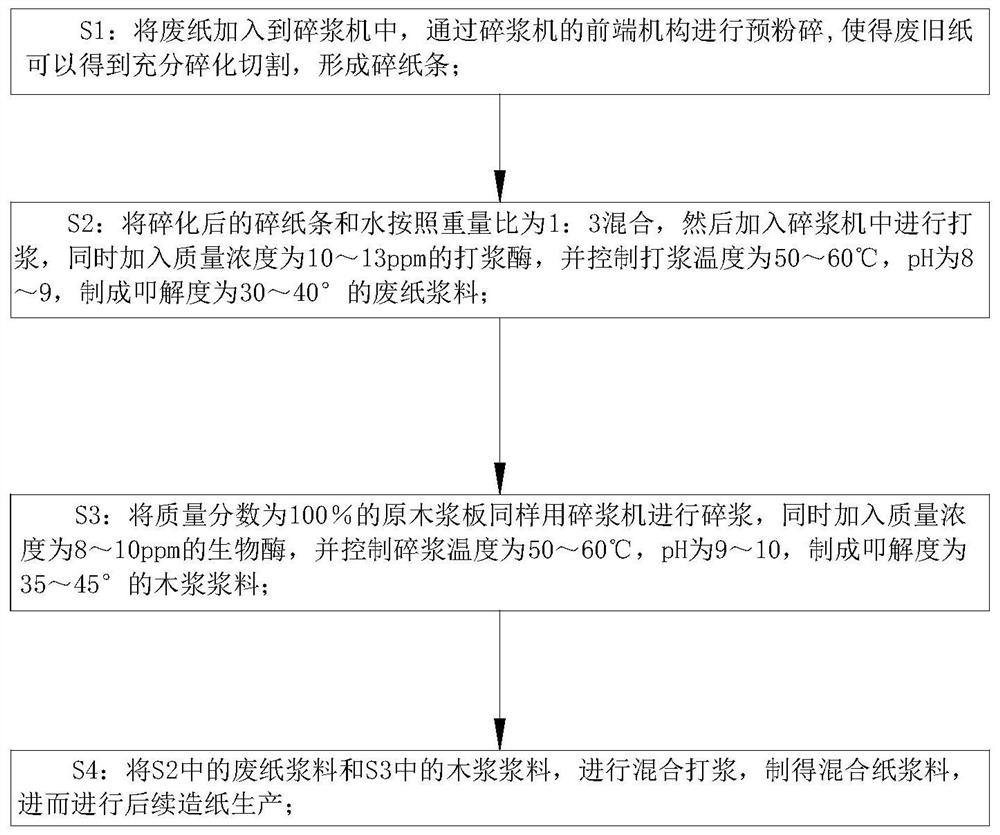

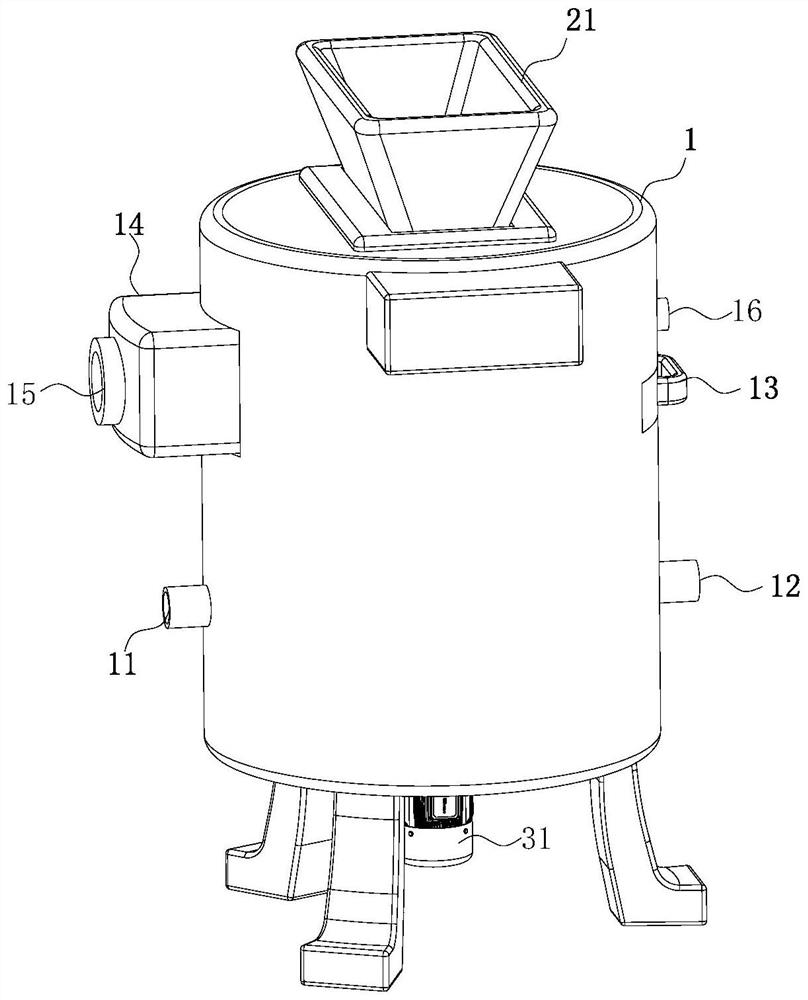

Mixed pulping and papermaking process

InactiveCN111663352AEfficient removalRealize integrated productionPaper recyclingSecondary cellulose fibresPapermakingEngineering

The invention belongs to the technical field of papermaking production, and particularly relates to a mixed pulping and papermaking process which comprises a pulping tank, pre-crushing rotating rollers and a rotor. A pre-crushing groove is formed in the upper wall of the pulping tank; a pulping rotating roller is rotatably connected to the interior of the pre-crushing groove; there are two pre-crushing rotating rollers, and the pre-crushing rotating rollers are symmetrically arranged left and right; the rotor is rotatably connected to the position, close to the lower surface of the pulping tank, of the interior of the pulping tank, an upper grinding disc and a lower grinding disc are arranged at the position, under the rotor, of the bottom wall of the pulping tank, and the upper grinding disc and the lower grinding disc are relatively rotatably connected; according to the invention, the integrated production of pre-crushing and pulping of waste paper is effectively realized, large-sheet waste paper is prevented from being directly thrown into a pulper and being wound on the surface of the rotor in quantity, the load of a power source is increased, a large amount of impurities in the waste paper can be effectively removed, and the quality of finished paper is improved.

Owner:闫文霞

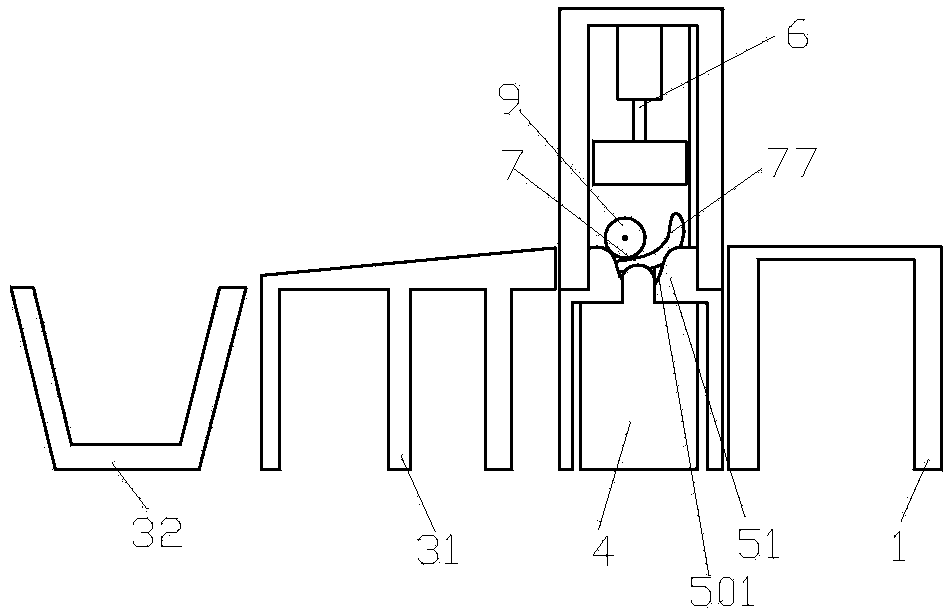

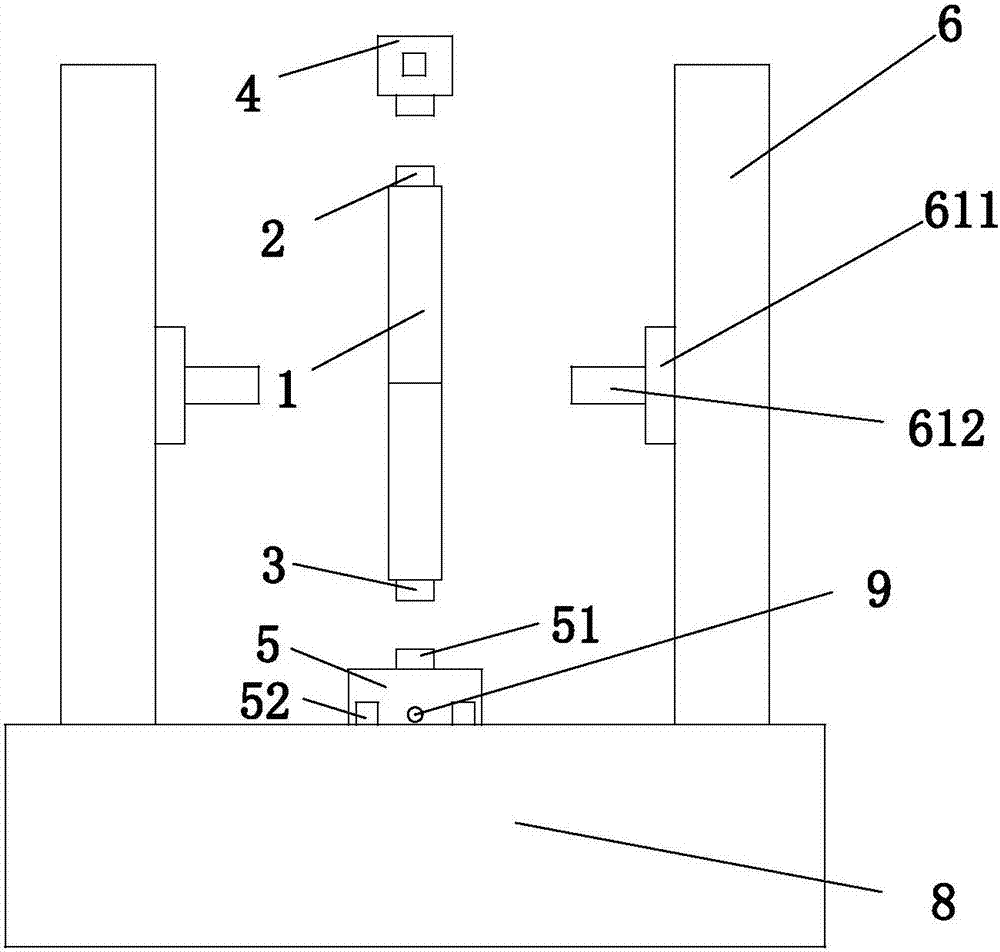

High-efficiency round steel central hole machining device

ActiveCN103386501AImprove protectionStable structureDrilling/boring measurement devicesMetal working apparatusEngineeringPipe

The invention relates to the field of steel pipe production equipment, in particular to a high-efficiency round steel central hole machining device, which comprises a feeding framework, a positioning framework and a receiving framework, a piece of round steel can sequentially pass the feeding framework, the positioning framework and the receiving framework, a drill is arranged on one side, which is located in the rolling direction of the round steel, of the positioning framework, the positioning framework is provided with a positioning channel rack corresponding to the drill, the positioning channel rack comprises a row of positioning blocks with positioning channel and forms a positioning channel passage, and the positioning framework is provided with a hold-down device over the positioning channel passage. The device can ensure that both the efficiency and precision of the central hole machining of the round steel are high.

Owner:ANJI PENGDA STEEL PIPE

Fillet production system

PendingCN107927129AReasonable structureRealize integrated productionFish washing/descalingFish filletingEngineeringBone removal

The invention provides a fillet production system. The system comprises a fish scale removing assembly, a main bone stripping assembly and a slicing assembly, wherein a removed scale conveying belt isarranged at an outlet of the fish scale removing assembly, the main bone stripping assembly is mounted at an output end of the removed scale conveying belt, a fish conveying belt is arranged at an output end of the main bone stripping assembly, the slicing assembly is mounted at an output end of the fish conveying belt, a drying conveying belt is arranged at an output end of the slicing assembly,and a drying oven is mounted on the drying conveying belt. With the adoption of the scheme, the system is reasonable in structure and can realize scale removal, bone removal and slicing integrated production.

Owner:湖南兴潮食品有限公司

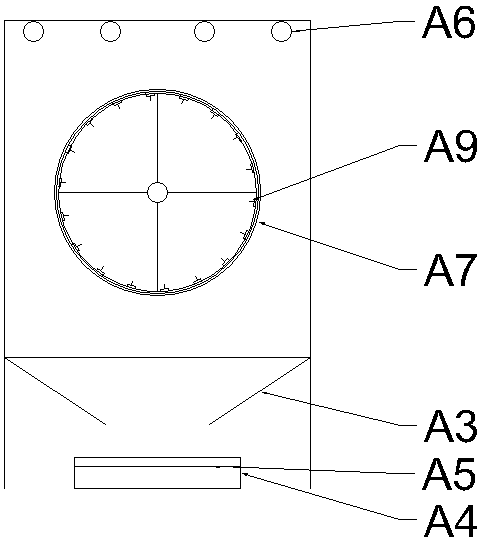

Paint spraying and drying integrated device for wooden door

InactiveCN107185764ARealize automatic deliveryShorten drying timeLiquid surface applicatorsSpraying apparatusEngineeringElectric control

The invention discloses an integrated device for spraying and drying wooden doors, which comprises a wooden door, a paint spraying mechanism and a drying mechanism sequentially arranged along the moving direction of the wooden door; There are matching upper sliders and upper slide rails, and the bottom of the upper slider is equipped with an electric control permanent magnet sucker a; the matching upper slider and upper slide rail are arranged under the wooden door, and the bottom of the lower slider is equipped with an electric control permanent magnet Suction cup b; the painting mechanism includes a mobile frame, the mobile frame is provided with a lifting mechanism with a lifting base, the lifting base is provided with a traversing mechanism with a traversing base, and the traversing base is provided with a spray gun The drying mechanism includes a main board, a rotating shaft is arranged next to the main board, side plates are fixed on the rotating shaft, and UV lamps are arranged on the main board and the side boards.

Owner:湖州南浔亨力木制品厂

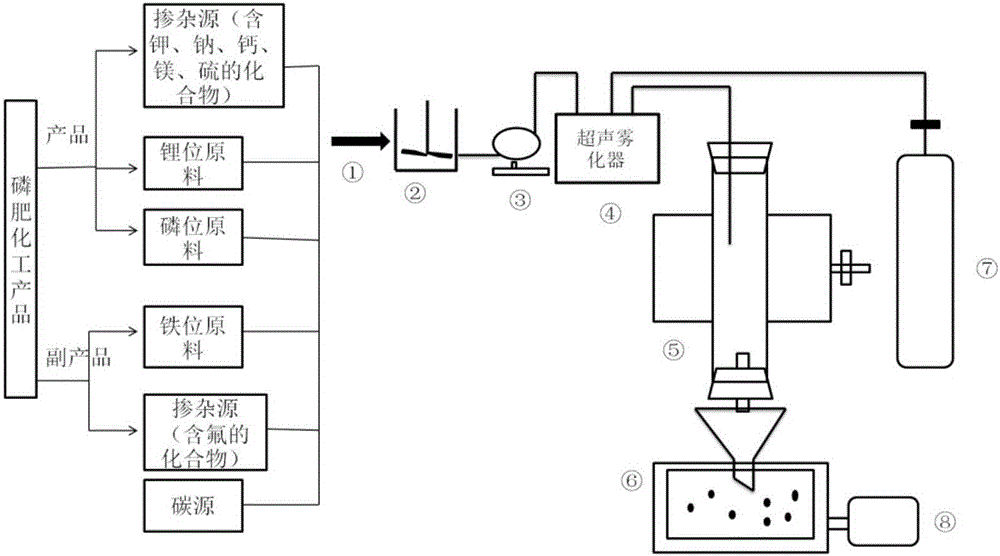

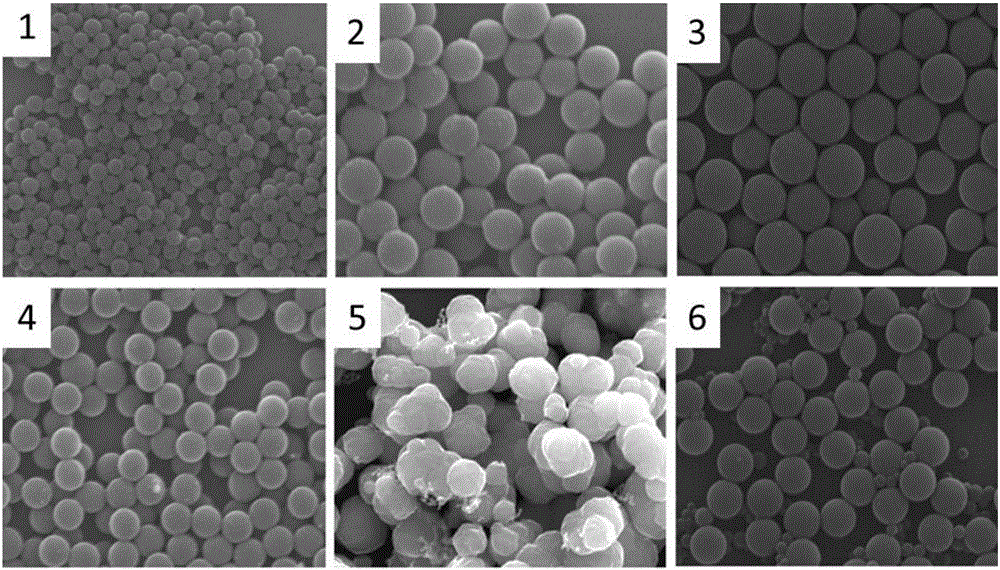

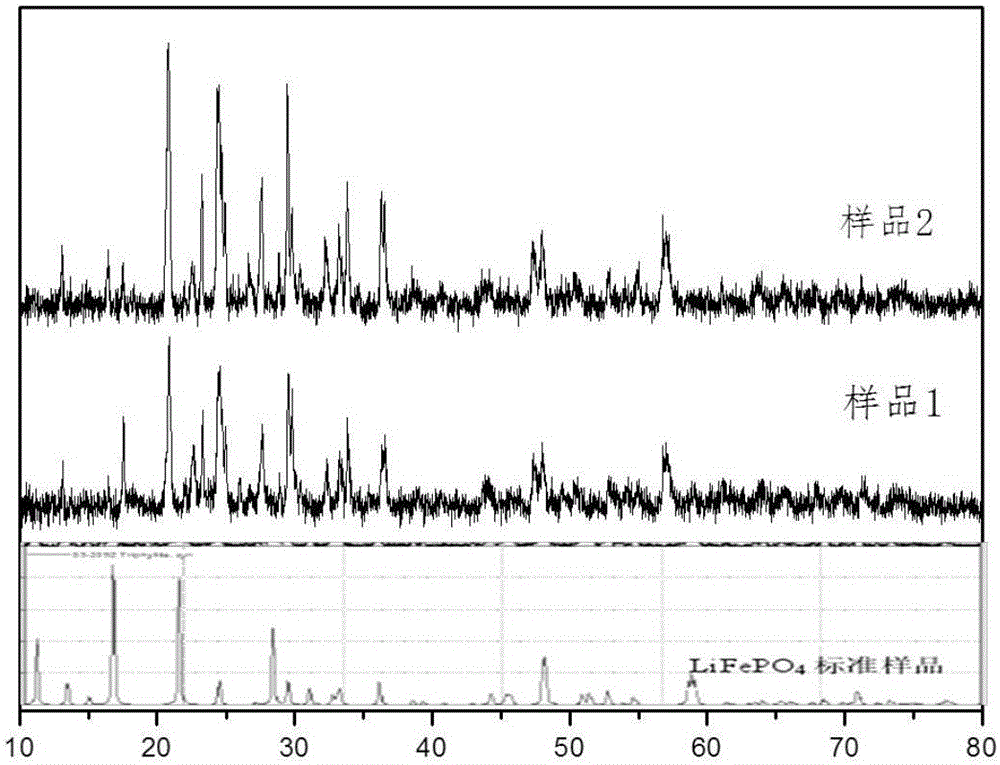

Method of adopting phosphorus fertilizer product for ultrasonic spraying to prepare multi-position collaborative doped LiFePO4/C

ActiveCN105870432ASolve excess capacityLow raw material costCell electrodesSecondary cellsLithium iron phosphateSource material

The invention belongs to the technical field of electrochemical power source materials and discloses a method of adopting phosphorus fertilizer product for ultrasonic spraying to prepare multi-position collaborative doped LiFePO4 / C. Raw materials of the multibit collaborative doped LiFePO4 / C are from the phosphorus fertilizer product and byproducts and include Li, P, Fe, doped element cations K, Na, Ca and Mg and anions S and F. The multibit collaborative doped lithium iron phosphate material is marked as Li1-alpha X alpha Fe1-beta Y beta PO4-gamma Z gamma / C, X refers to lithium position doping, Y refers to iron position doping, Z refers to oxygen position doping, 0< / =alpha< / =0.05, 0< / =beta< / =0.05, and 0< / =gamma< / =2. Collaborative doping of lithium position, iron position and oxygen position is realized, and doping amount is adjustable; compared with single doping, doping materials are extensive in source, and the material is better in performance. The multi-position collaborative doped LiFePO4 / C material is uniform in grain diameter and excellent in electrochemical performance.

Owner:宜春鑫合锂电材料有限公司

Sea tide energy directly driven seawater desalination-sterilization integrated device

InactiveCN106277492AReduce lossSelf-recyclingGeneral water supply conservationSeawater treatmentMechanical energyEngineering

The invention provides a sea tide energy directly driven seawater desalination-sterilization integrated device. The device comprises a tide energy acquisition device, a water drawing pressure accumulator system, a seawater desalination system and a concentrated seawater energy recovery and recycling system. Flexible blades can acquire water energy so that an impeller rotates along a fixed direction, rotation mechanical energy is transmitted to the water drawing pressure accumulator system through a speed increaser, the device sucks the seawater and continuously increases pressure, the reverse osmosis seawater desalination system produces fresh water and discharges the high-pressure concentrated seawater, and the concentrated seawater energy recovery and recycling system utilizes residual pressure of the high-pressure concentrated seawater discharged by the seawater desalination system to generate electricity, and fresh water secondary purification is realized by a UV sterilization disinfection module so that waste energy cycling use is realized. The device utilizes clean sea tide energy as motive power to carry out seawater desalination so that local materials are used, environmental protection and energy saving are realized and energy saving and sustainability requirements are satisfied.

Owner:CENT SOUTH UNIV

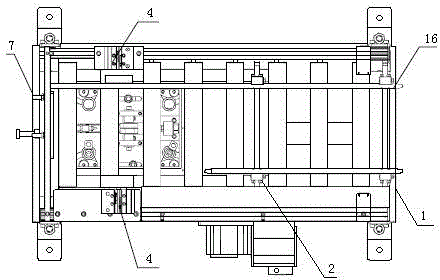

Drilling and deburring integrated machine for producing badminton rackets

ActiveCN109079517AIncrease productivityRealize integrated productionOther manufacturing equipments/toolsEngineeringMechanical engineering

The invention discloses a drilling and deburring integrated machine for producing badminton rackets. The drilling and deburring integrated machine comprises a base, wherein a first sliding chute is formed in one side of the upper surface of the base; an electric push rod base is arranged on one side inside the first sliding chute; an electric push rod is arranged on the electric push rod base; a fixed seat is welded on one side of the electric push rod; a high-speed drilling machine is fixedly arranged at the top end of the fixed seat through threads; two arc-shaped sliding chutes, namely a first arc-shaped sliding chute and a second arc-shaped sliding chute, are embedded into the upper surface of the operation platform; a first electric sliding block which can move around the first arc-shaped sliding chute is arranged inside the first arc-shaped sliding chute; a second electric sliding block which can move around the second arc-shaped sliding chute is arranged inside the second arc-shaped sliding chute; fixed frames are respectively welded at the top end of the first electric sliding block and the top end of the second electric sliding block; a locking bolt is arranged at the upper end of one fixed frame; abrasive discs are respectively arranged at the lower ends of adjacent sides of the two fixed frames.

Owner:磐安县天诚科技有限公司

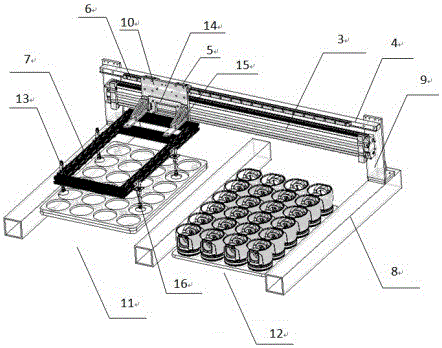

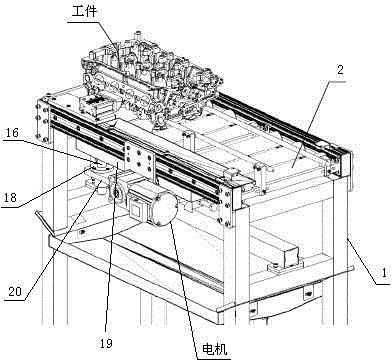

Automatic feeding roller way accurate in positioning

ActiveCN104444342ARealize integrated productionHigh degree of automationConveyor partsOptical axisEngineering

The invention relates to an automatic feeding roller way accurate in positioning. Rollers are arranged at the upper portion of a machine frame, push air cylinders are arranged on the two sides of the rollers, a linear guide rail is arranged on a lower base plate, an air cylinder installation base is fixedly installed on the lower base plate, a lifting air cylinder is fixedly connected to the air cylinder installation base and connected with a wedge block through a floating connector, the wedge block is fixedly arranged on a sliding block, linear bearings are arranged on the lower base plate, the lower base plate is connected with an upper base plate through base plate guide unthreaded shafts, proximity switches are arranged at the top end of the upper base plate, the upper base plate is fixedly arranged at the top of the interior of the machine frame through positioning pins and positioning supports, the base plate guide unthreaded shafts are connected with the upper base plate through base plate guide unthreaded shaft fixing bases, hydraulic buffers are perpendicularly arranged on curved surfaces of the base plate guide unthreaded shafts, cylindrical roller bearings are arranged at the two ends of a rotating shaft in a limited mode, the rotating shaft is limited to a fixing base, and the fixing base is arranged at the lower end of the upper base plate in a connected mode. The automatic feeding roller way has the advantages of being high in automation degree, high in efficiency and lower in manufacturing cost, and achieving integration production.

Owner:NINGXIA KOCEL MACHINE TOOL ACCESSORIES

Energy-saving and environment-friendly milling screening machine

The invention relates to the technical field of grinding equipment, in particular to an energy-saving and environment-friendly milling screening machine. The energy-saving and environment-friendly milling screening machine comprises a material feeding portion, a barrel body and a driving device, wherein a lining plate is arranged in the barrel body, the material feeding portion is connected with the barrel body through a hollow shaft, the barrel body is connected with the driving device through a transmission shaft, a barrel opening, away from the material feeding portion, of the barrel body is in a sealed shape, a material discharging hole is formed in the barrel body, a screen is arranged outside the barrel body, surrounds the outside of the barrel body, and is arranged in a barrel shape, a screening portion is formed between the screen and the barrel body, one end of the screening portion is open, the other end of the screening portion is closed, and the closed end of the screening portion and the closed end of the barrel body are connected with each other, and are located at the same side. According to the energy-saving and environment-friendly milling screening machine disclosed by the invention, milling and screening integrated production is realized without arranging a plurality of sets of equipment; energy consumption of equipment for screening and conveying can be reduced; the accumulation of materials can be effectively avoided as a strong exhaust hole is formed, and therefore the yield and production efficiency are increased, finer grinding phenomena can be reduced, and the pick-up rate of finished products is increased; moreover, the milling and screening in both dry and wet manners can be realized, so that production adaptability is enhanced, and the wet-type operation can also solve the problem of flying dust.

Owner:樊日宏 +1

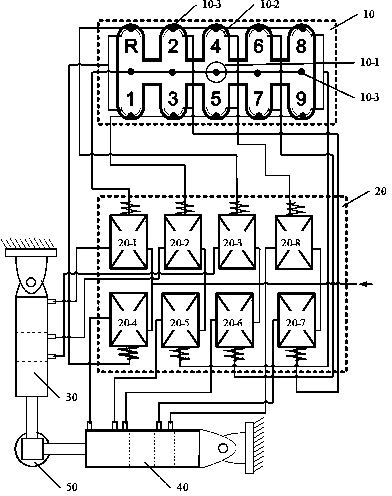

Control mechanism of numerically-controlled transmission

ActiveCN103453132AUniversalRealize integrated productionGearing controlControl devicesVehicle frameModularity

The invention provides a control mechanism of a numerically-controlled transmission. The control mechanism is characterized by comprising an electronic control command signal unit, wherein the electronic control command signal unit consists of a gear control handle, a gear selecting switch and a gear shifting switch on corresponding gears, the gear selecting switch and the gear shifting switch are connected with a command execution unit which is respectively connected with a gear shifting multi-position cylinder and a gear selecting multi-position cylinder, the gear shifting multi-position cylinder and the gear selecting multi-position cylinder are perpendicularly distributed, piston rods of the gear shifting multi-position cylinder and the gear selecting multi-position cylinder are connected with a gear shifting arm of the transmission through a connector, and rod-side end covers of the gear shifting multi-position cylinder and the gear selecting multi-position cylinder are respectively hinged to a frame. Compared with the prior art, the control mechanism of the numerically-controlled transmission replaces the control lever of the original automobile transmission, is strong in universality and capable of realizing modularized and integrated production so as not to consider the design of the control mechanism of the transmission when the automobile is upgraded, and the control mechanism of the numerically-controlled transmission is simple and convenient to install and debug; after a gear is engaged, the pressure applied by the gear shifting multi-position cylinder and the gear selecting multi-position cylinder continuously exists so as not to have the gear disengagement phenomenon.

Owner:龙口市锐东汽车配件有限公司

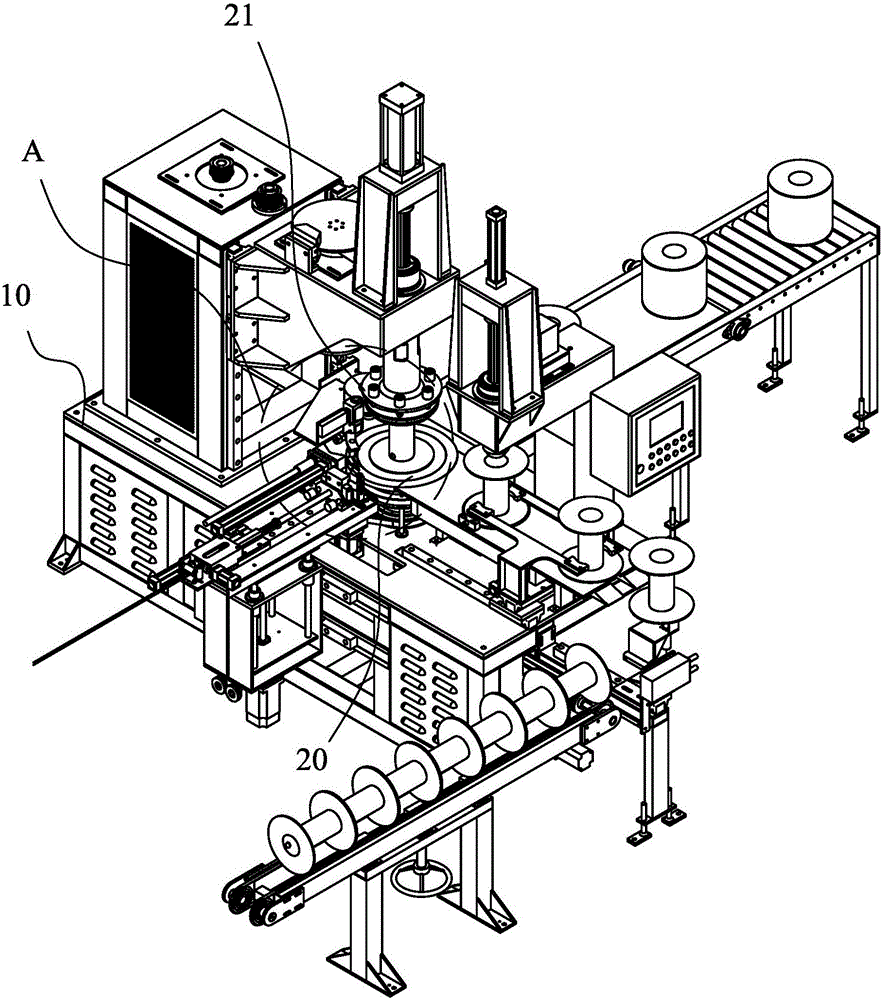

Automatic film winding mechanism for take-up rocking disc machine

InactiveCN105667861AIncrease productivityRealize integrated productionWrapping material feeding apparatusWrapping with article rotationWire rodEngineering

The invention discloses an automatic film winding mechanism for a take-up rocking disc machine. The automatic film winding mechanism comprises a rack, a film belt pressing and conveying mechanism and a take-up mechanism for driving a wire spool to rotate, wherein the film belt pressing and conveying mechanism and the take-up mechanism are arranged on the rack. The take-up mechanism comprises a rotary disc arranged on the rack and a pressing head arranged above the rotary disc. The film belt pressing and conveying mechanism comprises a film belt unwinding roller, a rotary ring arranged on the outer side of the rotary disc and a film belt pressing plate capable of moving up and down and rotating along with the rotary ring, wherein the rotary ring and the rotary disc are coaxially arranged. In work, the wire spool is clamped between the rotary disc and the pressing head, and the film belt pressing plate moves downwards to press a film belt unwound from the film belt unwinding roller to the rotary ring. The film belt rotates along with the rotary ring and is wound around the wire spool. The wire spool is driven by a drive element to rotate so that the film belt can be wound around the outer side of a wire rod on the wire spool in a wrapping manner. The film belt pressing and conveying mechanism is arranged on the rack, so that film winding and packaging can be directly conducted on the equipment after the wire rod is taken up to the wire spool, automation of film wrapping is achieved, and production efficiency of wire winding and packaging is improved.

Owner:DONGGUAN JINGTIE MACHINERY

Production method of high-gloss one-sided dual-color heat transfer anodized aluminum

InactiveCN102303440ARealize integrated productionExcellent adhesionSynthetic resin layered productsMetal layered productsFractionationEthyl acetate

The invention discloses a production method of high-gloss one-sided dual-color heat transfer anodized aluminum, which comprises the processes of release coating, color layer coating, heating and drying, accurate aluminizing and adhesive layer curing. In the processes, anatase metal powder enabling the gloss of the anodized aluminum to be increased is added in a color layer for spraying, and ethyl acetate is added in the anatase metal powder to be used as a developing agent of color chromatographic fractionation. By adopting an anodized aluminum production technology, printing and gold blocking effects are greatly improved, and especially, gloss of thermoprinted characters, patterns and lines is greatly increased.

Owner:江苏卫星新材料股份有限公司

Scuticociliatid ciliate resistant pharmaceutical composition and preparation method thereof

ActiveCN111603493AReduce infection rateAntibacterial and anti-inflammatoryOrganic active ingredientsPharmaceutical delivery mechanismBiotechnologyAlcohol ethyl

The invention provides a scuticociliatid ciliate resistant pharmaceutical composition and a preparation method thereof. The pharmaceutical composition is prepared from the following raw materials in parts by weight: 2-3 parts of sundew, 20-30 parts of food-grade ethanol with a concentration of 95%, and 0.3-0.6 part of fatty alcohol polyoxyethylene ether sodium sulfate. The preparation method comprises the following steps: taking 2-3 parts by weight of sundew, crushing sundew, putting crushed sundew into the upper part of a reaction kettle, adding 20-30 parts by weight of food-grade ethanol with a concentration of 95%, stirring and extracting the raw materials for 5 hours to obtain an extract, adding 0.3-0.6 part by weight of fatty alcohol polyoxyethylene ether sodium sulfate into the extract obtained in S1, uniformly mixing to obtain a mixed solution; adding 1000 parts of a turbot feed into the lower part of the reaction kettle, mixing the sundew residues obtained after extraction in S1 with a turbot feed, and fully stirring for 0.5 h. The pharmaceutical composition has the advantages that the toxicity to turbots is small, the pharmaceutical composition is environmentally friendly,the scuticociliatid ciliate infection rate is effectively reduced, and the extract and a mixed feed can be produced at the same time.

Owner:BEIJING CENT BIOLOGY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com