Automatic reversing inclined powder laying device and method for mechanical laser selective melting

A laser selective melting and automatic reversal technology, which is used in the improvement of process efficiency, energy efficiency, additive manufacturing, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

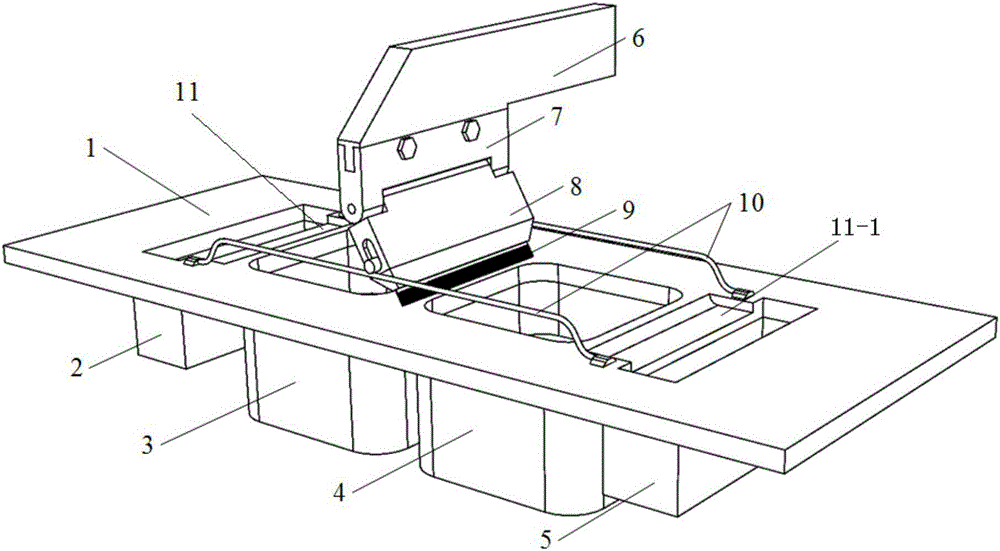

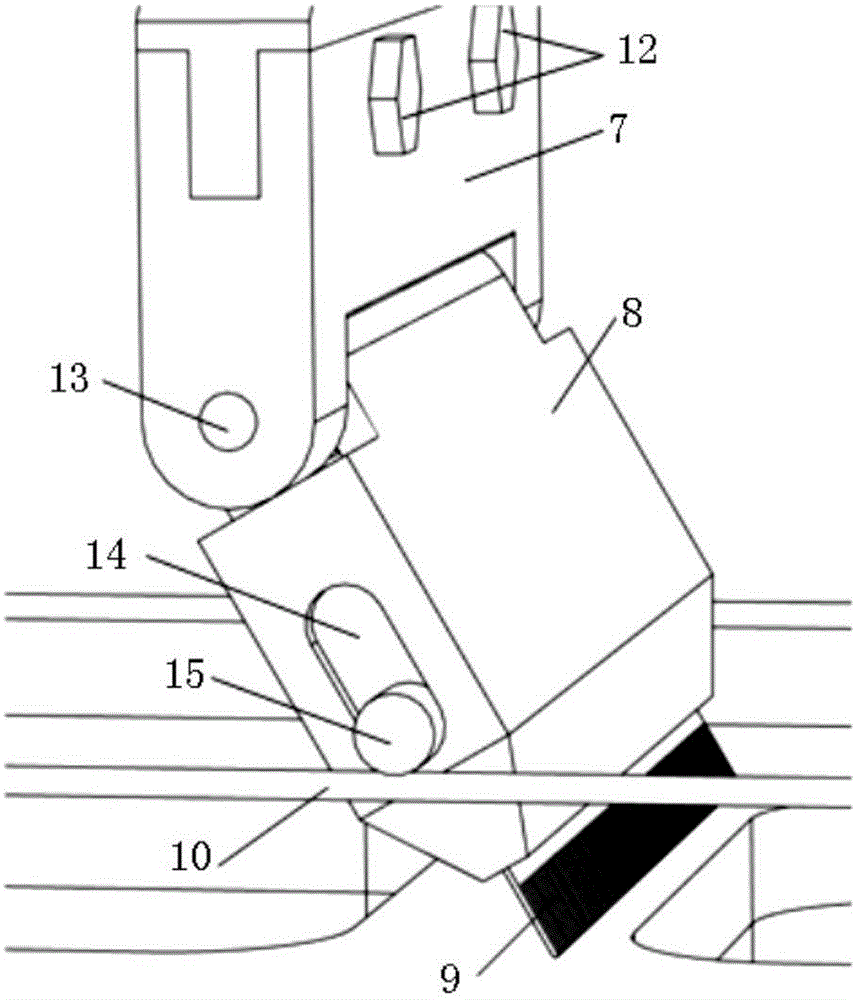

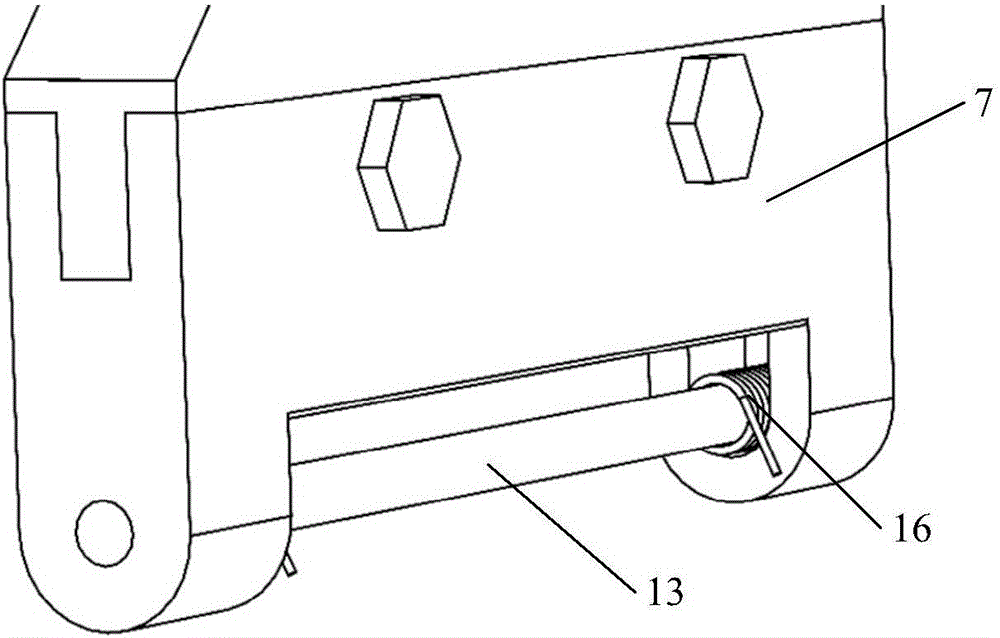

[0043] like Figure 1 to Figure 10shown. The invention discloses a mechanical laser selective area melting automatic reversing inclined powder spreading device, comprising a forming platform 1, a forming cylinder 3 and a powder material cylinder 4 arranged under the plane of the forming platform 1, and a powder spreading brush 9 above the forming platform 1 The movement mechanism; the first powder recovery cylinder 2, the second powder recovery cylinder 5, the first plastering and brushing return tank 11, and the second plastering and brushing return tank 11-1 are also arranged under the plane of the forming platform 1;

[0044] The first powder recovery cylinder 2, the first plastering tank 11, the forming cylinder 3, the powder tank 4, the second powdering tank 11-1, and the second powder recovery cylinder 5 are along the length of the forming platform 1 The directions are arranged in sequence;

[0045] Both side edges above the forming platform 1 are respectively symmetri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com