An Adsorption Surface Contact Flexible Powder Spreading Device for Laser Selective Melting Molding System

A laser selective melting and powder spreading device technology, which is applied in the field of parts forming and manufacturing, can solve the problems of high elasticity of metal sheets, affecting the quality of powder spreading, and dusting, so as to prevent dusting and springing, long service life, and The effect of high powder quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

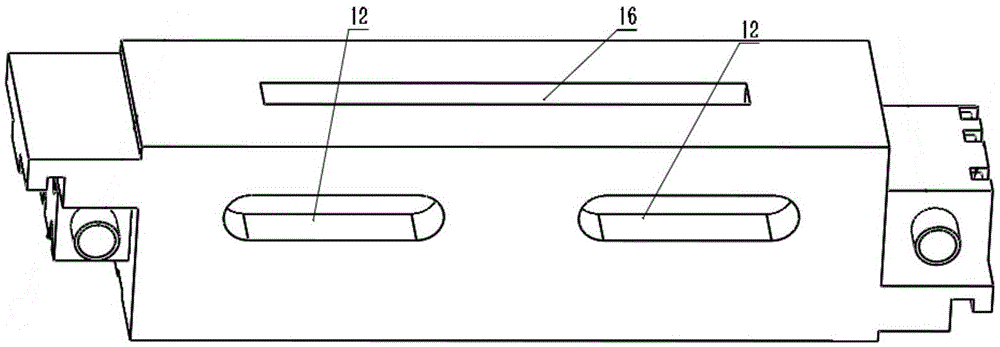

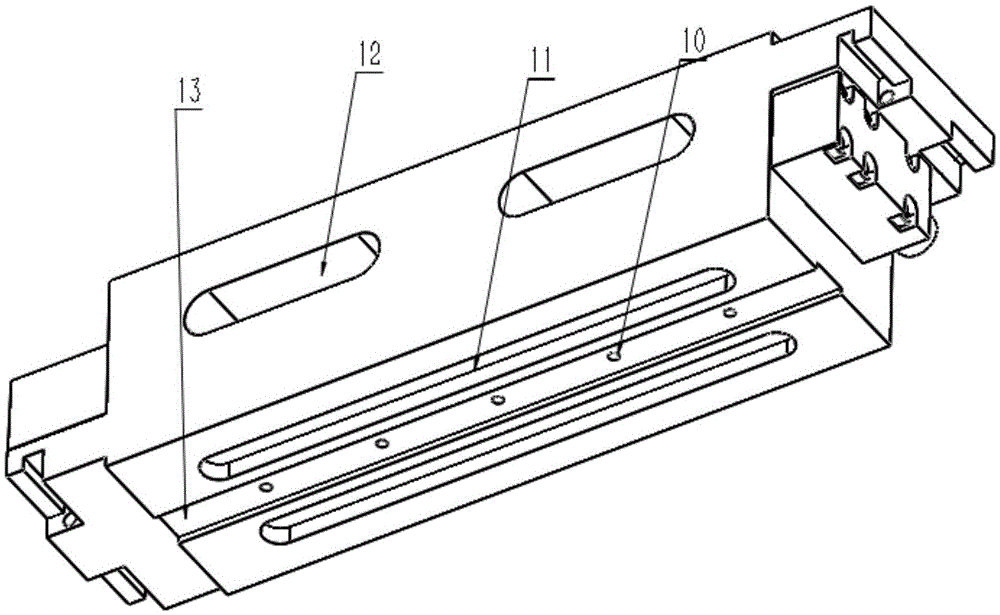

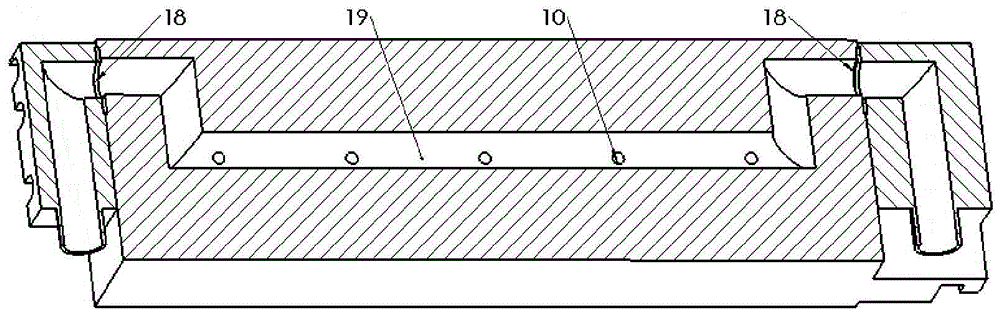

[0042] Such as Figures 1 to 8 shown. The present invention is an adsorption-type surface-contact flexible powder spreading device of a laser selective melting forming system, comprising A mobile bracket 1, A negative pressure channel device 2, flexible powder coating brush 4, mounting bracket 5, B negative pressure channel device 6, and B mobile Bracket 8;

[0043] A negative pressure chamber 19 is provided in the mounting bracket 5;

[0044] The A mobile bracket 1 and the B mobile bracket 8 are respectively fixed at the two ends of the mounting bracket 5;

[0045] The bottom of the mounting bracket 5 is provided with an adsorption tank 13 and a powder storage tank 11; the powder storage tank 11 is used for pre-storing powder and providing sufficient metal powder for the powder spreading process.

[0046] The upper plane 30 of the flexible plastering brush 4 is adsorbed in the suction groove 13, and the position of the flexible plastering brush 4 can be adjusted as require...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com