High-efficiency round steel central hole machining device

A processing device and center hole technology, which is applied in the field of high-efficiency round steel center hole processing devices, can solve the problems of insufficient efficiency, high cost, and low precision in the drilling process, and achieves simple and stable structure, good protection, and improved processing. The effect of efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

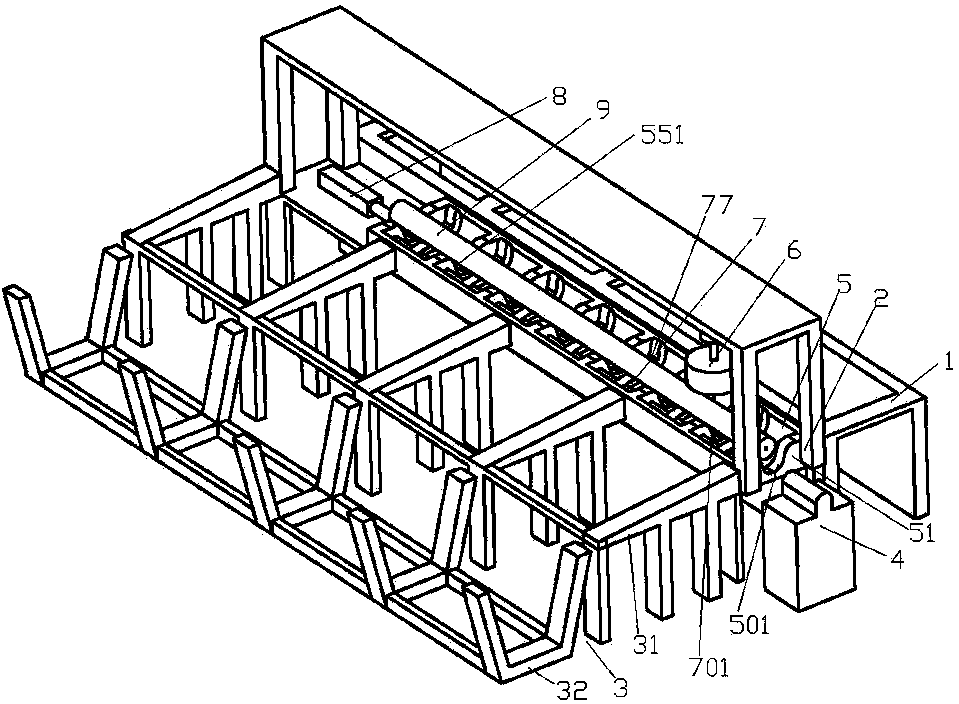

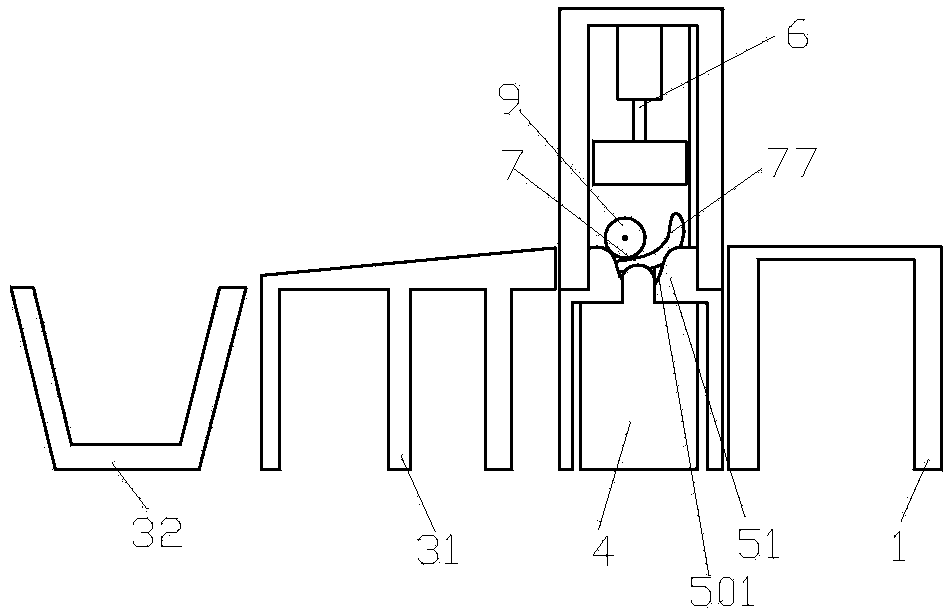

[0018] Example 1, such as figure 1 , 2 As shown, a kind of high-efficiency round steel center hole processing device comprises a feed rack 1, a positioning rack 2 and a receiving rack 3 for the round steel 9 to roll through in turn, and the positioning rack 2 is located on one side of the round steel 9 rolling direction. Drilling device 4 is arranged, and positioning frame 2 is provided with positioning groove frame 5 relative to drilling device 4, and positioning groove frame 5 comprises a row of positioning blocks 51 that are provided with positioning groove 501 and forms a positioning groove passage 551, and positioning frame 2 is positioned at A pressing device 6 is arranged above the groove channel 551 . The pressing device 6 comprises a pressing block and a pressing cylinder connected with the pressing block, and the pressing block is in the shape of a round cake. Drilling device 4 can select conventional equipment for use, comprises center hole drill, drilling mot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com