Connecting process of polar plate of lead acid batteries

A lead-acid battery, battery technology, applied in lead-acid battery electrodes, lead-acid batteries, battery pack components, etc., can solve the problems of restricting the production efficiency of enterprises, low battery quality, and high production costs, and achieve stable and consistent electrical performance. , The process steps are simple, and the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

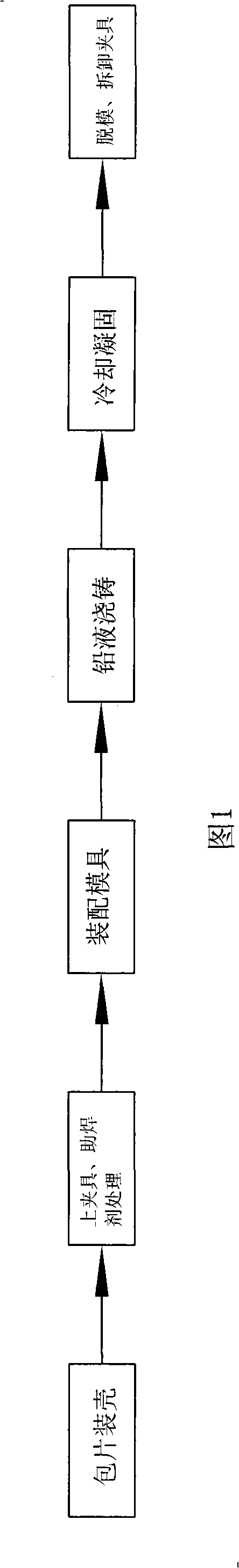

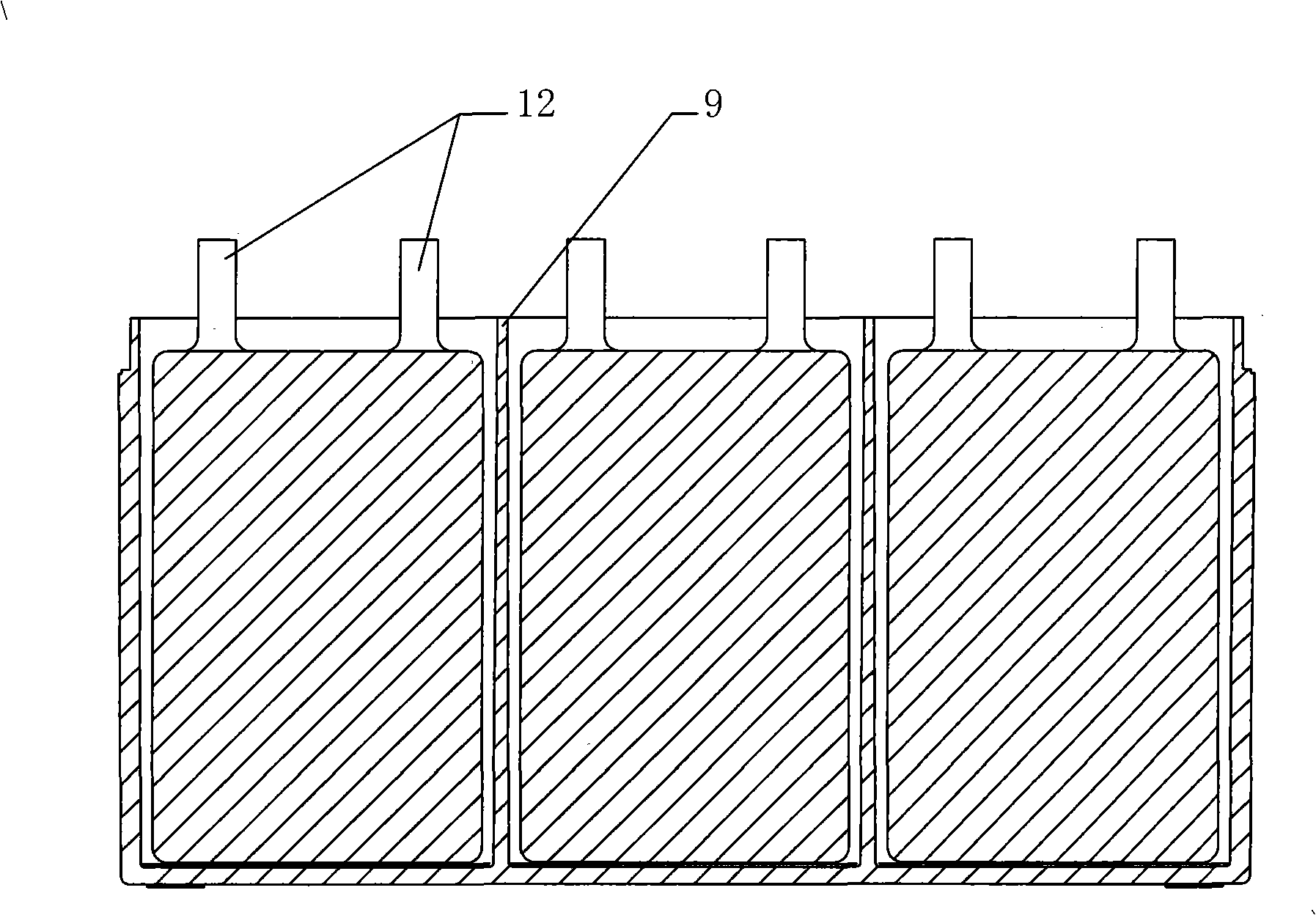

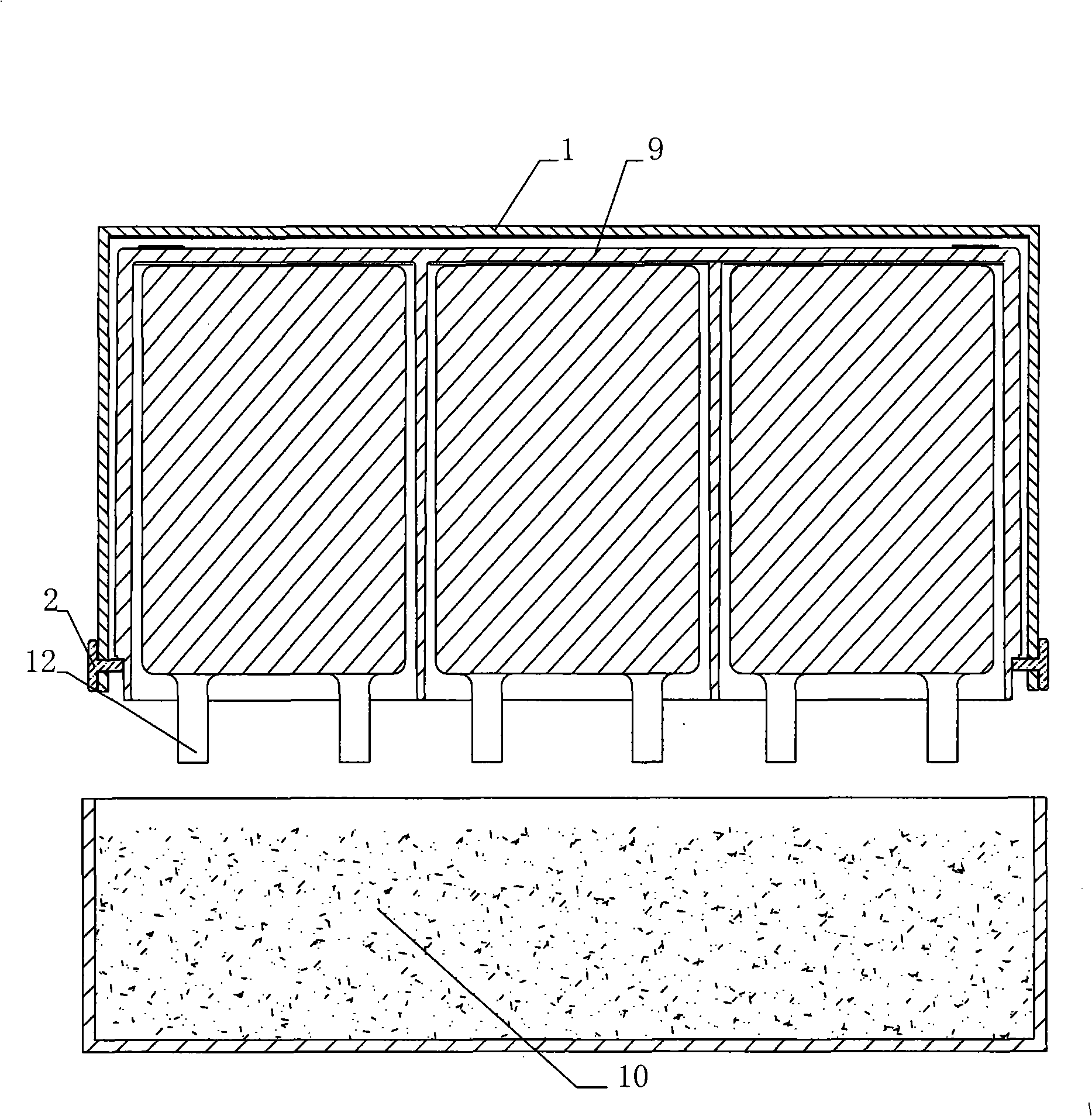

[0032] Such as Figure 8 , 9 , 10 The present invention provides a mold, the mold used for the connection process of the lead-acid battery plates includes a fixture 1 and a busbar mold. The clamp 1 is a rectangular parallelepiped and has the same shape as the housing 9 of the storage battery. An opening is provided on one side, and a telescopic member I2 is symmetrically provided on the edge of the opening. Both the left and right telescopic parts I 2 are screws, and the distance between the left and right screws can be changed by turning the screws, thereby performing the function of clamping. The bus bar mold includes a base 3 and two fixing plates 4. The length of the base 3 is longer than that of the fixture 1. The left end of the base 3 is provided with two side-by-side inline casting grooves 5. The far end is provided with an opening 7 for casting pole 13, and the right end of base 3 is provided with an inline casting groove 5, and two rows and two columns of n-type ca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com