Patents

Literature

51results about How to "Spread powder evenly" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

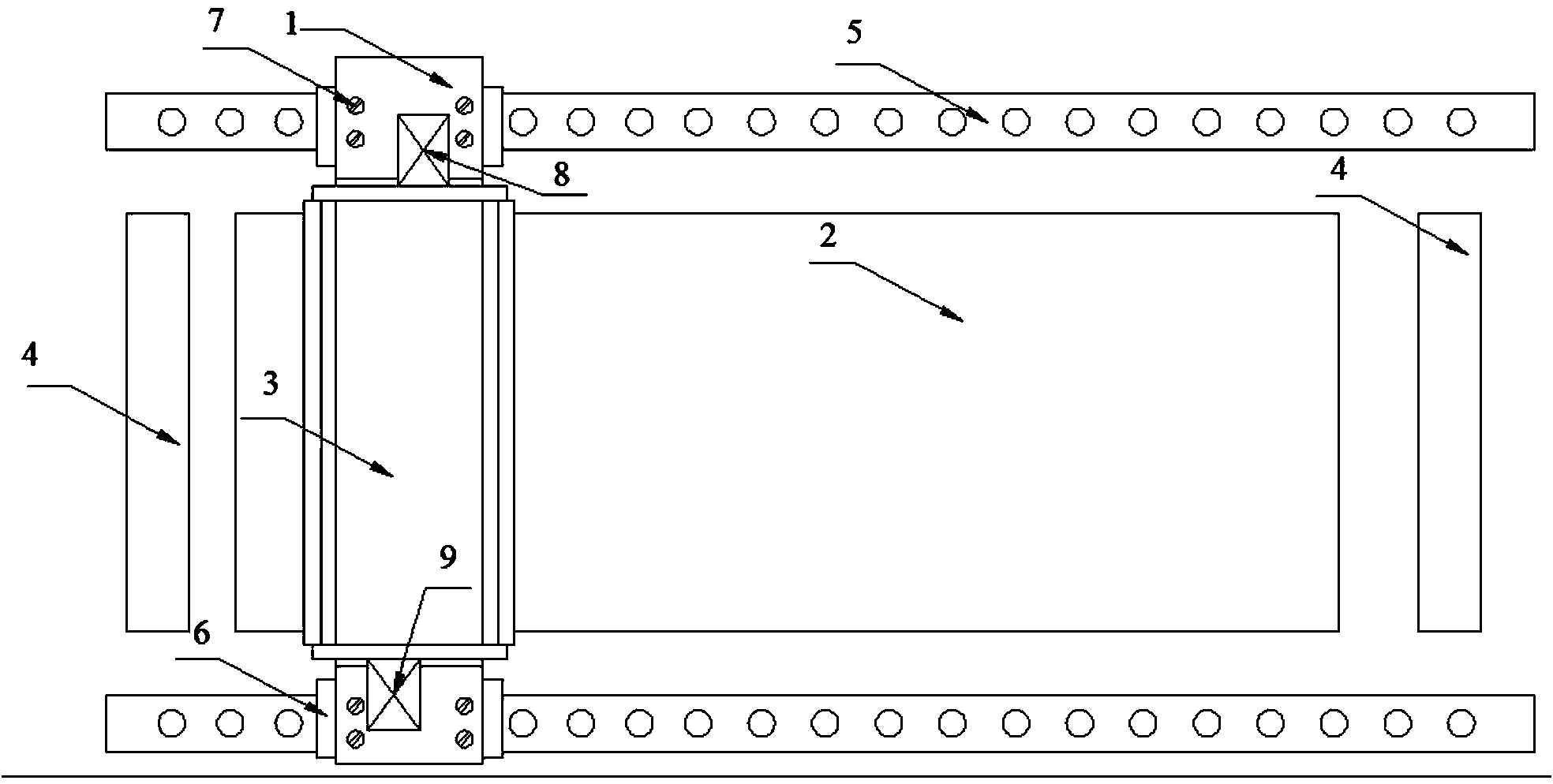

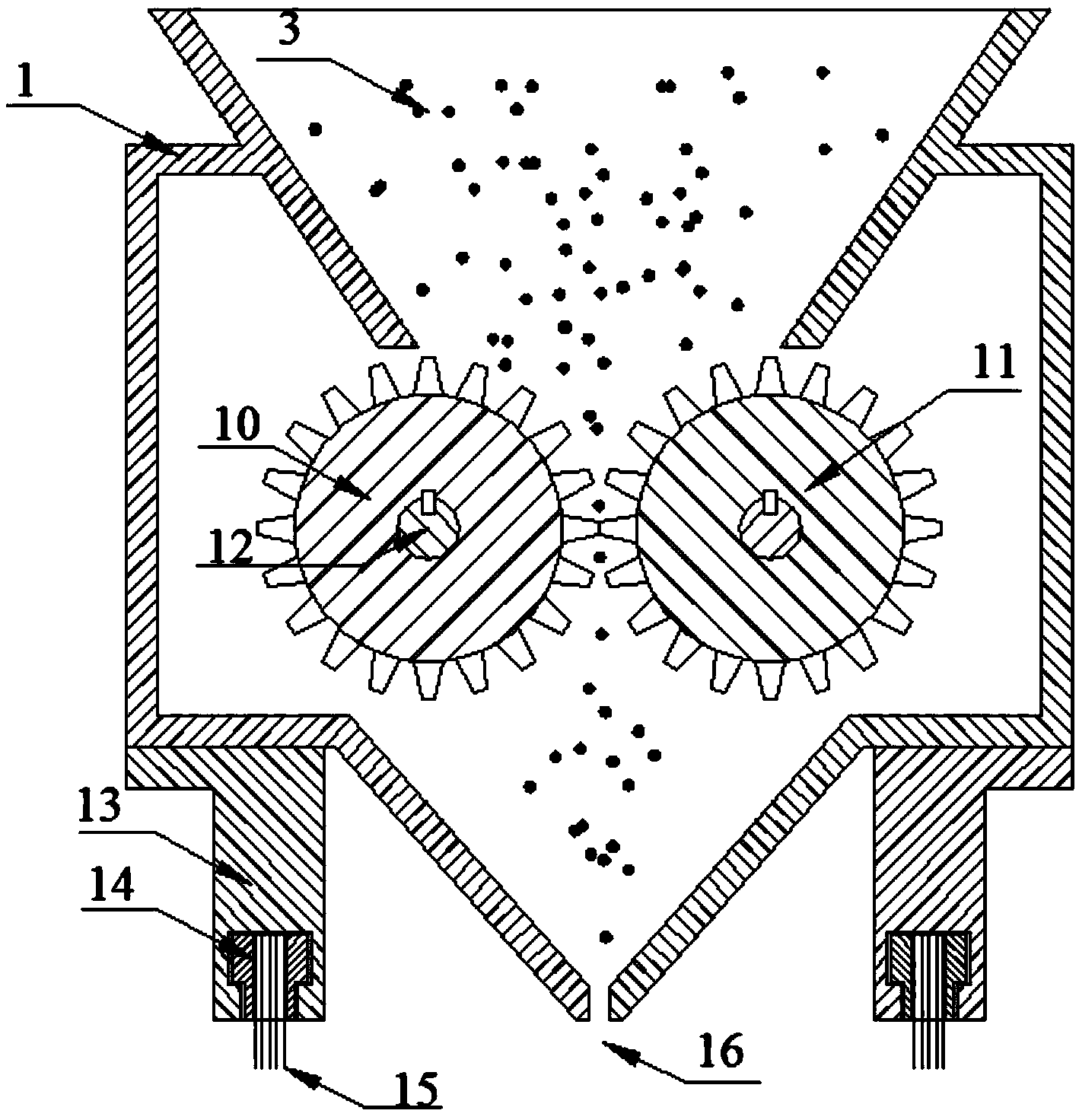

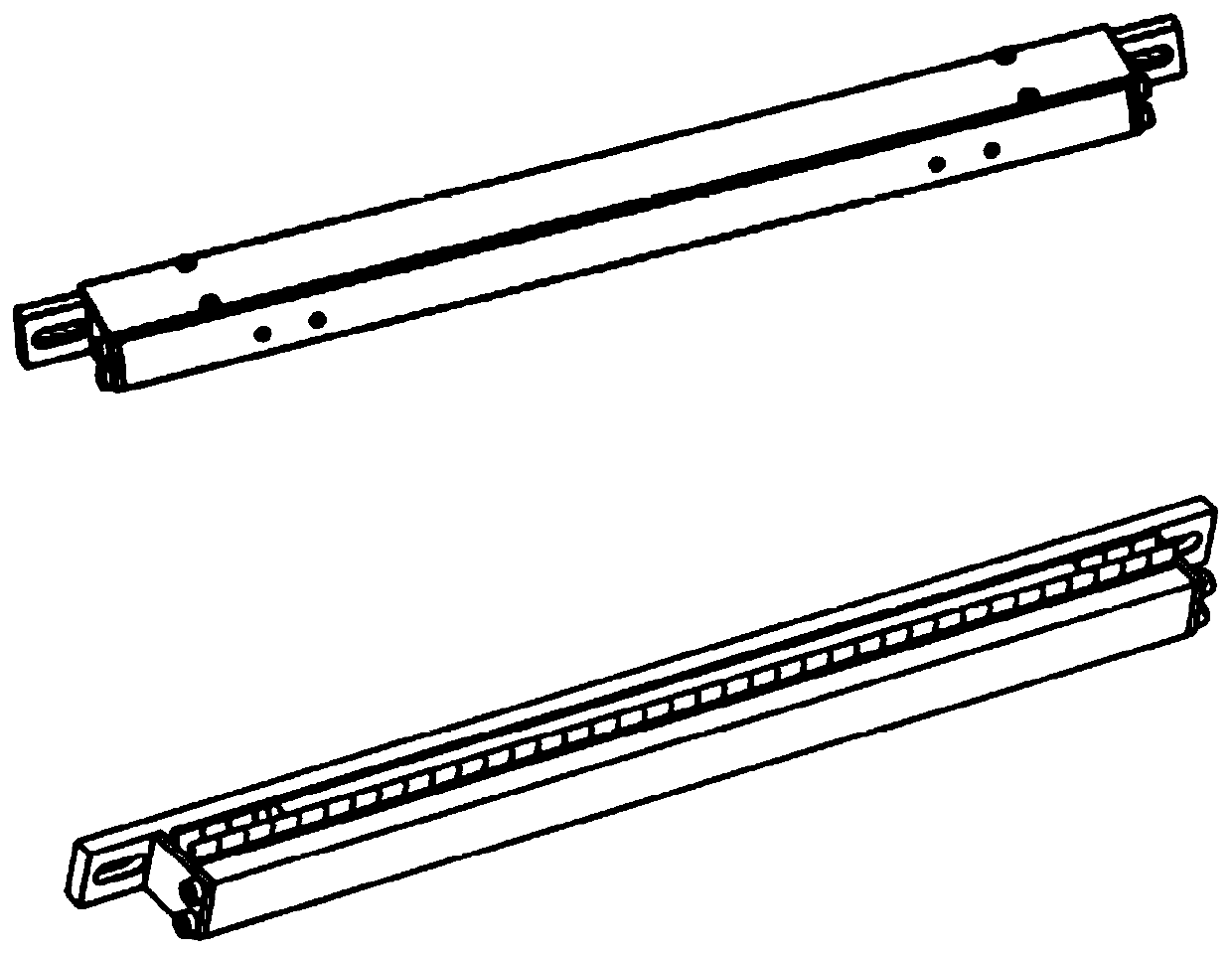

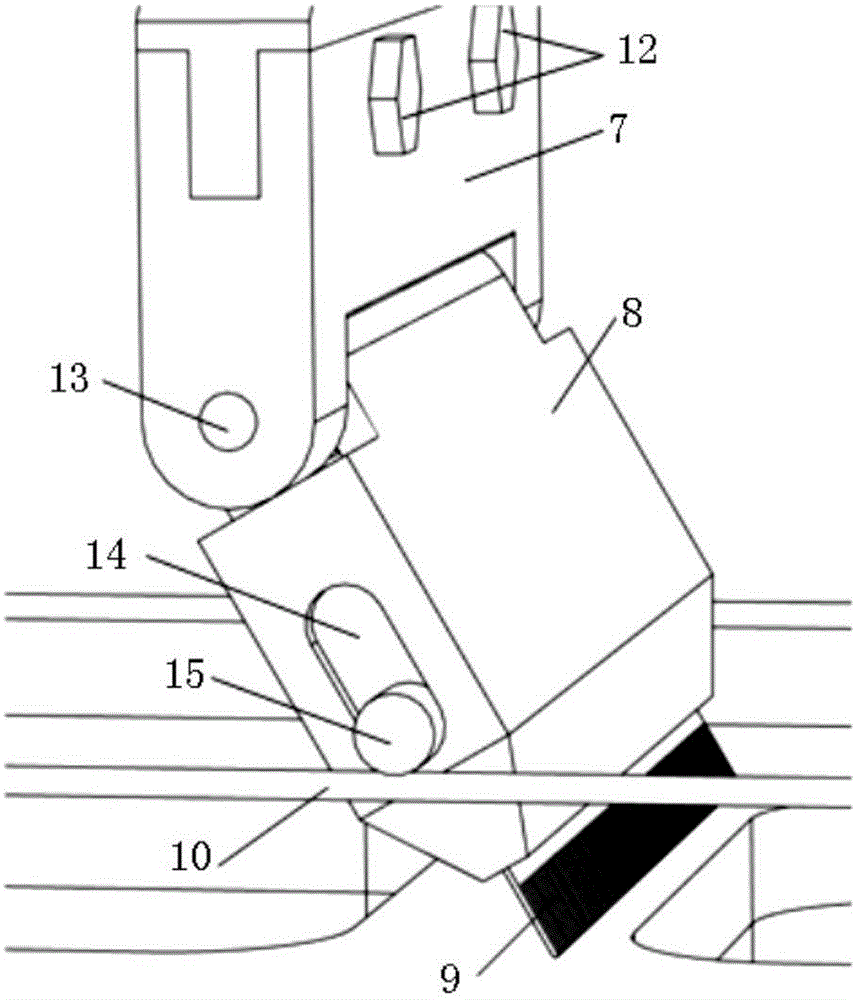

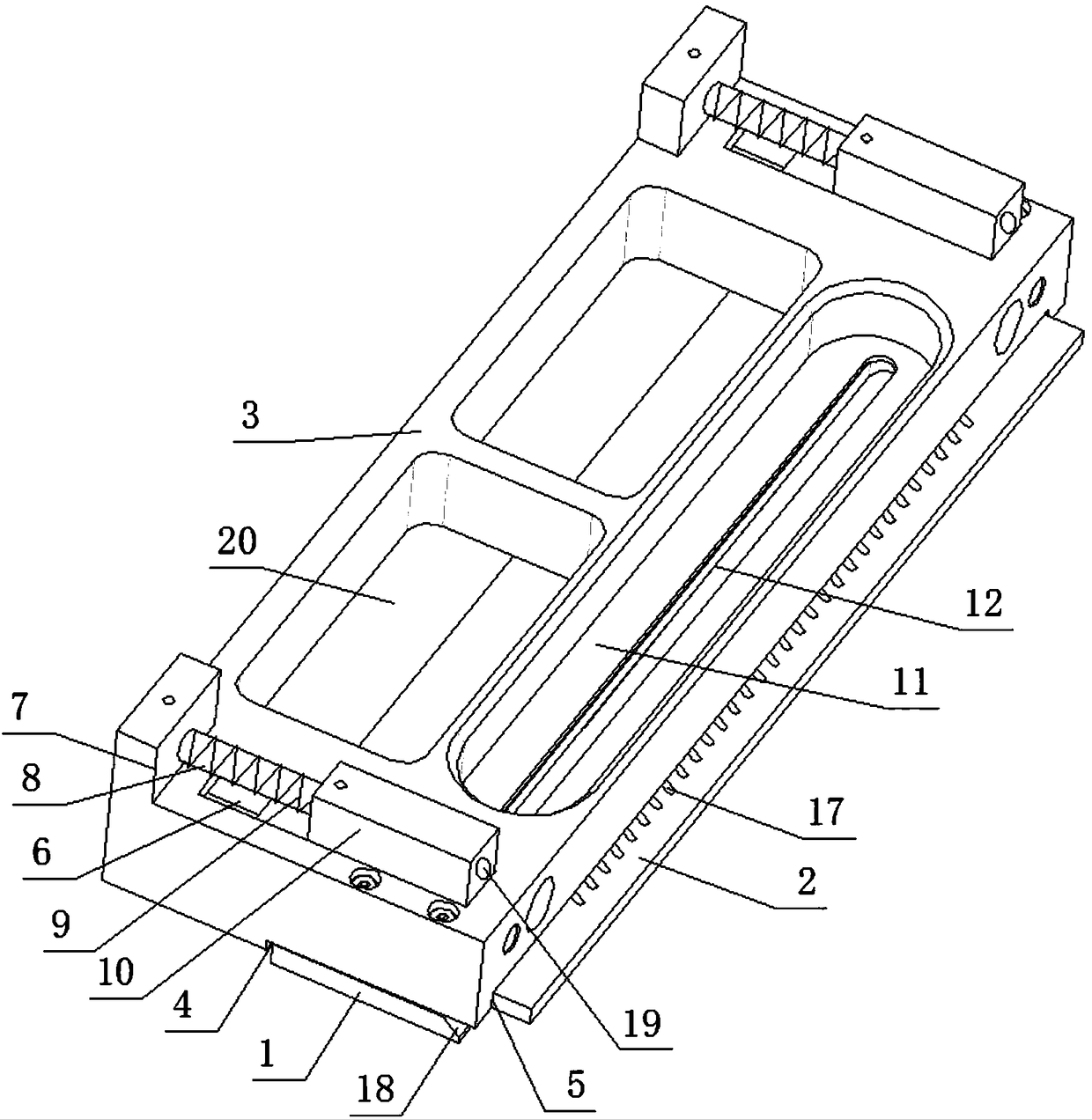

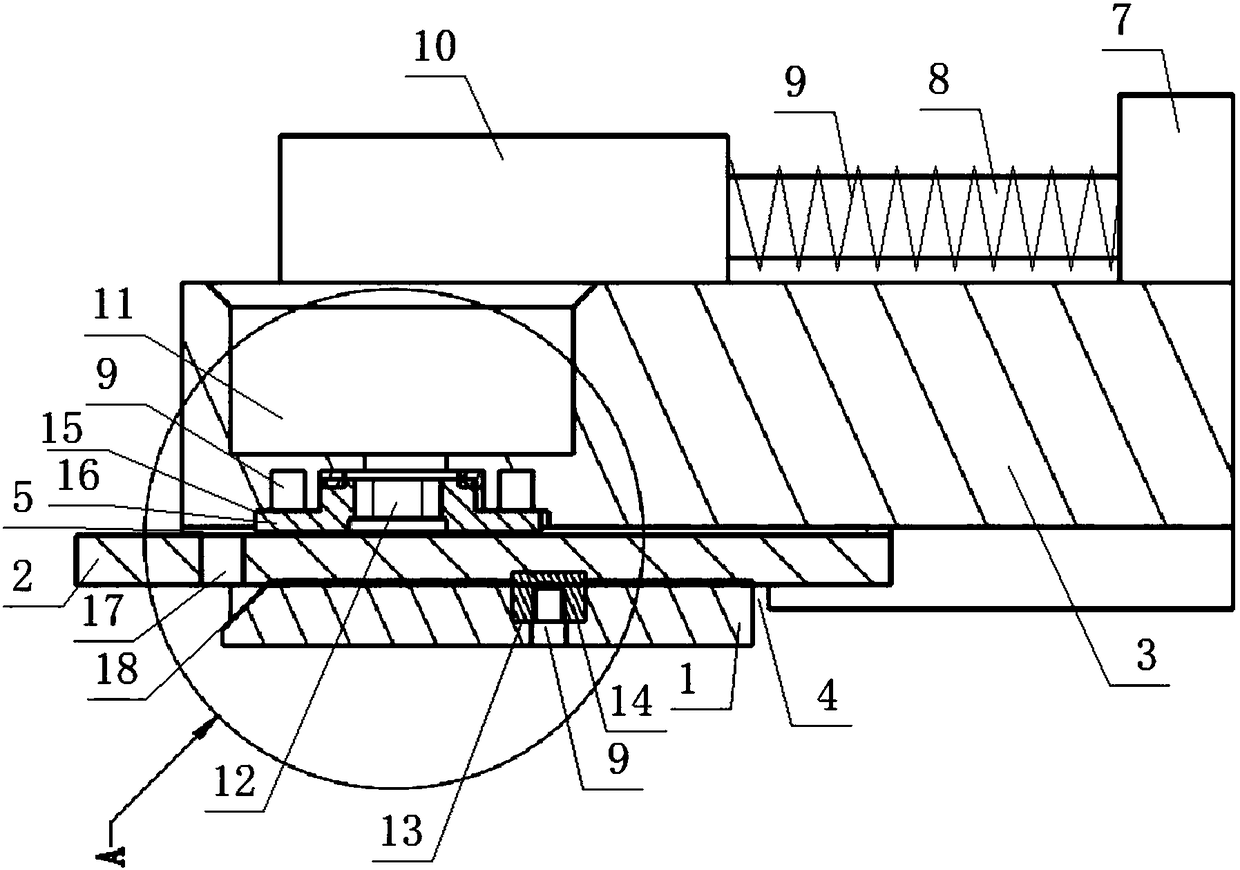

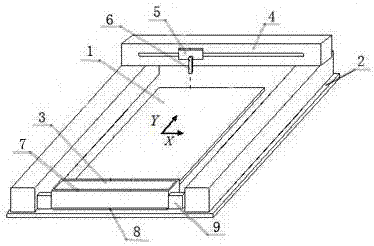

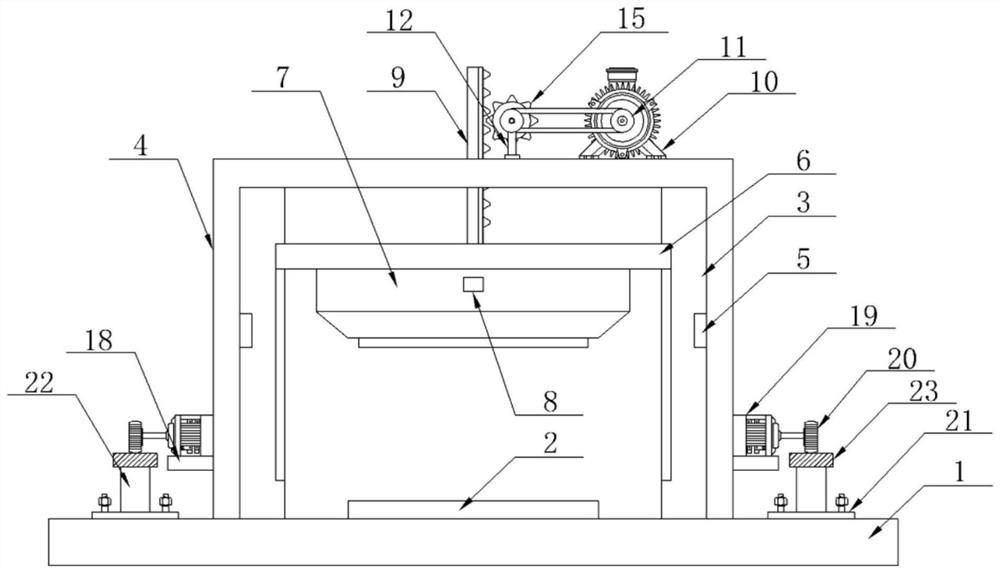

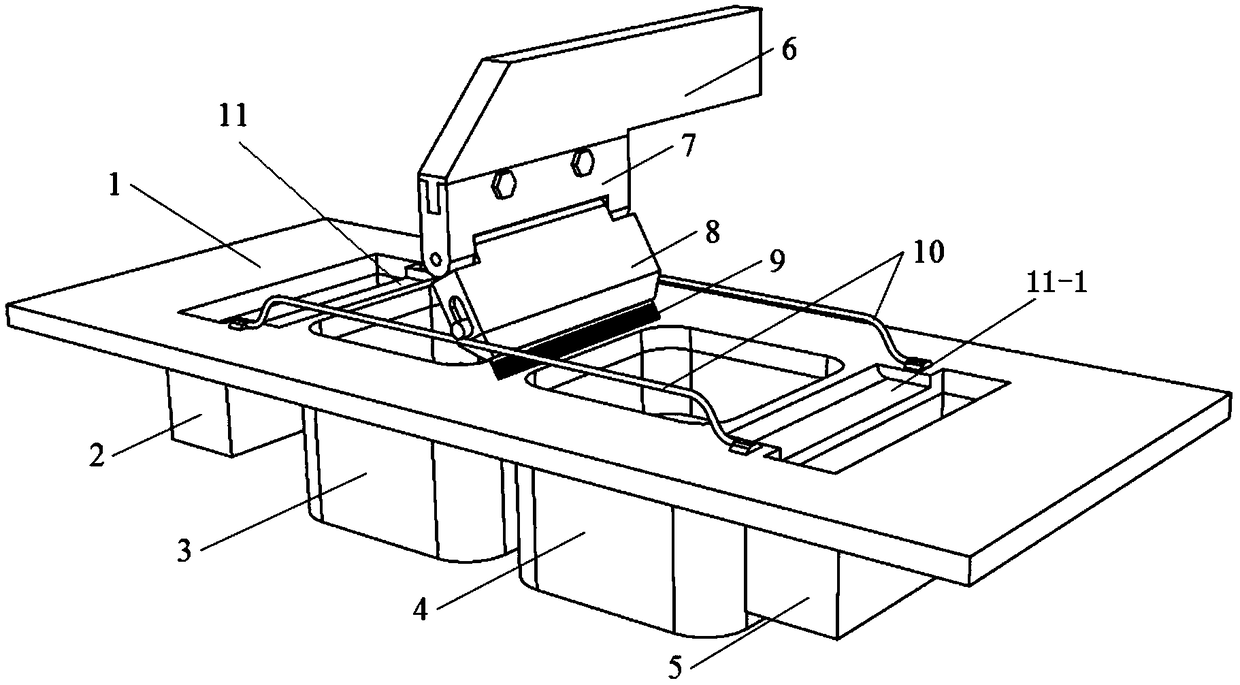

Two-way powder spreading device of SLM equipment and powder spreading method

ActiveCN103658646AGuaranteed uniformityGuaranteed flatnessIncreasing energy efficiencyDrive shaftInstability

The invention discloses a two-way powder spreading device of SLM equipment and a powder spreading method. The powder spreading device comprises a powder spreading device body, two parallel auxiliary linear motor guide rails and two parallel linear motor movable sliding blocks, wherein the linear motor movable sliding blocks are arranged on the auxiliary linear motor guide rails; the powder spreading device body is arranged on the linear motor movable sliding blocks in an erecting mode and comprises a powder carrying device and two powder supply gears arranged inside the powder carrying device; the circle center position of each powder supply gear is provided with a servo motor transmission shaft; the two powder supply gears are arranged at the equal altitude; the gear top circles of the two powder supply gears are tangent in the radial direction; flexible powder scraping brushes are arranged on the two sides of the powder carrying device. By means of the powder spreading device, the redundant steps in the powder spreading process are reduced, powder is spread in the back and forth direction, the evenness and flatness of the spread powder are ensured through the flexible powder scraping brushes on the two sides, and the good repairing function is achieved on the process instability.

Owner:SOUTH CHINA UNIV OF TECH

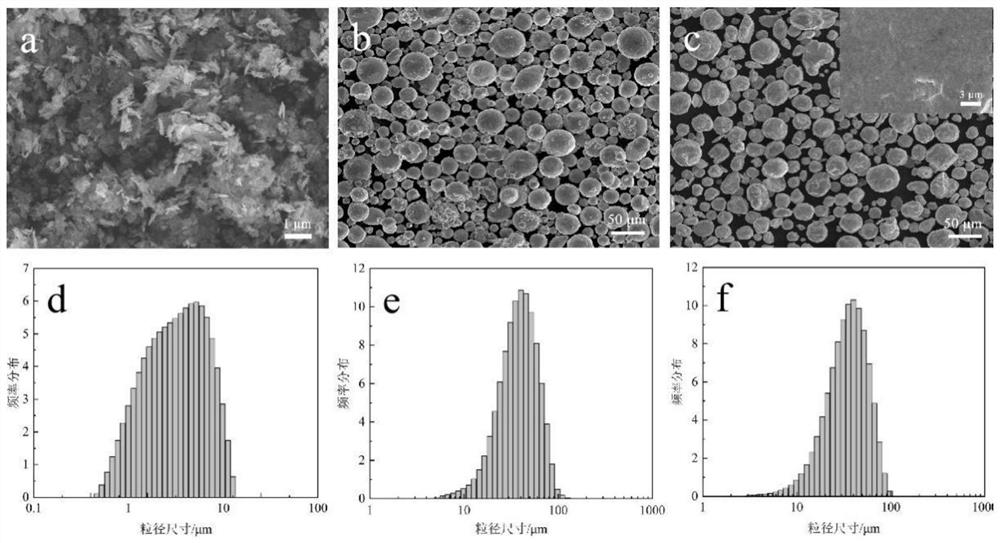

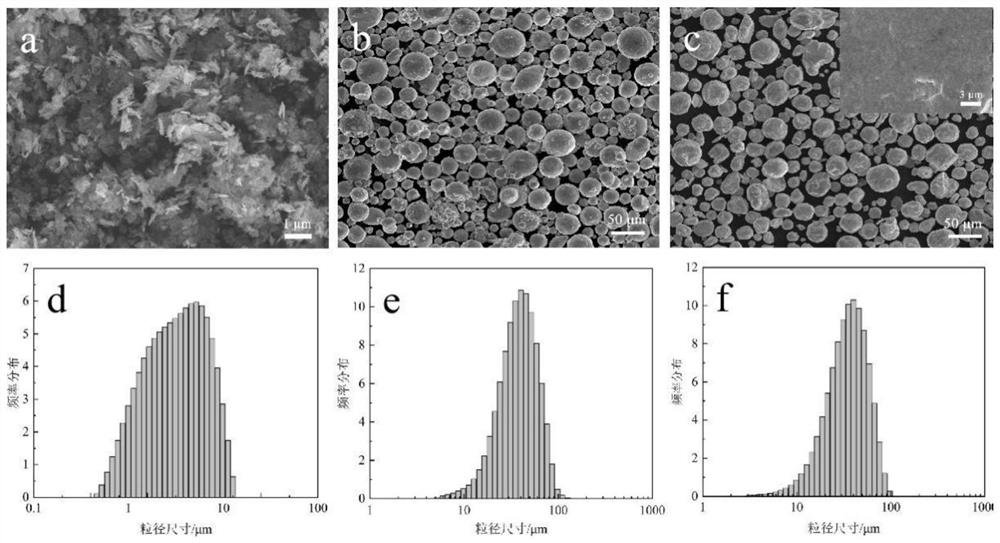

Preparation method for nickel-base superalloy powder for laser forming

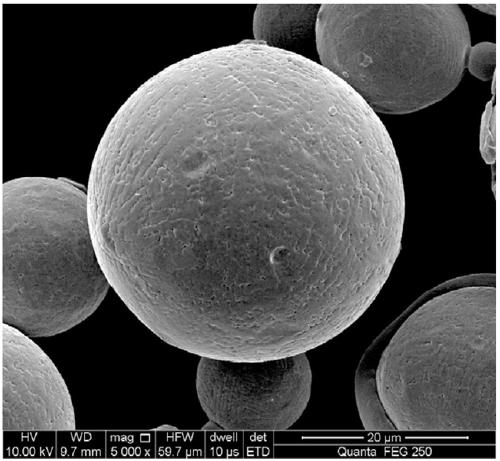

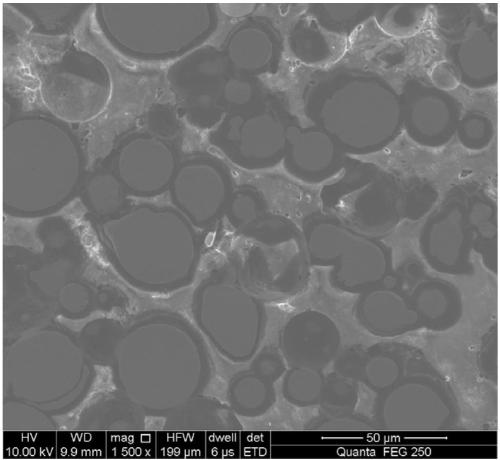

ActiveCN108941588AHigh sphericityHigh yieldAdditive manufacturing apparatusTransportation and packagingOxygen contentHot Temperature

The invention discloses a preparation method for nickel-base superalloy powder for laser forming, and belongs to the field of superalloy and powder metallurgy. According to the preparation method, vacuum induction melting and argon atomization powder making technologies are adopted, and the nickel-base superalloy powder suitable for laser forming is prepared. The nickel-base superalloy powder prepared through the method is high in small grain size powder, high in degree of sphericity, low in oxygen content, good in flowing performance, free of hollow defects, less in satellite powder and capable of meeting the technical requirement for laser forming.

Owner:CENT SOUTH UNIV

Wood-plastic composite powder for selective laser sintering rapid forming and preparation method thereof

InactiveCN101602871AImprove the safety of useSpread powder evenlySelective laser sinteringSurface roughness

The invention provides a wood-plastic composite powder for selective laser sintering rapid forming and a preparation method thereof, which relate to the wood-plastic composite powder and the preparation method thereof. The invention overcomes the defects that in the SLS processing with mixed powder consisting of wood powder and hot melt adhesive powder, the powder pushing is uneven, the processed components have large relative warp rate and internal stress, poor surface roughness and low strength, and are easily ruptured at the parts with 'defects'. The wood-plastic composite powder is prepared from the hot melt adhesive powder, the wood powder after alkalization treatment, a viscosity reducer, a coupling agent, an initiating agent, a light stabilizer and an organic packing material. The preparation method comprises the following steps: firstly, alkalizing the wood powder; secondly, preparing a base material; and thirdly, adding the viscosity reducer, the light stabilizer and the organic packing material, mixing the materials evenly, and drying the mixture. The wood-plastic composite powder can reduce the conglutination and aggregation caused by the moisture absorption of the wood powder, can be paved and formed evenly, and has high forming accuracy, and when the wood-plastic composite powder is applied to the components processed by the SLS technique, the relative warp rate is between 0.26 and 0.45 percent, and the surface roughness Ra is less than 0.01 millimeter.

Owner:哈尔滨自由智造科技开发有限公司

3D printing process method of high-strength aluminum-magnesium alloy

ActiveCN111872386ALow costImprove qualityAdditive manufacturing apparatusTransportation and packaging3D modelingMaterials science

The invention relates to a 3D printing process method of a high-strength aluminum-magnesium alloy, and belongs to the technical field of 3D printing. Firstly, high-strength aluminum-magnesium alloy raw materials are mixed evenly through heating and melting; then high-quality aluminum-magnesium alloy powder is prepared from the high-strength aluminum-magnesium alloy in a molten state through a gasatomization technology, and aluminum-magnesium alloy powder for 3D printing is obtained after drying; and printing parameters are adjusted, 3D printing is carried out according to 3D model data of parts in printing equipment with inert gas introduced, and a 3D printing product with the high-strength aluminum-magnesium alloy as a raw material is obtained. Compared with the prior art, as for the product printed through the process method, the relative density can reach 99% or above, the Vickers hardness can reach 110 HV or above, the tensile strength can reach 430 MPa or above, the elongation can reach 21%, through proper heat treatment, the Vickers hardness of a sample can reach 150 HV or above, the tensile strength can be further increased to 520 MPa or above, and the elongation is maintained at 17% or above.

Owner:TONGJI UNIV

3D printing process method of high-strength aluminum manganese alloy

InactiveCN111659889ALow costImprove qualityAdditive manufacturing apparatusTransportation and packagingManganese3D modeling

The invention relates to a 3D printing process method of a high-strength aluminum manganese alloy, and belongs to the technical field of 3D printing. The 3D printing process method comprises the stepsthat firstly, a high-strength aluminum manganese alloy is mixed evenly by heating and melting; then the melted high-strength aluminum manganese alloy is subjected to a gas atomization technology to prepare high-quality aluminum manganese alloy powder, and aluminum manganese alloy powder for 3D printing is obtained after drying; and printing parameters are adjusted, 3D printing is conducted according to three-dimensional model data of parts in printing equipment introduced with inert gas, and a 3D printing product with the high-strength aluminum manganese alloy as a raw material is obtained. Compared with the prior art, according to the product printed by the process method, the relative density can reach more than 99%, the Vickers hardness can reach more than 140 HV, the tensile strengthcan reach more than 440 MPa, the elongation can reach 20%, after proper hear treatment, the hardness of a sample can reach more than 180 HV, the tensile strength can be further increased to more than565 MPa, and the elongation is maintained at or above 19%.

Owner:TONGJI UNIV

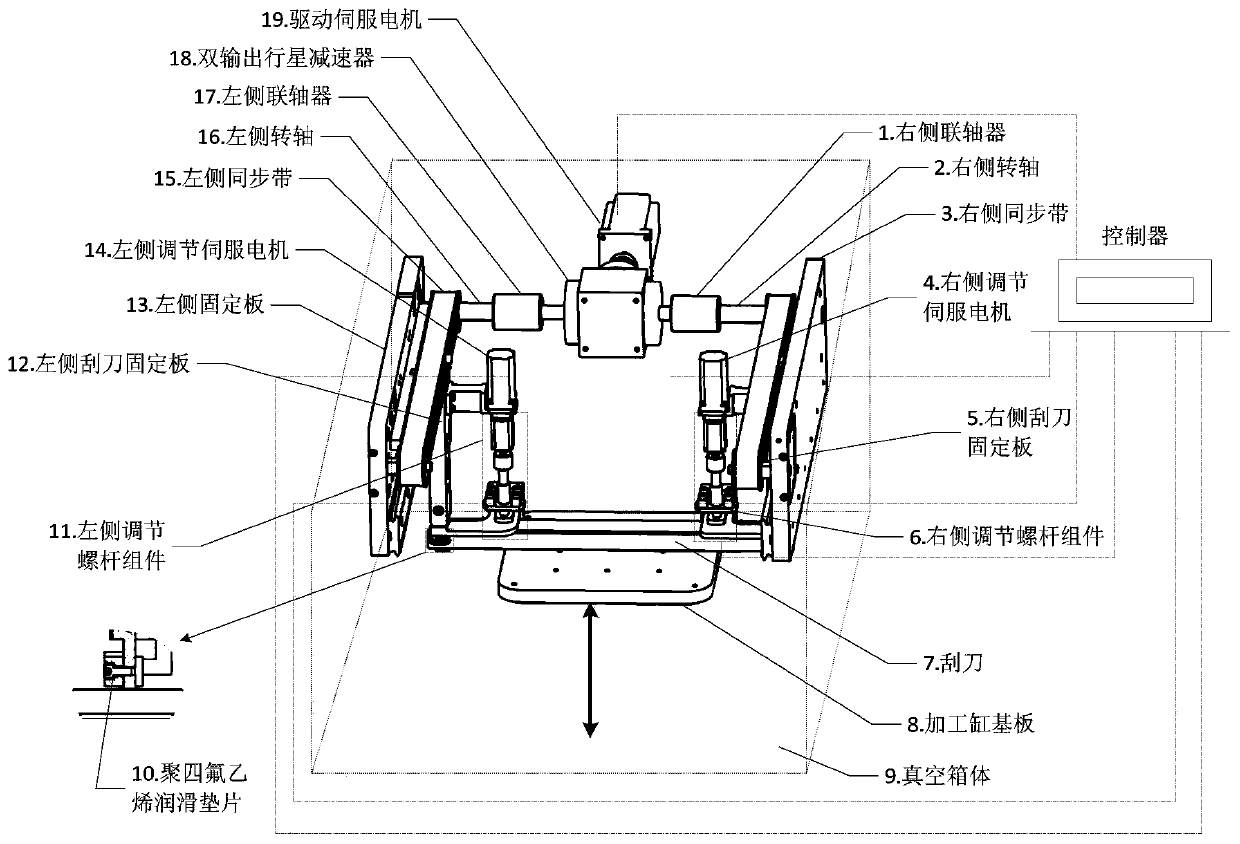

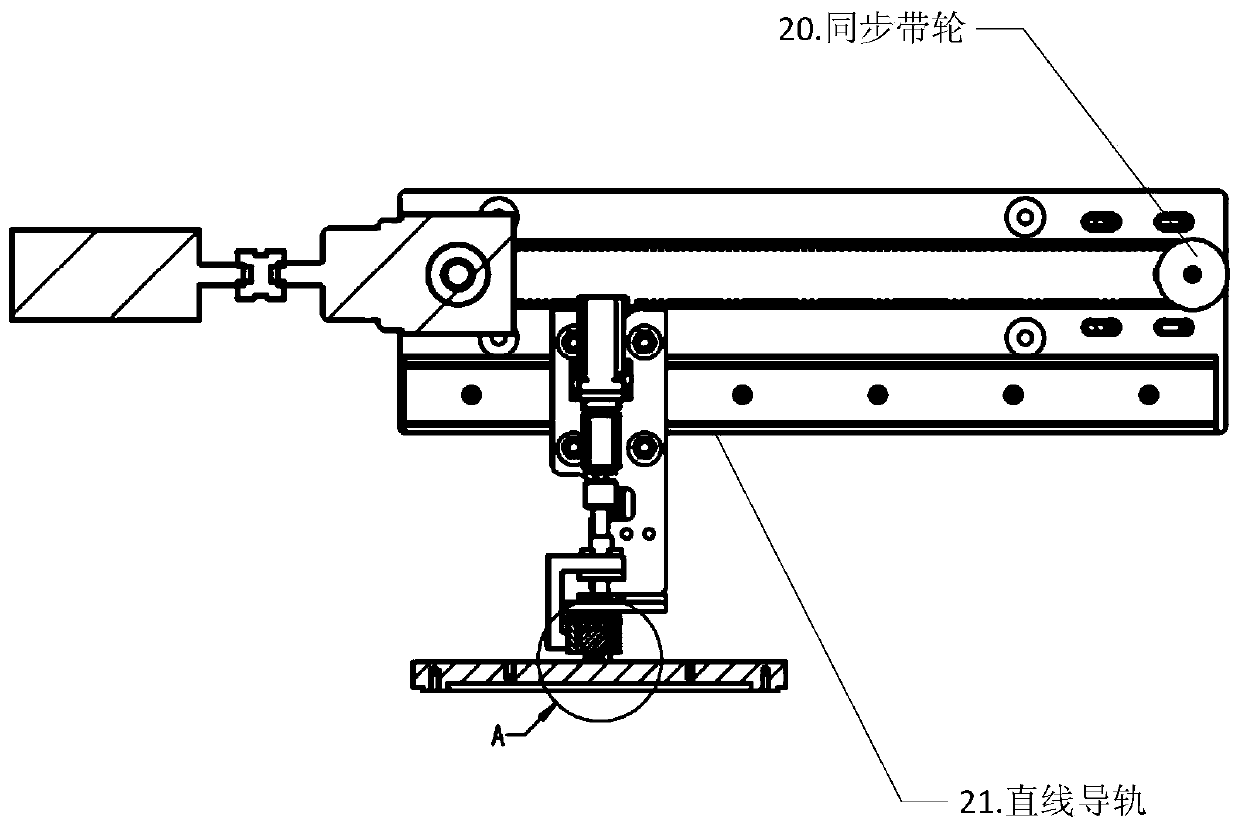

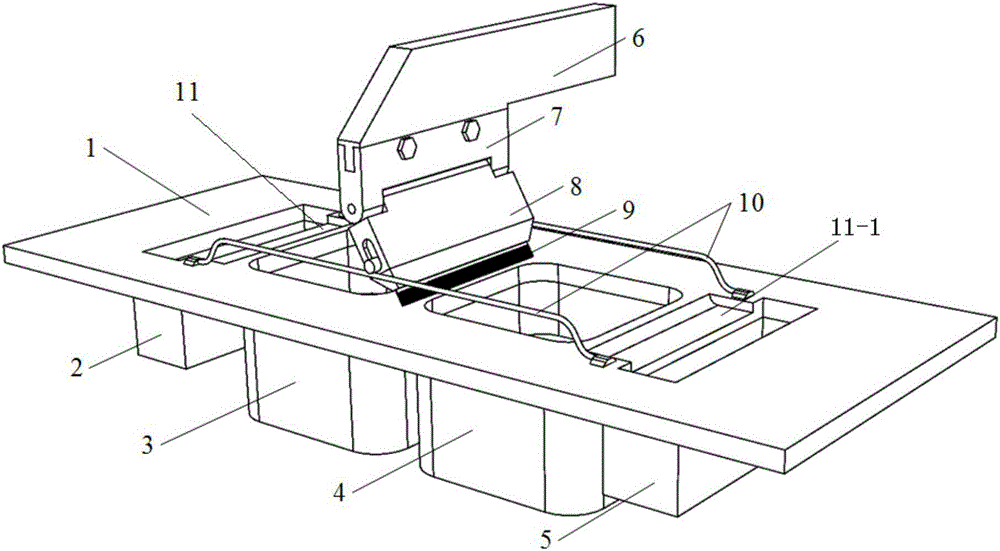

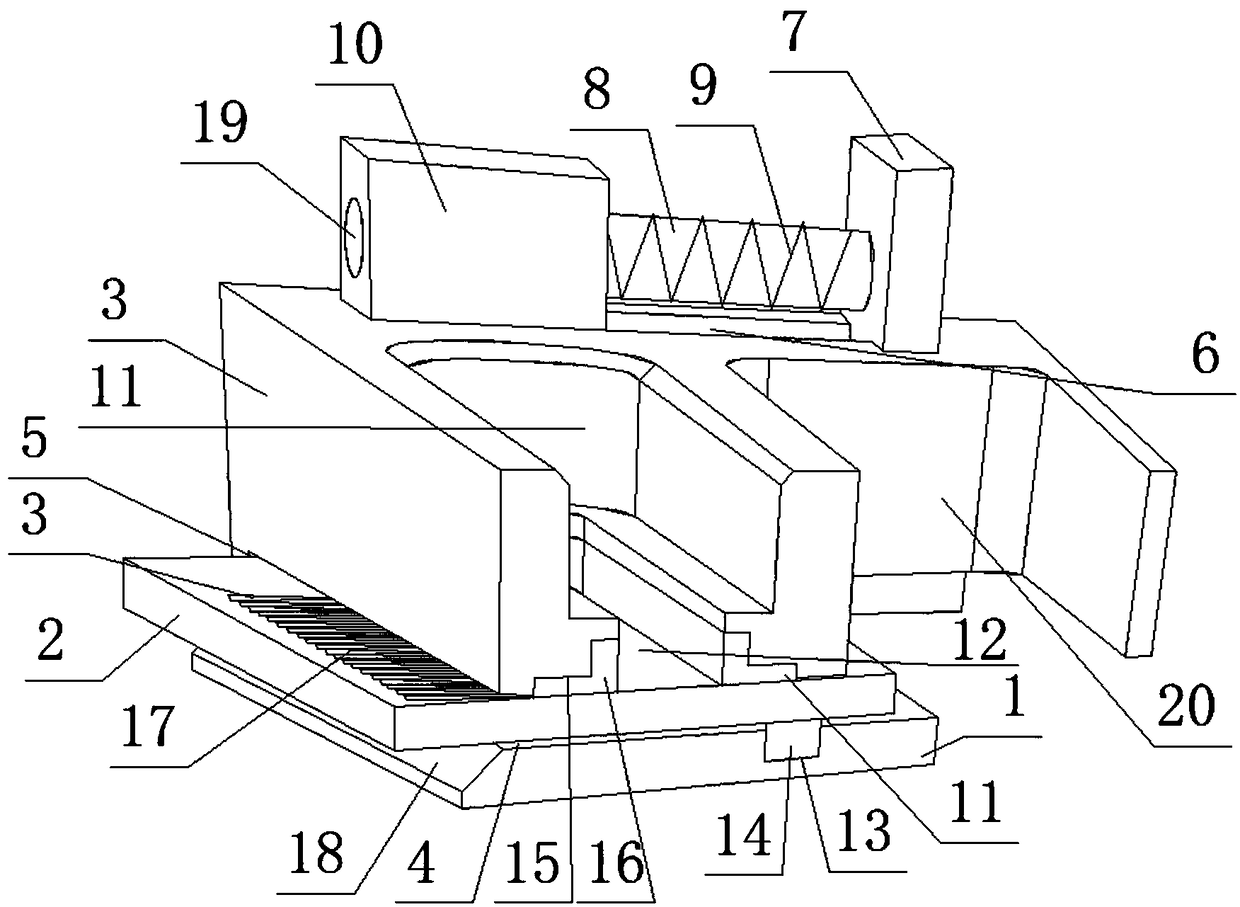

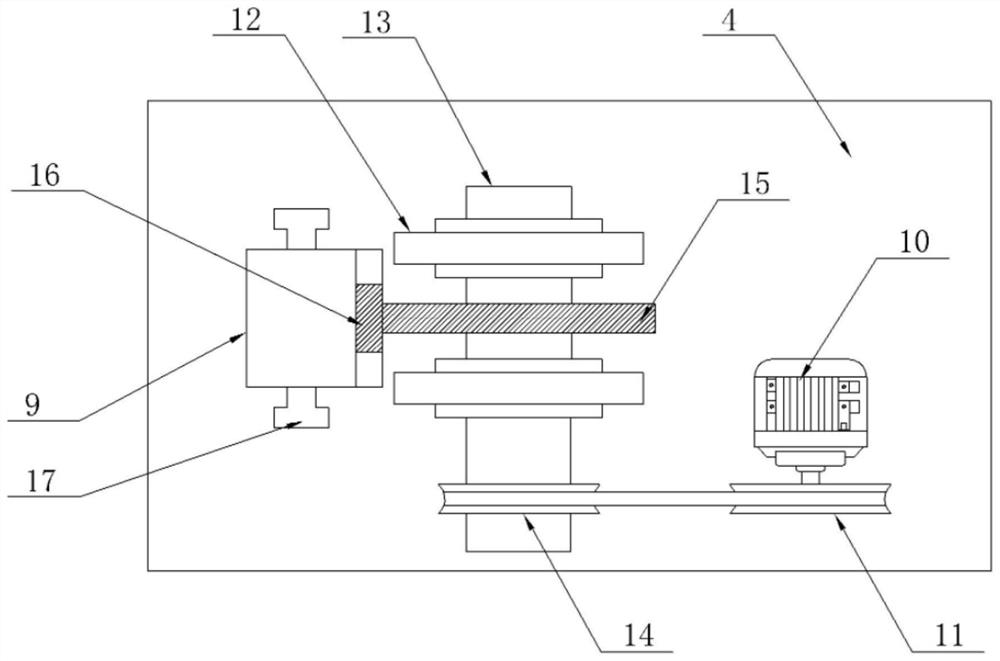

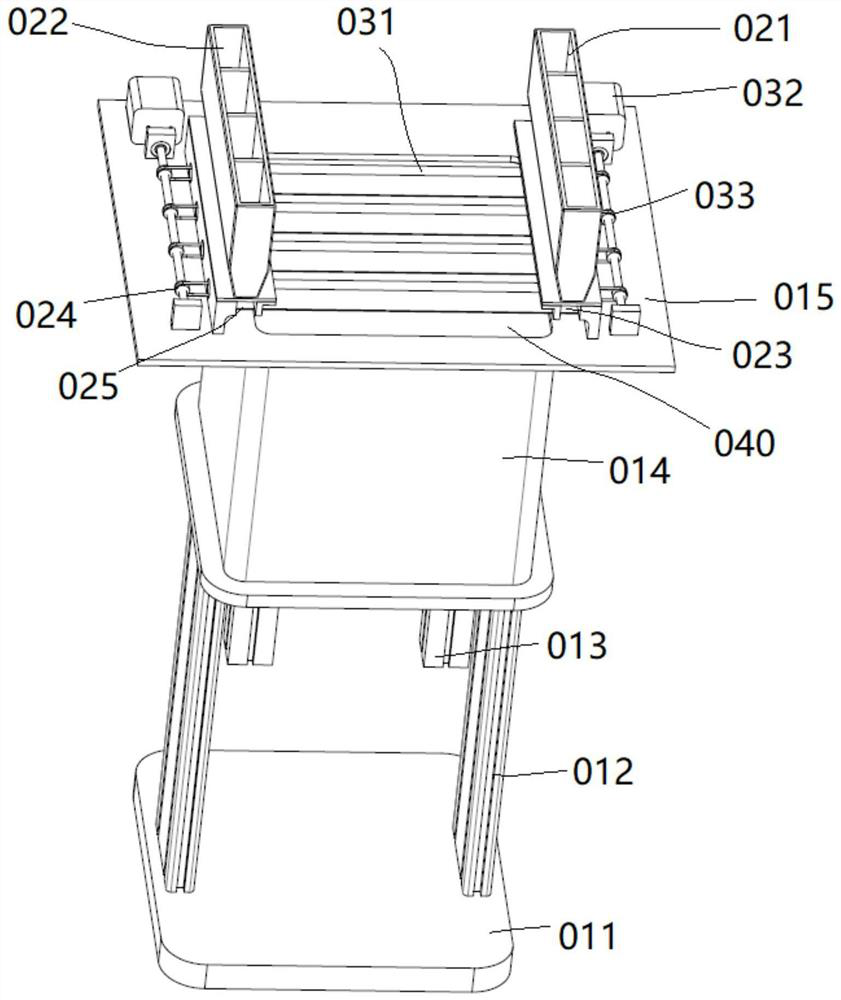

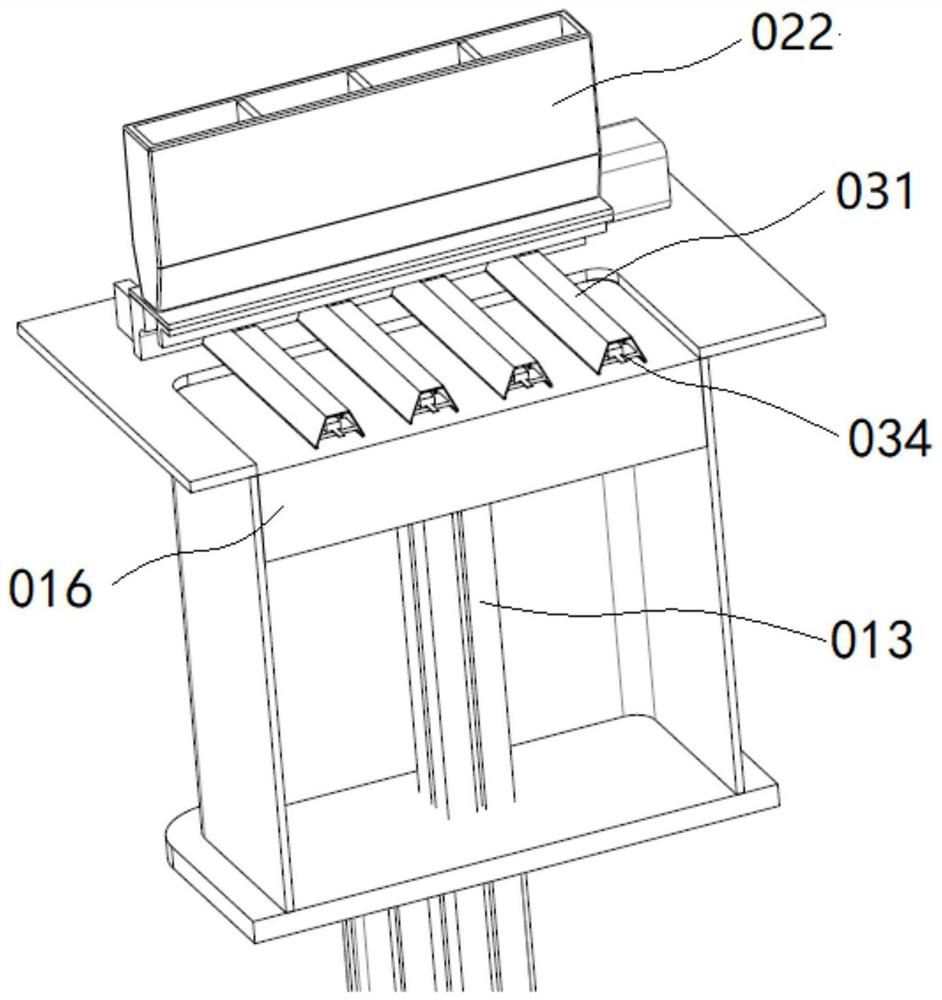

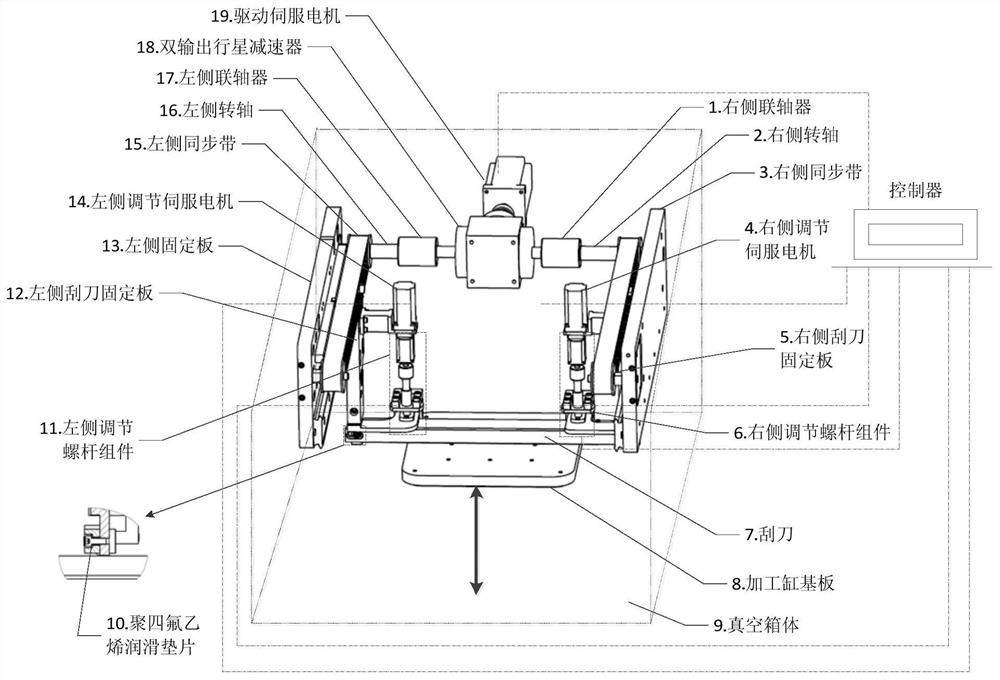

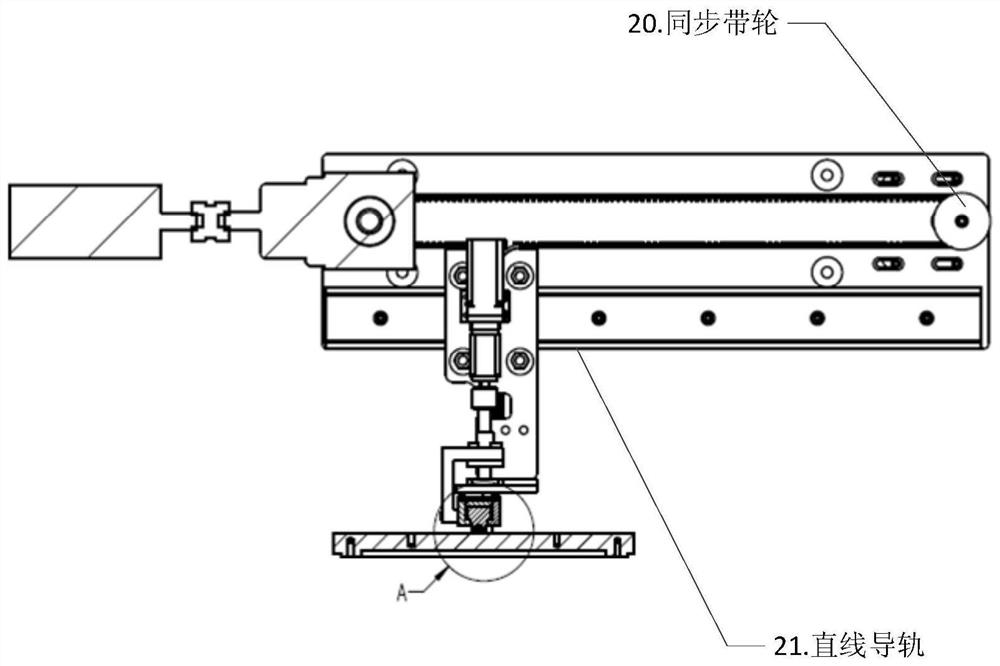

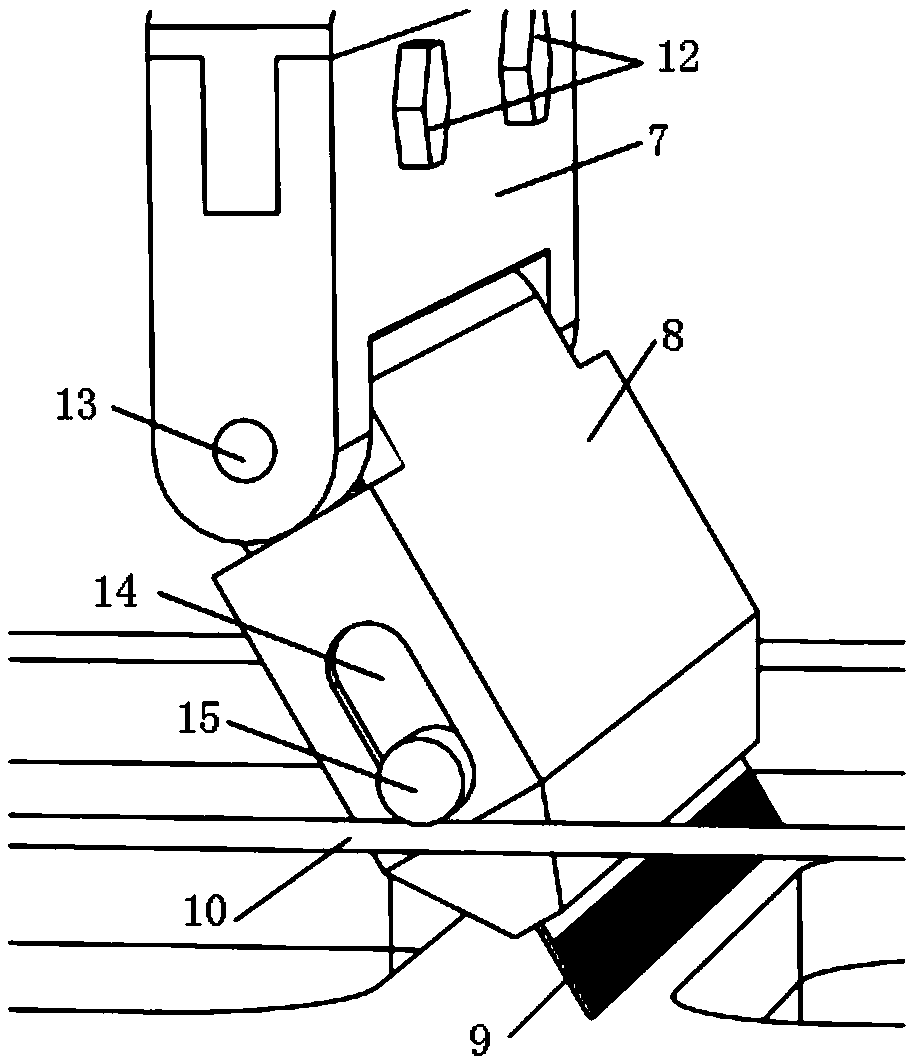

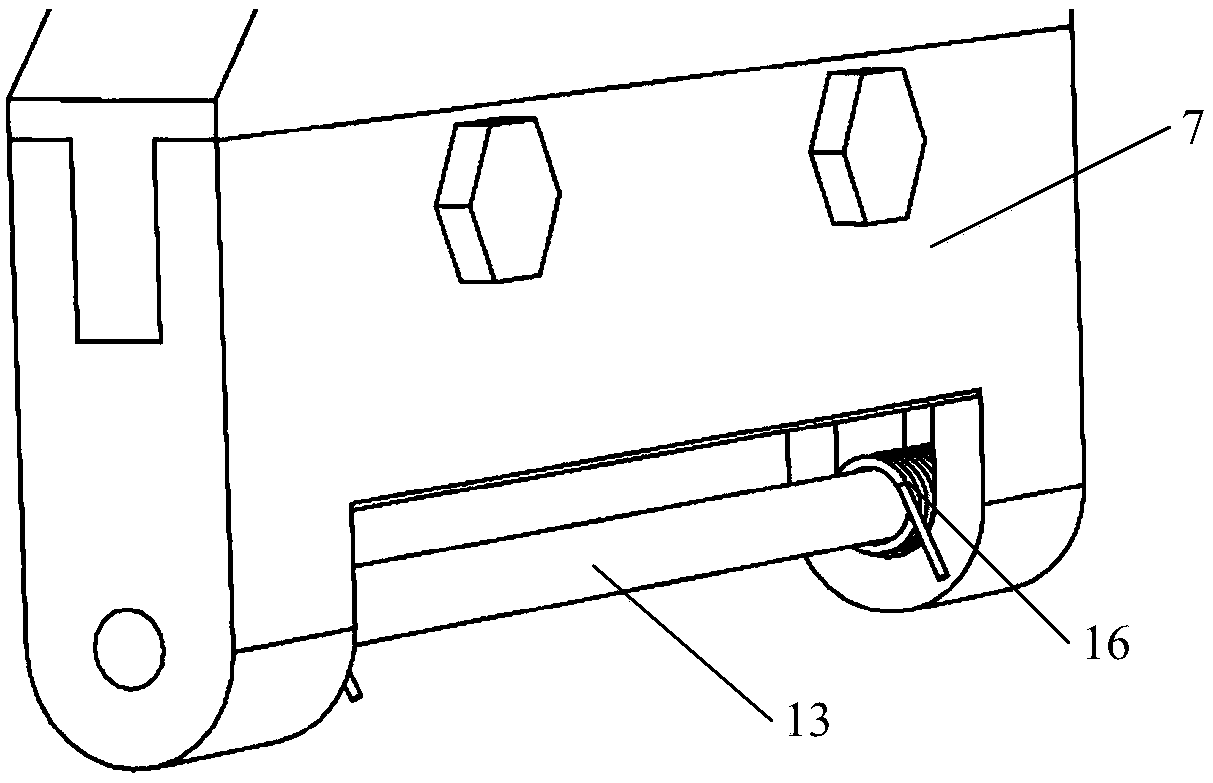

3D printing scraper integrated device and method for improving workpiece forming quality

ActiveCN110238392AImprove forming qualityReal-time monitoring of stress distributionAdditive manufacturing apparatusIncreasing energy efficiencyStress conditionsEngineering

The invention provides a 3D printing scraper integrated device and method for improving the workpiece forming quality. A output shaft of a driving servo motor is connected with a double-output planetary reducer, two output ends of the double-output planetary reducer are both connected with scraper moving devices, a scraper is fixed on two scraper fixing plates, and the scraper moving devices drive the scraper fixing plates so as to drive the scraper to move forward and backward in the powder spreading direction; the scraper is internally provided with a stress sensor array which is used for monitoring the stress condition in the scraper powder spreading process in real time, and transmitting measured data to a controller; and the controller judges whether stress value fluctuation failing to meet the preset condition occurs or not according to the measured data, and if the stress value fluctuation failing to meet the preset condition does not occur, the current operation continues to be executed; otherwise, the scraper is controlled to stop moving, the controller is used for controlling an adjusting device to lift the position of the scraper in the vertical direction according to the measured data, and the scraper is controlled to return to the initial powder spreading position to perform powder spreading printing operation again, so that the high-quality forming of parts is realized.

Owner:SHANGHAI AEROSPACE EQUIP MFG GENERAL FACTORY

3D printing process method for high-strength aluminum-zinc alloy

InactiveCN111850332ALow costImprove qualityAdditive manufacturing apparatusIncreasing energy efficiencyMolten stateZinc alloys

The invention relates to a 3D printing process method for a high-strength aluminum-zinc alloy, and belongs to the technical field of 3D printing. Firstly, high-strength aluminum-zinc alloy raw materials are uniformly mixed by heating and melting; then high-quality aluminum-zinc alloy powder is prepared from the high-strength aluminum-zinc alloy in the molten state by adopting an air atomization technology, and is dried to obtain aluminum-zinc alloy powder for 3D printing; and printing parameters are adjusted, and 3D printing is performed according to the three-dimensional model data of a partin printing equipment with the inert gas introduced, so that a 3D printing product with the high-strength aluminum-zinc alloy as the raw material is obtained. Compared with the prior art, the productprinted through the process has the advantages that the relative density can reach 99% or above, the Vickers hardness can reach 150 HV or above, the tensile strength can reach 420 MPa or above, the elongation rate can reach 7%, the hardness of a sample can reach 170 HV or above after appropriate heat treatment, the tensile strength can be further improved to 510 MPa or above, and the elongation rate is kept at 5% or above.

Owner:TONGJI UNIV

Medical cobalt, tantalum and molybdenum alloy 3D printing metal powder with biocompatibility and preparation method of medical 3D printing metal powder

InactiveCN105817635AImprove mechanical propertiesImprove solderabilityAdditive manufacturing apparatusBiocompatibility TestingManganese

The invention discloses medical cobalt, tantalum and molybdenum alloy 3D printing metal powder with biocompatibility and a preparation method of the medical 3D printing metal powder. The preparation method comprises the following steps: (1) smelting and fluxing a metal raw material to prepare a metal melted solution; (2) performing ultrasonic atomization and condensation on the metal melted solution to prepare alloy particles; (3) performing isostatic pressing treatment on the alloy particles to prepare the medical cobalt, tantalum and molybdenum alloy 3D printing metal powder, wherein the metal raw material consists of the following components in percentage by weight: 25 to 27 percent of tantalum, 10 to 15 percent of molybdenum, 0.06 to 0.5 percent of carbon, 0.01 to 0.02 percent of nickel, 0.5 to 4 percent of iron, 1 to 2 percent of silicon, 1.1 to 1.5 percent of boron, 1.1 to 2 percent of manganese and the balance of cobalt. The medical cobalt, tantalum and molybdenum alloy 3D printing metal powder prepared by the preparation method is excellent in biocompatibility, mechanical property and weldability.

Owner:ANHUI CHUNGU 3D PRINTING INTELLIGENT EQUIP IND TECH RES INST CO LTD

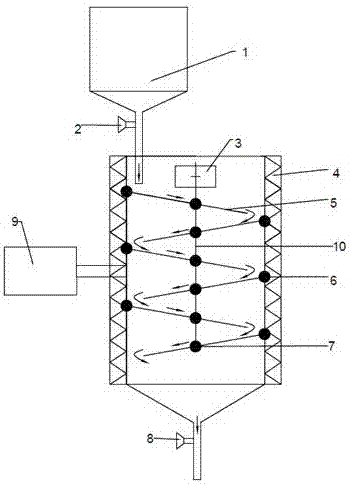

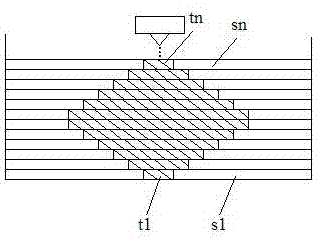

Metal powder degassing method and device

ActiveCN107234237AIncrease exposureFully degassedTransportation and packagingMetal-working apparatusMetal powderVacuum pump

A metal powder degassing method comprises the following steps: (1) closing a powder feeding vacuum valve, opening a powder discharging vacuum valve, opening a vacuum pump and a heating body, and degassing a sheath connected between an enclosed tank body and the powder discharging vacuum valve at the temperature lower than 600 DEG C; (2) when the vacuum degree of the enclosed tank body is lower than 0.01 Pa, adjusting the inclination angle of each powder spreading plate to 8-15 degrees through a control rod, wherein the vibration frequency is 50-100 Hz; (3) opening the powder feeding vacuum valve, wherein the powder dropping rate is lower than 80 kg / h; (4) in the powder dropping process, reducing the powder dropping rate if the vacuum degree is higher than 0.01 Pa; and (5) if the segregation of powder occurs, reducing the inclination angle of each powder spreading plate, improving the vibration frequency, and spreading the powder. A metal powder degassing device comprises a series of powder spreading plates, wherein the powder spreading plates are connected with the side wall of the enclosed tank body through hinges and connected with the control rod through sliding supports, thereby forming a folded-line path for the powder flow; through the control rod, the inclination angle of each powder spreading plate can be controlled and the vibrations can be transferred; and the gas adsorbed in the gaps among powder particles and on the surfaces of the powder particles can be effectively removed, thereby remarkably improving the part manufacturing performance after powder consolidation.

Owner:SINO EURO MATERIALS TECH OF XIAN CO LTD

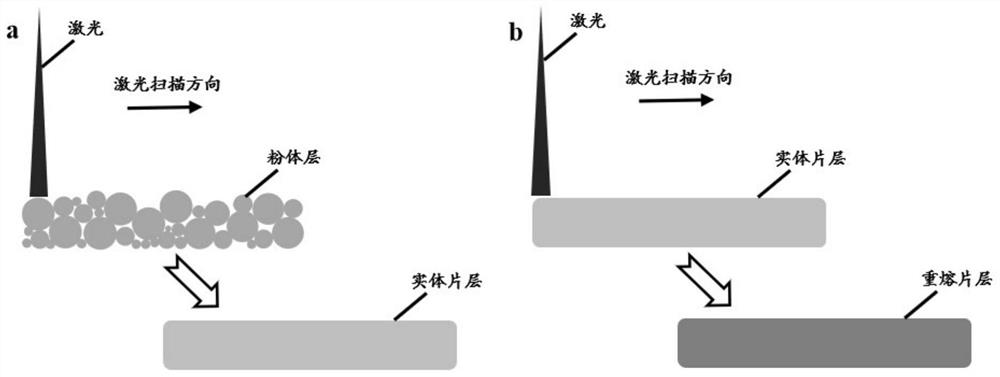

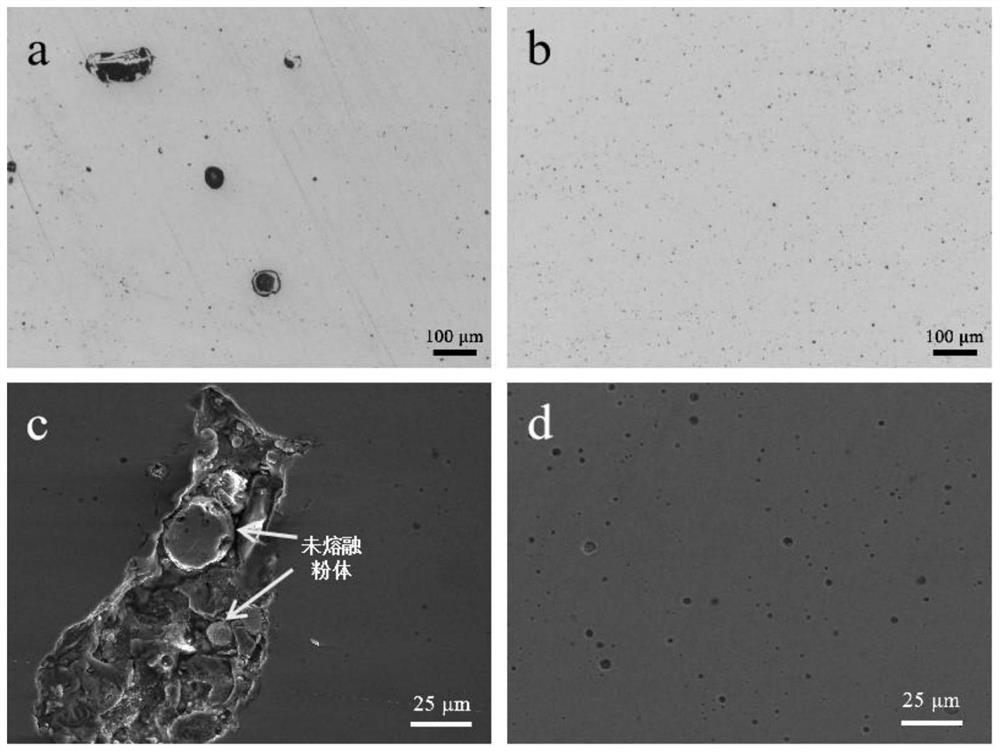

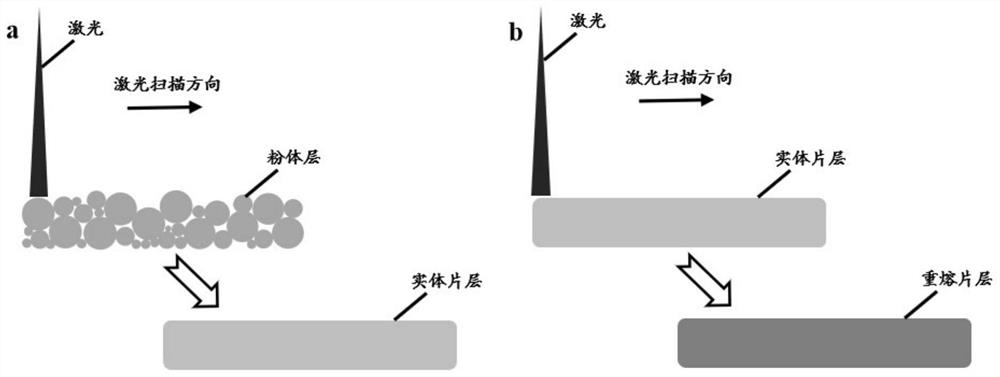

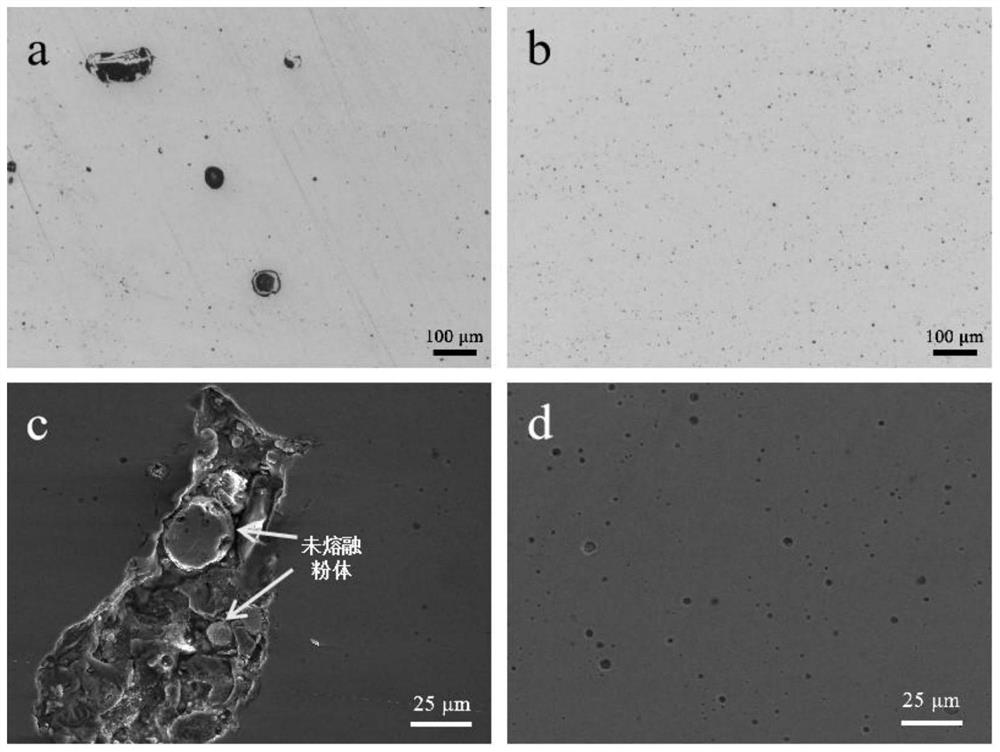

Laser additive manufacturing method of in-situ synthesized nano Al2O3 reinforced aluminum-based composite material

ActiveCN112176213AAchieve alloyingImprove mechanical propertiesAdditive manufacturing apparatusIncreasing energy efficiencySelective laser meltingMg composite

The invention discloses a laser additive manufacturing method of an in-situ synthesized nano Al2O3 reinforced aluminum-based composite material. The method comprises the following steps of (1) mixingZnO ceramic powders and AlSi10Mg aluminum alloy powders, and carrying out ball milling to obtain ZnO / AlSi10Mg composite powders; (2) carrying out additive manufacturing forming on the composite powders by adopting a selective laser melting process to form a solid sheet layer; (3) carrying out laser scanning on the solid sheet layer again to form a remelting sheet layer; (4) repeating the steps (2)and (3), and finally forming to obtain the in-situ synthesized nano Al2O3 reinforced aluminum-based composite material. A laser is used for exciting Al and ZnO to generate aluminothermic reactions between the Al and ZnO to generate Al2O3 ceramic particles in situ, the overall process design of the method is improved, selective laser melting and laser remelting scanning are matched, the prepared aluminum-based composite material is high in density and fine in microstructure, the in-situ synthesized Al2O3 particles are nanoscale in size and are uniformly distributed, and the phase interfaces ofthe Al2O3 particles are well combined with an aluminum matrix.

Owner:HUAZHONG UNIV OF SCI & TECH +1

High-strength cobalt-tantalum-molybdenum alloy medical 3D-printing metal powder and preparation method thereof

InactiveCN106041105AImprove mechanical propertiesImprove solderabilityAdditive manufacturing apparatusManganeseBiocompatibility Testing

The invention discloses high-strength cobalt-tantalum-molybdenum alloy medical 3D-printing metal powder and a preparation method thereof. The preparation method comprises the steps that (1) metal raw materials are smelted and slagged to obtain molten metal; (2) the molten metal is subjected to ultrasonic atomizing treatment and condensation to obtain alloy particles; and (3) the alloy particles are subjected to isostatic pressing treatment to obtain the cobalt-tantalum-molybdenum alloy medical 3D-printing metal powder. The metal raw materials comprise, with the total weight of the metal raw materials as the benchmark, 27-29% of tantalum, 10-15% of molybdenum, 0.06-0.5% of carbon, 0.01-0.02% of nickel, 0.5-4% of iron, 1-2% of silicon, 1.1-1.5% of boron, 1.1-2% of manganese and the balance cobalt. The cobalt-tantalum-molybdenum alloy medical 3D-printing metal powder prepared through the method has excellent biocompatibility, mechanical performance and weldability.

Owner:ANHUI CHUNGU 3D PRINTING INTELLIGENT EQUIP IND TECH RES INST CO LTD

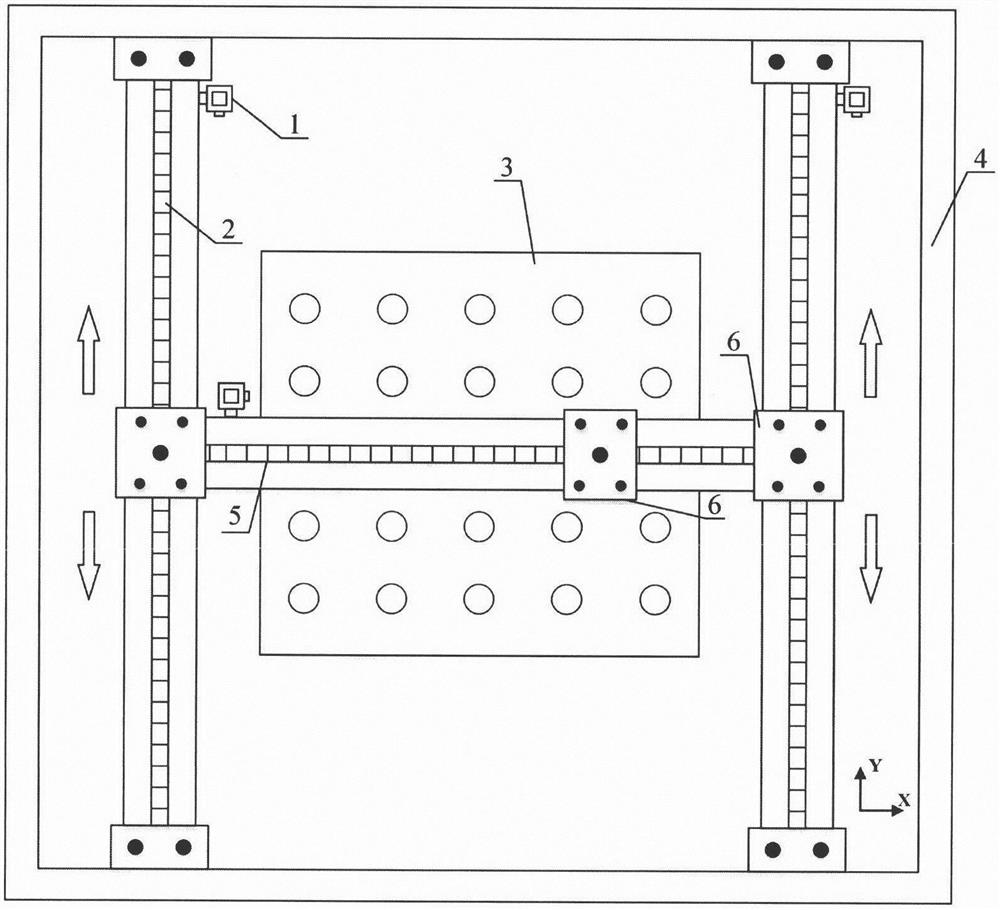

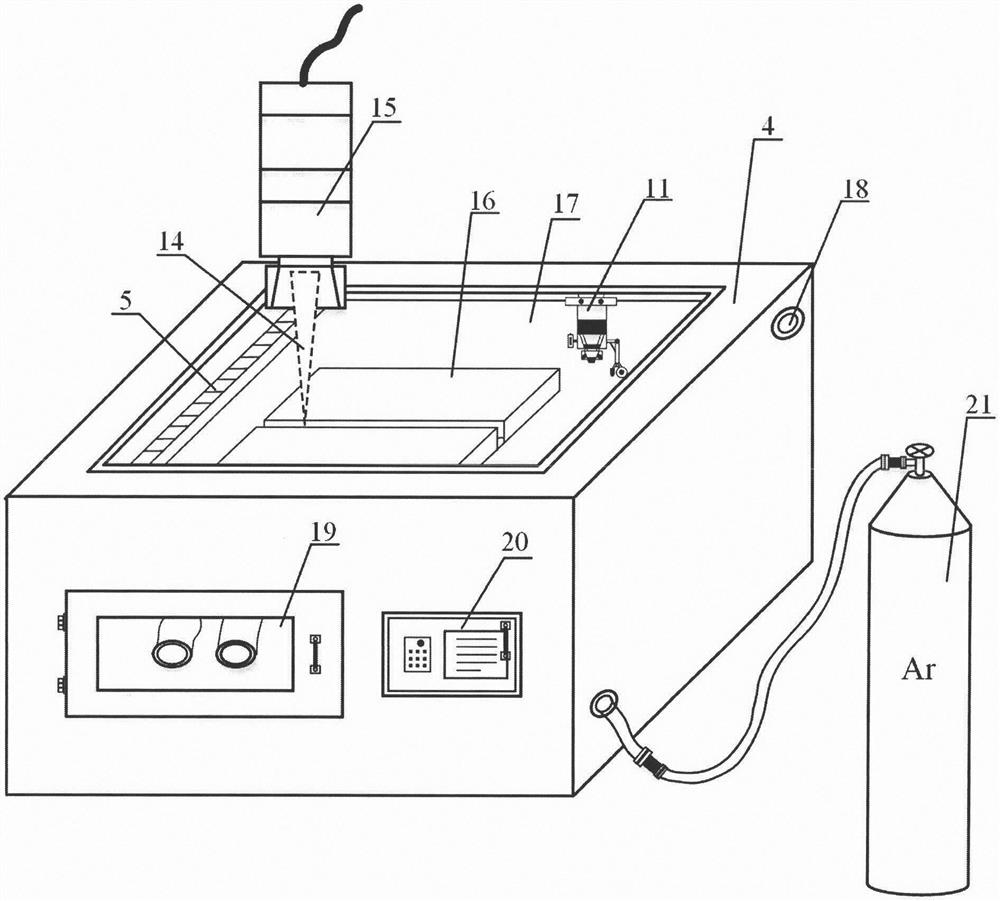

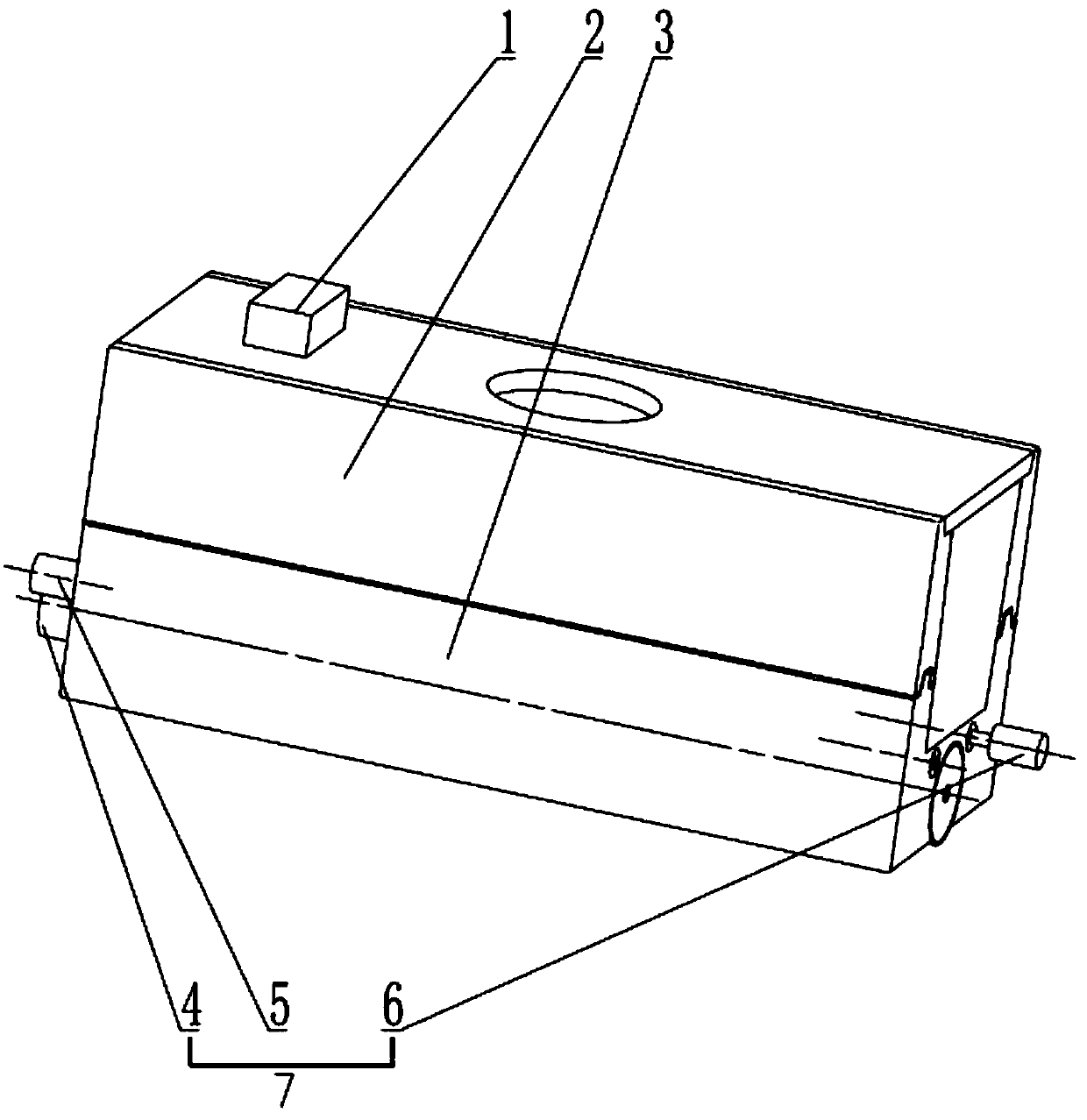

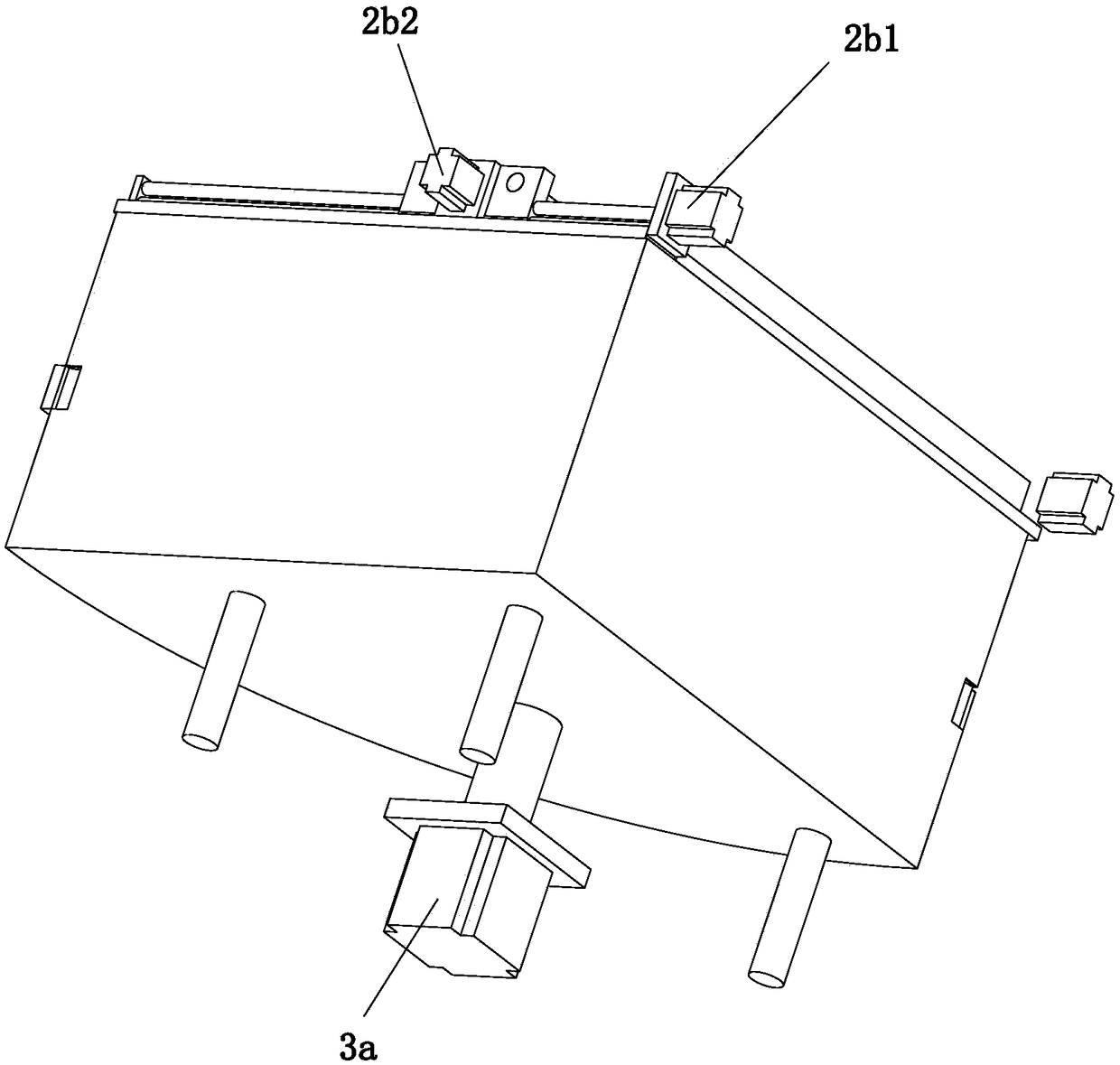

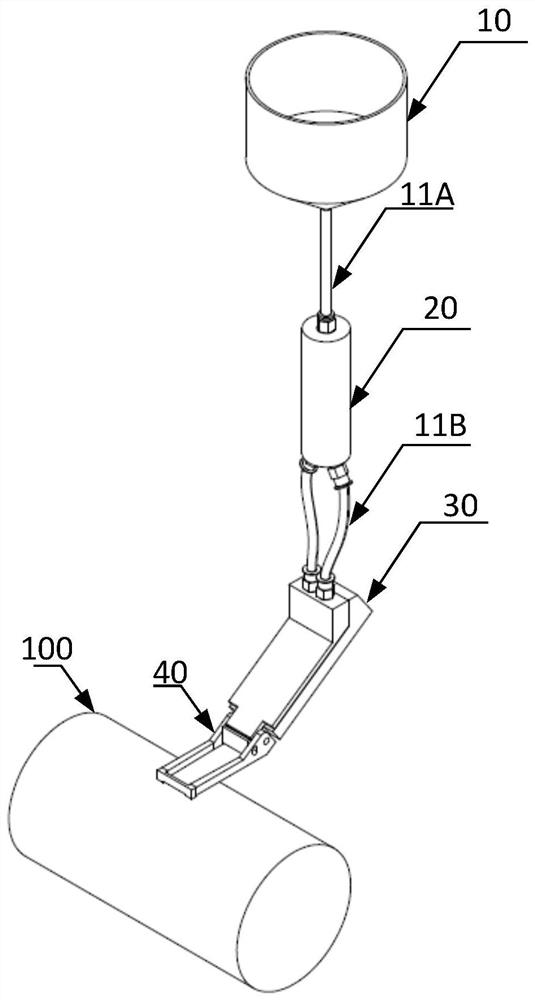

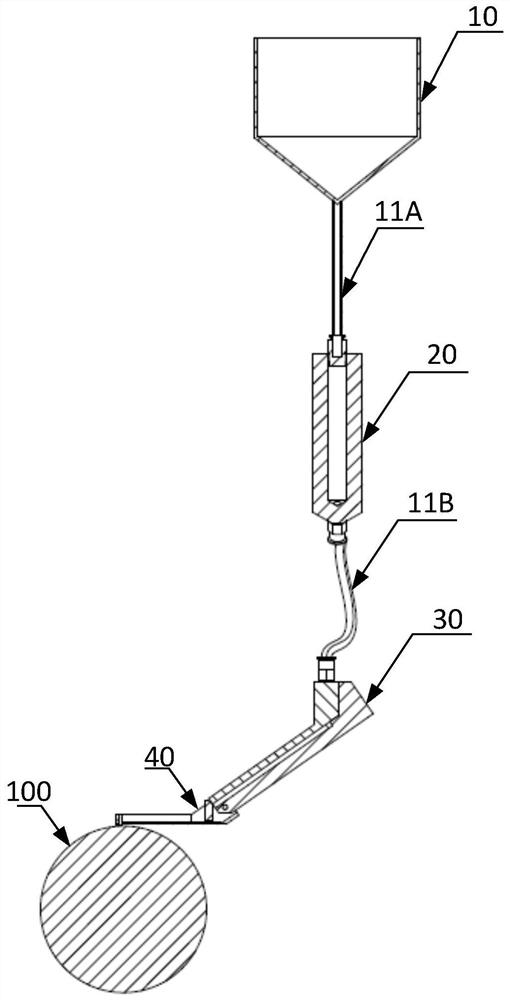

Large-thickness titanium alloy narrow-gap laser welding device and method based on automatic powder laying

PendingCN112453704ASpread powder evenlyIncrease profitWelding/soldering/cutting articlesLaser beam welding apparatusControl systemShielding gas

The invention relates to a large-thickness TC4 titanium alloy narrow-gap laser welding device and method based on automatic powder laying. The device mainly comprises a guide rail movement system, a powder distribution device, a closed argon box, a control system and laser welding equipment, wherein the guide rail movement system comprises an X-direction guide rail, a Y-direction guide rail, a driving mechanism and a sliding table. The powder distribution device is fixedly connected with the sliding table, movement in the horizontal plane is achieved through the guide rail system, and therefore the purposes of powder feeding and powder laying are achieved. Besides, the top of an argon box body is provided with low-reflection glass, a closed argon environment can be provided for the titanium alloy welding process, and laser welding in the protective gas environment is achieved. According to the device and method, the problem of a large-thickness titanium alloy narrow-gap laser powder filling welding process method is solved, a complete process solution is provided, a defect-free welding joint can be obtained after welding, and the application of a large-thickness titanium alloy narrow-gap laser welding technology to the aviation field is further improved.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

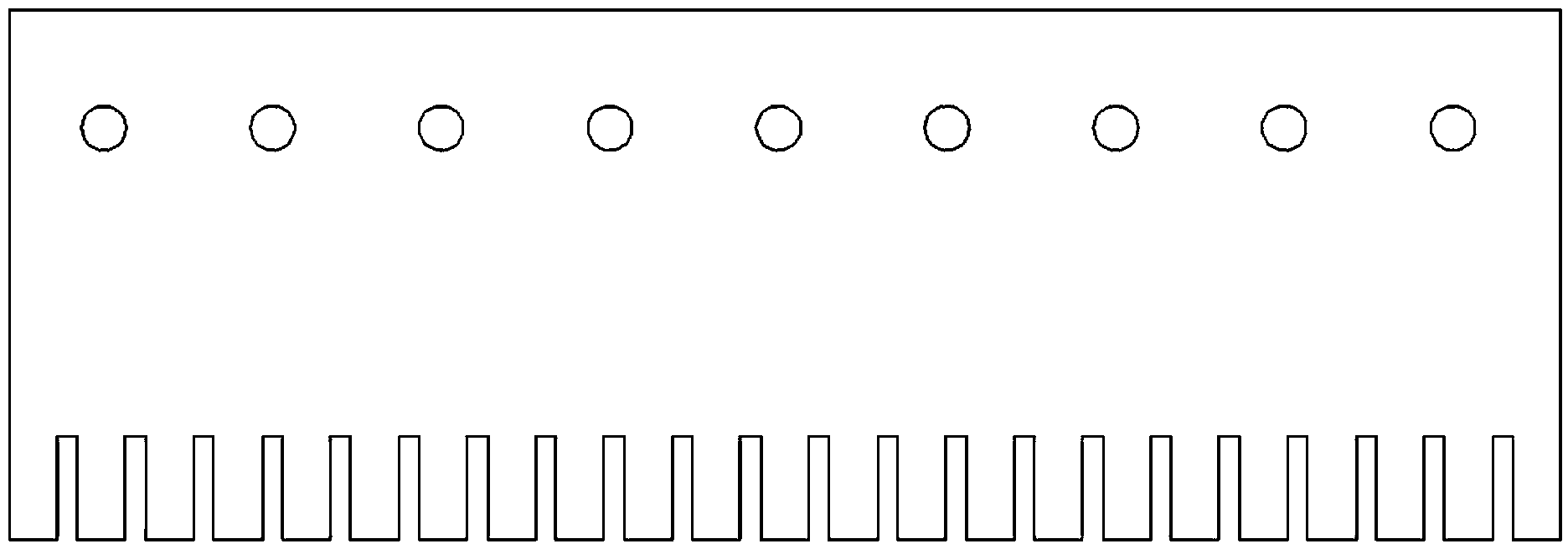

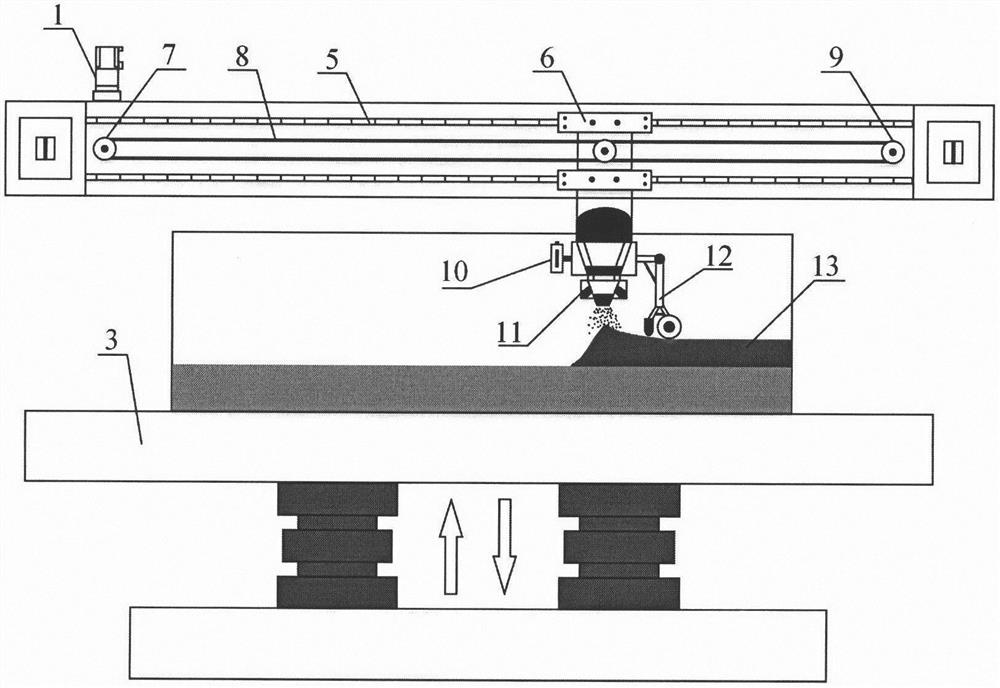

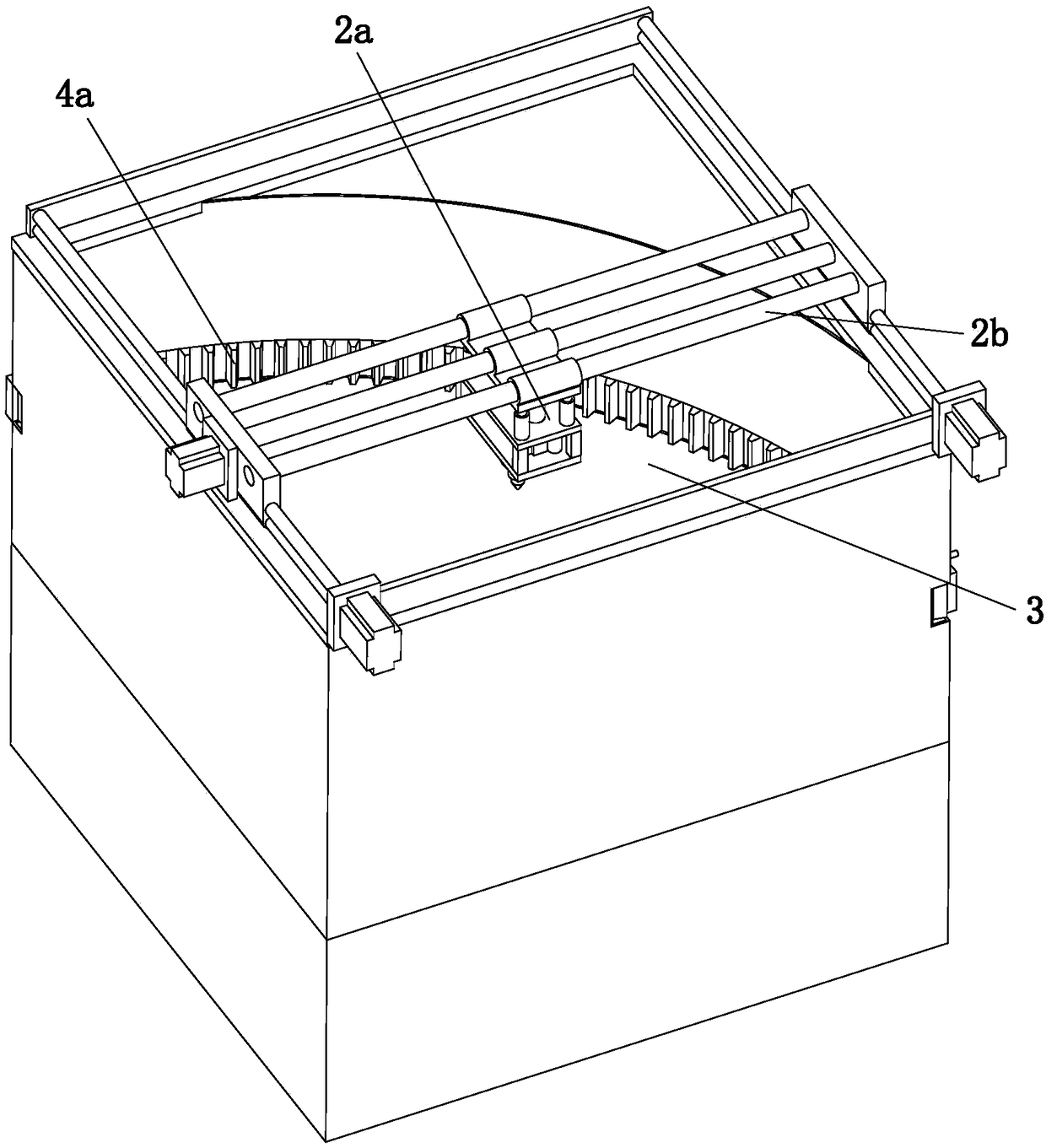

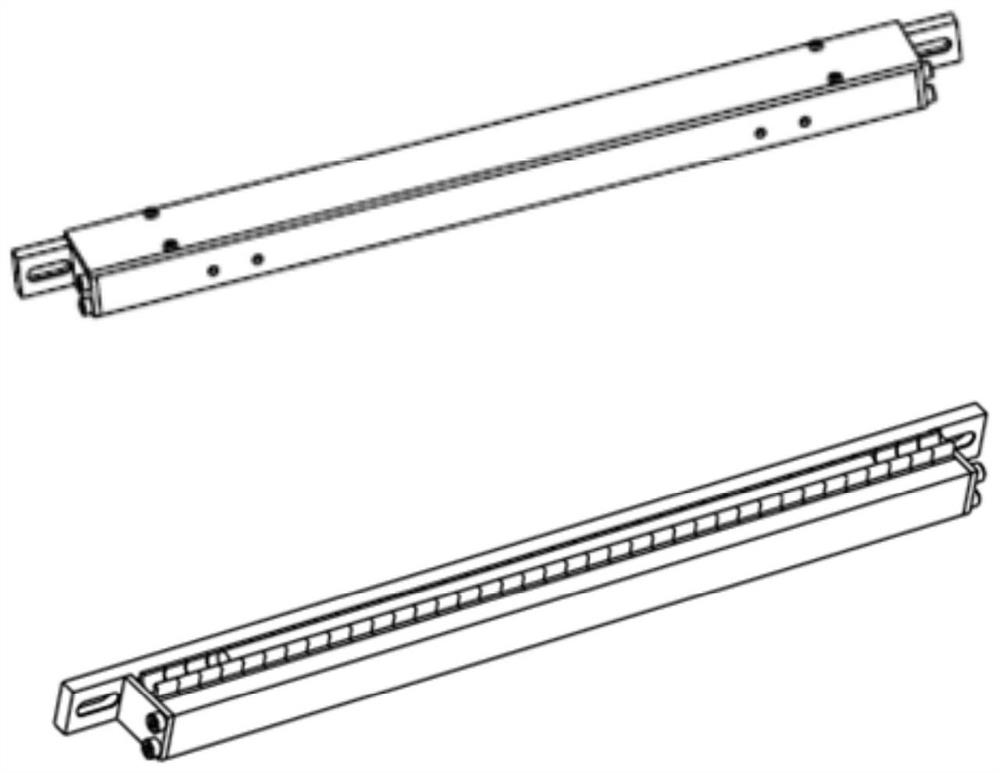

Automatic reversing inclined powder laying device and method for mechanical laser selective melting

ActiveCN106623918AImprove spreading efficiencyReduce the powder phenomenonAdditive manufacturing apparatusIncreasing energy efficiencyMetallurgyReciprocating motion

The invention discloses an automatic reversing inclined powder laying device and method for mechanical laser selective melting. A first powder recycling cylinder, a first powder laying brush reset groove, a forming cylinder, a powder cylinder, a second powder laying brush reset groove and a second powder recycling cylinder below a forming platform are arranged in sequence in the length direction of the forming platform. Guide rails for providing guiding and supporting and positioning actions for a powder laying brush are symmetrically arranged above the forming platform. When the powder laying brush is driven by a movement mechanism to move, the powder laying brush can perform reciprocating movement above the first powder recycling cylinder, the first powder laying brush reset groove, the forming cylinder, the powder cylinder, the second powder laying brush reset groove and the second powder recycling cylinder along the track of the guide rails. The device maintains advantages of a currently universal vertical powder laying brush that powder laying is uniform and high in precision, and the powder rebounding phenomenon frequently occurring to the currently universal vertical powder laying brush is also greatly lowered; and the inclined powder laying manner can make a powder laying layer be evener and denser, and meanwhile the service life of an elastic steel sheet is prolonged.

Owner:SOUTH CHINA UNIV OF TECH

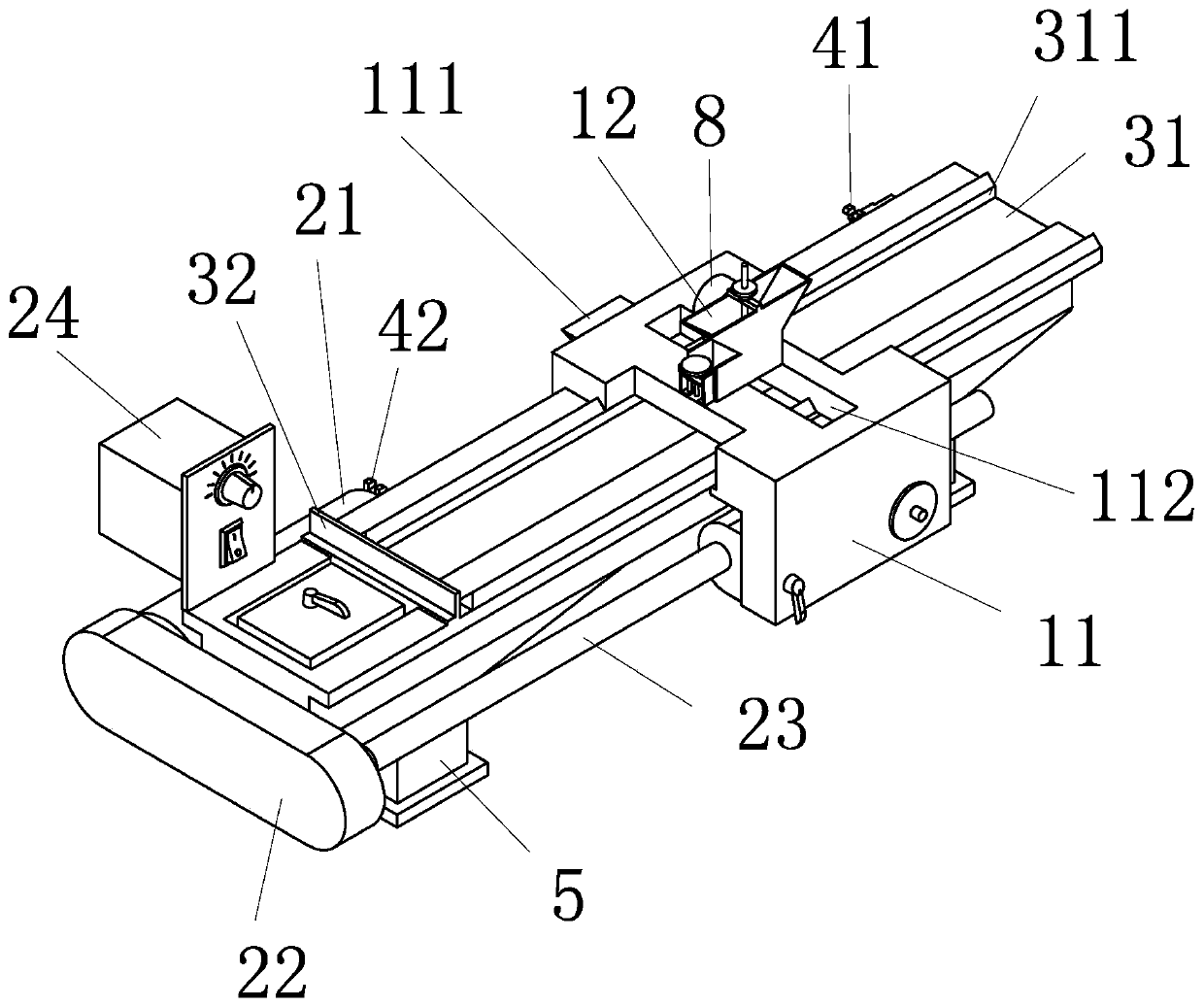

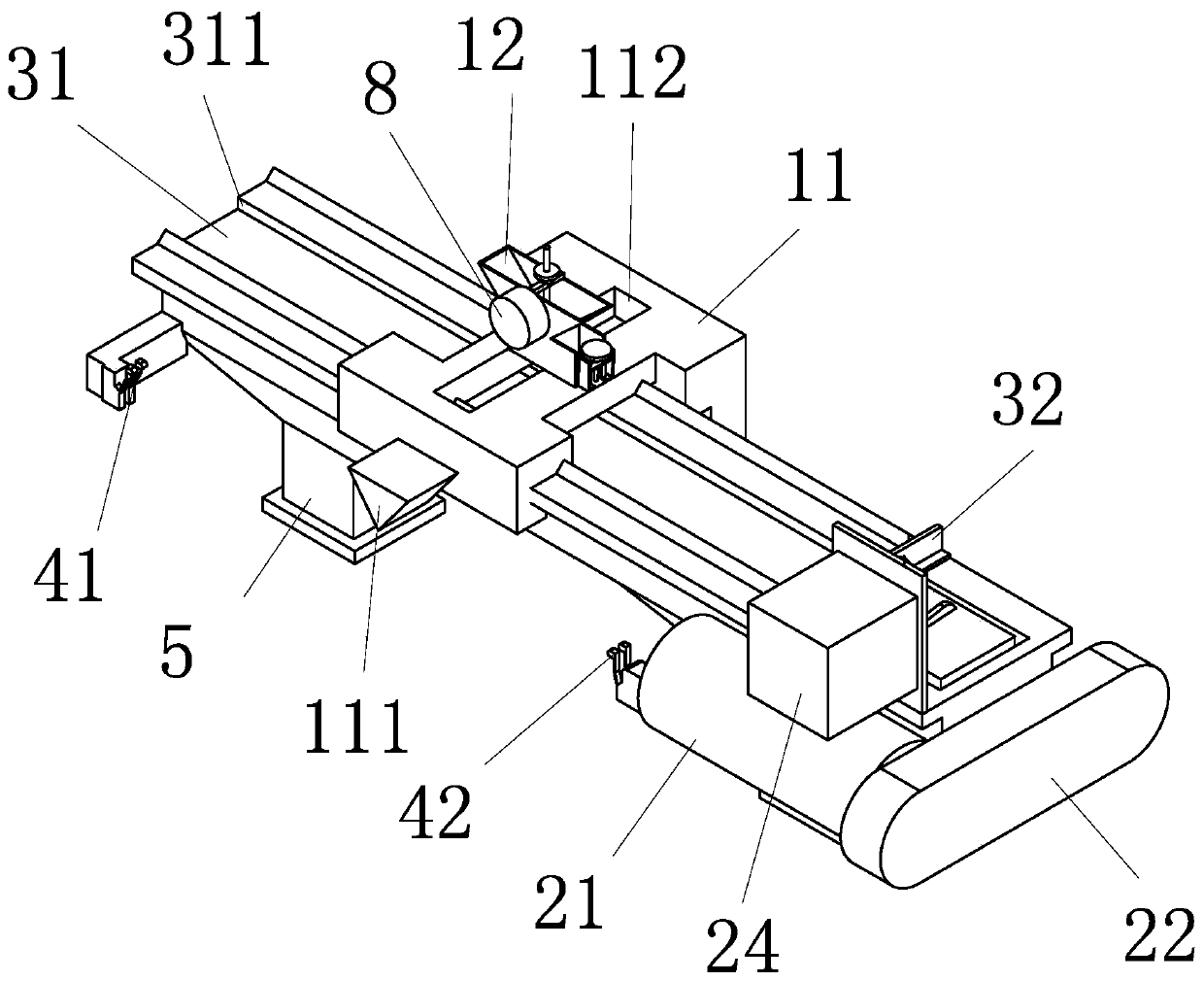

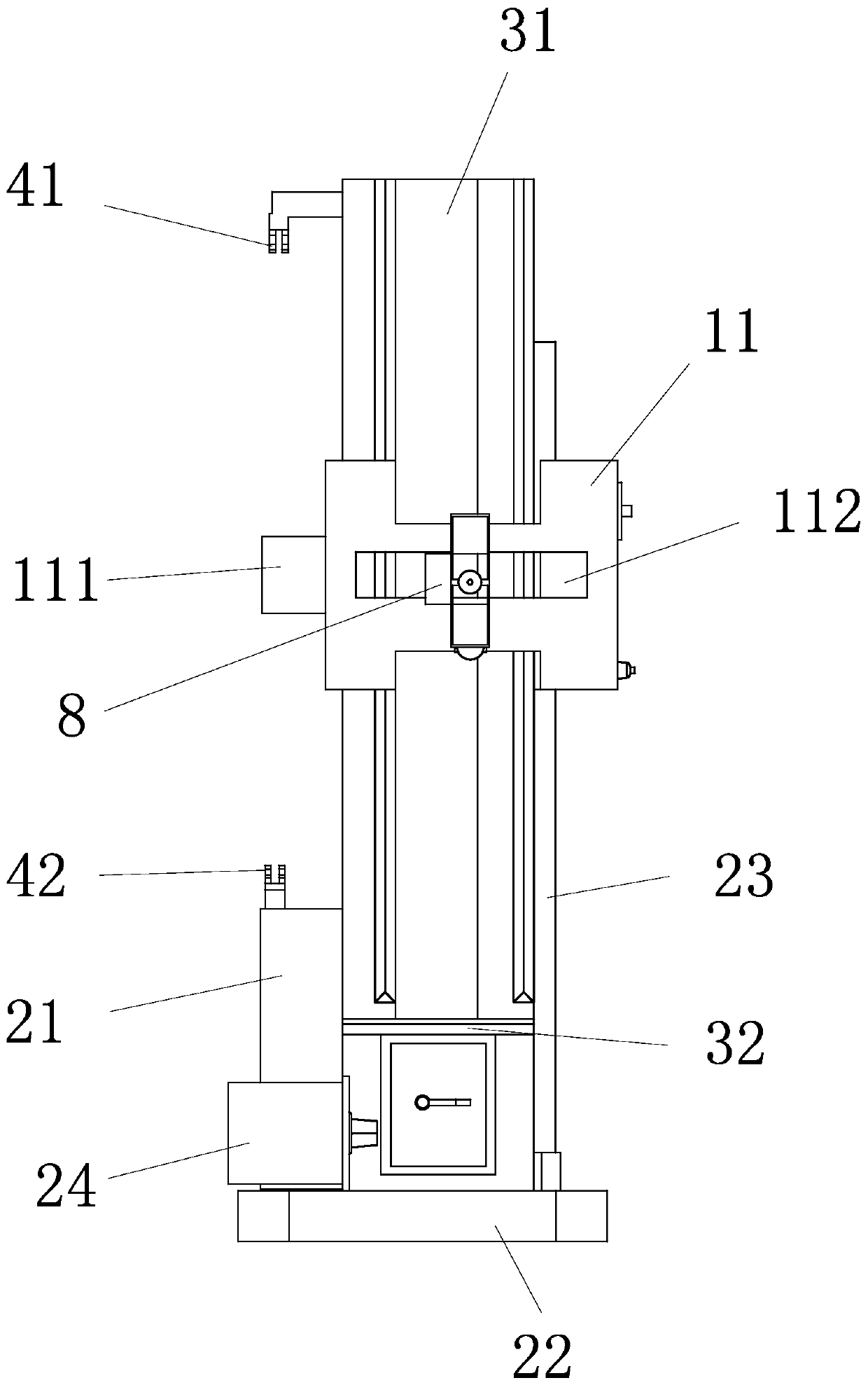

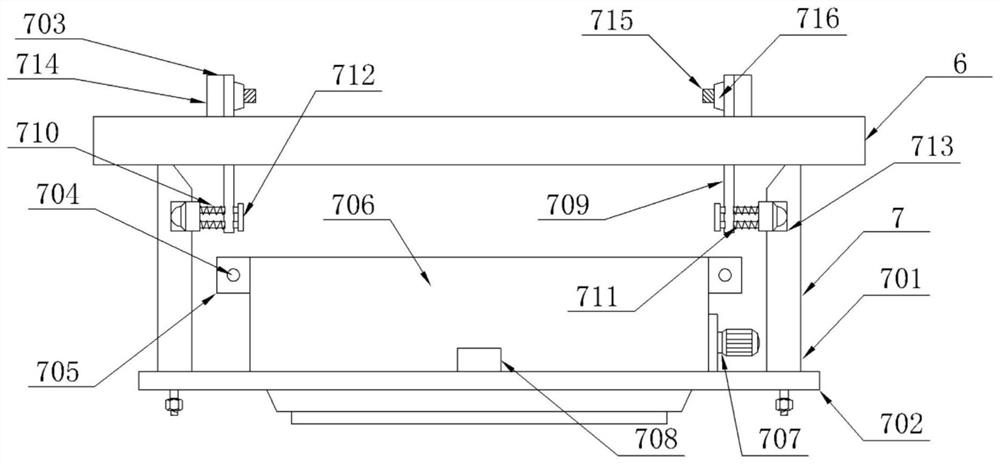

Rapid powder spreading device for powder plate rolling and compounding

The invention relates to a rapid powder spreading device for powder plate rolling and compounding. The device comprises a frame, a powder spreader, a vibration motor, a driving device and a control device, wherein the powder spreader is arranged above a metal plate and connected to the frame in a sliding manner, a powder outlet is formed in the bottom of the powder spreader, the vibration motor isfixedly connected to the powder spreader, the vibration motor is provided with a frequency modulation switch, the frequency modulation switch is electrically connected with the vibration motor, the driving device is fixedly connected to the frame, the driving device drives the powder spreader to move linearly in the powder spreading direction, and the control device controls the driving device toact. The powder spreader is driven by the driving device to linearly move in the powder spreading direction, powder can be quickly and uniformly spread on the metal plate through the powder outlet, powder cannot be brought or scratched in the powder spreading process, and the powder spreading effect is good.

Owner:SOUTH CHINA UNIV OF TECH

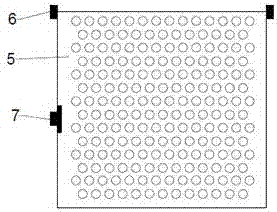

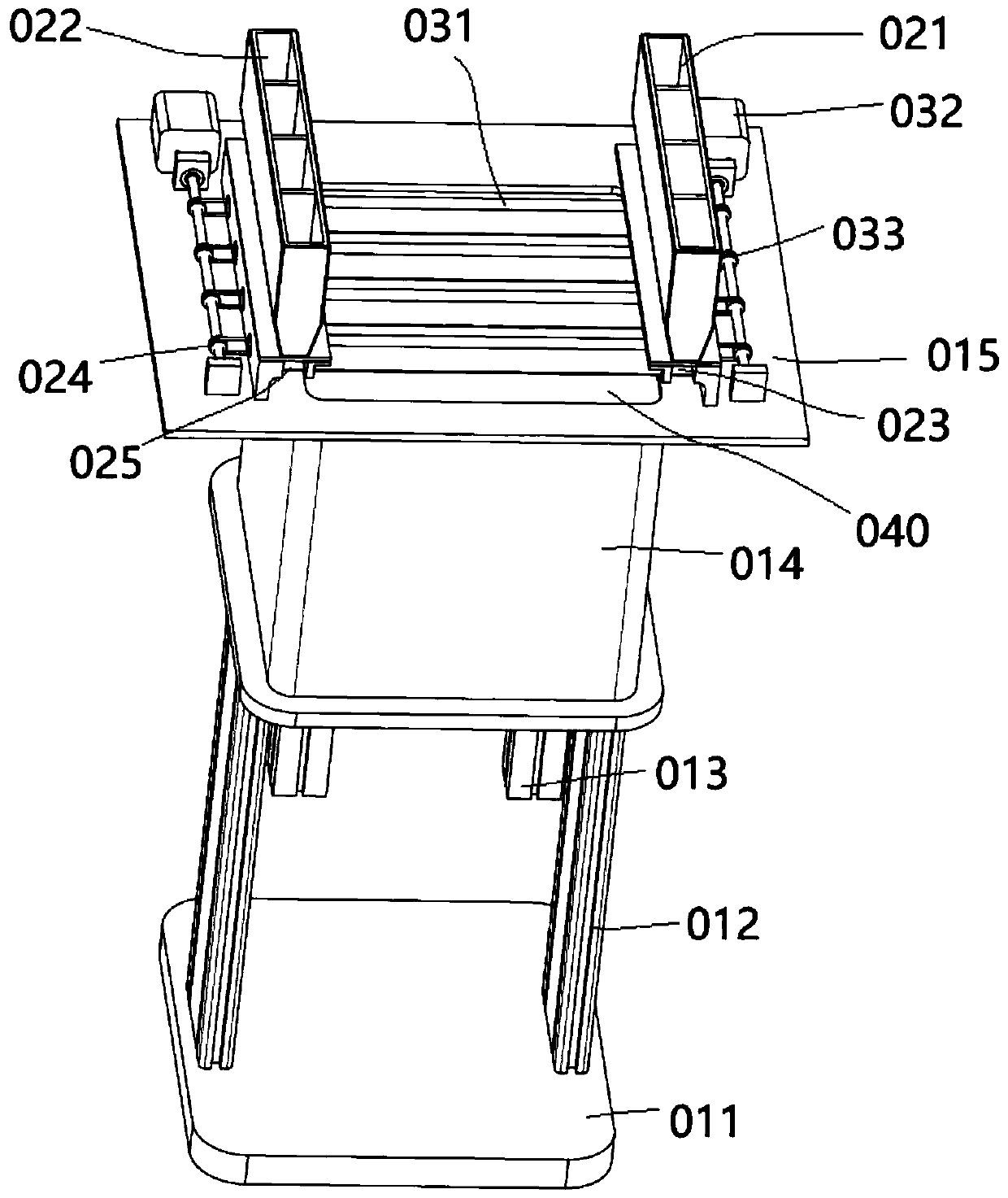

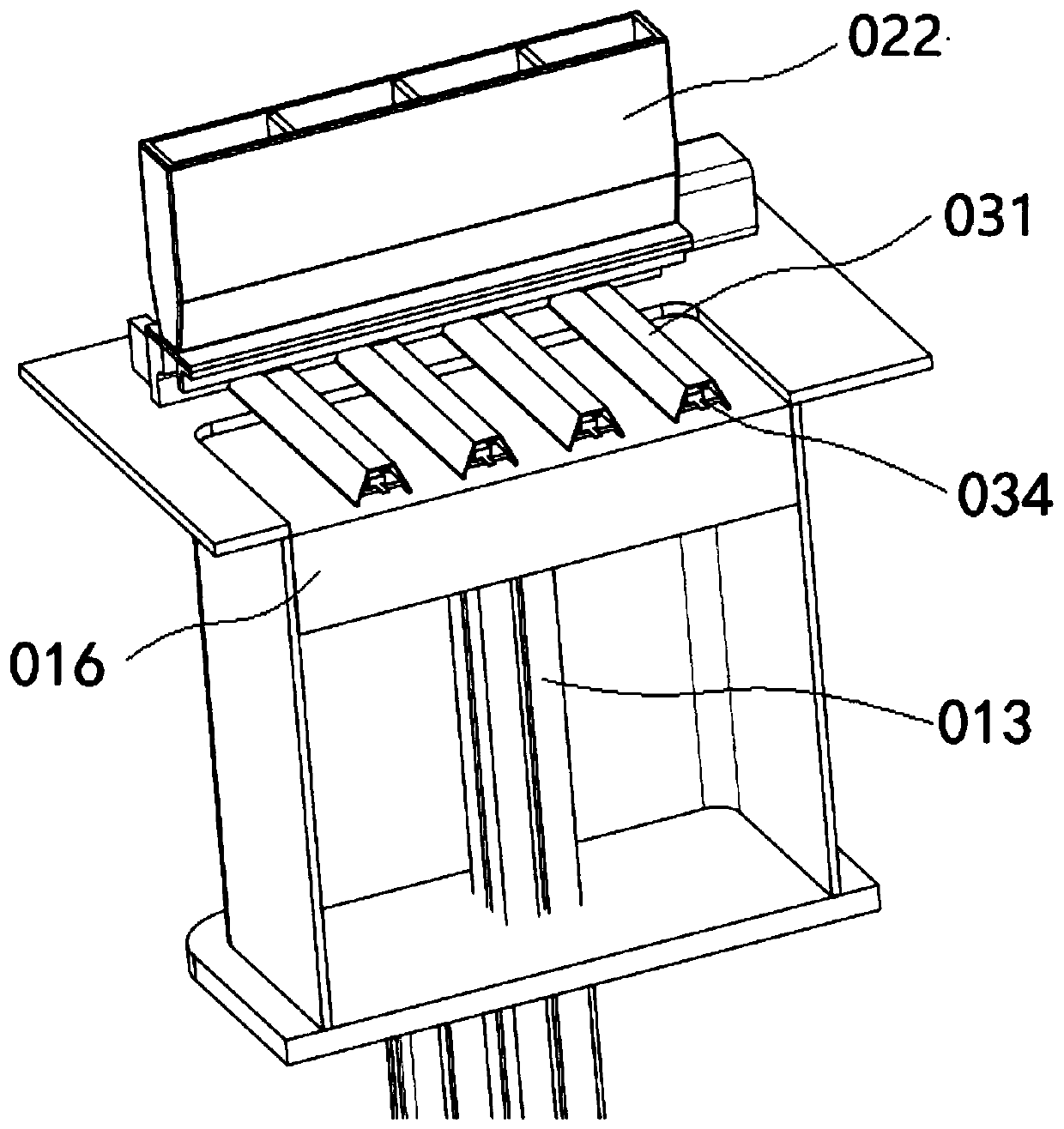

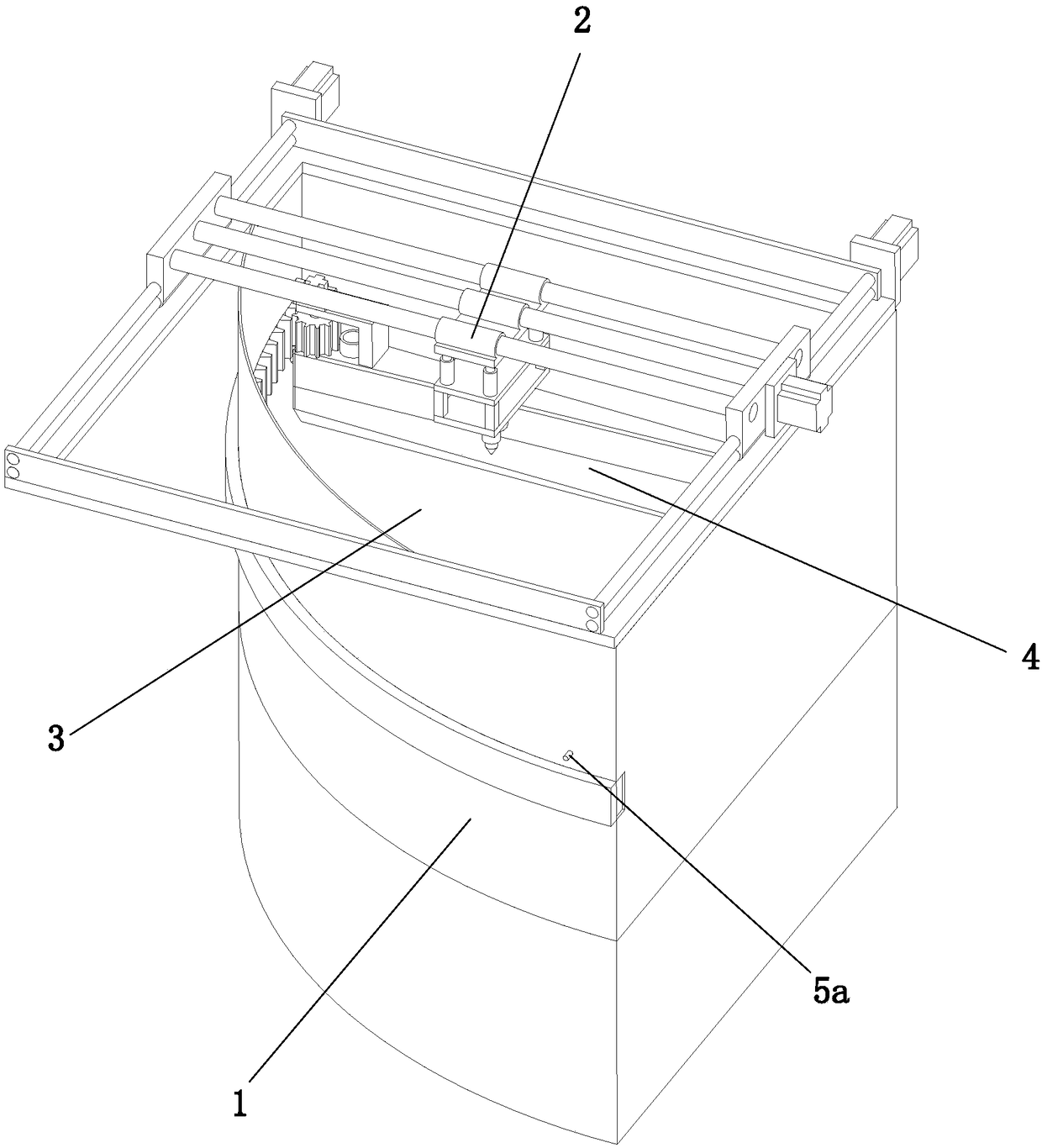

Multi-partition array type selective melting manufacturing equipment and process

ActiveCN111267344AReduce waiting time for spreading powderImprove processing efficiencyAdditive manufacturing apparatusIncreasing energy efficiencyElectric machineryEngineering

The invention relates to multi-partition array type selective melting manufacturing equipment and a process. The equipment is characterized in that a forming bin is internally connected with a formingbottom plate through a lifting guide rail, a forming platform is arranged at the upper end of the forming bin, a plurality of powder laying grids which are distributed in parallel are arranged on theforming platform, a powder forming area on the forming platform is divided into a plurality of array type powder selecting areas, a powder bin is arranged at each of the two ends of each powder laying grid, the two ends of each powder laying grid and the powder bins on the corresponding powder laying grid are connected with the forming platform through bin sliding bases, the bin sliding bases drive the powder laying grids and the powder bins to perpendicularly reciprocate on the forming platform in the powder laying direction, multi-partition powder laying is formed, and high-energy beams canbe used for printing in the middles of the powder laying grids, so that powder laying and printing are relatively isolated; and a plurality of small scrapers are arranged in each powder laying grid,the small scrapers are connected with scraper driving motors through scraper driving mechanisms, and the scraper driving motors drive the small scrapers to reciprocate in the powder laying grids through the scraper driving mechanisms to evenly lay powder in the powder laying grids.

Owner:UNIV OF SHANGHAI FOR SCI & TECH

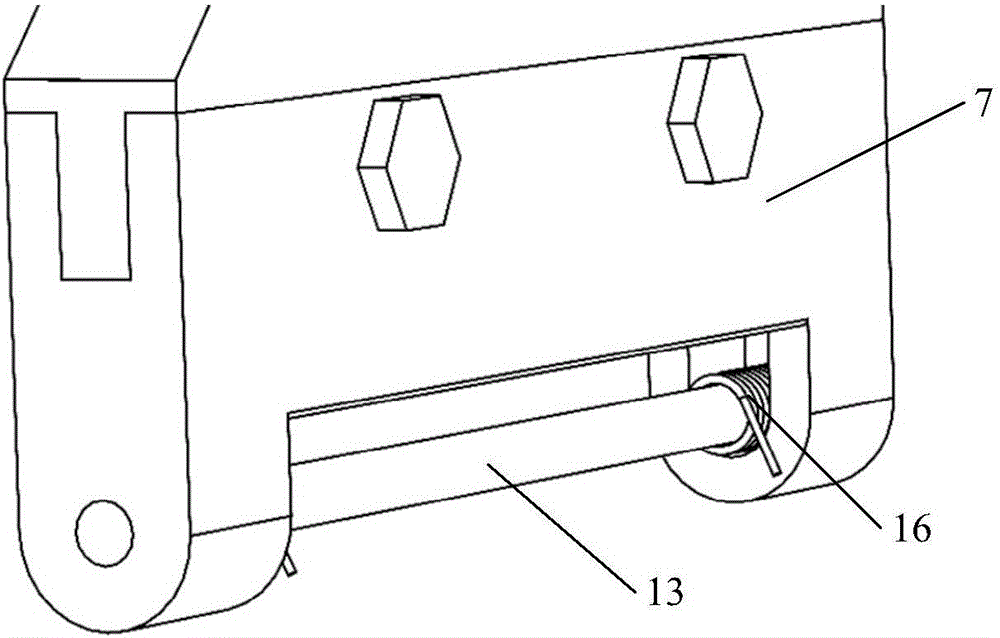

Powder sieving device of 3D printing device

InactiveCN108115932ASpread powder evenly3D object support structuresAdditive manufacturing with solidsSingle platePulp and paper industry

The invention discloses a powder sieving device of a 3D printing device. The device comprises a supporting plate, a sieving plate, a powder discharging plate and a linkage device, the lower end of thepowder discharging plate is sequentially provided with a transverse rectangular groove and a longitudinal rectangular groove from bottom to top, the supporting plate is arranged in the transverse rectangular groove, the sieving plate is arranged in the longitudinal rectangular groove, the two ends of the powder discharging plate are each provided with a sliding groove and a check block, a slidingrod is arranged on each check block, a spring and a sliding block are arranged on each sliding rod, the bottom end of each sliding block is connected with the sieving plate, a powder storage groove is formed in the powder discharging plate, a powder outlet is formed in the bottom of the powder storage groove, a mounting groove is formed in the supporting plate, a spring and a lower abutting blockare arranged in the mounting groove, the lower end of the lower abutting block is connected with the spring, the upper end of the lower abutting block is in contact fit with the lower end of the sieving plate, L-shaped grooves are formed in the two sides of the powder outlet, L-shaped abutting blocks and springs are arranged in the L-shaped grooves, the upper ends of the L-shaped abutting blocksare connected with the springs, and the lower ends of the L-shaped abutting blocks are in contact fit with the upper end of the sieving plate. The device can be matched with the motion period of a scraping knife, and powder output and powder laying are more uniform.

Owner:ANHUI TUO BAO ADDITIVE MFG TECH CO LTD

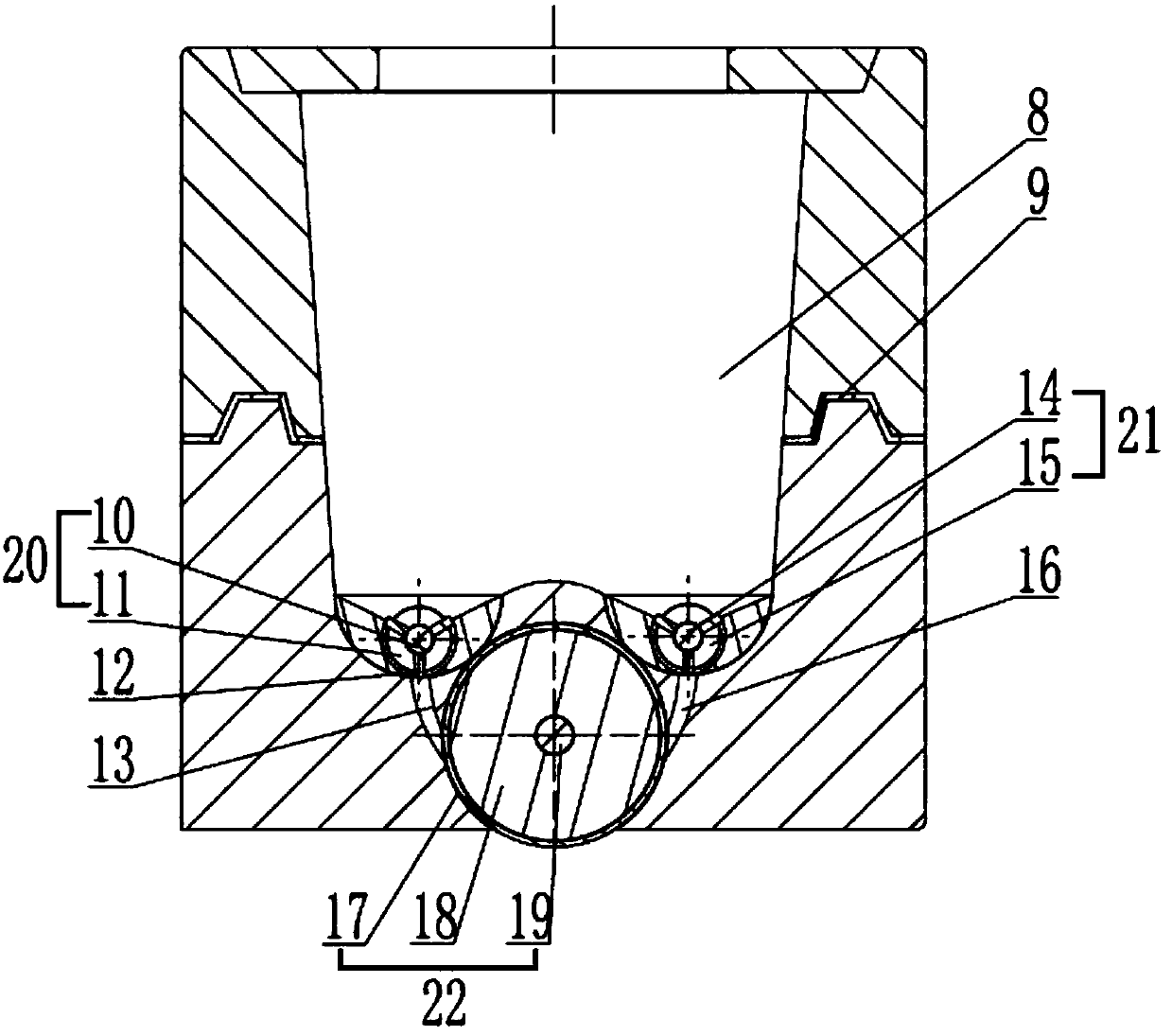

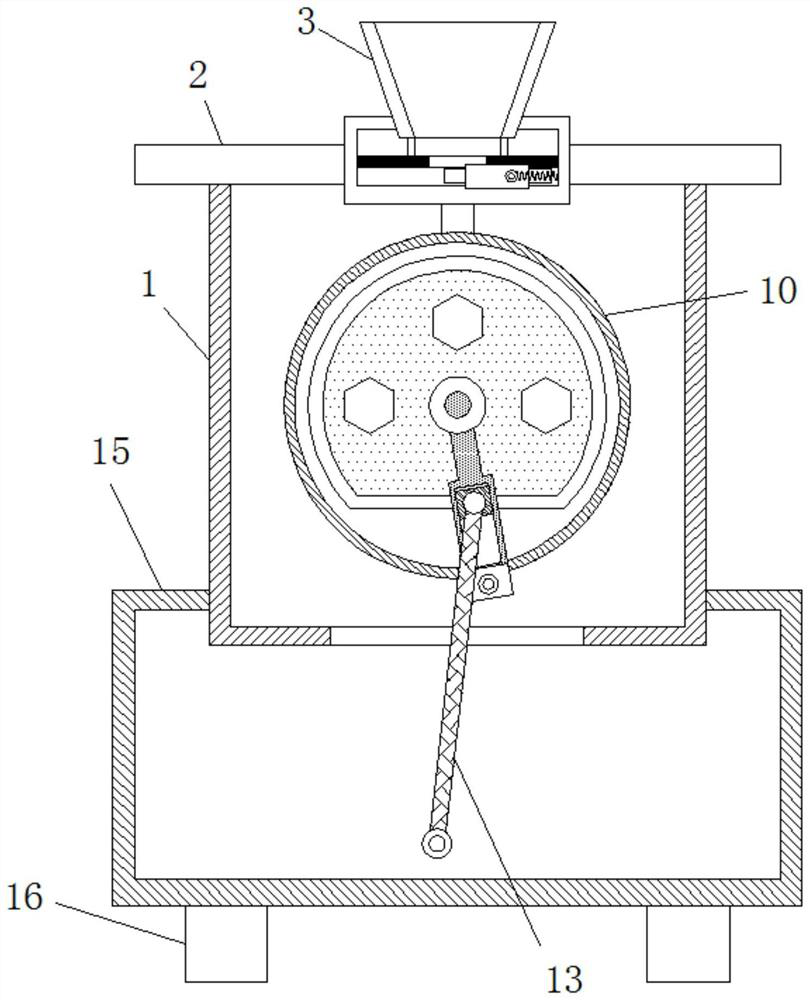

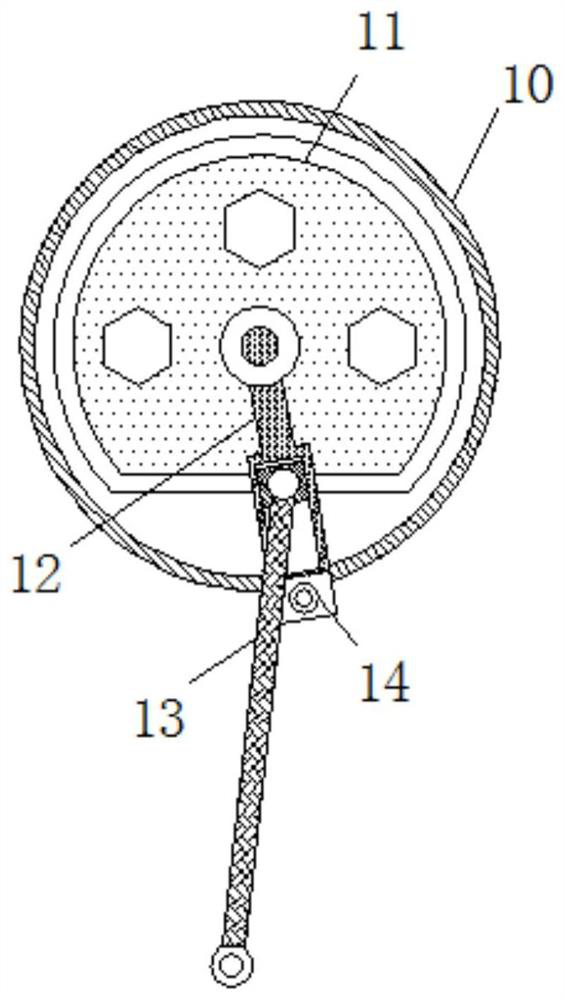

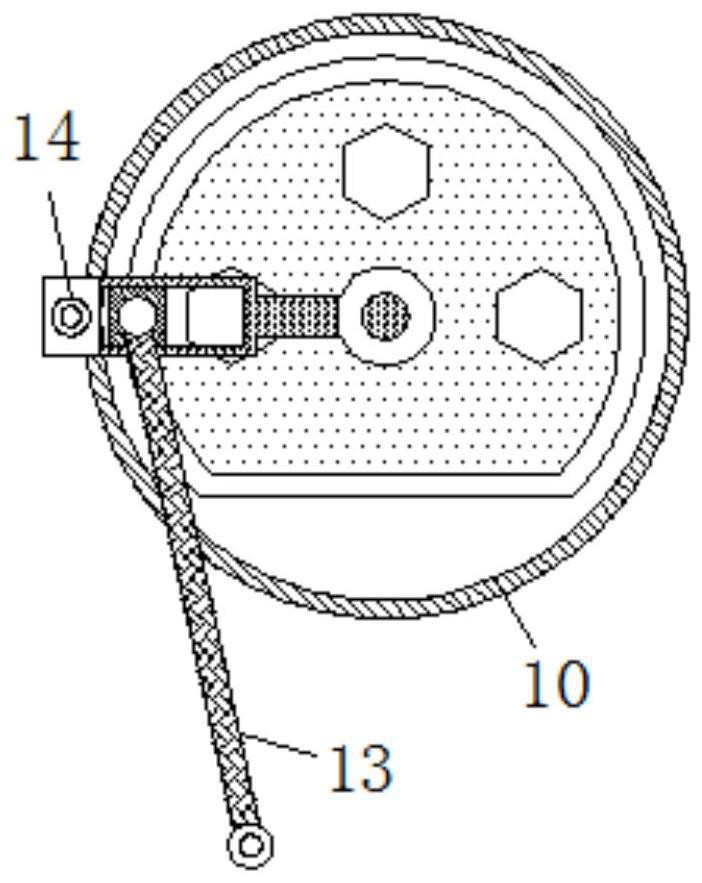

Powder supplying and spreading device

ActiveCN110549598ARealize quantitative powder supplySpread powder evenlyManufacturing enclosures3D object support structuresMetallurgyStorage tank

The invention discloses a powder supplying and spreading device, and belongs to the field of additive manufacturing. The powder supplying and spreading device comprises a powder storage chamber, a powder supplying roller, a powder spreading roller, a level detector and a power device. The powder supplying roller is of a rotor structure. The powder spreading roller is cylindrical. The powder supplying roller comprises a first powder supplying rotor, a first powder storage tank, a second powder supplying rotor and a second powder storage tank. The first powder storage tank and the second powderstorage tank are arranged at the bottom end in the powder storage chamber and are higher than the powder spreading roller. The first powder supplying rotor and the second powder supplying rotor are mounted in the first powder storage tank and the second powder storage tank separately, and the first powder supplying rotor and the second powder supplying rotor and the first powder storage tank and the second powder storage tank are symmetric to the powder spreading roller. The first powder supplying rotor and the second powder supplying rotor are provided with powder feeding blades fixed to thepowder supplying rotors at equal intervals. By the adoption of the rotor structures with the powder feeding blades, quantitative powder supplying and spreading can be achieved, the powder supplying amount is increased, and the efficiency is improved; and the cylindrical powder spreading roller is adopted, powder outlets are formed in the powder spreading roller, uniform powder spreading can be achieved, and the powder spreading quality is improved.

Owner:四川交大至信教育科技有限公司

Medical cobalt, tantalum and molybdenum alloy 3D printing metal powder with weldability and preparation method of medical 3D printing metal powder

InactiveCN105821252AImprove mechanical propertiesImprove solderabilityAdditive manufacturing apparatusBiocompatibility TestingManganese

The invention discloses medical cobalt, tantalum and molybdenum alloy 3D printing metal powder with weldability and a preparation method of the medical 3D printing metal powder. The preparation method comprises the following steps: (1) smelting and fluxing a metal raw material to prepare a metal melted solution; (2) performing ultrasonic atomization and condensation on the metal melted solution to prepare alloy particles; (3) performing isostatic pressing treatment on the alloy particles to prepare the medical cobalt, tantalum and molybdenum alloy 3D printing metal powder, wherein the metal raw material consists of the following components in percentage by weight: 29 to 30 percent of tantalum, 10 to 15 percent of molybdenum, 0.06 to 0.5 percent of carbon, 0.01 to 0.02 percent of nickel, 0.5 to 4 percent of iron, 1 to 2 percent of silicon, 1.1 to 1.5 percent of boron, 1.1 to 2 percent of manganese and the balance of cobalt. The medical cobalt, tantalum and molybdenum alloy 3D printing metal powder prepared by the preparation method is excellent in biocompatibility, mechanical property and weldability.

Owner:ANHUI CHUNGU 3D PRINTING INTELLIGENT EQUIP IND TECH RES INST CO LTD

Powder laying mechanism of 3D printer of fan-shaped structure

ActiveCN108262477AReduce usageSpread powder evenlyAdditive manufacturing apparatusIncreasing energy efficiency3d printerMetal powder

The invention relates to the technical field of 3D printing, in particular to a powder laying mechanism of a 3D printer of a fan-shaped structure. The powder laying mechanism comprises a powder falling mechanism, a second driving mechanism and a control device, wherein the second driving mechanism is used for driving the powder falling mechanism to rotate; the control device comprises a controllerand a sensor assembly electrically connected with the controller; the powder falling mechanism comprises a material carrying assembly used for carrying materials and a limitation assembly used for limiting the material falling quantity; the second driving mechanism comprises a circular arc-shaped inner gear ring and an engagement assembly engaged with the inner gear ring; the limitation assemblyis arranged in the material carrying assembly; the engagement assembly is fixedly arranged on the material carrying assembly; the engagement assembly, the material carrying assembly and the limitationassembly are all electrically connected with the controller. The powder laying structure is in the fan shape; the casing is of the fan-shaped structure; the consumption of metal powder during articleprinting in each time can be reduced; the production cost is reduced.

Owner:ANHUI TECHN COLLEGE OF MECHANICAL & ELECTRICAL ENG

Device for printing three-dimensional product layer by layer

InactiveCN106863788AQuality improvementSimple structureAdditive manufacturing apparatusIncreasing energy efficiencyMetallurgyProduct layer

The invention discloses a device for printing a three-dimensional product layer by layer. The device comprises a casting mould platform, a powder paving device, a printing head and a rack platform, wherein the casting mould platform is arranged on the rack platform; the powder paving device is arranged at one end of the casting mould platform by the rack platform; a sliding guide rail is arranged at the other end relative to the powder paving device by the rack platform; the printing head is arranged on the sliding guide rail through a sliding fixing seat; a feeding hole is formed in the upper end of the powder paving device; and a discharging hole matched with the feeding hole is formed in the lower end of the powder paving device. The device is simple and reasonable in structure, automatic powder paving and printing are finished through movement of the casting mould platform, the powder paving device and the printing head, the entire process is automatic operation, the working efficiency is high, powder paving is uniform, the entire process is excellent in continuity, and a formed product is high in quality.

Owner:江苏立元三维铸造科技有限公司

Wood-plastic composite powder for selective laser sintering rapid forming and preparation method thereof

InactiveCN101602871BImprove the safety of useSpread powder evenlySelective laser sinteringSurface roughness

The invention provides a wood-plastic composite powder for selective laser sintering rapid forming and a preparation method thereof, which relate to the wood-plastic composite powder and the preparation method thereof. The invention overcomes the defects that in the SLS processing with mixed powder consisting of wood powder and hot melt adhesive powder, the powder pushing is uneven, the processedcomponents have large relative warp rate and internal stress, poor surface roughness and low strength, and are easily ruptured at the parts with 'defects'. The wood-plastic composite powder is prepared from the hot melt adhesive powder, the wood powder after alkalization treatment, a viscosity reducer, a coupling agent, an initiating agent, a light stabilizer and an organic packing material. The preparation method comprises the following steps: firstly, alkalizing the wood powder; secondly, preparing a base material; and thirdly, adding the viscosity reducer, the light stabilizer and the organic packing material, mixing the materials evenly, and drying the mixture. The wood-plastic composite powder can reduce the conglutination and aggregation caused by the moisture absorption of the woodpowder, can be paved and formed evenly, and has high forming accuracy, and when the wood-plastic composite powder is applied to the components processed by the SLS technique, the relative warp rate is between 0.26 and 0.45 percent, and the surface roughness Ra is less than 0.01 millimeter.

Owner:哈尔滨自由智造科技开发有限公司

3D printing process for high-strength aluminium copper alloy

InactiveCN111842914ALow costImprove qualityAdditive manufacturing apparatusTransportation and packaging3D modelingHeat treated

The invention relates to a 3D printing process for high-strength aluminium copper alloy, and belongs to the technical field of 3D printing. The 3D printing process comprises the steps of firstly, mixing the raw materials of the high-strength aluminium copper alloy through heating and melting uniformly; then, making the molten high-strength aluminium copper alloy into high-quality aluminium copperalloy powder with a gas atomization technology, and obtaining the aluminium copper alloy powder for 3D printing after drying; and regulating printing parameters, and performing 3D printing according to 3D model data of a part in printing equipment with inert gas introduced to obtain a 3D printing product using the high-strength aluminium copper alloy as the raw materials. Compared with the prior art, the 3D printing process has the advantages that the relative density of the product printed with the process can reach 99% and above, and the Vickers hardness can reach 120HV and above; the tensile strength can reach 450 MPa and above, and the elongation rate can reach 10%; through proper heat treatment, the Vickers hardness of a sample can reach 135HV and above, and the tensile strength can be further improved to 500 MPa and above; and the elongation rate remains 10% or above.

Owner:TONGJI UNIV

Device capable of uniformly spreading powder in using process of screen printing machine

The invention relates to the technical field of printing coating, and discloses a device capable of uniformly spreading powder in the using process of a screen printing machine. The device comprises aframe, wherein a supporting plate is fixedly mounted at the upper end of the frame, a storage bin is fixedly mounted at the upper end of the supporting plate, a baffle is fixedly mounted at the lowerend of the storage bin, a discharging opening is formed in the baffle, a limiting plate is movably installed at the lower end of the baffle, return springs are fixedly mounted at the right end of thelimiting plate and inside the supporting plate correspondingly, and a notch corresponding to the discharging opening is formed in the limiting plate. According to the device capable of uniformly spreading the powder in the using process of the screen printing machine, a movable frame is driven by a driving device to move on a fixed disc, and a movable groove is formed in the fixed disc, so that the movable frame drives a connecting rod to firstly do circular motion and do linear motion when passing through the horizontal position of the lower end, a coating plate is driven to uniformly coat an adhesive film, and the effect of uniformly coating the adhesive film is achieved.

Owner:桑华超

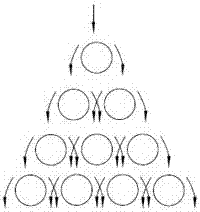

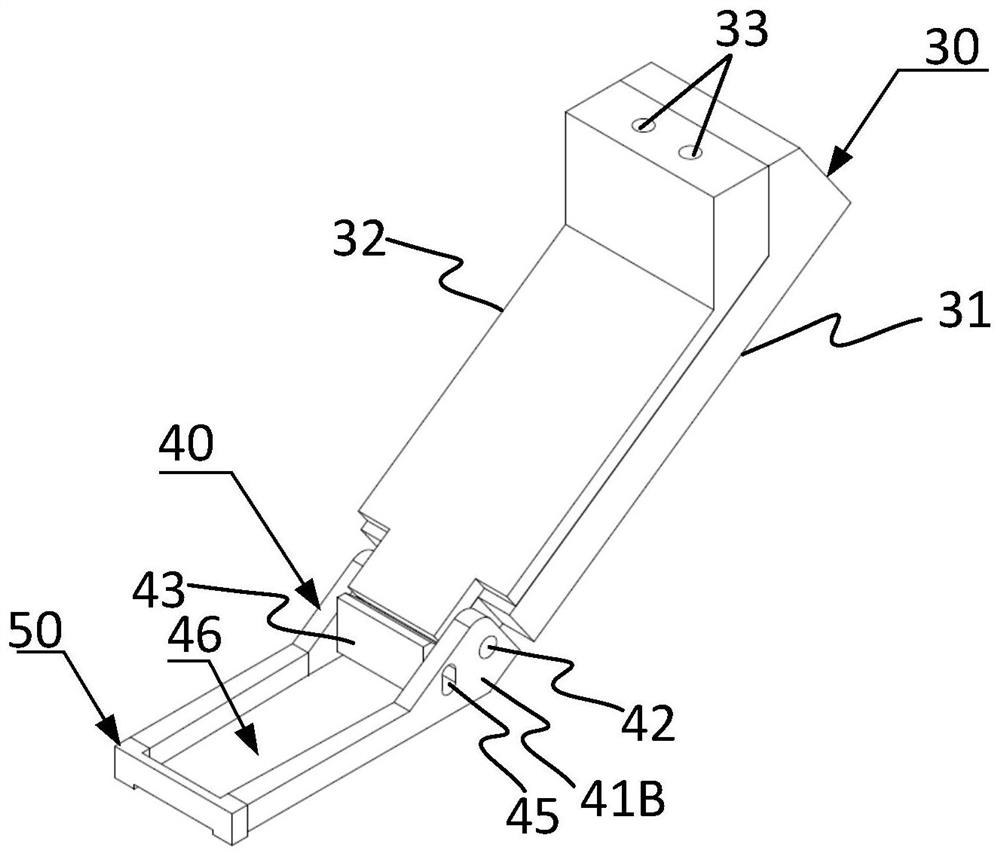

Powder feeding device and method for broadband laser cladding additive manufacturing

PendingCN113894292ATiled evenlySpread powder evenlyAdditive manufacturing apparatusIncreasing energy efficiencyEngineeringStructural engineering

The invention relates to the technical field of laser additive manufacturing, and provides a powder feeding device and method for broadband laser cladding additive manufacturing. A pressure relief device is arranged between a broadband powder feeding nozzle and the surface of a base material, the pressure relief device and the broadband powder feeding nozzle form a certain angle, and the pressure relief device is installed at the position below a first powder outlet of the broadband powder feeding nozzle. The pressure relief device is used for conducting pressure relief treatment on the powder flowing out of the first powder outlet. The pressure relief device comprises a first-stage pressure relief mechanism and a second-stage pressure relief mechanism which are arranged in a cascade connection mode, the first-stage pressure relief mechanism is used for conducting pressure relief on the powder flowing out of the first powder outlet, and the second-stage pressure relief mechanism is arranged at the tail end of the first-stage pressure relief mechanism and used for conducting secondary pressure relief on the powder subjected to pressure relief through the first-stage pressure relief mechanism. Therefore, the problems of poor uniformity during laser cladding, poor flatness after cladding and large machining allowance caused by non-uniform and uneven powder feeding of lateral preset powder for laser broadband cladding at present are solved.

Owner:NANJING ZHONGKE RAYCHAM TECH

Grain-refined metal powder for 3D (Three Dimensional) printing and preparation method thereof

ActiveCN109332679ASolve the problem of adding refinerImprove performanceAdditive manufacturing apparatusTransportation and packagingAcid washingMetal powder

The invention discloses grain-refined metal powder for 3D (Three Dimensional) printing and a preparation method thereof. The method comprises the following steps: carrying out acid washing treatment on a refining agent through hydrochloric acid to remove impurities and oil stain on the surface of the refining agent, so that the surface activity of the refining agent is improved and the compatibility of the refining agent with matrix powder is improved; then the refining agent is uniformly mixed with the matrix powder and final mixed powder has small crystalline grains; and the mechanical properties of printed parts are improved and the mechanical properties of metal parts are improved from the source.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

Powder laying device with convenient replacement function for 3D printer

InactiveCN111619112ASpread powder evenly3D object support structuresApplying layer meansComputer printingStructural engineering

The invention discloses a powder laying device with a convenient replacement function for a 3D printer. The powder laying device with the convenient replacement function for the 3D printer comprises aprinting platform and a powder laying plate arranged in the center of the outer wall of the top of the printing platform, wherein side plates are arranged on the left side and the right side of the outer wall of the top of the printing platform, a keel frame is movably arranged in the outer sides of the two side plates in a sleeving mode, a powder laying assembly is arranged at the bottom of a lifting plate, an up-and-down reciprocating driving assembly matched with a lifting rod is arranged on the right side of the outer wall of the top of the keel frame, and front-and-back reciprocating driving assemblies are symmetrically arranged at the bottoms of the outer walls of the left side and the right side of the keel frame. When overhaul work after emergency shutdown is carried out, the keelframe is pulled out forwards or backwards to screw locking blocks out to enable two inserting plates to slide towards the inner side, so that a self-locking assembly loses the effect of fixing a mounting frame, the whole mounting frame is directly taken down, then fixing bolts are screwed out to take out a bottom reinforcing plate so as to pull a machine shell out to overhaul each part, and theparts are sequentially mounted back after faults are removed.

Owner:熊婷婷

Multi-zone array selective melting manufacturing equipment and process

ActiveCN111267344BReduce waiting time for spreading powderImprove processing efficiencyAdditive manufacturing apparatusIncreasing energy efficiencyReciprocating motionElectric machinery

The invention relates to a multi-division array type selective melting manufacturing equipment and a process. A forming bin of the device is connected to a forming bottom plate through a lifting guide rail, a forming platform is arranged on the upper end of the forming bin, and a plurality of parallel powder spreading grids are arranged on the forming platform. The powder forming area on the forming platform is divided into a plurality of array powder selection areas, a powder silo is respectively provided on both ends of the powder spreading grid, and both ends of the powder spreading grid and the powder silos on it pass through respectively. The sliding base of the silo is connected with the forming platform, and the sliding base of the silo drives the powder spreading grid and the powder silo to reciprocate vertically along the powder spreading direction on the forming platform to form multi-zone powder spreading. Printing is carried out in the middle, so that powder spreading and printing are relatively isolated; there are several small scrapers in the powder spreading grid, and the small scrapers are connected to the scraper driving motor through the scraper driving mechanism, and the scraper driving motor drives the small scrapers on the powder spreading grid through the scraper driving mechanism. Internal reciprocating motion, spread the powder evenly in the powder grid.

Owner:UNIV OF SHANGHAI FOR SCI & TECH

In situ self-generated nano al 2 o 3 Laser additive manufacturing method for reinforced aluminum matrix composites

ActiveCN112176213BAchieve alloyingImprove mechanical propertiesAdditive manufacturing apparatusIncreasing energy efficiencyMg compositeHigh density

The invention discloses an in-situ self-generated nano-Al 2 o 3 A laser additive manufacturing method for strengthening an aluminum-based composite material, the method comprising the following steps: (1) mixing ZnO ceramic powder and AlSi10Mg aluminum alloy powder and ball milling to obtain a ZnO / AlSi10Mg composite powder; (2) preparing the composite powder The laser selective melting process is used for additive manufacturing forming to form a solid sheet; (3) The laser re-scans the solid sheet to form a remelted sheet; (4) Repeat steps (2) and (3) to finally form the original self-generated nano-Al 2 o 3 Reinforced aluminum matrix composites. In the present invention, laser is used to excite Al and ZnO to generate aluminum thermal reaction between them in situ. 2 o 3 Ceramic particles, and by improving the overall flow process design of the method, combining laser selective melting and laser remelting scanning, the aluminum matrix composite material obtained has high density, fine microstructure, and in-situ self-generated Al 2 o 3 The particle size is nanoscale, uniformly distributed, and its phase interface is well combined with the aluminum matrix.

Owner:HUAZHONG UNIV OF SCI & TECH +1

A 3D printing scraper integrated device and method for improving workpiece forming quality

ActiveCN110238392BImprove forming qualitySpread powder evenlyAdditive manufacturing apparatusIncreasing energy efficiencyReduction driveControl engineering

A 3D printing scraper integration device and method for improving the forming quality of workpieces. The output shaft of the drive servo motor is connected to a double-output planetary reducer, and the two output ends of the double-output planetary reducer are respectively connected to a scraper moving device, and the scraper is fixed on two scrapers. On the fixed plate, the scraper moving device drives the scraper fixed plate and then drives the scraper to move back and forth in the powder spreading direction; the scraper contains a stress sensor array, which is used to monitor the force of the scraper during the powder spreading process in real time and transmit the measurement data to the controller; the controller judges whether there is a stress value fluctuation that does not meet the preset conditions according to the measurement data. Position in the vertical direction, and control the scraper to return to the initial powder laying position to perform the powder laying and printing operation again, so as to achieve high-quality forming of parts.

Owner:SHANGHAI AEROSPACE EQUIP MFG GENERAL FACTORY

A Mechanical Laser Selective Melting Automatic Reversing Inclined Powder Spreading Device and Method

ActiveCN106623918BImprove spreading efficiencyReduce the powder phenomenonAdditive manufacturing apparatusIncreasing energy efficiencyReciprocating motionMetallurgy

The invention discloses a mechanical laser selective melting automatic reversing inclined powder spreading device and method; The stucco returning trough and the second powder recovery cylinder are arranged in sequence along the length direction of the forming platform; a guide rail is symmetrically arranged above the forming platform to provide guidance, support and positioning for the plastering; when the plastering is driven by the motion mechanism, the plastering can be Along the track of the guide rail, it reciprocates above the first powder recovery cylinder, the first plastering reverting trough, the forming cylinder, the powder material cylinder, the second plastering reverting trough and the second powder recycling cylinder. The device not only retains the advantages of the current general vertical powder coating uniformity and high powder coating accuracy, but also greatly reduces the phenomenon of powder springing that often occurs in the latter; the inclined powder coating method can make the powder coating layer more accurate Uniform and dense, while also increasing the service life of the elastic steel sheet.

Owner:SOUTH CHINA UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com