Prefabricated laminated floor slab with upturning side edge for slab descending area and construction method thereof

A technology of superimposing floor slabs and side flanging, applied in the direction of floor slabs, building materials processing, building components, etc., can solve the problems of lowering the slab and hanging formwork, insufficient lowering slab height, and difficult construction, etc., and achieves reduced construction difficulty and quality. Guaranteed, highly industrialized effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

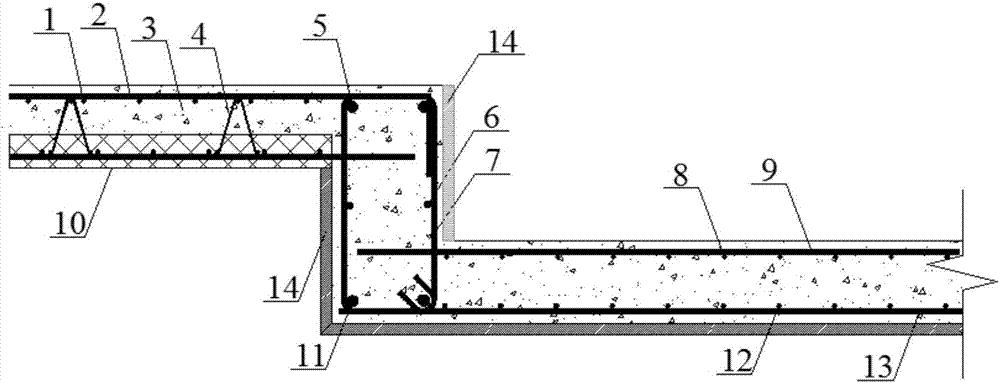

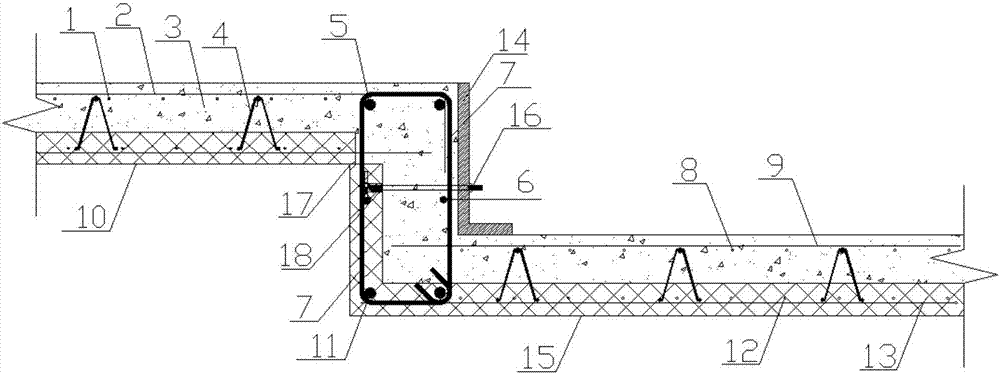

[0025] see figure 2 , a prefabricated laminated floor slab with side flanging for the lowering area, including an upper prefabricated laminated floor 10, a lower prefabricated laminated floor 15 with side flanging, a steel bar skeleton, embedded nuts 18, and tension bolts 16 , soft rubber strip 17, cast-in-place concrete side formwork 14; the side flanging top of the lower prefabricated laminated floor 15 is sealed and connected with the lower part of the upper prefabricated laminated floor 10 through the soft rubber strip 17; the embedded nut 18 is pre-embedded and fixed on the side flange, and one end of the pull bolt 16 is fixed with the embedded nut, and the other end is fixed with the cast-in-place concrete side template 14.

[0026] In this example, see figure 2 , the cast-in-place concrete side formwork 14 is L-shaped, one side is pa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com