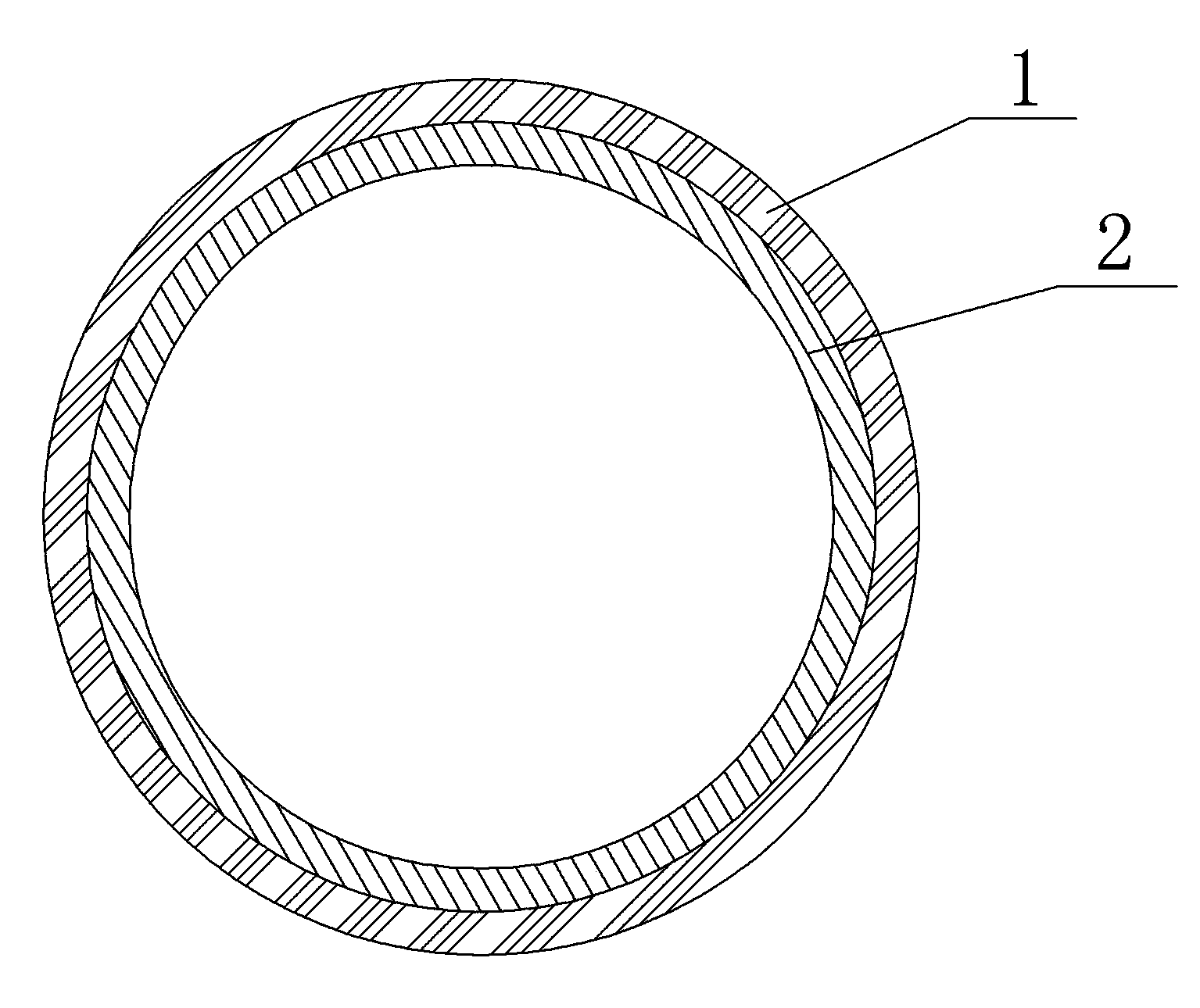

Double-layer composite tube and manufacturing method thereof

A double-layer composite and pipe technology, applied in the direction of hoses, pipes, mechanical equipment, etc., can solve the problems of rough inner walls of pipes, secondary pollution of water quality, and easy generation of scale, etc., to achieve good sealing, large flow, and enhanced The effect of stress resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] Embodiment 1: A double-layer composite pipe, including an inner layer and an outer layer, the inner layer is made of UHMW-9003 ultra-high molecular weight polyethylene (UHMW-9003 refers to ultra-high molecular weight polyethylene, the model is 9003) and 40% E / VAL-112A ethylene-vinyl alcohol copolymer (E / VAL-112A refers to ethylene-vinyl alcohol copolymer, model 112A), the outer layer is made of 90% by mass HDPE -2480H high-density polyethylene (HDPE-2480H refers to high-density polyethylene, the model is 2480H), 8% E / VAL-112A ethylene-vinyl alcohol copolymer and 2% PE special melanin particles C.

[0041] The ultra-high molecular weight polyethylene used is polyethylene with a molecular weight of more than 1 million, a density of 0.920-0.964g / cm3, a heat distortion temperature (under the condition of 0.46MPa) of 85°C, and a melting point of 130-136°C. It is a linear structure with excellent Comprehensive performance thermoplastic engineering plastics.

[0042] The high...

Embodiment 2

[0060] Embodiment 2: The difference from Embodiment 1 is that the inner layer of the double-layer composite pipe is made of 62% ultra-high molecular weight polyethylene and 38% low-density polyethylene.

Embodiment 3

[0061] Embodiment 3: The difference from Example 1 is that the inner layer of the double-layer composite pipe is made of 65% ultra-high molecular weight polyethylene and 35% ethylene-vinyl alcohol copolymer; the outer layer is made of It is made of 92% high-density polyethylene, 7% ethylene-vinyl alcohol copolymer and 1% PE special melanin particles C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| heat deflection temperature | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com