Patents

Literature

41results about How to "Improve spreading quality" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

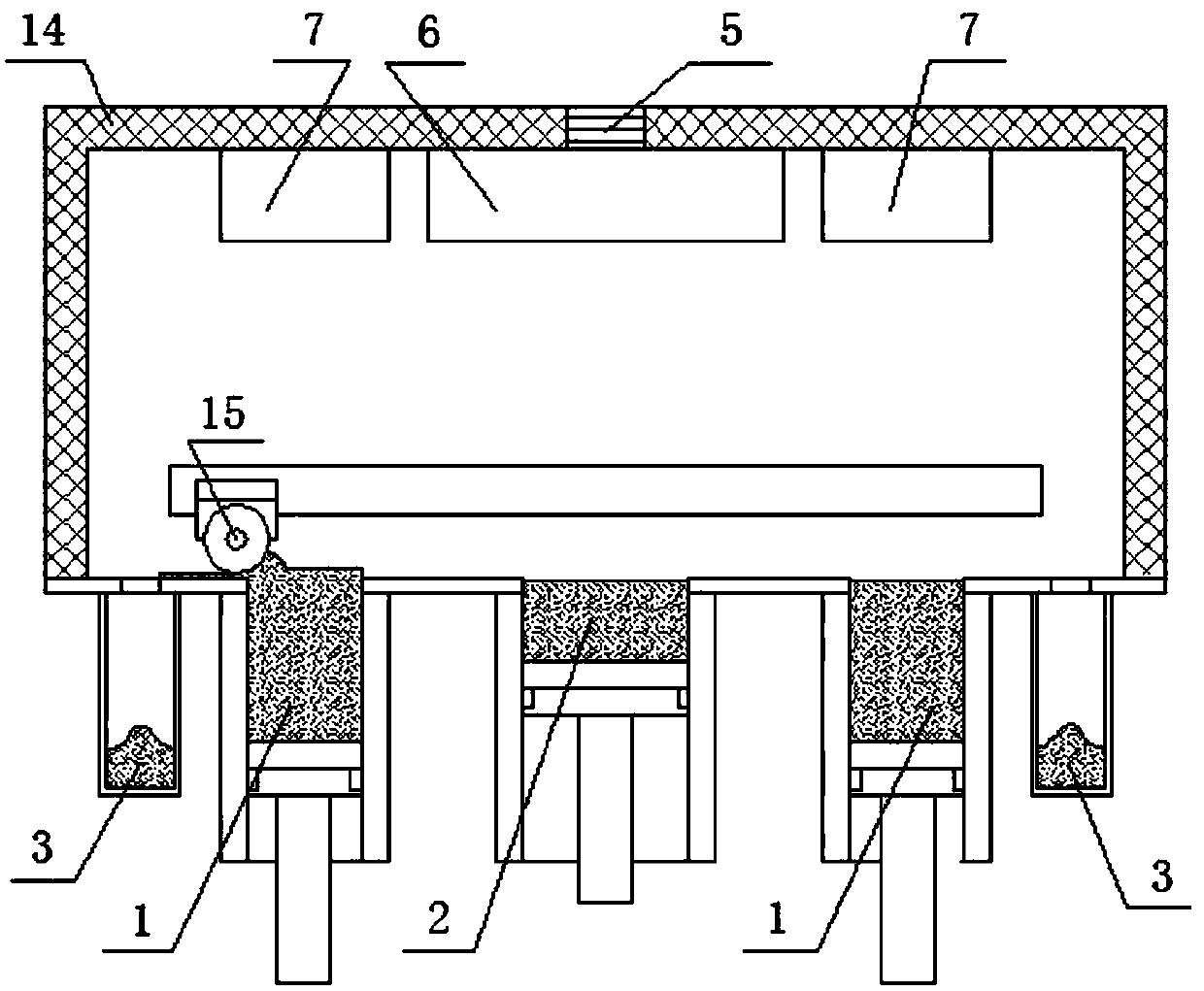

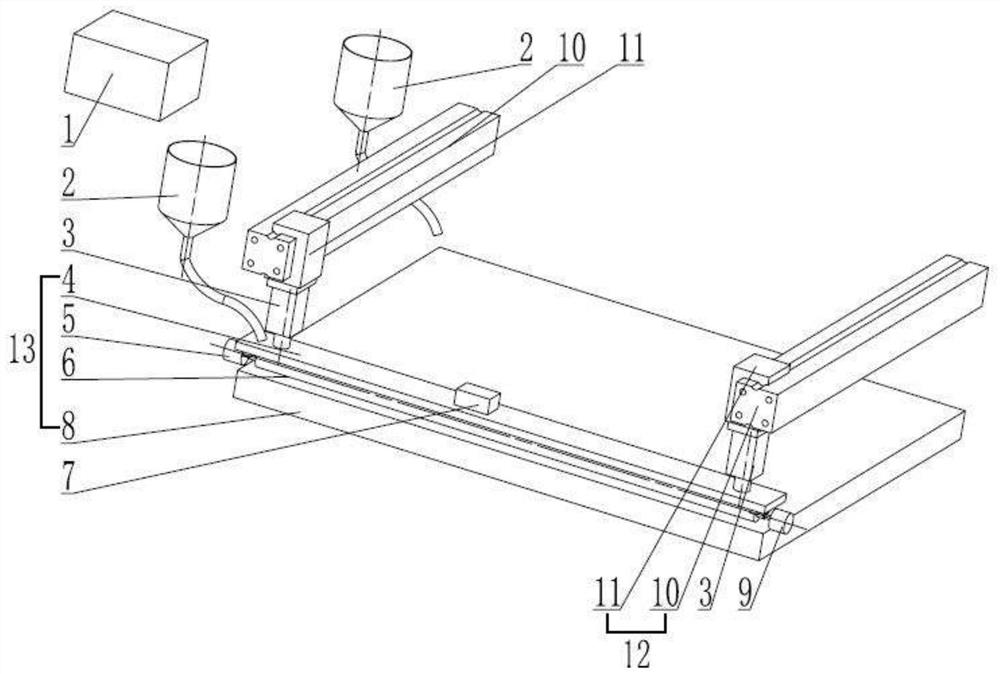

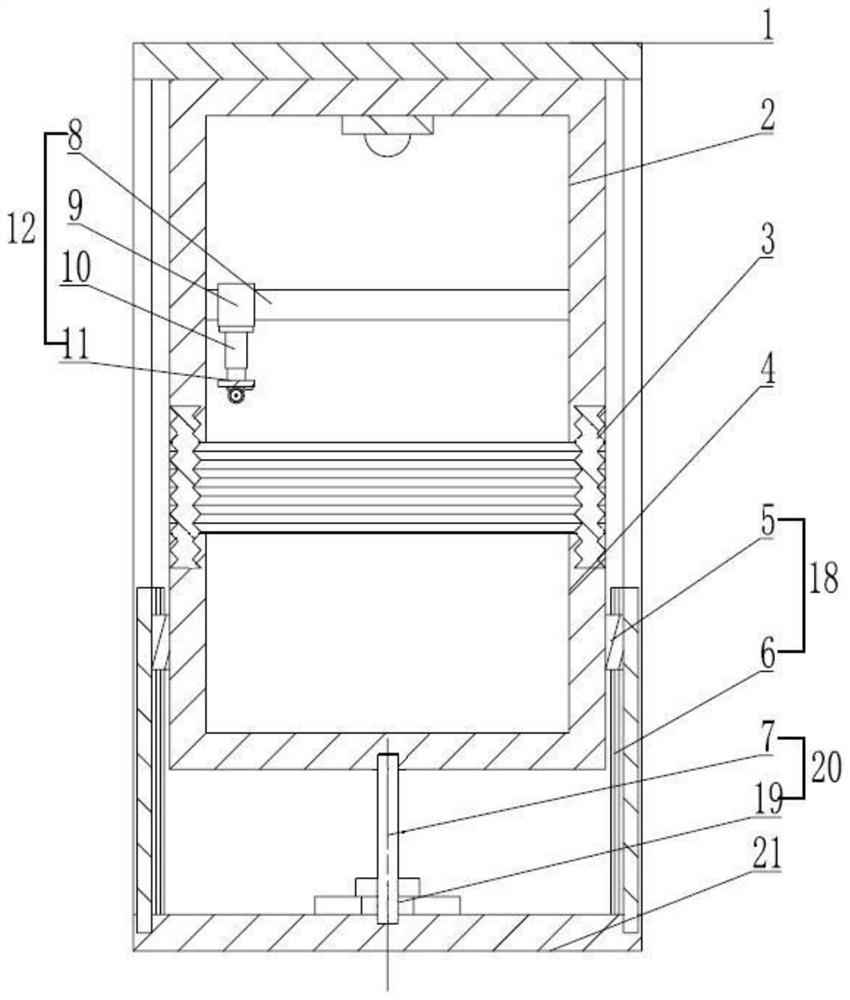

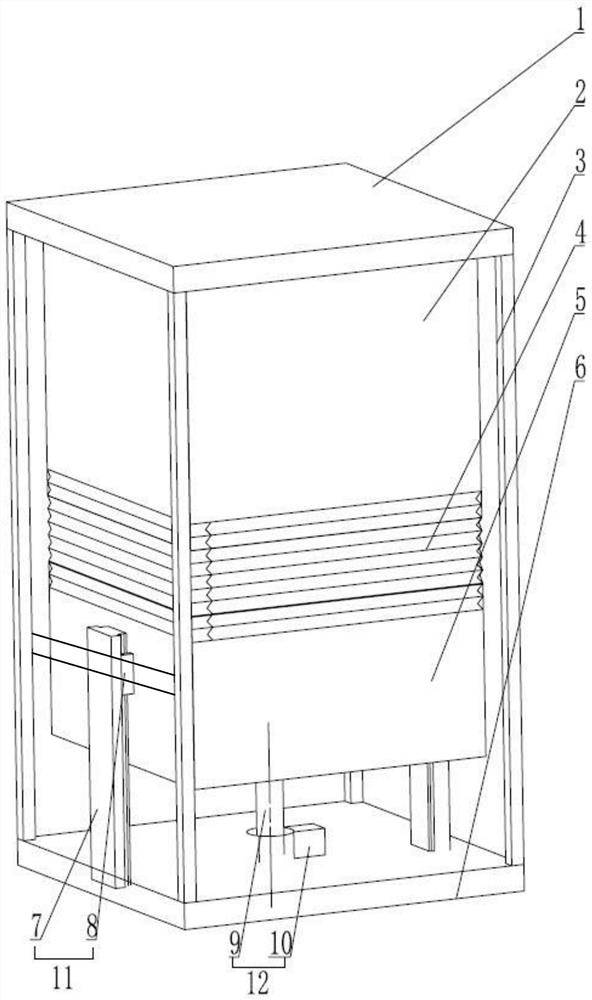

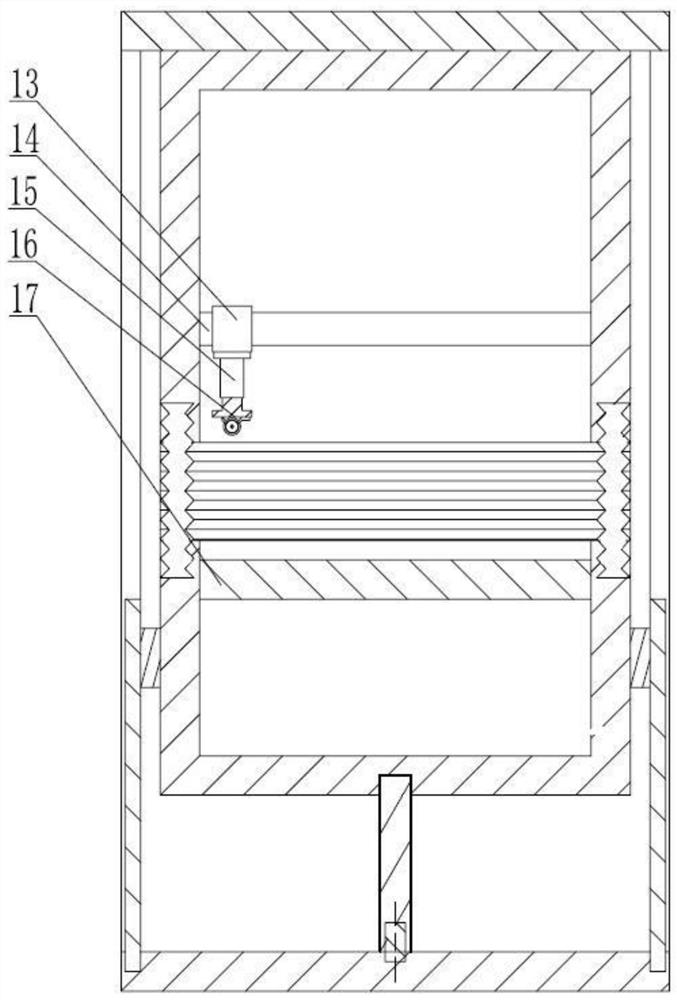

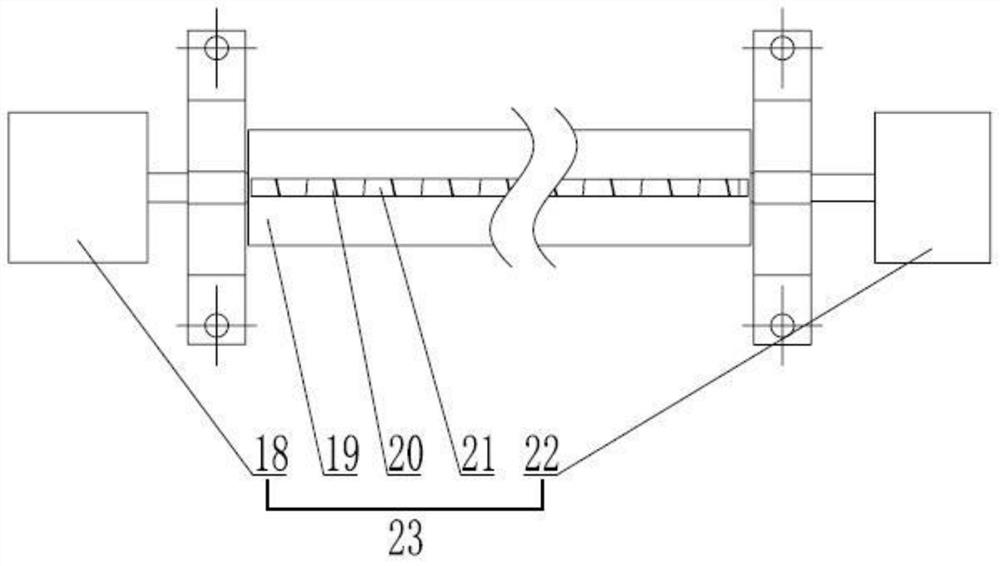

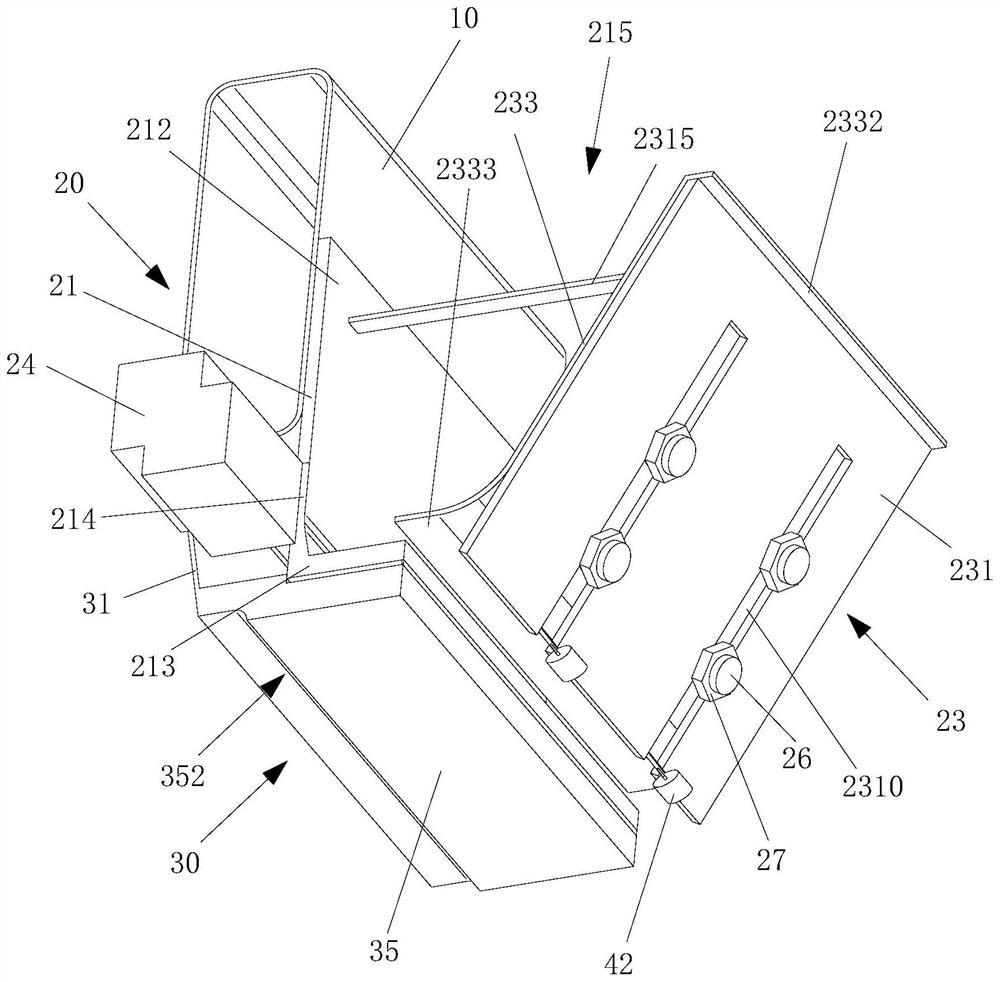

Novel rapid molding device and powder feeding and spreading method thereof

ActiveCN107745517AAccurate powder supplyGuaranteed smoothAdditive manufacturing apparatusIncreasing energy efficiencyRapid prototypingPiston

The invention discloses a novel rapid molding device and a powder feeding and spreading method thereof. The novel rapid molding device comprises a powder feeding cylinder, a molding cylinder, an overflow powder cylinder, a laser window, a powder feeding scraper plate and a bucket type double-scraper plate powder spreading mechanism, and also comprises a powder feeding cylinder heat preservation chamber, a powder feeding cylinder heater, a molding cylinder heat preservation chamber, a molding cylinder heater and a powder feeding cylinder working panel, the powder feeding scraper plate linearlymoves from the left to the right and pushes powder extruded through the lifting of the piston of the powder feeding cylinder to a powder falling opening at the right end of the powder feeding cylinderheat preservation chamber, the powder freely falls into two bucket scraper plates from top to bottom, and the bucket scraper plates horizontally move from the left to the right to push the powder tothe molding cylinder, spread the powder on the molding cylinder and send superfluous powder outside the two bucket scraper plates into the overflow powder cylinder in order to complete one-time powderspreading. The novel rapid molding device and the powder feeding and spreading method thereof have the advantages of effective improvement of the powder feeding and spreading manner, improvement of the powder spreading quality, reduction of material wastes, and improvement of the 3D printing quality and the printing efficiency.

Owner:武汉华科三维科技有限公司

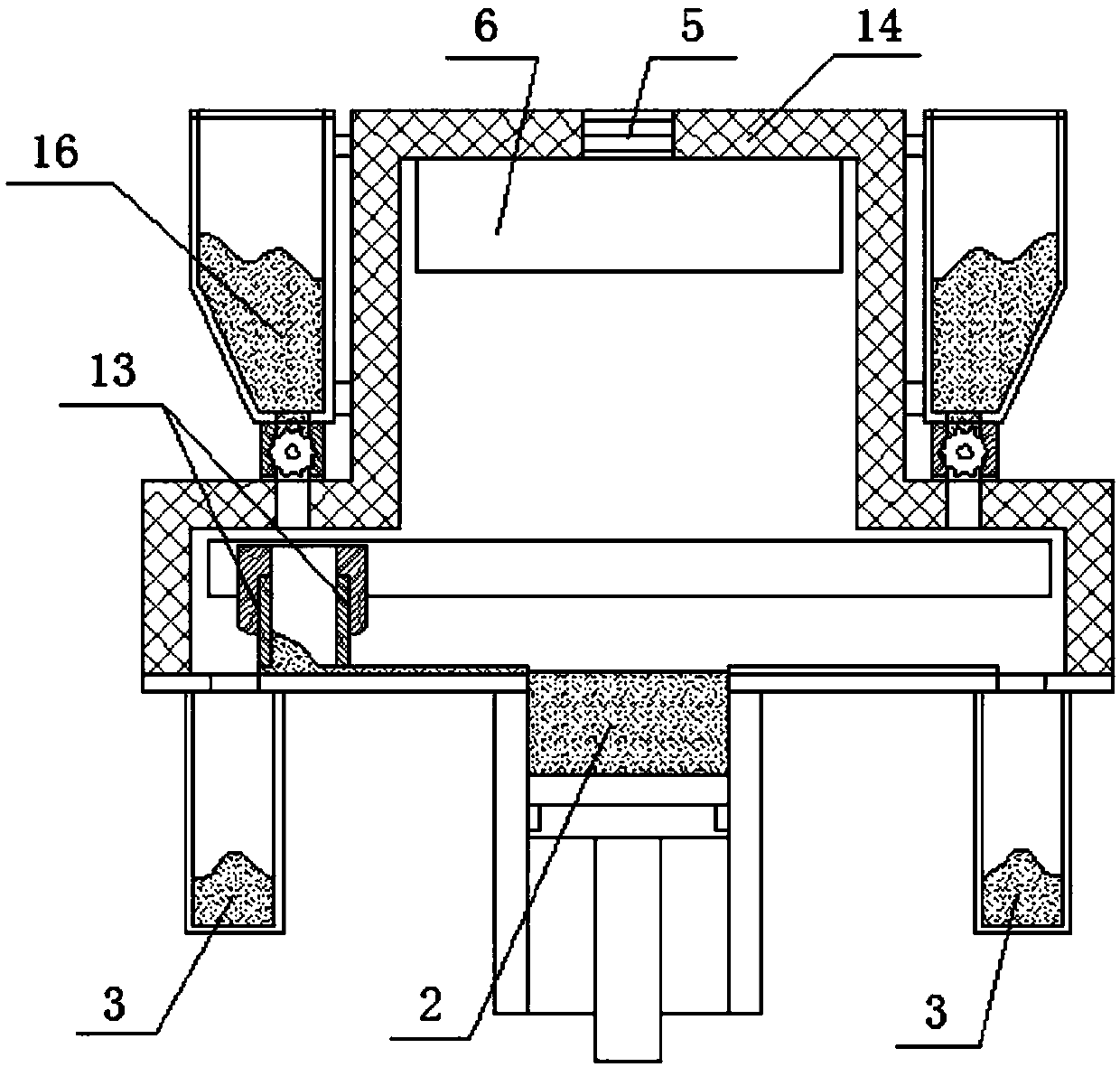

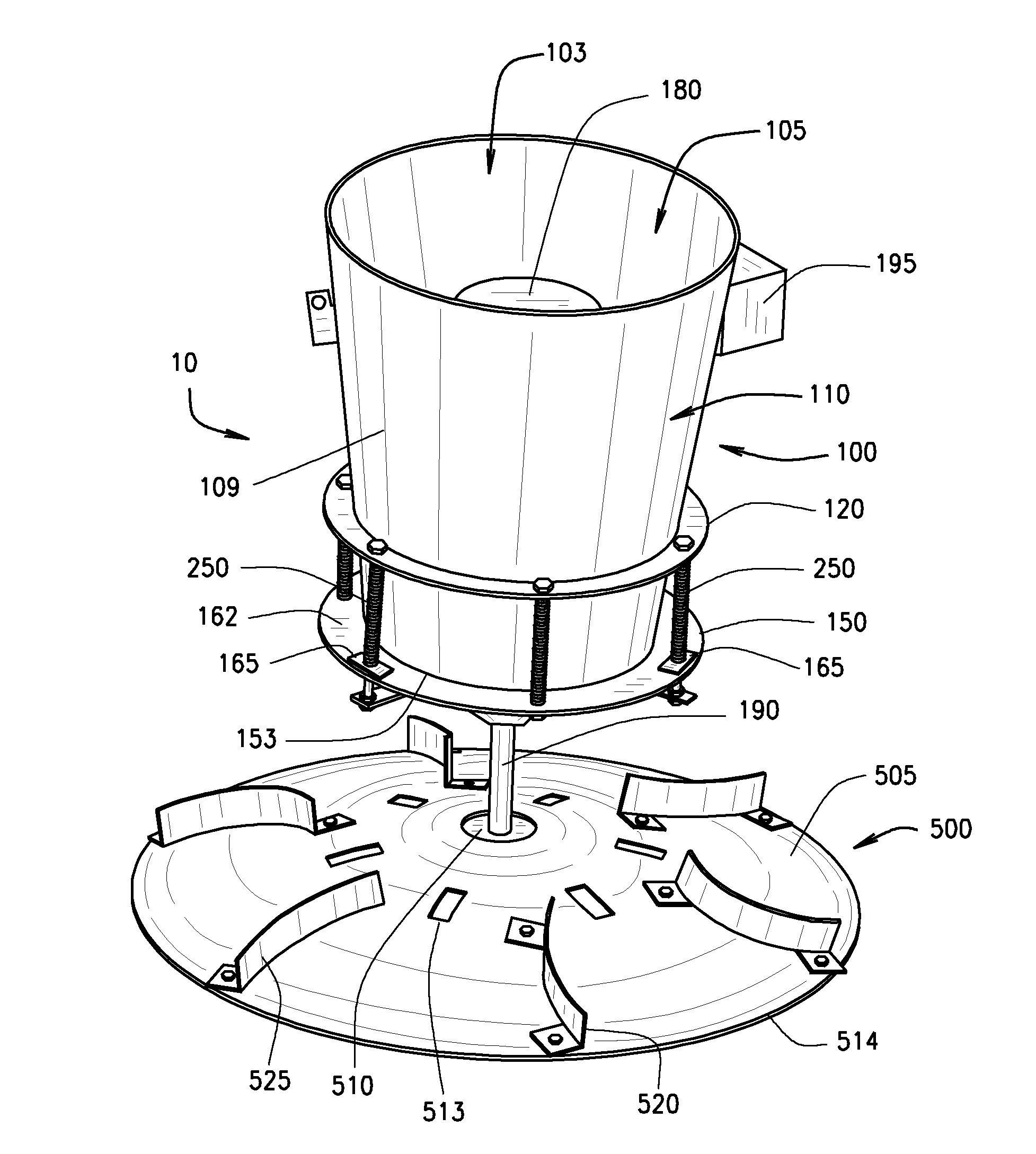

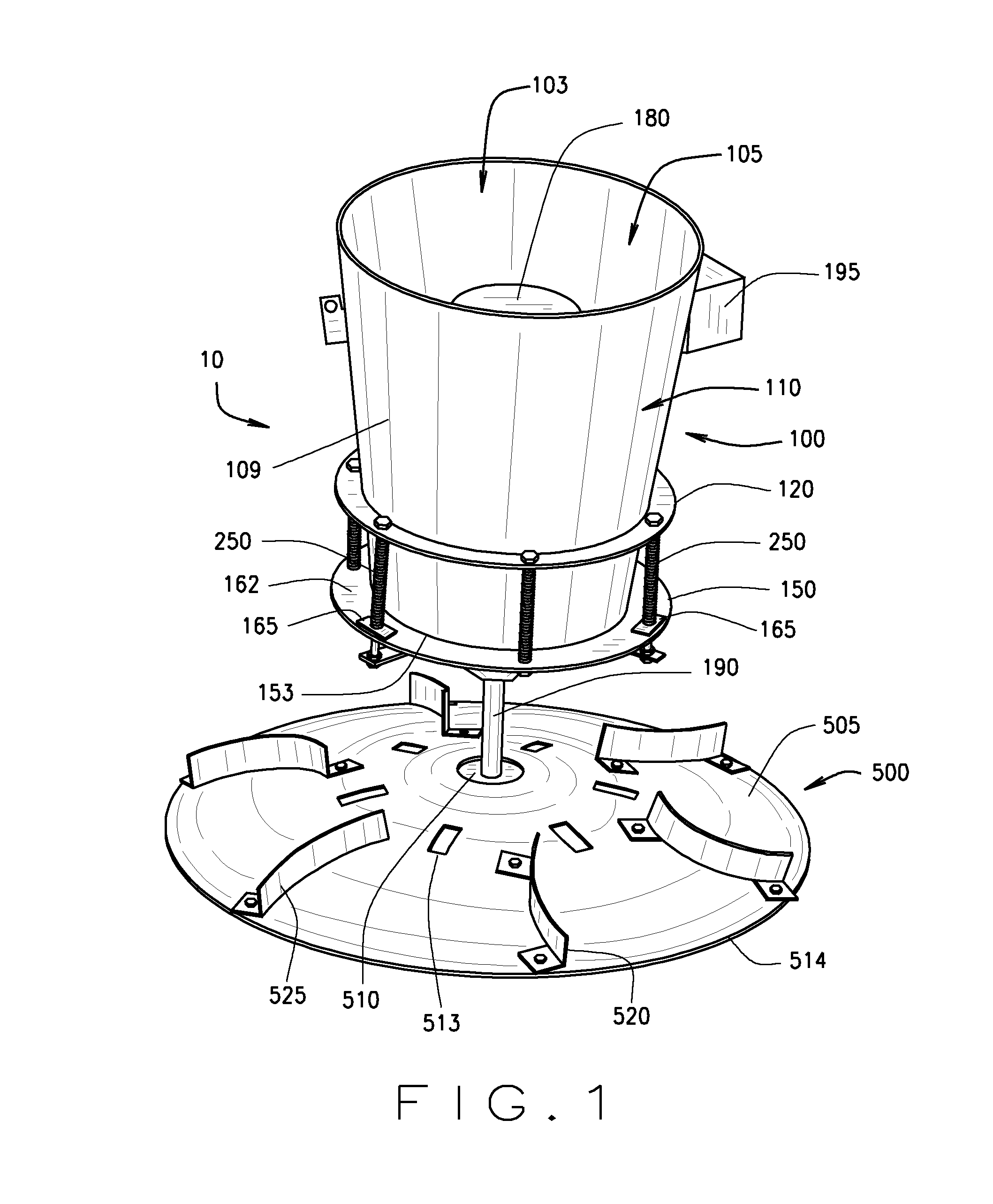

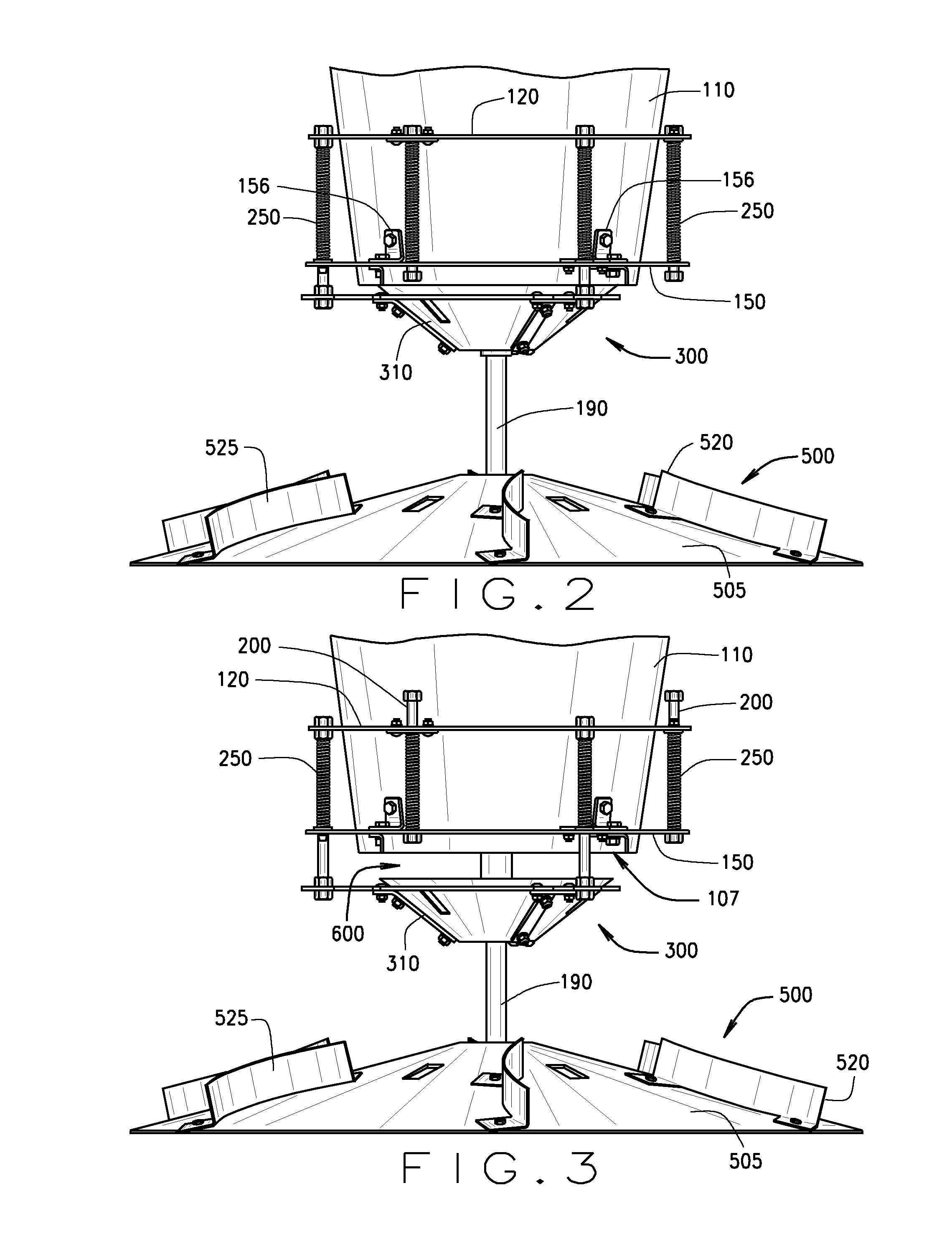

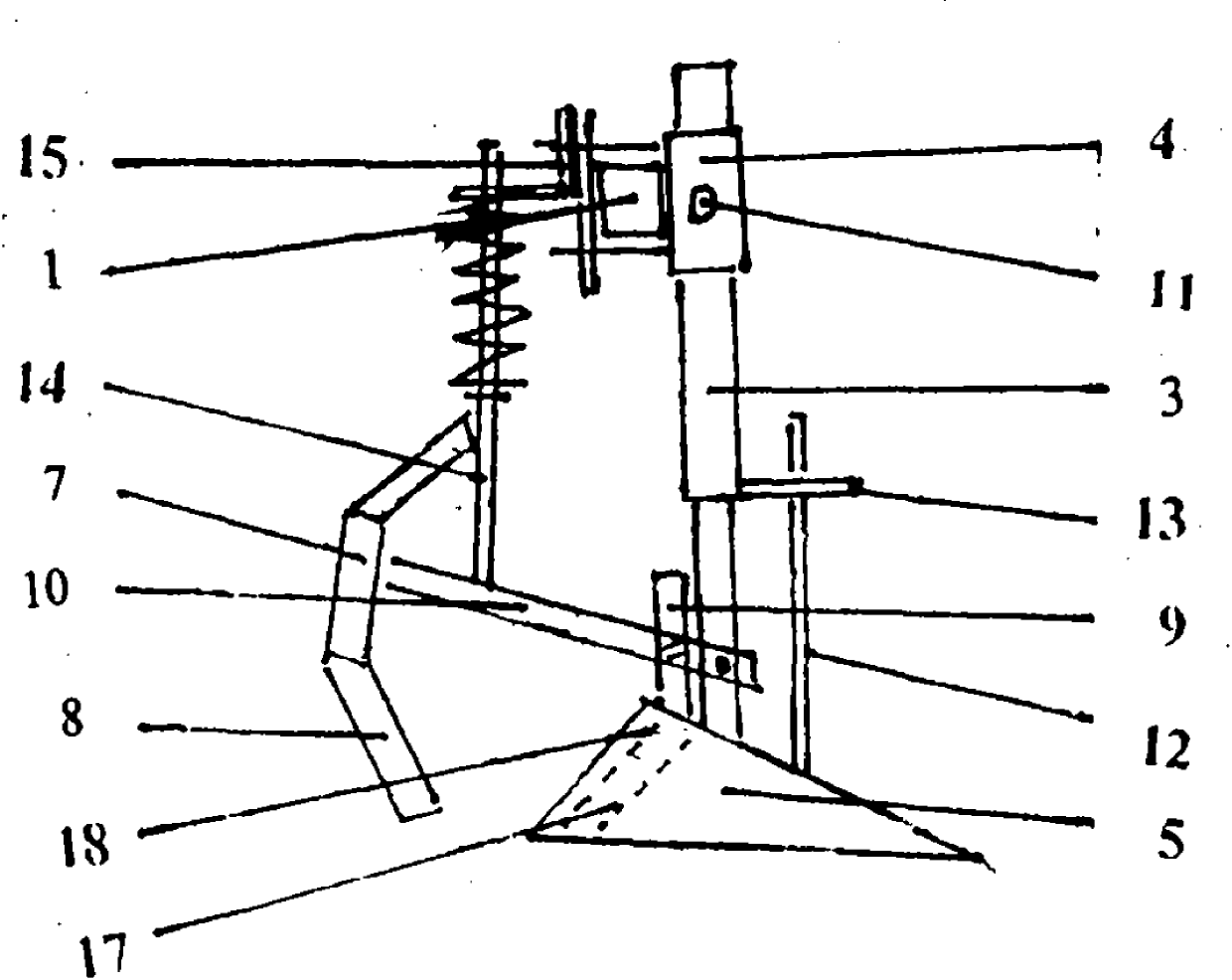

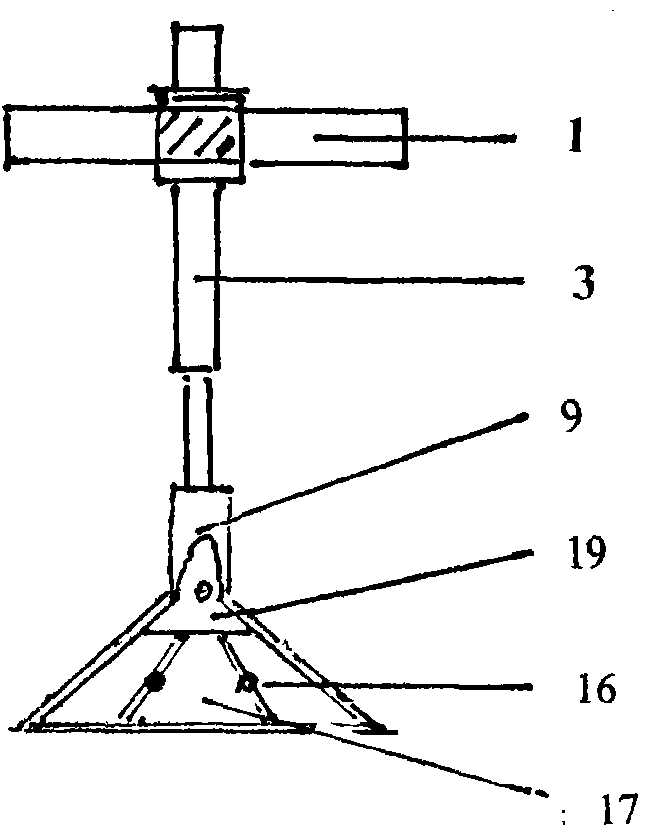

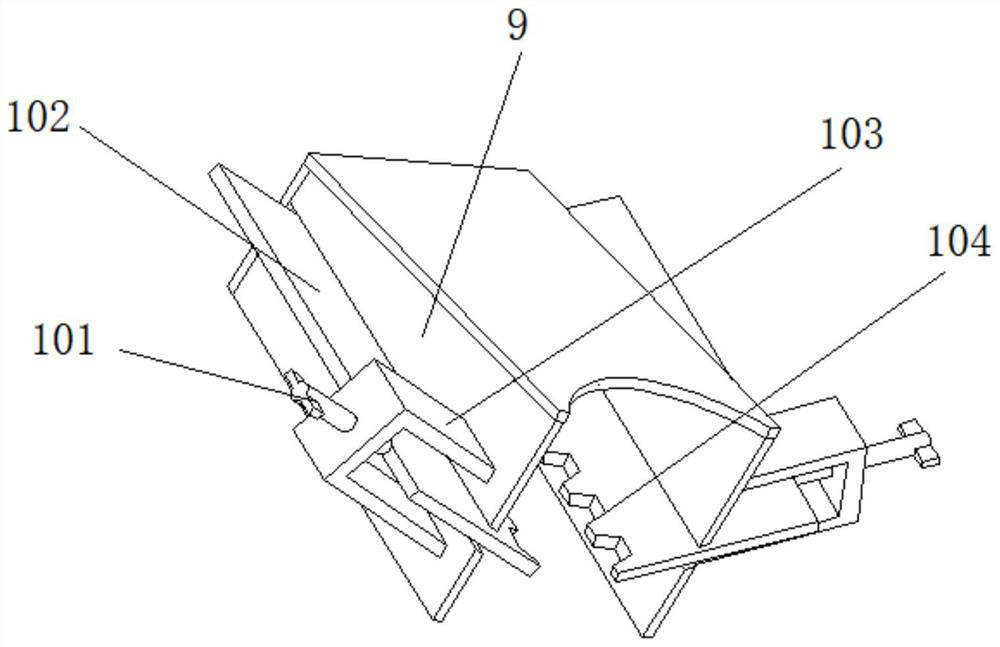

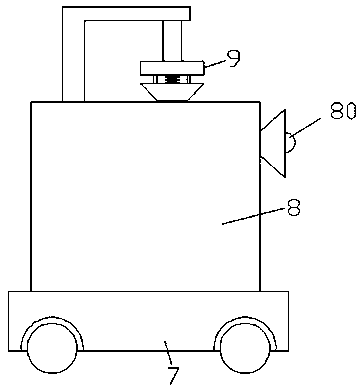

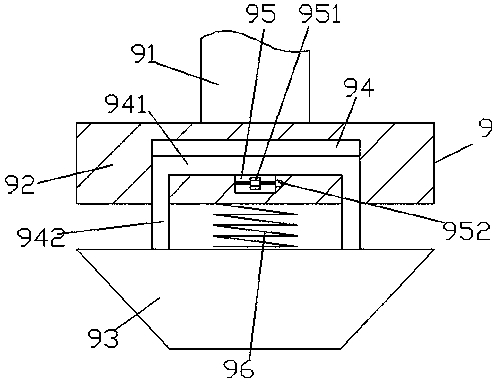

Active choking funnel for a grain spreader

InactiveUS20120237322A1Quality improvementImprove spreading qualityAgriculture tools and machinesHarvested fruit hanging devicesEngineeringDistributor

A grain spreader with an active choking funnel is described. The grain spreader includes an upper funnel assembly to receive grain. A choking funnel assembly is in a spring loaded engagement with the upper funnel assembly. The upper funnel assembly directs the grain to the choking funnel assembly. A spreader pan or a grain distributor is positioned beneath the choking funnel assembly. The choking funnel assembly spreads the grain on the spreader pan or the grain distributor.

Owner:GLOBAL IND

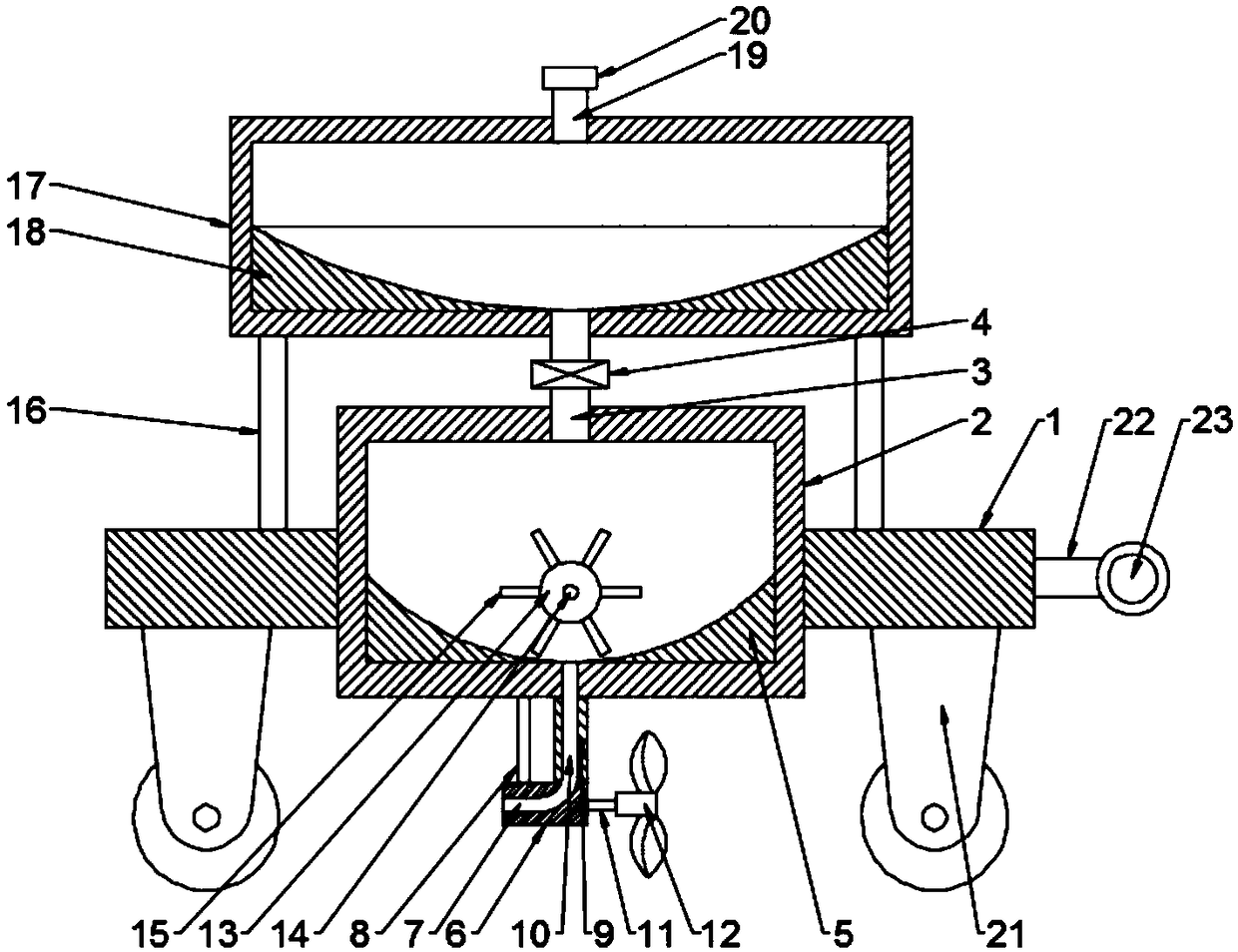

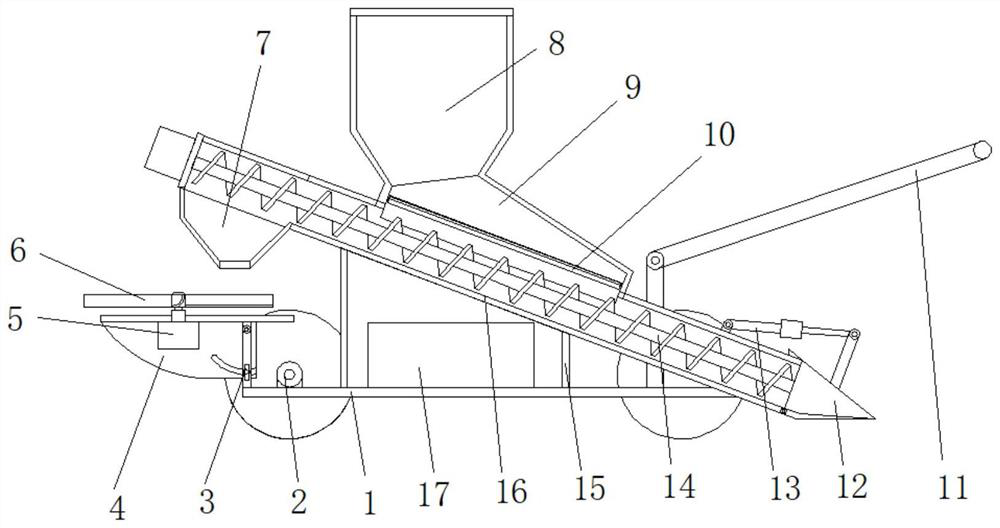

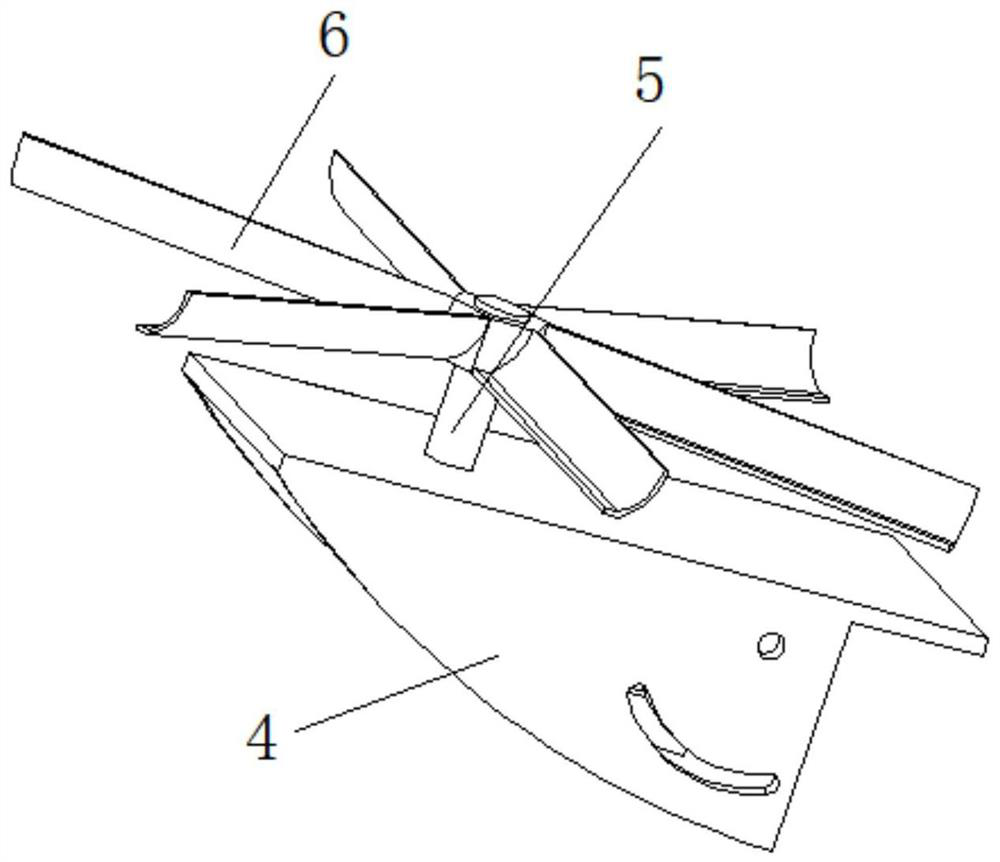

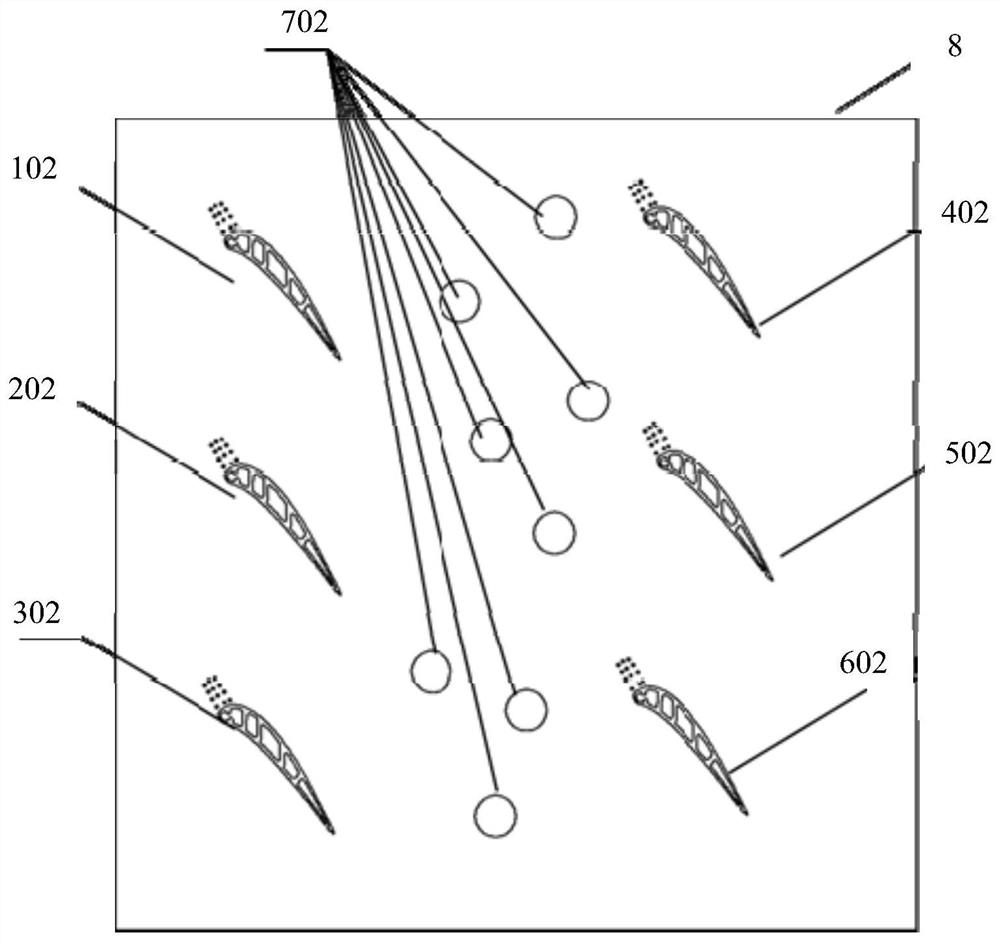

Agricultural seeding vehicle with earthing function

InactiveCN107258127ASpread evenlyImprove spreading qualitySpadesPlantingDrive shaftAgricultural engineering

An agricultural seeding vehicle with soil covering function, including a vehicle body, characterized in that a fixed bracket is fixedly installed in the vehicle body, a limit spring is arranged between the fixed bracket and the push-pull plate, a rotating motor is fixedly installed at the bottom of the slider, and the rotating motor The drive shaft is fixedly installed on the motor shaft, the diverter plate is fixedly installed at the bottom end of the drive shaft, the extension plate is fixedly installed on the outer wall of the left side of the car body, the drive motor is fixedly installed on the extension plate, and the motor shaft of the drive motor is fixedly installed with The driving pulley and the bottom of the extension plate are equipped with turning rollers; this invention has the functions of loosening soil, sowing and covering soil at the same time, and the mechanized operation solves the shortcomings of high labor intensity and heavy workload in the traditional manual sowing process, and speeds up the process. The speed of seeding is improved; the device has an ingenious structure and is easy to operate. The diversion effect on the seeds is realized through the rotating diverter plate, so that the seeds are evenly sown, the quality of seed sowing is improved, and the seed planting effect is enhanced.

Owner:安庆海维环保设备有限公司

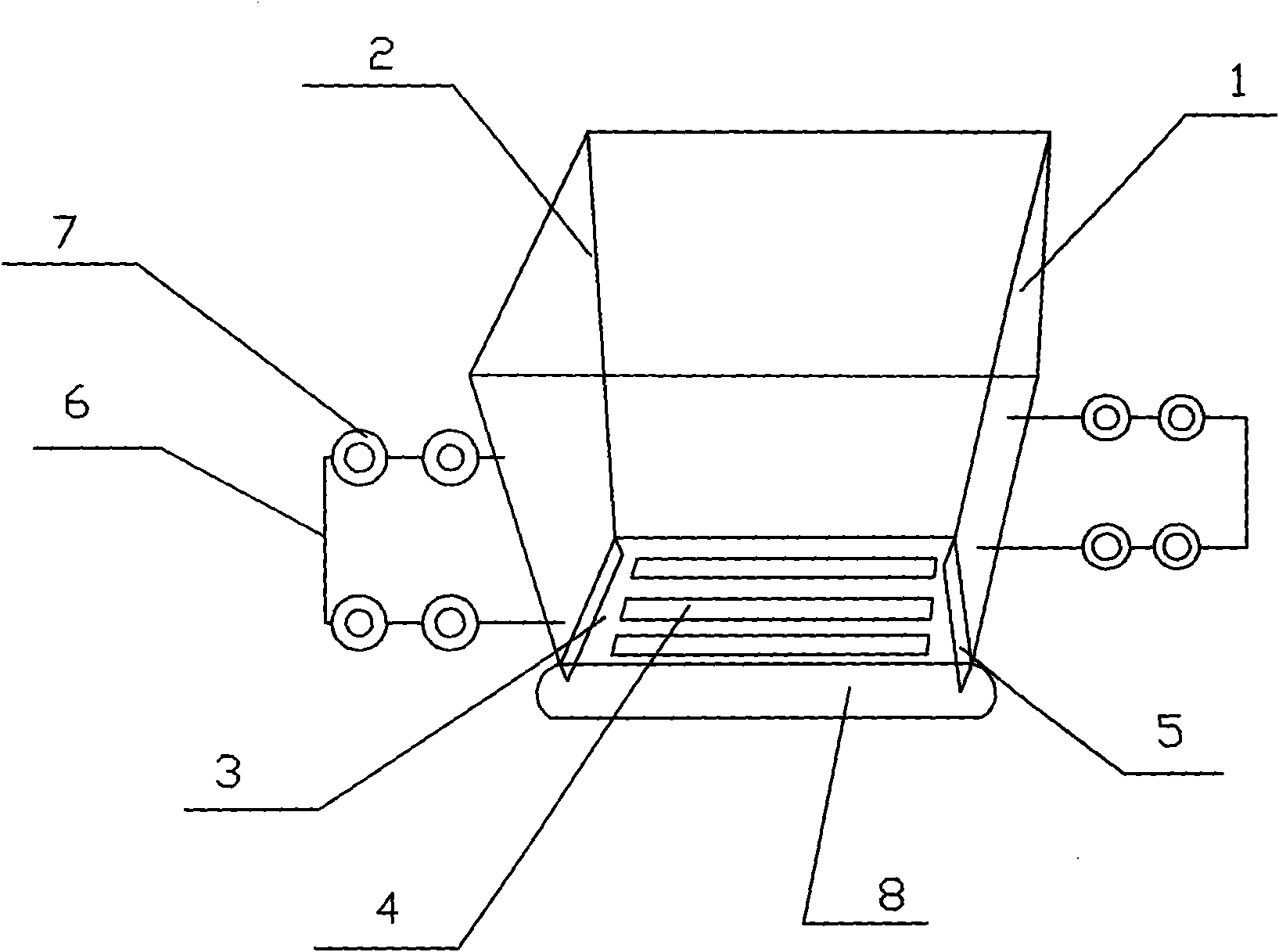

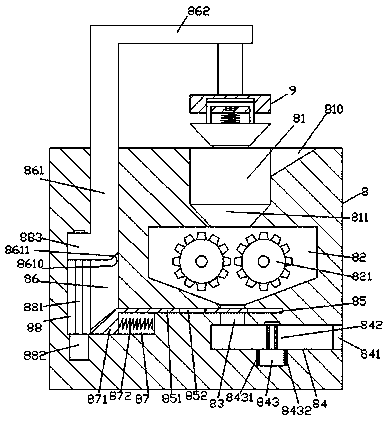

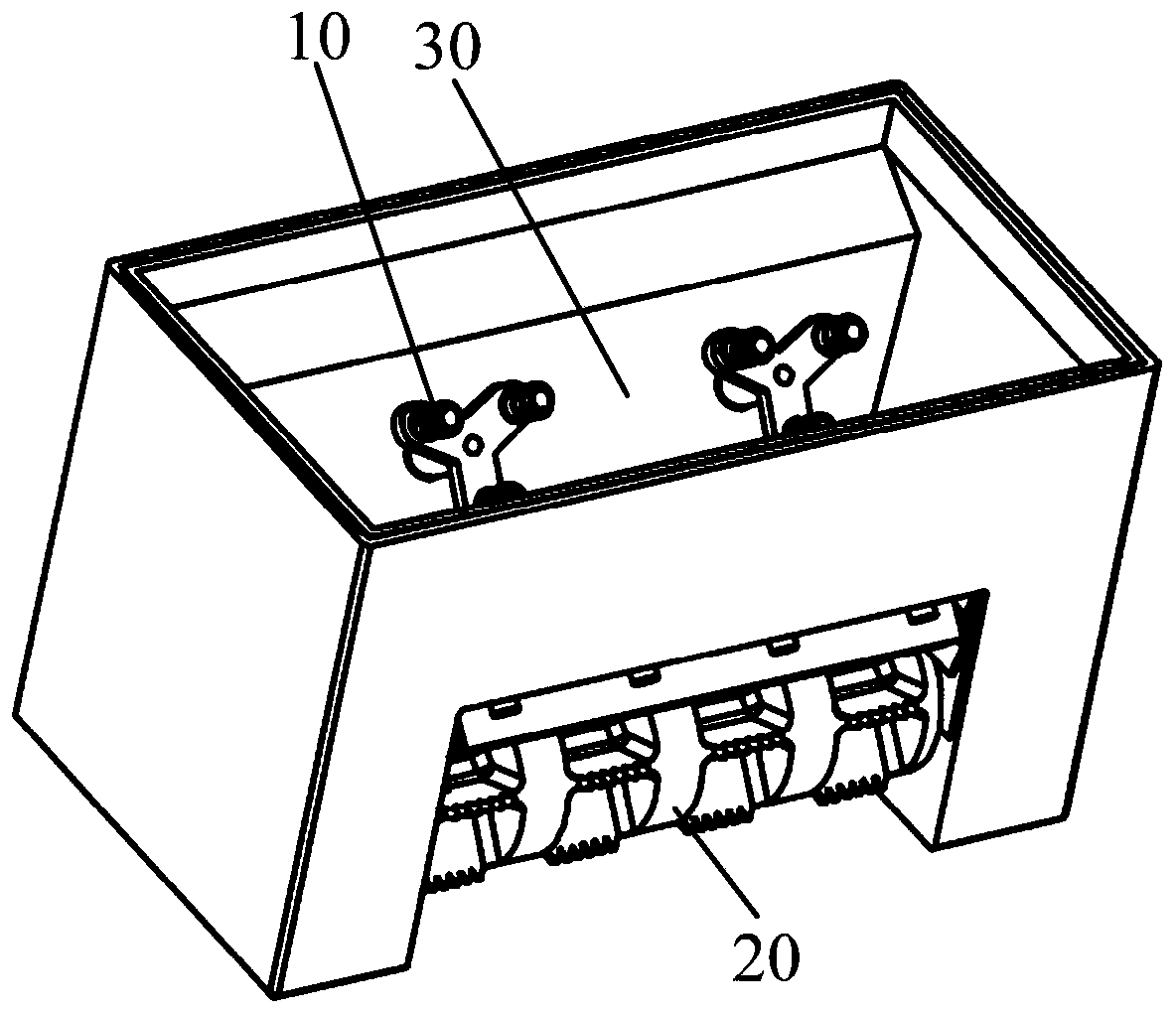

Fast mortar-spreading device for building brick wall

The invention discloses a fast mortar-spreading device for building a brick wall, comprising a hopper and two sets of vibrating wheels which are arranged in front of and behind the hopper; the hopperis wide at the top and is narrow at the bottom, the top end of the hopper is a feeding port and the bottom end of the hopper is a discharge end, three strip-shaped mortar outlets are arranged at the discharge end; a plastering iron bar is respectively arranged at the bottom ends of a front surface and a back surfaces of the hopper; two sets of the vibrating wheels are respectively arranged in front of and behind the hopper, each set of the vibrating wheels are formed by four gears, a base plane of each gear is lower 2 centimeters than the base plane of the plastering iron bar. The mortar is conveniently and fast spread, the working efficiency is greatly improved, the labor intensity is reduced and the spreading mortar quality is improved.

Owner:朱世友

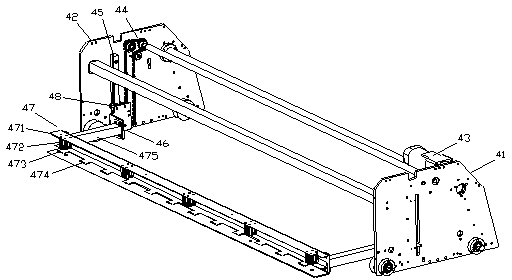

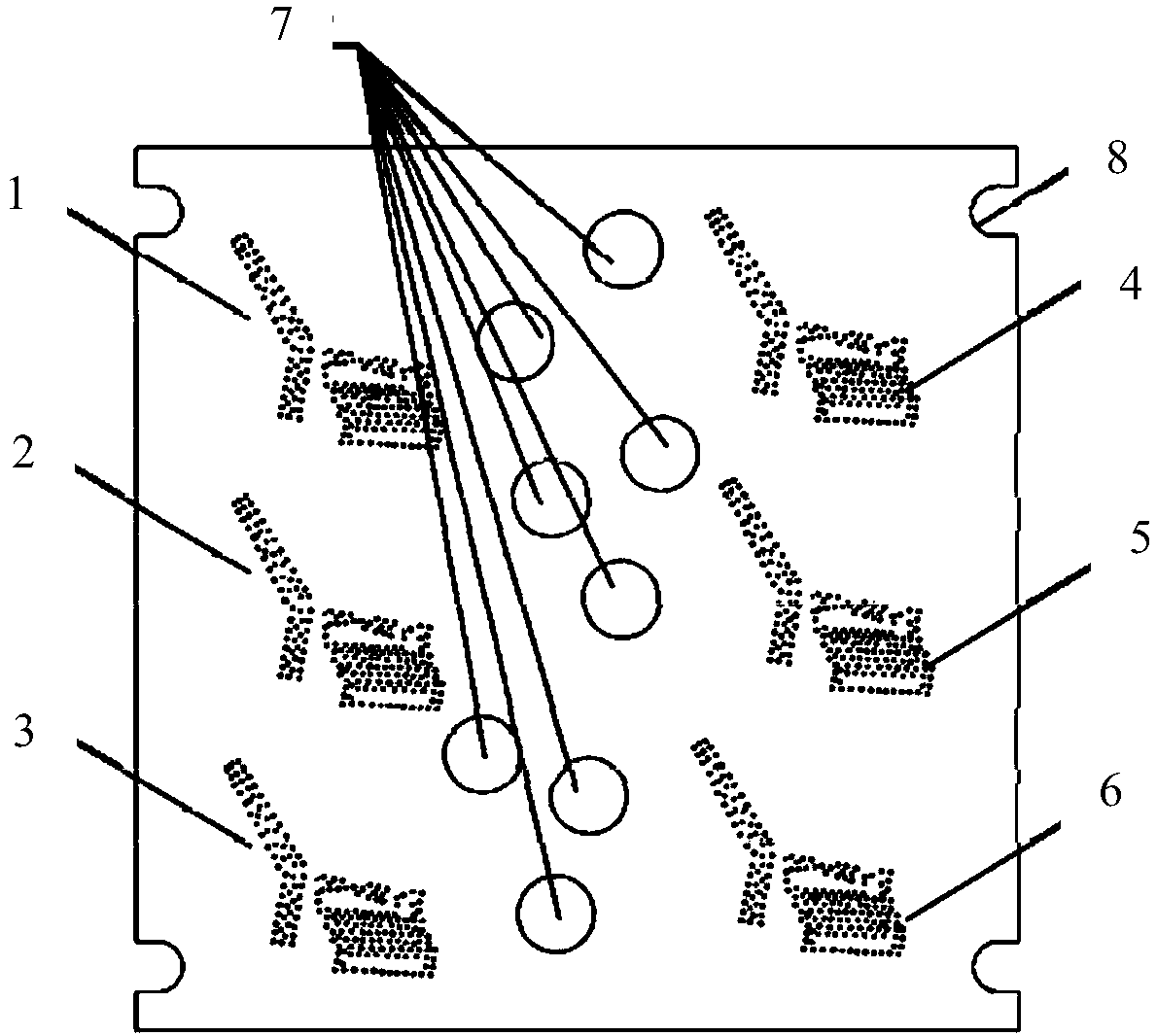

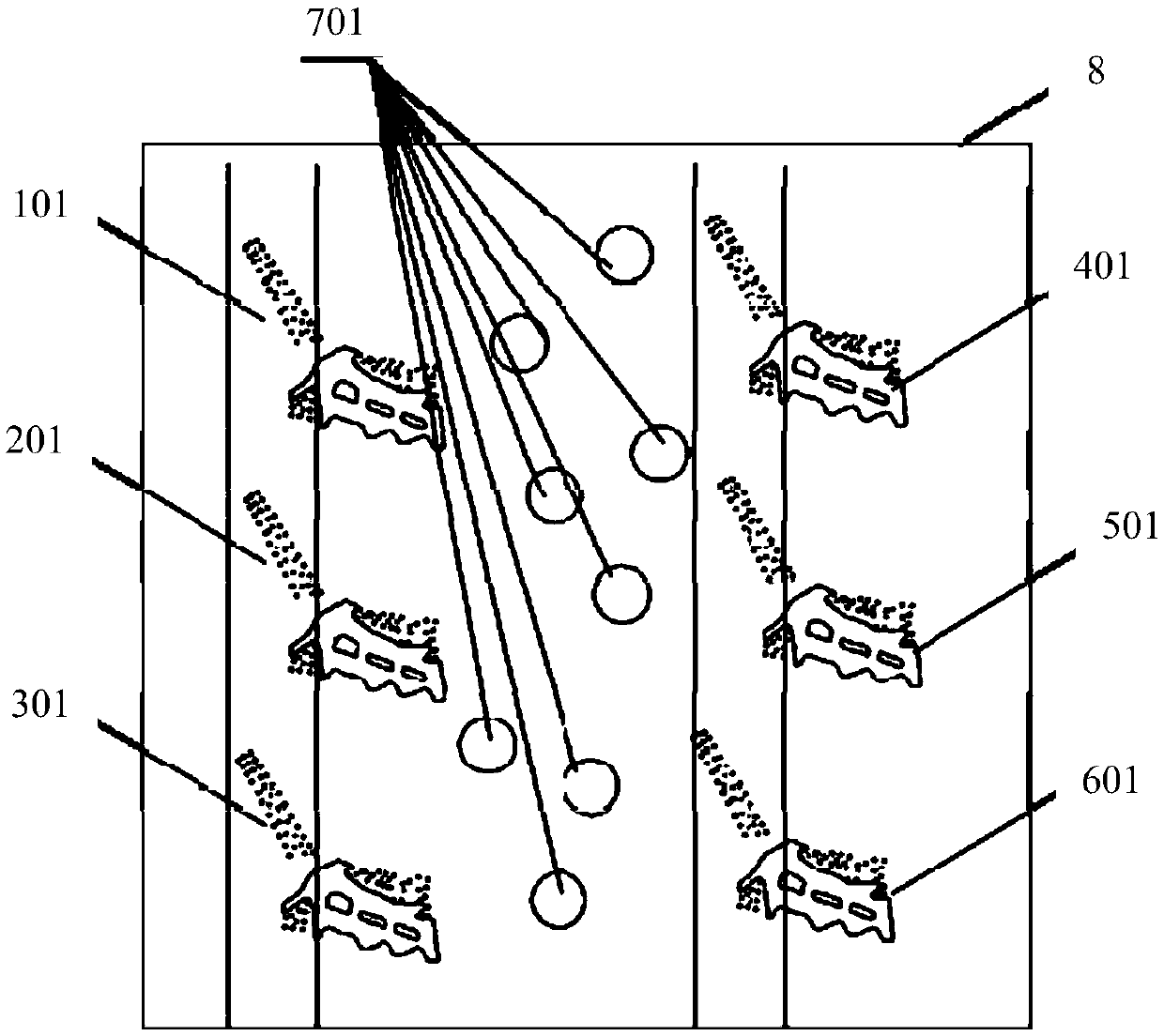

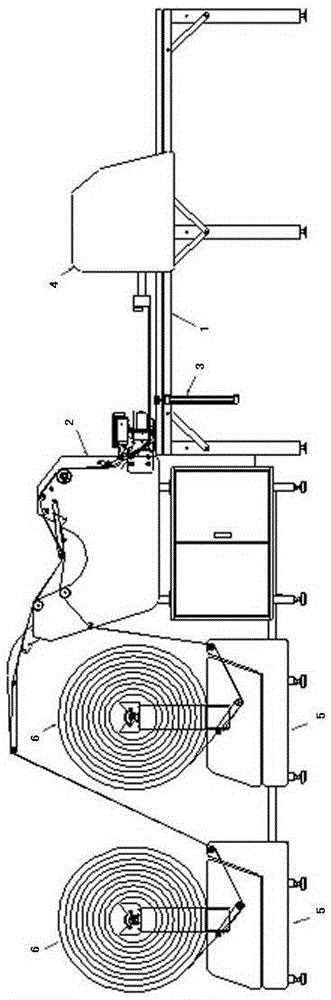

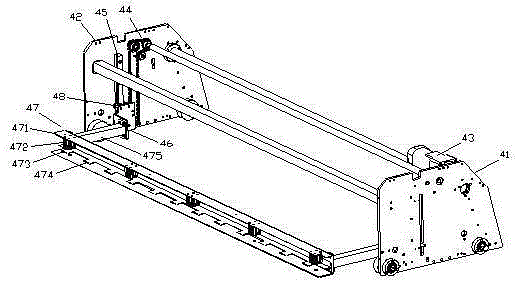

Double-roll cloth spreading machine

ActiveCN103318691AImprove work efficiencyImprove spread qualityUnfolding thin materialsArticle deliveryManipulatorTextile

The invention discloses a double-roll cloth spreading machine which comprises a bed, a main engine, a cloth pressing mechanism and a mechanical arm cloth clamping mechanism, wherein the cloth pressing mechanism is arranged on the bed, and the mechanical arm cloth clamping mechanism is arranged on the bed in a sliding mode. Two reel cloth supporting mechanisms which are arranged in a front-and-back mode are arranged on one side of the main engine so that double-roll reel cloth feeding is achieved. Two cloth spreading mechanisms are arranged on the main engine and used for spreading cloths on the two reel cloth supporting mechanisms, rear-arranged supports are arranged behind the two cloth spreading mechanisms and used for supporting one reel cloth supporting mechanism arranged in the rear portion to feed the cloths, front-arranged cloth spreading mechanisms are arranged in front of the two cloth spreading mechanisms, pressing rods are arranged among the two cloth spreading mechanisms and the front-arranged cloth spreading mechanisms, the cloths fed by the two cloth spreading mechanisms are overlapped under the pressing rods and fed to the front-arranged cloth spreading mechanisms, cloth feeding mechanisms are arranged in front of the front-arranged cloth spreading mechanisms, and cloth-cutting devices are arranged below the cloth feeding mechanisms. The double-roll cloth spreading machine has the advantages that double-roll reel cloth spreading can be carried out at the same time, single cloth-spreading and cloth-folding are carried out by the adoption of the mechanism arm cloth clamping, positioning is accurate, precision is high, cloth folding is orderly, and working efficiency is high.

Owner:YYC IND CO LTD CHINA

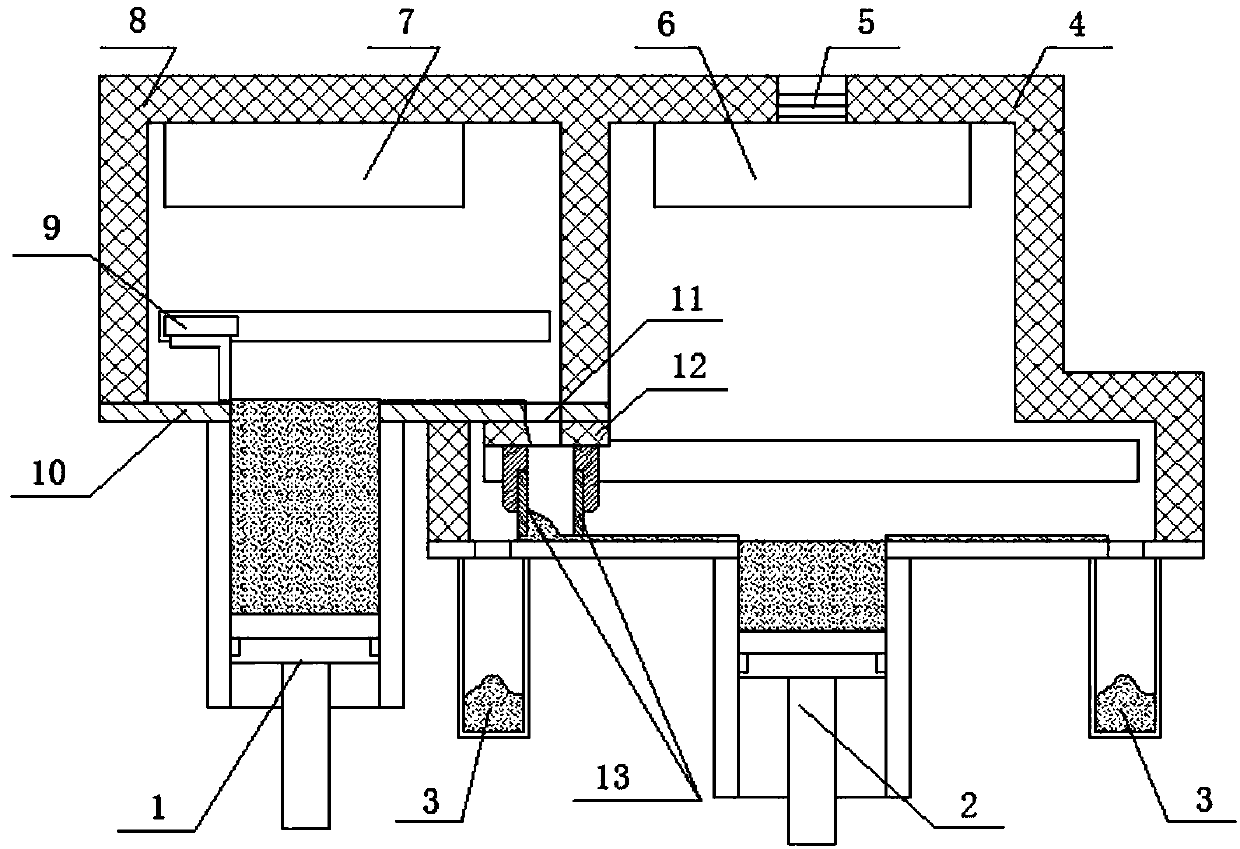

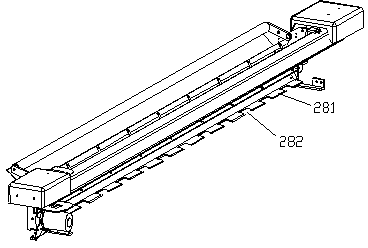

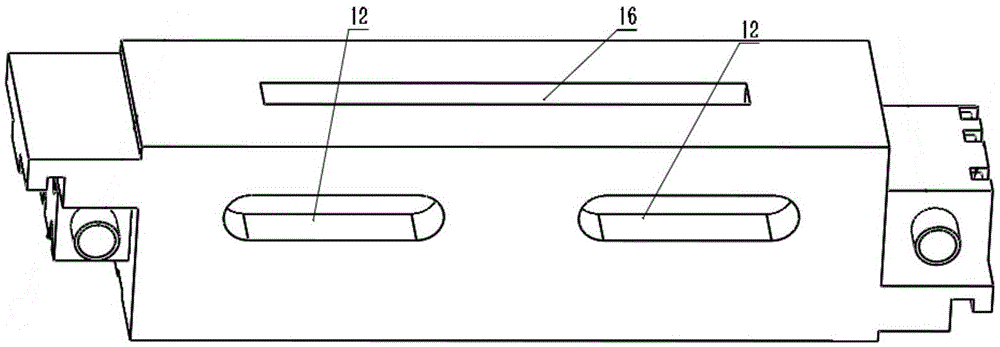

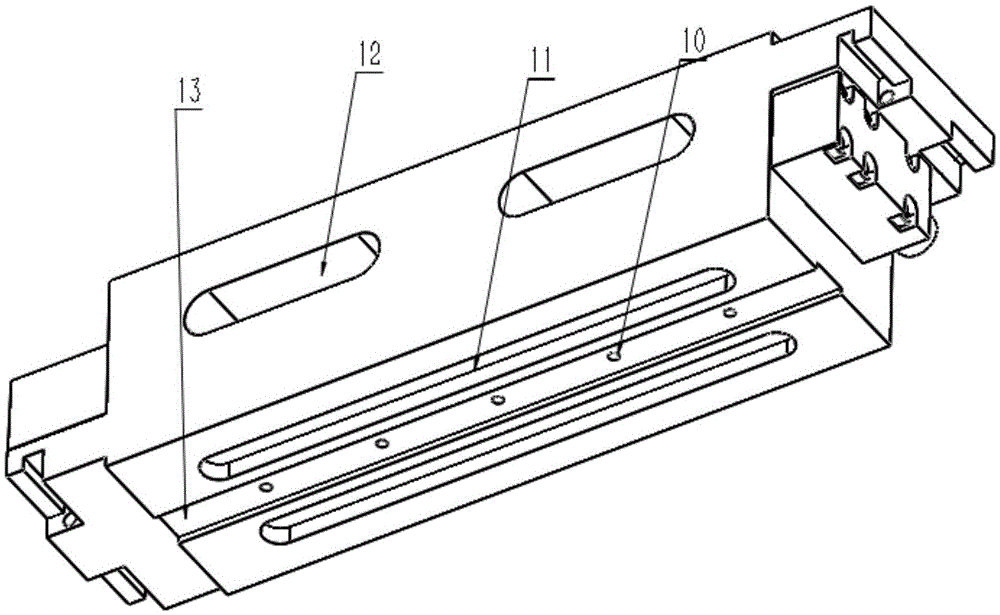

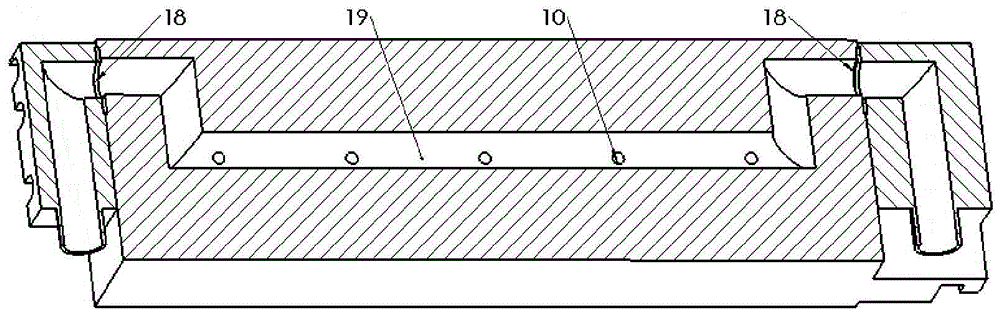

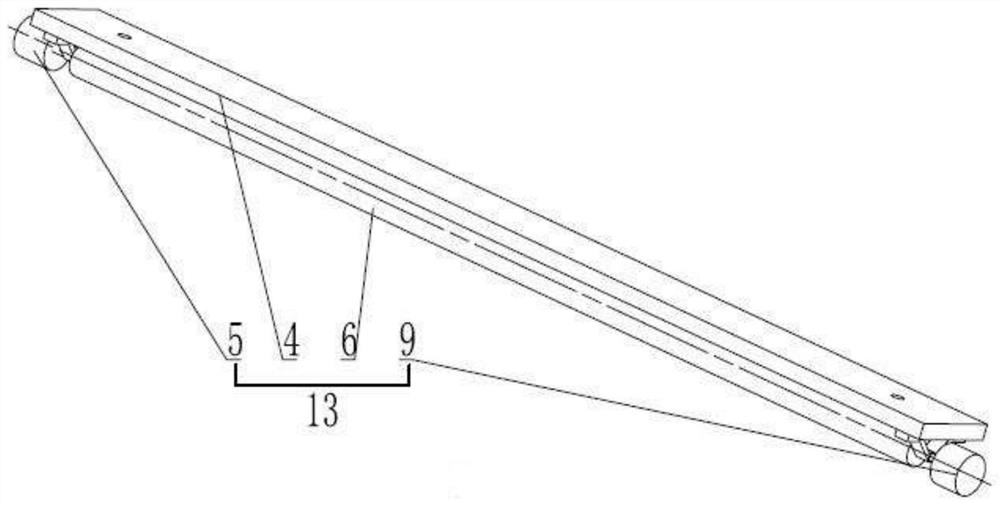

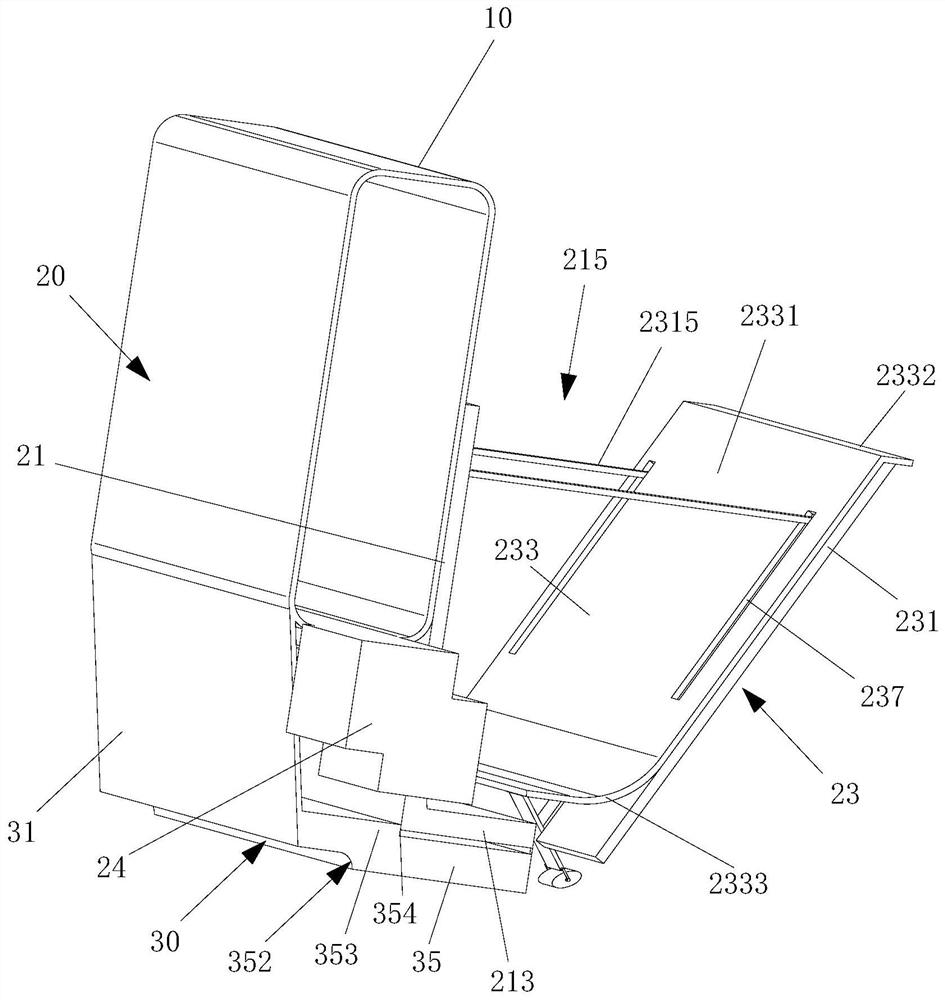

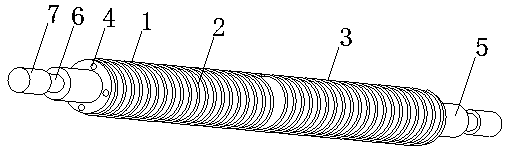

Powder falling and powder spreading device for additive manufacturing equipment

ActiveCN109760313ASimple structureImprove uniformityApplying layer meansIncreasing energy efficiencyControl systemSingle degree of freedom

The invention discloses a powder falling and powder spreading device for additive manufacturing equipment. The powder falling and powder spreading device comprises a powder spreading operation table,a powder spreading assembly and a driving assembly. The powder spreading assembly is installed on the powder spreading operation table in a front-back single degree-of-freedom sliding mode. The driving assembly drives the powder spreading assembly to slide. The powder spreading assembly comprises a flow guide block, a powder falling opening switching plate and hitting blocks. The flow guide blockis connected to the powder spreading operation table in a front-back sliding mode and is used for powder falling. The powder falling opening switching plate is arranged above the flow guide block andcan slide front and back. The hitting blocks are installed on the powder spreading operation table, are located on the front and rear sides of the powder spreading assembly and are used for hitting the powder falling opening switching plate. The powder falling opening switching plate is provided with a powder falling switching groove extending left and right. The flow guide block is provided withtwo powder falling grooves formed front and back and extending left and right. According to the powder spreading assembly, automatic switching of the powder falling grooves is achieved through hittingin the sliding process, no special driving device needs to be arranged for switching the powder falling grooves in the structure, the structure of the powder spreading assembly is simplified, a control system is simplified, and cost of the additive manufacturing equipment is lowered.

Owner:SUZHOU XIDIMO THREE DIMENSIONAL PRINTING TECH CO LTD

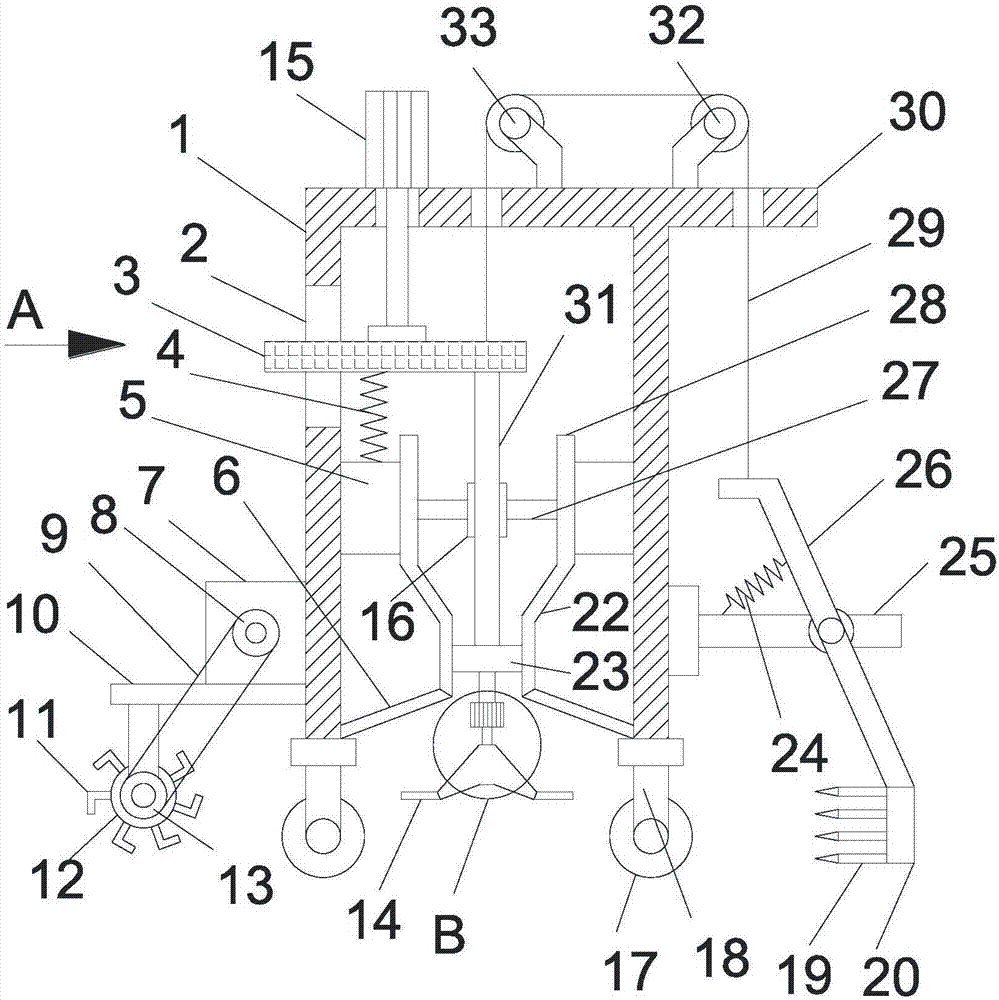

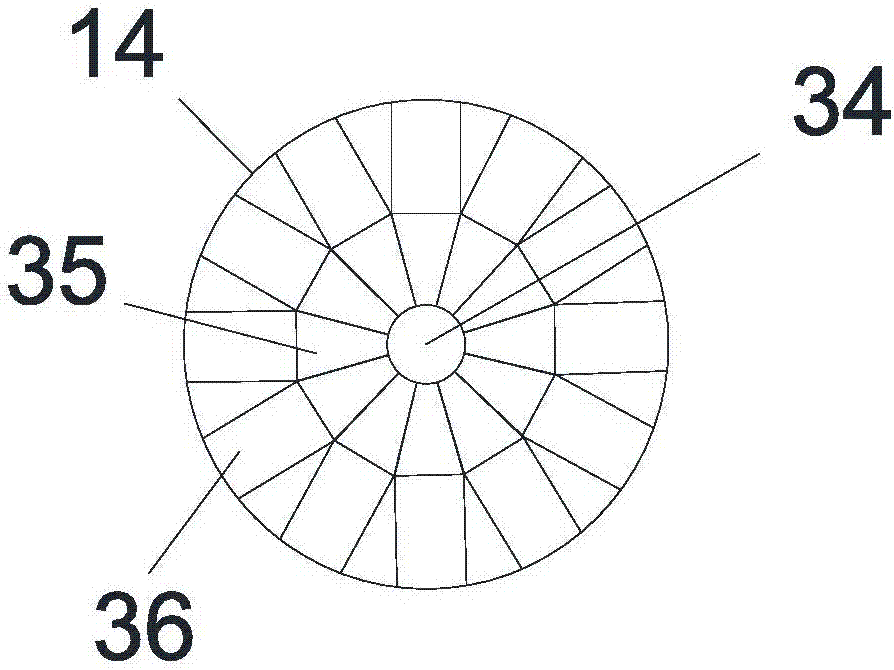

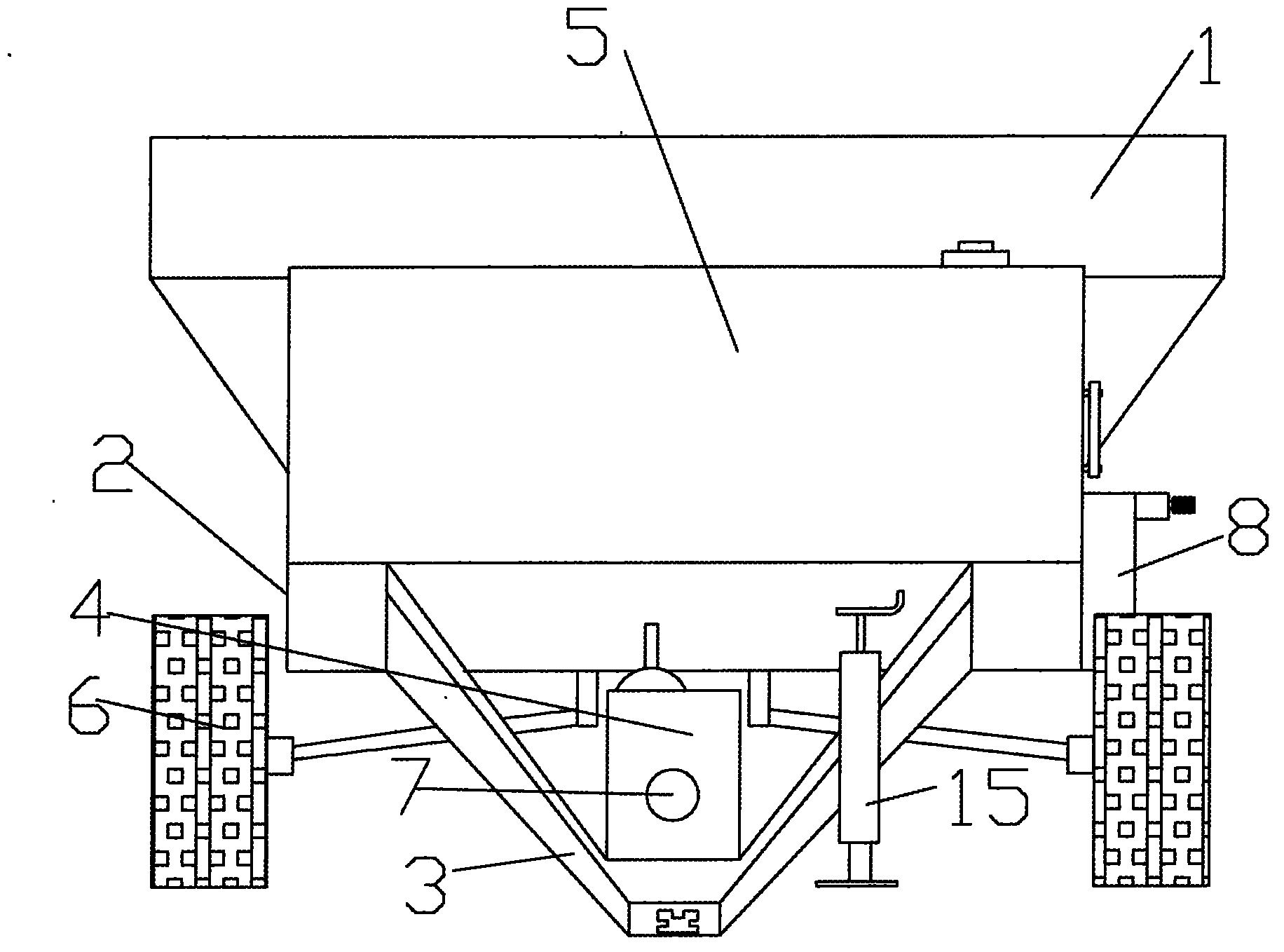

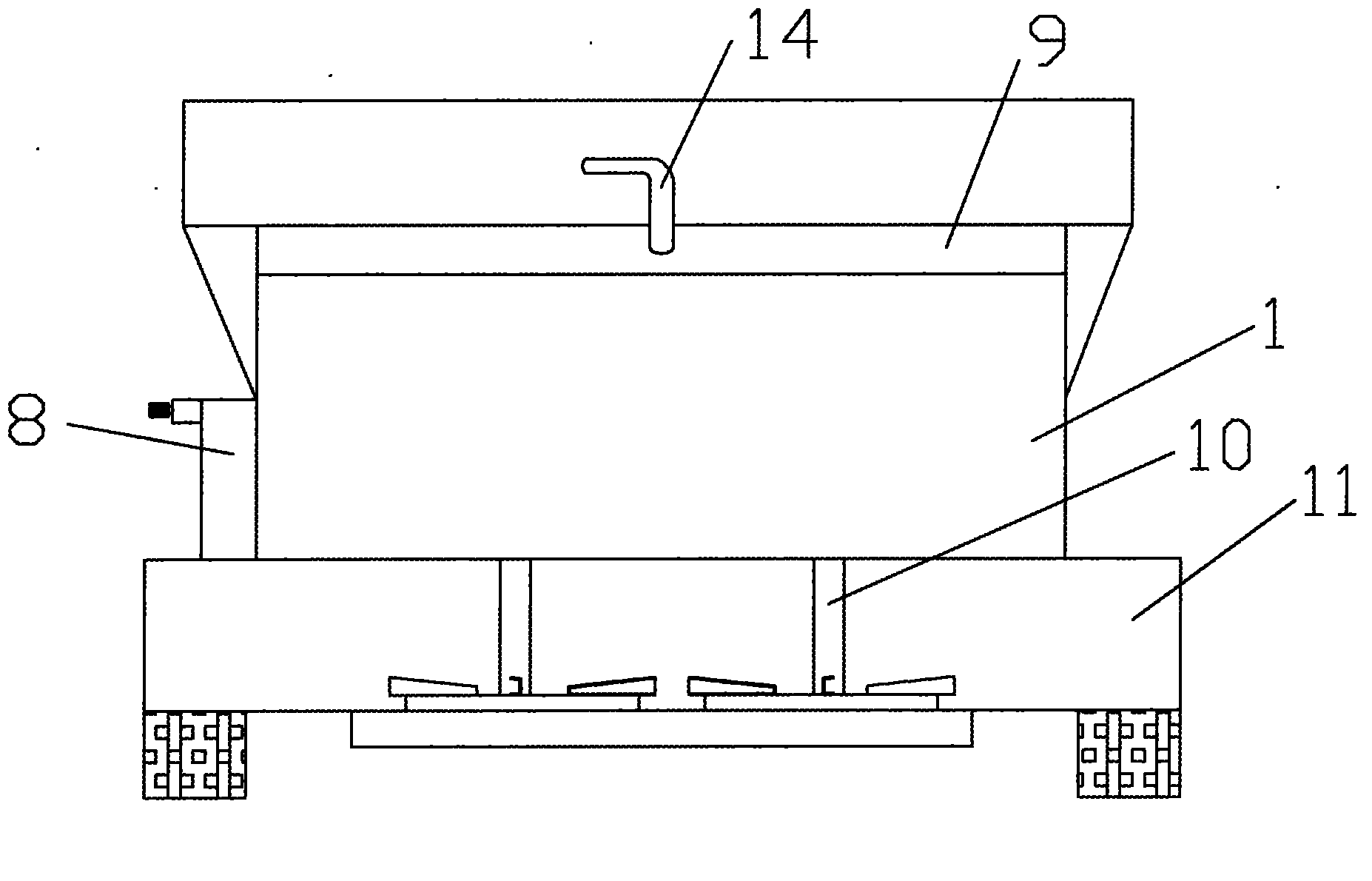

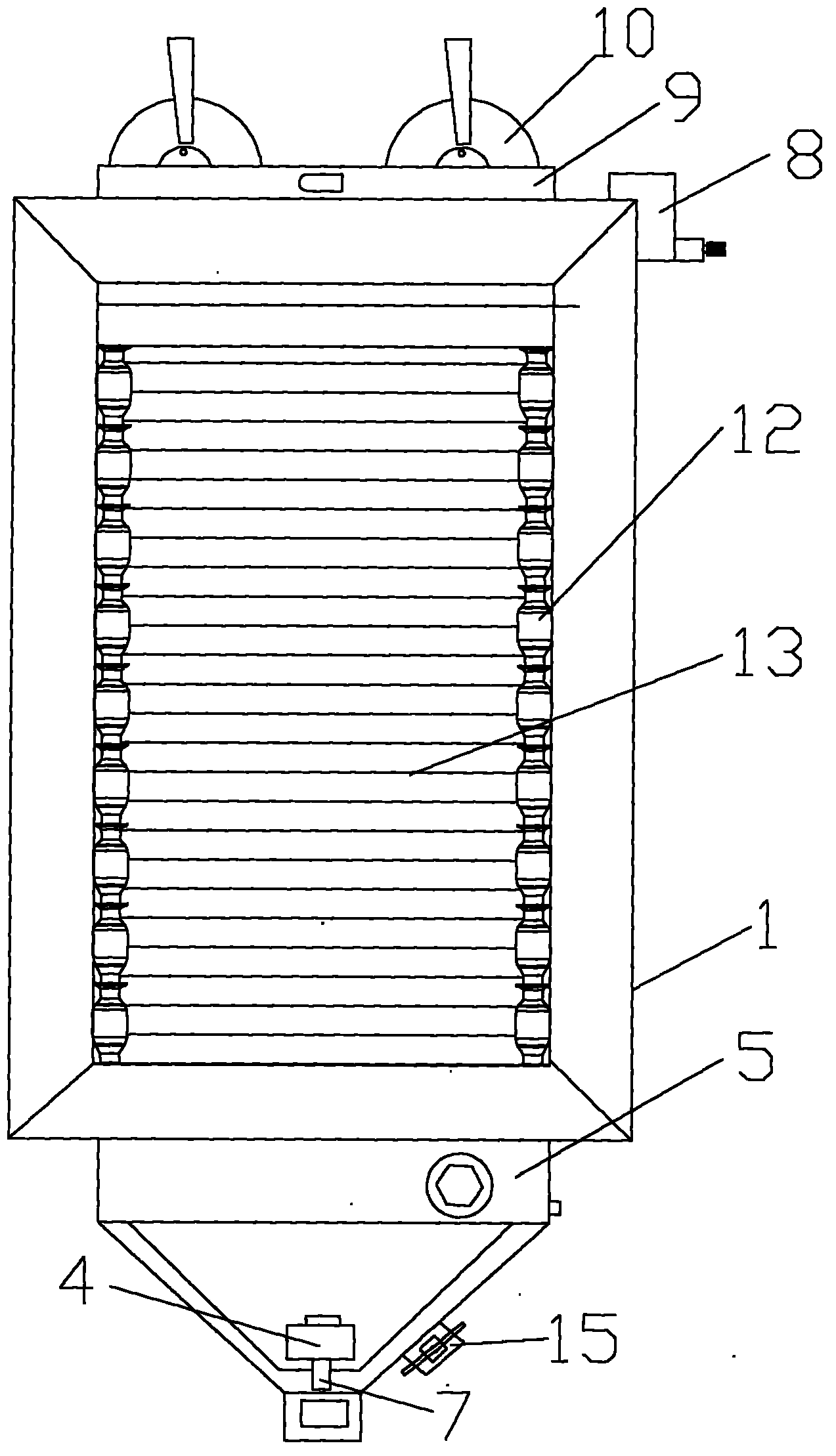

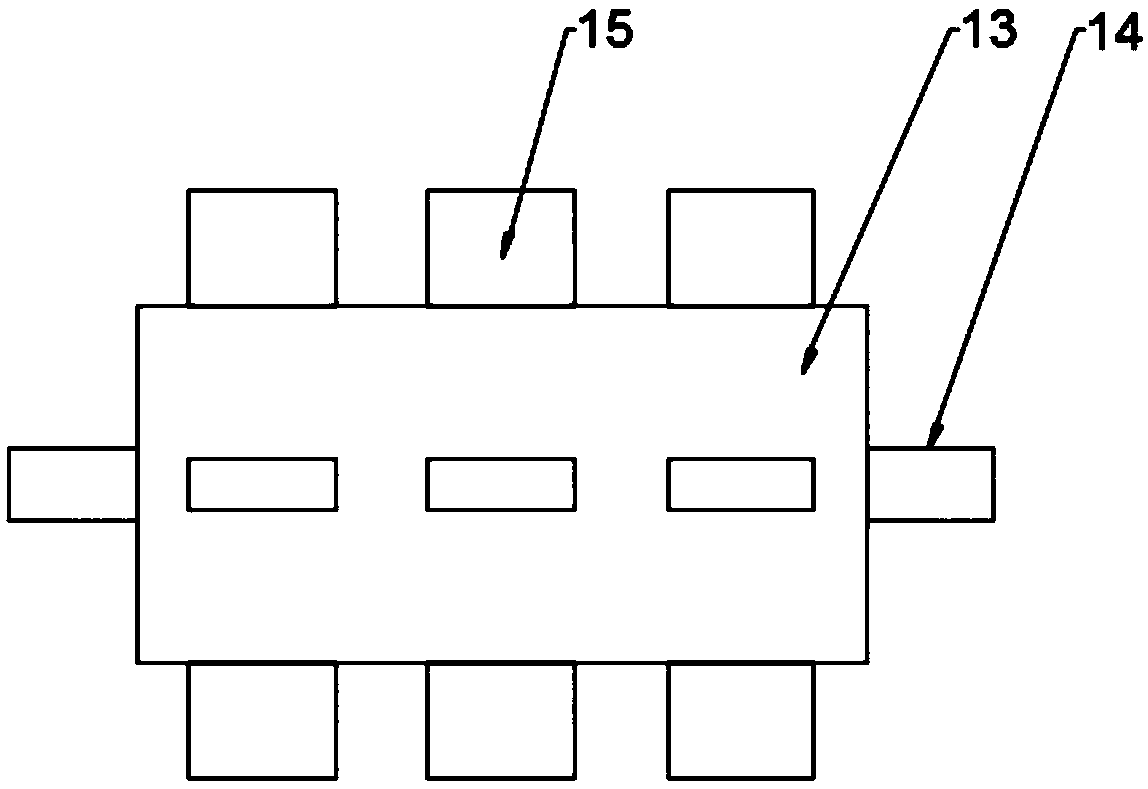

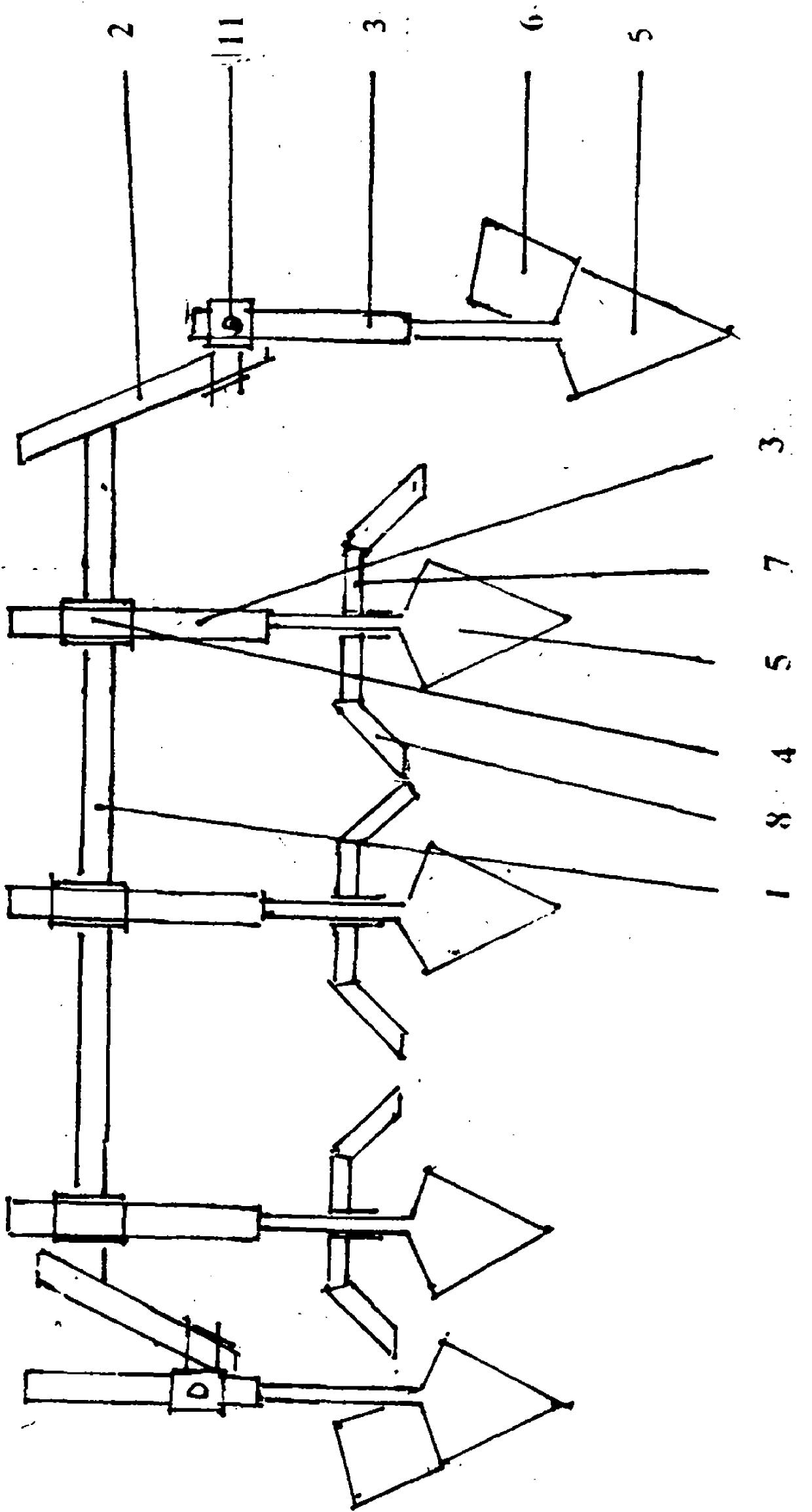

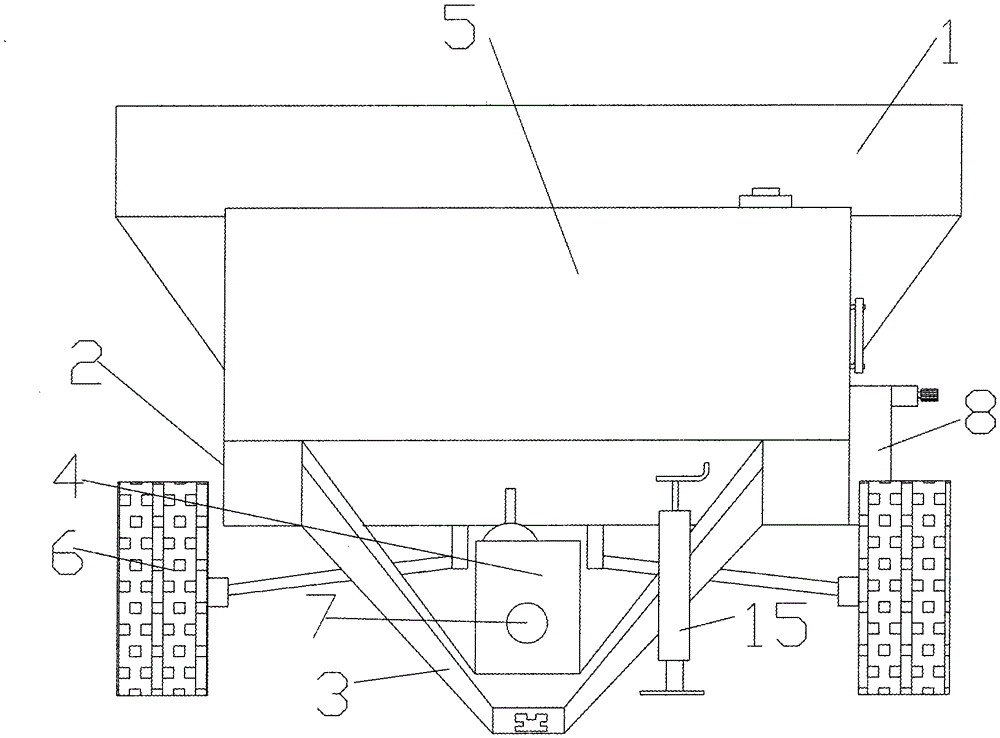

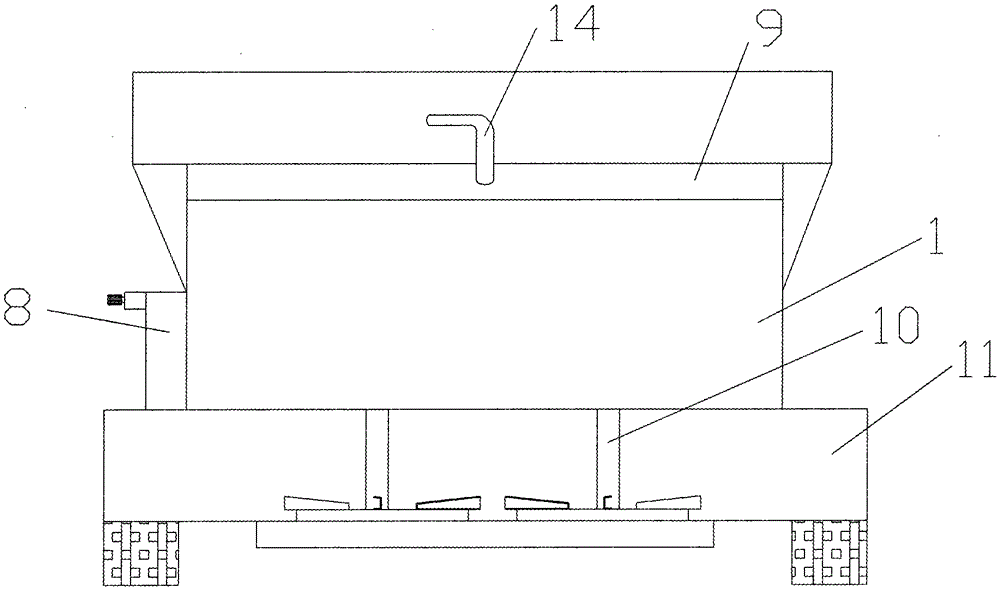

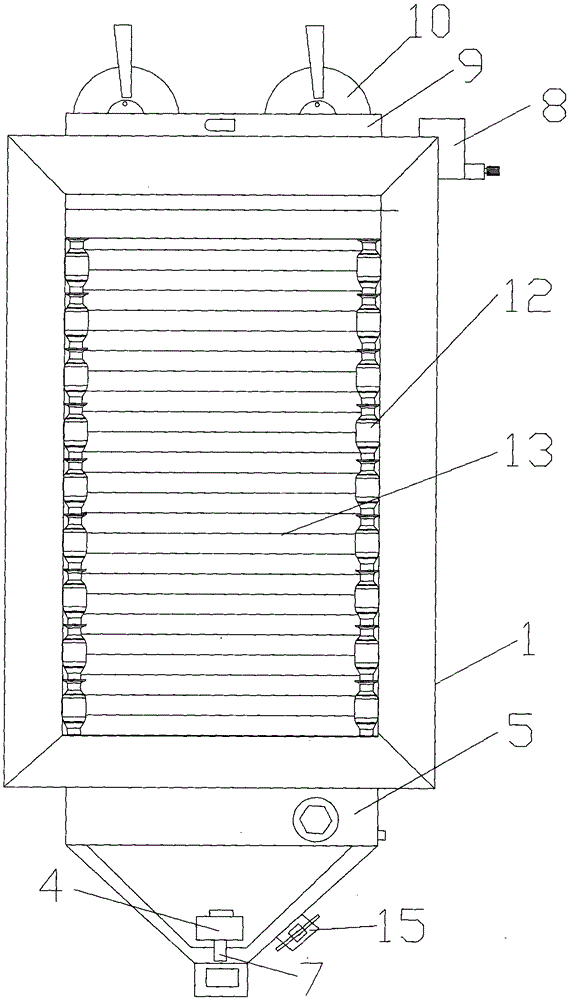

Fertilizer spreading machine

ActiveCN103283365AImprove spreading efficiencyImprove spreading qualityFertiliser distributersAgriculture gas emission reductionCircular discGear pump

The invention discloses a fertilizer spreading machine, relating to the technical field of agricultural machinery. The fertilizer spreading machine comprises a fertilizer tank, a chassis and a connection frame connected with a tractor, wherein a walking mechanism is arranged below the chassis; a gear pump is fixed on the connection frame; the gear pump is connected with a drive system of the tractor through a transmission shaft; a discharge door is arranged at the rear part of the fertilizer tank; the discharge door is lifted up and down through the opening / closing of the discharge door so as to control the fertilizer spreading quantity; multiple fertilizer spreaders are arranged below the discharge door; the fertilizer spreader comprises a disk, a rotary shaft arranged at the center of the disk and multiple fertilizer spreading slots uniformly distributed along the radial direction of the circumference of the disk; a gear shaft is arranged on the each of the two sides in the fertilizer tank; multiple transfer plates are arranged between the gear shafts; a speed reducer is arranged at the rear part of the fertilizer tank; the gear shafts are driven to run through the speed reducer. The fertilizer spreading machine disclosed by the invention realizes an automatic fertilizer spreading process, greatly improves the fertilizer spreading efficiency and the fertilizer spreading quality, and has the advantages of simplicity in operation, reliability in use, strong adaptability and high operation efficiency.

Owner:SHANDONG TIANSHENG MACHINERY

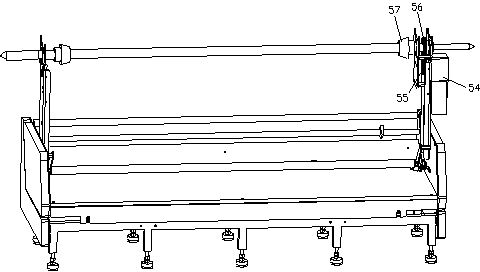

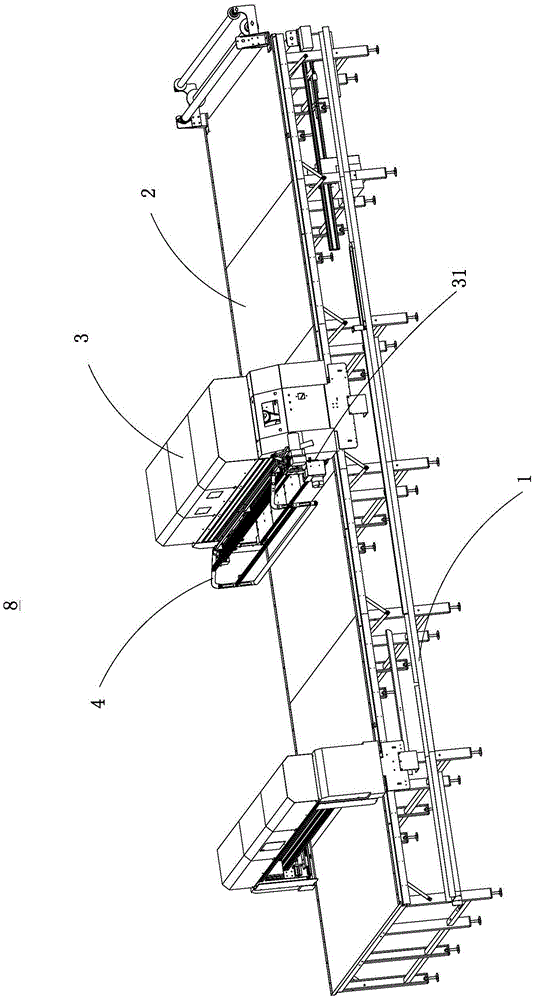

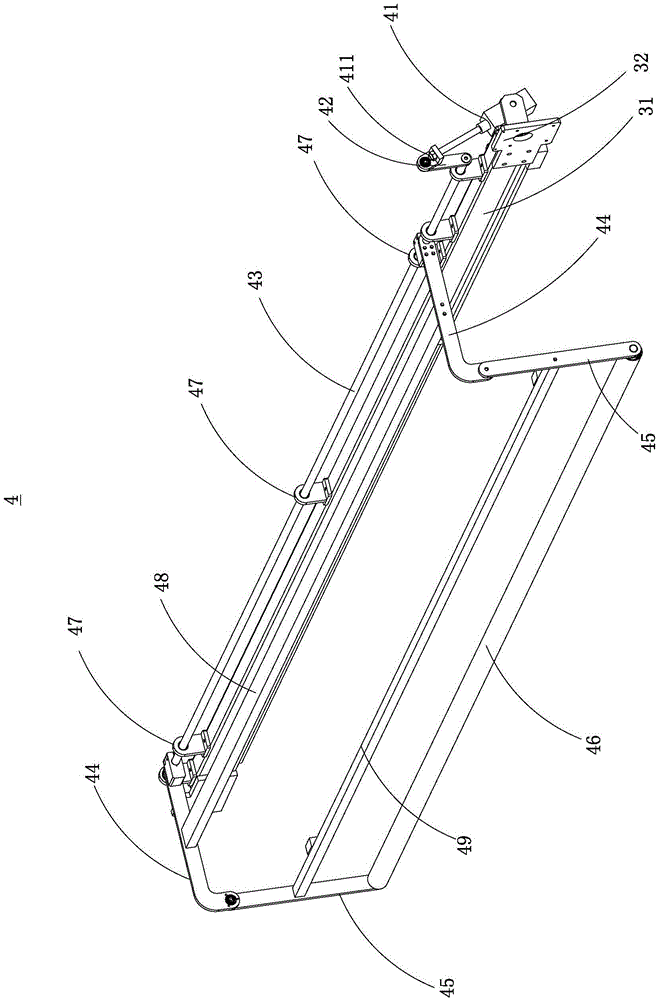

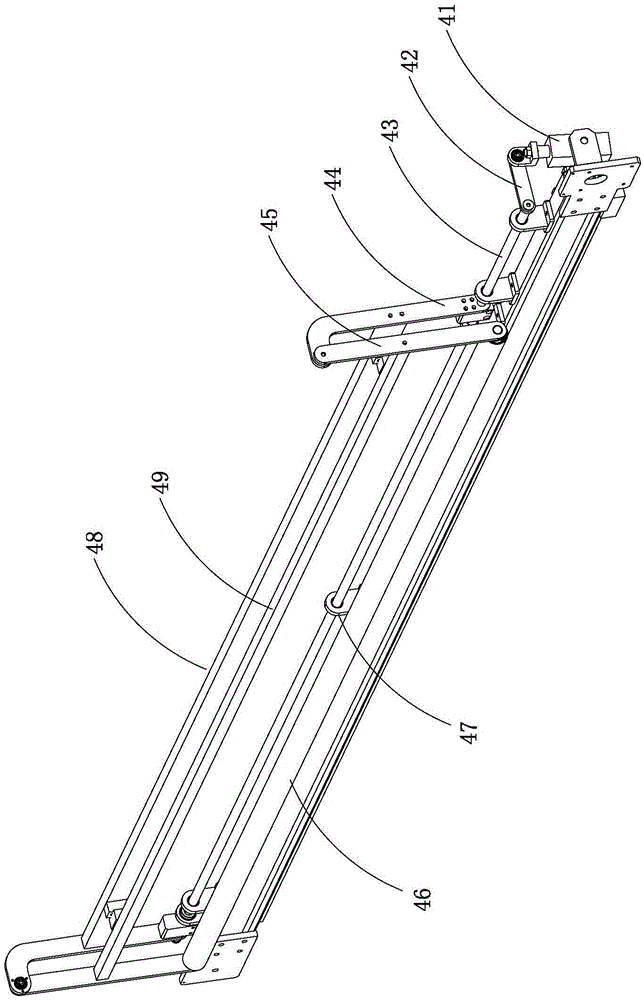

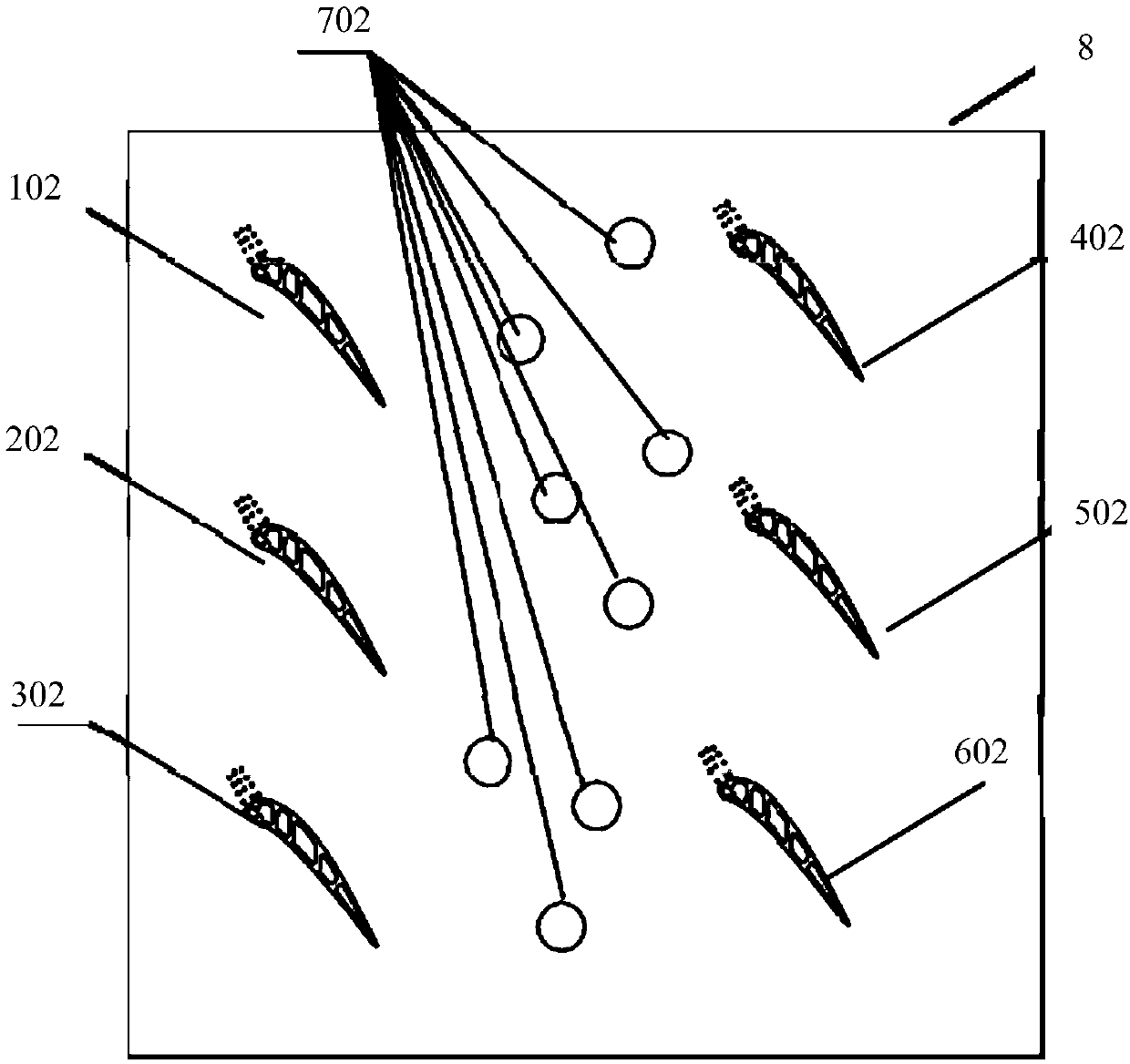

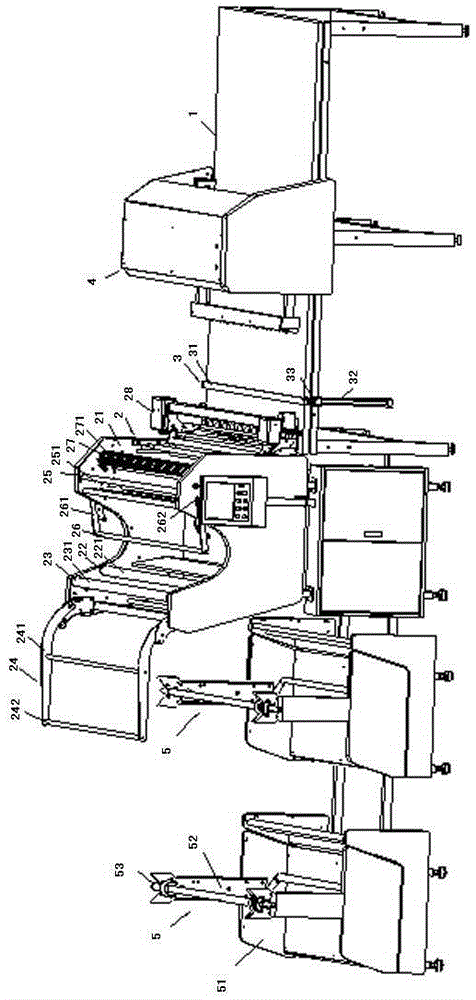

Automatic cloth laying machine and automatic cloth finishing device thereof

InactiveCN105480775AImprove spreading qualityImprove spreading efficiencyUnfolding thin materialsEngineeringMechanical engineering

An automatic cloth finishing device is arranged on a knife rest of an automatic cloth laying machine. The automatic cloth finishing device comprises a drive piece, drive connecting arms, a rotary shaft, first swing arms, second swing arms and a cloth finishing piece. One end of the rotary shaft is fixedly sleeved with one ends of the drive connecting arms. The rotary shaft is supported on the knife rest through multiple supporting seats arranged on the knife rest. The rotary shaft is rotationally connected with a supporting frame. One end of each first swing arm is fixedly connected to the rotary shaft. The other end of each first swing arm is movably connected with one end of the corresponding second swing arm. The second swing arms can rotate around the connecting points of the first swing arms and the second swing arms. The other ends of the second swing arms are connected with the cloth finishing piece. Drive pieces drive the drive connecting arms to rotate. The drive pieces drive the cloth finishing piece to be switched between the cloth finishing position and the collection position in a reciprocating manner through linkage of the drive connecting arms, the rotary shaft, the first swing arms and the second swing arms. The invention further discloses an automatic cloth laying machine with the automatic cloth finishing device.

Owner:SHAGNHAI YIN SCI&TECH CO LTD

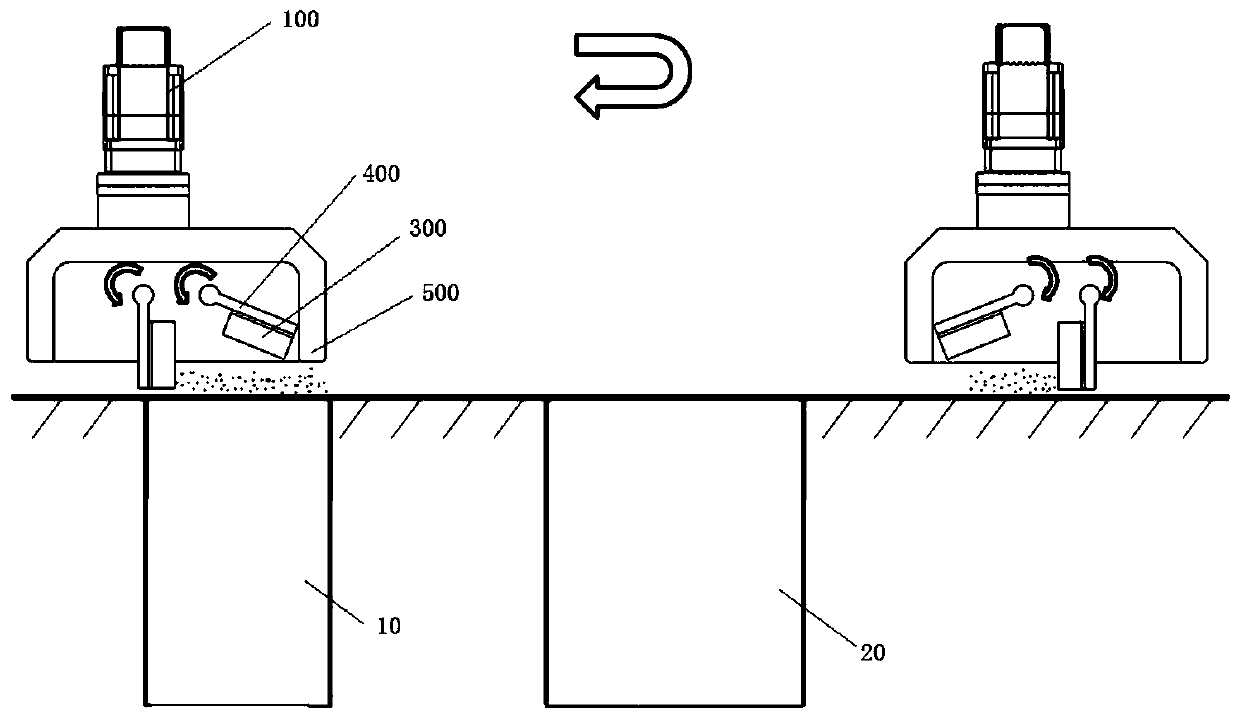

Automatic scraper judging and selecting method for powder bed additive manufacturing

ActiveCN110340354AReduced risk of deformationAvoid jamming the scraperAdditive manufacturing apparatusIncreasing energy efficiencyEngineeringSelf adaptive

The invention provides an automatic scraper judging and selecting method for powder bed additive manufacturing. The automatic scraper judging and selecting method for powder bed additive manufacturingcomprises the following steps of S1, calculating and judging information of a cross section to be sintered; S2, carrying out linkage operation through an automatic scraper replacement mechanism; andS3, actually forming a part. The automatic scraper judging and selecting method for powder bed additive manufacturing provided by the invention has the following advantages that (1) a scraper is prevented from getting stuck: the scraper is self-adaptively selected after judging the cross section, and the damage of a weak structure is avoided, so that the scraper is prevented from getting stuck, and the risk of the deformation of the weak structure is reduced; (2) the forming quality and the batch stability of parts are improved: the powder paving quality can be improved, the local deformationof a formed part is reduced, and the forming quality of each layer is improved, so that the forming quality and the batch stability of the parts are improved; and (3) the production efficiency is improved: a user has no need to spend time on handling the problem that the scraper gets stuck, so that the production efficiency is improved.

Owner:AECC COMML AIRCRAFT ENGINE CO LTD

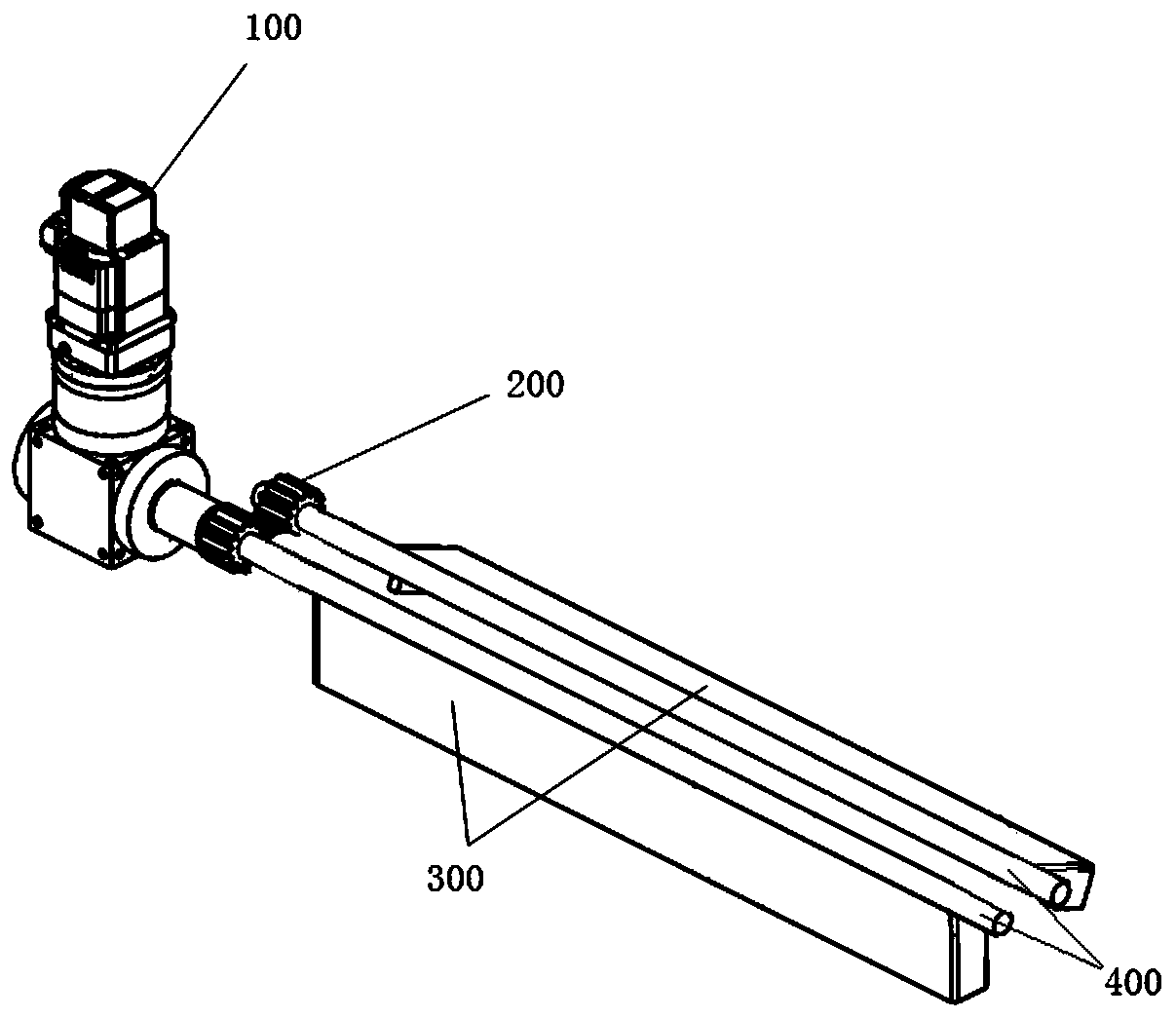

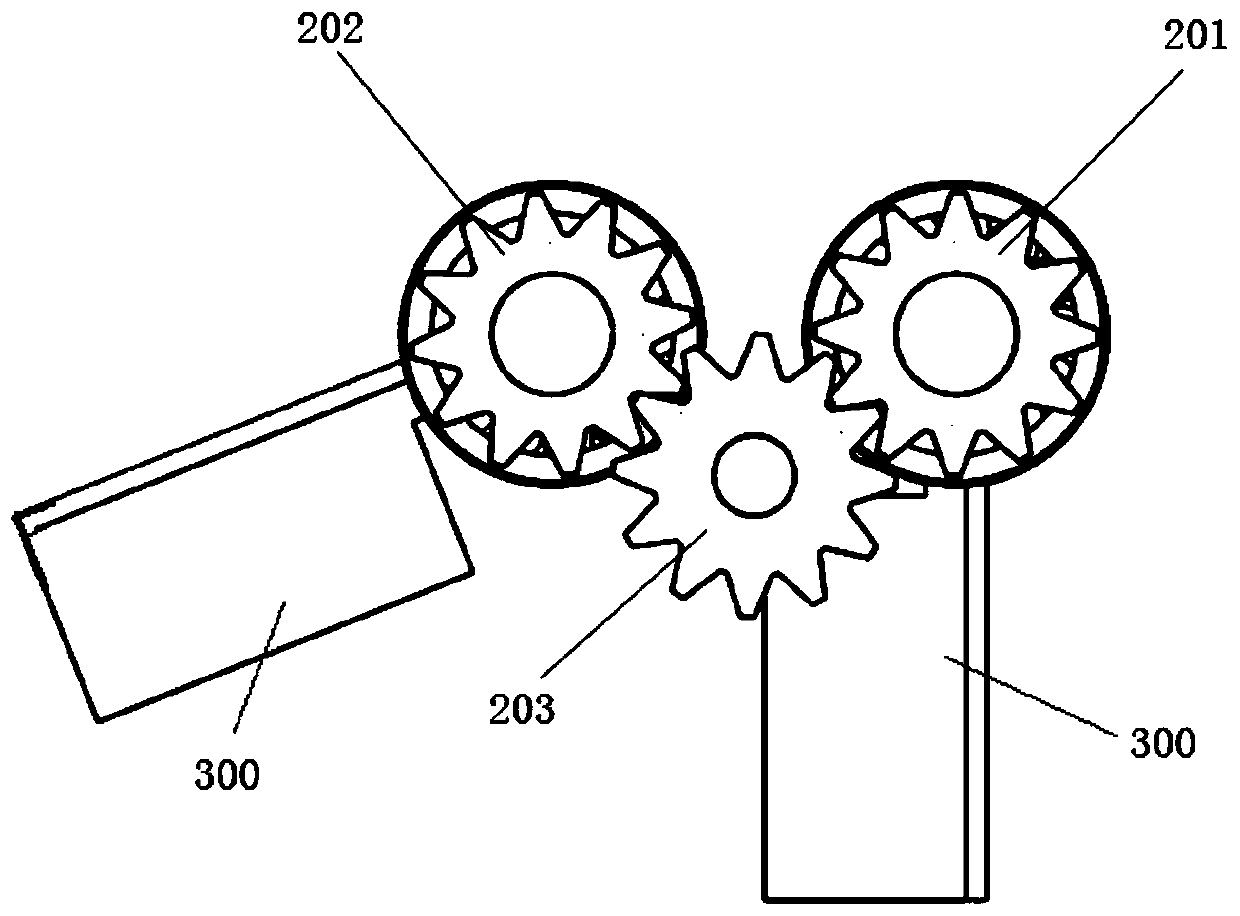

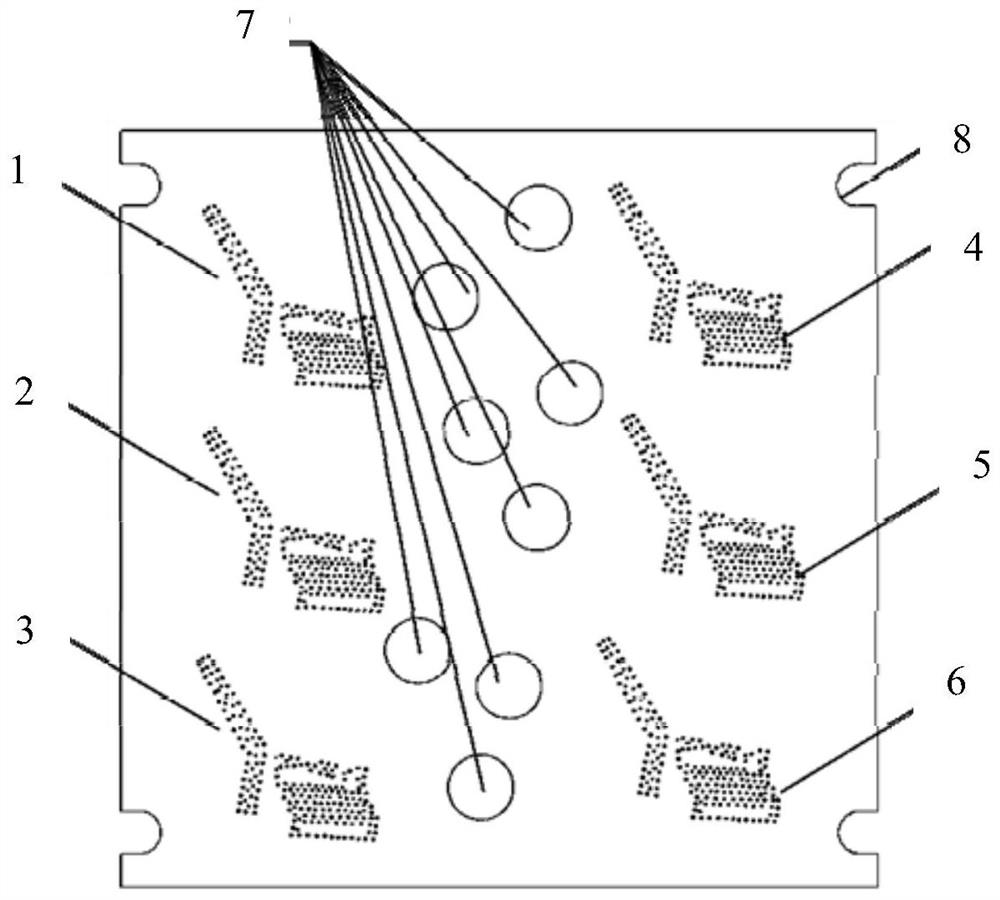

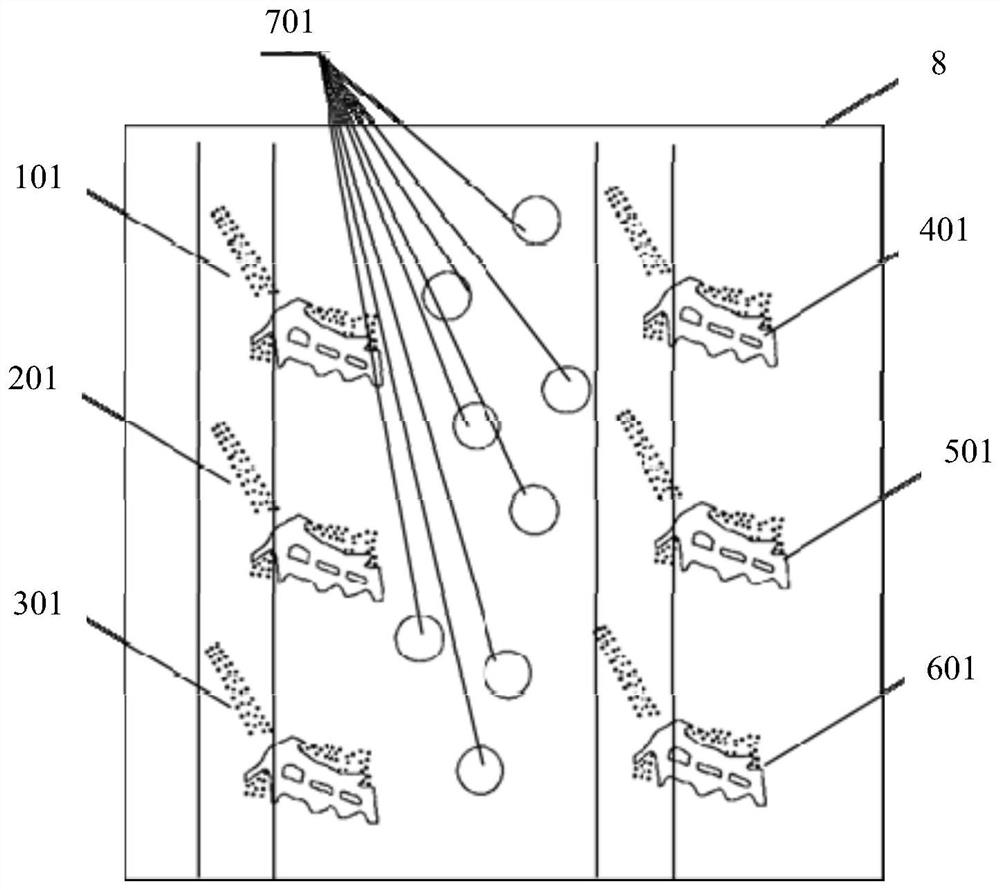

Powder spreading device and 3D printing apparatus

ActiveCN110947967AImprove printing qualityImprove spreading qualityAdditive manufacturing apparatusIncreasing energy efficiencyGear wheelElectrical and Electronics engineering

The embodiment of the invention relates to a powder spreading device and a 3D printing apparatus. The powder spreading device comprises a driving device, a transmission gear set and two scrapers. Thetransmission gear set is driven by the driving device to rotate. The two scrapers is connected with the transmission gear set and driven by the transmission gear set to rotate. The two scrapers of thepowder spreading device can be driven by the transmission gear set to rotate by a certain angle, powder spreading can be performed both in the power sending process and the powder returning process,the powder spreading quality is improved, and therefore the printing quality of parts is improved.

Owner:西安赛隆增材技术股份有限公司

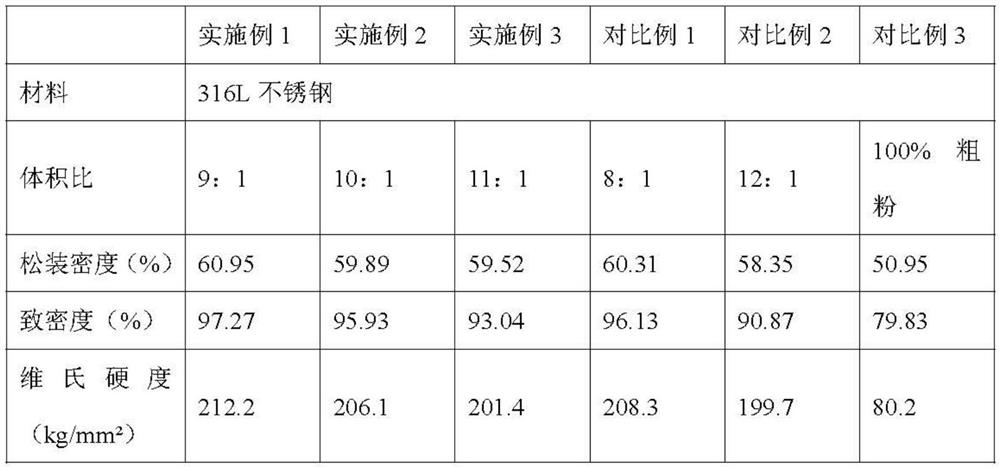

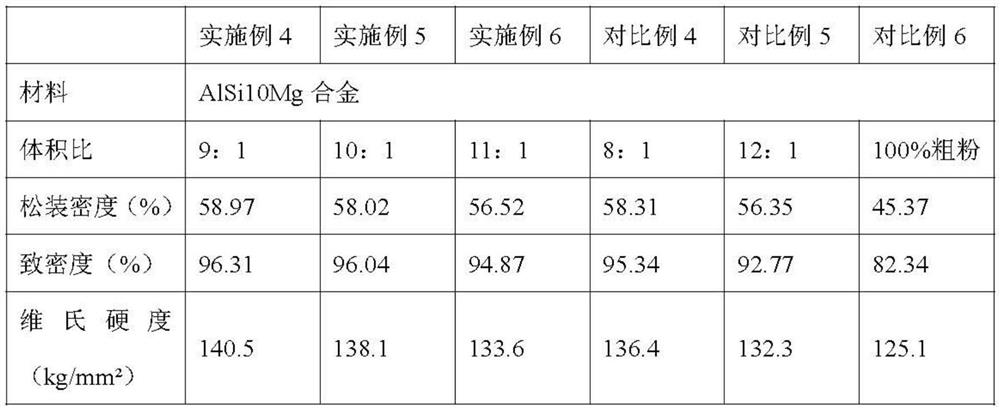

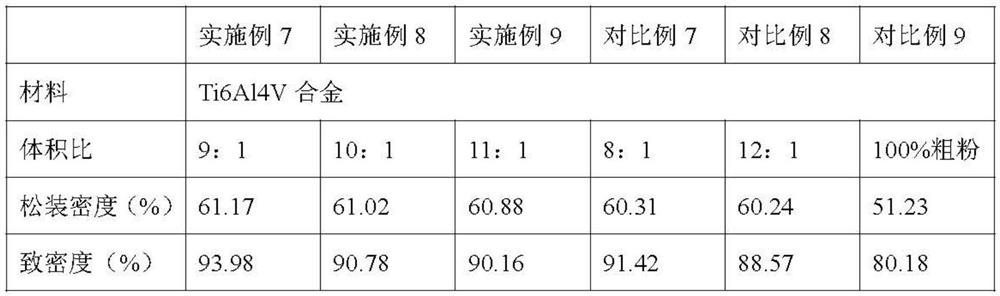

Mixed powder for 3D printing and 3D printing method

PendingCN114535596AGood powder spreading effectHigh bulk densityAdditive manufacturing apparatusTransportation and packaging3d printHigh density

The invention discloses mixed powder for 3D printing and a 3D printing method.The mixed powder for 3D printing comprises coarse powder and fine powder, the particle size of the coarse powder ranges from 15 micrometers to 43 micrometers, the particle size of the fine powder ranges from 5 micrometers to 7 micrometers, the volume ratio of the coarse powder to the fine powder ranges from 8: 1 to 11: 1, and the particle size of the fine powder ranges from 5 micrometers to 7 micrometers. The coarse powder is selected from at least one of metal powder, and the coarse powder is spherical powder. The fine powder is used for filling pore parts among coarse powder particles, the surface roughness of a powder layer is reduced, the powder laying quality of the 3D printing powder is effectively improved, and therefore better powder stability is achieved; the mixed powder has very high bulk density on a powder bed, so that higher density of a printed green body is obtained, and the final sintering density and mechanical property of a printed piece are remarkably improved.

Owner:广东金瓷三维技术有限公司 +2

Double roll cloth cloth machine

ActiveCN103318691BImprove work efficiencyImprove spreading qualityUnfolding thin materialsArticle deliveryMechanical engineeringCotton material

This double-roll cloth cloth machine includes a bed, a main machine, a cloth pressing mechanism on the bedding bed, and a manipulator clamping mechanism slid on the bedding bed. On the side of the main machine, there are two roll fabric supports arranged in front and rear. Mechanism, implements double-roll roll cloth feeding. There are two spreading mechanisms on the main machine, which respectively spread the fabric on the two roll fabric support mechanisms. Behind the two spreading mechanisms, there is a rear rack to support A reel cloth supporting mechanism is installed at the rear to feed the cloth, and a front spreading mechanism is set in front of the two spreading mechanisms, and a pressing bar is set between the two spreading mechanisms and the front spreading mechanism, and the two spreading mechanisms send The cloth is overlapped under the pressure bar and then sent to the front spreading mechanism; there is a cloth feeding mechanism in front of the front spreading mechanism, and a cloth cutting device is installed under the feeding mechanism. The advantage is that it can carry out double-roll roll cloth spreading at the same time, and it uses the manipulator to clamp the cloth for single pulling and folding, with accurate positioning, high precision, neat folding and high work efficiency.

Owner:YYC IND CO LTD CHINA

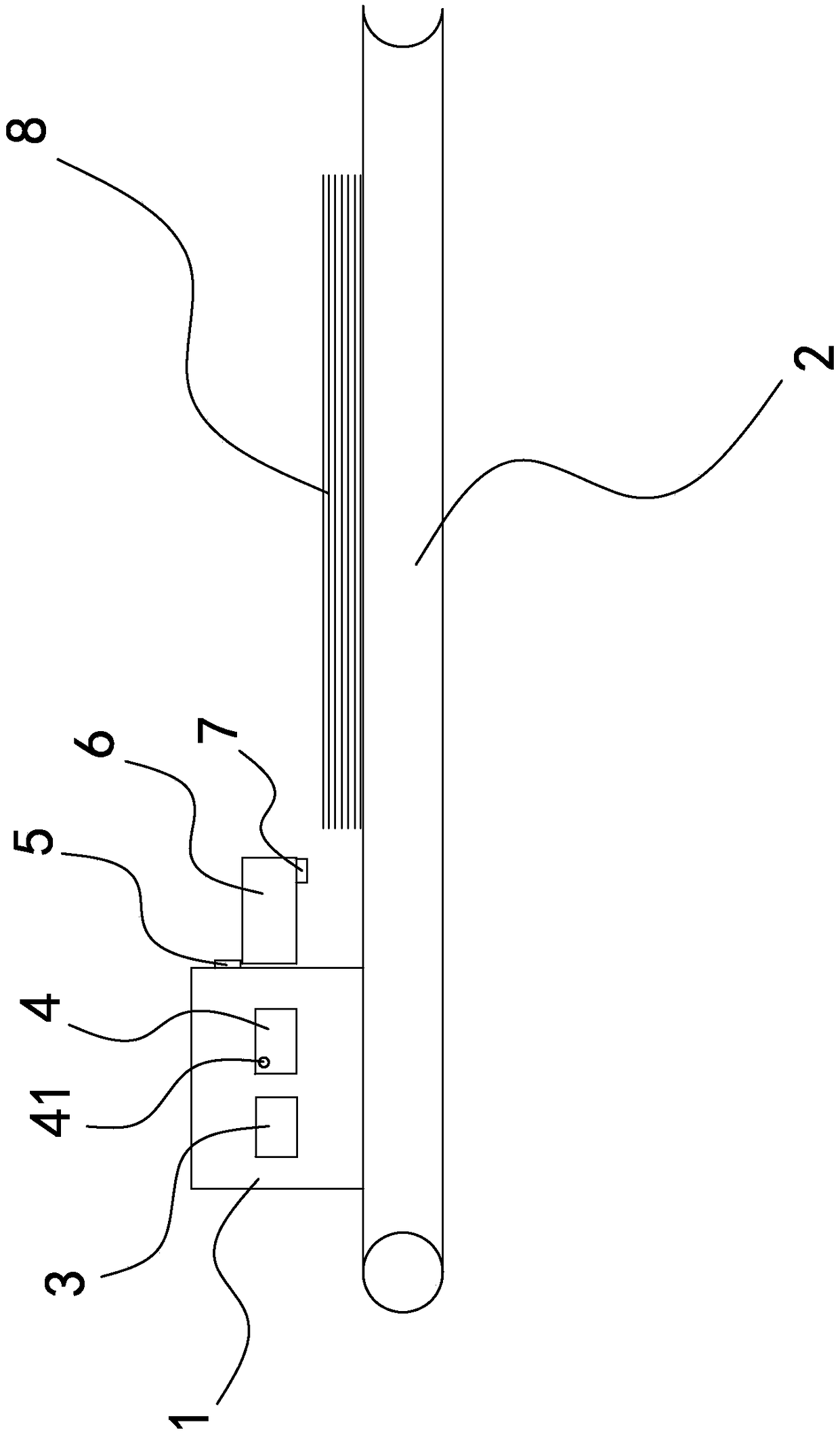

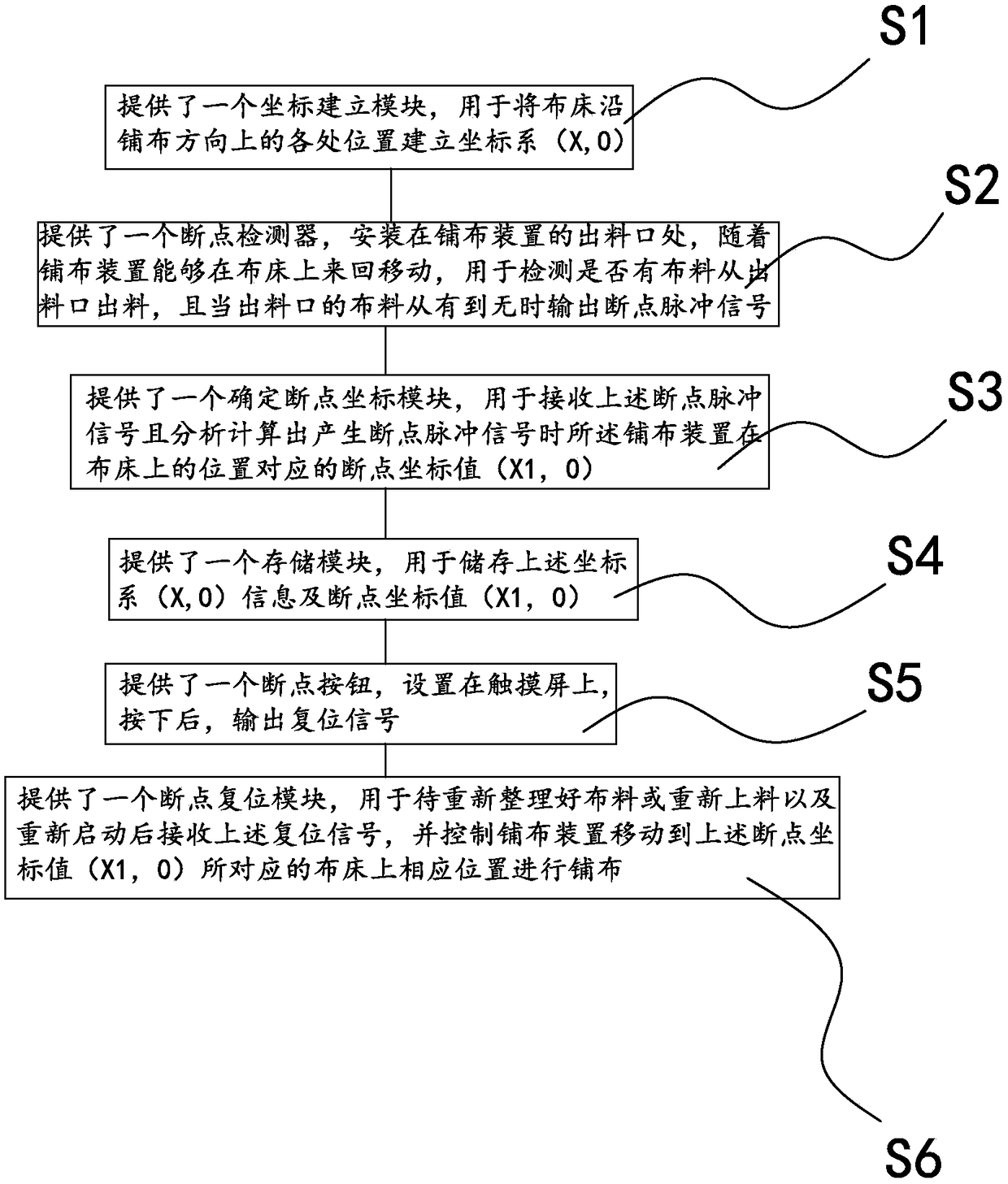

Automatic break point memory returning system for cloth spreader and control method

ActiveCN108776454AHigh degree of automationImprove spreading qualityProgramme control in sequence/logic controllersBreak pointBreaking point

The invention provides an automatic break point memory returning system for a cloth spreader and a control method, belongs to the cloth spreader control technology field and solves problems of low efficiency and low automation degree caused by manual movement to the break point position after a cloth spreader has a cloth break point in the prior art. The automatic returning system comprises a break point detector, a break point button and a controller used for establishing a coordinate system (X, 0) along the position of a cloth bed in the cloth spreading direction, receiving a break point pulse signal, analyzing and calculating a break point coordinate value (X1, 0) corresponding to the position of the cloth spreader on the cloth bed when the break point pulse signal is generated, receiving a reset signal and further controlling the cloth spreader for moving to the corresponding position on the cloth bed corresponding to the break point coordinate value (X1, 0) for cloth spreading. The automatic break point memory returning system is advantaged in that the break point can be automatically identified, the cloth spreader can be automatically reset to the break point, the automationdegree is high, and efficiency is high.

Owner:BULLMER ELECTROMECHANICAL TECH

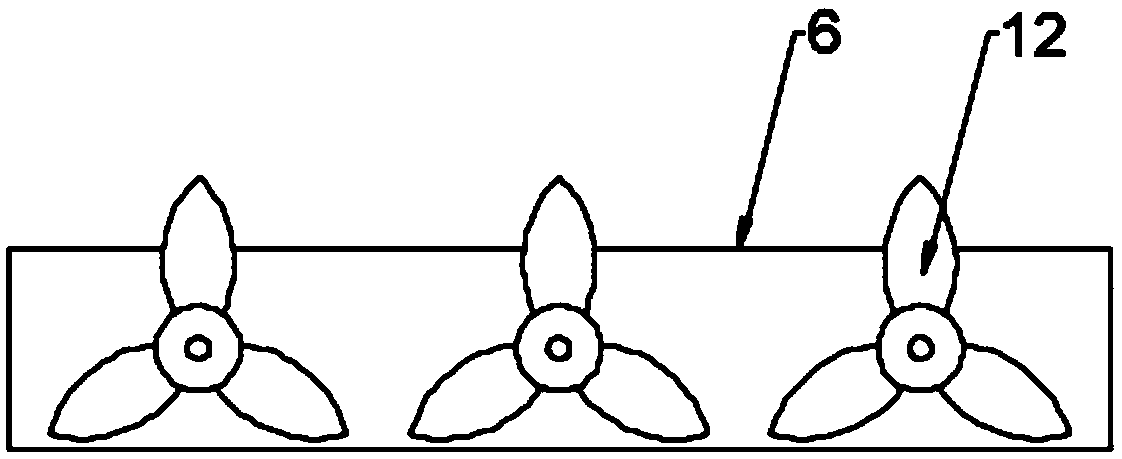

Soil pollution restoration material spreading equipment based on blowing and spreading technology

InactiveCN108620424AImprove spreading qualityGuaranteed normal spreadingSoil lifting machinesContaminated soil reclamationEngineeringWindmill

The invention discloses soil pollution restoration material spreading equipment based on a blowing and spreading technology. The soil pollution restoration material spreading equipment comprises a bottom disc, a material spreading box and a material storage box, wherein the material spreading box is embedded in the center of the bottom disc; the top end of the material spreading box is in throughconnection with a connection pipe; a material spreading plate is arranged under the material spreading box; a plurality of fixing rods and a plurality of discharging pipes are uniformly arranged on the top end of the material spreading plate; the left side end of the material spreading plate is uniformly provided with a plurality of material spreading holes; the right side end of the material spreading plate is uniformly provided with a plurality of support frame rods; the other ends of the support frame rods are rotationally connected with a windmill; the edge of the top end surface of the bottom disc is uniformly provided with a plurality of support rods; the top ends of the support rods are fixedly connected with a material storage box; the top end of the material storage box is communicated and connected with a feeding pipe; the bottom end of the bottom disc is uniformly provided with a plurality of walking wheels. Through the arrangement of the windmill, during the walking, the windmill rotates, so that the airflow near the material spreading plate becomes spiral airflow; the restoration material discharged from the material spreading holes can be blown, so that the restoration material can be spread in the fixed direction; therefore the spreading quality of the restoration material can be greatly improved.

Owner:COMMON TECH DEV CO LTD

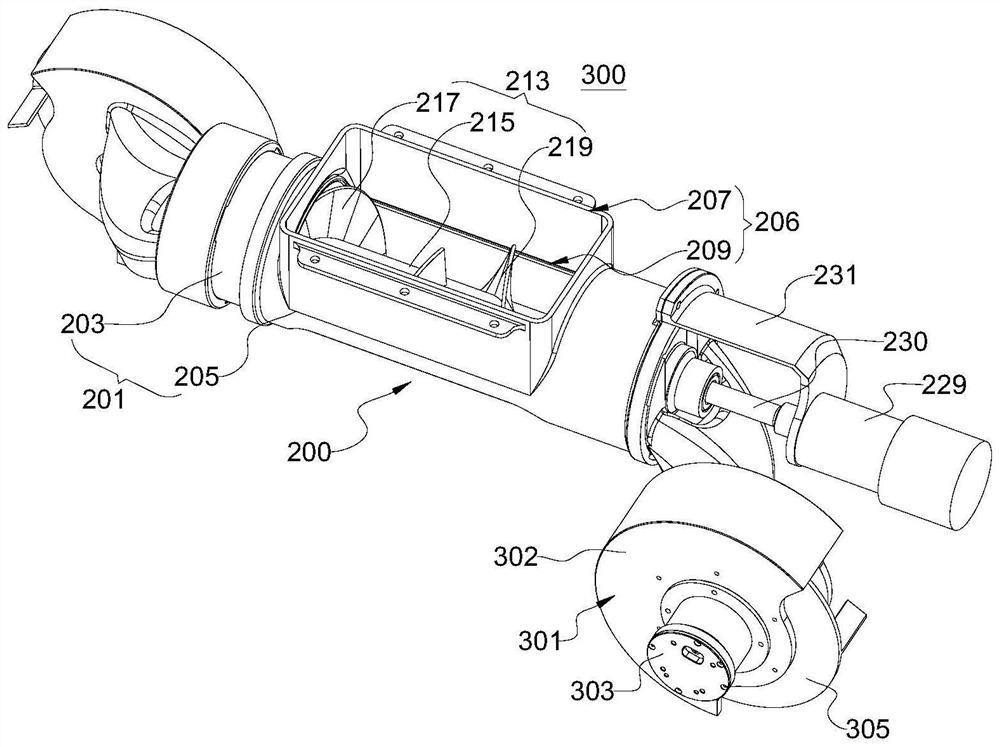

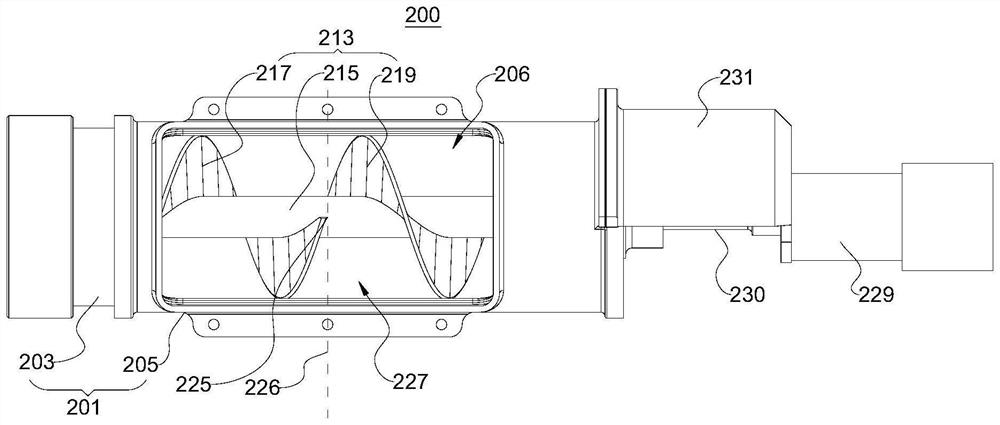

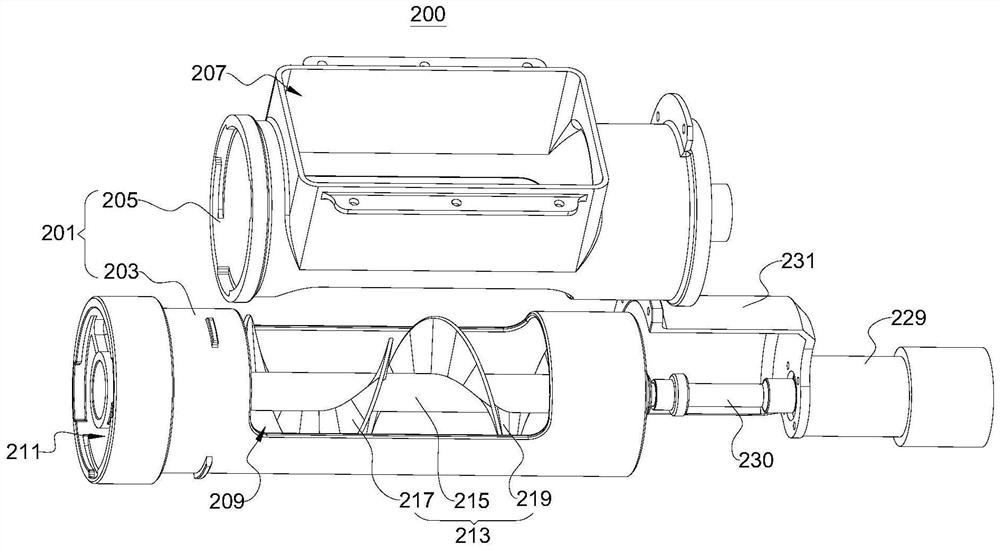

Feeding device, sowing equipment and unmanned aerial vehicle

PendingCN114229354ASimplify the feeding structureImprove the single feeding methodAircraft componentsFertiliser distributersAgricultural engineeringSowing

The invention discloses a feeding device, sowing equipment and an unmanned aerial vehicle, and relates to the field of material conveying. The feeding device comprises a feeding shell and a feeding piece. The feeding shell is provided with an inlet and two outlets, the inlet is used for inputting materials, and the outlets are used for outputting the materials; the feeding part comprises a feeding shaft and blades spirally arranged in the circumferential direction of the feeding shaft, the feeding shaft is movably arranged in the feeding shell, at least part of the blades are opposite to the inlet, and the blades are used for equivalently conveying materials to the two outlets when the feeding shaft rotates. On one hand, the feeding device can convey materials to the two outlets at the same time, the feeding structure can be effectively simplified, the problem that the feeding mode is single is solved, various feeding requirements are met, the feeding device can be suitable for sowing operation with two sowing devices, and therefore the sowing amplitude is fully guaranteed; and on the other hand, the two outlets are used for discharging in an equivalent manner, so that the discharging uniformity of the two outlets can be ensured, the uniformity of the sowing operation of each sowing device is ensured, and the sowing quality is ensured.

Owner:GUANGZHOU XAIRCRAFT TECH CO LTD

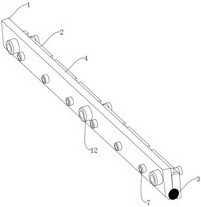

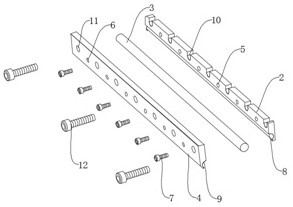

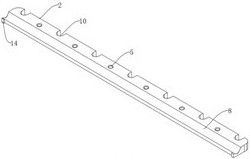

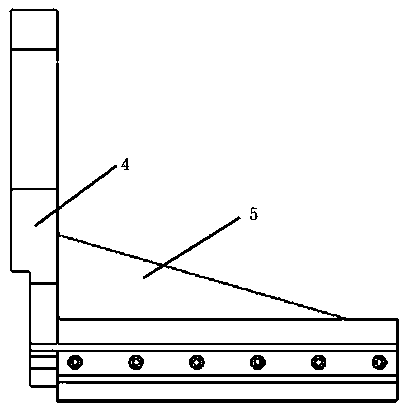

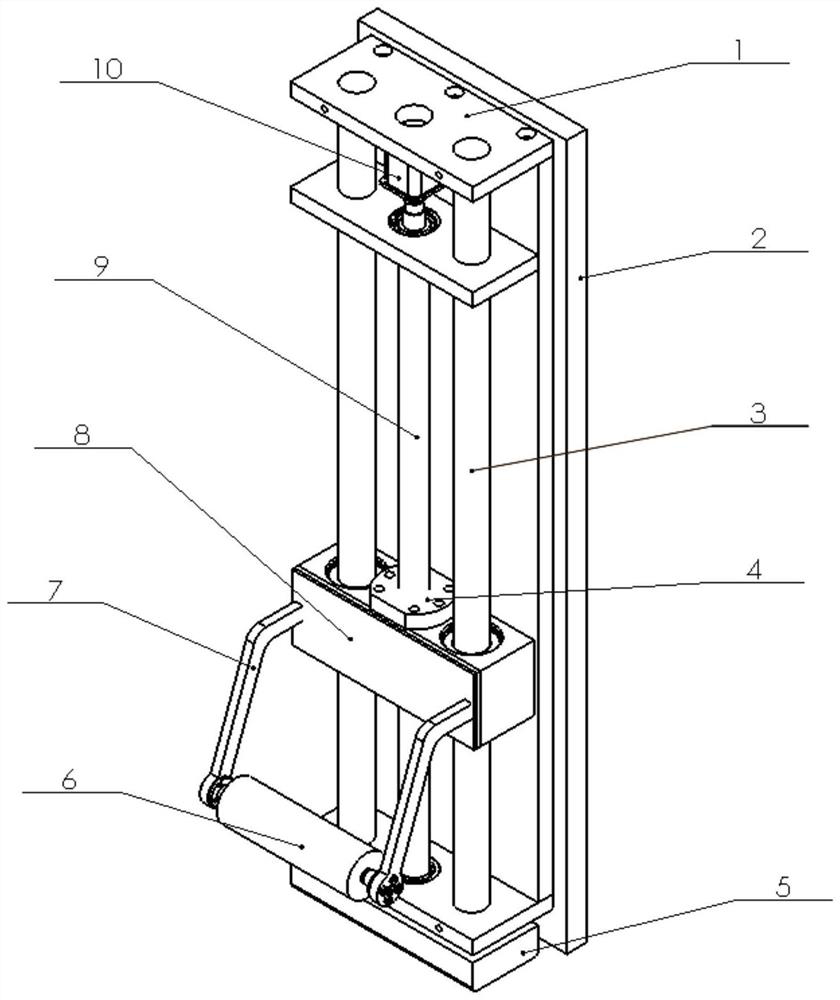

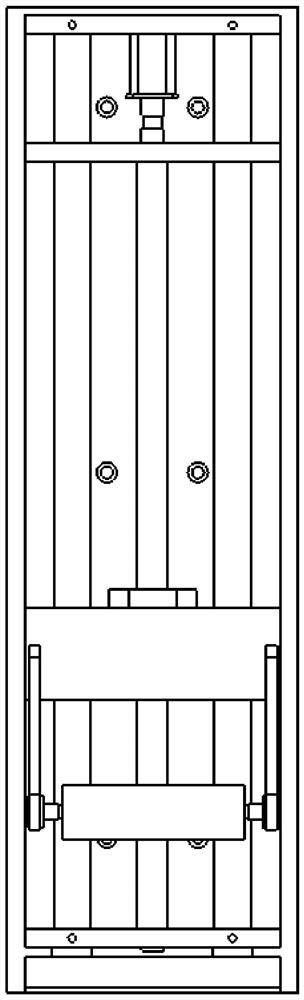

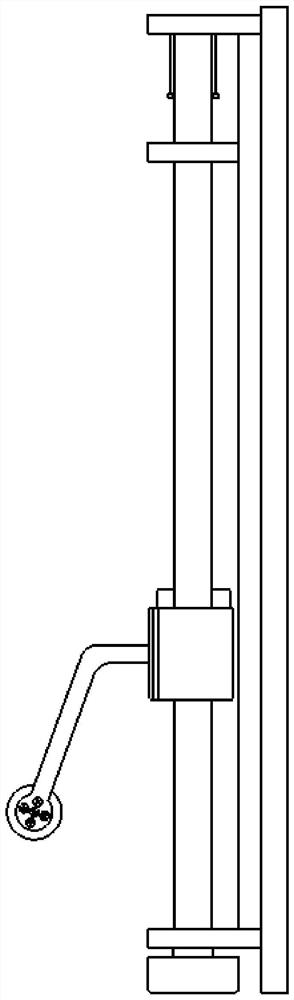

Powder laying device suitable for metal selective laser melting forming equipment

InactiveCN112372000ARealize fast installationStable supportAdditive manufacturing apparatusSelective laser meltingEngineering

The invention discloses a powder laying device suitable for metal selective laser melting forming equipment. The powder laying device suitable for the metal selective laser melting forming equipment comprises a device body, the device body is composed of a scraper bottom plate, an adhesive tape and a scraper cover plate, and a plurality of first threaded holes distributed in a linear array mode are formed in the outer side of the scraper bottom plate. A plurality of second threaded holes distributed in a linear array mode are formed in the surface of the scraper cover plate, and first fastening screws are arranged between the interiors of the first threaded holes and the interiors of the second threaded holes. According to the powder laying device suitable for the metal selective laser melting forming equipment, the device body is fixed to an equipment material boot through second fastening screws, under cooperation of a bottom plate concave groove, a cover plate concave groove and a boss, it is guaranteed that through holes have good supporting performance on the adhesive tape, a deformation tolerance space is reserved, it is guaranteed that a production task is smoothly completedunder the condition of local deformation, and stable and uniform powder laying operation is facilitated; and the powder laying device is provided with a rubber soft scraper between a hard scraper anda brush scraper, and the printing success rate is increased on the premise that the forming quality is guaranteed.

Owner:吉凯恩(丹阳)工业有限公司

Multifunctional plow leg and sowing turnplow

InactiveCN102210210AEasy to manufactureEasy to useSeed depositing seeder partsBroadcast seedersEngineeringHilling

The invention discloses a multifunctional plow leg and a sowing turnplow. The multifunctional plow leg and the sowing turnplow are mounted and adjusted according to needs so as to achieve multiple functions, and are widely applied to sowing (most of crops are suitable for sowing), row seeding, lifting ridges, cutting stubbles, forming gullies, hilling and doing other farm work. The structure is that: the upper part of the plow leg is provided with square steel; a sleeve is arranged on the square steel and is fixed with a seeder; the lower part of the plow leg is provided with an improved hoeing leg; the sowing turnplow is arranged at the top end of the plow leg; a pull rod is arranged on the sowing turnplow; the upper end of the pull rod is arranged on a clamp on front of the plow leg; a screw cap is screwed for fixation; rotatable left and right sowing plates are arranged inside the sowing turnplow, and are adjustable to spread seed manure widely and uniformly; the sowing plates rotate outwards to perform row seeding and rotate inwards to perform double-ridge row seeding; a soil covering device is arranged behind the plow leg; an upper end of a spring rod of the soil covering device is arranged on a spring rod clamp for fixing the plow leg; and for lifting ridges, forming gullies and hilling, the soil covering device is not arranged, a reverse turnplow is arranged on one side of the sowing turnplow to lift ridges, and reverse turnplows are arranged on two side of the sowing turnplow to perform gully formation and hilling.

Owner:武宗成

Biological strain throwing device for agricultural straws returning to lands

InactiveCN111630968AImprove spreading efficiencyEvenly distributedSoil lifting machinesAgricultural machinesAgricultural scienceElectric machinery

The invention discloses a biological strain throwing device for agricultural straws returning to lands, and relates to the technical field of agriculture. The biological strain throwing device aims atsolving the problems that in a manual throwing process, the phenomenon that local biological strains are too many or too little is likely to be caused, and the phenomenon of incomplete rotting or strain waste is caused. The biological strain throwing device specifically comprises a frame, driving motors are fixedly installed on the two sides of the frame, a rolling wheel is fixedly installed on an output shaft of each driving motor, and a supporting frame is fixedly installed at the top end of the frame. According to the biological strain throwing device, due to the mixing range and the mixing efficiency between biological strains and soil particles, after floating soil is contaminated by the biological strains, the floating soil falls onto throwing blades rotating rapidly, the two throwing blades rotating in a staggered mode throw the falling soil particles to the periphery rapidly, the biological strain throwing efficiency is improved, the labor amount of workers is reduced, the biological strains are distributed more evenly, the straw rotting speed is increased, rotting dead zones are prevented from being left in a field, and the yield is increased.

Owner:烟台浩景农业科技有限公司

Improved new energy power vehicle

The invention discloses an improved new energy power vehicle. The improved new energy power vehicle comprises a base and a seeder installed at the top of the base, a seed adding groove is formed in the top surface of the seeder, a through groove is formed in the bottom of the seed adding groove in a penetrating manner, an inclined slide groove is formed in the top of the inner wall on the right side of the seed adding groove, a stirring cavity is arranged at the bottom of the through groove in a penetrating manner, a rotary stirring device is arranged in the stirring cavity, a seed discharge port is formed in the bottom of the stirring cavity in a penetrating manner, a sowing cavity extending to the right side is arranged at the bottom part of the seed discharge port in a penetrating manner, a sowing device is arranged in the sowing cavity, a second slide groove extending left and right is formed in the interior of the seed discharge port in a penetrating manner, a first slide guide groove extending downwards is formed in the extending tail end of the left side of the second slide groove in a penetrating manner, a first slide groove extending upwards is formed in the tail end of the left side of the first slide guide groove in a penetrating manner, and a slide stopping plate extending left and right is smoothly connected with the second slide groove in a matched way. The improved new energy power vehicle is simple in structure and convenient to operate, the electric energy power is clean and pollution-free, and the sowing quality of seeds is improved.

Owner:方新刚

Automatic scraper judgment and selection method for powder bed additive manufacturing

ActiveCN110340354BReduced risk of deformationAvoid jamming the scraperAdditive manufacturing apparatusIncreasing energy efficiencyStructural deformationPowder bed

Owner:AECC COMML AIRCRAFT ENGINE CO LTD

fertilizer spreader

ActiveCN103283365BImprove spreading efficiencyImprove spreading qualityFertiliser distributersAgriculture gas emission reductionDrive shaftAgricultural engineering

The invention discloses a fertilizer spreading machine, relating to the technical field of agricultural machinery. The fertilizer spreading machine comprises a fertilizer tank, a chassis and a connection frame connected with a tractor, wherein a walking mechanism is arranged below the chassis; a gear pump is fixed on the connection frame; the gear pump is connected with a drive system of the tractor through a transmission shaft; a discharge door is arranged at the rear part of the fertilizer tank; the discharge door is lifted up and down through the opening / closing of the discharge door so as to control the fertilizer spreading quantity; multiple fertilizer spreaders are arranged below the discharge door; the fertilizer spreader comprises a disk, a rotary shaft arranged at the center of the disk and multiple fertilizer spreading slots uniformly distributed along the radial direction of the circumference of the disk; a gear shaft is arranged on the each of the two sides in the fertilizer tank; multiple transfer plates are arranged between the gear shafts; a speed reducer is arranged at the rear part of the fertilizer tank; the gear shafts are driven to run through the speed reducer. The fertilizer spreading machine disclosed by the invention realizes an automatic fertilizer spreading process, greatly improves the fertilizer spreading efficiency and the fertilizer spreading quality, and has the advantages of simplicity in operation, reliability in use, strong adaptability and high operation efficiency.

Owner:SHANDONG TIANSHENG MACHINERY

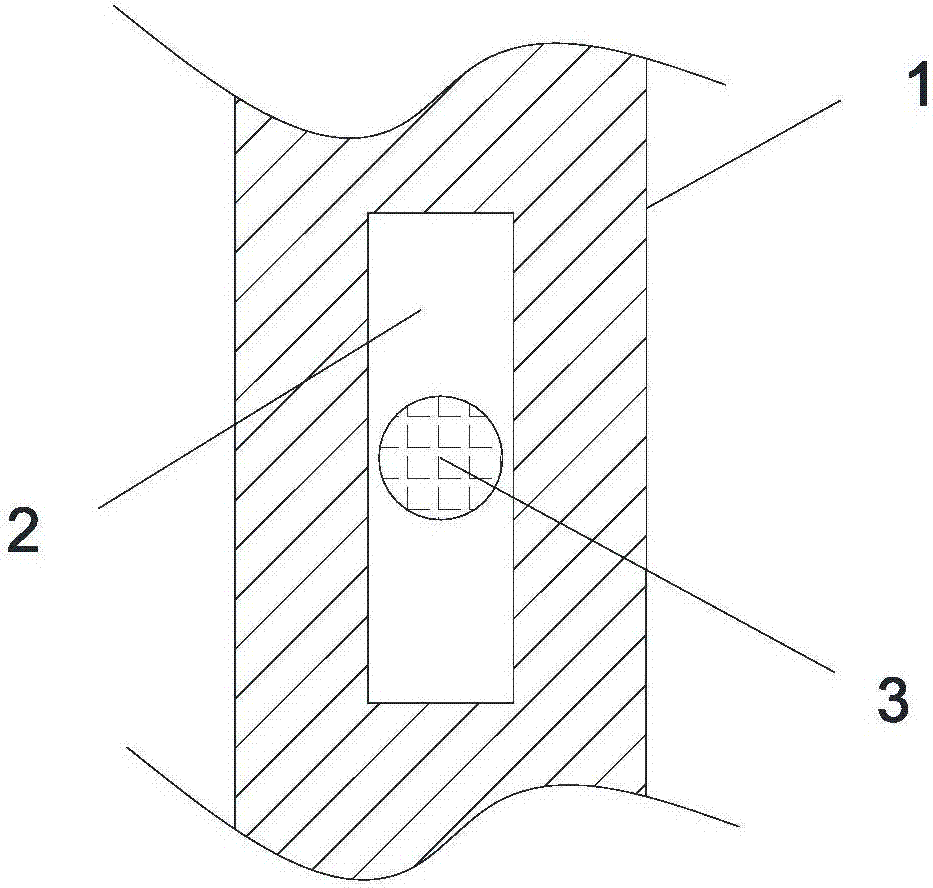

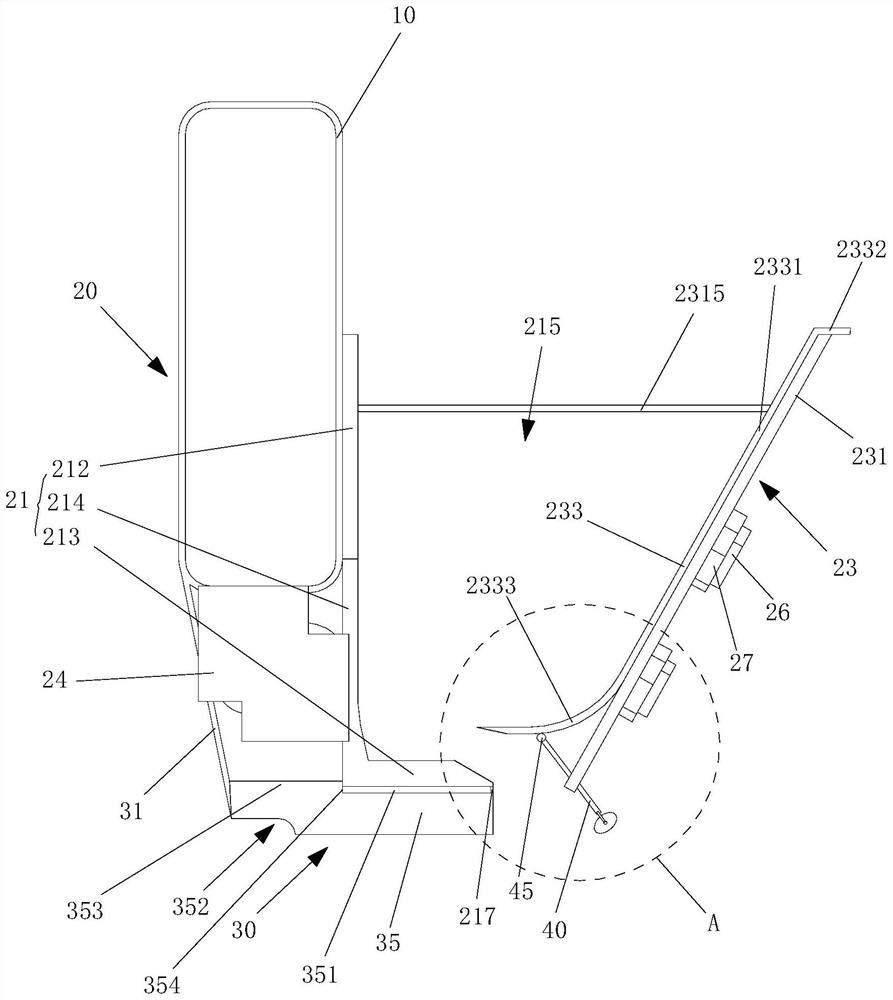

An Adsorption Surface Contact Flexible Powder Spreading Device for Laser Selective Melting Molding System

The invention discloses an adsorption type surface contact flexible powder spreading device of a selective laser melting molding system. The adsorption type surface contact flexible powder spreading device of the selective laser melting molding system comprises a movable bracket A, a negative pressure channel device A, a flexible powder spreading brush, a mounting bracket, a negative pressure channel device B, a movable bracket B; the mounting bracket is internally provided with a negative pressure cavity; the movable bracket A and the movable bracket B are fixed at the two ends of the mounting bracket respectively; an adsorption groove and a powder storage groove are formed in the bottom part of the mounting bracket; the upper plane of the flexible powder spreading brush is adsorbed inside the adsorption groove; a lateral clamping groove of the flexible powder spreading brush is overlapped with the side surface of the adsorption groove; the powder spreading plane of the flexible powder spreading brush protrudes out of the adsorption groove; the negative pressure channel device A and the negative pressure channel device B are mounted on the two ends of the mounting bracket respectively and are communicated with the negative pressure cavity. The adsorption type surface contact flexible powder spreading device of the selective laser melting molding system not only can spread the powder flatly, but also can avoid powder flying phenomenon when a molding surface of a part is uneven. Meanwhile, due to the adoption of the adsorption type mounting way, the adsorption type surface contact flexible powder spreading device is convenient to detach and mount, and has the advantages of good powder spreading effect, use convenience and the like.

Owner:SOUTH CHINA UNIV OF TECH

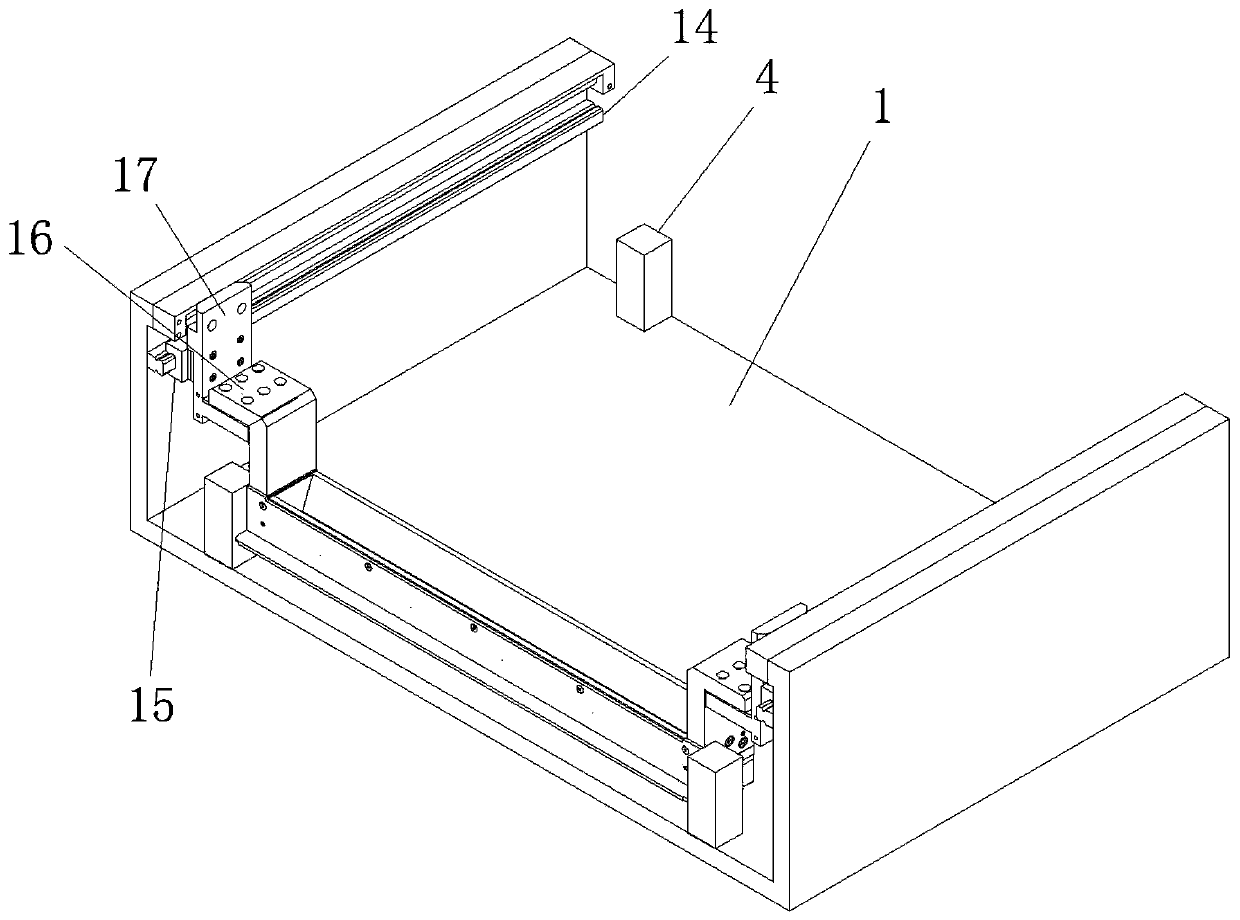

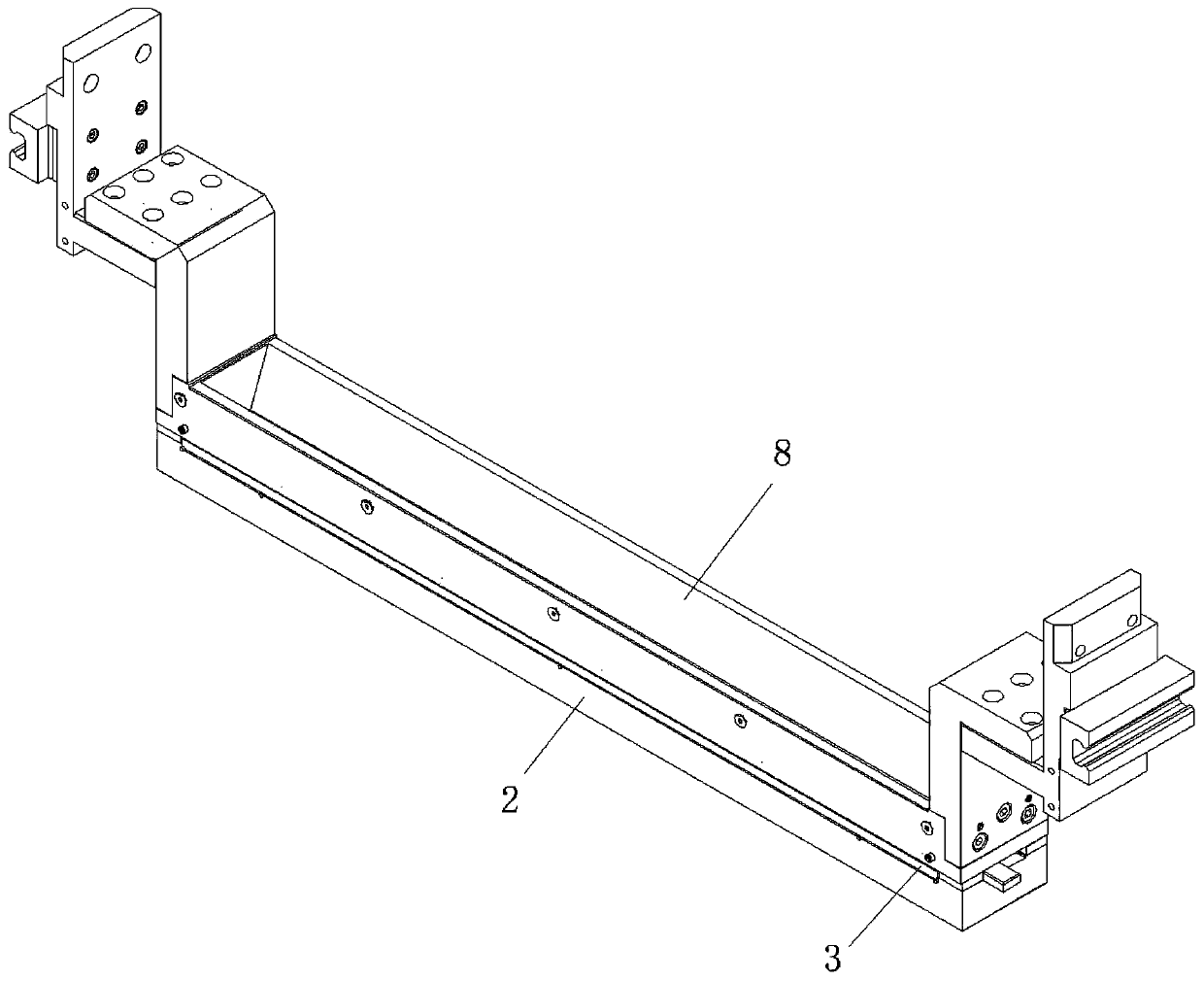

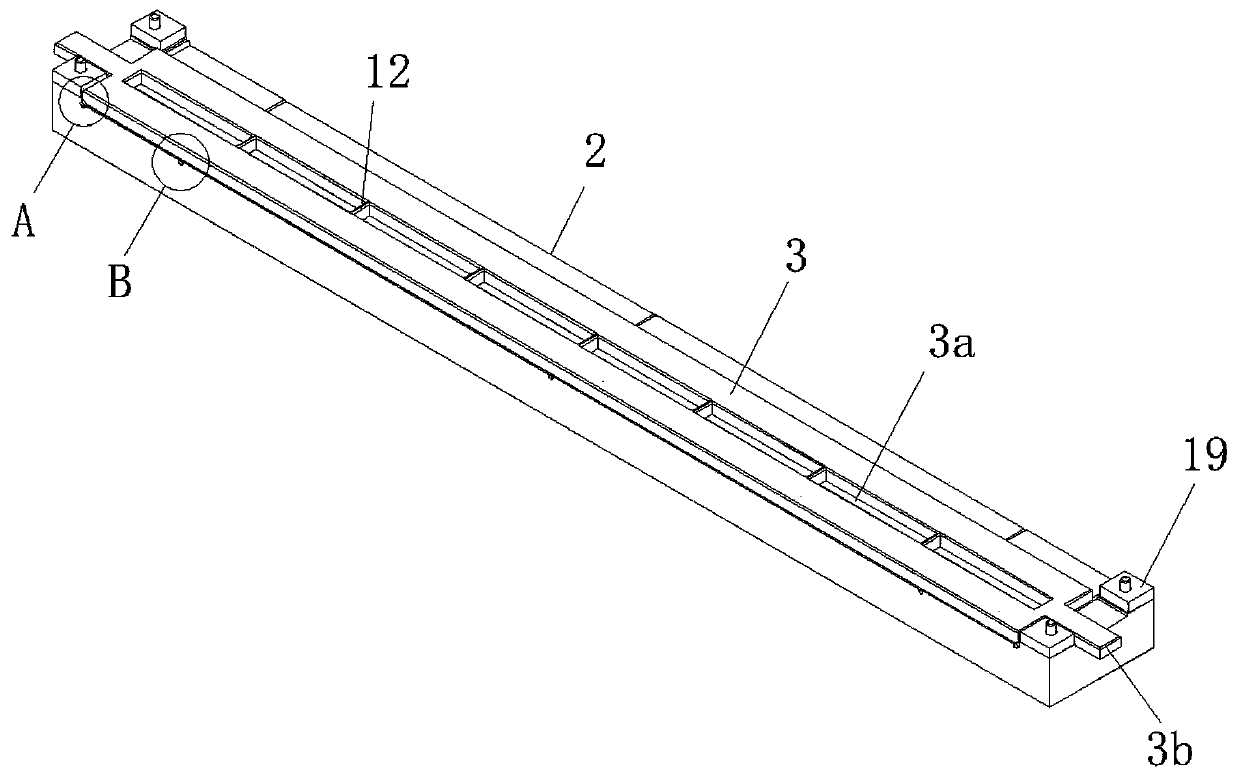

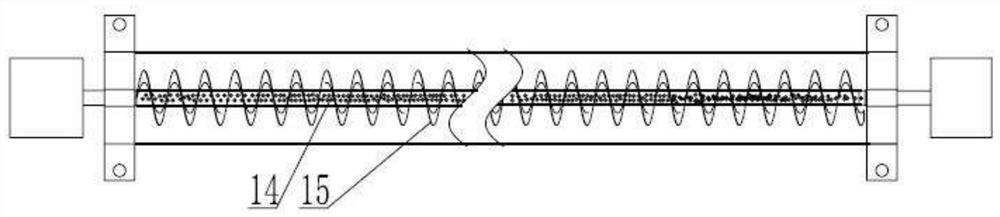

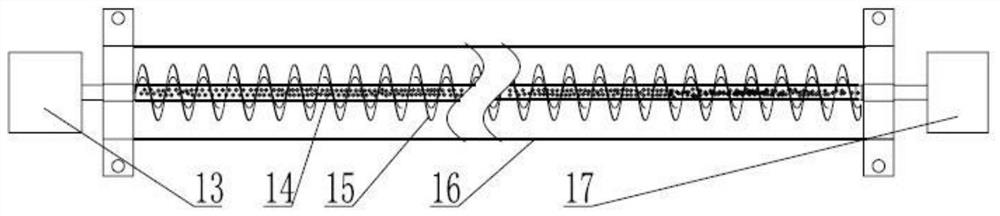

A powder supply and powder spreading mechanism for a laser sintering 3D printer

ActiveCN110549610BImprove efficiencySend powder evenly3D object support structuresAdditive manufacturing with solidsComputer printing3d printer

The invention discloses a powder supply and spreading mechanism, comprising a powder supply cylinder, a level detector, a cylinder, a workbench, a power device, a guide rail, a frame, a powder supply and spread cover, and a screw powder supply mechanism. The powder cover is a cylindrical ring whose length is consistent with the length of the workbench; a powder outlet sieve is provided on any 1 / 4 circumference of the powder supply and spread powder cover, and the remaining 3 / 4 circumference is used as a scraper; The powder outlet sieve is provided with tiny powder outlet holes; the screw powder feeding mechanism is arranged in the powder supply and spreading sleeve. The powder supply and spreading mechanism proposed by the present invention combines scraping and spreading together, and scrapes while spreading the powder, so as to realize the improvement of efficiency; the screw powder feeding mechanism is used to send the powder from one end of the powder supply and spreading sleeve to the other end , to achieve uniform powder delivery and improve the quality of powder spreading.

Owner:武汉斑鹿科技股份有限公司

A kind of laser sintering equipment

ActiveCN110549600BSolve the sealing problemFix cleanupManufacturing platforms/substratesManufacturing enclosuresCylinder blockPowder coating

The invention discloses a laser sintering equipment, which belongs to the field of additive manufacturing, and includes a frame, a cylinder body, and a screw nut pair, and is characterized in that: the cylinder body includes an upper cylinder body and a lower cylinder body, and the upper and lower cylinder bodies Connected by a telescopic structure; the screw nut pair is located at the center of the bottom end of the lower cylinder body, which is consistent with the Z-axis direction of the cylinder body; the lower cylinder body is equipped with a supporting cylinder body and cooperates with the screw nut pair to make the lower cylinder body lift Moving directional guide rails; the powder supply and spreading mechanism includes a powder supply and spreading cover and a screw powder feeding mechanism; compared with the prior art, the scheme adopted by the present invention can completely solve the sealing and cleaning problems, and the scraping and spreading The powder is combined together, and the powder is scraped while spreading to improve the efficiency; the powder feeding mechanism is used to send the powder from one end of the powder supply and spreading sleeve to the other end, so as to achieve uniform powder feeding and improve the quality of powder spreading.

Owner:SHAANXI HENGTONG INTELLIGENT MACHINE

A laser sintering printer

ActiveCN110549609BReduce weightAchieve sealing3D object support structuresAdditive manufacturing with solidsComputer printingEngineering

The invention discloses a laser sintering printer, which belongs to the field of additive manufacturing and includes a frame, a cylinder body, a workbench, a lead screw and a nut pair, and a powder supply and spreading mechanism; the cylinder body includes an upper cylinder body and a lower cylinder body, The upper and lower cylinders are connected by a telescopic structure; the workbench is located inside the lower cylinder and is fixedly connected with the lower cylinder; the screw nut pair is located at the center of the outer bottom of the lower cylinder, and is aligned with the Z axis of the cylinder. Consistent; the outside of the lower cylinder is provided with a directional guide rail that supports the cylinder and cooperates with the screw nut pair to make the lower cylinder move up and down. The purpose of the present invention is to provide a retractable laser sintering printer which can solve the problems of sealing, cleaning, reducing the quality of the molding cylinder, and improving the quality and efficiency of powder spreading.

Owner:四川交大至信教育科技有限公司

3D printer and powder spreading mechanism therefor

ActiveCN112123759ANot affected by vibrationImprove spreading qualityAdditive manufacturing apparatusIncreasing energy efficiencyComputer printingElectric machinery

The invention relates to a 3D printer and a powder spreading mechanism therefor. The powder spreading mechanism for the 3D printer comprises a square steel frame, a powder discharge assembly and a powder spreading assembly; the powder discharge assembly comprises a vibration plate, a guide plate structure, a vibration motor and a vibration cam; the top of the vibration plate is fixed to the squaresteel frame; a flexible vibration plate portion is formed at the lower portion of the vibration plate; the guide plate structure is obliquely arranged relative to the vibration plate; a powder outletspace is formed between the vibration plate and the guide plate structure; and the vibration motor is mounted at the bottom of the square steel frame through a connecting frame. The powder spreadingmechanism for the 3D printer is better in powder spreading effect.

Owner:江西康齿云科技有限公司

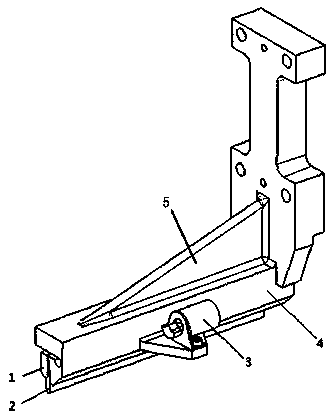

Laser selective melting forming equipment vibration powder spreading device

ActiveCN107803502BSimple structureSimple exerciseIncreasing energy efficiencyAdditive manufacturing with solidsStructural engineeringMechanical engineering

The invention discloses a vibrating powder spreading device for laser selective melting and forming equipment, which includes a pressing plate, a scraper, a scraper seat and a vibrating device, wherein the scraper is fixed on the scraper seat through a pressing plate and a connecting piece, and the The vibrating device is fixed to the scraper seat through a connecting piece, and the scraper seat is an elastic structure; the structure and movement mode of the present invention are simple and easy to control; it is more effective to use vibration to compact the powder layer, and the scraper does not need to be designed before powder spreading. The angle can reduce the phenomenon of powder trapping; the use of vibration can make the scraper sticky powder fall off in advance, improve the quality of powder spreading; it can also improve the fluidity of powder, reduce the performance requirements for powder materials, and save processing costs.

Owner:SICHUAN AEROSPACE LONG MARCH EQUIP MFG CO LTD

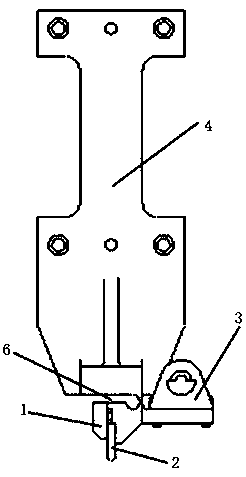

Device for improving powder laying quality in metal powder bed additive manufacturing process

ActiveCN111842891AAchieve rollingReduce gapAdditive manufacturing apparatusIncreasing energy efficiencyMetallurgyBall screw

The invention discloses a device for improving the powder laying quality in the metal powder bed additive manufacturing process, and belongs to the field of additive manufacturing. The device comprises a supporting base, a lead screw nut, a rolling cylinder, a support, a lifting mechanism, a ball screw and a stepping motor, wherein the supporting base is fixed to a powder laying mechanism of a metal powder bed additive manufacturing device; the stepping motor is located at the upper end of the supporting base, connected with one end of the ball screw through a gear and used for driving the ball screw to rotate; the lead screw nut is in threaded connection with the ball screw and is used for moving up and down when the ball screw rotates; the lifting mechanism is fixedly connected with thelead screw nut and used for moving up and down under driving of the lead screw nut; and the rolling cylinder is fixedly connected with the lifting mechanism through the support and used for moving under driving of the lifting mechanism, so that the pressing force of the rolling cylinder on a powder layer is adjusted. According to the device for improving the powder laying quality in the metal powder bed additive manufacturing process, a powder pile is finally rolled by adjusting the pressing force, so that gaps of powder particles are reduced, and the filling density in the powder laying process is improved.

Owner:HUAZHONG UNIV OF SCI & TECH

Stainless steel distribution roller

InactiveCN109338645AAvoid offsetLight in massTextile treatment machine partsFabric finishing guides/expandersMetallurgyWhole body

The invention discloses a stainless steel distribution roller which comprises a stainless steel roller, a left screw thread and a right screw thread, wherein the left screw thread and the right screwthread are respectively arranged on the stainless steel roller; hollow holes are formed inside the stainless steel roller; a connecting rod is fixedly connected to the axis of the stainless steel roller; a guide rail rod is fixedly connected to the axis of the connecting rod. According to the stainless steel distribution roller disclosed by the invention, the stainless steel roller is subjected tointegral pouring by the left screw thread and the right screw thread, so that the stainless steel distribution roller disclosed by the invention is stable compared with an inlaid distribution roller,and deflection is avoided. Meanwhile, due to the arrangement of the hollow holes, the total body mass can be effectively reduced, so that the stainless steel distribution roller is convenient to assemble and detach. Meanwhile, the production cost can be reduced, and the distribution roller is convenient to use and high in practicality. Due to the guide rail rod, the external transmission device is further butted by utilizing the guide rail rod, so that position deflection does not occur when the roller is stressed by external force during transmission. Therefore, the distribution quality canbe improved, and the distribution efficiency can be improved.

Owner:江苏福安特纺织机械制造有限公司

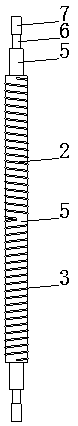

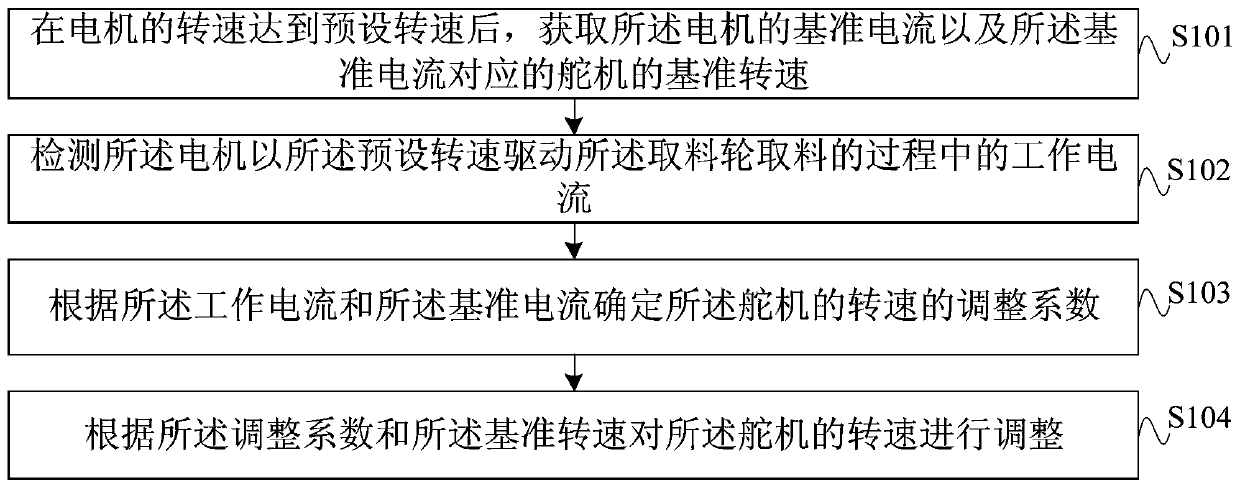

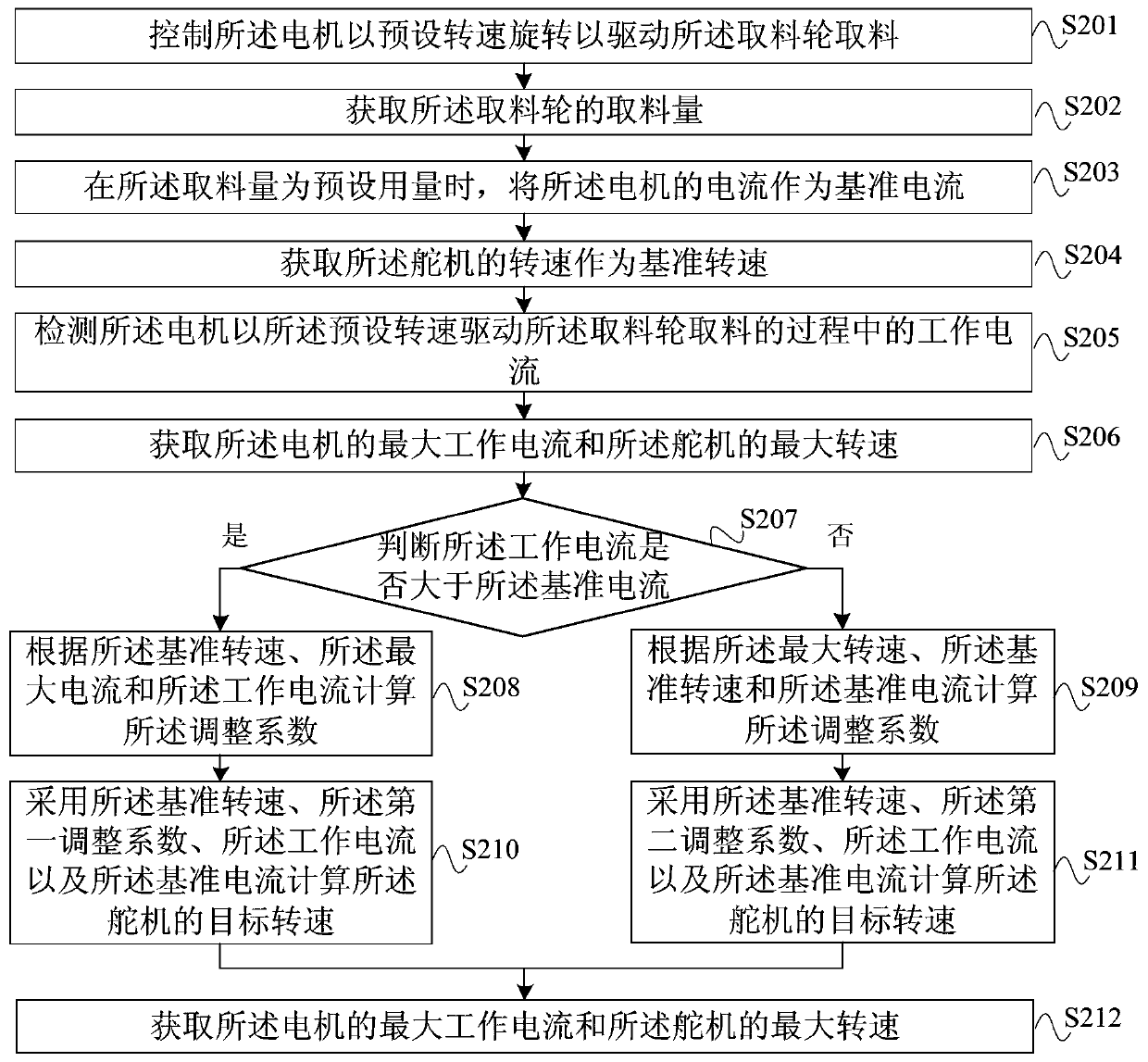

Turbolator rotation speed adjusting method, device, broadcasting equipment and storage medium

ActiveCN109917827AGuaranteed accurate feedingImprove spreading qualityAircraft componentsSpeed/accelaration control using electric meansReference currentElectric machine

The embodiment of the invention discloses a turbolator rotation speed adjusting method, device, broadcasting equipment and a storage medium. The rotation speed adjusting method comprises steps: afterthe rotation speed of a motor reaches a preset rotation speed, the reference current of the motor and a reference rotation speed of an actuator corresponding to the reference current are acquired; theworking current during the process of enabling the motor to drive a material taking wheel to take a material at the preset rotation speed is detected; the adjustment coefficient of the rotation speedof the actuator is determined according to the working current and the reference current; and according to the adjustment coefficient and the reference rotation speed, the rotation speed of the actuator is adjusted. As the working current of the motor reflects the load condition of the motor when the motor rotates and drives the material taking wheel to take a material at the preset rotation speed, the working current can further sense the effect of disturbing the material by the turbolator, the rotation speed of disturbing the material by the turbolator can be dynamically adjusted accordingto the working current of the motor, the turbolator can disturb the material into the material taking wheel timely at a proper rotation speed, accurate material taking by the material taking wheel isensured, and the broadcasting quality is improved.

Owner:GUANGZHOU XAIRCRAFT TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com