Method of adopting phosphorus fertilizer product for ultrasonic spraying to prepare multi-position collaborative doped LiFePO4/C

A phosphate fertilizer product and ultrasonic technology, applied in the field of electrochemical power supply material preparation, can solve problems such as lack of performance, large particle size of materials, unfavorable mass production, etc., and achieve the effect of increasing added value, good dispersibility, and good cycle performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

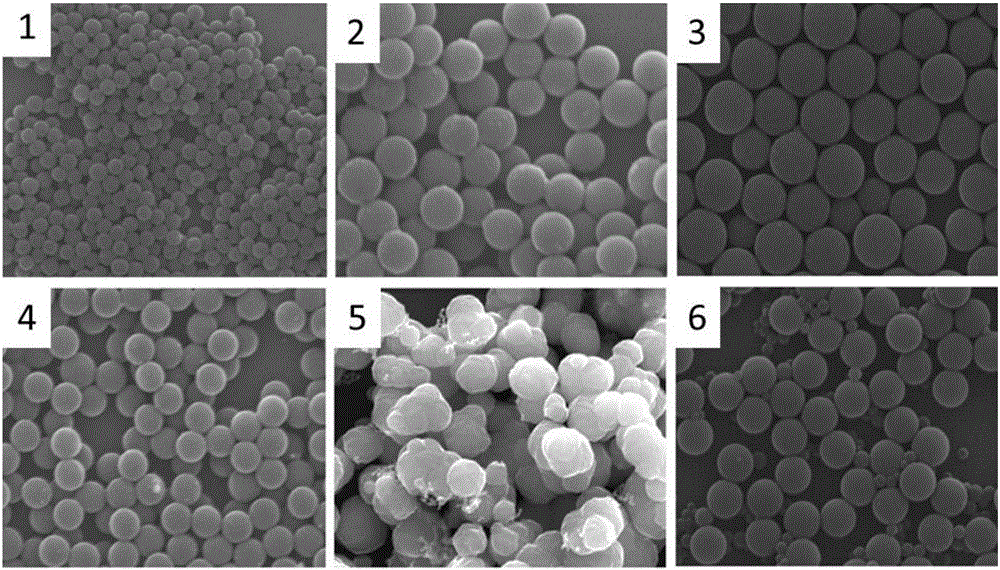

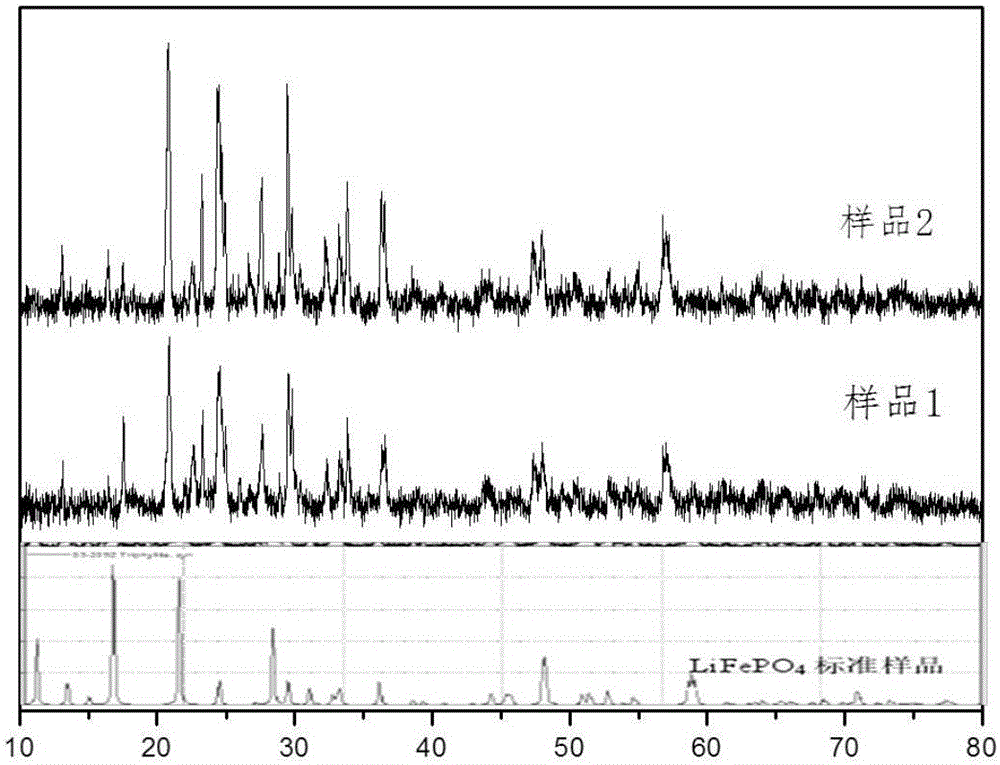

[0037] Example 1 Oxygen doping

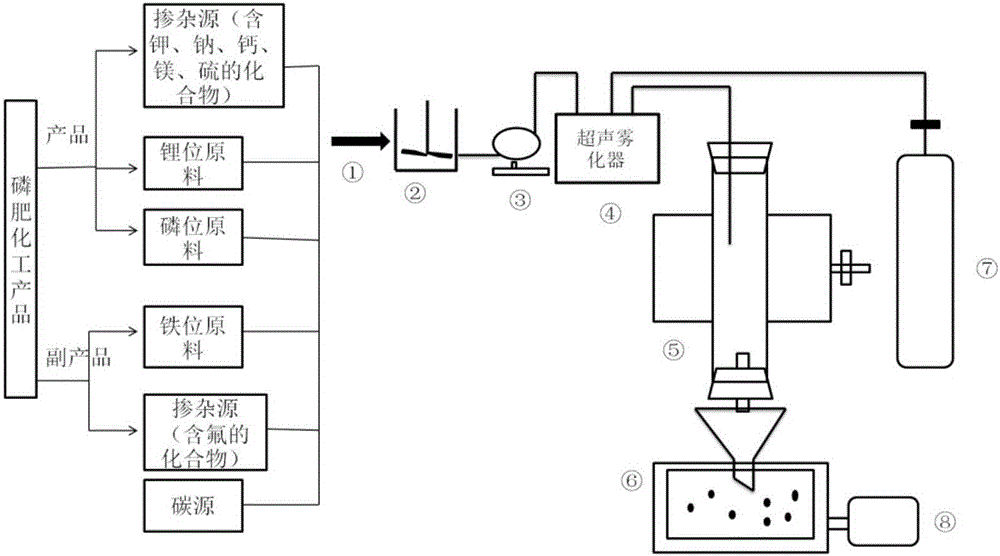

[0038] A preparation of multi-position synergistically doped LiFePO by ultrasonic spraying of phosphate fertilizer products 4 / C method, the steps are as follows:

[0039] (1) Primary mixing of parent material and dopant

[0040] Mix lithium hydroxide as raw material for lithium, ferric nitrate as raw material for iron, ammonium dihydrogen phosphate as raw material for phosphorus, and ammonium sulfide as doping source for oxygen at a molar ratio of 1:1:1:0.15, add water-soluble starch, and the mass of water-soluble starch It is 10% of the quality of ferric nitrate, with deionized water as a solvent, fully stirred in a stirring device (rotating speed=200 rev / min) until the raw materials are all dissolved, filtered to obtain a precursor solution, the concentration of lithium ions in the precursor solution is 1mol / L.

[0041] (2) Ultrasonic spray

[0042] The prepared precursor solution is sent into the ultrasonic nebulizer with an inert gas a...

Embodiment 2

[0047] Example 2 Oxygen site doping

[0048] A preparation of multi-position synergistically doped LiFePO by ultrasonic spraying of phosphate fertilizer products 4 / C method, the steps are as follows:

[0049] (1) Primary mixing of parent material and dopant

[0050] Mix lithium acetate as raw material for lithium, ferric nitrate as raw material for iron, ammonium dihydrogen phosphate as raw material for phosphorus, and ammonium fluoride as doping source for oxygen at a molar ratio of 1:1:1:0.4, add glucose, and the mass of glucose is the mass of ferric nitrate Using deionized water as a solvent, fully stir in a stirring device (rotating speed = 200 rpm) until all the raw materials are dissolved, filter to obtain a precursor solution, the concentration of lithium ions in the precursor solution is 1mol / L.

[0051] (2) Ultrasonic spray

[0052] The prepared precursor solution is sent into the ultrasonic nebulizer with an inert gas as the carrier gas through an air compression...

Embodiment 3

[0057] Example 3 Lithium and oxygen doping

[0058] A preparation of multi-position synergistically doped LiFePO by ultrasonic spraying of phosphate fertilizer products 4 / C method, the steps are as follows:

[0059] (1) Primary mixing of parent material and dopant

[0060] The lithium-site raw material lithium oxalate, the iron-site raw material iron nitrate, the phosphorus-site raw material ammonium dihydrogen phosphate, the lithium-site doping source potassium dihydrogen phosphate, and the oxygen-site doping source ammonium sulfide in a molar ratio of 0.49:1:0.98:0.02:0.3 Mixing, adding sucrose, the quality of sucrose is 10% of the mass of ferric nitrate, using deionized water as solvent, fully stirring in a stirring device (speed = 200 rpm) until all the raw materials are dissolved, filtering to obtain a precursor solution, The lithium ion concentration in the precursor solution was 0.98mol / L.

[0061] (2) Ultrasonic spray

[0062] The prepared precursor solution is se...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com